Abstract

Low impact on the environment and low cost are the key drivers for today’s technology uptake. There are many concerns for cement production in terms of negative environmental impact due to greenhouse gas (GHG) emission, deficiency of raw materials, as well as high energy consumption. Replacement of the cement by appropriate additives known as supplementary cementitious materials (SCMs) could result in reduction in GHG emission. Limestone-calcined clay cement (LC3) is a promising binder in the concrete sector for its improvements to environmental impact, durability, and mechanical properties. On the other hand, the advantages of fiber-reinforced concrete such as improved ductility, versatility, and durability have resulted in increasing demand for this type of concrete and introduction of new standards for considering the mechanical properties of fibers in structural design. Thus, using natural fibers instead of synthetic fibers can be another step toward the sustainability of the concrete industry, which is facing increasing demand for cement-based materials. This review studies the potential of natural Kenaf fiber-reinforced concrete containing LC3 binder as a step toward green cementitious composite. While studies show that energy consumption and GHG emission can be reduced and there is a significant potential to enhance mechanical and durability properties of concrete using this composition, adjustment of the mix design, assessing the long-term performance and standardization, are the next steps for the use of the material in practice.

1. Introduction

Introducing environmentally friendly materials is one of the most fascinating research fields in engineering. In civil engineering and related disciplines, concrete is a high-demand material for the building and construction sector. Nearly one ton of CO2 is released in the production of every ton of ordinary Portland cement (OPC) [1,2,3]. In addition, SO2 and NOx which have a role in greenhouse effects and acidic rains are also released during OPC manufacturing [4]. Therefore, different countries and communities should have plans to reduce air pollution. For example, the European Commission has a plan to reduce CO2 emissions under the EU’s emissions trading system, to speed the transition to a low-carbon economy in four phases by 2031. Scientists are continuously trying to improve concrete mixes not only to enhance different properties but also to reduce the material impact on the environment. Fiber-reinforced concrete and supplementary cementitious materials (SCMs) have also emerged in alignment with such goals. While fiber-reinforced concrete is becoming more commonly used and fibers are becoming an alternative to steel reinforcing bars, using natural fibers would be interesting from a sustainability point of view [5]. On the other hand, the cementitious binder needs to be compatible and in alignment with sustainability goals, which has sparked the interest in using natural fibers. There is still an important issue regarding the use of natural fibers in the cementitious binder as natural fiber-reinforced concrete (NFRC). The main drawback of the NFRC is the deterioration of fiber in the alkaline surrounding of OPC concrete [6,7]. Moreover, less greenhouse gas (GHG) emission, less energy consumption, and avoiding deficiency in binder quality makes SCMs an attractive option [8,9,10,11,12]. The use of by-products (slag, fly ash (FA), silica fume (SF), and other waste materials) as SCMs is an effective solution for mitigating air pollution, but the appropriate SCM for NFRC should cause a decrement in pore solution alkalinity in the binder. Since the resources for by-products as SCM are limited and may be challenging to approach in the near future, limestone-calcined clay cement (LC3) is an alternative for a compatible binder for natural fibers. A review of the latest developments in SCMs (especially LC3) and NFRC (specifically in combination with SCMs) are the goals of this paper.

2. Supplementary Cementitious Material (SCM)

Green buildings are essential elements for acquiring sustainability, and the concrete industry can move toward sustainability by introducing SCMs [13,14], which can also lead to improved durability and mechanical properties of concrete [15,16]. Industrial residues, such as SF and FA, are extensively employed as SCMs due to the high pozzolanic reactivity [16,17,18,19]. Furthermore, continuous effort is made to introduce agriculturally sourced pozzolanic substances, such as rice husk ash (RHA) [20,21], corn cob ash [22,23], wood ash [24], natural zeolite [4,25], bamboo leaf ash [26], and palm oil fuel ash [27,28,29,30,31]. As an example, when cement is replaced by micro-palm oil fuel ash (mPOFA) at certain levels, the compressive strength will be increased [32,33]. Replacing 10% weight of cement with mPOFA increases compressive strength up to 33%. This could be caused by mPOFA occupying the space between the particles of cement and enhancing the creation of calcium-silicate-hydrate (C-S-H) gel [34]. Table 1 expresses the composition and properties of typical OPC and some common SCMs. The higher value of SiO2 and Al2O3 and Fe2O3 means the higher pozzolanic feature of SCM. According to ASTM C618, the value of all these three oxide compositions together should be more than 70%, as the requirement of material to be considered to be class N or F natural pozzolan.

Table 1.

Typical composition and properties of ordinary Portland cement (OPC), SF, FA, limestone, metakaolin and calcined clay [6,13,35,36,37,38,39,40,41].

FA is known as one of the most common SCMs which can reduce GHG emission of concrete and enhance durability, fracture toughness, and compressive strength of this material [13,42,43]. On the other hand, it is noted in previous studies that although enhancement in durability and compressive strength was observed by using FA, extensive usage may lead to challenges such as higher carbonation and delayed hydration [43]. Moreover, SF is the other commonly used pozzolanic substance that can also enhance the strength and durability significantly due to the high purity of silica content with fine particle size increasing its reactivity [35,41,44]. However, the main challenge for SCMs which are by-products of other industries (such as SF and FA) is the limitation in global production [45]. Furthermore, the quality of by-products is the other issue. For example, over 66% of the accessible FA, which has one of the highest quantities between these by-products, is not appropriate for mixing with cement [46].

Calcined clay is a kind of artificial pozzolan and its pozzolanic activity is affected by parameters such as the quantity of calcined minerals, impurity measure, activation technique, and post-calcination. [47]. Calcined clays appear as a confident source of SCM, able to offer a considerable replacement of the Portland cement clinker in mixed cement [48]. Various types of clay minerals include illite, kaolinite, palygorskite, and montmorillonite [49,50]. It is documented that among the different type of clay minerals, kaolinite has the highest pozzolanic activity [47,51]. After calcining the kaolinite-containing clay, metakaolin is created that is an amorphous alumino-silicate (Al2Si2O7), which may make a reaction with calcium hydroxide to provide calcium-aluminate-silicate-hydrate (C-A-S-H) and aluminate hydrates [45]. Furthermore, carbo-aluminate hydrates could be produced as the reaction between the alumina and limestone [52]. The metakaolin (clay) is an abundant material and also its quality is further stable compared to FA and slag [53,54,55,56]. Mayo and Hassan reported that by the presence of 20% metakaolin in the self-compacting concrete mixture, the tensile and compressive strengths (28 days) could be increased to 25% and 30%, respectively [57]. This indicates that calcined clay has the potential to show higher pozzolanic reactivity than FA.

Increase in compressive strength of mortar blending at an early age was also observed by using metakaolin as SCM [48,58,59]. Furthermore, combination of limestone and metakaolin resulted in higher compressive strength compared to using typical OPC [58]. Avet et al. stated that compressive strength of mortars containing different types of calcined clay appeared mainly dependent on the calcined kaolinite content irrespective to the other parameters [59]. Sulfate resistance is also reported to be significantly good for the investigated mortars with calcined clays (either calcined montmorillonite or metakaolin), non-dependent to the pore structures and compressive strength [48].

2.1. Limestone-Calcined Clay Cement (LC3)

Among various SCMs available for substituting Portland cement clinker, the features of a ternary blend identified as LC3 is evaluated broadly in terms of its benefits over OPC [45,52,59,60]. Calcination at temperatures between 600 and 800 °C results in the pozzolanic activity of kaolinite [50]. Limestone and kaolinitic clay are present in the earth crust abundantly, and much lower heating temperature compared to Portland cement clinker is required to produce calcined clay. Only 0.3 tons of CO2 may be emitted for producing 1 ton of calcined clay [45,61], which is much less than the production of the same mass of OPC [62] (which is typically 1 ton of CO2). There are many types of clay with different mineral composition depending on the region. Usually, most of clay types have about 40% kaolinite content or higher, which means they are suitable for calcination to produce highly reactive pozzolan. There are three common methods for calcination including rotary kilns, flash calcination and fluidized bed [56,63,64]. Therefore, LC3 mixes have considerable variations in performance and color, based on the material source as well as calcination and use method. It is noteworthy that by substitution of clinker with limestone in LC3 blends, both cost and the environmental impacts are reduced [45]. Optimal mechanical characteristics and enhancement in durability tests are observed with the replacement of 50% of clinker [45,52]. The viability of any technology depends on four key elements, including economic viability, technical feasibility, easy accessibility of raw materials and low capital investment. The developed LC3 technology meets all the mentioned criteria [45]. One of the challenges with using limestone and calcined clay as SCM is the reduction in workability compared to the OPC binder. This issue could be managed by using the appropriate dosage of superplasticizer (SP) and also viscosity-modifying admixture (VMA) [56,64]. The relation between the dosage of SP and VMA with the content of calcined clay and limestone is still unformulated properly. There are many parameters related to the physical and chemical features of materials (e.g., particle size distribution, calcination temperature and chemical adsorption) and application of binder for getting the proper correlation and formula. Developing a chemical admixture designed for LC3 mixes is still under demand.

2.1.1. Mechanical Properties of LC3 Cement Binder

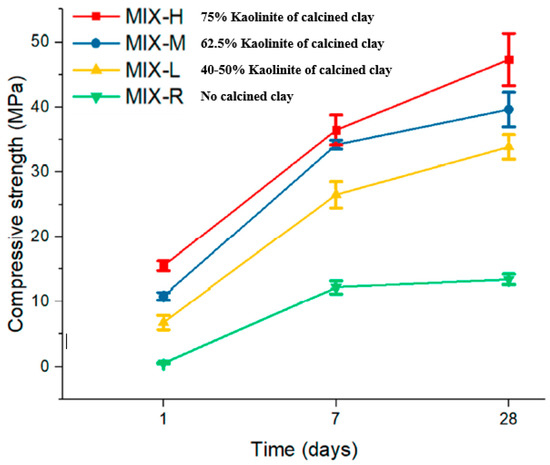

Antoni et al. and Avet et al. reported the highest compressive strength was found by the weight proportion of 1:2 for the limestone to metakaolin [52,59]. The most significant parameter of the calcined clay is kaolinitic content leading the mechanical properties of calcined clay-based binder systems. The comparable pozzolanic reactivity is also obtained by the lower levels of metakaolin in calcined clay (metakaolin content: 40–50%) which was confirmed by Avet et al. [59]. Moreover, Chen et al. showed an increase in the metakaolin content of calcined clay, increases the compressive strength (Figure 1). MIX-R in Figure 1 is the reference mixture with no calcined clay and MIX-L, MIX-M, and MIX-H contain low (40–50%), medium (62.5%), and high (75%) amounts of metakaolin content of calcined clay, respectively [65]. Moreover, recent studies indicate that improvement in mechanical and durability properties is significant even by introducing low or medium kaolinite content to the mix [59,66]. The LC3 mortars with different kaolinite content (41.9%, 50.3%, 79.4% and 95.0%) indicated 9%, 9%, 27%, and 34% greater compressive strength compared to OPC mortar, respectively [66]. The results of previous studies introduce the LC3 mixture as a promising ternary blend for improving the mechanical properties of concrete or mortar. Moreover, using calcine clay with low kaolinite content which is widely accessible seems to be an economical choice for the concrete industry. These statements are verified by other studies. [65,67].

Figure 1.

Compressive strength of concrete containing calcined clay with different metakaolin content [65].

2.1.2. Durability and Microstructure of LC3 Cement Binder

In LC3 technology, not only can the larger amount of OPC be replaced by SCMs to enhance the mechanical properties and reduce GHG emission, but also carbo-aluminate hydrates are generated, which can occupy the capillary pores [45]. Considerable incorporation of aluminum is discovered for LC3 blends compared to the OPC and the C-A-S-H gel of LC3 system shows significant variations in the composition. The kaolinite content of calcined clay has the main role of increasing the aluminum incorporation and its integration [39]. Furthermore, the chemical composition of calcium carbonate and alumina creates supplemental aluminate ferrite monosulfate (AFm) phases and stabilizes ettringite [52].

LC3 has shown considerable improvement in chloride resistance of concrete compared to the other mixes with similar compressive strength [67,68]. This is mainly due to the creation of a large quantity of C-A-S-H and a synergetic impact between limestone and calcined clay [52,69]. Resistance against chloride ingress is tested by using high to intermediate grades of kaolinite content in clay and where it was found that chloride resistance of clay containing intermediate amount of kaolinite was in a similar range to high kaolinite content (which is an expensive choice) [66]. Furthermore, studies indicated that the chloride penetration in OPC mortar after two years of exposure was four times higher than the LC3 mixtures (of 50% and higher kaolinite content) [66]. The main reason for this feature was ascribed to the denser structure of the LC3 compared to OPC. The action against capillary water absorption and gas permeability indicates that LC3 can provide significant performance in comparison to OPC. Moreover, using hydrophobic agents can lead to a material with considerably higher resistance to moisture ingress [70,71,72,73,74] meaning that LC3 concrete has the potential to be exploited at environmental conditions where there is a risk of chloride ingress, including marine environments [67].

Furthermore, sulfate attack and Alkali–Silica Reaction (ASR) could both be mitigated by the LC3 binder. A minimum quantity of limestone and calcined clay (around 30%) is reported to mitigate the sulfate attack [75]. Shi et al. suggested that LC3 could be involved in standards as an innovative kind of sulfate-resisting Portland pozzolan cement [48].

3. Fiber-Reinforced Concrete (FRC)

Regardless of numerous benefits, concrete has some weaknesses including low energy-absorption capacity and low tensile resistance resulting in spalling, cracking, and lower lifespan of the structures [76,77]. Recently, using macro fibers as concrete reinforcement has become prevalent to present a solution for enhancing the mechanical properties of the OPC concrete [5,78,79,80]. The use of fiber in concrete matrix has less or no impact on concrete pre-cracking behavior. However, fibers improve post-cracking response, control the brittle fracture process, provide strength, and offer post-cracking toughness through the advantage of reliable deformation behavior and post-cracking strength [81,82,83]. Furthermore, incorporating fibers in cementitious substances has become important to some extent, because of reducing the shrinkage cracking, which is able to enhance the material durability. The preventing of shrinkage cracks may contribute to diminishing the material permeability [84]. When considering the structural behavior of a material, it is important to consider both strength and toughness together. The capacity of the material to absorb energy in the plastic range is considered to be the toughness index [83]. The propagation of the crack is inhibited by adding fibers to the concrete matrix, resulting in improvement of energy-absorption capacity [85,86,87]. The range of the enhancement in the mechanical properties and toughness index of concrete mixture depends on the fiber length and its amount [88,89,90,91].

Toughness index of FRC is increased by reduction in fiber cross-sectional area. Higher specific surface area is achieved by reduction in the diameter of the fibers, leading to higher contact areas between fibers and the matrix. Moreover, it causes a significant increment in FRC energy absorption compared to plain concrete [92]. In the mechanisms of energy-absorption in FRC, de-bonding and fiber pull-out are features related to the fiber surface area. Therefore, fiber-specific surface (FSS), the fiber content (FC), and the reinforcement area are relevant parameters to be investigated to find their effect on FRC properties. The implication is that the length of individual fibers influences computing the reinforcement area. To calculate these parameters, many analytical expressions are mentioned in reference [81].

Hasan et al. stated that the splitting tensile, compressive, and flexural strengths reached their maximum with 0.36% fiber volume fraction in comparison to plain concrete. The concrete strengths started to decrease due to high-volume fiber interface with the cohesiveness of the concrete matrix causing difficulty in concrete compaction lowering its workability [93].

According to past scientific findings, short fiber reinforcement in concrete could enhance the properties of plain concrete in the appropriate fiber volume fraction. Presently, regarding financial problems and environmental concerns, natural fibers are fascinating for industrial applications. Therefore, the natural (bio) fiber-reinforced concrete (NFRC) is an attractive subject for further research.

3.1. Natural-Fiber-Reinforced Concrete (NFRC)

Recently, many studies have considered bio-fibers for reinforcement of Portland cement-based concrete structures to increase the tensile strength, flexural strength, tensile ductility, and flexural toughness, reducing the drying shrinkage and density of concrete [94,95,96,97,98,99]. The benefits of NFRC, such as incremented toughness, improved cracking behavior, greater durability, and enhanced impact resistance and fatigue were well demonstrated formerly [91,97,100,101,102]. Also, research outcome has shown NFRC possesses the potential for repairing, retrofitting, and rehabilitation of reinforced concrete structures and as a new construction material [103].

3.1.1. Mechanical Properties of NFRC

In terms of impact resistance, Zhou et al. [104] and Wang et al. [105] reported the positive effects of the impact resistance of concrete reinforced by jute fiber and hybrid bamboo-steel fiber, respectively. More results on impact energy absorption of NFRC slabs were reported by Ramakrishna and Sundararajan [101]. Investigations of jute FRC show that compressive strength is not considerably influenced by adding fibers; however, flexural, tensile strengths and toughness are all considerably incremented [91]. Moreover, it is stated that the modulus of elasticity, compressive strength, and repetitive impact resistance of coconut FRC (CFRC) were reduced by increasing the length of the fiber [106]. Also, a similar finding reported that the short flax fiber (12 mm) had the most effects on the flexural strength of flax FRC [107]. Al-Oraimi and Seibi tested many FRC samples by using the different FC of glass and palm trees. They stated that adding fibers, in general, improves the toughness of concrete and enhances its impact resistance; also, bio-fibers are comparable to the synthetic fibers in improving the toughness and impact resistance [83]. Moreover, from another study, hemp fibers improve the concrete fracture energy for 70% in NFRC. By bridging the cracks, fibers provide a post-cracking ductility, leading to significant improvement of toughness [102]. Furthermore, higher flexural strength is exhibited by alkaline treatment of hemp fibers compared to their non-treated equivalents [7].

3.1.2. Durability of Bio Fiber-Reinforced Concrete

Degradation of natural fibers are investigated by treatment in aging environments [108,109,110,111,112,113,114]. Pretreatment of natural fibers is a well-documented method to enhance the degradation resistance. Silane coating [115,116], out-of-autoclave method [117], hornification [118], sodium silicate [119], potassium silicate [119], alkaline treatment [115,120], and coating fibers with bacterial nano-cellulose [121] were used to enhance the durability and mechanical characteristics of NFRC by creating protective layers on the fiber surface or enhancing cellulose structure of natural fiber.

The other method for increasing the durability of natural fibers is use of appropriate SCMs in the concrete matrix. The lignin quantity of natural fiber has a main role in the sensitivity of NFRC to natural weathering. This is caused by the more susceptibility of hemicelluloses and lignin to chemical deterioration and alkaline environment of cement. The findings show that by combining the calcined clay minerals, alkalinity of pore solution is decreased which can lead to mitigating fiber deterioration. Both alkali hydrolysis and mineralization of natural fiber can be alleviated significantly by this technique [6]. Different studies agree that decreasing the alkalinity of the matrix using SCMs as cement replacement can prevent the chemical attack to lignocellulosic fibers in the matrix [6,7,110,111,122,123,124,125].

The rate of natural fiber deterioration in cementitious materials could be reduced by using some SCMs such as nano-calcined clay [7]. Hakamy et al. stated that the substitution of cement with 1 wt.% nano-calcined clay results in not only enhancing the microstructure but also facilitating the pozzolanic activity which results in stronger bonds between the matrix and the surface of treated hemp fibers [7]. Furthermore, initial flexural strength as well as durability of NFRC are improved by the coupled replacement of metakaolin and montmorillonite, due to modifying the mineralization and alkaline degradation of the fibers. For example, the degradation of sisal fibers was moderated most considerably at high cement substitution level (about 50%) [6]. Using short-length natural fibers and the effects of cement and SCMs on fiber degradation is well documented [6,7,75,111]. Moreover, incorporating a pozzolanic substance into the matrix results in a considerable reduction in capillary absorption and chloride penetration. Overall, the use of appropriate amount and quality of SCMs can enhance the mechanical and durability properties of FRC [84]. Table 2 shows the effect of SCMs on the mechanical performance of natural fiber cementitious composites. Future studies need to be conducted on the adjustment of the mix design, assessing the long-term performance and standardization of the natural-fiber-reinforced LC3 concrete.

Table 2.

The effect of SCMs on the natural fiber performance in cementitious binder.

3.2. Kenaf Fiber-Reinforced Concrete (KFRC)

The kenaf plant is able to grow to heights of 3.5–4.5 m within 4–5 months [126]. Studies indicate that the kenaf plant had the optimal CO2 absorption among the investigated plants. Kenaf plant can absorb 1.5 times the carbon dioxide by its weight [127]. The findings show that the tensile strength of kenaf fibers vary between 223 MPa and 1191 MPa and the elastic modulus and final tensile strain of the kenaf fiber vary within 2860 MPa to 60,000 MPa and 0.012 to 0.1, respectively [120]. Kenaf fiber shows a linear stress–strain diagram [120,128]. Currently, kenaf fiber is used in bio-materials with a wide application area [94,129,130,131,132]. Table 3 presents the mechanical properties of some natural fibers. The elastic modulus of some natural fibers such as hemp, kenaf, and flax are comparable to glass fibers, while the density of these natural fibers is one half the density of glass fiber. According to the nature of bio-fibers, the properties may differ in different origins, so the range of properties are reported in the following table.

Table 3.

Mechanical properties of natural fiber.

Surface treatment of kenaf fibers by sodium hydroxide (NaOH) can reduce its hydrophilic properties [120]. This reduction in the fiber water sorption characteristic causes an improvement of fiber durability and reduces its biodegradability [147]; however, it may affect the bond strength with the cementitious matrix.

According to the literature, higher toughness is exhibited by NFRC (such as KFRC) generally compared to the normal concrete [94,104,124]. Also, microstructural analysis by scanning electron microscopy (SEM) shows a good bonding between the kenaf fibers and concrete matrix [124]. Lam and Yatim conducted research on KFRC by changing the fiber volume content and the fiber length. They stated the indirect tensile and flexural strength increased by an increment of FC and fiber length [94]. This statement seems to be in contrast with the previous statement about coconut FRC in terms of the effects of fiber length [106] but both studies suggested that the 50 mm fiber length was suitable. Moreover, the ductile failure mode was observed compared to plain concrete, which resulted in an enhancement in cracking behavior and ductility. Moreover, another study reported a toughness index in KFRC almost 3 times higher than the OPC concrete control samples [124]. Use of natural fibers such as kenaf fiber to cast NFRC (specifically KFRC) can result in not only economic profit in terms of production cost and material weight, but also in terms of health benefits for society when compared to synthetic fibers [104,147]. The green concrete developed has an environmental benefit which is of immense importance in the present context of the sustainability of natural resources [127,147]. Moreover, the quantity of CO2 would be reduced in the atmosphere by using kenaf fibers in concrete. It may decline the high CO2 released within the manufacturing of Portland cement. Thus, kenaf fiber-reinforced concrete (KFRC) is a potential green material for various construction purposes [94,124].

4. Discussion and Conclusions

Using natural fibers as an alternative for concrete reinforcement is of interest not only due to increasing ductility and versatility of the material but also from an environmental perspective. On the other hand, the binder needs to be compatible with the fibers and be environmentally friendly to make a favorable composition. SCMs including SF, FA, slag, and LC3 can enhance mechanical and durability properties, reduce the environmental impacts, and adjust the alkaline environment and pore structure of the matrix. The latter can be of interest when dealing with the durability of nature-based materials into concrete. While resources for SCM materials which are industrial by/products are limited and may be challenging to approach in the near future, LC3 can be an available choice in most parts of the world. Furthermore, the clay can be calcined by using renewable energy which can lead to zero emissions for the calcination process. The weight proportion of calcined clay to limestone as 2:1 and the cement replacement ratio of 50% are reported to be optimal for normal uses in different studies.

The kaolinite content of the clay, which is reported to play an important role in cementitious functionality of calcined clay, varies significantly in different types of clay. However, studies have shown that calcined clay with low or medium kaolinite content can also be used in LC3 achieving acceptable mechanical properties for common applications. This means the LC3 is not sensitive to kaolinite concentration and different types of clay available with minimum transport can be suitable for concrete production leading to reduction in cost and environmental impacts. Furthermore, improvement in durability properties in terms of chloride resistance, ASR, and sulfate attack are reported for LC3 concrete with medium kaolinite content in the clay.

On the other hand, the performance of kenaf fibers as short-length natural fiber concrete mixture is investigated in different studies mainly using OPC. Mechanical properties of concrete such as toughness, tensile strength, and impact resistance can be improved using this type of fiber. Moreover, durability properties such as carbonation, sulfate, and chloride resistance were reported to be enhanced compared to OPC concrete. Natural fiber volume content under 1% and fiber length of about 50 mm are reported to be a proper performance in the concrete mix.

Combination of LC3 with natural fibers such as kenaf fiber can be a promising composition to get green concrete with low GHG emission and energy consumption due to the replacement of cement by LC3 as well as significant properties of kenaf plant in absorbing the CO2 from the air and introducing proper fibers for concrete mix. Current studies on this composition are limited and need to be taken into account for further investigation. Furthermore, adjustment of the mix design, assessing the long-term performance, as well as standardization, are the next steps for use of the kenaf fiber-reinforced LC3 concrete in practice.

Funding

The APC was funded by Department of Manufacturing and Civil Engineering, Norwegian University of Science and Technology (NTNU).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Naqi, A.; Jang, J.; Naqi, A.; Jang, J.G. Recent Progress in Green Cement Technology Utilizing Low-Carbon Emission Fuels and Raw Materials: A Review. Sustainability 2019, 11, 537. [Google Scholar] [CrossRef]

- Hasanbeigi, A.; Price, L.; Lu, H.; Lan, W. Analysis of energy-efficiency opportunities for the cement industry in Shandong Province, China: A case study of 16 cement plants. Energy 2010, 35, 3461–3473. [Google Scholar] [CrossRef]

- Meyer, C. The greening of the concrete industry. Cem. Concr. Compos. 2009, 31, 601–605. [Google Scholar] [CrossRef]

- Valipour, M.; Yekkalar, M.; Shekarchi, M.; Panahi, S. Environmental assessment of green concrete containing natural zeolite on the global warming index in marine environments. J. Clean. Prod. 2014, 65, 418–423. [Google Scholar] [CrossRef]

- Afroughsabet, V.; Biolzi, L.; Ozbakkaloglu, T. High-performance fiber-reinforced concrete: A review. J. Mater. Sci. 2016, 51, 6517–6551. [Google Scholar] [CrossRef]

- Wei, J.; Meyer, C. Degradation of natural fiber in ternary blended cement composites containing metakaolin and montmorillonite. Corros. Sci. 2017, 120, 42–60. [Google Scholar] [CrossRef]

- Hakamy, A.; Shaikh, F.U.A.; Low, I.M. Effect of calcined nanoclay on microstructural and mechanical properties of chemically treated hemp fabric-reinforced cement nanocomposites. Constr. Build. Mater. 2015, 95, 882–891. [Google Scholar] [CrossRef]

- Yang, K.-H.; Jung, Y.-B.; Cho, M.-S.; Tae, S.-H. Chapter 5—Effect of Supplementary Cementitious Materials on Reduction of CO2 Emissions from Concrete. In Handbook of Low Carbon Concrete; Nazari, A., Sanjayan, J., Eds.; Butterworth-Heinemann: Oxford, UK, 2017; pp. 89–110. ISBN 978-0-12-804524-4. [Google Scholar]

- Crossin, E. The greenhouse gas implications of using ground granulated blast furnace slag as a cement substitute. J. Clean. Prod. 2015, 95, 101–108. [Google Scholar] [CrossRef]

- Li, C.; Sun, H.; Li, L. A review: The comparison between alkali-activated slag (Si + Ca) and metakaolin (Si + Al) cements. Cem. Concr. Res. 2010, 40, 1341–1349. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Castro-Gomes, J.; Jalali, S. Alkali-activated binders: A review: Part 1. Historical background, terminology, reaction mechanisms and hydration products. Constr. Build. Mater. 2008, 22, 1305–1314. [Google Scholar] [CrossRef]

- Scrivener, K.L.; Gartner, E.M. Eco-efficient cements: Potential economically viable solutions for a low-CO2 cement-based materials industry. Cem. Concr. Res. 2018, 114, 2–26. [Google Scholar] [CrossRef]

- Golewski, G.L. Green concrete composite incorporating fly ash with high strength and fracture toughness. J. Clean. Prod. 2018, 172, 218–226. [Google Scholar] [CrossRef]

- Tahanpour Javadabadi, M.; De Lima Kristiansen, D.; Bayene Redie, M.; Baghban, M.H. Sustainable Concrete: A Review. Int. J. Struct. Civ. Eng. Res. 2019, 8, 126–132. [Google Scholar]

- Fallah, S.; Nematzadeh, M. Mechanical properties and durability of high-strength concrete containing macro-polymeric and polypropylene fibers with nano-silica and silica fume. Constr. Build. Mater. 2017, 132, 170–187. [Google Scholar] [CrossRef]

- Chatterji, S.; Thaulow, N.; Christensen, P. Puzzolanic activity of byproduct silica-fume from ferro-silicom production. Cem. Concr. Res. 1982, 12, 781–784. [Google Scholar] [CrossRef]

- Mehta, P.K.; Gjørv, O.E. Properties of portland cement concrete containing fly ash and condensed silica-fume. Cem. Concr. Res. 1982, 12, 587–595. [Google Scholar] [CrossRef]

- Diamond, S. The utilization of flyash. Cem. Concr. Res. 1984, 14, 455–462. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Jaturapitakkul, C.; Sinsiri, T. Effect of fly ash fineness on microstructure of blended cement paste. Constr. Build. Mater. 2007, 21, 1534–1541. [Google Scholar] [CrossRef]

- Rodríguez de Sensale, G. Effect of rice-husk ash on durability of cementitious materials. Cem. Concr. Compos. 2010, 32, 718–725. [Google Scholar] [CrossRef]

- Zain, M.F.M.; Islam, M.N.; Mahmud, F.; Jamil, M. Production of rice husk ash for use in concrete as a supplementary cementitious material. Constr. Build. Mater. 2011, 25, 798–805. [Google Scholar] [CrossRef]

- Adesanya, D.A.; Raheem, A.A. Development of corn cob ash blended cement. Constr. Build. Mater. 2009, 23, 347–352. [Google Scholar] [CrossRef]

- Adesanya, D.A.; Raheem, A.A. A study of the permeability and acid attack of corn cob ash blended cements. Constr. Build. Mater. 2010, 24, 403–409. [Google Scholar] [CrossRef]

- Sigvardsen, N.M.; Kirkelund, G.M.; Jensen, P.E.; Geiker, M.R.; Ottosen, L.M. Impact of production parameters on physiochemical characteristics of wood ash for possible utilisation in cement-based materials. Resour. Conserv. Recycl. 2019, 145, 230–240. [Google Scholar] [CrossRef]

- Vejmelková, E.; Koňáková, D.; Kulovaná, T.; Keppert, M.; Žumár, J.; Rovnaníková, P.; Keršner, Z.; Sedlmajer, M.; Černý, R. Engineering properties of concrete containing natural zeolite as supplementary cementitious material: Strength, toughness, durability, and hygrothermal performance. Cem. Concr. Compos. 2015, 55, 259–267. [Google Scholar] [CrossRef]

- Villar-Cociña, E.; Morales, E.V.; Santos, S.F.; Savastano, H.; Frías, M. Pozzolanic behavior of bamboo leaf ash: Characterization and determination of the kinetic parameters. Cem. Concr. Compos. 2011, 33, 68–73. [Google Scholar] [CrossRef]

- Aprianti, E.; Shafigh, P.; Bahri, S.; Farahani, J.N. Supplementary cementitious materials origin from agricultural wastes—A review. Constr. Build. Mater. 2015, 74, 176–187. [Google Scholar] [CrossRef]

- Kroehong, W.; Sinsiri, T.; Jaturapitakkul, C. Effect of Palm Oil Fuel Ash Fineness on Packing Effect and Pozzolanic Reaction of Blended Cement Paste. Procedia Eng. 2011, 14, 361–369. [Google Scholar] [CrossRef]

- Lim, N.H.A.S.; Ismail, M.A.; Lee, H.S.; Hussin, M.W.; Sam, A.R.M.; Samadi, M. The effects of high volume nano palm oil fuel ash on microstructure properties and hydration temperature of mortar. Constr. Build. Mater. 2015, 93, 29–34. [Google Scholar] [CrossRef]

- Rajak, M.A.A.; Majid, Z.A.; Ismail, M. Morphological Characteristics of Hardened Cement Pastes Incorporating Nano-palm Oil Fuel Ash. Procedia Manuf. 2015, 2, 512–518. [Google Scholar] [CrossRef]

- Islam, M.M.U.; Mo, K.H.; Alengaram, U.J.; Jumaat, M.Z. Mechanical and fresh properties of sustainable oil palm shell lightweight concrete incorporating palm oil fuel ash. J. Clean. Prod. 2016, 115, 307–314. [Google Scholar] [CrossRef]

- Jaturapitakkul, C.; Tangpagasit, J.; Songmue, S.; Kiattikomol, K. Filler effect and pozzolanic reaction of ground palm oil fuel ash. Constr. Build. Mater. 2011, 25, 4287–4293. [Google Scholar] [CrossRef]

- Jaturapitakkul, C.; Kiattikomol, K.; Tangchirapat, W.; Saeting, T. Evaluation of the sulfate resistance of concrete containing palm oil fuel ash. Constr. Build. Mater. 2007, 21, 1399–1405. [Google Scholar] [CrossRef]

- Wi, K.; Lee, H.-S.; Lim, S.; Ismail, M.A.; Hussin, M.W. Effect of Using Micropalm Oil Fuel Ash as Partial Replacement of Cement on the Properties of Cement Mortar. Adv. Mater. Sci. Eng. 2018, 2018, 1–8. [Google Scholar] [CrossRef]

- Khodabakhshian, A.; Ghalehnovi, M.; de Brito, J.; Asadi Shamsabadi, E. Durability performance of structural concrete containing silica fume and marble industry waste powder. J. Clean. Prod. 2018, 170, 42–60. [Google Scholar] [CrossRef]

- Lothenbach, B.; Le Saout, G.; Gallucci, E.; Scrivener, K. Influence of limestone on the hydration of Portland cements. Cem. Concr. Res. 2008, 38, 848–860. [Google Scholar] [CrossRef]

- Song, Q.; Yu, R.; Wang, X.; Rao, S.; Shui, Z. A novel Self-Compacting Ultra-High Performance Fibre Reinforced Concrete (SCUHPFRC) derived from compounded high-active powders. Constr. Build. Mater. 2018, 158, 883–893. [Google Scholar] [CrossRef]

- Avet, F.; Scrivener, K. Hydration Study of Limestone Calcined Clay Cement (LC3) Using Various Grades of Calcined Kaolinitic Clays. In Calcined Clays for Sustainable Concrete; Springer: Dordrecht, The Netherlands, 2018; pp. 35–40. [Google Scholar]

- Avet, F.; Boehm-Courjault, E.; Scrivener, K. Investigation of C-A-S-H composition, morphology and density in Limestone Calcined Clay Cement (LC3). Cem. Concr. Res. 2019, 115, 70–79. [Google Scholar] [CrossRef]

- Sharaky, I.A.; Megahed, F.A.; Seleem, M.H.; Badawy, A.M. The influence of silica fume, nano silica and mixing method on the strength and durability of concrete. SN Appl. Sci. 2019, 1, 575. [Google Scholar] [CrossRef]

- Meddah, M.S.; Ismail, M.A.; El-Gamal, S.; Fitriani, H. Performances evaluation of binary concrete designed with silica fume and metakaolin. Constr. Build. Mater. 2018, 166, 400–412. [Google Scholar] [CrossRef]

- Saha, A.K. Effect of class F fly ash on the durability properties of concrete. Sustain. Environ. Res. 2018, 28, 25–31. [Google Scholar] [CrossRef]

- Uthaman, S.; Vishwakarma, V.; George, R.P.; Ramachandran, D.; Kumari, K.; Preetha, R.; Premila, M.; Rajaraman, R.; Mudali, U.K.; Amarendra, G. Enhancement of strength and durability of fly ash concrete in seawater environments: Synergistic effect of nanoparticles. Constr. Build. Mater. 2018, 187, 448–459. [Google Scholar] [CrossRef]

- King, D. The effect of silica fume on the properties of concrete as defined in concrete society report 74, cementitious materials. In Proceedings of the 37th Conference on Our World in Concrete and Structures, Singapore, 29–31 August 2012; pp. 29–31. [Google Scholar]

- Scrivener, K.; Martirena, F.; Bishnoi, S.; Maity, S. Calcined clay limestone cements (LC3). Cem. Concr. Res. 2018, 114, 49–56. [Google Scholar] [CrossRef]

- Snellings, R. Assessing, Understanding and Unlocking Supplementary Cementitious Materials. Rilem Tech. Lett. 2016, 1, 50. [Google Scholar] [CrossRef]

- Tironi, A.; Trezza, M.A.; Scian, A.N.; Irassar, E.F. Assessment of pozzolanic activity of different calcined clays. Cem. Concr. Compos. 2013, 37, 319–327. [Google Scholar] [CrossRef]

- Shi, Z.; Ferreiro, S.; Lothenbach, B.; Geiker, M.R.; Kunther, W.; Kaufmann, J.; Herfort, D.; Skibsted, J. Sulfate resistance of calcined clay—Limestone—Portland cements. Cem. Concr. Res. 2019, 116, 238–251. [Google Scholar] [CrossRef]

- Taylor-Lange, S.C.; Lamon, E.L.; Riding, K.A.; Juenger, M.C.G. Calcined kaolinite–bentonite clay blends as supplementary cementitious materials. Appl. Clay Sci. 2015, 108, 84–93. [Google Scholar] [CrossRef]

- Fernandez, R.; Martirena, F.; Scrivener, K.L. The origin of the pozzolanic activity of calcined clay minerals: A comparison between kaolinite, illite and montmorillonite. Cem. Concr. Res. 2011, 41, 113–122. [Google Scholar] [CrossRef]

- Garg, N.; Skibsted, J. Thermal Activation of a Pure Montmorillonite Clay and Its Reactivity in Cementitious Systems. J. Phys. Chem. C 2014, 118, 11464–11477. [Google Scholar] [CrossRef]

- Antoni, M.; Rossen, J.; Martirena, F.; Scrivener, K. Cement substitution by a combination of metakaolin and limestone. Cem. Concr. Res. 2012, 42, 1579–1589. [Google Scholar] [CrossRef]

- Tafraoui, A.; Escadeillas, G.; Lebaili, S.; Vidal, T. Metakaolin in the formulation of UHPC. Constr. Build. Mater. 2009, 23, 669–674. [Google Scholar] [CrossRef]

- Souza, P.S.L.; Dal Molin, D.C.C. Viability of using calcined clays, from industrial by-products, as pozzolans of high reactivity. Cem. Concr. Res. 2005, 35, 1993–1998. [Google Scholar] [CrossRef]

- Ding, J.-T.; Li, Z. Effects of metakaolin and silica fume on properties of concrete. Mater. J. 2002, 99, 393–398. [Google Scholar]

- Chen, Y.; Chaves Figueiredo, S.; Yalçinkaya, Ç.; Çopuroğlu, O.; Veer, F.; Schlangen, E. The Effect of Viscosity-Modifying Admixture on the Extrudability of Limestone and Calcined Clay-Based Cementitious Material for Extrusion-Based 3D Concrete Printing. Materials 2019, 12, 1374. [Google Scholar] [CrossRef] [PubMed]

- Hassan, A.A.A.; Mayo, J.R. Influence of mixture composition on the properties of SCC incorporating metakaolin. Mag. Concr. Res. 2014, 66, 1036–1050. [Google Scholar] [CrossRef]

- Alvarez, G.L.; Nazari, A.; Bagheri, A.; Sanjayan, J.G.; De Lange, C. Microstructure, electrical and mechanical properties of steel fibres reinforced cement mortars with partial metakaolin and limestone addition. Constr. Build. Mater. 2017, 135, 8–20. [Google Scholar] [CrossRef]

- Avet, F.; Snellings, R.; Alujas Diaz, A.; Ben Haha, M.; Scrivener, K. Development of a new rapid, relevant and reliable (R3) test method to evaluate the pozzolanic reactivity of calcined kaolinitic clays. Cem. Concr. Res. 2016, 85, 1–11. [Google Scholar] [CrossRef]

- Sánchez Berriel, S.; Favier, A.; Rosa Domínguez, E.; Sánchez Machado, I.R.; Heierli, U.; Scrivener, K.; Martirena Hernández, F.; Habert, G. Assessing the environmental and economic potential of Limestone Calcined Clay Cement in Cuba. J. Clean. Prod. 2016, 124, 361–369. [Google Scholar] [CrossRef]

- Huang, W.; Kazemi-Kamyab, H.; Sun, W.; Scrivener, K. Effect of replacement of silica fume with calcined clay on the hydration and microstructural development of eco-UHPFRC. Mater. Des. 2017, 121, 36–46. [Google Scholar] [CrossRef]

- Arbi, K.; Nedeljković, M.; Zuo, Y.; Ye, G. A Review on the Durability of Alkali-Activated Fly Ash/Slag Systems: Advances, Issues, and Perspectives. Ind. Eng. Chem. Res. 2016, 55, 5439–5453. [Google Scholar] [CrossRef]

- Almenares, R.S.; Vizcaíno, L.M.; Damas, S.; Mathieu, A.; Alujas, A.; Martirena, F. Industrial calcination of kaolinitic clays to make reactive pozzolans. Case Stud. Constr. Mater. 2017, 6, 225–232. [Google Scholar] [CrossRef]

- Ferreiro, S.; Herfort, D.; Damtoft, J.S. Effect of raw clay type, fineness, water-to-cement ratio and fly ash addition on workability and strength performance of calcined clay—Limestone Portland cements. Cem. Concr. Res. 2017, 101, 1–12. [Google Scholar] [CrossRef]

- Chen, Y.; Li, Z.; Chaves Figueiredo, S.C.; Çopuroğlu, O.; Veer, F.; Schlangen, E.; Chen, Y.; Li, Z.; Chaves Figueiredo, S.; Çopuroğlu, O.; et al. Limestone and Calcined Clay-Based Sustainable Cementitious Materials for 3D Concrete Printing: A Fundamental Study of Extrudability and Early-Age Strength Development. Appl. Sci. 2019, 9, 1809. [Google Scholar] [CrossRef]

- Maraghechi, H.; Avet, F.; Wong, H.; Kamyab, H.; Scrivener, K. Performance of Limestone Calcined Clay Cement (LC3) with various kaolinite contents with respect to chloride transport. Mater. Struct. 2018, 51, 125. [Google Scholar] [CrossRef]

- Dhandapani, Y.; Sakthivel, T.; Santhanam, M.; Gettu, R.; Pillai, R.G. Mechanical properties and durability performance of concretes with Limestone Calcined Clay Cement (LC3). Cem. Concr. Res. 2018, 107, 136–151. [Google Scholar] [CrossRef]

- Pillai, R.G.; Gettu, R.; Santhanam, M.; Rengaraju, S.; Dhandapani, Y.; Rathnarajan, S.; Basavaraj, A.S. Service life and life cycle assessment of reinforced concrete systems with limestone calcined clay cement (LC3). Cem. Concr. Res. 2019, 118, 111–119. [Google Scholar] [CrossRef]

- Steenberg, M.; Herfort, D.; Poulsen, S.L.; Skibsted, J.; Damtoft, J.S. Composite cement based on Portland cement clinker, limestone and calcined clay. In Proceedings of the Xiii International Congress on the Chemistry of Cement, Madrid, Spain, 3–8 July 2011. [Google Scholar]

- Baghban, M.H.; Hovde, P.J.; Jacobsen, S. Effect of internal hydrophobation, silica fume and w/c on water sorption of hardened cement pastes. In Proceedings of the International Conference on Durability of Building Materials and Components, Porto, Portugal, 12–15 April 2011. [Google Scholar]

- Baghban, M.H. Water Sorption of Hardened Cement Pastes. Cem. Based Mater. 2018. [Google Scholar] [CrossRef]

- Justnes, H.; Østnor, T.; Barnils Vila, N. Vegetable oils as water repellents for mortars. In Proceedings of the 1st International Conference of Asian Concrete Federation, Chiang Mai, Thailand, 28–29 October 2004; pp. 28–29. [Google Scholar]

- Baghban, M.; Hovde, P.; Jacobsen, S. Effect of internal hydrophobation, silica fume and w/c on compressive strength of hardened cement pastes. World J. Eng. 2012, 9, 7–12. [Google Scholar] [CrossRef]

- Baghban, M.H.; Holvik, O.K.; Hesselberg, E.; Javadabadi, M.T. Cementitious Composites with Low Water Permeability through Internal Hydrophobicity. Key Engineering Materials. 2018, 779, 37–42. [Google Scholar] [CrossRef]

- Favier, A.; Scrivener, K. Alkali Silica Reaction and Sulfate Attack: Expansion of Limestone Calcined Clay Cement. In Calcined Clays for Sustainable Concrete; Springer: Dordrecht, The Netherlands, 2018; pp. 165–169. [Google Scholar]

- Carpinteri, A.; Cadamuro, E.; Ventura, G. Fiber-reinforced concrete in flexure: A cohesive/overlapping crack model application. Mater. Struct. 2015, 48, 235–247. [Google Scholar] [CrossRef]

- Oh, B.H.; Kim, J.C.; Choi, Y.C. Fracture behavior of concrete members reinforced with structural synthetic fibers. Eng. Fract. Mech. 2007, 74, 243–257. [Google Scholar] [CrossRef]

- Yin, S.; Tuladhar, R.; Shi, F.; Combe, M.; Collister, T.; Sivakugan, N. Use of macro plastic fibres in concrete: A review. Constr. Build. Mater. 2015, 93, 180–188. [Google Scholar] [CrossRef]

- Mobasher, B. Mechanics of Fiber and Textile Reinforced Cement Composites; CRC Press: New York, NY, USA, 2011; ISBN 9780429131387. [Google Scholar]

- Choe, G.; Kim, G.; Kim, H.; Hwang, E.; Lee, S.; Nam, J. Effect of amorphous metallic fiber on mechanical properties of high-strength concrete exposed to high-temperature. Constr. Build. Mater. 2019, 218, 448–456. [Google Scholar] [CrossRef]

- Zollo, R.F. Fiber-reinforced concrete: An overview after 30 years of development. Cem. Concr. Compos. 1997, 19, 107–122. [Google Scholar] [CrossRef]

- Brandt, A.M. Fibre reinforced cement-based (FRC) composites after over 40 years of development in building and civil engineering. Compos. Struct. 2008, 86, 3–9. [Google Scholar] [CrossRef]

- Al-Oraimi, S.K.; Seibi, A.C. Mechanical characterisation and impact behaviour of concrete reinforced with natural fibres. Compos. Struct. 1995, 32, 165–171. [Google Scholar] [CrossRef]

- De Gutiérrez, R.M.; Díaz, L.N.; Delvasto, S. Effect of pozzolans on the performance of fiber-reinforced mortars. Cem. Concr. Compos. 2005, 27, 593–598. [Google Scholar] [CrossRef]

- Mobasher, B.; Li, C.Y. Effect of interfacial properties on the crack propagation in cementitious composites. Adv. Cem. Based Mater. 1996, 4, 93–105. [Google Scholar] [CrossRef]

- Alberti, M.G.; Enfedaque, A.; Gálvez, J.C. On the mechanical properties and fracture behavior of polyolefin fiber-reinforced self-compacting concrete. Constr. Build. Mater. 2014, 55, 274–288. [Google Scholar] [CrossRef]

- Fujikake, K. Impact Performance of Ultra-High Performance Fiber Reinforced Concrete Beam and its Analytical Evaluation. Int. J. Prot. Struct. 2014, 5, 167–186. [Google Scholar] [CrossRef]

- Soroushian, P.; Marikunte, S. Moisture effects on flexural performance of wood fiber-cement composites. J. Mater. Civ. Eng. 1992, 4, 275–291. [Google Scholar] [CrossRef]

- Soroushian, P.; Marikunte, S. Moisture Sensitivity of Cellulose Fiber Reinforced Cement. In Proceedings of the Durability of Concrete: Second International Conference, Montreal, QC, Canada, 4 August 1991; Volume II, pp. 821–835. [Google Scholar]

- Soroushian, P.; Marikunte, S. Reinforcement of cement-based materials with cellulose fibers. Spec. Publ. 1990, 124, 99–124. [Google Scholar]

- Mansur, M.A.; Aziz, M.A. A study of jute fibre reinforced cement composites. Int. J. Cem. Compos. Lightweight Concr. 1982, 4, 75–82. [Google Scholar] [CrossRef]

- Rostami, R.; Zarrebini, M.; Sanginabadi, K.; Mostofinejad, D.; Abtahi, S.M.; Fashandi, H. The effect of specific surface area of macro fibers on energy absorption capacity of concrete. J. Text. Inst. 2019, 110, 707–714. [Google Scholar] [CrossRef]

- Hasan, A.; Maroof, N.; Ibrahim, Y. Effects of Polypropylene Fiber Content on Strength and Workability Properties of Concrete. Polytech. J. 2019, 9, 7–12. [Google Scholar] [CrossRef]

- Lam, T.F.; Yatim, J.M. Mechanical properties of kenaf fiber reinforced concrete with different fiber content and fiber length. J. Asian Concr. Fed. 2015, 1, 11. [Google Scholar] [CrossRef]

- Ramaswamy, H.S.; Ahuja, B.M.; Krishnamoorthy, S. Behaviour of concrete reinforced with jute, coir and bamboo fibres. Int. J. Cem. Compos. Lightweight Concr. 1983, 5, 3–13. [Google Scholar] [CrossRef]

- Hasan, N.M.S.; Sobuz, H.R.; Sayed, M.S.; Islam, M.S. The Use of Coconut Fibre in the Production of Structural Lightweight Concrete. J. Appl. Sci. 2012, 12, 831–839. [Google Scholar]

- Ali, M.; Liu, A.; Sou, H.; Chouw, N. Mechanical and dynamic properties of coconut fibre reinforced concrete. Constr. Build. Mater. 2012, 30, 814–825. [Google Scholar] [CrossRef]

- Vajje, S.; Murthy, N.R.K. Study On Addition Of The Natural Fibers Into Concrete. Int. J. Sci. Technol. Res. 2013, 2, 213–218. [Google Scholar]

- Güneyisi, E.; Gesoğlu, M.; Akoi, A.O.M.; Mermerdaş, K. Combined effect of steel fiber and metakaolin incorporation on mechanical properties of concrete. Compos. Part B Eng. 2014, 56, 83–91. [Google Scholar] [CrossRef]

- Uzomaka, O.J. Characteristics of akwara as a reinforcing fibre. Mag. Concr. Res. 1976, 28, 162–167. [Google Scholar] [CrossRef]

- Ramakrishna, G.; Sundararajan, T. Impact strength of a few natural fibre reinforced cement mortar slabs: A comparative study. Cem. Concr. Compos. 2005, 27, 547–553. [Google Scholar] [CrossRef]

- Merta, I.; Tschegg, E.K. Fracture energy of natural fibre reinforced concrete. Constr. Build. Mater. 2013, 40, 991–997. [Google Scholar] [CrossRef]

- Banthia, N.; Zanotti, C.; Sappakittipakorn, M. Sustainable fiber reinforced concrete for repair applications. Constr. Build. Mater. 2014, 67, 405–412. [Google Scholar] [CrossRef]

- Zhou, X.; Ghaffar, S.H.; Dong, W.; Oladiran, O.; Fan, M. Fracture and impact properties of short discrete jute fibre-reinforced cementitious composites. Mater. Des. 2013, 49, 35–47. [Google Scholar] [CrossRef]

- Wang, X.D.; Zhang, C.; Huang, Z.; Chen, G.W. Impact Experimental Research on Hybrid Bamboo Fiber and Steel Fiber Reinforced Concrete. Appl. Mech. Mater. 2013, 357–360, 1049–1052. [Google Scholar] [CrossRef]

- Wang, W.; Chouw, N. The behaviour of coconut fibre reinforced concrete (CFRC) under impact loading. Constr. Build. Mater. 2017, 134, 452–461. [Google Scholar] [CrossRef]

- Page, J.; Khadraoui, F.; Boutouil, M.; Gomina, M. Multi-physical properties of a structural concrete incorporating short flax fibers. Constr. Build. Mater. 2017, 140, 344–353. [Google Scholar] [CrossRef]

- Toledo Filho, R.D.; Scrivener, K.; England, G.L.; Ghavami, K. Durability of alkali-sensitive sisal and coconut fibres in cement mortar composites. Cem. Concr. Compos. 2000, 22, 127–143. [Google Scholar] [CrossRef]

- Mohr, B.J.; Biernacki, J.J.; Kurtis, K.E. Supplementary cementitious materials for mitigating degradation of kraft pulp fiber-cement composites. Cem. Concr. Res. 2007, 37, 1531–1543. [Google Scholar] [CrossRef]

- Harper, S. Developing asbestos-free calcium silicate building boards. Composites 1982, 13, 123–128. [Google Scholar] [CrossRef]

- Bergström, S.G.; Gram, H.-E. Durability of alkali-sensitive fibres in concrete. Int. J. Cem. Compos. Lightweight Concr. 1984, 6, 75–80. [Google Scholar] [CrossRef]

- Sivaraja, M.; Velmani, N.; Pillai, M.S. Study on durability of natural fibre concrete composites using mechanical strength and microstructural properties. Bull. Mater. Sci. 2010, 33, 719–729. [Google Scholar] [CrossRef]

- Omoniyi, T.; Akinyemi, B. Durability based suitability of bagasse cement composite for roofing sheets. J. Civ. Eng. Const. Tech. 2012. [Google Scholar] [CrossRef]

- Ramakrishna, G.; Sundararajan, T.; Kothandaraman, S. Evaluation of durability of natural fibre reinforced cement mortar composite-a new approach. ARPN J. Eng. Appl. Sci. 2010, 5, 44–51. [Google Scholar]

- Javadi, A.; Srithep, Y.; Pilla, S.; Lee, J.; Gong, S.; Turng, L.S. Processing and characterization of solid and microcellular PHBV/coir fiber composites. Mater. Sci. Eng. C 2010, 30, 749–757. [Google Scholar] [CrossRef]

- Bilba, K.; Arsene, M.-A. Silane treatment of bagasse fiber for reinforcement of cementitious composites. Compos. Part Appl. Sci. Manuf. 2008, 39, 1488–1495. [Google Scholar] [CrossRef]

- Cooke, A.M. Durability of Autoclaved Cellulose Fiber Cement Composites. In Proceedings of the 7th Inorganic-Bonded Wood and Fibre Conference, Sun Valley, ID, USA, 25–27 September 2000; Available online: www.fibrecementconsulting.com/publications/990925.durabilitypaper.pdf (accessed on 15 October 2019).

- Claramunt, J.; Ardanuy, M.; García-Hortal, J.A.; Filho, R.D.T. The hornification of vegetable fibers to improve the durability of cement mortar composites. Cem. Concr. Compos. 2011, 33, 586–595. [Google Scholar] [CrossRef]

- Pehanich, J.L.; Blankenhorn, P.R.; Silsbee, M.R. Wood fiber surface treatment level effects on selected mechanical properties of wood fiber–cement composites. Cem. Concr. Res. 2004, 34, 59–65. [Google Scholar] [CrossRef]

- Mahjoub, R.; Yatim, J.M.; Mohd Sam, A.R.; Hashemi, S.H. Tensile properties of kenaf fiber due to various conditions of chemical fiber surface modifications. Constr. Build. Mater. 2014, 55, 103–113. [Google Scholar] [CrossRef]

- Mohammadkazemi, F.; Doosthoseini, K.; Ganjian, E.; Azin, M. Manufacturing of bacterial nano-cellulose reinforced fiber−cement composites. Constr. Build. Mater. 2015, 101, 958–964. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Yatim, J.M.; Sam, A.R.M.; Awal, A.S.M.A. Durability performance of green concrete composites containing waste carpet fibers and palm oil fuel ash. J. Clean. Prod. 2017, 144, 448–458. [Google Scholar] [CrossRef]

- Sharman, W.R.; Vautier, B.P. Durability Studies on Wood Fibre Reinforced Cement Sheet; Building Research Association of New Zealand: Rochdale, UK, 1986. [Google Scholar]

- Elsaid, A.; Dawood, M.; Seracino, R.; Bobko, C. Mechanical properties of kenaf fiber reinforced concrete. Constr. Build. Mater. 2011, 25, 1991–2001. [Google Scholar] [CrossRef]

- Marikunte, S.; Soroushian, P. Statistical evaluation of long-term durability characteristics of cellulose fiber reinforced cement composites. Mater. J. 1995, 91, 607–616. [Google Scholar]

- Zaveri, M.D. Absorbency Characteristics of Kenaf Core Particles. Ph.D. Thesis, North Carolina State University, Raleigh, NC, USA, 2004. [Google Scholar]

- Mohanty, A.K.; Misra, M.; Drzal, L.T. Natural Fibers, Biopolymers, and Biocomposites; CRC Press: Boca Raton, FL, USA, 2005; ISBN 0203508203. [Google Scholar]

- Akil, H.M.; Omar, M.F.; Mazuki, A.A.M.; Safiee, S.; Ishak, Z.A.M.; Abu Bakar, A. Kenaf fiber reinforced composites: A review. Mater. Des. 2011, 32, 4107–4121. [Google Scholar] [CrossRef]

- Mahjoub, R.; Yatim, J.M.; Mohd Sam, A.R.; Raftari, M. Characteristics of continuous unidirectional kenaf fiber reinforced epoxy composites. Mater. Des. 2014, 64, 640–649. [Google Scholar] [CrossRef]

- Kumar, K.K.; Karunakar, C.; ChandraMouli, B. Development and Characterization of Hybrid Fibres Reinforced Composites Based on Glass and Kenaf Fibers. Mater. Today Proc. 2018, 5, 14539–14544. [Google Scholar] [CrossRef]

- Ochi, S. Mechanical properties of kenaf fibers and kenaf/PLA composites. Mech. Mater. 2008, 40, 446–452. [Google Scholar] [CrossRef]

- Mahjoub, R.; Yatim, J.M.; Sam, A.M.; Zulkarnain, N.A.; Raftari, M. The Use of Kenaf Fiber Reinforced Polymer to Confine the Concrete Cylinder. Mater. Today Proc. 2016, 3, 459–463. [Google Scholar] [CrossRef]

- Jawaid, M.; Abdul Khalil, H.P.S.; Abu Bakar, A. Mechanical performance of oil palm empty fruit bunches/jute fibres reinforced epoxy hybrid composites. Mater. Sci. Eng. A 2010, 527, 7944–7949. [Google Scholar] [CrossRef]

- Jarukumjorn, K.; Suppakarn, N. Effect of glass fiber hybridization on properties of sisal fiber-polypropylene composites. Compos. Part B Eng. 2009, 40, 623–627. [Google Scholar] [CrossRef]

- Joseph, K.; Varghese, S.; Kalaprasad, G.; Thomas, S.; Prasannakumari, L.; Koshy, P.; Pavithran, C. Influence of interfacial adhesion on the mechanical properties and fracture behaviour of short sisal fibre reinforced polymer composites. Eur. Polym. J. 1996, 32, 1243–1250. [Google Scholar] [CrossRef]

- Holbery, J.; Houston, D. Natural-fiber-reinforced polymer composites in automotive applications. JOM 2006, 58, 80–87. [Google Scholar] [CrossRef]

- Ku, H.; Wang, H.; Pattarachaiyakoop, N.; Trada, M. A review on the tensile properties of natural fiber reinforced polymer composites. Compos. Part B Eng. 2011, 42, 856–873. [Google Scholar] [CrossRef]

- Ranakoti, L.; Pokhriyal, M.; Kumar, A. Natural fibers and biopolymers characterization: A future potential composite material. Bratisl. J. Mech. Eng. Stroj. Časopis 2018, 68, 33–50. [Google Scholar]

- Mishra, S.; Mohanty, A.K.; Drzal, L.T.; Misra, M.; Parija, S.; Nayak, S.K.; Tripathy, S.S. Studies on mechanical performance of biofibre/glass reinforced polyester hybrid composites. Compos. Sci. Technol. 2003, 63, 1377–1385. [Google Scholar] [CrossRef]

- Nabi, S.D.; Jog, J.P. Natural Fiber Polymer Composites: A Review. Adv. Polym. Technol. 1999, 18, 351–363. [Google Scholar]

- Jawaid, M.; Abdul Khalil, H.P.S. Cellulosic/synthetic fibre reinforced polymer hybrid composites: A review. Carbohydr. Polym. 2011, 86, 1–18. [Google Scholar] [CrossRef]

- Sreekala, M.S.; Kumaran, M.G.; Thomas, S. Oil palm fibers: Morphology, chemical composition, surface modification, and mechanical properties. J. Appl. Polym. Sci. 1997, 66, 821–835. [Google Scholar] [CrossRef]

- Mahjoub, R.; Bin Mohamad Yatim, J.; Mohd Sam, A.R. A review of structural performance of oil palm empty fruit bunch fiber in polymer composites. Adv. Mater. Sci. Eng. 2013, 2013. [Google Scholar] [CrossRef]

- Davoodi, M.M.; Sapuan, S.M.; Ahmad, D.; Ali, A.; Khalina, A.; Jonoobi, M. Mechanical properties of hybrid kenaf/glass reinforced epoxy composite for passenger car bumper beam. Mater. Des. 2010, 31, 4927–4932. [Google Scholar] [CrossRef]

- Park, J.K.; Cho, D.; Kang, T.J. A comparison of the interfacial, thermal, and ablative properties between spun and filament yarn type carbon fabric/phenolic composites. Carbon 2004, 42, 795–804. [Google Scholar] [CrossRef]

- Huang, C.; Chen, T.; Feng, S. Finite element analysis of fatigue crack growth in CFRP-repaired four-point bend specimens. Eng. Struct. 2019, 183, 398–407. [Google Scholar] [CrossRef]

- Babatunde Ogunbode, E.; Mohamad Yatim, J.; Yunus Ishak, M.; Abdul Hamid, H. An Evaluation of the Interfacial Bond Strength of Kenaf Fibrous Concrete and Plain Concrete Composite Cleaner and Sustainable Housing View Project Strength, Durability and Microstructural properties of concrete composites View project. Int. J. Built Environ. Sustain. 2019, 6, 1–6. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).