Abstract

Through laboratory testing, this research studied the connection between air-void structures of hardened concrete and fresh concrete and discussed the effects of the air-void structure on the salt-frost durability of the concrete. The results demonstrate that, in comparison with fresh concrete, the air-void spacing factor shows a close correlation with hardened concrete air-content and decreases in the form of a power function as the air-content increases. When the fresh concrete air-content is more than 6% and the hardened concrete air-void spacing factor is less than 0.18 mm, the influence of parameters of air-void structure on the salt-frost resistance of the concrete reduces. The air-void spacing factor more significantly affects the salt-frost resistance of the concrete compared with air content and the correlation reaches 0.93. Therefore, air-content and air-void spacing factor are recommended for dual control.

1. Introduction

Deicing salt inducing salt-frost damage to road and bridge concrete in cold regions has been an important adverse factor for the durability of concrete structures. Earlier studies have pointed out that micro-air-void structures in concrete exert important effects on durability [1]. The osmotic hypothesis [2] proposed by Powers and Helmuth in 1953 further shows confirmation of how an air-void structure affects the frost resistance durability of concrete. Air entrainment has been proved to be an effective measure for improving the frost resistance and the salt-frost resistance of concrete. After air entrainment in the concrete, air voids are able to effectively buffer diverse stress generated in cement mortars, thus taking on the function as a buffer airbag [3]. The research of G. Fagerlund [4] shows that too high air content causes a less stable air-void structure and forms continuous air voids, raising the absorption amount of water during freezing and thawing, which is disadvantage to frost resistance. At present, air-void testing technology [5] has been gradually developed from a single index (i.e., air content of fresh concrete in the early stages into multi-index, such as air-void spacing factor and air-void specific surface area of hardened concrete currently). This also leads to in-depth researches on the salt-frost resistance of concrete. A number of studies [6,7,8] have found that the necessary condition to protect concrete from frost damage is not the air content, but, rather, a good air-void structure in hardened cement pastes, especially the air-void spacing factor. It is generally believed that concrete has good frost resistance when the air-void spacing factor is less than 0.25 mm. Previous studies [9,10] also reveal that, except for air-void structures, surface conditions also have great effects on the salt-frost resistance of concrete. Even if the air-void spacing factor of the concrete is smaller than 0.25 mm, salt-frost durability can be dramatically reduced if the surface performance of the concrete is attenuated in the process of plastering and usage. Furthermore, salt-frost durability of concrete under coupling effects in the load environment is different from that in a single environment [11]. This study mainly analyzed the air-void structure in concrete by using an air-void analyzer (AVA) and a tester for parameters of the air-void structure in hardened concrete, and discussed the influence laws of air content and parameters of the air-void structure on the salt-frost durability of concrete. In addition, in view of the salt-frost durability of concrete, control indexes (i.e., appropriate air content and air-void spacing factor) were put forward.

2. Materials and Test

2.1. Test Materials

The P O 42.5 ordinary Portland cement (Table 1) and well-graded medium sand with fineness modulus of 2.67 were used. The syenite was used as coarse aggregate (Table 2) and the two graded aggregates with particle sizes of 5~20 mm and 20~40 mm were adopted. The ratio was 3:7. Moreover, naphthalene-based superplasticizer and MicroAir aqueous surfactant solution-type air entraining agent were utilized. Mixing water was tap water.

Table 1.

Chemical composition of cement/%.

Table 2.

Test results of limestone aggregate.

2.2. Mixing Ratio of the Concrete

The ratio of cement, water, sand and pebble sand, pebble and water was 447:170:674:1,099,674:1099:170. Air entraining agent was added according to mass percentage of cement content and its amount of mixing was adjusted in accordance with air content of fresh concrete. Moreover, the slump of the concrete was controlled in the range of 30~50 mm.

2.3. Test Equipment and Methods

An AVA produced by the Sanyo Company in Japan was used to test air content of fresh concrete, as shown in Figure 1. The RapidAir 457 image analyzer for the air-void structure in hardened concrete, from the Germann Instruments Company in the Kingdom of Denmark, was utilized to test the air-void spacing factor, as shown in Figure 2. Furthermore, salt-frost scaling resistance of the concrete was tested by using the Collider Detector at Fermilab (CDF) experimental machine, as shown in Figure 3.

Figure 1.

Air content analyzer of fresh concrete.

Figure 2.

Air-void analyzer of hardened concrete.

Figure 3.

Collider Detector at Fermilab (CDF) test machine.

Salt-frost test was conducted in light of the CDF test method recommended by RILEM (International Union of Laboratories and Experts in Construction Materials, Systems and Structures) [12] and concrete specimens were molded in accordance with the designed ratio of mixing. After inserting a PTEF (polytetrafluoroethylene) partition into the sample, molding was performed through vibration. There were five molded specimens with the dimension of 150 × 150 × 150 mm in each group. After curing for 28 d in a standard curing room, the specimens were split into half and the surfaces (Figure 4) formed with the partition were used in the salt-frost test, with the dimension of 150 × 150 mm. After drying the specimen outside, butyl rubber with aluminum foil was used to seal the specimens for 28 d. After that, they were immediately immersed into salt solution of 3% concentration in a test chamber in the depth of 5 mm. Freezing and thawing test was carried out immediately afterwards.

Figure 4.

Isolation face.

3. Result Discussion and Analysis

3.1. The Relationship between Air-Void Parameters of Fresh Concrete and Hardened Concrete

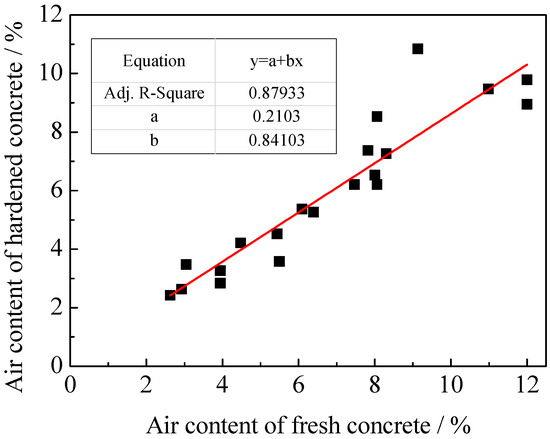

Firstly, the relationship between air contents of fresh concrete and hardened concrete determined by the RapidAir 457 image analyzer was studied and the results are shown in Figure 5. Air content of hardened concrete was linearly correlated with that of fresh concrete [13] and the correlation coefficient reaches 0.88. In addition, the air content of hardened concrete has an average loss of about 16% compared with that of fresh concrete and the maximum loss rate is about 30%.

Figure 5.

The relationship between the air contents of fresh and hardened concrete.

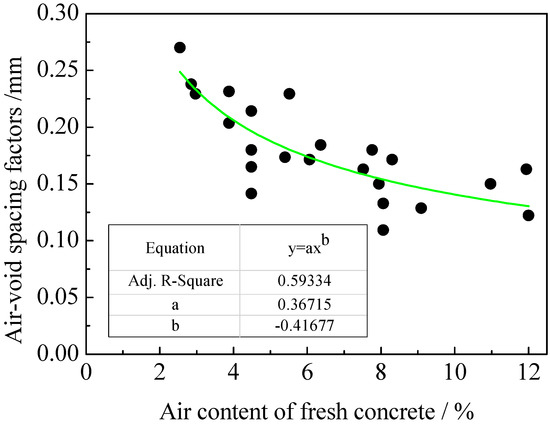

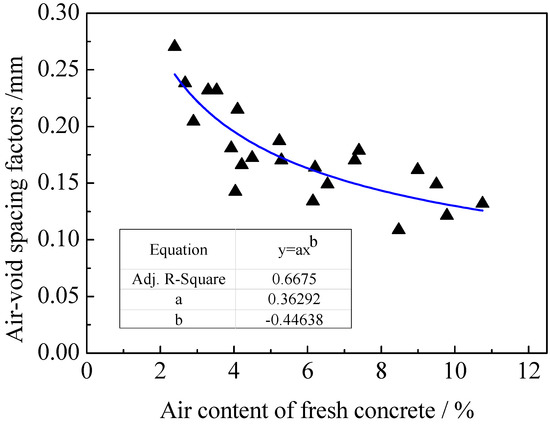

The determined air content of fresh concrete and the air-void spacing factor of hardened concrete, tested by the RapidAir 457 image analyzer, were analyzed and the results are presented in Figure 6. Figure 7 demonstrates the relationship between air content and the air-void spacing factor of hardened concrete, tested by the RapidAir 457 image analyzer. The results in the two figures show that the air-void spacing factor reduces in the form of a power function with the rise of air content. When air content reaches 12% from 2.6%, the air-void spacing factor decreases from 0.280 to 0.120 mm. The correlation coefficient between air content and the air-void spacing factor of fresh concrete reaches 0.59, while that of hardened concrete is 0.67. As air content rises, the decreasing amplitude of the air-void spacing factor gradually slows down.

Figure 6.

The relationship between air content and the air-void spacing factor of fresh concrete.

Figure 7.

The relationship between air-content and the air-void spacing factor of hardened concrete.

3.2. The Relationship between Air-Void Parameters and Salt-Frost Resistance of the Concrete

3.2.1. Air Content of Fresh Concrete

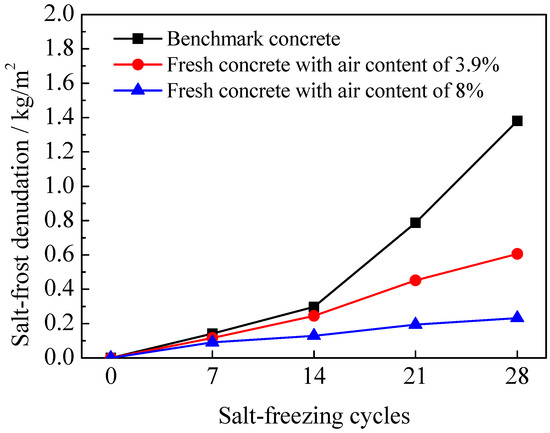

Figure 8 demonstrates the changes of the scaled mass of fresh concrete, with different air contents, with the number of salt-freezing cycles [14]. It can be seen that an increase in the scaled mass of the benchmark concrete specimens, without mixing air entraining agent, accelerates after reaching 14 cycles, and reaches about 1.3 kg/m2 after 28 cycles. It is followed by the increase trend of the scaled mass of the fresh concrete specimens with air content of 3.9%, which reaches about 0.7 kg/m2 after 28 cycles. Moreover, the scaled mass of the fresh concrete specimens with air content of 8% shows a small change trend and is only about 0.2 kg/m2 after 28 cycles.

Figure 8.

The change of scaled mass of the concrete with different air contents due to salt-frost.

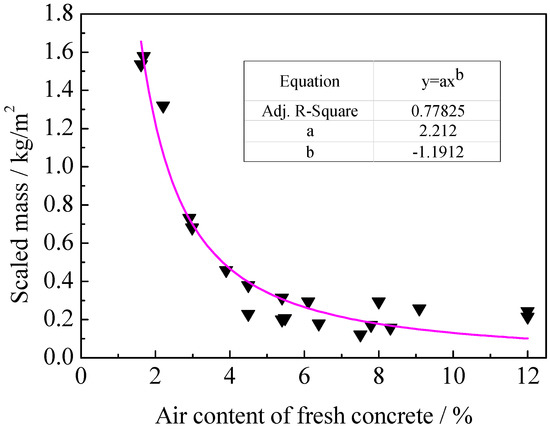

By further analyzing data of the salt-frost scaling of the concrete with different air contents after 28 cycles, as presented in Figure 9, it is found that the scaled mass of the concrete due to salt-frost reduces [15] in the form of a power function with the increase of air content and the correlation coefficient is up to 0.78. When the air content of fresh concrete is higher than 6%, the trend of the scaled mass of the concrete decreasing with the rise of air content gradually slows down.

Figure 9.

The relationship between the air content and the scaled mass of fresh concrete due to salt-frost.

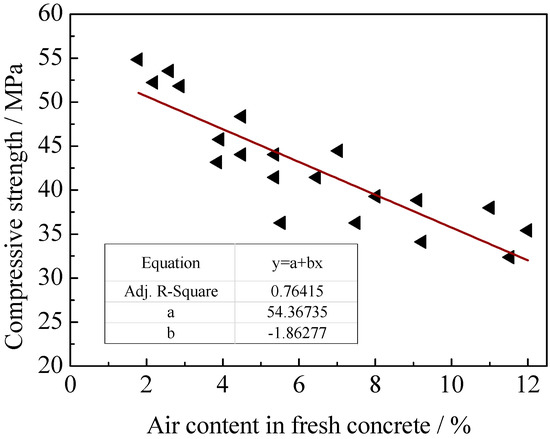

Figure 10 demonstrates the compressive strength of the concrete linearly declined with the growth of air content in the fresh concrete, with the correlation coefficient of 0.76. Moreover, the compressive strength of the concrete reduced by about 4% every time the air content rose by 1%, as shown in Figure 10.

Figure 10.

Effect of air content on the compressive strength of hardened concrete.

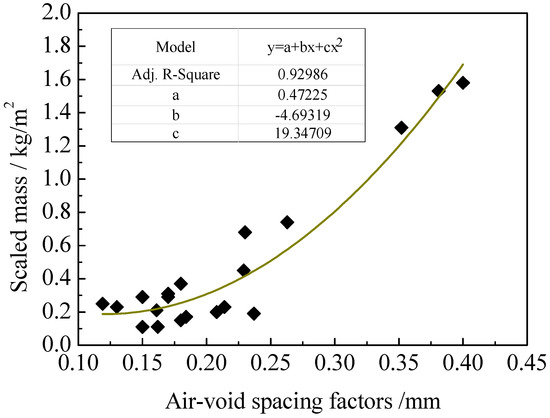

3.2.2. Air-Void Spacing Factor

Based on further analysis of the data of the air-void spacing factor of hardened concrete and the scaled mass of the concrete due to salt-frost, as presented in Figure 11, it is found that the air-void factor shows a good relationship with the salt-frost scaling of the concrete [16], and their correlation reaches 0.93. With the constant decrease of the air-void spacing factor, the scaled mass of the concrete specimens due to salt-frost rapidly reduces. When the air-void spacing factor decreases from 0.4 to 0.2 mm, the scaled mass reduces from 1.6 to about 0.3 kg/m2, by about 80%. When the air-void spacing factor is smaller than 0.18 mm, its influence on salt-frost scaling resistance reduces.

Figure 11.

The relationship between the air-void spacing factor and the scaled mass of hardened concrete due to salt-frost.

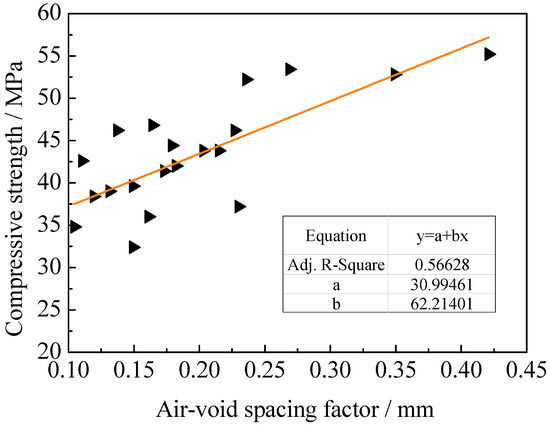

Figure 12 presents the relationship between the compressive strength and the air-void spacing factor. The lower the air-void spacing factor was, the denser the air voids and the lower the compressive strength of concrete, as presented in Figure 9. The correlation coefficient between the air-void spacing factor and the compressive strength of the concrete was 0.57.

Figure 12.

Effect of the air-void spacing factor on the compressive strength of hardened concrete.

4. Conclusions

- (1)

- The air content of hardened concrete was linearly correlated with that of fresh concrete and showed an average loss of about 16% in comparison with that of the fresh concrete.

- (2)

- The air-void spacing factor was closely related to air content. The air-void spacing factor showed a decreasing trend in the form of a power function with the increase of air content, and was more closely correlated with the air content of hardened concrete compared with that of fresh concrete.

- (3)

- The compressive strength of concrete linearly changed with increasing air content, with the correlation coefficient of 0.76. Moreover, there was a certain linear relationship between the compressive strength of concrete and the air-void spacing factor, showing the correlation coefficient of 0.57.

- (4)

- In comparison with air content, the salt-frost resistance of the concrete was more closely correlated with the air-void spacing factor. When the air-void spacing factor was smaller than 0.18 mm, the effect of air-void parameters on the salt-frost resistance of the concrete showed a decreasing trend. If the air content of fresh concrete is adopted to control the quality of concrete, 6% is recommended as the standard.

Author Contributions

Data curation, H.Z.; Formal analysis, H.Z.; Funding acquisition, P.G.; Project administration, Z.Z. and Y.P.; Resources, W.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This paper is supported by the project supported by the Jiangsu Natural Science Foundation for Youth Fund (Grant No. BK20180113), the Surface Project of Jiangsu Natural Science Foundation (Grant No. BK20181112), the High-level Talent Project Funding Scheme of Jiangsu (Grant No. XCL-CXTD-007), the Post-Doctoral Fund of China (Grant No. 2018M630559, Grant No. 2014M551588), and the Project of Traffic Construction in Shanxi Province (Grant No. 16-2-08).

Conflicts of Interest

The authors declare that they have no conflicts of interest to this work and do not have any commercial or associative interest that represents a conflict of interest in connection with the work submitted.

References

- Mehta, P.K.; Monteiro, P.J. Concrete Microstructure, Properties and Materials; Tan, W., Wang, D., Ding, J., Eds.; Power Press: Beijing, China, 2008. [Google Scholar]

- Power, T.C.; Helmuth, R.A. Theory of volume change in hardened Portland cement pastes during freezing. Proc. Highw. Res. Board. 1949, 32, 285–297. [Google Scholar]

- Du, L.; Folliard, K.J. Mechanisms of air entrainment in concrete. Cem. Concr. Res. 2005, 35, 1463–1471. [Google Scholar] [CrossRef]

- Fagerlund, G. Scaling, freezing absorption and dilation of cement mortars exposed to Freezing and thawing in NaCl solution. In Freeze-Thaw of Concrete; E&FN Spon: Lund, Skane County, Sweden, 1997. [Google Scholar]

- Zhang, H.; Ding, J.T.; Gao, P.W. Analysis on the air-void system test methods of concrete. Low Temp. Archit. Technol. 2009, 12, 7–9. [Google Scholar]

- Giergiczny, Z.; Glinicki, M.A.; Sokołowski, M.; Zielinski, M. Air void system and frost-salt scalingof concrete containing slag-blended cement. Constr. Build. Mater. 2009, 23, 2451–2456. [Google Scholar] [CrossRef]

- Huaquan, Y.; Shihua, Z.; Jie, S. Effect of Air Void Parameters on Properties of Air Entraining Concrete. Water Power 2009, 35, 1–3. [Google Scholar]

- Zhang, J.; Guo, M.Y.; Yang, R.J.; Zhang, L. Effect of Air-entraining Admixtures on the Structure and Properties of Hardened Concrete. J. Wuhan Univ. Oftechnol. 2008, 30, 38–41. [Google Scholar]

- Hazrati, K.; Abesque, C.; Pigeon, M. Efficiency of sealers to prevent the deicer salt scaling resistance of concrete. In Proceedings of the International Workshop on the Resistance of Concrete to Freezing in the Presence of Deicing Salts, Quebec, QC, Canada, 30–31 August 1993; pp. 191–228. [Google Scholar]

- Pigeon, M.; Marchand, J.; Pleau, R. Frost resistant concrete. Constr. Build. Mater. 1996, 10, 339–348. [Google Scholar] [CrossRef]

- Hui, Z.; Yonqiang, P.; Jian, Z.; Lei, Z. Influence Factors of Frost-Salt Resistance of Cement Concrete. J. Chongqing Jiaotong Univ. 2013, 4, 34–37. [Google Scholar]

- Setzer, M.J.; Auberg, R. Freezeing-thaw and decing salt resistance of concrete testing by CDF method, CDF resistance limit and evaluationof precision. Mater. Struct. 1995, 28, 16–31. [Google Scholar] [CrossRef]

- Zhang, H.; Gao, P.; Pan, Y.; Zhang, Z. Effects of surface states on salt-frost scaling resistance of cement concrete. Case Stud. Constr. Mater. 2019, 11, 1–7. [Google Scholar] [CrossRef]

- Wang, F.; Zhang, Z.; Li, M.; Huang, D.; Zhu, Y. Influence of Chloride Solution Concentration Difference on Salt Frost Scaling of Concrete. J. Build. Mater. 2014, 17, 138–142. [Google Scholar]

- Liu, Y.; Chen, Y.; Niu, W. Effects of water-binder ratio and gas content on the frost-salt resistant ability of concrete. Concrete 2019, 4, 63–65. [Google Scholar]

- Guo, Y.C.; Shen, A.Q.; Zheng, P.F.; Li, P. Study on Salt-freeze Resistance of Bridge Deck Concrete in Alpine Region. J. Highw. Transp. Res. Dev. 2019, 36, 73–79. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).