Abstract

Time-varying lumped disturbance and measurement noise are primary obstacles that restrict the control performance of permanent magnet synchronous motor (PMSM) drives. To tackle these obstacles, an adaptive nonsingular terminal sliding mode (ANTSM) algorithm is combined with augmented recursive sliding mode observer (ARSMO) for PMSM speed regulation system in this paper. Generally, conventional nonsingular terminal sliding mode (NTSM) controller adopts a fixed and conservative control gain to suppress the time-varying disturbance, which will lead to unsatisfactory steady-state performance. Without requiring any information of the time-varying disturbance in advance, a novel barrier function adaptive algorithm is utilized to adjust the gain of NTSM controller online according to the amplitude of disturbance. In addition, the ARSMO is emoloyed to estimate the total disturbance and motor speed simultaneously, thereby alleviating the negative impact of measurement noise and excessive control gain. Comprehensive experimental results verify that the proposed enhanced ANTSM strategy can optimize the dynamic performance of PMSM system without sacrificing its steady-state performance.

1. Introduction

With the characteristics of rapid response, high tracking precision, and simple structure, permanent magnet synchronous motor (PMSM) has extensively utilized in various industry applications [1,2,3]. However, the control performance of PMSM system may be inevitably influenced by time-varying disturbance and measurement noise. Generally, the total disturbance generated by load torque and parameter perturbation will cause aperiodic speed fluctuation, thereby affecting the anti-disturbance property of PMSM system [4]. The measurement noise generated by position sensors may degrade the steady-state performance of PMSM drive. Hence, the research on disturbance and measurement noise suppression has drawn great attention recently [5,6,7,8,9].

To improve the time-varying disturbance suppression property, many advanced control algorithms have been adopted to optimize the performance of PMSM drive system, such as backstepping control [10], fuzzy control [11], active disturbance rejection control (ADRC) [12], and sliding mode control (SMC) [13,14,15], etc. Owing to insensitivity to parameter mismatch and strong robustness against load torque, the SMC stands out from the aforementioned algorithms. Distinguished from the linear sliding surface used in conventional SMC, a terminal sliding mode (TSM) controller was proposed in [16] to obtain rapid response and strong anti-disturbance property. With the benefit of nonlinear sliding surface, the speed tracking error can converge to origin in finite time.

Generally, a sufficiently large control gain should be chosen to suppress the time-varying and unknown disturbance [17]. Consequently, a fixed and conservative control gain may cause undesired chattering phenomenon, thus damaging the system hardware. On the contrary, the small control gain may lead to the instability of PMSM system in some extreme cases, where the stable condition of SMC cannot be satisfied. In [18], a neural adaptive TSM control method was constructed to automatically tune the control gain of conventional TSM. However, the utilization of neural network technique heavily depends on the computing power of hardware devices, which limits its large-scale industrial applications. A fuzzy logic controller was employed in [19] to avoid serious chattering phenomenon generated by overestimated gain of TSM control algorithm. However, the formulation of fuzzy rules is based on the experience of previous parameter tuning, which brings great challenges to the reasonable selection of the control gain. With the development of control theory, a typical gain-increasing adaptive algorithm was proposed in [20] to adjust the control gain as the disturbance increases. The aim of the above adaptive algorithm is to increase the control gain until the closed-loop system stabilizes, and then the control gain is fixed. Unfortunately, this kind of adaptive law lacks the ability to reduce the controller gain as the disturbance decreases. To address this tough issue, a novel adaptive algorithm was constructed in [21] to online adjust the control gain with the change of disturbance. As the disturbance decreases, the gain will also decrease correspondingly. However, the size of convergence neighborhood depends on some priori knowledge about the upper bound of disturbance, which is unreasonable in the practical engineering system.

Even though several SMC strategies have shown significant success in suppressing time-varying disturbance, the problems of measurement noise and excessive control gain still restrict the control accuracy of PMSM drive system. In [22], the widely used disturbance observer (DOB) was adopted to estimate and compensate the total disturbance, which alleviates the control gain of NTSM controller. Nevertheless, two significant drawbacks exist in the aforementioned control strategy. On one hand, conventional DOB can only guarantee the asymptotic convergence of the estimation error, which results in low estimation accuracy. On the other hand, conventional DOB is unable to estimate the system states, which result in the inability to suppress the measurement noise. In [23], the high-order phase-locking loop observer (PLLO) was employed to estimate the actual motor speed and lumped disturbance simultaneously, which can suppress the measurement noise and improve the low-frequency disturbance rejection performance. Unfortunately, introducing the PLLO may deteriorate the stability of PMSM drive system. In [24], two cascaded extended stated observer was utilized to filter out the measurement noise without sacrificing the robustness of the closed-loop system. However, complex control structure may increase the computational burden and parameter tuning workload.

This article presents a barrier function based adaptive nonsingular terminal sliding mode (ANTSM) algorithm combined with augmented recursive sliding mode observer (ARSMO) for PMSM speed regulation system. Firstly, utilizing the barrier function to adjust the control gain of NTSM in real time, the severe chattering generated by conservative control gain can be greatly mitigated. Secondly, considering the adverse effect of measurement noise generated by position sensors, a concise and effective ARSMO is adopted to estimate the motor speed signal. Finally, the superior advantages of the proposed PMSM speed loop control strategy are demonstrated by experimental results. The major contributions of this paper mainly include:

- (1)

- A barrier function is exploited to adjust the control gain of the conventional NTSM controller, which is simpler and more reasonable than existing adaptive algorithms that can only ensure that the convergence region of the sliding variable is related to the upper bound of the lumped disturbance. Without requiring any priori information of time-varying disturbance, the proposed ANTSM controller can drive the speed error and maintain it in a predefined neighborhood of origin.

- (2)

- By proving that the closed-loop system will not diverge to infinity before the observation error of the proposed ARSMO converges to zero, the stability of the entire closed-loop system is theoretically guaranteed. Meanwhile, according to the bode diagrams obtained by the frequency-sweep method, it can be seen from the frequency domain perspective that the proposed ARSMO has satisfactory measurement noise suppression capability.

2. Mathematical Model and Conventional Control Method

2.1. PMSM Mechanical Dynamics with Disturbance

Ignoring the effects of hysteresis loss, core saturation, and eddy current, the motion equation of the PMSM system can be described by

where is the rotor angular velocity, B is the viscous frictional coefficient, is the electromagnetic torque, J is the moment of inertia, and denotes the load torque.

Taking the reference electromagnetic torque as the control input, Equation (1) can be rewritten as

where .

Considering the parameter mismatch issue, the system model can be reconstructed as

where , denotes the nominal inertia, and is the total disturbance.

The actual motor speed signal is typically calculated from the derivative of the rotor position, and the procedure will result in the introduction of measurement noise. Therefore, the measured motor speed signal contaminated by high-frequency noise is shown as

2.2. Conventional TSM Controller Design

In this subsection, the conventional NTSM algorithm is utilized as the speed loop controller for PMSM system. Defining the reference mechanical angular speed as , then the speed error can be written as

To obtain excellent tracking performance, the terminal sliding surface is given as

According to [16], the NTSM controller can be designed as

where and .

Assuming that and is a positive constant, then the speed error can converge to zero in finite time if the control gain satisfies [22].

In order to guarantee the stability of the PMSM drive system, the control gain of conventional NTSM controller should always be larger than the upper bound of total disturbance. In addition, the control performance of conventional NTSM controller with fixed control gain is unsatisfactory in the presence of time-varying disturbance. Thus, it is essential to develop an adaptive law to adjust the control gain of the feedback controller online.

3. Proposed Speed Loop Control Strategy

3.1. Barrier Function Based Adaptive NTSM Controller

By constructing an adaptive law to adjust the control gain of conventional NTSM algorithm, the ANTSM controller is constructed as

where is the variable control gain.

The basic strategy of the proposed adaptive algorithm is to first increase the variable control gain until s reaches the region at some time . Then, the barrier function is adopted to adjust the variable control gain in real time, which ensures that the tracking error remains within a predefined neighborhood of origin . According to the above analysis, the adaptive algorithm is constructed as follows

where and are positive constants. The barrier function is designed as

with being a positive constant.

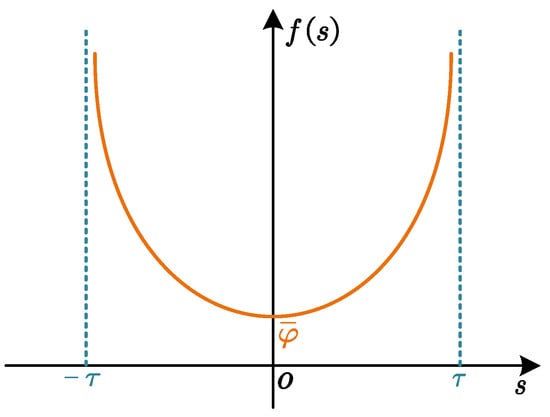

Meanwhile, the relationship between the sliding variable s and the output of barrier function is shown in Figure 1. Obviously, as the sliding variable s increases within , the output of barrier function tends to infinity. As a result, the anti-disturbance property of the proposed ANTSM controller can be enhanced by increasing the control gain. On the contrary, once the sliding variable s decreases, the output of barrier function will decrease accordingly, thus alleviating the chattering phenomenon caused by large control gain.

Figure 1.

Illustration of barrier function .

Increasing the values of parameters and can reduce the time for sliding variable s to converge from the initial state to the region . Appropriate parameters and need to be chosen to avoid overshoot of the control gain with respect to the bound of total disturbance. The parameter is related to the minimum value of the barrier function. Increasing the value of can obviously optimize the disturbance rejection capacity of the PMSM drive system. However, an excessively large parameter may cause the controller gain calculated by barrier function to be conservative. The parameter determines the predefined region of the sliding variable. Decreasing the value of parameter will result in better disturbance rejection property and stronger robustness. However, excessively large control gain calculated by barrier function with small parameter may lead to undesired chattering phenomenon.

The sliding variable s will be shown to converge and remain in the region in this subsection. Since the function is monotonically increasing, the sliding variable will reach the region at some time by choosing appropriate parameters and .

Next, consider the case when . In this case, the adaptive algorithm is reduced to . Inspired by [25], the following Lyapunov function is constructed as

Evaluating the derivative of yields

To make the expression compact, define

Since , an intermediate variable is introduced to prove that s will remain in the region when . The intermediate variable is designed as

It can be deduced from (10) that is monotonically increasing on . When , one has by (14) that . Hence, and are positive. Under this case, one obtains from (12) and (13) that

where .

Obviously, Equation (15) satisfies the finite-time stability criterion in [16]. As a result, the sliding variable s can finite-time converge to the region , which is a subset of .

3.2. Design of ARSMO

Due to the fact that the time-varying total disturbance and high-frequency measurement noise always exist in practical engineering, the ARSMO is utilized to estimate the total disturbance and suppress the measurement noise, which performs as the feed-forward compensation in the control design. Assuming that there exists a positive constant such that , then the ARSMO can be constructed as

where is the augmented state of the motor speed , , and denote the estimation values of , and , respectively. Besides, , , are the positive observer gains and L being a Lipschitz constant for total disturbance . In particular, the positive observer gains can be selected as , , and , respectively [26].

Then, we will demonstrate that the actual motor speed and total disturbance can be estimated by ARSMO in finite time. First of all, setting , , and , one has

and

According to (17), it can be deduced that

Thus, one obtains

With the help of (19), one has

Hence, it can be deduced from (21) that

which is understood in the Filippov sense. Combining (17), (20), and (23) together, one has the following differential inclusion

According to the detailed theoretical analysis in [27], the estimation error can converge to zero in finite time. On this basis, the proposed ANTSM+ARSMO controller can be given as

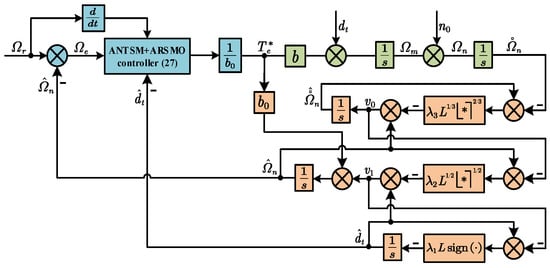

Meanwhile, the block diagram of the ANTSM+ARSMO controller is shown in Figure 2.

Figure 2.

Block diagram of the proposed ANTSM+ARSMO controller.

In order to illustrate the benefits of the proposed ARSMO in suppressing the high-frequency measurement noise, a basic recursive sliding mode observer (RSMO) without the augmented structure is designed to compare with the ARSMO in frequency domain, which is structured as

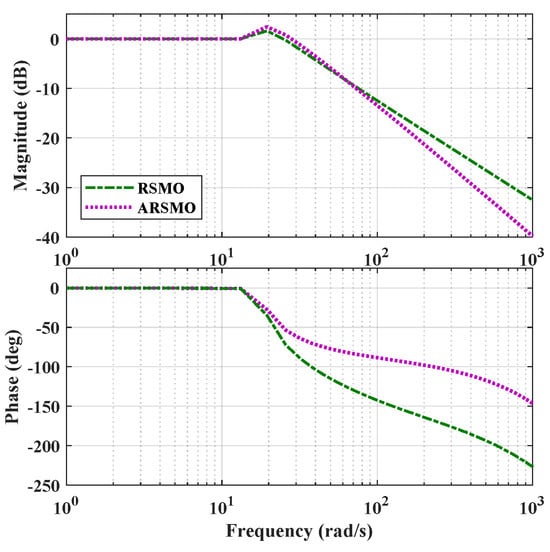

Generally, the bode diagram of the observer is employed to analyze its frequency domain characteristics. Since the proposed ARSMO and basic RSMO have nonlinear terms, these transfer functions are difficult to obtain. Consequently, a unified frequency-sweep method is utilized to obtain the bode diagrams of ARSMO and RSMO.

Choosing , the bode diagrams of ARSMO and RSMO are shown in Figure 3. Obviously, the proposed ARSMO performs as a low-pass filter and has satisfactory high-frequency measurement noise suppression property. Let be the open loop cutoff frequency of the ARSMO, we can find that there is almost no phenomenon of magnitude attenuation and phase lag when . Furthermore, the magnitude curve of the ARSMO resembles a slope, and the phase decreases rapidly when . Thus, the ARSMO is effective in suppressing high-frequency measurement noise. In addition, the magnitude curve of the ARSMO is below the magnitude curve of the RSMO. Thus, the measurement noise suppression performance of the proposed ARSMO is better than conventional RSMO.

Figure 3.

Bode diagrams of ARSMO and RSMO.

3.3. Stability Analysis of Closed-Loop System

Utilizing the estimation values of motor speed and total disturbance, the proposed enhanced ANTSM controller can be given as

where .

The finite time convergence of the ANTSM controller and ARSMO has been demonstrated previously. To prove the stability of the closed-loop system, it is only necessary to prove that the closed-loop system will not diverge to infinity within the time interval . Next, we will give the rigorous theoretical analysis.

Since , we have . With the help of , the enhanced controller (27) can be rewritten as

By a simple calculation, one has

Choose a Lyapunov function as

Differentiating the function yields

Since , one obtains . Due to the fact that and can converge to zero in finite time T, and are bounded during the time interval . Meanwhile, the variable control gain and are bounded for . Hence, there exists a positive constant such that

When , the speed tracking error is obviously bounded. On the contrary, when , one can obtain from (32) that

where . Then, it can be deduced from (33) that

Consequently, the speed tracking error is bounded and does not diverge within the time interval .

According to (6), one obtains

Due to the fact that parameter is a positive constant and , the sliding variable s is bounded and does not diverge for .

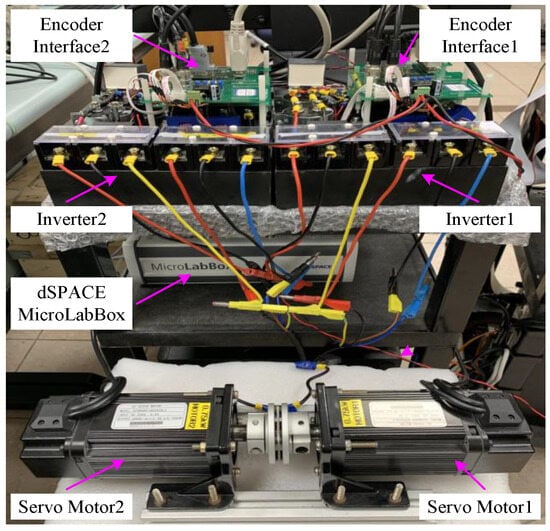

4. Experiment Results

In order to investigate the advantages of the proposed control scheme, a series of comparative experiments are conducted on the test platform based on dSPACE DS1202 in this subsection. The experimental setup is shown in Figure 4, and the nominal parameters of the test motor are listed in Table 1. The other identical motor is mechanically coupled with the test motor to generate the load torque. The dc-bus voltage is 150 V. The saturation limit of q-axis reference current is 9 A. The field-oriented control method is employed to control the test motor, and the control period is 10 kHz. Decoupled PI regulators are employed in the current-loop to control and . Meanwhile, the well-known ADRC method is employed to compare with the proposed control scheme.

Figure 4.

PMSM experimental bench.

Table 1.

Main parameters of the pmsm system.

The value of parameter L in RSMO and ARSMO is selected as . The values of parameters and in NTSM and ANTSM controllers are chosen as and , respectively. The control gain of conventional NTSM controller is selected as , while the control gain of the proposed ANTSM controller is generated by the adaptive algorithm. The parameters of the adaptive law are chosen as , and .

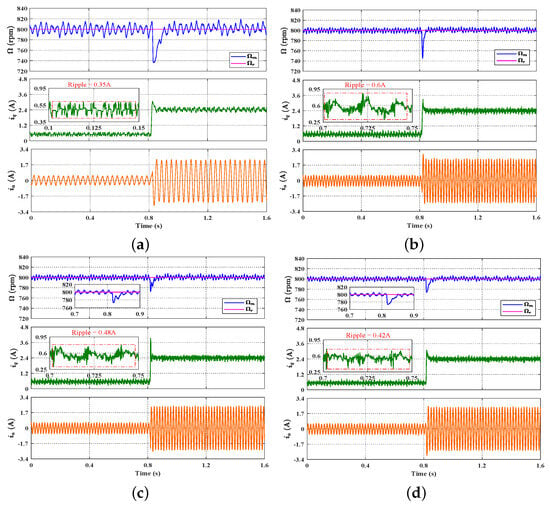

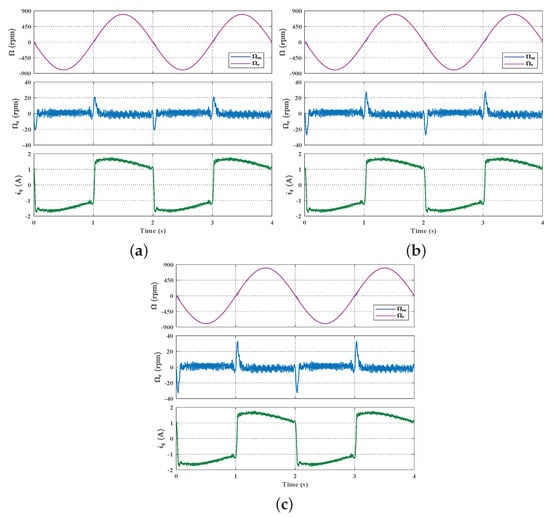

To illustrate the superior performance of the proposed ANTSM+ARSMO control scheme, experiments are implemented among the ADRC controller, NTSM+RSMO controller, ANTSM+RSMO controller, and the proposed ANTSM+ARSMO controller. The corresponding experimental results are given in Figure 5 and Figure 6. Figure 5 shows the disturbance rejection properties of these four control algorithms. The experimental results from top to bottom include the reference motor speed, actual motor speed, q-axis current, and A-phase current, respectively. It can be seen from Figure 5a,b that the conventional ADRC method with linear terms and conventional NTSM controller with fixed control gain is insufficient to suppress the adverse effect of load torque variation. Due to the fact that the NTSM+RSMO controller adopts a sufficiently large control gain to suppress the time-varying total disturbance, the chattering phenomenon during the stable operation of the motor is larger than that under the ANTSM controller. According to the experimental results of q-axis current, it can be concluded that the proposed ARSMO has better high-frequency measurement noise suppression performance compared to the conventional RSMO. The comparative results of the four controllers under load cariation are summarized in Table 2.

Figure 5.

Disturbance rejection performance of four control methods. (a) ADRC. (b) NTSM+RSMO. (c) ANTSM+RSMO. (d) ANTSM+ARSMO.

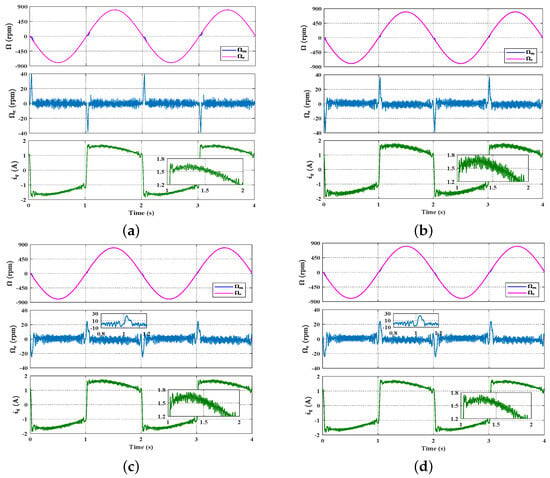

Figure 6.

Tracking performance of four control methods under sinusoidal reference. (a) ADRC. (b) NTSM+RSMO. (c) ANTSM+RSMO. (d) ANTSM+ARSMO.

Table 2.

Comparison of performance indices under load variation.

Figure 6 demonstrates the tracking performance of these four control strategies. The experimental results from top to bottom include the reference motor speed, actual motor speed, speed tracking error, and q-axis current, respectively. The reference motor speed signal is chosen as . Owing to the utilization of barrier function to adjust the control gain online, the speed tracking error under the proposed ANTSM controller is significantly smaller than that of the conventional NTSM controller. In addition, the maximum speed tracking error under the proposed ANTSM+ARSMO controller is almost the same as that under ANTSM+RSMO controller. However, it can be clearly observed from the experimental results of q-axis current, the control performance of the ANTSM+ARSMO control strategy is better than that of ANTSM+RSMO control algorithm. The comparative results of the four controllers under sinusoidal reference are summarized in Table 3.

Table 3.

Comparison of performance indices under sinusoidal reference.

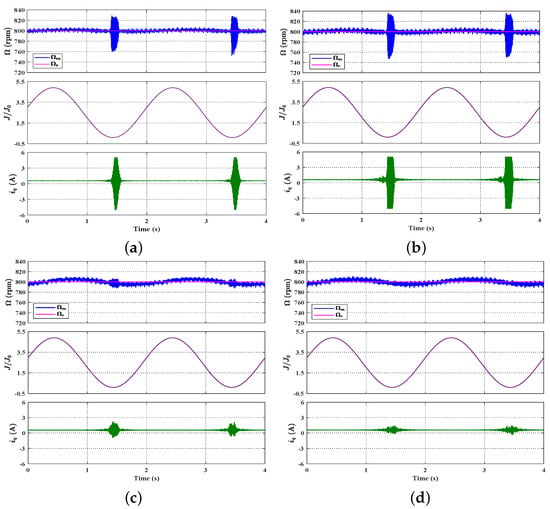

Figure 7 shows the robustness of these four control methods. The experimental results from top to bottom include the reference motor speed, actual motor speed, ratio of actual inertia to nominal inertia, and q-axis current, respectively. Obviously, the conventional NTSM+RSMO control method has the worst robustness. The motor has severe oscillation phenomenon during operation, and the actual amplitude of the q-axis reaches its limit. At the same time, the actual motor speed under the ANTSM+RSMO controller also has slight oscillation phenomenon. Overall, the proposed ANTSM+ARSMO control strategy has satisfactory robustness in the presence of inertia mismatch.

Figure 7.

Robustness of four control methods. (a) ADRC. (b) NTSM+RSMO. (c) ANTSM+RSMO. (d) ANTSM+ARSMO.

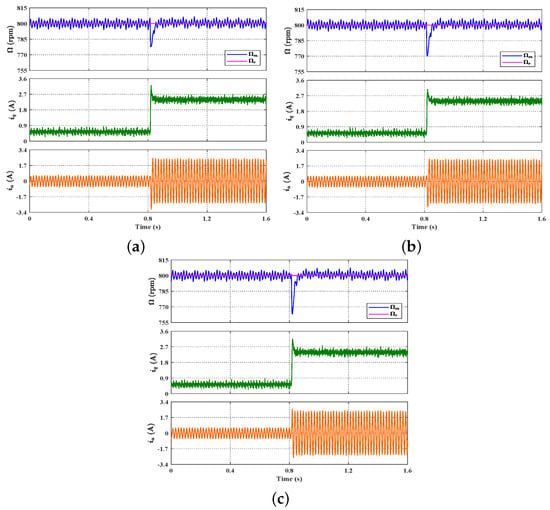

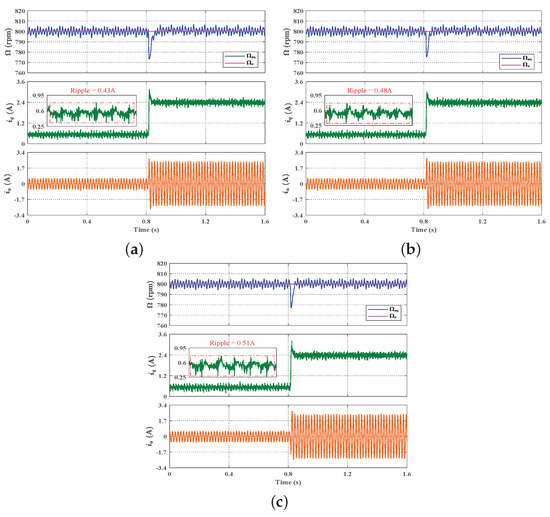

The experimental results of ANTSM+ARSMO control method under different values of parameter are shown in Figure 8 and Figure 9. The values of parameter are chosen as 2.5, 3.5, and 4.5, respectively. According to Figure 8, it is clear that decreasing parameter can diminish the speed drop under load torque variation. Since the value of parameter is related to the range of speed tracking error, a smaller parameter can improve the disturbance rejection performance of the PMSM system. Similarly, as shown in Figure 9, decreasing the value of parameter can reduce the motor speed tracking error under the sinusoidal reference speed signal. However, the change of parameter has little effect on the current ripple. Overall, the variation of parameter causes a important impact on the dynamic performance of the PMSM drive system. The comparative results of the proposed controller under different parameter are summarized in Table 4.

Figure 8.

Disturbance rejection performance of ANTSM controller under different . (a) . (b) . (c) .

Figure 9.

Tracking performance of ANTSM controller under different . (a) . (b) . (c) .

Table 4.

Comparison of performance indices under different parameter .

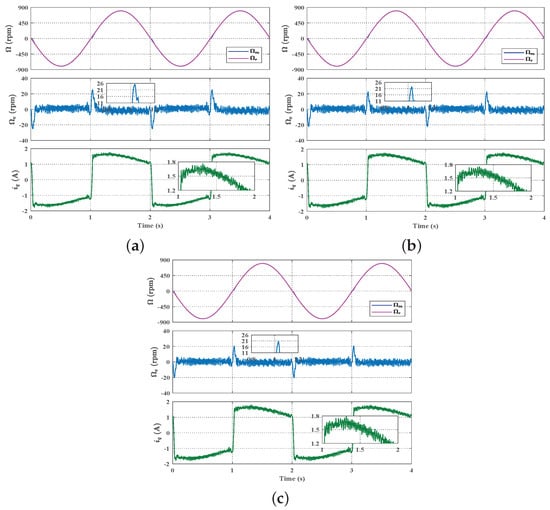

Figure 10 and Figure 11 illustrate the performance of ANTSM+ARSMO control algorithm under different parameter . The values of are selected as 80, 160, and 240, respectively. According to the experimental results of actual motor speed in Figure 10 and speed tracking error in Figure 11, it is evident that increasing parameter can diminish the speed drop under load torque variation and the speed tracking error under sinusoidal reference signal at the same time. Since the value of parameter is related to the minimum value of control gain, increasing parameter may cause the chattering phenomenon, which is reflected in the experimental results of the q-axis current ripple. The comparative results of the proposed controller under different parameter are summarized in Table 5.

Figure 10.

Disturbance rejection performance of ANTSM controller under different . (a) . (b) . (c) .

Figure 11.

Tracking performance of ANTSM controller under different . (a) . (b) . (c) .

Table 5.

Comparison of performance indices under different parameter .

5. Conclusions

This paper presents a combination of the ANTSM controller and ARSMO algorithm for PMSM speed regulation system. By employing the barrier function to adjust the control gain of conventional NTSM controller, the dynamic performance of PMSM system can be significantly improved without sacrificing its steady-state performance. Meanwhile, the adverse effect of measurement noise generated by position sensors is alleviated by adopting the ARSMO with filtering characteristics, while avoiding excessive feedback control gain. The comprehensive experimental results illustrate that the proposed control strategy can effectively suppress the total disturbance and measurement noise compared with conventional NTSM controller and basic RSMO without the augmented structure. Our future work will focus on verifying the effectiveness of the proposed algorithm in more complex industrial environments and at low sampling frequencies.

Author Contributions

Conceptualization, Q.H.; methodology, Q.H.; software, B.M., B.S. and C.D.; validation, Q.H., B.M. and Y.S.; formal analysis, B.S. and C.D.; investigation, Y.S. and C.D.; resources, Q.H., B.S. and C.D.; data curation, B.M. and C.D.; writing—original draft, Q.H.; writing—review and editing, B.M. and Y.S.; supervision, Q.H., B.S. and C.D. All authors have read and agreed to the published version of the manuscript.

Funding

This work is supported by the National Natural Science Foundation of China under Grant 62403079, and the Natural Science Foundation of Jiangsu Province under Grant BK20240963, the Jiangsu Agriculture Science and Technology Innovation Fund (Grant number CX(22)3111), the Scientific Research Program of Fuyang Normal University under Grant2024KY00095 and 2024FSKJ28ZD, and the Excellent Young Teacher Cultivation Program of the Higher Education Institutions of Anhui Province under Grant YQZD2023091.

Data Availability Statement

Data are contained within the article.

Acknowledgments

Thank you for acknowledging the contributions of the references in this field. We appreciate the journal’s provision of valuable and accessible resources.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Zhang, C.; Yang, Y.; Gong, Y.; Guo, Y.; Song, H.; Zhang, J. Angle-based RGN-enhanced ADRC for PMSM compressor speed regulation considering aperiodic and periodic disturbances. Actuators 2025, 14, 276. [Google Scholar] [CrossRef]

- Pan, L.; Fu, C.; Chen, B. Adaptive super-twisting controller-based modified extended state observer for permanent magnet synchronous motors. Actuators 2025, 14, 161. [Google Scholar] [CrossRef]

- Sun, J.; Xu, S.; Ding, S.; Pu, Z.; Yi, J. Adaptive conditional disturbance negation-based nonsmooth-integral control for PMSM drive system. IEEE-ASME Trans. Mechatron. 2024, 29, 3602–3613. [Google Scholar] [CrossRef]

- Dai, B.; Wang, J.; Zhao, J.; Shi, L. Critical current-constrained continuous nonsingular terminal sliding mode control for PMSM based on control barrier function. IEEE Trans. Power Electron. 2025, 40, 15093–15103. [Google Scholar] [CrossRef]

- Wang, L.; Du, H.; Zhang, W. Implementation of integral fixed-time sliding mode controller for speed regulation of PMSM servo system. Nonlinear Dyn. 2020, 102, 185–196. [Google Scholar] [CrossRef]

- Wang, T.; Zhu, Z.; Freire, N.; Wu, Z.; Foster, M.; Stone, D. Study on noise and disturbance issues of generalized predictive speed control for permanent magnet synchronous machines. IET Electr. Power Appl. 2021, 15, 6378. [Google Scholar] [CrossRef]

- Sun, J.; Xia, J.; Ding, S.; Yu, X. Exact-feedback linearization-based adaptive second-order sliding mode control design for DC-DC boost converters. IEEE Trans. Ind. Electron. 2025, 72, 5397–5407. [Google Scholar] [CrossRef]

- Cao, H.; Deng, Y.; Li, H.; Wang, J.; Liu, X.; Sun, Z.; Yang, T. Generalized active disturbance rejection with reduced-order vector resonant control for PMSM current disturbances suppression. IEEE Trans. Power Electron. 2023, 38, 6407–6421. [Google Scholar] [CrossRef]

- Hou, Q.; Ding, S.; Yu, X.; Mei, K. A super-twisting-like fractional controller for SPMSM drive system. IEEE Trans. Ind. Electron. 2022, 69, 9376–9384. [Google Scholar] [CrossRef]

- Linares-Flores, J.; Garcia-Rodriguez, C.; Sira-Ramirez, H.; Ramirez-Cardenas, O. Robust backstepping tracking controller for low-speed PMSM positioning system: Design, analysis, and implementation. IEEE Trans. Ind. Inform. 2015, 11, 1130–1141. [Google Scholar] [CrossRef]

- Shanmugam, L.; Joo, Y. Design of interval type-2 fuzzy-based sampled-data controller for nonlinear systems using novel fuzzy lyapunov functional and its application to PMSM. IEEE Trans. Syst. Man Cybern. Syst. 2011, 51, 542–551. [Google Scholar] [CrossRef]

- Qu, L.; Qiao, W.; Qu, L. An extended-state-observer-based sliding-mode speed control for permanent-magnet synchronous motors. IEEE J. Emerg. Sel. Topics Power Electron. 2021, 9, 1605–1613. [Google Scholar] [CrossRef]

- Hou, Q.; Ding, S.; Yu, X. Composite super-twisting sliding Mode control design for PMSM speed regulation problem based on a novel disturbance observer. IEEE Trans. Energy Convers. 2021, 36, 2591–2599. [Google Scholar] [CrossRef]

- Junejo, A.; Xu, W.; Mu, C.; Ismail, M.; Liu, Y. Adaptive speed control of PMSM drive system based a new sliding-mode reaching law. IEEE Trans. Power Electron. 2020, 35, 12110–12121. [Google Scholar] [CrossRef]

- Hou, Q.; Ding, S. Generalized proportional integral observer based super-twisting sliding mode control for PMSM. IEEE Trans. Circuits Syst. II Exp. Briefs 2020, 68, 747–751. [Google Scholar]

- Yu, S.; Yu, X.; Shirinzadeh, B.; Man, Z. Continuous finite-time control for robotic manipulators with terminal sliding mode. Automatica 2005, 41, 1957–1964. [Google Scholar] [CrossRef]

- Zheng, J.; Wang, H.; Man, Z.; Jin, J.; Fu, M. Robust motion control of a linear motor positioner using fast nonsingular terminal sliding mode. IEEE/ASME Trans. Mechatron. 2015, 20, 1743–1752. [Google Scholar] [CrossRef]

- Qi, L.; Shi, H. Adaptive position tracking control of permanent magnet synchronous motor based on RBF fast terminal sliding mode control. Neurocomputing 2013, 115, 23–30. [Google Scholar] [CrossRef]

- Divandari, M.; Rezaie, B.; Noei, A. Speed control of switched reluctance motor via fuzzy fast terminal sliding-mode control. Comput. Electr. Eng. 2019, 80, 106472. [Google Scholar] [CrossRef]

- Incremona, G.; Cucuzzella, M.; Ferrara, A. Adaptive suboptimal second-order sliding mode control for microgrids. Int. J. Control 2016, 89, 1849–1867. [Google Scholar] [CrossRef]

- Li, P.; Yu, X.; Xiao, B. Adaptive quasi-optimal higher order sliding-mode control without gain overestimation. IEEE Trans. Ind. Inform. 2018, 14, 3881–3891. [Google Scholar] [CrossRef]

- Li, S.; Zhou, M.; Yu, X. Design and implementation of terminal sliding mode control method for PMSM speed regulation system. IEEE Trans. Ind. Inform. 2013, 9, 1879–1891. [Google Scholar] [CrossRef]

- Zuo, Y.; Mei, J.; Jiang, C.; Yuan, X.; Xie, S.; Lee, C. Linear active disturbance rejection controllers for PMSM speed regulation system considering the speed filter. IEEE Trans. Power Electron. 2021, 36, 14579–14592. [Google Scholar] [CrossRef]

- Lakomy, K.; Madonski, R. Cascade extended state observer for active disturbance rejection control applications under measurement noise. ISA Trans. 2021, 109, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Obeid, H.; Fridman, L.; Laghrouche, S.; Harmouche, M. Barrier function-based adaptive sliding mode control. Automatica 2018, 93, 540–544. [Google Scholar] [CrossRef]

- Levant, A. Quasi-continuous high-order sliding-mode controllers. IEEE Trans. Autom. Control 2005, 50, 1812–1816. [Google Scholar] [CrossRef]

- Levant, A. Higher-order sliding modes, differentiation and output-feedback control. Int. J. Control 2003, 76, 924–941. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).