Abstract

In recent years, computer-based simulations have been used to enhance production processes, and sustainable industrial strategies are increasingly being considered in the manufacturing industry. In order to evaluate the performance of a gasification process, the Life Cycle Thinking (LCT) technique gathers relevant impact assessment tools to offer quantitative indications across different domains. Following the PRISMA guidelines, the present paper undertakes a scoping review of gasification processes’ environmental, economic, and social impacts to reveal how LCT approaches coping with sustainability. This report categorizes the examined studies on the gasification process (from 2017 to 2022) through the lens of LCT, discussing the challenges and opportunities. These studies have investigated a variety of biomass feedstock, assessment strategies and tools, geographical span, bioproducts, and databases. The results show that among LCT approaches, by far, the highest interest belonged to life cycle assessment (LCA), followed by life cycle cost (LCC). Only a few studies have addressed exergetic life cycle assessment (ELCA), life cycle energy assessment (LCEA), social impact assessment (SIA), consequential life cycle assessment (CLCA), and water footprint (WLCA). SimaPro® (PRé Consultants, Netherlands), GaBi® (sphere, USA), and OpenLCA (GreenDelta, Germany) demonstrated the greatest contribution. Uncertainty analysis (Monte Carlo approach and sensitivity analysis) was conducted in almost half of the investigations. Most importantly, the results confirm that it is challenging or impossible to compare the environmental impacts of the gasification process with other alternatives since the results may differ based on the methodology, criteria, or presumptions. While gasification performed well in mitigating negative environmental consequences, it is not always the greatest solution compared to other technologies.

1. Introduction

After coal, petroleum, and natural gas, biomass is the world’s fourth-largest energy source, accounting for a considerable amount of global primary energy consumption [1]. Biomass presently contributes roughly 14% of the world’s yearly energy consumption in all forms [2]. As an alternative, biomasses, such as agricultural waste, forestry waste, municipal solid, and industrial waste, are renewable energy resources used for producing either solid or liquid fuels [3,4]. There are different processes to produce biomass energy, such as thermochemical, biological, and physical conversion (oilseed extraction). Thermochemical conversions can be categorized into combustion, pyrolysis, and gasification. Biological conversion can be achieved by fermentation or anaerobic digestion [5,6,7,8]. Moreover, there are some novel approaches to merging microbiology, electrochemistry, and electronics, such as microbial electrochemical technologies (METs) [9]. Converting organic sources into electricity and treating organic waste stream in microbial fuel cells (MFCs) [10], hydrogen or methane generation in microbial electrolysis cells (MEC) [11], CO2 elongation to volatile fatty acids (VFAs) in microbial electro-synthesis (MES) cells [12], low-cost desalination in microbial desalination cells (MDCs) [13], and microbial reverse electrodialysis cells (MRCs) using a combination of MFC and reverse electro-dialysis (RED) stack [14] are all examples of MET that may be used for wastewater treatment.

Contributing significantly to generating renewable energy, biomass gasification is an efficient and promising technology that can transform any biomass into valuable products via thermochemical process [15]. Gasification, pyrolysis, and direct combustion are the main thermochemical conversion technologies [16], where gasification is the most efficient process [17]. Gasification is the partially oxidation of carbonaceous materials at elevated temperatures to generate syngas, primarily carbon monoxide and hydrogen [18]. Moreover, this process produces variable amounts of biochar, pyroligneous acids, and tars [16].

Table 1 provides a list of main reactions in biomass gasification processes. One of the most severe problems encountered during biomass gasification is the formation of tar [19]. Tar condenses at lower temperatures and forms sticky deposits, increasing the difficulty of downstream handling and treatment [20]. Due to its numerous applications and benefits, the gasification process has received much interest worldwide. Biomass gasification may be widely used for different purposes, including biodiesel production through the Fischer Tropsch synthesis or conversion to valuable chemical products such as methanol, methyl ether, and polymers [21]. Moreover, the produced gas from the gasification (syngas) process can be used as a source of heat energy and electricity generation [16,22] or for the biological production of chemicals and biofuels through anaerobic fermentation processes [23,24,25].

Table 1.

Main reactions in biomass gasification processes adapted with permission from [20], biomass and bioenergy; published by Elsevier, 2022.

However, replacing fossil fuels with biobased fuels can positively impact the environment; since biomass is considered a renewable resource, every technology has its limitations, and biomass gasification is no exception.

Unless suitable and efficient preventive measures are implemented and consistently enforced, biomass gasification plants result in environmental pollution, occupational health, and safety risks [22]. For example, the produced gas in its normal state is highly contaminated with condensable hydrocarbons, soot, char particles, and ash [26]. Gasification plants have many environmental issues, such as mass-burn incinerators, water, air pollution, ash, and other by-product disposals [27]. Economy, society, and the environment are the three elements of sustainability [28]. The LCT broadens the idea of cleaner production to include the product’s complete life cycle and sustainability [29]. The term “life cycle thinking” refers to how a product’s life cycle assessment (LCA), life cycle cost (LCC), and social impact assessment (SIA) are considered over its entire life cycle [30].

More precisely, LCT is a theoretical approach that studies improvements and reductions in all mentioned impacts at all processing stages (cradle-to-grave). These stages include extraction, conversion, transformation, distribution, use, demolition, and end-of-life treatment [31]. Nevertheless, it is not clear what kind of information is available in the literature about the scopes and challenges of assessing the environmental impacts of the biomass gasification process. Therefore, the present study aims to conduct a systematic review of biomass gasification processes’ environmental, economic, and social impacts through a scoping review to discover how much LCT research has been undertaken. This study follows the PRISMA guidelines [32]. The problem is addressed in this study by answering the following four research questions:

- What are the significant interests in the most recent investigations on life cycle thinking of gasification processes?

- Which dimension (environmental, economic, and social) is these studies’ most frequently used aspect?

- What are the main life cycle assessment tools, methodologies, and impact categories?

The research focuses on the challenges associated with the gasification process. However, the question remains whether or not this process has a lower environmental impact than commercial processes for producing chemicals and fuels from fossil sources. The remainder of the article is organized as follows. Section 2 provides a background to gasification process technology and its environmental impacts; Section 3 describes the research methodology; Section 4 gives research results; Section 5 discusses them; and Section 6 concludes the review.

2. Gasification Technology

Biomass gasification for energy generation may appear to be a new technique, although it has been around for over a century [33]. Even though gasification technology has been around for decades, it has yet to reach its full potential. The fundamental principles governing its operation, notably feedstock variability and the type of gasification system, are still ambiguous [34]. Gasification technology is a thermochemical process used to convert organic substances into valuable gas (so-called syngas, a mixture of CO and H2). Temperature, equivalent ratio, and pressure impact the syngas composition [35]. The gasifier (reactor) and its configuration are the most critical factors affecting the reactions and products [36]. Generally, gasifiers are classified based on their fluidization regime (gas–solid contacting mode) and gasifying medium [37,38]. Based on the gas–solid contacting mode, fixed bed gasifiers (also known as the moving bed (a moving bed is also known as this type of gasifier since the fuel moves downward in the gasifier)), fluidized bed gasifiers, and entrained flow gasifiers are the three main types of gasifiers with commercial or near-commercial applications [34,39]. However, there are some other uses that employ specific gasifier types or gasification processes.

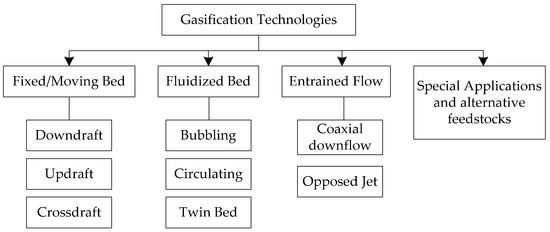

These technologies are usually targeted at utilizing a wider variety of feedstock than only coal and demonstrate innovative applications of gasification [40]. As illustrated in Figure 1, each type can be further subdivided into specific commercial types. In all gasification processes, however, the phenomena of pyrolysis followed by partial oxidation of the residual carbon are prevalent [41]. In general, due to the wide range of raw materials available, developing a valid theory to describe the entire gasification process is quite challenging [42]. Over the years, different suppliers have developed gasifiers commercially. Table 2 summarizes the technological development of the gasification process during the past decades [40,42,43,44,45,46,47,48,49].

Figure 1.

Gasification technologies.

Table 2.

Gasifier technology development.

2.1. Process Challenges

The gasification process still has to be optimized to reduce the energy loss caused by pretreatment of the biomass prior to the conversion process, optimizing the carbon conversion efficiency in the reactor, reducing tar production, and cleaning the syngas for further processing [16].

Both the gasifier’s performance and the composition of syngas are affected by the moisture content of the biomass. Brammer and Bridgwater showed that high moisture content in the biomass has a negative impact on the quality of the produced syngas and the system’s overall performance [50].

Although a high moisture content might not be a big problem in a fluidized bed due to using steam as the fluidizing agent, the entrained gasifier is more sensitive to the moisture. A downdraft gasifier’s maximum moisture content is typically 25%, whereas an updraft gasifier’s maximum moisture content is often 50% [51]. Drying biomass before gasification might result in high capital and energy expenditures in small- and medium-scale gasification plants [16].

The contaminants within the biomass might reduce the efficiency of the thermochemical conversion process [52]. The most significant challenge for chemical production and energy generation using biomass gasification may be the high cost of auxiliary equipment required to produce clean contaminant-free syngas. Consequently, the overall cost of the process increases significantly, accounting for more than half of the ultimate price of biofuel produced [53].

One of the most severe problems encountered throughout the various biomass gasification methods is tar formation [54]. Condensable hydrocarbons, with or without additional oxygen-containing hydrocarbons, and more complex polycyclic aromatic hydrocarbons make up the tars formed during gasification [55]. Tar formation results in the deactivation of catalysts, the halting of the downstream operations, and the generation of carcinogenic compounds [56].

2.2. Gasification’s Environmental Impacts

The environmental impact of biomass gasification is related to input and output values of material flows, energy flows, emissions to air and water, and by-products. The input material composition depends on the type of biomass used and its origin. The gasification process is robust, and mixtures of biomasses can be used, which challenges the evaluation of the biomass feed. The contaminants in the material will vary and affect the environmental impact assessment. Other input flows related to water resources, the energy sources for heating the reactor, and catalytic compounds used in the reactor must be considered in the assessment. The output of emissions to air and water needs to be carefully monitored. Fly ash generation, dust, gaseous emissions, and water pollution are significant adverse environmental impacts [57]. Moreover, combustible gases, vapors, dust, fire risks, carbon monoxide poisoning, and gas leaks are the primary hazards of gasifier operation [58].

Dust is created during storage, handling, feeding, feedstock preparation, and fly ash removal [59]. Because of the acidic conditions in landfills, the ash that remains after gasification is hazardous and poses particular problems [60]. The gasification process produces many tiny solid particles, mostly fly ash and char (unburned carbons). These cause a similar issue as dust and biomass ash. Ash may also constitute a fire hazard, demonstrating the need to keep it wet and sealed [22]. During the cooling and cleaning of produced syngas, wastewater is produced as an effluent [61]. The disposal of some contaminates in effluents, such as phenolic and terry components, reveals severe environmental problems and requires adequate pretreatment before discharging into the environment [26].

3. Research Design

The present study adopts a scoping review methodology to summarize and analyze the history and status of life cycle thinking in the gasification technology context and indicate related challenges and limitations. In addition, the possible promising areas for improvement and knowledge gaps were identified. A scoping review, at a general level, aims to map the key concepts rapidly underpinning a research area and the main sources and types of evidence available which can be undertaken as stand-alone projects in their own right, especially where an area is complex or has not been reviewed comprehensively before [62]. At least four frequent reasons exist for conducting a scoping study: to evaluate the study’s scope, range, and nature; to assess the practicality of conducting a comprehensive systematic review study; to summarize and share findings; and to explore knowledge gaps in the literature [63]. This technique is chosen because it is much more rigorous than a simple search and requires multiple and systematic searches [64].

There is a contrast between systematic and scoping reviews [65]. In the systematic review, the main concern is based on a well-defined research question with a relatively narrow range for answers, while a scoping review addresses broader questions and topics [63].

3.1. Searching Procedure

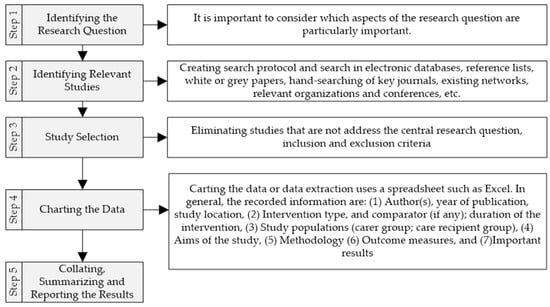

The following steps were conducted under the scoping review protocol illustrated in Figure 2:

Figure 2.

Overall research process scheme.

- Four main research questions were defined.

- After multiple tries and errors, an initial search was undertaken utilizing available scientific databases (Scopus, ScienceDirect, and Web of Science (WoS)). The search strings are provided in Table 3. At this level, no limitations were set to the initial search. The search was applied to the title, abstract, and keywords in Scopus and ScienceDirect and all WoS categories. As a result, 6682, 9755, and 2460 documents (in all categories) were listed in Scopus, WoS, and ScienceDirect, respectively. Because of the number of AND/OR operator limitations, the string was divided into three strings. The asterisk (*) is a regularly employed symbol that broadens a search by finding terms with identical initial letters. It may be used in conjunction with distinctive word stems to obtain variants of a phrase with less keystrokes. For example assess* can find assess, assessing, assessment, assessed, etc.

Table 3. Initial strings used in databases.

Table 3. Initial strings used in databases. - Since life cycle studies on gasification technologies have mainly gained prominence over the past two decades, this study focused on published literature (2017–2022). Applying this limit, the number of documents dropped to 2363, 5515, and 1310 for Scopus, WoS, and ScienceDirect, respectively.

- As another limitation, the language of the studies was limited to English. As a result, only a few documents were eliminated. The remaining studies became 2275, 5480, and 1310 for Scopus, WoS, and ScienceDirect, respectively.

- By applying the search strings to only the title, a significant reduction in the number of documents was observed. The listed studies experienced a significant drop to 144, 116, and 91 for Scopus, WoS, and ScienceDirect, respectively.

- For the final step at the screening stage, by tailoring the string and eliminating “OR environmental,” more accurate results were achieved, and the number of documents was reduced to 40, 43, and 35 for Scopus, WoS, and ScienceDirect, respectively (118 studies in total).

- There were many duplicates in the list. Therefore, in this stage (step 3 in Figure 2), by trimming the list and removing duplicates, 48 documents remained. These were listed in Excel to perform the necessary investigation.

- The eligibility of the studies was assessed by a full-text screening. As a result, six studies were considered non-relevant and were eliminated from the list. All in all, the final list consisted of 42 publications.

- The bolographic information of the results, such as the title, the country of origin, the technology, the year of publication, the aim of the study and scope, the methodology, and the barriers and challenges, was extracted.

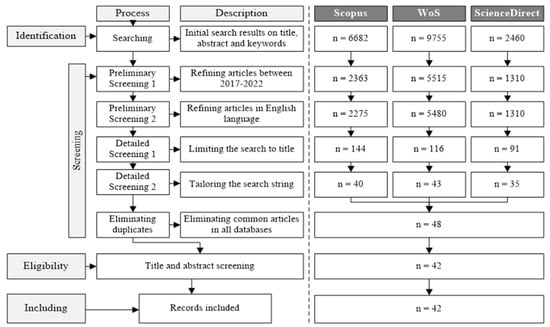

Figure 3 illustrates the PRISMA flow diagram of the present study. PRISMA methodology is a well-established reporting template for scoping reviews. It illustrates the screening processes’ results to report the remaining studies at each stage.

Figure 3.

PRISMA flow diagram.

3.2. Limitations

The present study is limited to English language studies and the literature published after 2017. Furthermore, although it covers conference papers and proceedings, this study did not cover grey literature such as publicly accessible records and reports.

4. Results

This section provides the descriptive information associated with the latest studies on life cycle assessment (LCA), life cycle cost (LCC), and social impact assessment (SIA) of the gasification process.

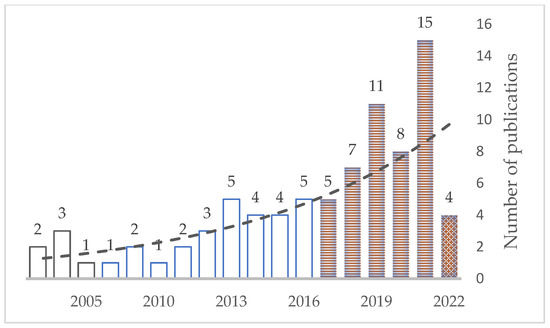

4.1. Number of Publications

The year-wise analysis gives a picture of the research progress. It may be challenging to discern a clear trend based on recent studies. To better understand how interest has grown in this topic, the years 2000–2016 were added to the research period. Figure 4 provides information about the number of published studies from 2000 to February 2022. The overall trend emphasizes accelerated growing interest in gasification technologies’ study through the lens of life cycle thinking. The highest contribution belongs to 2021 by 15 publications, almost 100% higher than publications in 2018. Although there are four listed publications within the first two months of 2022 so far, it is expected to have many more upcoming publications. The significant drop in 2020 may be due to the COVID-19 pandemic when it reaches its peak.

Figure 4.

The number of selected studies and overall trend from 2000 to February 2022.

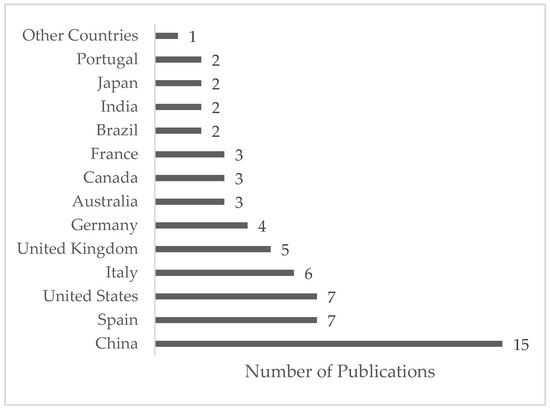

4.2. The Origin of Studies

Country-wise analysis of the selected publications shows that twenty-eight countries contributed to this topic. As seen in Figure 5, the highest contribution belongs to China with 15 studies, followed by the United States and Spain with seven publications each, and Italy with six. Fifteen countries were involved in only a single study categorized under “Other Countries.” Austria, Chile, Colombia, Denmark, Iran, Ireland, Malaysia, Philippines, Qatar, Romania, Saudi Arabia, Singapore, South Africa, Switzerland, and Thailand belong to the group with one publication. In another classification, over seventy percent of the contribution belongs to the developed countries.

Figure 5.

Country’s contribution to publications (from 2017 to February 2022).

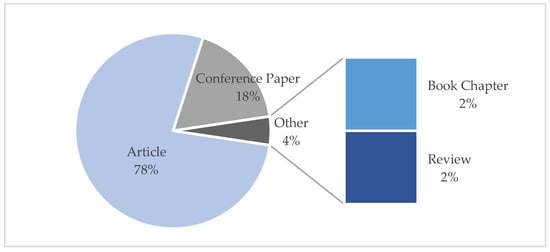

4.3. Publications by Document Type

As discussed earlier, all types of publications were considered in this review. Over eighty percent of selected documents were articles, followed by conference papers (fifteen percent) and book chapters and reviews (two percent each). As seen in Figure 6, only two review articles demonstrated the study’s significance. Ramos and Rouboa [66] reviewed different aspects of life cycle thinking (environmental, social, and economic) on plasma gasification. On the other hand, Michaga et al. [67] conducted a techno-economic and life cycle assessment review on jet fuel produced through biomass gasification.

Figure 6.

Categorization based on document types.

4.4. Publications by Subject Area

Fourteen studies on gasification processes addressed the life cycle thinking approaches (based on extracted data from Scopus). As seen in Table 4, energy, environmental science, and engineering have the highest contribution with 30, 27, and 17 percent, respectively, followed by chemical engineering.

Table 4.

Subject areas in the selected publications.

5. Discussion

A comprehensive content-based analysis was performed to answer several research questions. This section focuses on recent research conducted during the previous five years. Among 48 selected studies belonging to the period between 2017 to February 2022, 42 studies were considered relevant to the topic. Except for review articles by Ramos and Rouboa [66] and Michaga et al. [67], other studies focused on a specific aspect of life cycle thinking in the gasification process. Table 5 lists different life cycle thinking aspects and their frequencies in the selected publications.

Table 5.

LCT aspects and frequencies in the studies.

Among seven different approaches, LCA was dominating, followed by LCC. Most of the studies (over seventy percent) studied a single aspect. Almost twenty percent studied two different aspects, and ten percent studied three aspects. For example, Korre et al. [68] performed a life cycle environmental impact assessment on the underground coal gasification process, including CO2 capture and storage. Li et al. [69] assessed ELCA and LCA of hydrogen production from biomass-staged gasification, and Li and Cheng [70] compared hydrogen production from coke oven gas and coal gasification from three different points of view (life cycle energy assessment, carbon emissions, and life cycle costs).

Different software and databases were employed to carry out the life cycle assessment. The software SimaPro® (PRé Consultants, Netherlands) and GaBi® (sphere, USA) showed the highest contribution, followed by OpenLCA. Ecoinvent and ELCD were at the top of the list of employed databases. Table 6 provides an overview of the selected articles’ life cycle methods and different approaches using software and databases. The cradle-to-grave approach encompasses the whole life cycle of a resource, from its extraction (‘cradle’) to its use and disposal (‘grave’) [71]. Cradle-to-gate is another approach studied by different researchers [70,72,73,74]. Cradle-to-gate examines a product’s partial life cycle, beginning with resource extraction (cradle) and ending at the factory gate before transporting to the consumer [75]. Cradle-to-gate evaluations are occasionally used to develop environmental product declarations (EPDs), referred to as business-to-business EDPs [71]. As mentioned earlier, all the assessments were performed based on process simulations. Among fourteen studies that referred to their process software, eleven simulations were conducted using Aspen Plus® (Aspen Technology, Inc., USA) versions 8.8, 11, 9 [21,68,69,73,76,77,78,79,80,81,82]. The other three software were EASETECH [83], the integrated environmental control model (IECM) [84], and DeST [85]. Uncertainty analysis was considered in fifty percent (22 out of 42) studies. Only sensitivity analysis and Monte Carlo simulation were employed among many methods and tools to model and analyze uncertainty in a system. Sixteen studies only used sensitivity analysis, three applied Monte Carlo simulation to cope with uncertainty, and the remaining three employed both methods. More information is given in Table 6.

Table 6.

Overview of life cycle methods, approaches, used software, and databases in 42 articles.

Table 7 summarizes the different processes and their used feedstock, the number of scenarios in the analysis, and the year of publication in 42 recent articles. As seen, a wide range of raw materials has been covered, such as municipal solid wastes [78,86,89,90,91,111], wheat straw [69,92,93], biomass, water for supercritical water gasification processes [81,94], pinewood [80], etc. The majority of the articles used scenario-based analysis to compare different alternatives.

Table 7.

Overview of processes, feedstock, and the number of publication scenarios in 42 articles.

Among selected articles, fourteen studies compared gasification and another method for biomass conversion or disposal, such as incineration, pyrolysis and fast pyrolysis, landfilling, hydrothermal carbonization, combustion, fermentation, and steam reforming. Keller et al. [83] conducted a comparative life cycle analysis of two feedstock recycling technologies: waste gasification and pyrolysis. Although both feedstock recycling paths decrease greenhouse gas emissions under similar production system assumptions, gasification resulted in a greater reduction than pyrolysis. Similarly, Alcazar-Ruiz et al. [76] conducted a comparative life cycle study to measure the sustainability of two processes (gasification and fast pyrolysis) for bio-oil production from agricultural wastes. Separation stages were the primary contributors to all mid-point impact categories in the fast pyrolysis. Finally, contrary to the results reported in [83], the most ecologically beneficial method of creating one MJ bio-oil was not the gasification process. Bianco et al. [86] focused on the environmental consequences of generating power from the incineration and gasification of municipal solid waste. The study revealed that, depending on the accounting rules, the effect outcomes might vary greatly and can lead to opposing conclusions for some impact categories. Corvalán et al. [100] performed a comparative LCA analysis on the hydrothermal carbonization (HTC) of urban organic solid waste and gasification process. Upon evaluating the conversion of 1 ton of organic fraction USW, the results indicated that gasification performed better than HTC. Considering the generation of 1 MWh, HTC has a lower environmental effect than gasification because of its better energy efficiency. Similarly, Parascanu et al. [73] compared the LCA of four scenarios of gasification and combustion with two feedstock each (agave bagasse and sugarcane bagasse) in Mexico.

The results indicated that, environmentally, agave bagasse combustion is the best option, followed by agave bagasse gasification, sugarcane bagasse gasification, and sugarcane bagasse combustion. A comprehensive LCA was conducted by Sun et al. [77] to compare the environmental performance of converting corn stover to biofuels in fermentation, pyrolysis, and gasification processes. They conclude that the total environmental performance of the system for producing high-grade jet fuel from maize stover by gasification synthesis is optimum. Moreover, fermentation scores poorly in almost all environmental effect categories for 1 GJ of biofuel, whereas pyrolysis has the greatest comparable CO2 emission. Similarly, Tang et al. [91] found that, in comparison with incineration, although gasification-based systems were excellent in mitigating environmental impacts, they had a greater impact on global warming. Muthudineshkumar and Anand [97] reported that for biofuel production from biomass, between gasification and syngas fermentation, gasification reduced pollution emissions and was an ecologically friendly method of fuel use. Nevertheless, in contrast, due to economic and societal problems, Valente et al. [103,104] found that hydrogen from biomass gasification cannot currently be regarded as a viable alternative to conventional hydrogen. On the other hand, considering economic and economic performances separately, environmentally, hydrogen from biomass gasification performs substantially better than hydrogen from steam methane reforming, although the opposite result was reached in economics. Zang et al. [80] examined the technological alternatives of biomass gasification, syngas combustion, and CO2 emission control in the LCA of eight biomass-integrated gasification combined cycles (BIGCCs). Results showed that the GWP of BIGCC systems is less than 240 kg CO2-equivalent/MWh, which is negative when BIGCC systems are integrated with CO2 capture and storage technology. In addition, the exterior syngas combustion technique has a lower GWP, human toxicity potential, and ozone depletion potential than the internal syngas combustion technology, and the Selexol CO2 capture [112] method is more environmentally friendly than the MEA CO2 capture [113] method.

In another approach, two studies addressed by Ouedraogo et al. [90] compared LCA of gasification and landfilling for the disposal of MSW. The LCA found that, in comparison with gasification, landfilling is a significant contributor to global warming, ecotoxicity, eutrophication, acidification, smog formation, and cancer and non-cancer human health outcomes. Finally, Demetrious and Crossin [99] assessed the environmental performance of mixed paper and mixed plastic waste management in landfills, incineration, and combined gasification–pyrolysis using LCA for impacts mentioned in Table 8. According to the data, mixed paper handled with incineration or gasification–pyrolysis created fewer greenhouse gas emissions than mixed plastic managed in landfill. The studies above confirm that it is impossible to make conclusions about the gasification process because the studies could have opposite results under different methodology, boundaries, or assumptions.

Six studies have investigated a combined process (gasification combined with one or more processes). Through LCA, Reaño et al. [74] evaluated the environmental performance and energy efficiency of rice straw power generation utilizing a combination of gasification and an internal combustion engine (G/ICE). The results showed that the GWP of this process was 27% lower than the GWP of rice straw on-site burning, and that biogenic methane emissions from flooded rice fields may be mitigated to lower the system’s GWP by 34%. Using energy generated by the G/ICE system to supply farm and plant activities might reduce the environmental impact and increase the effectiveness of the process. Iannotta et al. [78] investigated the environmental performance of a novel integrated process based on supercritical water gasification and oxidation for treating carbon black and used oil as model wastes. It is demonstrated that this process decreases effects in several categories and results in a positive energy balance during the life cycle, ensuring good environmental performance. Moretti et al. [72] offered the LCA of novel high-efficiency bio-based power technology that combines biomass gasification with a 199 kW solid oxide fuel cell to generate heat and electricity.

Table 8.

Overview of impact categories and life cycle methodology in 42 articles.

Table 8.

Overview of impact categories and life cycle methodology in 42 articles.

| Impact Category | Methodology | Reference |

|---|---|---|

| GWP, ODP, SF, AP, EP, CP, NCP, RE, ETP, FFD | GREET | [21] |

| GWP, ADP, AP, EP, FAExP, HTP, ODP, MAExP, POFP, TExP | CML2011 | [68] |

| GWP, POFP | [69] | |

| GWP, En-C, Ec-C | IPCC AR5,GWP100 | [70] |

| CCP, MFRRD, PF, POFP, AP, TEP, WRD | Attributional LCA | [72] |

| GWP, AP, EP, HTP, MExP, ODP, FDP | Midpoint ReCiPe 2016 | [73] |

| GWP, NER | ReCiPe | [74] |

| GWP, ODP, HOFP, EOFP, TAP, FEP, MEP, HTPs, HTPnc, FFP, WCP | Mid-point ReCiPe | [76] |

| GWP, AP, EP, HTP, ODP | CML 2001 | [77] |

| CCP, ODP, HTPc, HTPnc, PF, IR-HH, IR-E, POFP, AP, TEP, FEP, MEP, MExP, LO, WRD, MFRRD | [78] | |

| GWP, ADP, AP, EP, En-C | CML 2015 | [79] |

| GWP, AP, EP, HTP, ODP | [80] | |

| GWP, AP, EP, ODP | [81] | |

| GREET | [82] | |

| GWP | IPCC AR5, GWP100 | [83] |

| GWP | [84] | |

| GWP, AP, POFP, HTP, SWP, AEP, NRDP, PF | [85] | |

| GWP, AP, EP, HTP, MExP, ODP, FDP | Mid-point ReCiPe | [86] |

| GWP, HTPnc, LO, IR, TE, MEP, FEP, CCP, HTPc, AEP, TAP, FAP | Environmental Footprint 3.0 | [87] |

| GWP, WRD, MEP, AEP, FRD | IMPACT World+, IPCC, GWP100 | [88] |

| EDIP 2003 | [89] | |

| GWP, SF, AP, EP, HH, ExP | GREET, LandGEM, HELP | [90] |

| GWP, AP, NEP, POFP | EDIP 9 | [91] |

| WRD | [92] | |

| GWP, ODP, AEP, AAP, AExP, TExP, IR, MRD, LO, RI | IMPACT 2002+ | [93] |

| GWP, ADP, AP, EP, ODP, POFP | CML-IA, ReCiPe Endpoint, CED | [94] |

| GWP, ODP, HH, MEP, TAP, AEP, C, NC, FExP | SDU model | [95] |

| GWP | ReCiPe | [96] |

| GWP | [97] | |

| GWP, AP, E, HTP, MExP, ODP, FDP | CML baseline | [98] |

| AP, CCP, EP, POFP | IPCC AR4,GWP100 | [99] |

| GWP, AP, EP, HTP, MExP, ODP, FDP | ReCiPe, DALY | [100] |

| GWP, AP, EP, HTP, MExP, ODP, FDP | CML 2001 | [101] |

| GWP | ReCiPe midpoint, CED | [102] |

| GWP, AP | [103] | |

| GWP, AP, CED | ISO | [104] |

| - | - | [105] |

| IPCC | [106] | |

| GWP | [107] | |

| GWP, AP, TEP, POFP, HT-a, HT-s, Exs | [108] | |

| GWP | GWP100 | [109] |

| CML 2001 | [110] |

It demonstrated superior environmental performance compared to natural gas and the German/European grid. The other two studies were also discussed above [80,99].

In another approach, Li et al. [107] performed a multi-criteria optimization model (TOPSIS) based on LCA for a biomass gasification-integrated combined cooling, heating, and power system to study the overall performance criterion, the primary energy saving ratio, the total cost saving ratio, and the CO2 emission reduction ratio. It is concluded that the system fueled by biomass greatly differs from that fueled by fossil fuels in energetic, economic, and environmental aspects. Consequently, exclusive assessments and optimizations are required.

The remaining 23 studies have addressed different aspects of LCT (mostly LCA) for a single gasification process in different impact categories. Table 8 gives an overview of covered different impact categories and the life cycle methodologies employed by these articles.

6. Conclusions

The current research addresses a need left by the absence of thorough reviews on life cycle thinking approaches for gasification processes. Even though the gasification process’s environmental and techno-economic aspects are well recognized, measuring their social impacts is still infrequent. Following the PRISMA methodology and a scoping review, 42 studies between 2017 and 2022 were selected. Among different LCT approaches, LCA received the most attention, followed by LCC. In a limited number of studies, exergetic life cycle assessment (ELCA), life cycle energy assessment (LCEA), social impact assessment (SIA), consequential life cycle assessment (CLCA), and water footprint (WLCA) were investigated. It can be concluded that the life cycle impact and cost assessments have received the most attention since 2017. SimaPro®, GaBi®, and OpenLCA were employed significantly. The uncertainty analysis was performed in more than half of the studies using sensitivity analysis and Monte Carlo simulation.

Moreover, the results indicate that the recent studies were interested in adopting scenario-based and comparative life cycle assessments. The results confirm that it is hard to draw conclusions regarding the environmental impacts of the gasification process since findings may vary depending on the technique, parameters, or assumptions. Although the gasification process significantly reduces negative environmental impacts, it is not always the best alternative compared to different processes. While these studies suffer greatly from the uncertainties, in future works, it is suggested that uncertainty analysis should be considered in all the investigations.

Author Contributions

Conceptualization, Z.B. and M.S.E.; methodology, Z.B. and M.S.E.; analysis and investigation, Z.B. and M.S.E.; data curation, Z.B.; writing—original draft preparation, Z.B.; writing—review and editing, M.S.E.; visualization, Z.B.; supervision, M.S.E. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| ADP | abiotic depletion potential | LO | land occupation |

| AP | acidification potential | LCA | life cycle assessment |

| AW | agricultural waste | LCC | life cycle cost |

| AAP | aquatic acidification potential | LCEA | life cycle energy assessment |

| AEx | aquatic ecotoxicity potential | MAExP | marine aquatic ecotoxicity potential |

| AEP | aquatic eutrophication potential | MEP | marine eutrophication potential |

| C | carcinogens | MExP | marine ecotoxicity potential |

| CCP | climate change potential | MRP | materials rich in plastics |

| CED | cumulative energy demand | MRD | mineral resource depletion |

| CLCA | consequential life cycle assessment | MFRRD | mineral, fossil, and renewable resource depletion |

| Ec-C | economic Costs | MCS | Monte Carlo simulation |

| ExP | ecotoxicity Potential | MSW | municipal solid waste |

| Ex-s | ecotoxicity via solid | NRDP | National Rural Development Program |

| En-C | energy Consumption | NER | net energy ratio |

| EF | entrained Flow | NC | non-carcinogens |

| EP | eutrophication potential | NEP | nutrient enrichment potential |

| ELCA | exergetic life cycle assessment | ODP | ozone depletion potential |

| FB | fluidized bed | PF | particulate formation |

| FDP | fossil depletion potential | POFP-E | photochemical oxidation formation potential—ecosystems |

| FFP | fossil fuel potential | POFP-H | photochemical oxidation formation potential—humans |

| FRD | fossil resource depletion | RDF | refuse-derived fuel |

| FAP | freshwater acidification potential | RI | respiratory inorganics |

| FAExP | freshwater aquatic ecotoxicity potential | SA | sensitivity analysis |

| FExP | freshwater ecotoxicity potential | SF | smog formation |

| FEP | freshwater eutrophication potential | SIA | social impact assessment |

| GWP | global warming potential | SRF | solid recovered fuel |

| HH | human health | SWP | sustainable water partnership |

| HTPc | human toxicity potential—cancer | TAP | terrestrial acidification potential |

| HTPnc | human toxicity potential—non-cancer | TExP | terrestrial ecotoxicity potential |

| HT-a | human toxicity via air | TE | terrestrial eutrophication |

| HT-s | human toxicity via solid | USW | urban solid waste |

| HTP | human toxicity potential | WCP | water consumption potential |

| IR | ionizing radiation | WLCA | water footprint |

| IR-E | ionizing radiation—environment | WRD | water resource depletion |

| IR-HH | ionizing radiation—human health |

References

- Shah, S.; Venkatramanan, V. Chapter 5—Advances in Microbial Technology for Upscaling Sustainable Biofuel Production. In New and Future Developments in Microbial Biotechnology and Bioengineering; Gupta, V.K., Pandey, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 69–76. ISBN 978-0-444-63504-4. [Google Scholar]

- Ankolekar, V.; Kulkarni, S. Briquetting of Agricultural Biomass: An Overview. Int. J. Res. Appl. Sci. Eng. Technol. 2018, 6, 1681–1685. [Google Scholar]

- Fung, D.P.C.; Kim, S.D. Gasification Kinetics of Coals and Wood. Korean J. Chem. Eng. 1990, 7, 109–114. [Google Scholar] [CrossRef]

- Roh, S.A.; Son, S.R.; Kim, S.D. Steam Gasification and Combustion Kinetics of Gingko Nut Shell in a Thermobalance Reactor. In Studies in Surface Science and Catalysis; Rhee, H.-K., Nam, I.-S., Park, J.M., Eds.; New Developments and Application in Chemical Reaction Engineering; Elsevier: Amsterdam, The Netherlands, 2006; Volume 159, pp. 569–572. [Google Scholar]

- Adams, P.; Bridgwater, T.; Lea-Langton, A.; Ross, A.; Watson, I. Chapter 8—Biomass Conversion Technologies. In Greenhouse Gas Balances of Bioenergy Systems; Thornley, P., Adams, P., Eds.; Academic Press: Cambridge, MA, USA, 2018; pp. 107–139. ISBN 978-0-08-101036-5. [Google Scholar]

- McKendry, P. Energy Production from Biomass (Part 2): Conversion Technologies. Bioresour. Technol. 2002, 83, 47–54. [Google Scholar] [CrossRef]

- Chen, H.; Wang, L. Technologies for Biochemical Conversion of Biomass; Academic Press: Cambridge, MA, USA, 2016; ISBN 978-0-12-802594-9. [Google Scholar]

- Faaij, A. Modern Biomass Conversion Technologies. Mitig. Adapt. Strateg. Glob. Chang. 2006, 11, 343–375. [Google Scholar] [CrossRef] [Green Version]

- Sánchez, C.; Dessì, P.; Duffy, M.; Lens, P.N.L. Microbial Electrochemical Technologies: Electronic Circuitry and Characterization Tools. Biosens. Bioelectron. 2020, 150, 111884. [Google Scholar] [CrossRef]

- Tran, H.V.; Kim, E.; Jung, S.P. Anode Biofilm Maturation Time, Stable Cell Performance Time, and Time-Course Electrochemistry in a Single-Chamber Microbial Fuel Cell with a Brush-Anode. J. Ind. Eng. Chem. 2022, 106, 269–278. [Google Scholar] [CrossRef]

- Pawar, A.A.; Karthic, A.; Lee, S.; Pandit, S.; Jung, S.P. Microbial Electrolysis Cells for Electromethanogenesis: Materials, Configurations and Operations. Environ. Eng. Res. 2022, 27, 200484. [Google Scholar] [CrossRef]

- Dessì, P.; Rovira-Alsina, L.; Sánchez, C.; Dinesh, G.K.; Tong, W.; Chatterjee, P.; Tedesco, M.; Farràs, P.; Hamelers, H.M.V.; Puig, S. Microbial Electrosynthesis: Towards Sustainable Biorefineries for Production of Green Chemicals from CO2 Emissions. Biotechnol. Adv. 2021, 46, 107675. [Google Scholar] [CrossRef]

- Zahid, M.; Savla, N.; Pandit, S.; Thakur, V.K.; Jung, S.P.; Gupta, P.K.; Prasad, R.; Marsili, E. Microbial Desalination Cell: Desalination through Conserving Energy. Desalination 2022, 521, 115381. [Google Scholar] [CrossRef]

- Kang, H.; Kim, E.; Jung, S.P. Influence of Flowrates to a Reverse Electro-Dialysis (RED) Stack on Performance and Electrochemistry of a Microbial Reverse Electrodialysis Cell (MRC). Int. J. Hydrogen Energy 2017, 42, 27685–27692. [Google Scholar] [CrossRef]

- Rhee, H.-K.; Nam, I.-S.; Park, J.M. New Developments and Application in Chemical Reaction Engineering. In Proceedings of the 4th Asia-Pacific Chemical Reaction Engineering Symposium (APCRE ’05), Gyeongju, Korea, 12–15 June 2005; Elsevier: Amsterdam, The Netherlands, 2006. ISBN 978-0-08-045651-5. [Google Scholar]

- Pereira, E.G.; da Silva, J.N.; de Oliveira, J.L.; Machado, C.S. Sustainable Energy: A Review of Gasification Technologies. Renew. Sustain. Energy Rev. 2012, 16, 4753–4762. [Google Scholar] [CrossRef]

- Purohit, P. Economic Potential of Biomass Gasification Projects under Clean Development Mechanism in India. J. Clean. Prod. 2009, 17, 181–193. [Google Scholar] [CrossRef]

- Zamarripa, M.; Hjaila, K.; Silvente, J.; Espuña, A. Simplified Model for Integrated Supply Chains Planning. In Computer Aided Chemical Engineering; Kraslawski, A., Turunen, I., Eds.; 23 European Symposium on Computer Aided Process Engineering; Elsevier: Amsterdam, The Netherlands, 2013; Volume 32, pp. 547–552. [Google Scholar]

- Devi, L.; Ptasinski, K.J.; Janssen, F.J.J.G. A Review of the Primary Measures for Tar Elimination in Biomass Gasification Processes. Biomass Bioenergy 2003, 24, 125–140. [Google Scholar] [CrossRef]

- Valderrama Rios, M.L.; González, A.M.; Lora, E.E.S.; Almazán del Olmo, O.A. Reduction of Tar Generated during Biomass Gasification: A Review. Biomass Bioenergy 2018, 108, 345–370. [Google Scholar] [CrossRef]

- Okeke, I.J.; Adams, T.A. Life Cycle Assessment of Petroleum Coke Gasification to Fischer-Tropsch Diesel. In Computer Aided Chemical Engineering; Kiss, A.A., Zondervan, E., Lakerveld, R., Özkan, L., Eds.; 29 European Symposium on Computer Aided Process Engineering; Elsevier: Amsterdam, The Netherlands, 2019; Volume 46, pp. 1495–1500. [Google Scholar]

- Mishra, A.; Singh, R.; Mishra, P. Effect of Biomass Gasification on Environment. Available online: https://www.semanticscholar.org/paper/Effect-of-Biomass-Gasification-on-Environment-Mishra-Singh/43432d0e18d2d2d73db3a23552997dbb81704ac5 (accessed on 15 March 2022).

- Ayol, A.; Peixoto, L.; Keskin, T.; Abubackar, H.N. Reactor Designs and Configurations for Biological and Bioelectrochemical C1 Gas Conversion: A Review. Int. J. Environ. Res. Public Health 2021, 18, 11683. [Google Scholar] [CrossRef] [PubMed]

- Latif, H.; Zeidan, A.A.; Nielsen, A.T.; Zengler, K. Trash to Treasure: Production of Biofuels and Commodity Chemicals via Syngas Fermenting Microorganisms. Curr. Opin. Biotechnol. 2014, 27, 79–87. [Google Scholar] [CrossRef] [Green Version]

- Wainaina, S.; Horváth, I.S.; Taherzadeh, M.J. Biochemicals from Food Waste and Recalcitrant Biomass via Syngas Fermentation: A Review. Bioresour. Technol. 2018, 248, 113–121. [Google Scholar] [CrossRef]

- Mehta, V.; Chavan, A. Physico-Chemical Treatment of Tar-Containing Wastewater Generated from Biomass Gasification Plants. World Acad. Sci. Eng. Technol. 2009, 57, 161–168. [Google Scholar]

- Bergman, P.; Boerrigter, H. The Novel “OLGA” Technology for Complete Tar Removal from Biomass Producer Gas. In Proceedings of the Pyrolysis and Gasification of Biomass and Waste, Expert Meeting, Strasbourg, France, 30 September–1 October 2002. [Google Scholar]

- Byrne-Jiménez, M.; Orr, M.T. Thinking in Three Dimensions: Leadership for Capacity Building, Sustainability, and Succession. J. Cases Educ. Leadersh. 2012, 15, 33–46. [Google Scholar] [CrossRef]

- Mazzi, A. Chapter 1—Introduction. Life Cycle Thinking. In Life Cycle Sustainability Assessment for Decision-Making; Ren, J., Toniolo, S., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 1–19. ISBN 978-0-12-818355-7. [Google Scholar]

- Farjana, S.H.; Mahmud, M.A.P.; Huda, N. (Eds.) Chapter 1—Introduction to Life Cycle Assessment. In Life Cycle Assessment for Sustainable Mining; Elsevier: Amsterdam, The Netherlands, 2021; pp. 1–13. ISBN 978-0-323-85451-1. [Google Scholar]

- Jacob-Lopes, E.; Zepka, L.Q.; Deprá, M.C. (Eds.) Chapter 5—Assistant’s Tools toward Life Cycle Assessment. In Sustainability Metrics and Indicators of Environmental Impact; Elsevier: Amsterdam, The Netherlands, 2021; pp. 77–90. ISBN 978-0-12-823411-2. [Google Scholar]

- Tricco, A.; Lillie, E.; Zarin, W.; O’Brien, K.; Colquhoun, H.; Levac, D.; Moher, D.; Peters, M.; Horsley, T.; Weeks, L.; et al. PRISMA Extension for Scoping Reviews (PRISMA-ScR): Checklist and Explanation. Ann. Intern. Med. 2018, 169, 467–473. [Google Scholar] [CrossRef] [Green Version]

- Pereira, E.G.; Martins, M.A. Gasification Technologies. In Encyclopedia of Sustainable Technologies; Abraham, M.A., Ed.; Elsevier: Oxford, UK, 2017; pp. 315–325. ISBN 978-0-12-804792-7. [Google Scholar]

- Mohammadi, A.; Anukam, A. The Technical Challenges of the Gasification Technologies Currently in Use and Ways of Optimizing Them: A Review; IntechOpen: London, UK, 2022; ISBN 978-1-80355-610-9. [Google Scholar]

- El-Emam, R.S.; Dincer, I.; Naterer, G.F. Energy and Exergy Analyses of an Integrated SOFC and Coal Gasification System. Int. J. Hydrogen Energy 2012, 37, 1689–1697. [Google Scholar] [CrossRef]

- Arena, U. Process and Technological Aspects of Municipal Solid Waste Gasification. A Review. Waste Manag. 2012, 32, 625–639. [Google Scholar] [CrossRef] [PubMed]

- Bell, D.A.; Towler, B.F.; Fan, M. (Eds.) Chapter 4—Gasifiers. In Coal Gasification and Its Applications; William Andrew Publishing: Boston, MA, USA, 2011; pp. 73–100. ISBN 978-0-8155-2049-8. [Google Scholar]

- Basu, P. (Ed.) Chapter 8—Design of Biomass Gasifiers. In Biomass Gasification, Pyrolysis and Torrefaction; Academic Press: Cambridge, MA, USA, 2018; pp. 263–329. ISBN 978-0-12-812992-0. [Google Scholar]

- Basu, P. (Ed.) Chapter 6—Design of Biomass Gasifiers. In Biomass Gasification and Pyrolysis; Academic Press: Boston, MA, USA, 2010; pp. 167–228. ISBN 978-0-12-374988-8. [Google Scholar]

- Gasifipedia. Available online: https://netl.doe.gov/carbon-management/energy-systems/gasification/gasifipedia (accessed on 1 July 2022).

- Reed, T.B.; Das, A. Handbook of Biomass Downdraft Gasifier Engine Systems; Biomass Energy Foundation: Golden, CO, USA, 1988; ISBN 978-1-890607-00-5. [Google Scholar]

- Higman, C. Chapter 11—Gasification. In Combustion Engineering Issues for Solid Fuel Systems; Miller, B.G., Tillman, D.A., Eds.; Academic Press: Cambridge, MA, USA, 2008; pp. 423–468. ISBN 978-0-12-373611-6. [Google Scholar]

- Breault, R.W. Gasification Processes Old and New: A Basic Review of the Major Technologies. Energies 2010, 3, 216–240. [Google Scholar] [CrossRef] [Green Version]

- Shadle, L.J.; Breault, R.W. Integrated Gasification Combined Cycle (IGCC). In Handbook of Climate Change Mitigation; Chen, W.-Y., Seiner, J., Suzuki, T., Lackner, M., Eds.; Springer: New York, NY, USA, 2012; pp. 1545–1604. ISBN 978-1-4419-7991-9. [Google Scholar]

- Mauerhofer, A.M.; Schmid, J.C.; Benedikt, F.; Fuchs, J.; Müller, S.; Hofbauer, H. Dual Fluidized Bed Steam Gasification: Change of Product Gas Quality along the Reactor Height. Energy 2019, 173, 1256–1272. [Google Scholar] [CrossRef]

- Belke, W.H.; Goloff, A.; Grim, G.B. Rotating Fluidized Bed Gasifier System. EP0038795A4, 16 January 1985. [Google Scholar]

- Nieminen, J.; Kivelä, M. Biomass CFB Gasifier Connected to a 350 MWth Steam Boiler Fired with Coal and Natural Gas—THERMIE Demonstration Project in Lahti in Finland. Biomass Bioenergy 1998, 15, 251–257. [Google Scholar] [CrossRef]

- Toporov, D.; Abraham, R. Entrained Flow Gasifiers: The Thyssenkrupp’s Prenflo Technology. In Proceedings of the Conference on Energy for a Clean Environment, Lisbon, Portugal, 5 July 2015. [Google Scholar]

- Squires, A.M. The Story of Fluid Catalytic Cracking: The First Circulating Fluidized Bed. In Circulating Fluidized Bed Technology; Basu, P., Ed.; Pergamon: Oxford, UK, 1986; pp. 1–19. ISBN 978-0-08-031869-1. [Google Scholar]

- Brammer, J.G.; Bridgwater, A.V. The Influence of Feedstock Drying on the Performance and Economics of a Biomass Gasifier–Engine CHP System. Biomass Bioenergy 2002, 22, 271–281. [Google Scholar] [CrossRef]

- Seggiani, M.; Vitolo, S.; Puccini, M.; Bellini, A. Cogasification of Sewage Sludge in an Updraft Gasifier. Fuel 2012, 93, 486–491. [Google Scholar] [CrossRef]

- Munasinghe, P.C.; Khanal, S.K. Biomass-Derived Syngas Fermentation into Biofuels: Opportunities and Challenges. Bioresour. Technol. 2010, 101, 5013–5022. [Google Scholar] [CrossRef]

- Cummer, K.R.; Brown, R.C. Ancillary Equipment for Biomass Gasification. Biomass Bioenergy 2002, 23, 113–128. [Google Scholar] [CrossRef]

- Yu, H.; Zhang, Z.; Li, Z.; Chen, D. Characteristics of Tar Formation during Cellulose, Hemicellulose and Lignin Gasification. Fuel 2014, 118, 250–256. [Google Scholar] [CrossRef]

- Michel, R.; Rapagnà, S.; Burg, P.; Mazziotti di Celso, G.; Courson, C.; Zimny, T.; Gruber, R. Steam Gasification of Miscanthus X Giganteus with Olivine as Catalyst Production of Syngas and Analysis of Tars (IR, NMR and GC/MS). Biomass Bioenergy 2011, 35, 2650–2658. [Google Scholar] [CrossRef]

- Huang, B.-S.; Chen, H.-Y.; Chuang, K.-H.; Yang, R.-X.; Wey, M.-Y. Hydrogen Production by Biomass Gasification in a Fluidized-Bed Reactor Promoted by an Fe/CaO Catalyst. Int. J. Hydrogen Energy 2012, 37, 6511–6518. [Google Scholar] [CrossRef]

- Kamińska-Pietrzak, N.; Smoliński, A. Selected Environmental Aspects of Gasification and Co-Gasification of Various Types of Waste. J. Sustain. Min. 2013, 12, 6–13. [Google Scholar] [CrossRef] [Green Version]

- Rollinson, A.N. Fire, Explosion and Chemical Toxicity Hazards of Gasification Energy from Waste. J. Loss Prev. Process Ind. 2018, 54, 273–280. [Google Scholar] [CrossRef]

- Malik, A.; Mohapatra, S. Biomass-Based Gasifiers for Internal Combustion (IC) Engines—A Review. Sadhana 2013, 38, 461–476. [Google Scholar] [CrossRef] [Green Version]

- The Blue Ridge Environmental Defense League. Waste Gasification: Impacts on the Environment and Public Health; The Blue Ridge Environmental Defense League: Boone, NC, USA, 2009. [Google Scholar]

- Tripathi, L.; Dubey, A.K.; Gangil, S.; Singh, P.L. Waste Water Treatment of Biomass Based Power Plant. Int. J. ChemTech Res. 2013, 5, 761–764. [Google Scholar]

- Mays, N.; Roberts, E.; Popay, J. Synthesising Research Evidence. In Studying the Organisation and Delivery of Health Services; Routledge: London, UK, 2001; ISBN 978-0-203-48198-1. [Google Scholar]

- Arksey, H.; O’Malley, L. Scoping Studies: Towards a Methodological Framework. Int. J. Soc. Res. Methodol. 2005, 8, 19–32. [Google Scholar] [CrossRef] [Green Version]

- Vanhuyse, F.; Fejzić, E.; Ddiba, D.; Henrysson, M. The Lack of Social Impact Considerations in Transitioning towards Urban Circular Economies: A Scoping Review. Sustain. Cities Soc. 2021, 75, 103394. [Google Scholar] [CrossRef]

- Prabowo, B.; Salaj, A.; Lohne, J. Urban Heritage Facility Management: A Scoping Review. Appl. Sci. 2021, 11, 9443. [Google Scholar] [CrossRef]

- Ramos, A.; Rouboa, A. Life Cycle Thinking of Plasma Gasification as a Waste-to-Energy Tool: Review on Environmental, Economic and Social Aspects. Renew. Sustain. Energy Rev. 2022, 153, 111762. [Google Scholar] [CrossRef]

- Michaga, M.F.R.; Michailos, S.; Hughes, K.J.; Ingham, D.; Pourkashanian, M. 10—Techno-Economic and Life Cycle Assessment Review of Sustainable Aviation Fuel Produced via Biomass Gasification. In Sustainable Biofuels; Ray, R.C., Ed.; Applied Biotechnology Reviews; Academic Press: Cambridge, MA, USA, 2021; pp. 269–303. ISBN 978-0-12-820297-5. [Google Scholar]

- Korre, A.; Durucan, S.; Nie, Z. Life Cycle Environmental Impact Assessment of Coupled Underground Coal Gasification and CO2 Capture and Storage: Alternative End Uses for the UCG Product Gases. Int. J. Greenh. Gas Control. 2019, 91, 102836. [Google Scholar] [CrossRef]

- Li, Q.; Song, G.; Xiao, J.; Hao, J.; Li, H.; Yuan, Y. Exergetic Life Cycle Assessment of Hydrogen Production from Biomass Staged-Gasification. Energy 2020, 190, 116416. [Google Scholar] [CrossRef]

- Li, J.; Cheng, W. Comparative Life Cycle Energy Consumption, Carbon Emissions and Economic Costs of Hydrogen Production from Coke Oven Gas and Coal Gasification. Int. J. Hydrogen Energy 2020, 45, 27979–27993. [Google Scholar] [CrossRef]

- Cao, C. 21—Sustainability and Life Assessment of High Strength Natural Fibre Composites in Construction. In Advanced High Strength Natural Fibre Composites in Construction; Fan, M., Fu, F., Eds.; Woodhead Publishing: Cambridge, UK, 2017; pp. 529–544. ISBN 978-0-08-100411-1. [Google Scholar]

- Moretti, C.; Corona, B.; Rühlin, V.; Götz, T.; Junginger, M.; Brunner, T.; Obernberger, I.; Shen, L. Combining Biomass Gasification and Solid Oxid Fuel Cell for Heat and Power Generation: An Early-Stage Life Cycle Assessment. Energies 2020, 13, 2773. [Google Scholar] [CrossRef]

- Parascanu, M.M.; Kaltschmitt, M.; Rödl, A.; Soreanu, G.; Sánchez-Silva, L. Life Cycle Assessment of Electricity Generation from Combustion and Gasification of Biomass in Mexico. Sustain. Prod. Consum. 2021, 27, 72–85. [Google Scholar] [CrossRef]

- Reaño, R.L.; de Padua, V.A.N.; Halog, A.B. Energy Efficiency and Life Cycle Assessment with System Dynamics of Electricity Production from Rice Straw Using a Combined Gasification and Internal Combustion Engine. Energies 2021, 14, 4942. [Google Scholar] [CrossRef]

- Wu, W.; Chang, J.-S. Integrated Algal Biorefineries from Process Systems Engineering Aspects: A Review. Bioresour. Technol. 2019, 291, 121939. [Google Scholar] [CrossRef]

- Alcazar-Ruiz, A.; Ortiz, M.L.; Dorado, F.; Sanchez-Silva, L. Gasification versus Fast Pyrolysis Bio-Oil Production: A Life Cycle Assessment. J. Clean. Prod. 2022, 336, 130373. [Google Scholar] [CrossRef]

- Sun, H.; Luo, Z.; Li, S.; Xue, S.; Zhou, Q.; Wei, T.; Du, L. Comparative Life Cycle Assessment (LCA) of Biofuel Production via Corn Stover: Fermentation to Ethanol, Pyrolysis to Bio-Oil, and Gasification to Jet Fuel. Biomass Convers. Biorefinery 2021. [Google Scholar] [CrossRef]

- Iannotta, P.; Caputo, G.; Scargiali, F.; Longo, S.; Cellura, M.; Brucato, A. Combined Gasification-Oxidation System for Waste Treatment with Supercritical Water: LCA and Performance Analysis. Sustainability 2021, 13, 82. [Google Scholar] [CrossRef]

- Sugihara, H.; Kameyama, M.; Dowaki, K. An LCA and Energy Analysis of a Biomass Integrated-Pyrolysis Gasification/SOFC System with H2S Removal. IOP Conf. Ser. 2020, 460, 012013. [Google Scholar] [CrossRef]

- Zang, G.; Zhang, J.; Jia, J.; Lora, E.S.; Ratner, A. Life Cycle Assessment of Power-Generation Systems Based on Biomass Integrated Gasification Combined Cycles. Renew. Energy 2020, 149, 336–346. [Google Scholar] [CrossRef]

- Wang, C.; Jin, H.; Peng, P.; Chen, J. Thermodynamics and LCA Analysis of Biomass Supercritical Water Gasification System Using External Recycle of Liquid Residual. Renew. Energy 2019, 141, 1117–1126. [Google Scholar] [CrossRef]

- Salkuyeh, Y.K.; Saville, B.A.; MacLean, H.L. Techno-Economic Analysis and Life Cycle Assessment of Hydrogen Production from Different Biomass Gasification Processes. Int. J. Hydrogen Energy 2018, 43, 9514–9528. [Google Scholar] [CrossRef]

- Keller, F.; Voss, R.L.; Lee, R.P.; Meyer, B. Life cycle assessment of global warming potential of feedstock recycling technologies: Case study of waste gasification and pyrolysis in an integrated inventory model for waste treatment and chemical production in Germany. Resour. Conserv. Recycl. 2021, 179, 106106. [Google Scholar] [CrossRef]

- Rani, A.; Singh, U.; Singh, A.K.; Mahapatra, S.S. Performance, Cost and Environmental Assessment of Gasification-Based Electricity in India: A Preliminary Analysis. IOP Conf. Ser. 2017, 76, 012007. [Google Scholar] [CrossRef] [Green Version]

- Yang, K.; Zhu, N.; Yuan, T. Analysis of Optimum Scale of Biomass Gasification Combined Cooling Heating and Power (CCHP) System Based on Life Cycle Assessment(LCA). Procedia Eng. 2017, 205, 145–152. [Google Scholar] [CrossRef]

- Bianco, I.; Panepinto, D.; Zanetti, M. Environmental Impacts of Electricity from Incineration and Gasification: How the LCA Approach Can Affect the Results. Sustainability 2022, 14, 92. [Google Scholar] [CrossRef]

- Innocenzi, V.; Cantarini, F.; Zueva, S.; Amato, A.; Morico, B.; Beolchini, F.; Prisciandaro, M.; Vegliò, F. Environmental and Economic Assessment of Gasification Wastewater Treatment by Life Cycle Assessment and Life Cycle Costing Approach. Resour. Conserv. Recycl. 2021, 168, 105252. [Google Scholar] [CrossRef]

- Sharara, M.; Kim, D.; Sadaka, S.; Thoma, G. Consequential Life Cycle Assessment of Swine Manure Management within a Thermal Gasification Scenario. Energies 2019, 12, 4081. [Google Scholar] [CrossRef] [Green Version]

- Dong, J.; Tang, Y.; Nzihou, A.; Chi, Y.; Weiss-Hortala, E.; Ni, M.; Zhou, Z. Comparison of Waste-to-Energy Technologies of Gasification and Incineration Using Life Cycle Assessment: Case Studies in Finland, France and China. J. Clean. Prod. 2018, 203, 287–300. [Google Scholar] [CrossRef]

- Ouedraogo, A.S.; Frazier, R.S.; Kumar, A. Comparative Life Cycle Assessment of Gasification and Landfilling for Disposal of Municipal Solid Wastes. Energies 2021, 14, 7032. [Google Scholar] [CrossRef]

- Tang, Y.; Dong, J.; Li, G.; Zheng, Y.; Chi, Y.; Nzihou, A.; Weiss-Hortala, E.; Ye, C. Environmental and Exergetic Life Cycle Assessment of Incineration- and Gasification-Based Waste to Energy Systems in China. Energy 2020, 205, 118002. [Google Scholar] [CrossRef]

- Li, G.; Ma, S.; Liu, F.; Zhou, X.; Wang, K.; Zhang, Y. Life Cycle Water Footprint Assessment of Syngas Production from Biomass Chemical Looping Gasification. Bioresour. Technol. 2021, 342, 125940. [Google Scholar] [CrossRef]

- Loy, A.C.M.; Alhazmi, H.; Lock, S.S.M.; Yiin, C.L.; Cheah, K.W.; Chin, B.L.F.; How, B.S.; Yusup, S. Life-Cycle Assessment of Hydrogen Production via Catalytic Gasification of Wheat Straw in the Presence of Straw Derived Biochar Catalyst. Bioresour. Technol. 2021, 341, 125796. [Google Scholar] [CrossRef]

- Chen, J.; Xu, W.; Zuo, H.; Wu, X.; Jiaqiang, E.; Wang, T.; Zhang, F.; Lu, N. System Development and Environmental Performance Analysis of a Solar-Driven Supercritical Water Gasification Pilot Plant for Hydrogen Production Using Life Cycle Assessment Approach. Energy Convers. Manag. 2019, 184, 60–73. [Google Scholar] [CrossRef]

- Ren, K.; Zhang, T.; Tan, X.; Zhai, Y.; Bai, Y.; Shen, X.; Jia, Y.; Hong, J. Life Cycle Assessment of Ammonia Synthesis Based on Pulverized Coal Entrained Flow Gasification Technology in China. J. Clean. Prod. 2021, 328, 129658. [Google Scholar] [CrossRef]

- Al-Moftah, A.M.S.H.; Marsh, R.; Steer, J. Life Cycle Assessment of Solid Recovered Fuel Gasification in the State of Qatar. ChemEngineering 2021, 5, 81. [Google Scholar] [CrossRef]

- Muthudineshkumar, R.; Anand, R. Life Cycle Assessment on Biofuel Production from Biomass Gasification and Syngas Fermentation. IOP Conf. Ser. 2019, 312, 012016. [Google Scholar] [CrossRef]

- Marzeddu, S.; Cappelli, A.; Ambrosio, A.; Décima, M.; Viotti, P.; Boni, M. A Life Cycle Assessment of an Energy-Biochar Chain Involving a Gasification Plant in Italy. Land 2021, 10, 1256. [Google Scholar] [CrossRef]

- Demetrious, A.; Crossin, E. Life cycle assessment of paper and plastic packaging waste in landfill, incineration, and gasification-pyrolysis. J. Mater. Cycles Waste Manag. 2019, 21, 850–860. [Google Scholar] [CrossRef]

- Corvalán, C.; Espinoza Pérez, A.T.; Díaz-Robles, L.A.; Cubillos, F.; Vallejo, F.; Gómez, J.; Pino-Cortés, E.; Espinoza-Pérez, L.; Pelz, S.K.; Paczkowski, S.; et al. Life Cycle Assessment for Hydrothermal Carbonization of Urban Organic Solid Waste in Comparison with Gasification Process: A Case Study of Southern Chile. Environ. Prog. Sustain. Energy 2021, 40, e13688. [Google Scholar] [CrossRef]

- Li, F.; Chu, M.; Tang, J.; Liu, Z.; Wang, J.; Li, S. Life-Cycle Assessment of the Coal Gasification-Shaft Furnace-Electric Furnace Steel Production Process. J. Clean. Prod. 2021, 287, 125075. [Google Scholar] [CrossRef]

- Ramos, A.; Berzosa, J.; Clarens, F.; Marin, M.; Rouboa, A. Environmental and Socio-Economic Assessment of Cork Waste Gasification: Life Cycle and Cost Analysis. J. Clean. Prod. 2020, 249, 119316. [Google Scholar] [CrossRef]

- Valente, A.; Iribarren, D.; Dufour, J. Life Cycle Sustainability Assessment of Hydrogen from Biomass Gasification: A Comparison with Conventional Hydrogen. Int. J. Hydrogen Energy 2019, 44, 21193–21203. [Google Scholar] [CrossRef]

- Valente, A.; Iribarren, D.; Gálvez-Martos, J.-L.; Dufour, J. Robust Eco-Efficiency Assessment of Hydrogen from Biomass Gasification as an Alternative to Conventional Hydrogen: A Life-Cycle Study with and without External Costs. Sci. Total Environ. 2019, 650, 1465–1475. [Google Scholar] [CrossRef]

- Thunman, H.; Gustavsson, C.; Larsson, A.; Gunnarsson, I.; Tengberg, F. Economic Assessment of Advanced Biofuel Production via Gasification Using Cost Data from the GoBiGas Plant. Energy Sci. Eng. 2019, 7, 217–229. [Google Scholar] [CrossRef]

- Yang, Q.; Zhou, H.; Zhang, X.; Nielsen, C.P.; Li, J.; Lu, X.; Yanga, H.; Chen, H. Hybrid Life-Cycle Assessment for Energy Consumption and Greenhouse Gas Emissions of a Typical Biomass Gasification Power Plant in China. J. Clean. Prod. 2018, 205, 661–671. [Google Scholar] [CrossRef]

- Li, C.Y.; Wu, J.Y.; Chavasint, C.; Sampattagul, S.; Kiatsiriroat, T.; Wang, R.Z. Multi-Criteria Optimization for a Biomass Gasification-Integrated Combined Cooling, Heating, and Power System Based on Life-Cycle Assessment. Energy Convers. Manag. 2018, 178, 383–399. [Google Scholar] [CrossRef]

- Dong, J.; Tang, Y.; Nzihou, A.; Chi, Y.; Weiss-Hortala, E.; Ni, M. Life Cycle Assessment of Pyrolysis, Gasification and Incineration Waste-to-Energy Technologies: Theoretical Analysis and Case Study of Commercial Plants. Sci. Total Environ. 2018, 626, 744–753. [Google Scholar] [CrossRef]

- Śliwińska, A.; Burchart-Korol, D.; Smoliński, A. Environmental Life Cycle Assessment of Methanol and Electricity Co-Production System Based on Coal Gasification Technology. Sci. Total Environ. 2017, 574, 1571–1579. [Google Scholar] [CrossRef]

- Ramos, A.; Teixeira, C.A.; Rouboa, A. Environmental Assessment of Municipal Solid Waste by Two-Stage Plasma Gasification. Energies 2019, 12, 137. [Google Scholar] [CrossRef] [Green Version]

- Ramos, A.; Berzosa, J.; Espí, J.; Clarens, F.; Rouboa, A. Life Cycle Costing for Plasma Gasification of Municipal Solid Waste: A Socio-Economic Approach. Energy Convers. Manag. 2020, 209, 112508. [Google Scholar] [CrossRef]

- Ghasem, N. Chapter 21—CO2 Removal from Natural Gas. In Advances in Carbon Capture; Rahimpour, M.R., Farsi, M., Makarem, M.A., Eds.; Woodhead Publishing: Cambridge, UK, 2020; pp. 479–501. ISBN 978-0-12-819657-1. [Google Scholar]

- Jung, J.; Jeong, Y.S.; Lim, Y.; Lee, C.S.; Han, C. Advanced CO2 Capture Process Using MEA Scrubbing: Configuration of a Split Flow and Phase Separation Heat Exchanger. Energy Procedia 2013, 37, 1778–1784. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).