Damage Assessment of Laboratory-Scale Reinforced Concrete Columns Under Localized Blast Loading

Abstract

1. Introduction

- (1)

- To investigate damage mechanisms in blast-loaded circular RC columns.

- (2)

- To analyze crack evolution and damage accumulation over time.

- (3)

- To explore the impact of column detailing on damage severity.

- (4)

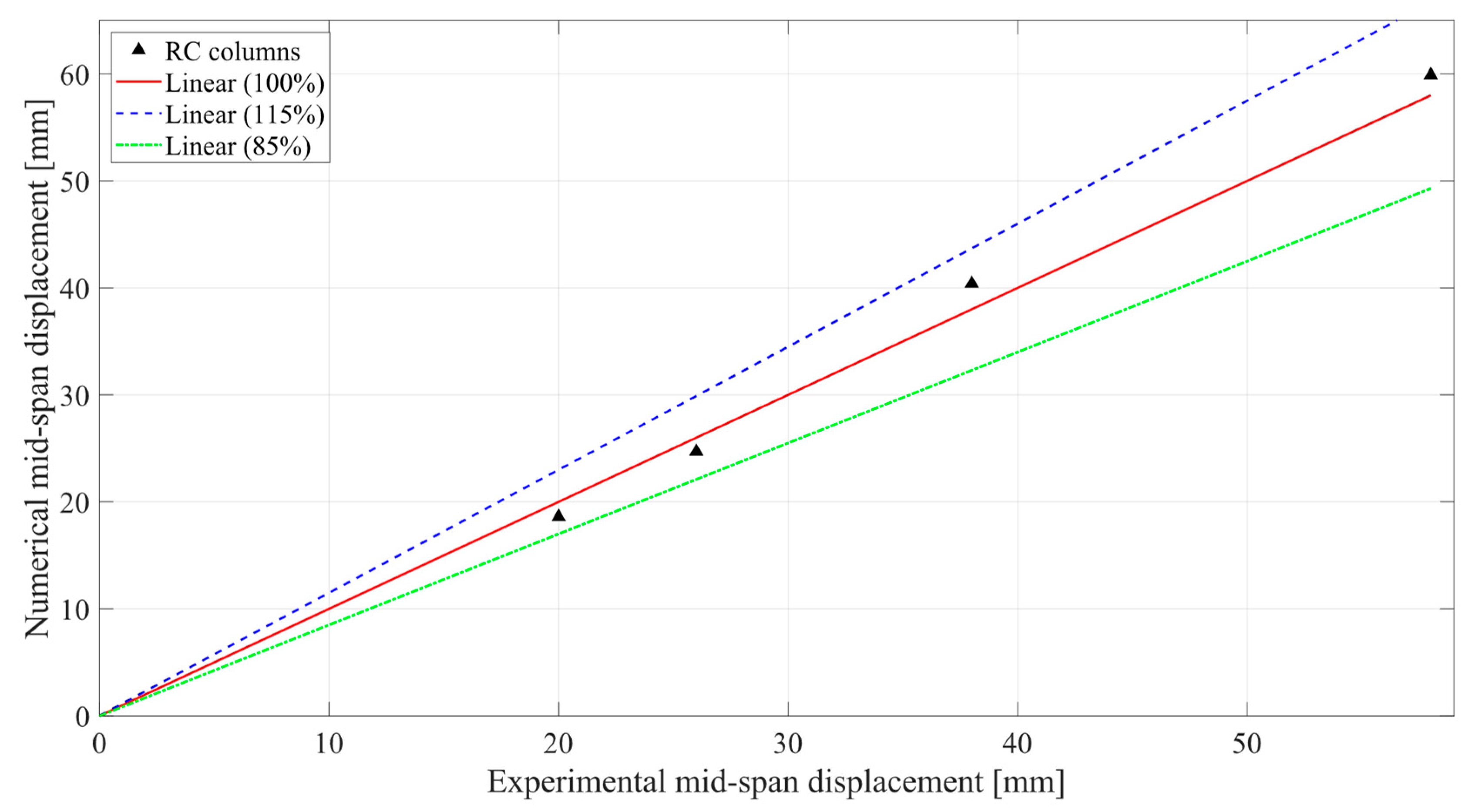

- To validate the numerical model by comparing predicted fracture patterns, displacements, and failure modes with experimental results.

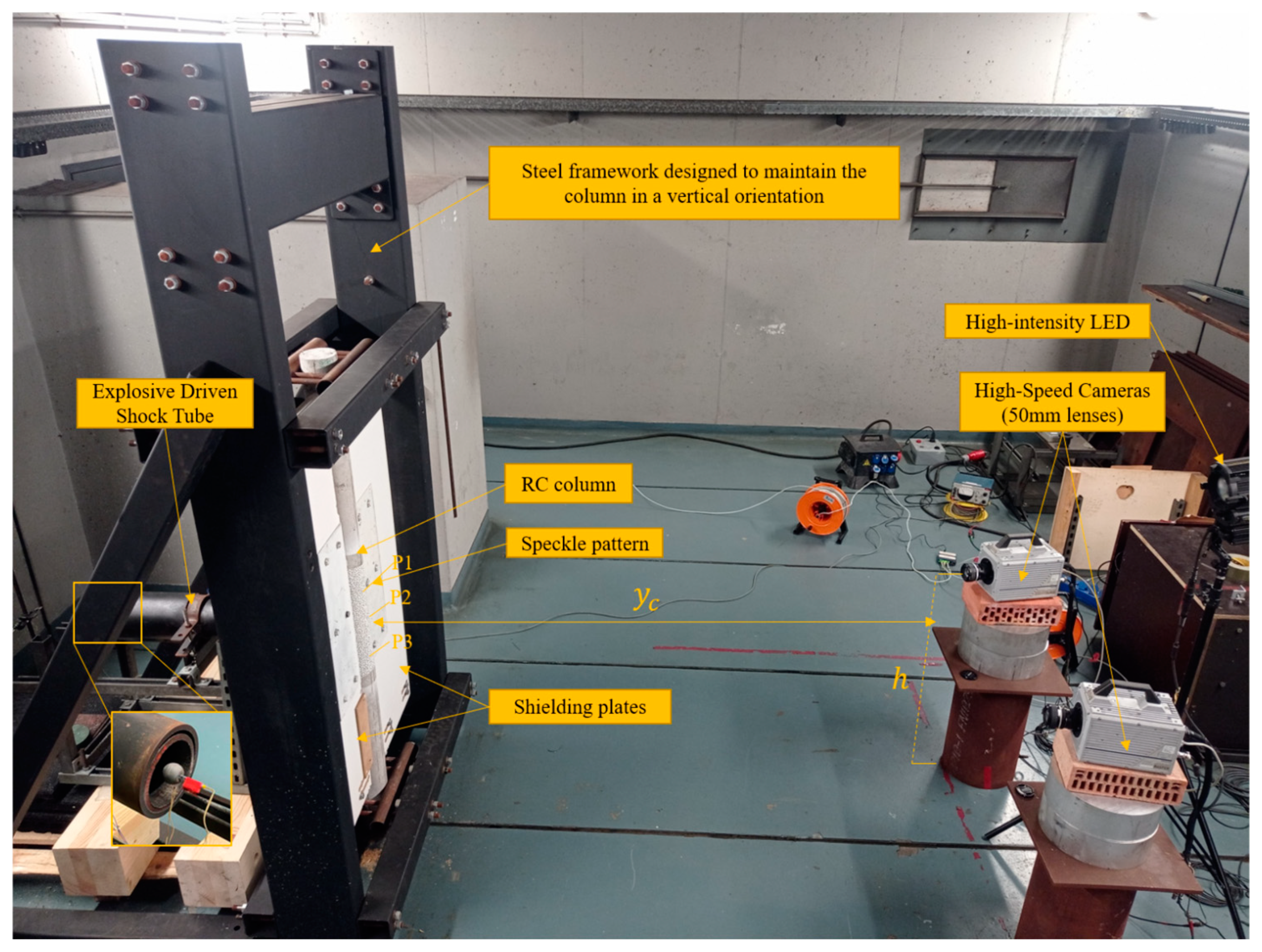

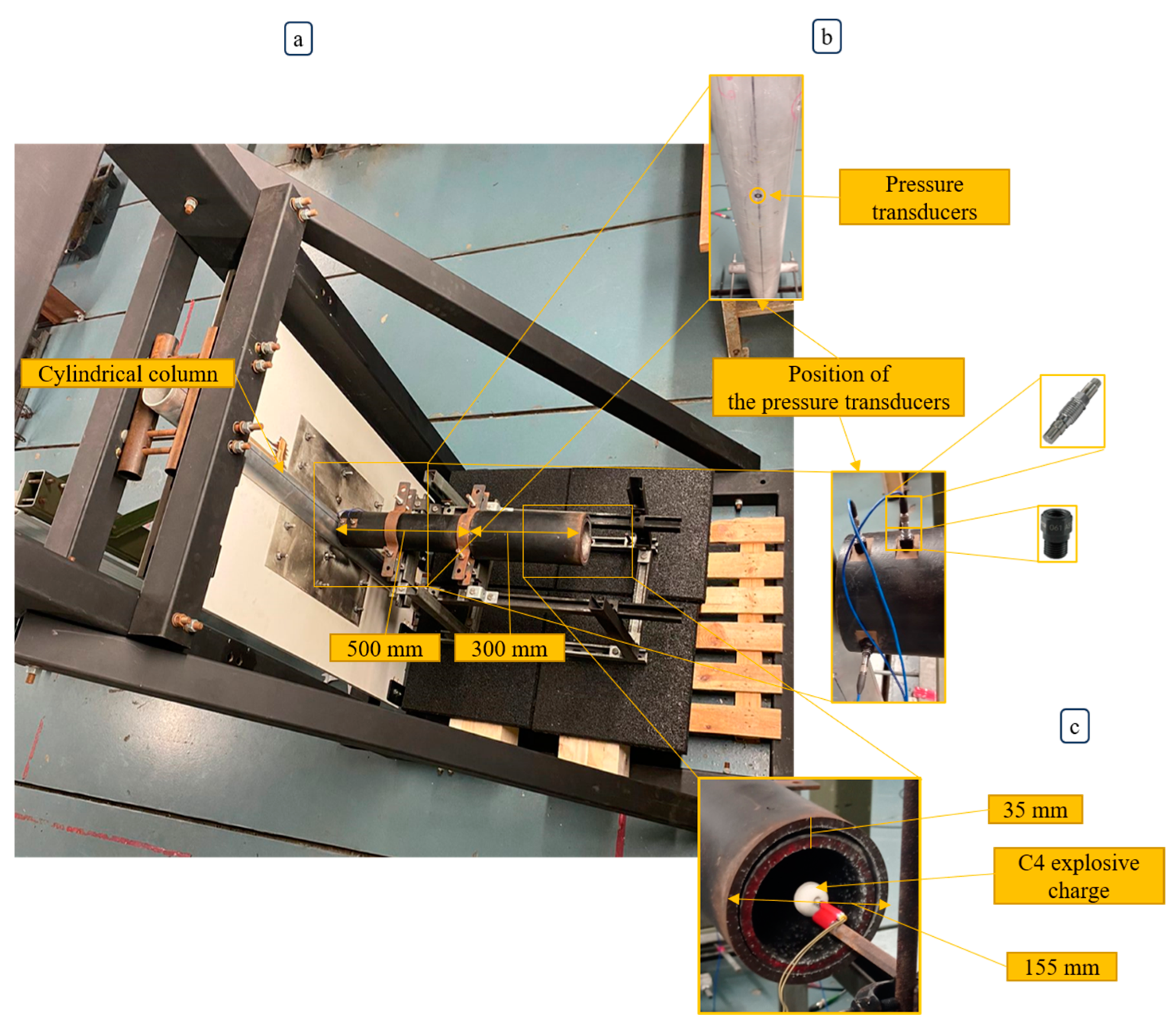

2. Overview of the Test Configuration

2.1. Introduction to the Study

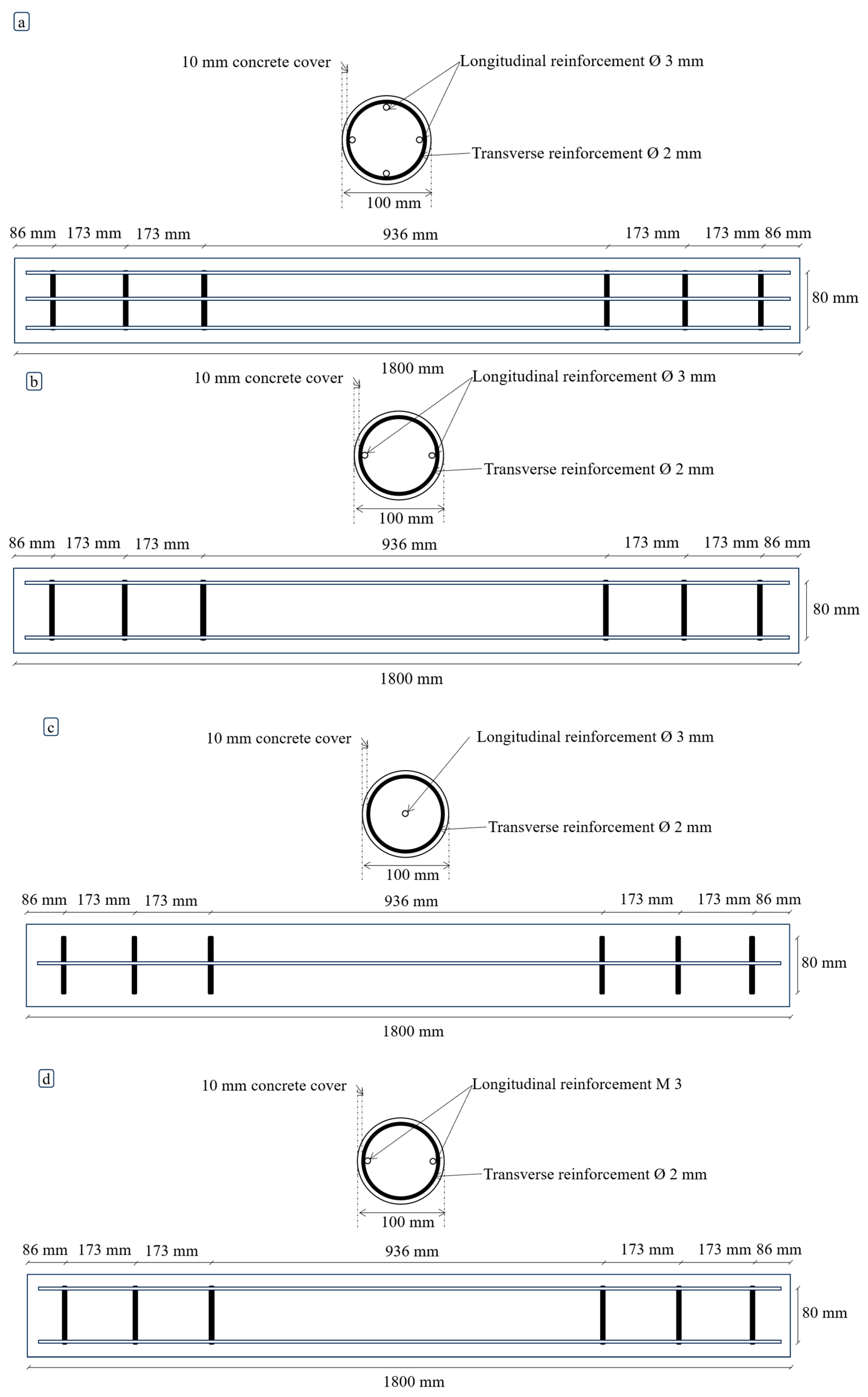

2.2. Details of the Test Specimens

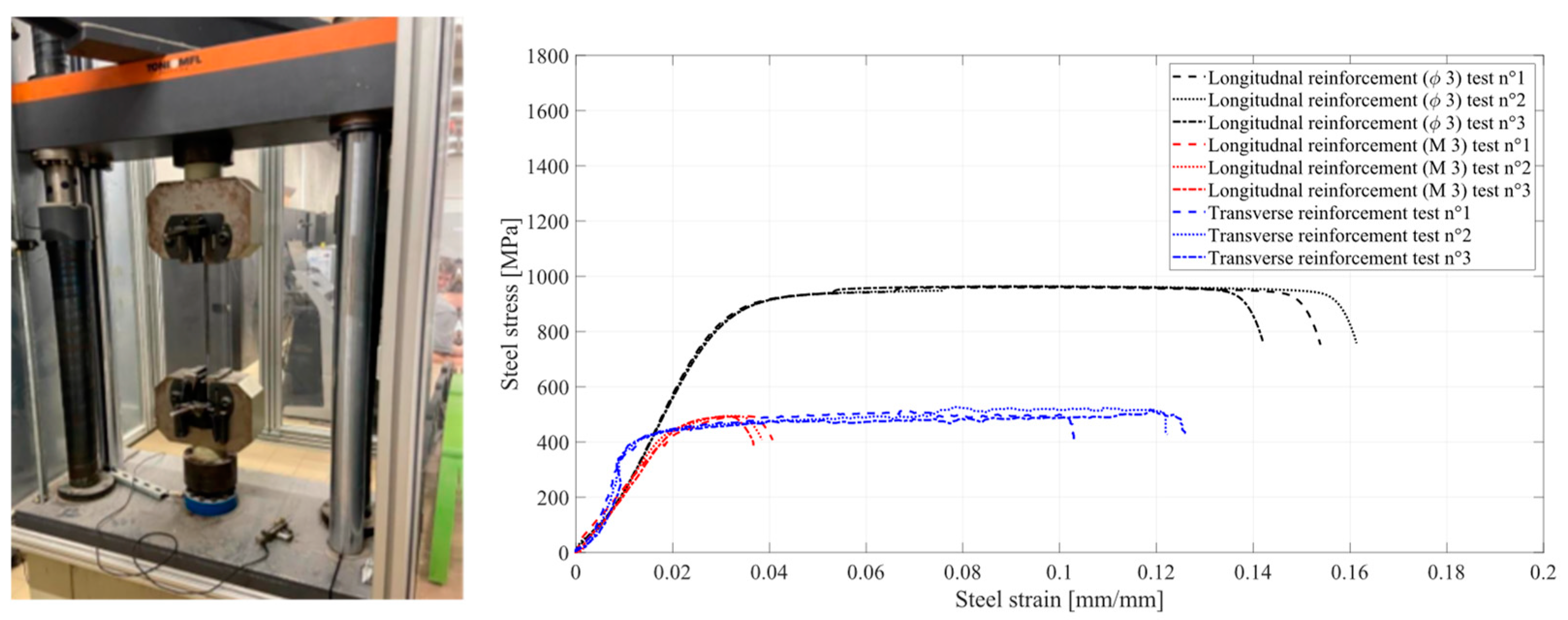

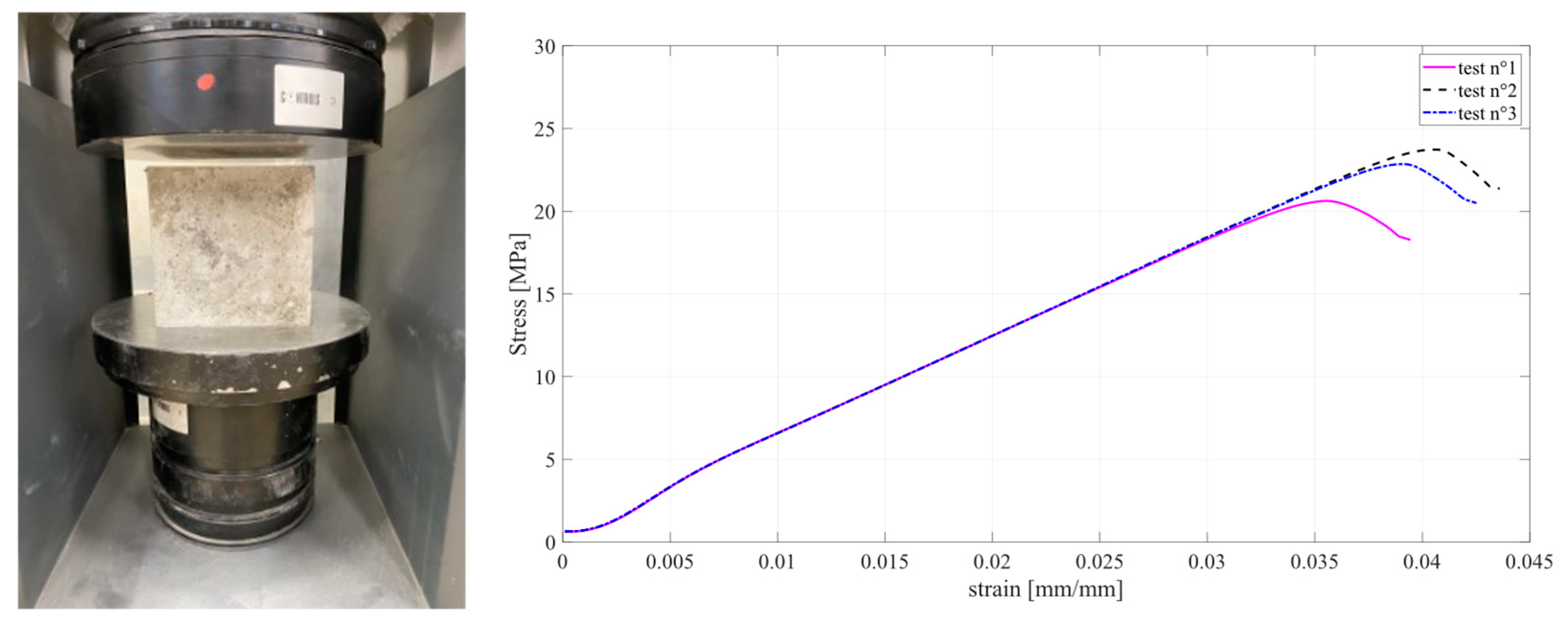

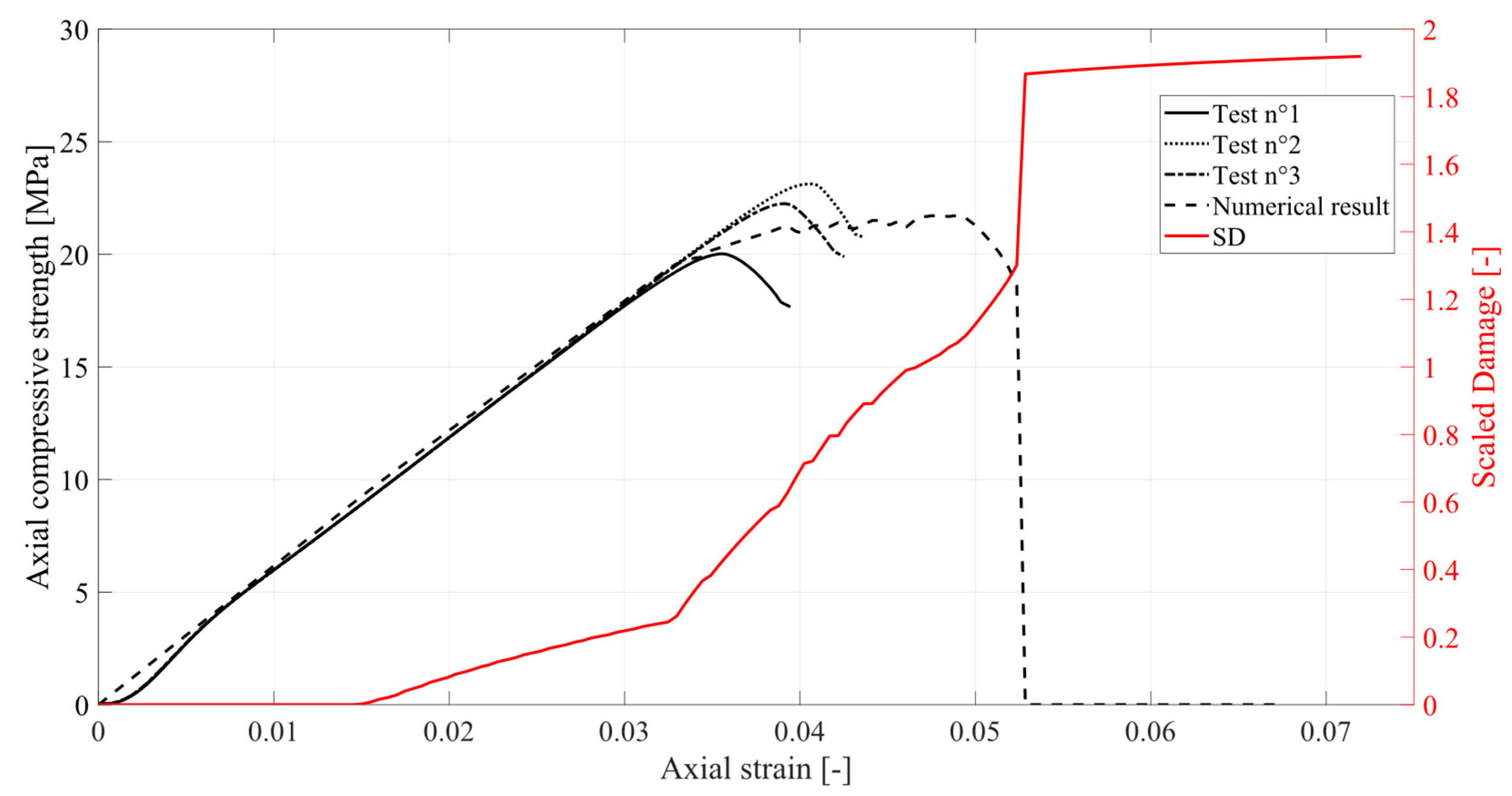

2.3. Material Properties of Concrete and Reinforcement Bars

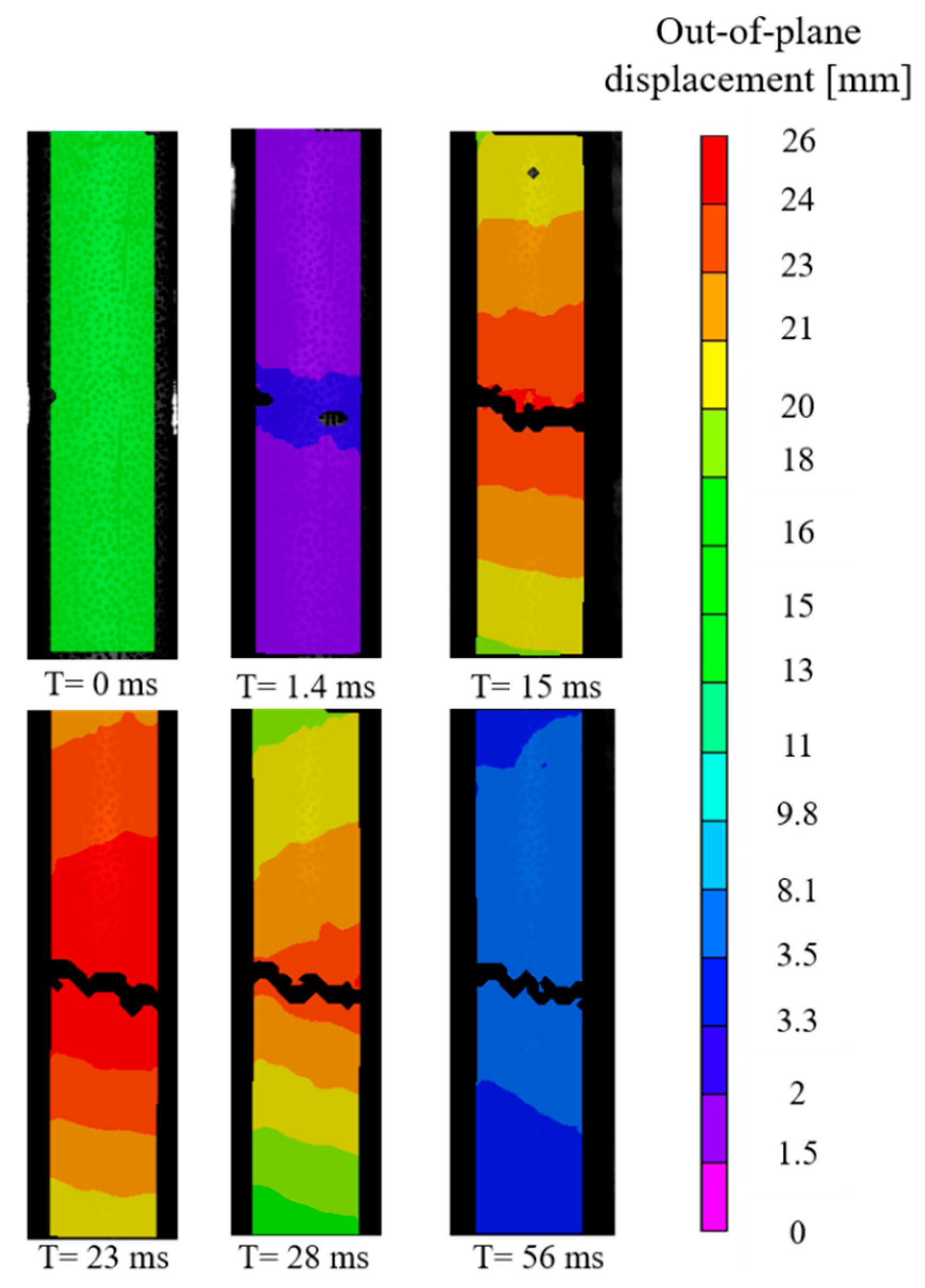

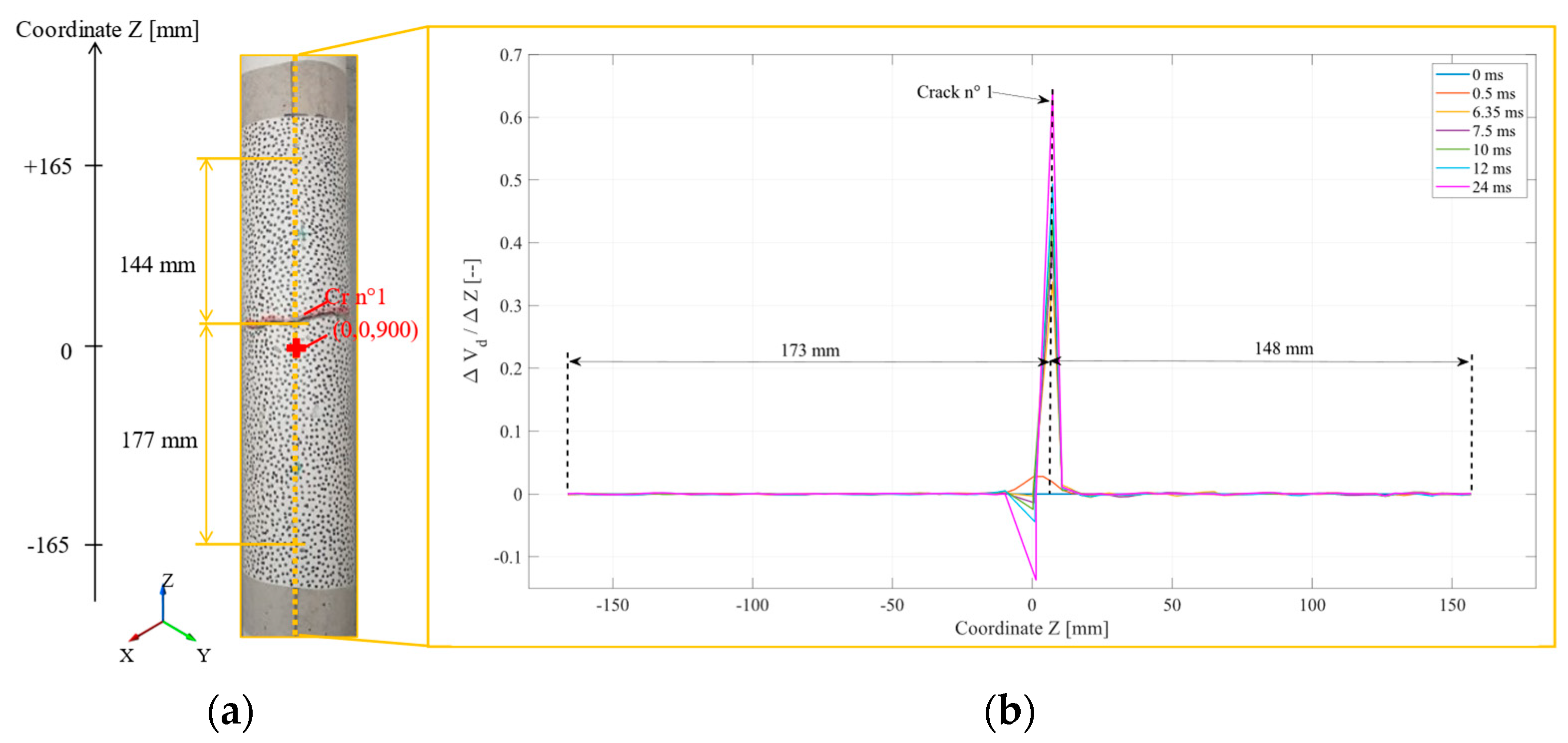

2.4. Deflection Analysis Using DIC

3. Test Results

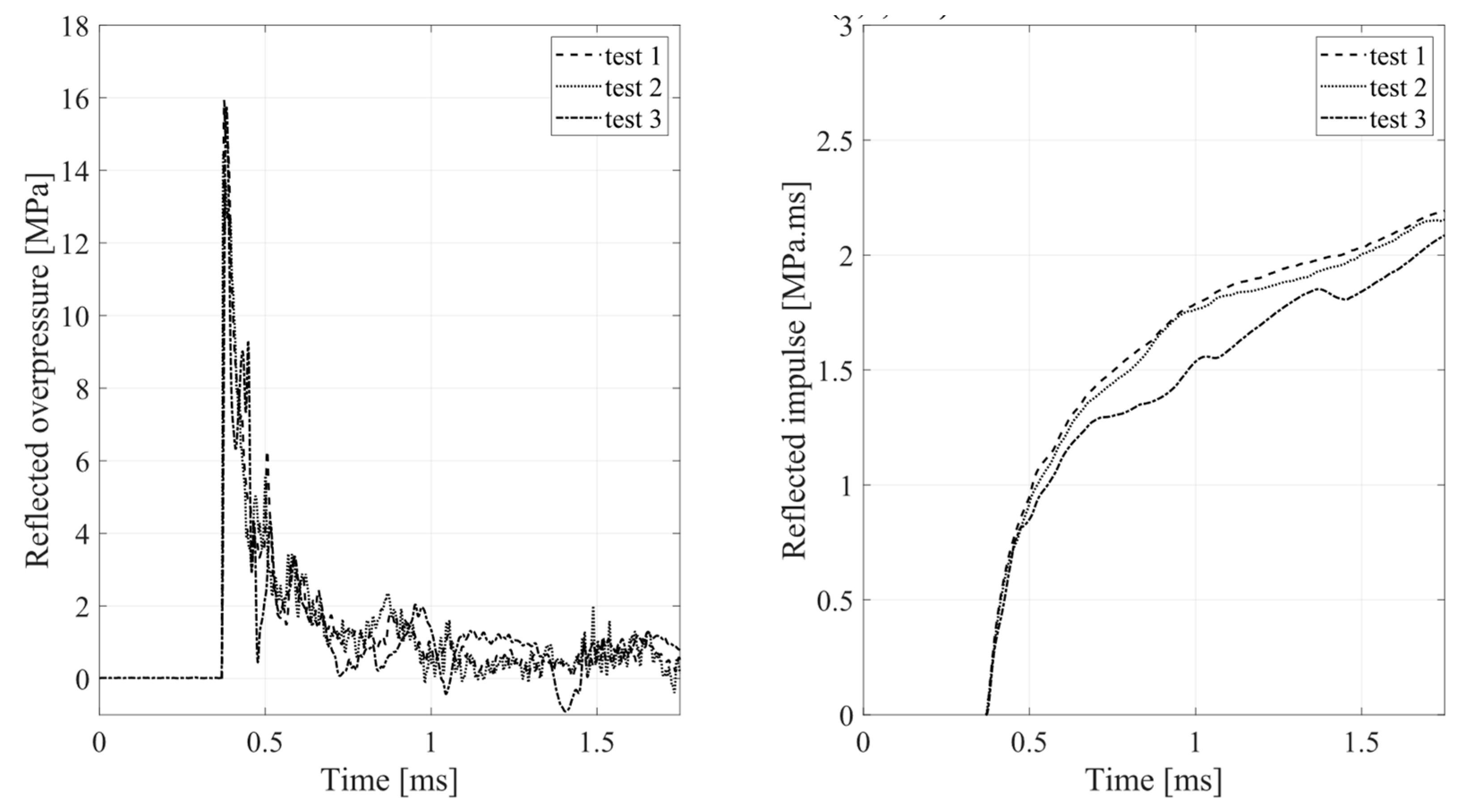

3.1. Characterization of the Blast Loading

3.2. Dynamic Behavior of Test Specimens

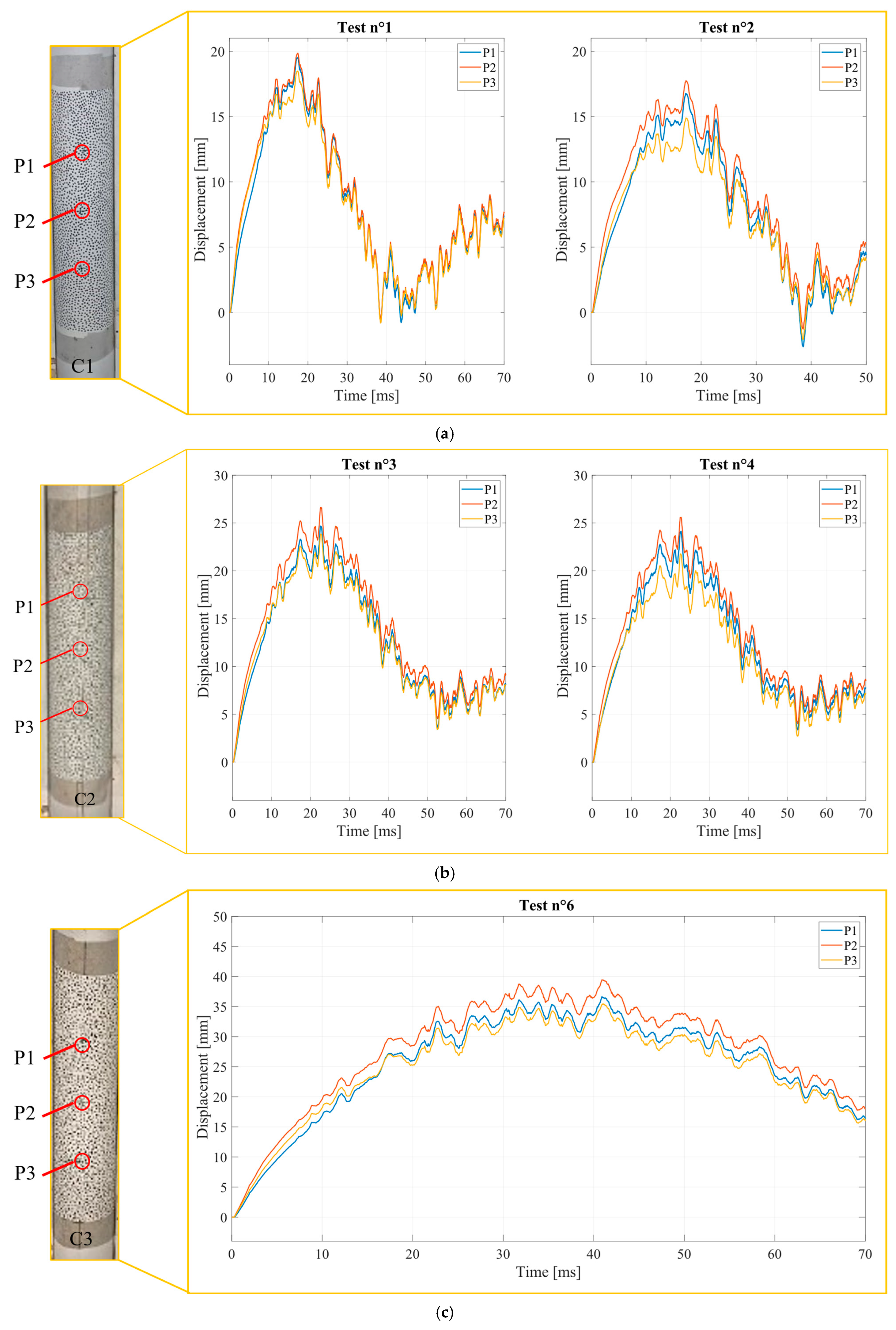

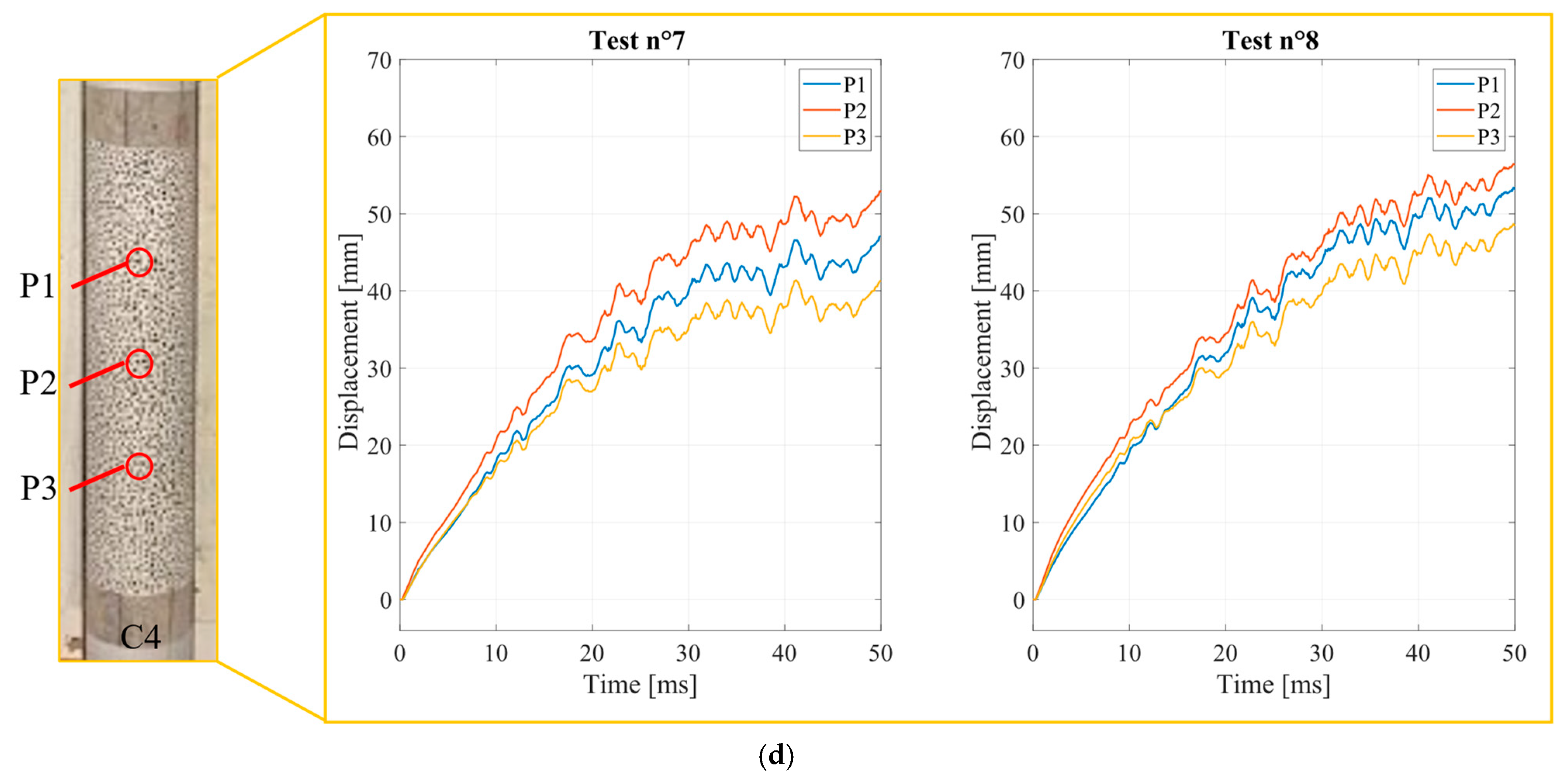

3.2.1. Deflection Versus Time Data

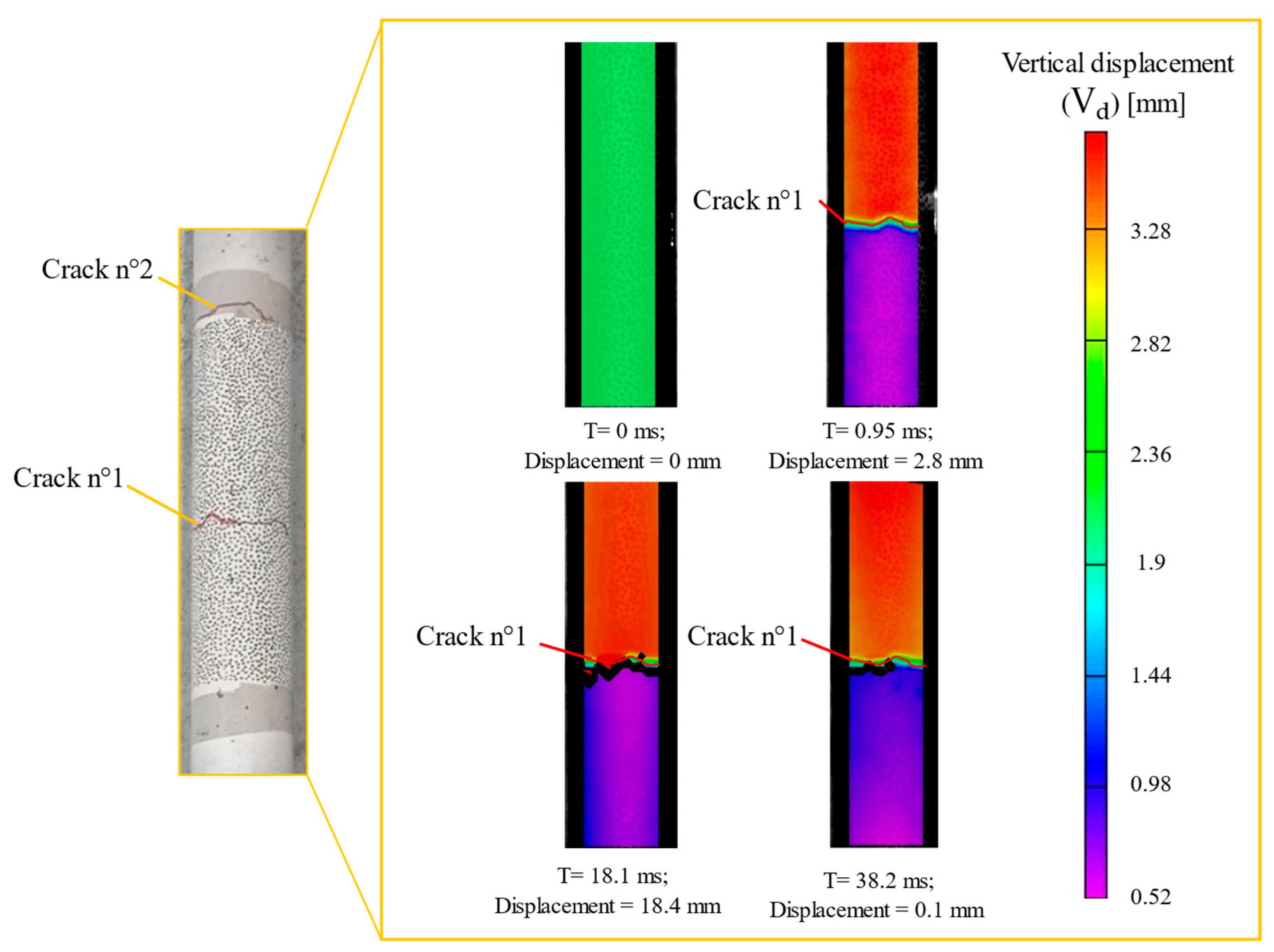

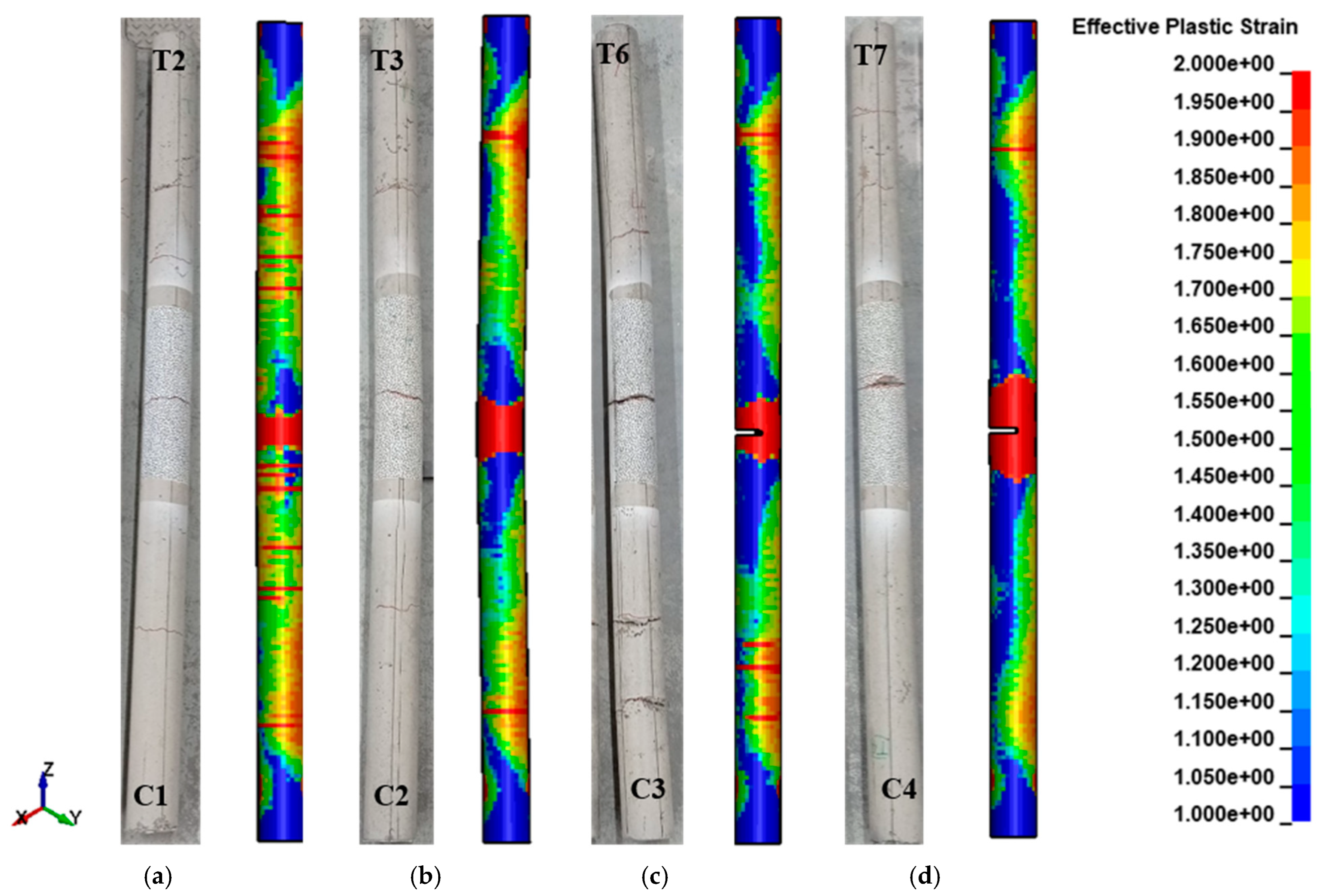

3.2.2. Damage Pattern

4. Numerical Modeling

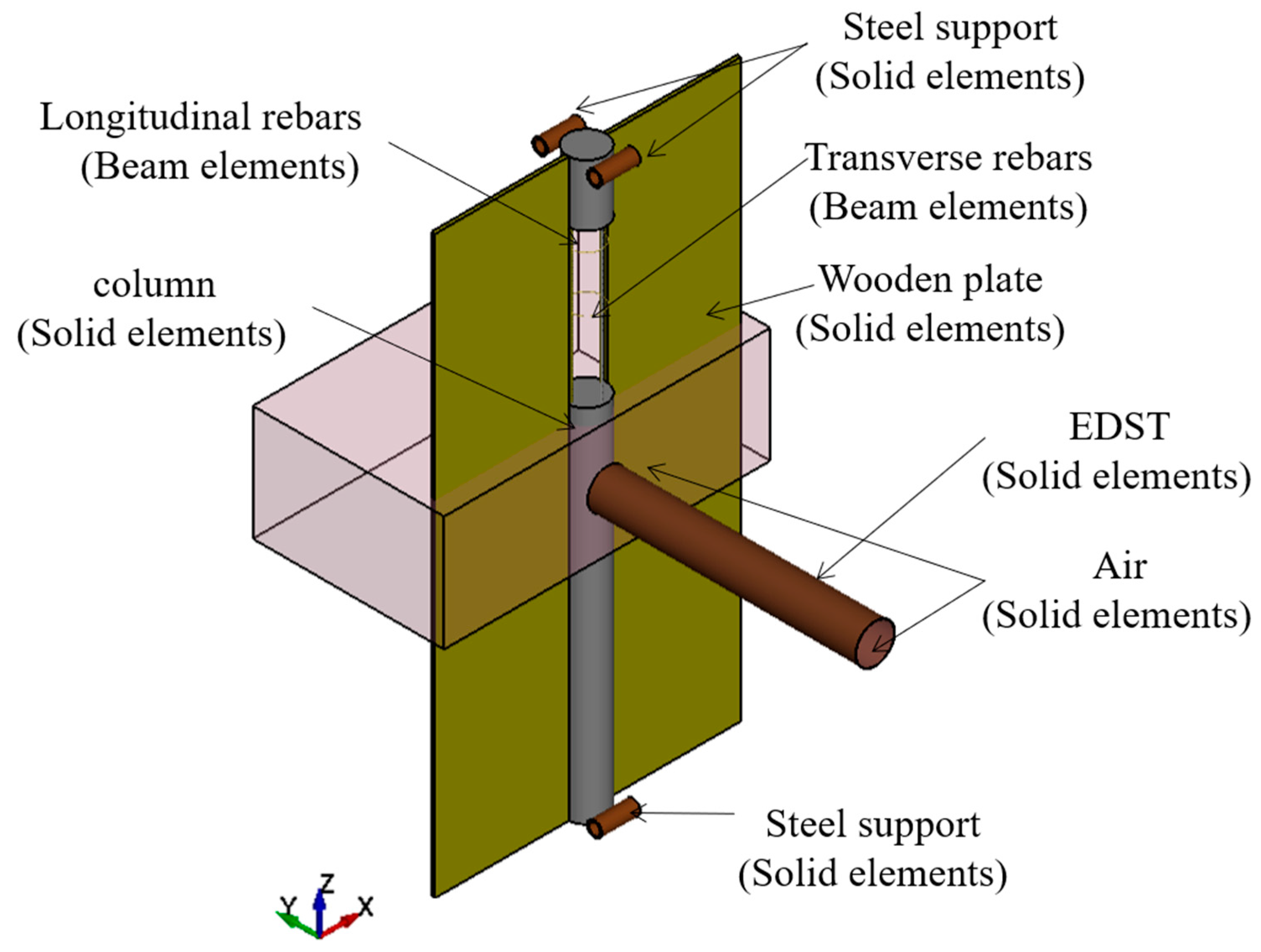

4.1. Finite Element Model

4.2. Modeling of Air and Detonation

4.3. RC Column Modeling

4.3.1. Concrete Modeling

4.3.2. Steel Rebars Modeling

5. Numerical Results

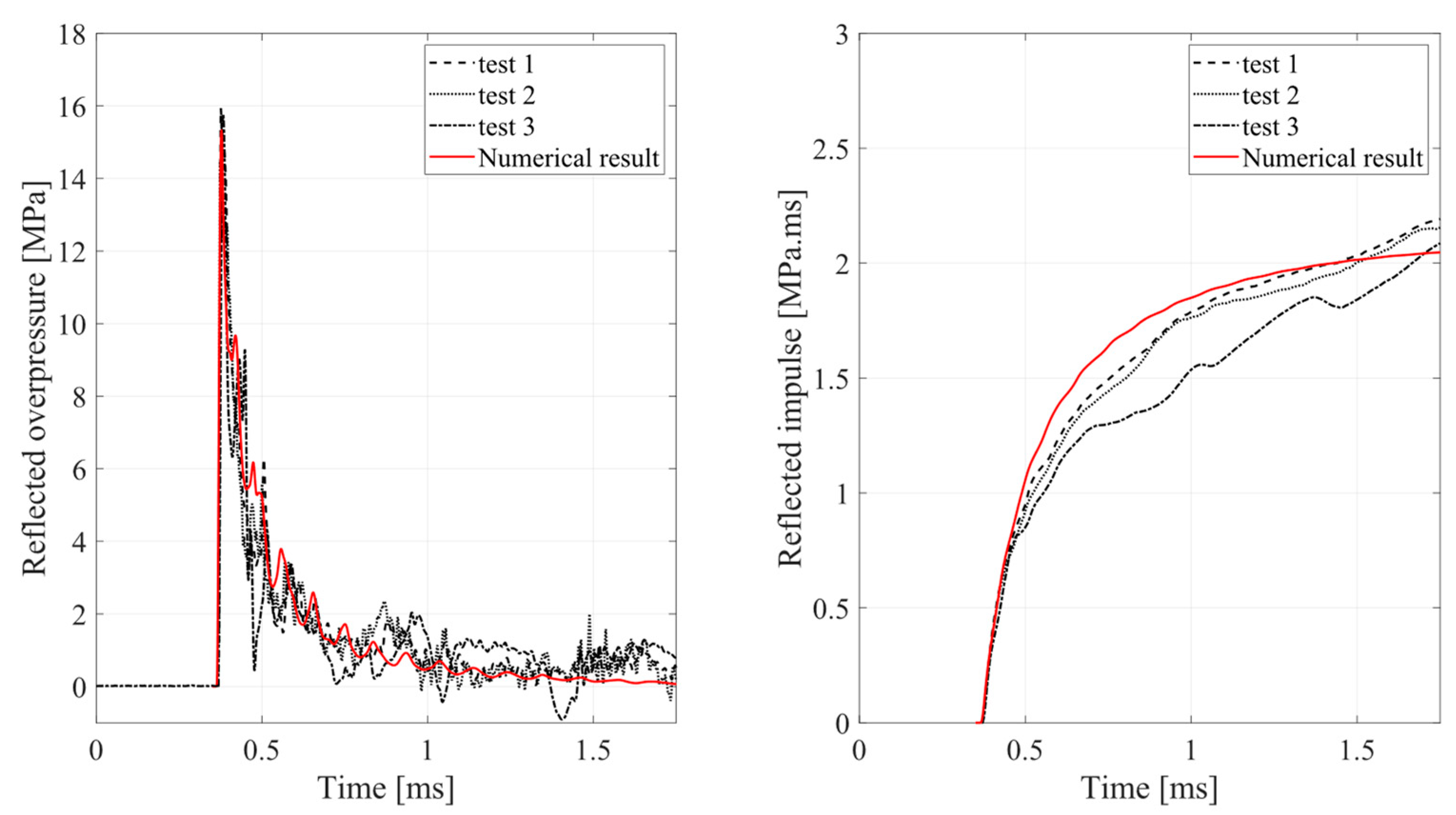

5.1. Blast Load

5.2. Blast Load Response of the Columns

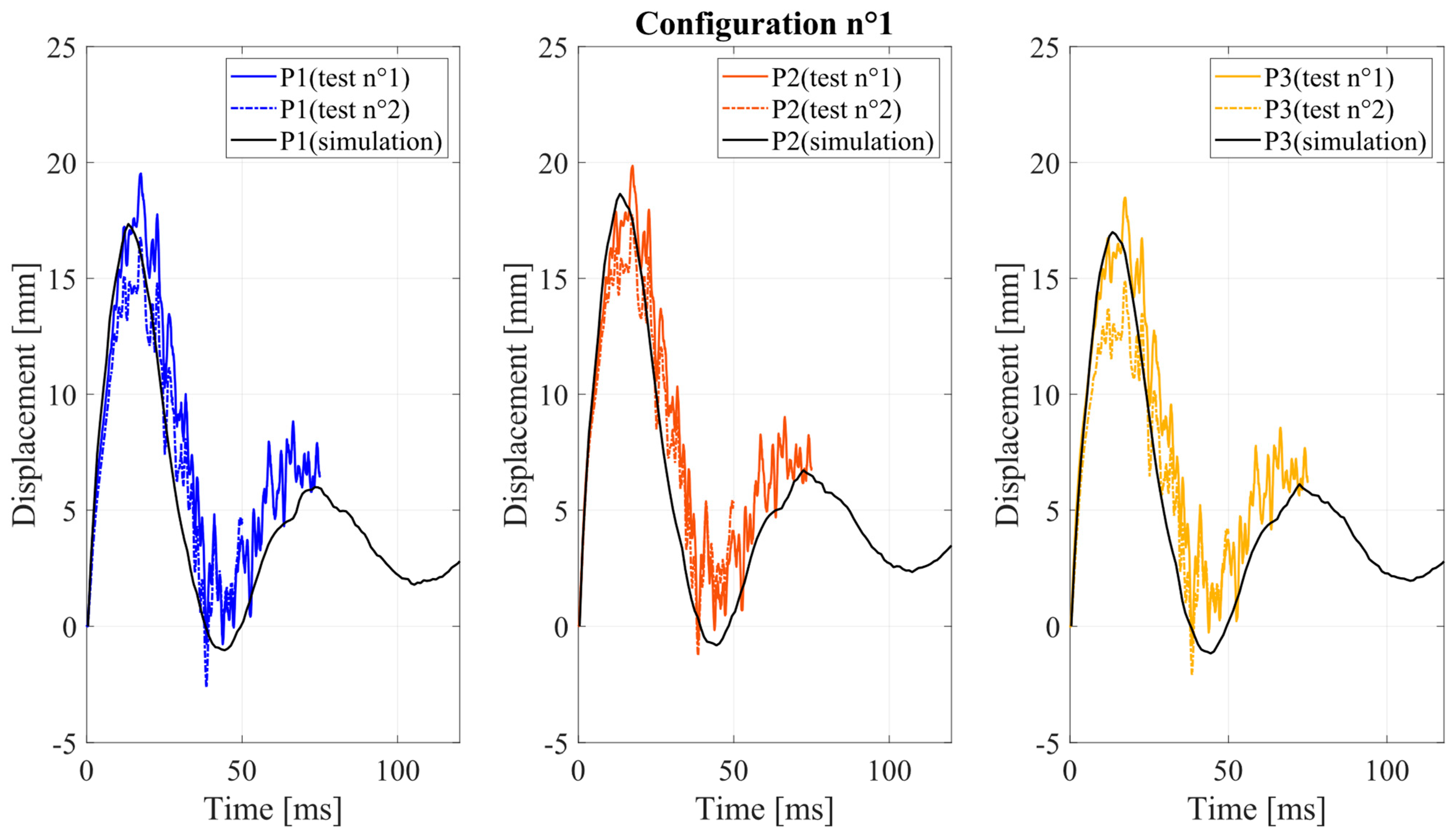

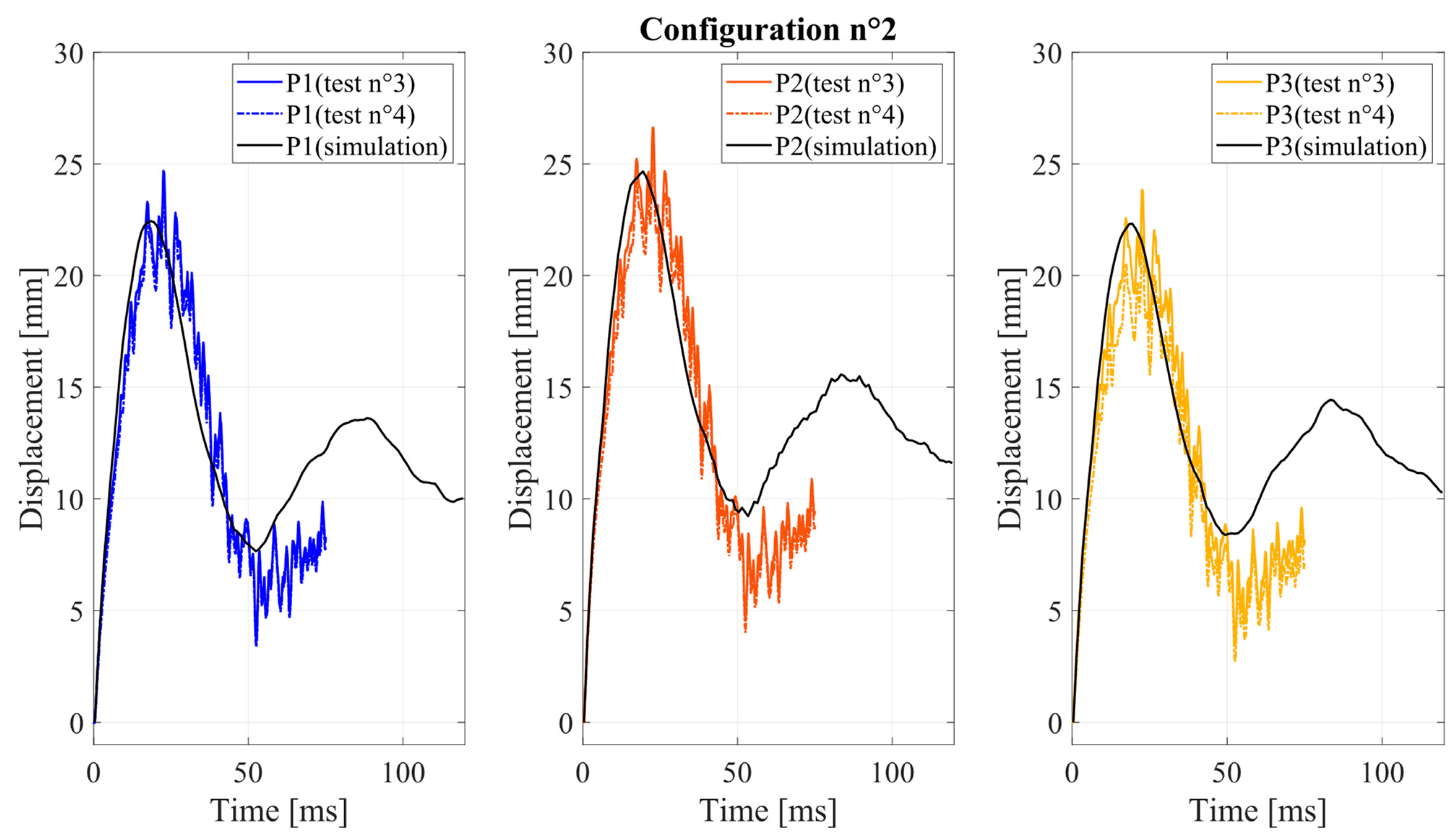

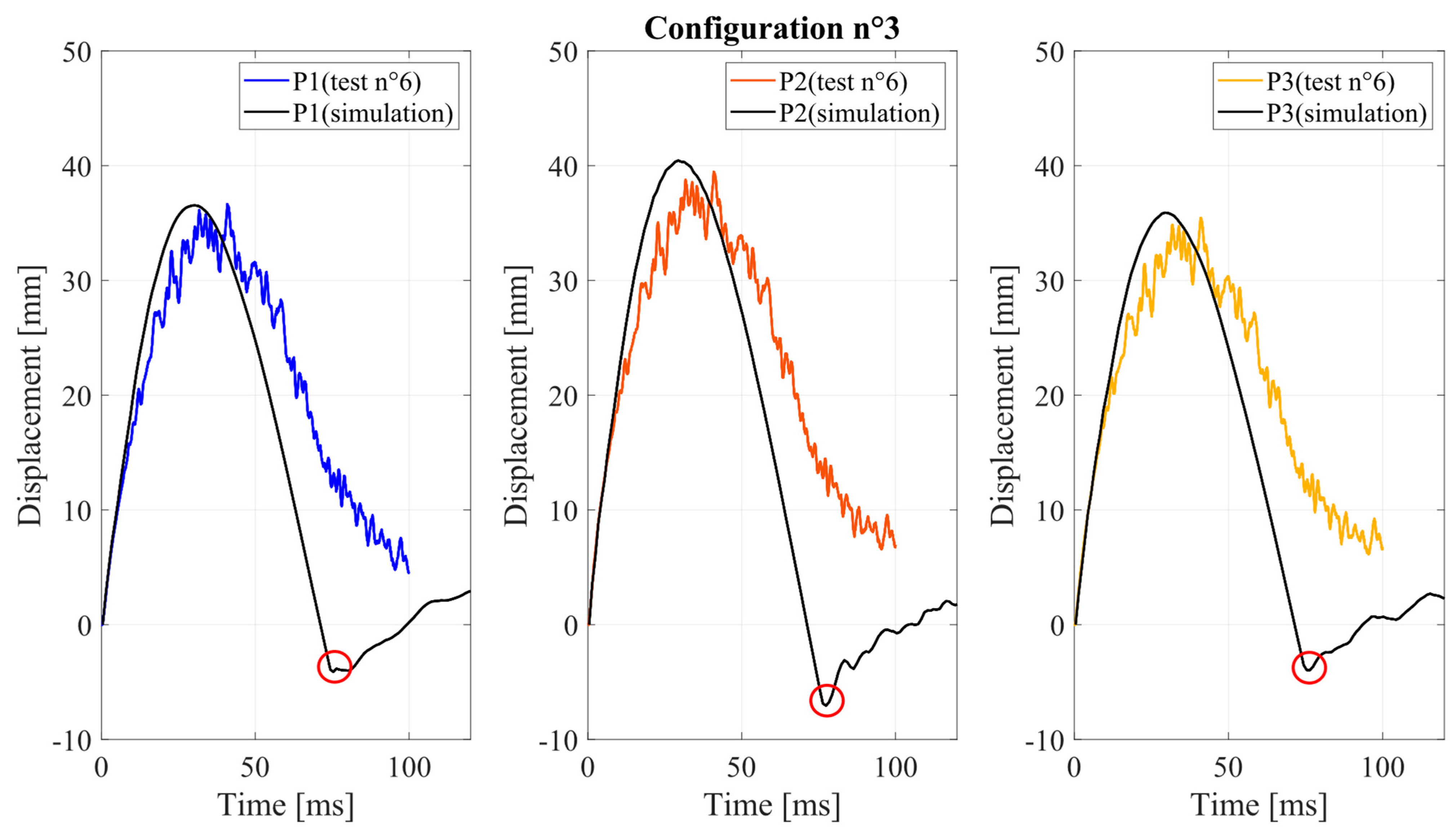

5.2.1. Deflection over Time

5.2.2. Numerical Analysis of the Damage Pattern

6. Conclusions

- (1)

- A reduction in the longitudinal reinforcement ratio is associated with increased damage severity in RC columns. The rotation-based damage assessment of columns subjected to a 30 g explosive charge (tests n°1 and 2) indicates moderate damage, with a fixity rotation (ϴ) of 1.35°. In comparison, specimens from tests n°5 and 6 show heavy damage, characterized by a considerably higher fixity rotation (ϴ) of 2.8°.

- (2)

- The DIC technique effectively identifies the crack distribution in the blast-loaded RC column. The locations of individual cracks along the columns are accurately determined by analyzing the gradient of the vertical deflection field.

- (3)

- The DIC technique investigates the time histories of crack propagation and failure progression.

- (4)

- The FE model can replicate the blast effects from an EDST, particularly concerning the maximum pressures and impulse. The variations observed in the maximum reflected pressures and impulse are 1.3% and 7.3%, respectively.

- (5)

- The FE model provides valuable insights into the damage mechanism of RC columns subjected to a local blast load produced by an EDST.

- (6)

- The FE model effectively replicates the blast response of RC columns. For instance, in config. n°1, the relative discrepancy between the model and the experimentally captured peak deflections at positions P1, P2, and P3 is 1.7%, 1.1%, and 1.8%, respectively.

- (7)

- The damage pattern simulated by the numerical model shows good agreement with the observed experimental data.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Report on Improvised Explosive Device (IED) Incidents. Available online: https://reliefweb.int/report/world/report-improvised-explosive-device-ied-incidents-january-june-2023 (accessed on 17 July 2023).

- Tagel-Din, H.; Rahman, N.A. Simulation of the Alfred P. Murrah federal building collapse due to blast loads. In Proceedings of the 2006 Architectural Engineering National Conference, AEI 2006 Building Integration Solutions, Omaha, NE, USA, 29 March–1 April 2006; p. 32. [Google Scholar] [CrossRef]

- Li, Z.; Du Hao, B.C. Review of current researches on blast load effects of building structures in China. Trans. Tianjin Univ. 2006, 12, 35–41. [Google Scholar]

- United States of America. UFC 3-340-02 Structures to Resist the Effects of Accidental Explosions; Unified Facil Criteria: Washington, DC, USA, 2008; pp. 1–12. Available online: https://www.wbdg.org/FFC/DOD/UFC/ufc_3_340_02_2008_c2.pdf (accessed on 20 January 2024).

- CSA CSAS. Design and Assessment of Buildings Subjected to Blast Loads 2012; CSA: Toronto, ON, Canada, 2012.

- UFC 3-340-02 2008. Structures to Resist the Effects ofAccidental Explosions. Available online: https://ntrl.ntis.gov/NTRL/dashboard/searchResults/titleDetail/ADA446084.xhtml (accessed on 28 February 2025).

- Army U.S. Fundamentals of protective design for conventional weapons. Tech. Man. TM 1986, 5–855. Available online: https://www.nrc.gov/docs/ml1019/ml101970069.pdf (accessed on 1 February 2025).

- Swisdak, M.M. Simplified Kingery Airblast Calculations. In Proceedings of the Twenty-Sixth DoD Explosives Safety Seminar, Miami, FL, USA, 16–18 August 1994; p. 17. Available online: https://apps.dtic.mil/sti/pdfs/ADA526744.pdf (accessed on 2 March 2024).

- Abedini, M.; Zhang, C.; Mehrmashhadi, J.; Akhlaghi, E. Comparison of ALE, LBE and pressure time history methods to evaluate extreme loading effects in RC column. Structures 2020, 28, 456–466. [Google Scholar] [CrossRef]

- Liu, Y.; Yan, J.B.; Huang, F.L. Behavior of reinforced concrete beams and columns subjected to blast loading. Def. Technol. 2018, 14, 550–559. [Google Scholar] [CrossRef]

- Mutalib, A.A.; Hao, H. Development of P-I diagrams for FRP strengthened RC columns. Int. J. Impact Eng. 2011, 38, 290–304. [Google Scholar] [CrossRef]

- Louar, M.A.; Belkassem, B.; Ousji, H.; Spranghers, K.; Kakogiannis, D.; Pyl, L.; Vantomme, J. Explosive driven shock tube loading of aluminium plates: Experimental study. Int. J. Impact Eng. 2015, 86, 111–123. [Google Scholar] [CrossRef]

- Hargather, M.J.; Settles, G.S. Laboratory-Scale techniques for the measurement of a material response to an explosive blast. Int. J. Impact Eng. 2009, 36, 940–947. [Google Scholar] [CrossRef]

- Jacinto, A.C.; Ambrosini, R.D.; Danesi, R.F. Experimental and computational analysis of plates under air blast loading. Int. J. Impact Eng. 2001, 25, 927–947. [Google Scholar]

- Svingala, F.; Biss, M.; Hargather, M.; Settles, G. Laboratory-Scale blast testing of materials using air-shock loading. APS Div. Fluid Dyn. Meet. Abstr. 2009, 62, EM-002. [Google Scholar]

- Hu, Y.; Chen, L.; Fang, Q.; Xiang, H. Blast loading model of the RC column under close-in explosion induced by the double-end-initiation explosive cylinder. Eng. Struct. 2018, 175, 304–321. [Google Scholar] [CrossRef]

- Sherkar, P.; Shin, J.; Whittaker, A.; Aref, A. Influence of Charge Shape and Point of Detonation on Blast-Resistant Design. J. Struct. Eng. 2016, 142, 04015109. [Google Scholar] [CrossRef]

- Pearson, R.J.; Wisniewski, H.L.; Szabados, P.; Wilson, A.W. The Effects of Thermal/Blast Synergism on the Nuclear Vulnerability of a Generic Aircraft Structure. 1984. Available online: https://apps.dtic.mil/sti/pdfs/ADA137730.pdf (accessed on 28 February 2025).

- Bryson, A.E.; Gross, R.W.F. Diffraction of strong shocks by cones, cylinders, and spheres. J. Fluid Mech. 1961, 10, 1–16. [Google Scholar] [CrossRef]

- Woodson, S.C.; Baylot, J.T. Quarter-Scale building/column experiments. Adv. Technol. Struct. Eng. 2000, 1–8. [Google Scholar] [CrossRef]

- Xu, K.; Deng, Q.; Cai, L.; Ho, S.; Song, G. Damage detection of a concrete column subject to blast loads using embedded piezoceramic transducers. Sensors 2018, 18, 1377. [Google Scholar] [CrossRef]

- Zhang, D.; Yao, S.; Lu, F.; Chen, X.; Lin, G.; Wang, W.; Lin, Y. Experimental study on scaling of RC beams under close-in blast loading. Eng. Fail. Anal. 2013, 33, 497–504. [Google Scholar] [CrossRef]

- Woodson, S.C.; Baylot, J.T. Structural Collapse: Quarter-Scale Model Experiments. 1999. 176. Available online: https://apps.dtic.mil/sti/tr/pdf/ADA369355.pdf (accessed on 28 February 2025).

- Siba, F. Near-Field Explosion Effects on Reinforced Concrete Columns: An Experimental Investigation. Master’s Thesis, Carleton University, Ottawa, ON, Canada, 2014. [Google Scholar]

- Lin, S.C.; Hu, Z.Q.; Han, J.Q.; Yang, B.; Elchalakani, M. Failure time of reinforced concrete column under blast load. Structures 2023, 53, 1122–1134. [Google Scholar] [CrossRef]

- Yan, J.; Liu, Y.; Xu, Z.; Li, Z.; Huang, F. Experimental and numerical analysis of CFRP strengthened RC columns subjected to close-in blast loading. Int. J. Impact Eng. 2020, 146, 103720. [Google Scholar] [CrossRef]

- Dua, A.; Braimah, A.; Kumar, M. Experimental and numerical investigation of rectangular reinforced concrete columns under contact explosion effects. Eng. Struct. 2020, 205, 109891. [Google Scholar] [CrossRef]

- .Aminou, A.; Ben Rhouma, M.; Belkassem, B.; Ousji, H.; Pyl, L.; Lecompte, D. Experimental and Numerical Evaluation of Calcium-Silicate-Based Mineral Foam for Blast Mitigation. Appl. Sci. 2024, 14, 9656. [Google Scholar] [CrossRef]

- Li, Y.; Lv, Z.; Wang, Y. Blast response of aluminum foam sandwich panel with double V-shaped face plate. Int. J. Impact Eng. 2020, 144, 103666. [Google Scholar] [CrossRef]

- Mejía, N.; Peralta, R.; Tapia, R.; Durán, R.; Sarango, A. Damage assessment of RC columns under the combined effects of contact explosion and axial loads by experimental and numerical investigations. Eng. Struct. 2022, 254, 113776. [Google Scholar] [CrossRef]

- Rhouma, M.B.; Maazoun, A.; Aminou, A.; Belkassem, B.; Vandenbruwane, I.; Tysmans, T.; Lecompte, D. Blast Loading of Small-Scale Circular RC Columns Using an Explosive-Driven Shock Tube. Buildings 2024, 14, 921. [Google Scholar] [CrossRef]

- Fujikake, K.; Aemlaor, P. Damage of reinforced concrete columns under demolition blasting. Eng. Struct. 2013, 55, 116–125. [Google Scholar] [CrossRef]

- Shi, Y.; Hao, H.; Li, Z.X. Numerical derivation of pressure-impulse diagrams for prediction of RC column damage to blast loads. Int. J. Impact Eng. 2008, 35, 1213–1227. [Google Scholar] [CrossRef]

- Chen, L.; Hu, Y.; Ren, H.; Xiang, H.; Zhai, C.; Fang, Q. Performances of the RC column under close-in explosion induced by the double-end-initiation explosive cylinder. Int. J. Impact Eng. 2019, 132, 103326. [Google Scholar] [CrossRef]

- Kwaffo, I.; Hussein Abdallah, M.; Braimah, A. Experimental assessment of the residual capacity of axially loaded blast-damaged square RC columns. Structures 2022, 40, 469–484. [Google Scholar] [CrossRef]

- Kyei, C.; Braimah, A. Effects of transverse reinforcement spacing on the response of reinforced concrete columns subjected to blast loading. Eng. Struct. 2017, 142, 148–164. [Google Scholar] [CrossRef]

- Wu, Y.; Xie, Q.; Mu, C. Sensitivity Analysis of Factors Influencing the Blast Resistance of Reinforced Concrete Columns Based on Grey Relation Degree. Sustainability 2023, 15, 12285. [Google Scholar] [CrossRef]

- Aoude, H.; Dagenais, F.P.; Burrell, R.P.; Saatcioglu, M. Behavior of ultra-high performance fiber reinforced concrete columns under blast loading. Int. J. Impact Eng. 2015, 80, 185–202. [Google Scholar] [CrossRef]

- Baylot, J.T.; Bevins, T.L. Effect of responding and failing structural components on the airblast pressures and loads on and inside of the structure. Comput. Struct. 2007, 85, 891–910. [Google Scholar] [CrossRef]

- Chen, W.; Hao, H.; Chen, S. Numerical analysis of prestressed reinforced concrete beam subjected to blast loading. Mater. Des. 2015, 65, 662–674. [Google Scholar] [CrossRef]

- Vapper, M.; Lasn, K. Blast protection of concrete columns with thin strips of GFRP overlay. Structures 2020, 25, 491–499. [Google Scholar] [CrossRef]

- ISO EN 6892-1; Metallic Materials-Tensile Testing-Part 1: Method of Test at Room Temperature. International Organization for Standardization: Geneva, Switzerland, 2009.

- DIN EN 12390-3: 2019-10; Testing Hardened Concrete. Compressive Strength of Test Specimens. CEN: Brussels, Belgium, 2019; Volume 3, pp. 12390–12393.

- PCB Dynamic Pressure Sensors for High Frequency Measurements. Available online: https://www.pcb.com/contentstore/mktgcontent/linkeddocuments/pressure/tm-prs-113b-102b_lowres.pdf (accessed on 19 January 2023).

- Alok, D.; Abass, B.; Manish, K. Contact explosion response of reinforced concrete columns: Experimental and validation of numerical model. In Proceedings of the 6th International Disaster Mitigation Specialty Conference, Held as Part Canadian Society for Civil Engineering Annual Conference, Montreal, QC, Canada, 12–15 June 2018; pp. 60–69. [Google Scholar]

- Wu, Y.; Crawford, J.E.; Lan, S.; Magallanes, J.M. Validation Studies for Concrete Constitutive Models with Blast Test Data. In Proceedings of the 13th International LS-DYNA Users Conference, Dearborn, MI, USA, 8–10 June 2014; pp. 1–12. [Google Scholar]

- Shuaib, M.; Daoud, O.M.A.; Daoud, O. Numerical Analysis of RC Slab under Blast Loads Using the Coupling of LBE and ALE Method in LS-DYNA. Fib Symposium. 2016. Available online: https://www.researchgate.net/profile/Mujtaba-Shuaib/publication/311454353_Numerical_Analysis_of_RC_Slab_under_Blast_Loads_Using_The_Coupling_of_LBE_and_ALE_Method_in_LS-DYNA/links/5847876708ae8e63e6308fb2/Numerical-Analysis-of-RC-Slab-under-Blast-Loads-Using-The-Coupling-of-LBE-and-ALE-Method-in-LS-DYNA.pdf (accessed on 28 February 2025).

- Maazoun, A.; Matthys, S.; Atoui, O.; Belkassem, B.; Lecompte, D. Finite element modelling of RC slabs retrofitted with CFRP strips under blast loading. Eng. Struct. 2022, 252, 113597. [Google Scholar] [CrossRef]

- Wu, Y.; Crawford, J.E.; Magallanes, J.M. Concrete Constitutive Models. In Proceedings of the 12th International LS-DYNA Users Conference, Dearborn, MI, USA, 3–5 June 2012; pp. 1–14. [Google Scholar]

- Malvar, L.J.; Crawford, J.E.; Wesevich, J.W.; Simons, D. A plasticity concrete material model for DYNA3D. Int. J. Impact Eng. 1997, 19, 847–873. [Google Scholar] [CrossRef]

- Rhouma, M.B.; Kailou, A.A.M.; Maazoun, A.; Belkassem, B.; Tysmans, T.; Lecompte, D. Numerical investigation of the blast performance of reinforced concrete columns subjected to close-in explosion. In Proceedings of the 6th International Conference on Protective Structures, Auburn, AL, USA, 14–17 May 2023; Auburn University: Auburn, AL, USA, 2023; p. 1712. [Google Scholar]

- Malvar, L.J.; Ross, C.A. Review of Strain Rate Effects for Concrete in Tension. ACI Mater. J. 2017, 153, 846–856. [Google Scholar] [CrossRef]

- Malvar, L.J.; Crawford, J.E. Dynamic Increase Factors for Steel Reinforcing Bars. In Proceedings of the 28th DDESB Seminar, Orlando, FL, USA, 18–20 August 1998; pp. 1–18. [Google Scholar]

- Liu, L.; Zong, Z.; Gao, C.; Yuan, S.; Lou, F. Experimental and numerical study of CFRP protective RC piers under contact explosion. Compos. Struct. 2020, 234, 111658. [Google Scholar] [CrossRef]

- LS-DYNA—Keyword User’s Manual, Version 970; Livermore Software Technology Corporation: Livermore, CA, USA, 2003; Volume I.

- Singh, N.K.; Cadoni, E.; Singha, M.K.; Gupta, N.K. Quasi-Static and dynamic tensile behavior of CP800 steel. Mech. Adv. Mater. Struct. 2014, 21, 531–537. [Google Scholar] [CrossRef]

| Test n° | Charge Mass [g] | Configuration n° | Longitudinal Reinforcement Type | Longitudinal Reinforcement Ratio [%] |

|---|---|---|---|---|

| 1–2 | 30 | 1 | A | 0.56 |

| 3–4 | 2 | A | 0.28 | |

| 5–6 | 3 | A | 0.14 | |

| 7–8 | 4 | B | 0.28 |

| Steel Rebar | Diameter (mm) | Elastic Modulus (GPa) | Elastic Limit | Maximum | ||

|---|---|---|---|---|---|---|

| Strain (-) | Stress (MPa) | Strain (-) | Stress (MPa) | |||

| Longitudinal Ø 3 | 3 | 209 | 0.0037 | 941 | 0.15 | 961 |

| Longitudinal M 3 | 3 | 209 | 0.0026 | 474 | 0.038 | 491 |

| Transverse | 2 | 199 | 0.0021 | 443 | 0.113 | 513 |

| Test n° | Explosive Mass [g] | [mm] | [mm] | Fixity Rotation Ɵm [°] | UFC-3-340-02 | Failure Mode |

|---|---|---|---|---|---|---|

| 1 | 30 | 19.9 | 18.9 | 1.35 | Moderate damage | Multiple fine cracks on the unloaded side extend along the entire length of the column. |

| 2 | 17.8 | |||||

| 3 | 26.5 | 26.1 | 1.9 | Moderate damage | Multiple fine cracks on the unloaded side extend along the entire length of the column. | |

| 4 | 25.6 | |||||

| 5 | -- | 39.4 | 2.8 | Heavy damage | Significant cracks on the unloaded side extend along the entire length of the column. | |

| 6 | 39.4 | |||||

| 7 | 52.9 | 54.7 | 3.9 | Heavy damage | Plastic deformation of the first steel rebar on the loading side. Failure of the second longitudinal bar of the non-loaded side. Deep flexural crack in the central region of the column. Significant cracks on the unloaded side extend along the entire length of the column. | |

| 8 | 56.4 |

| Material Characteristics | Parameter |

|---|---|

| Mass density, (kg/m3) | 2255 |

| Uniaxial compressive strength, (MPa) | 22.4 |

| Poisson’s Ratio | 0.3 |

| Material Characteristics | Longitudinal Rebar (Type A) | Longitudinal Rebar (Type B) | Transverse Rebar |

|---|---|---|---|

| Mass density, (kg/m3) | 7800 | 7800 | 7800 |

| Yield strength, (MPa) | 941 | 474 | 443 |

| Elastic modulus, (GPa) | 209 | 209 | 199 |

| Poisson’s ratio | 0.33 | 0.33 | 0.33 |

| Failure strain | 15% | 3.8% | 11.3% |

| Columns | Maximum Mid-Span Deflections | ||

|---|---|---|---|

| Exp [mm] | Num [mm] | Ratio [Num/Exp] | |

| C1 | 18.9 | 18.6 | 0.98 |

| C2 | 26.1 | 24.7 | 0.95 |

| C3 | 39.4 | 40.4 | 1.03 |

| C4 | 54.7 | 59.9 | 1.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rhouma, M.B.; Maazoun, A.; Aminou, A.; Belkassem, B.; Tysmans, T.; Lecompte, D. Damage Assessment of Laboratory-Scale Reinforced Concrete Columns Under Localized Blast Loading. Buildings 2025, 15, 1003. https://doi.org/10.3390/buildings15071003

Rhouma MB, Maazoun A, Aminou A, Belkassem B, Tysmans T, Lecompte D. Damage Assessment of Laboratory-Scale Reinforced Concrete Columns Under Localized Blast Loading. Buildings. 2025; 15(7):1003. https://doi.org/10.3390/buildings15071003

Chicago/Turabian StyleRhouma, Mohamed Ben, Azer Maazoun, Aldjabar Aminou, Bachir Belkassem, Tine Tysmans, and David Lecompte. 2025. "Damage Assessment of Laboratory-Scale Reinforced Concrete Columns Under Localized Blast Loading" Buildings 15, no. 7: 1003. https://doi.org/10.3390/buildings15071003

APA StyleRhouma, M. B., Maazoun, A., Aminou, A., Belkassem, B., Tysmans, T., & Lecompte, D. (2025). Damage Assessment of Laboratory-Scale Reinforced Concrete Columns Under Localized Blast Loading. Buildings, 15(7), 1003. https://doi.org/10.3390/buildings15071003