A Modular Soft Gripper with Embedded Force Sensing and an Iris-Type Cutting Mechanism for Harvesting Medium-Sized Crops

Abstract

1. Introduction

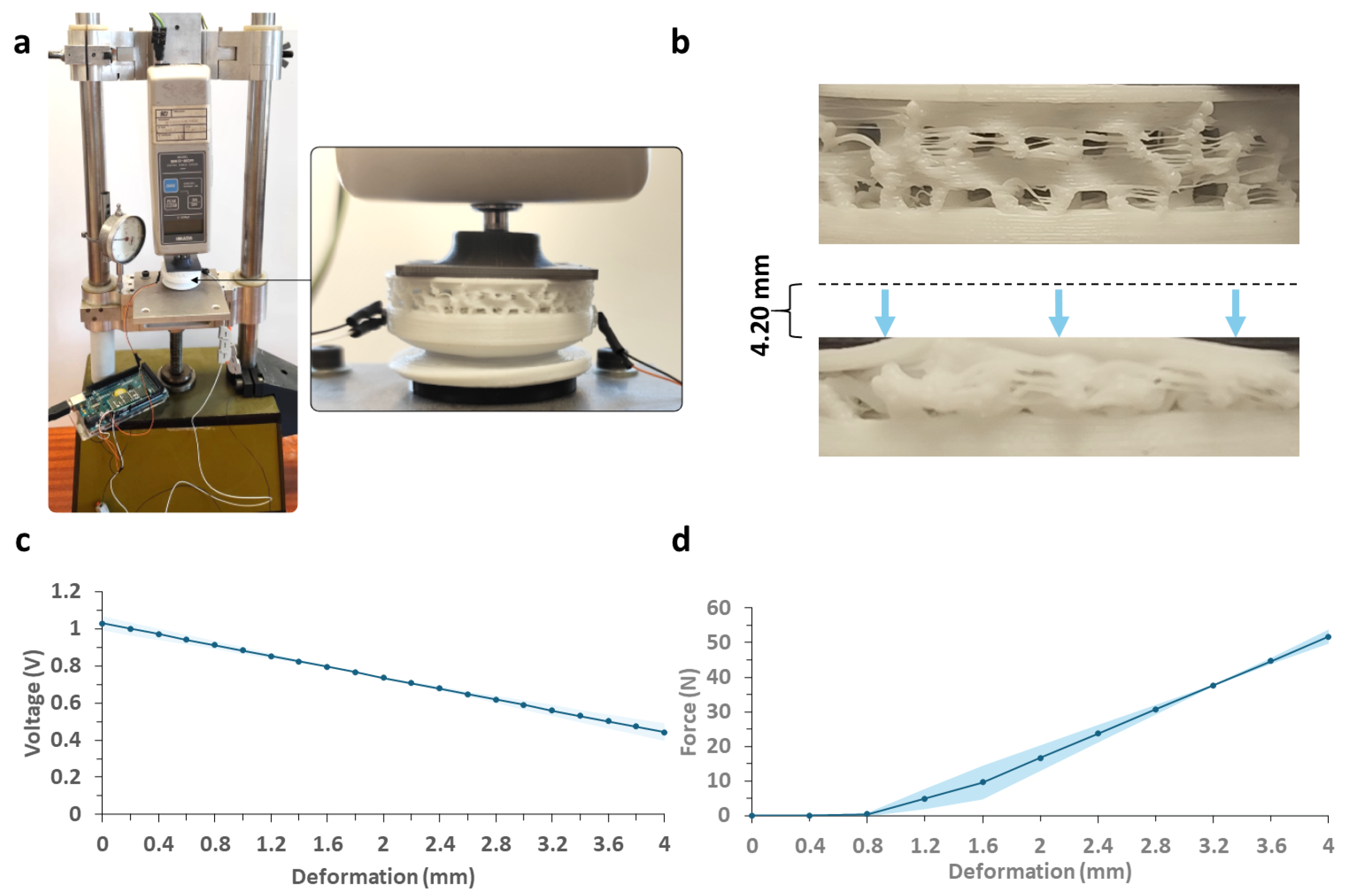

2. Soft Gripper

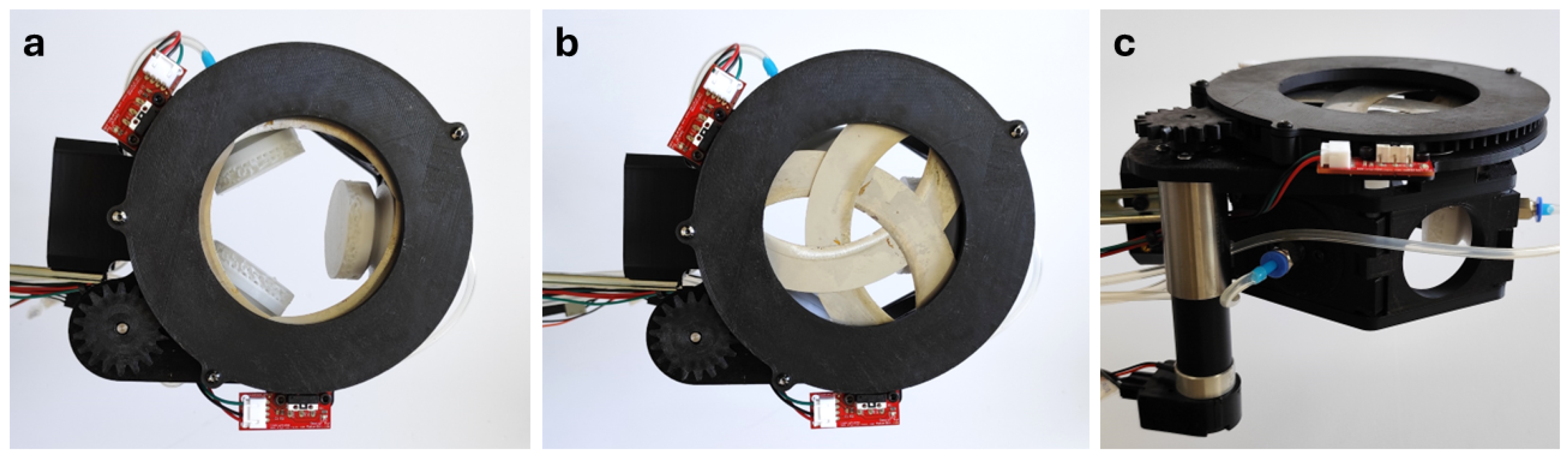

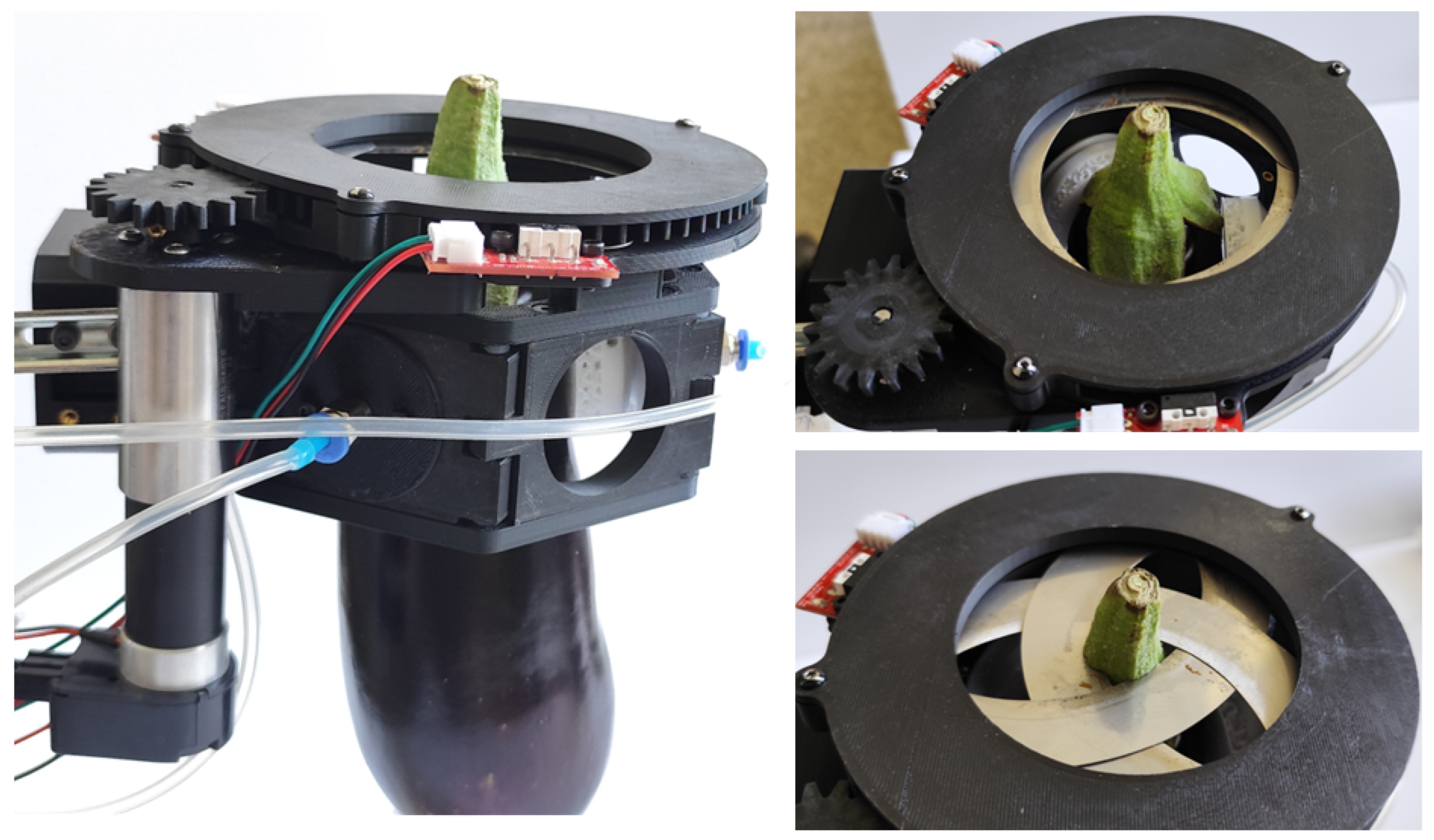

2.1. Rigid Structure Design

2.2. Soft Actuators

2.3. Iris Cutting Mechanism

2.4. Manufacturing

3. Characterization

4. Experimental Results

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lytridis, C.; Kaburlasos, V.G.; Pachidis, T.; Manios, M.; Vrochidou, E.; Kalampokas, T.; Chatzistamatis, S. An overview of cooperative robotics in agriculture. Agronomy 2021, 11, 1818. [Google Scholar] [CrossRef]

- Gonzalez-de Santos, P.; Fernández, R.; Sepúlveda, D.; Navas, E.; Emmi, L.; Armada, M. Field robots for intelligent farms—inhering features from industry. Agronomy 2020, 10, 1638. [Google Scholar] [CrossRef]

- Oliveira, L.F.; Moreira, A.P.; Silva, M.F. Advances in agriculture robotics: A state-of-the-art review and challenges ahead. Robotics 2021, 10, 52. [Google Scholar] [CrossRef]

- Navas, E.; Fernández, R.; Sepúlveda, D.; Armada, M.; Gonzalez-de Santos, P. Soft grippers for automatic crop harvesting: A review. Sensors 2021, 21, 2689. [Google Scholar] [CrossRef]

- Yap, H.K.; Lim, J.H.; Goh, J.C.H.; Yeow, C.H. Design of a Soft Robotic Glove for Hand Rehabilitation of Stroke Patients With Clenched Fist Deformity Using Inflatable Plastic Actuators. J. Med. Devices 2016, 10, 1932–6181. [Google Scholar] [CrossRef]

- Burgner-Kahrs, J.; Rucker, D.C.; Choset, H. Continuum Robots for Medical Applications: A Survey. IEEE Trans. Robot. 2015, 31, 1261–1280. [Google Scholar] [CrossRef]

- Polygerinos, P.; Wang, Z.; Galloway, K.C.; Wood, R.J.; Walsh, C.J. Soft robotic glove for combined assistance and at-home rehabilitation. Robot. Auton. Syst. 2015, 73, 135–143. [Google Scholar] [CrossRef]

- Ansari, Y.; Falotico, E.; Mollard, Y.; Busch, B.; Cianchetti, M.; Laschi, C. A Multiagent Reinforcement Learning approach for inverse kinematics of high dimensional manipulators with precision positioning. In Proceedings of the 2016 6th IEEE International Conference on Biomedical Robotics and Biomechatronics (BioRob), Singapore, 26–29 June 2016; pp. 457–463. [Google Scholar] [CrossRef]

- Goldfield, E.C.; Park, Y.L.; Chen, B.R.; Hsu, W.H.; Young, D.; Wehner, M.; Kelty-Stephen, D.G.; Stirling, L.; Weinberg, M.; Newman, D.; et al. Bio-Inspired Design of Soft Robotic Assistive Devices: The Interface of Physics, Biology, and Behavior. Ecol. Psychol. 2012, 24, 300–327. [Google Scholar] [CrossRef]

- Katzschmann, R.K.; DelPreto, J.; MacCurdy, R.; Rus, D. Exploration of underwater life with an acoustically controlled soft robotic fish. Sci. Robot. 2018, 3, 300–327. [Google Scholar] [CrossRef] [PubMed]

- Tolley, M.; Shepherd, R.; Mosadegh, B.; Galloway, K.; Wehner, M.; Karpelson, M.; Wood, R.; Whitesides, G. A Resilient, Untethered Soft Robot. Soft Robot. 2014, 1, 213–223. [Google Scholar] [CrossRef]

- Birrell, S.; Hughes, J.; Cai, J.Y.; Iida, F. A field-tested robotic harvesting system for iceberg lettuce. J. Field Robot. 2020, 37, 225–245. [Google Scholar] [CrossRef] [PubMed]

- Hohimer, C.J.; Wang, H.; Bhusal, S.; Miller, J.; Mo, C.; Karkee, M. Design and field evaluation of a robotic apple harvesting system with a 3D-printed soft-robotic end-effector. Trans. ASABE 2019, 62, 405–414. [Google Scholar] [CrossRef]

- Galley, A.; Knopf, G.K.; Kashkoush, M. Pneumatic Hyperelastic Actuators for Grasping Curved Organic Objects. Actuators 2019, 8, 76. [Google Scholar] [CrossRef]

- Pettersson, A.; Davis, S.; Gray, J.O.; Dodd, T.J.; Ohlsson, T. Design of a magnetorheological robot gripper for handling of delicate food products with varying shapes. J. Food Eng. 2010, 98, 332–338. [Google Scholar] [CrossRef]

- Wang, Z.; Chathuranga, D.S.; Hirai, S. 3D printed soft gripper for automatic lunch box packing. In Proceedings of the 2016 IEEE International Conference on Robotics and Biomimetics (ROBIO), Qingdao, China, 3–7 December 2016; pp. 503–508. [Google Scholar]

- Wang, Z.; Torigoe, Y.; Hirai, S. A prestressed soft gripper: Design, modeling, fabrication, and tests for food handling. IEEE Robot. Autom. Lett. 2017, 2, 1909–1916. [Google Scholar] [CrossRef]

- Wang, Z.; Hirai, S. Chamber dimension optimization of a bellow-type soft actuator for food material handling. In Proceedings of the 2018 IEEE International Conference on Soft Robotics (RoboSoft), Livorno, Italy, 24–28 April 2018; pp. 382–387. [Google Scholar]

- Kuriyama, Y.; Okino, Y.; Wang, Z.; Hirai, S. A wrapping gripper for packaging chopped and granular food materials. In Proceedings of the 2019 2nd IEEE International Conference on Soft Robotics (RoboSoft), Seoul, Republic of Korea, 14–18 April 2019; pp. 114–119. [Google Scholar]

- Wang, Z.; Or, K.; Hirai, S. A dual-mode soft gripper for food packaging. Robot. Auton. Syst. 2020, 125, 103427. [Google Scholar] [CrossRef]

- Wang, Z.; Kanegae, R.; Hirai, S. Circular Shell Gripper for Handling Food Products. Soft Robot. 2020, 8, 542–554. [Google Scholar] [CrossRef]

- Chen, S.; Pang, Y.; Yuan, H.; Tan, X.; Cao, C. Smart Soft Actuators and Grippers Enabled by Self-Powered Tribo-Skins. Adv. Mater. Technol. 2020, 5, 1901075. [Google Scholar] [CrossRef]

- Gafer, A.; Heymans, D.; Prattichizzo, D.; Salvietti, G. The Quad-Spatula Gripper: A Novel Soft-Rigid Gripper for Food Handling. In Proceedings of the 2020 3rd IEEE International Conference on Soft Robotics (RoboSoft), New Haven, CT, USA, 15 May–15 July 2020; pp. 39–45. [Google Scholar]

- Tawk, C.; Gillett, A.; in het Panhuis, M.; Spinks, G.M.; Alici, G. A 3D-printed omni-purpose soft gripper. IEEE Trans. Robot. 2019, 35, 1268–1275. [Google Scholar] [CrossRef]

- Bac, C.W.; Hemming, J.; Van Tuijl, B.; Barth, R.; Wais, E.; van Henten, E.J. Performance evaluation of a harvesting robot for sweet pepper. J. Field Robot. 2017, 34, 1123–1139. [Google Scholar] [CrossRef]

- Lehnert, C.; English, A.; McCool, C.; Tow, A.W.; Perez, T. Autonomous sweet pepper harvesting for protected cropping systems. IEEE Robot. Autom. Lett. 2017, 2, 872–879. [Google Scholar] [CrossRef]

- Arad, B.; Balendonck, J.; Barth, R.; Ben-Shahar, O.; Edan, Y.; Hellström, T.; Hemming, J.; Kurtser, P.; Ringdahl, O.; Tielen, T.; et al. Development of a sweet pepper harvesting robot. J. Field Robot. 2020, 37, 1027–1039. [Google Scholar] [CrossRef]

- Hegde, C.; Mysa, R.C.; Chooi, A.; Dontu, S.; Tan, J.M.R.; Wong, L.H.; Alvarado, P.V.y.; Magdassi, S. 3D-Printed Mechano-Optic Force Sensor for Soft Robotic Gripper Enabled by Programmable Structural Metamaterials. Adv. Intell. Syst. 2024, 6, 2400057. [Google Scholar] [CrossRef]

- Pattabiraman, V.; Huang, Z.; Panozzo, D.; Zorin, D.; Pinto, L.; Bhirangi, R. eFlesh: Highly customizable Magnetic Touch Sensing using Cut-Cell Microstructures. arXiv 2025, arXiv:2506.09994. [Google Scholar]

- Wang, X.; Hao, W.; Zhang, J.; He, Z.; Ding, X.; Cui, Y. Development and evaluation of a soft end effector for kiwifruit harvesting. N. Z. J. Crop Hortic. Sci. 2025, 53, 2324–23529. [Google Scholar] [CrossRef]

- Navas, E.; Fernández, R.; Armada, M.; Gonzalez-de Santos, P. Diaphragm-type pneumatic-driven soft grippers for precision harvesting. Agronomy 2021, 11, 1727. [Google Scholar] [CrossRef]

- Xiao, X.; Wang, Y.; Jiang, Y. End-Effectors developed for citrus and other spherical crops. Appl. Sci. 2022, 12, 7945. [Google Scholar] [CrossRef]

- Park, Y.; Seol, J.; Pak, J.; Jo, Y.; Jun, J.; Son, H.I. A novel end-effector for a fruit and vegetable harvesting robot: Mechanism and field experiment. Precis. Agric. 2023, 24, 948–970. [Google Scholar] [CrossRef]

- Yin, H.; Sun, Q.; Ren, X.; Guo, J.; Yang, Y.; Wei, Y.; Huang, B.; Chai, X.; Zhong, M. Development, integration, and field evaluation of an autonomous citrus-harvesting robot. J. Field Robot. 2023, 40, 1363–1387. [Google Scholar] [CrossRef]

- Mu, L.; Cui, G.; Liu, Y.; Cui, Y.; Fu, L.; Gejima, Y. Design and simulation of an integrated end-effector for picking kiwifruit by robot. Inf. Process. Agric. 2020, 7, 58–71. [Google Scholar] [CrossRef]

- Duckett, T.; Pearson, S.; Blackmore, S.; Grieve, B.; Chen, W.H.; Cielniak, G.; Cleaversmith, J.; Dai, J.; Davis, S.; Fox, C.; et al. Agricultural robotics: The future of robotic agriculture. arXiv 2018, arXiv:1806.06762. [Google Scholar] [CrossRef]

- Navas, E.; Fernandez, R.; Sepúlveda, D.; Armada, M.; Gonzalez-de Santos, P. A design criterion based on shear energy consumption for robotic harvesting tools. Agronomy 2020, 10, 734. [Google Scholar] [CrossRef]

- Sepúlveda, D.; Fernández, R.; Navas, E.; González-de Santos, P.; Armada, M. ROS framework for perception and dual-arm manipulation in unstructured environments. In Proceedings of the Iberian Robotics Conference, Porto, Portugal, 20–22 November 2019; pp. 137–147. [Google Scholar]

- Li, Z.; Miao, F.; Yang, Z.; Wang, H. An anthropometric study for the anthropomorphic design of tomato-harvesting robots. Comput. Electron. Agric. 2019, 163, 104881. [Google Scholar] [CrossRef]

- Yaguchi, H.; Nagahama, K.; Hasegawa, T.; Inaba, M. Development of an autonomous tomato harvesting robot with rotational plucking gripper. In Proceedings of the 2016 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Daejeon, Republic of Korea, 9–14 October 2016; pp. 652–657. [Google Scholar]

- Huang, Z.; Sklar, E.; Parsons, S. Design of automatic strawberry harvest robot suitable in complex environments. In Proceedings of the Companion of the 2020 ACM/IEEE International Conference on Human-Robot Interaction, Cambridge, UK, 23–26 March 2020; pp. 567–569. [Google Scholar]

- The future of plastic. Nat. Commun. 2018, 9, 2157. [CrossRef]

- Krishnan, S.; Pandey, P.; Mohanty, S.; Nayak, S.K. Toughening of polylactic acid: An overview of research progress. Polym.-Plast. Technol. Eng. 2016, 55, 1623–1652. [Google Scholar] [CrossRef]

- Odent, J.; Raquez, J.M.; Dubois, P. Highly toughened polylactide-based materials through melt-blending techniques. Biodegrad. Polyesters 2015, 235–274. [Google Scholar]

- Zeng, J.B.; Li, K.A.; Du, A.K. Compatibilization strategies in poly (lactic acid)-based blends. RSC Adv. 2015, 5, 32546–32565. [Google Scholar] [CrossRef]

- Kfoury, G.; Raquez, J.M.; Hassouna, F.; Odent, J.; Toniazzo, V.; Ruch, D.; Dubois, P. Recent advances in high performance poly (lactide): From “green” plasticization to super-tough materials via (reactive) compounding. Front. Chem. 2013, 1, 32. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Zhang, J. Research progress in toughening modification of poly (lactic acid). J. Polym. Sci. Part B Polym. Phys. 2011, 49, 1051–1083. [Google Scholar] [CrossRef]

- Anderson, K.S.; Schreck, K.M.; Hillmyer, M.A. Toughening polylactide. Polym. Rev. 2008, 48, 85–108. [Google Scholar] [CrossRef]

- Rasal, R.M.; Janorkar, A.V.; Hirt, D.E. Poly (lactic acid) modifications. Prog. Polym. Sci. 2010, 35, 338–356. [Google Scholar] [CrossRef]

- Nagarajan, V.; Mohanty, A.K.; Misra, M. Perspective on polylactic acid (PLA) based sustainable materials for durable applications: Focus on toughness and heat resistance. ACS Sustain. Chem. Eng. 2016, 4, 2899–2916. [Google Scholar] [CrossRef]

- Navas, E.; Rodríguez-Nieto, D.; Rodríguez-González, A.A.; Fernández, R. Parallel Fin Ray Soft Gripper with Embedded Mechano-Optical Force Sensor. Appl. Sci. 2025, 15, 2576. [Google Scholar] [CrossRef]

- Hsiao, L.Y.; Jing, L.; Li, K.; Yang, H.; Li, Y.; Chen, P.Y. Carbon nanotube-integrated conductive hydrogels as multifunctional robotic skin. Carbon 2020, 161, 784–793. [Google Scholar] [CrossRef]

- Mosadegh, B.; Polygerinos, P.; Keplinger, C.; Wennstedt, S.; Shepherd, R.F.; Gupta, U.; Shim, J.; Bertoldi, K.; Walsh, C.J.; Whitesides, G.M. Pneumatic networks for soft robotics that actuate rapidly. Adv. Funct. Mater. 2014, 24, 2163–2170. [Google Scholar] [CrossRef]

- De Barrie, D.; Margetts, R.; Goher, K. Simpa: Soft-grasp infant myoelectric prosthetic arm. IEEE Robot. Autom. Lett. 2020, 5, 698–703. [Google Scholar] [CrossRef]

- Shih, B.; Drotman, D.; Christianson, C.; Huo, Z.; White, R.; Christensen, H.I.; Tolley, M.T. Custom soft robotic gripper sensor skins for haptic object visualization. In Proceedings of the 2017 IEEE/RSJ international conference on intelligent robots and systems (IROS), Vancouver, BC, Canada, 24–28 September 2017; pp. 494–501. [Google Scholar]

- Connolly, F.; Walsh, C.J.; Bertoldi, K. Automatic design of fiber-reinforced soft actuators for trajectory matching. Proc. Natl. Acad. Sci. USA 2017, 114, 51–56. [Google Scholar] [CrossRef]

- Seibel, A.; Yıldız, M.; Zorlubaş, B. A Gecko-Inspired Soft Passive Gripper. Biomimetics 2020, 5, 12. [Google Scholar] [CrossRef]

- Teeple, C.B.; Koutros, T.N.; Graule, M.A.; Wood, R.J. Multi-segment soft robotic fingers enable robust precision grasping. Int. J. Robot. Res. 2020, 39, 1647–1667. [Google Scholar] [CrossRef]

- Galloway, K.C.; Becker, K.P.; Phillips, B.; Kirby, J.; Licht, S.; Tchernov, D.; Wood, R.J.; Gruber, D.F. Soft robotic grippers for biological sampling on deep reefs. Soft Robot. 2016, 3, 23–33. [Google Scholar] [CrossRef]

- Wang, W.; Rodrigue, H.; Kim, H.I.; Han, M.W.; Ahn, S.H. Soft composite hinge actuator and application to compliant robotic gripper. Compos. Part B Eng. 2016, 98, 397–405. [Google Scholar] [CrossRef]

- Rodrigue, H.; Wang, W.; Kim, D.R.; Ahn, S.H. Curved shape memory alloy-based soft actuators and application to soft gripper. Compos. Struct. 2017, 176, 398–406. [Google Scholar] [CrossRef]

- Modabberifar, M.; Spenko, M. A shape memory alloy-actuated gecko-inspired robotic gripper. Sens. Actuators A Phys. 2018, 276, 76–82. [Google Scholar] [CrossRef]

- Friend, J.; Yeo, L. Fabrication of microfluidic devices using polydimethylsiloxane. Biomicrofluidics 2010, 4, 026502. [Google Scholar] [CrossRef]

| System Type | Ref. | Grasping | Soft Actuators | Sensorized Grasping | CuttingMechanism | Self-CenteringCutting Mechanism | Modular | 3D-Printed |

|---|---|---|---|---|---|---|---|---|

| Soft | [13,30] | Yes | Yes | No | No | - | No | Yes |

| [14,31] | Yes | Yes | No | No | - | Yes | No | |

| [32,33] | Yes | Yes | No | Yes | No | No | No | |

| This work | Yes | Yes | Yes | Yes | Yes | Yes | Yes | |

| Rigid | [27,34] | Passive | No | No | Yes | No | No | No |

| [25,26] | Yes | Yes | No | Yes | No | No | No | |

| [35] | Yes | No | Yes | No | - | No | Yes |

| Faulhaber Motor 2342S024CR | Faulhaber Planetary Gearhead 26/1R | Faulhaber Encoder HEDS 5540 | |||

|---|---|---|---|---|---|

| Characteristic | Value | Characteristic | Value | Characteristic | Value |

| Nominal voltage () | 24 V | N° of gear stages | 4 | Resolution | 1024/rev |

| Nominal speed () | 5660 rpm | Continuous torque | 7 | Supply voltage | 5 V |

| Nominal torque () | 20.5 mNm | Efficiency, max. | 69 % | Max. count frequency | 100 kHz |

| Nominal current () | 0.846 A | Reduction ratio | 246:1 | ||

| No-load speed () | 93.2 mNm | Mass | 162 g | ||

| Stall torque () | 93.2 mNm | ||||

| Torque constant () | 28.6 mNm/A | ||||

| Maximum efficiency () | 79 % | ||||

| Mass | 88 g | ||||

| Parameter | TPE Value | PLA Value | Unit |

|---|---|---|---|

| Nozzle diameter | 0.4 | 0.4 | mm |

| Layer height | 0.2 | 0.2 | mm |

| Infill | 100 | 20 | % |

| Material temp | 230 | 200 | °C |

| Build plate temp | 50 | 50 | °C |

| Print speed | 20 | 50 | mm/s |

| Extrusion multiplier | 115 | 100 | % |

| Mass of a single module when fully mounted | 69 · 10−3 kg |

| Max. displacement of the soft actuator (150 kPa) | 0.010 m |

| Max. contact force (150 kPa) | 54 N |

| Operating pressure range | 0–150 kPa |

| Mass of a fully assembled hexagonal soft gripper | 0.615 kg |

| Slip payload test (150 kPa) | 3 kg |

| Max. opening | 61.4 mm |

| Min. opening | 33.4 mm |

| Mean grasp response time | s |

| Cutting force | 10 N |

| Cutting time | s at 24 V |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Navas, E.; Blanco, K.; Rodríguez-Nieto, D.; Fernández, R. A Modular Soft Gripper with Embedded Force Sensing and an Iris-Type Cutting Mechanism for Harvesting Medium-Sized Crops. Actuators 2025, 14, 432. https://doi.org/10.3390/act14090432

Navas E, Blanco K, Rodríguez-Nieto D, Fernández R. A Modular Soft Gripper with Embedded Force Sensing and an Iris-Type Cutting Mechanism for Harvesting Medium-Sized Crops. Actuators. 2025; 14(9):432. https://doi.org/10.3390/act14090432

Chicago/Turabian StyleNavas, Eduardo, Kai Blanco, Daniel Rodríguez-Nieto, and Roemi Fernández. 2025. "A Modular Soft Gripper with Embedded Force Sensing and an Iris-Type Cutting Mechanism for Harvesting Medium-Sized Crops" Actuators 14, no. 9: 432. https://doi.org/10.3390/act14090432

APA StyleNavas, E., Blanco, K., Rodríguez-Nieto, D., & Fernández, R. (2025). A Modular Soft Gripper with Embedded Force Sensing and an Iris-Type Cutting Mechanism for Harvesting Medium-Sized Crops. Actuators, 14(9), 432. https://doi.org/10.3390/act14090432