Abstract

Prefabricated technology addresses inefficiencies and quality variations in traditional construction but exhibits insufficient adaptability to pipeline systems in mountain rail transit equipment rooms (PPMRR), with obvious gaps in schedule and full-life-cycle economic quantification. This study aims to quantify the schedule and economic advantages of prefabrication for PPMRR and explore mountain-adapted implementation pathways. Taking Chongqing Rail Transit as the empirical context, this study employs case studies, field investigations, and semi-structured interviews as research methods. Results show that compared with the traditional mode, the prefabricated mode shortens the total project duration of PPMRR by 62–70% and reduces the 30-year full-life-cycle cost by 38.6%. This study addresses the research gap in schedule–economic quantification for the prefabricated mode of pipeline systems in mountain rail transit equipment rooms. It can provide critical references for construction planning, cost management and control, and the formulation of local prefabrication technical standards for mountain rail transit projects, thereby promoting the scalable application of prefabricated technology in complex terrain infrastructure.

1. Introduction

1.1. Background

As urbanization in China has advanced into mountainous regions, rail transit—serving as critical infrastructure—has witnessed escalating construction demand. In 2025, over 40% of ongoing rail transit projects nationwide are located in mountainous zones. Such projects, characterized by rugged topography and spatially constrained station equipment rooms, impose substantially higher demands for construction industrialization and precision compared to plain regions.

Amid the construction industry’s transition toward “intelligent construction and construction industrialization,” due to complex terrain and limited space between equipment, electromechanical pipeline construction requires a higher level of industrialization. The conventional on-site cutting and welding mode presents some limitations: extended site occupancy, heavy reliance on manual labor, high rework rates, and elevated operational maintenance costs. Although the prefabricated assembly technology can make up for these pain points, the existing technology is mostly suitable for plain scenes, and the promotion of rail transit equipment in mountain areas is hindered due to the differences in mountain space, transportation constraints, and inadequate adaptation of construction teams.

Current research efforts predominantly concentrate on building construction industrialization or plain-region scenarios, revealing a significant gap in dedicated solutions for PPMRR. Accordingly, this study adopts Chongqing rail transit as an empirical case to systematically examine the application outcomes and limitations of the prefabricated mode. It further explores mountain-adapted implementation pathways for industrialized construction, thereby providing practical references for the sector’s transformation.

1.2. Overview of Pipeline System Prefabrication Mode

1.2.1. Prefabrication Mode

Prefabricated Mode (also Prefabricated Assembly/Industrialized Prefabrication) is a construction method widely used in building, municipal, and rail transit projects. Guided by “standardized factory production—modular on-site assembly,” it enables integrated management of fully/semi-preassembled components from design to construction [], and as a key path for construction industrialization, aims to cut on-site work, boost precision, and save time/costs [].

Originating in mid-20th-century Western Europe and North America (initially for postwar housing via precast concrete), it expanded to industrial facilities and infrastructure in the 1980s with material and Building Information Modeling (BIM) advancements. Driven by intelligent construction policies [] in the 21st century, it evolved into “whole-system modular integration,” resolving traditional construction’s inefficiency and quality issues [].

1.2.2. Application of Prefabricated Mode

Countries like Armenia, Belize, and Russia initiated prefabricated construction early, accumulating substantial experience in standardization and institutionalization. China has been advancing building industrialization via policy coordination: in August 2020, the Ministry of Housing and Urban-Rural Development of China, with 13 ministries, issued the “Guidance on Promoting Coordinated Development of Intelligent Construction and Building Industrialization,” ref. [] aiming to establish an intelligent construction policy framework by 2035 and fully achieve building industrialization [].

Prefabricated construction centers on modular architecture, with modular integrated construction decomposing buildings into modules—manufactured off-site, transported by trucks, and assembled on-site [], reducing on-site material/equipment storage and assembly time. Despite its advantages in efficiency and quality [], it faces limitations: the design phase requires high scheme stability, as mid-phase changes, even with BIM coordination, increase rework risks []; costs rise (material protection, transportation, storage) [,,]; construction needs high-cost specialized cranes, and management is complex (just-in-time scheduling, change control) [].

1.2.3. Overview of Pipeline System Construction

In recent years, with the increasing complexity of construction projects, prefabrication technology has expanded from building engineering fields (e.g., precast concrete components, curtain walls) to mechanical, electrical, and plumbing (MEP) systems [].

In schedule control, the traditional mode—relying on on-site work—has flaws like insufficient design detailing, low efficiency, long component search time, material waste, and heavy dependence on workers’ proficiency []. Rational application of prefabrication in pipelines boosts efficiency and quality but faces challenges [,,]. Scholars have used BIM + prefabrication to solve spatial conflicts between equipment/pipelines and reduce on-site errors [,,,]. BIM-driven modular decomposition and 3D design also enhance pipeline prefabrication efficiency and enable schedule control [,].

In technological innovation, lifecycle-focused studies refine pipeline assembly via reform. In planning design, Fernanda S. Bataglin’s BIM-based 4D simulation resolved 83% of traditional design spatial conflicts []. Hisham Said developed a prefabrication feasibility assessment model based on BIM capabilities and supply chain coordination with vendors, aiming to optimize modular segmentation strategies []. Tharindu Samarasinghe developed an efficient automated modularization algorithm, maintaining design–installation–transport links, cutting costs while achieving 18% lower transport fees via optimization []. During the prefabrication phase, technological breakthroughs have primarily focused on quality inspection and process innovation. Mahdi Safa used high-precision point cloud technology to control component accuracy to 0.5 mm and quadruple inspection efficiency []. In the installation and construction phase, technological innovation is prominently reflected in collaborative construction and intelligent assembly. Atul Khanzode utilized BIM/VDC tools and processes to coordinate MEP systems, achieving a 20–30% reduction in labor during installation while eliminating on-site installation conflicts entirely []. Furthermore, BIM also manages MEP systems maintenance [].

In terms of economic costs, there are certain differences in the degree and depth of attention among participating units []. General contractors, pipeline subcontractors, and prefabrication plants emphasize costs. Factory production improves material utilization to reduce costs [], but projects need a certain scale to gain benefits [], leaving prefabrication’s economic benefits in construction uncertain [,,].

1.2.4. Summary

Current research on prefabrication technology predominantly concentrates on infrastructure in plain regions or building construction, failing to incorporate the distinctive constraints of “steep mountain roads and spatially confined equipment rooms” in mountain rail transit. This limitation hinders effective adaptation to transportation clearance limits and assembly requirements in mountainous settings. Moreover, existing benefit analyses largely remain at the level of qualitative descriptions or short-term cost calculations, lacking systematic quantitative comparison of schedule efficiency and full-life-cycle economics. Critical issues such as embedding design constraints and information coordination have also been overlooked, thus failing to provide adequate support for the industrial transformation of mountain scenarios.

This study aims to address these research gaps by quantitatively delineating the schedule and economic advantages of prefabricated pipeline systems in mountain rail transit equipment rooms, exploring mountain-adapted implementation pathways, and providing empirical support for industrial transformation. The central objective is to establish a mountain-adapted technical framework for the entire prefabrication workflow, clarifying the implementation value and refinement pathways of the prefabricated mode.

2. Research Methods

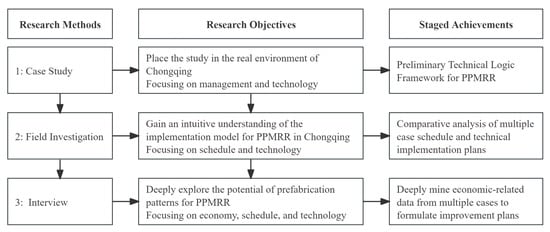

This study adopts a series of qualitative and quantitative methods, including case studies, field visits, and semi-structured interviews in Chongqing. It is difficult to introduce the research object into the laboratory in this study, and the sample size is limited []. Encourage projects that use qualitative research. In order to enhance the empirical nature of the case study, this study uses multi-source evidence for logical reproduction. Therefore, this paper prefers the mixed method. Figure 1 shows the flow chart of the method used in this study.

Figure 1.

Flow chart of research method.

2.1. Case Study

This case study focuses on Chongqing, a megacity in southwestern China characterized by extreme topographic complexity. Encompassing 82,400 km2 of predominantly hilly terrain, Chongqing features a multi-dimensional urban structure that has earned it the nickname “8D magical capital”. By July 2025, Chongqing had established the world’s largest mountain urban rail transit network, comprising 13 operational lines—including Circular Line, Lines 1–6, 9–10, 18, Guobo Line, Jiangtiao Line, and Bitong Line—with a total operational mileage of 582.5 km. The network serves 267 stations (excluding duplicate transfer stations), distributed as 200 underground stations (75%), 62 elevated stations (23%), and 5 semi-underground stations (2%). Currently, 9 additional lines (including extensions) spanning 220 km are under construction, covering metro, regional express rail, and suburban railway systems.

Over the past decade, Chongqing’s rail transit equipment room pipeline construction has completed a transformative shift from traditional extensive methods to collaborative construction. Prior to 2015, reliance on 2D design and segregated MEP drafting resulted in frequent pipeline clashes during cross-trade construction. The pivotal transition occurred post-2016 with large-scale BIM adoption, enabling clash-free pipeline layouts through detailed BIM coordination. Since 2021, prefabricated technology has been comprehensively implemented, as exemplified by Shipingqiao Station (Chongqing rail transit line 18), where BIM-prefabrication integration addressed typical mountainous challenges like arched equipment rooms and limited clearances through factory production and precision installation, achieving a paradigm shift from “on-site remediation” to “proactive control”.

In order to promote the pipeline construction of Chongqing rail transit machine room to a higher quality development, the local standard of engineering construction “Technical Standard for Application of Prefabricated Integrated Support and Hanger” (DBJ50/T-514-2025, Chongqing, China) [] implemented in July 2025 promotes the multi-disciplinary sharing of prefabricated support and hanger electromechanical, and standardizes the design, production, installation, acceptance and maintenance of prefabricated support and hanger system. For these reasons, Chongqing is a suitable case in this study.

2.2. Site Visit

The purpose of an on-the-spot investigation is to intuitively grasp the on-site operation status of the research point by collecting real environmental data, and to obtain non-encoded first-hand information (such as implicit operation, situational details) that is difficult to cover by second-hand information (such as literature, reports, data). In this study, through on-the-spot visits, the construction mode of Chongqing PPMRR is investigated in depth. The identification of research points follows two criteria: first, the types of research points need to be diversified enough so that the author can fully investigate the line’s construction mode; secondly, the research points are representative, so the author can obtain more real and in-depth technical operation details and schedule control background details. From April 2023 to February 2025, a total of six research activities were arranged in Chongqing (see Table 1). The investigation includes the equipment room of the four line platforms (including the construction drawing mode). The platform types include the most core underground and elevated types. The stage of the platform equipment room during the investigation includes all stages of construction, and the construction mode includes the two modes of this study. The on-site investigation gradually revealed the progress control and technical implementation process of the pipeline system prefabrication mode. The two design stage investigations deepened the understanding of the design optimization timeliness under the prefabrication mode. In general, these six surveys represent the status quo of the renewal of Chongqing PPMRR.

Table 1.

Basic information on on-site investigations.

Tracking and investigating the first phase project of Chongqing rail transit line 18, in addition to obtaining first-hand data through on-site investigation, also relies on the project collaborative management platform (BIM + GIS intelligent management platform of Chongqing Rail line 18) to supplement key information. The platform covers five core functional modules: survey and design management, production schedule management, electromechanical system management, cost management, and log management, which can realize real-time recording and structured storage of information in all aspects of the project. At the same time, in order to supplement the unstructured key information not covered by the platform, this study synchronously collected the non-platform documents archived by the project, including the meeting minutes of each stage (including design disclosure meeting, prefabrication coordination meeting, installation technology seminar, etc.), project management system documents (including prefabrication quality control procedures, on-site installation safety management methods, BIM model application standards, etc.), technical results documents (including pipeline system design drawings and calculation books, prefabricated component processing process documents, BIM model optimization reports, etc.). And change coordination documents (including design change notice, on-site problem coordination record, component transportation plan adjustment letter, etc.). The above non-platform files complement the platform data and jointly guarantee the integrity and credibility of the research data.

2.3. Interview

In order to further explore the key coordination problems, technical details and economic control points of each stage, and make up for the information gap between observation records and document data, this study carried out a series of semi-structured interviews, and proposed a series of pre-designed open questions for stakeholders at different stages, covering progress management, technological innovation, and economic cost dimensions. Combined with the data triangulation method, the BIM + GIS intelligent management platform data (including cost management module) and non-platform archive files (including budget and cost ledger) mentioned above were cross-checked to ensure the validity and reliability of the data.

In this study, since stakeholders have accumulated rich practical experience in the field of PPMRR, the reasonable opinions collected through semi-structured interviews will provide an important basis for the construction of a prefabricated mode of PPMRR. From April 2023 to February 2025, a total of 12 in-depth interviews were conducted in Chongqing. Table 2 shows the general characteristics of the respondents. The interviewee screening process mainly follows two criteria. First, the interviewee needs to have relevant experience in pipeline system prefabrication. Second, the background should be diverse, covering all stages involved in the prefabrication mode.

Table 2.

Basic information of respondents.

Responses mainly involve the openness of their roles corresponding to the core construction stage and its upstream and downstream stages, except for some project leaders and research scholars. The sample size of 12 people is enough to meet the data requirements and interview objectives. Each respondent was interviewed more than once—more than 2 times on average—in order to obtain richer and more in-depth information than with a single interview. Each interview lasted approximately 1 h and was audio-recorded via smartphones, following written informed consent from all interviewees. The researchers sorted out and analyzed 12 interview records, screened out the progress control, technological innovation, and economic cost information of different modes according to the frequency mentioned by the interviewees, and compared them with the management platform information and archived documents collected by field research to eliminate the information that was only mentioned once with obvious conflicts. Other conflict information was communicated with the interviewees to confirm their information background and confirm whether to retain it. In this study, only the information mentioned by at least three respondents was selected as the basis for the comparison of the two models, and the accuracy of the information was reconfirmed and verified with the respondents. The details of the interview questions at each stage are shown in Appendix A, Table A1.

3. Analysis and Discussion of Typical Case Studies

Based on the previous case study, field investigation and interview results, this study selects the typical station of the first phase of Chongqing rail transit line 18 as the core typical case (its data is the average level of the corresponding form platform of the line), and the first phase of Chongqing rail transit line 4 as the traditional model benchmark case (its data is the corresponding mean value of the corresponding form platform), supplemented by other mountain rail transit projects in Chongqing as supplementary cases.

3.1. Overview of Typical Cases of Chongqing Rail Transit

3.1.1. Chongqing Rail Transit Line 18 Project

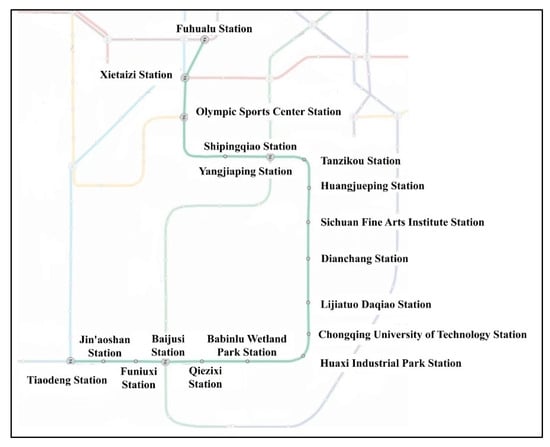

Chongqing rail transit line 18 Project (Line 18) serves as a crucial north–south arterial route, spanning a total length of 29.016 km. The alignment comprises 18.712 km of underground tunnels and 9.544 km of elevated sections, connecting central urban districts including Yuzhong District, Jiulongpo District, and Dadukou District. The line incorporates 19 stations, consisting of 8 underground stations constructed by mining method, 4 underground stations built by cut-and-cover technique, and 7 elevated stations, as illustrated in the route schematic diagram (Figure 2).

Figure 2.

Route diagram of Line 18.

All stations have adopted the prefabricated mode for pipeline system installation in both refrigeration plant rooms and fire pump rooms, primarily including: (1) Fire pump room systems: pipe fabrication and installation, support structure fabrication and erection, valve installation, fire hydrant pumps, sprinkler pumps, and control cabinet deployment; (2) Refrigeration plant systems: prefabricated piping, support fabrication and installation, valve and instrument installation, thermal insulation for chilled water pipelines, and positioning of equipment control cabinets (excluding electrical wiring).

The terrain of Line 18 is complex, the mountains are steep, and the ground is undulating. It crosses over/under existing rail transit lines, ditches, and passes close to buildings/structures, leading to varied station forms. This further affects the buried depth and internal spatial structure of station equipment rooms, requiring customized design optimization for each station’s unique layout before prefabrication. The interior of the equipment pipeline not only includes the water pipeline system of the refrigeration system and the fire protection system, but also includes the air duct system of the ventilation system and the smoke exhaust system, and the bridge pipe system of the electrical system (Figure 3), which greatly increases the construction difficulty between the equipment pipelines and requires the construction departments to strengthen communication and coordination. Once the main structure of the whole station is completed, the station must be put into operation as soon as possible, resulting in a very tight construction period between equipment and pipelines, and the schedule is very urgent.

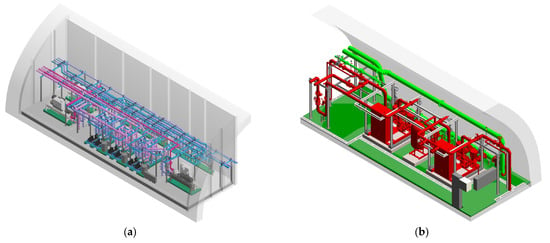

Figure 3.

Schematic diagram of the pipeline system model in the equipment rooms of Shipingqiao Station of Line 18. In (a), the blue pipeline is the chilled water supply system, the light purple pipeline is the chilled water return system, the light pink pipeline is the cooling water supply system, and the rose red pipeline is the cooling water return system; in (b), the red pipe is the fire-pressurized water supply system, and the green pipe is the fire water supply system. (a) Pipeline system model of the cold-water machine room; (b) pipeline system model of the fire pump room.

3.1.2. Chongqing Rail Transit Line 4 Project

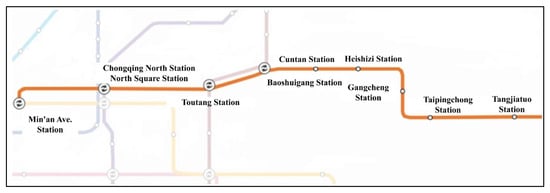

Chongqing rail transit line 4 (Line 4), subsequently referred to as Line 4, represents the eighth urban rail transit line to commence operations in Chongqing. Spanning a total length of 15.66 km, the line strategically connects several key urban areas, including Xinpaifang District, Chongqing North Station Comprehensive Transportation Hub, Lianglu Cuntan Bonded Port Zone, Tangjiatuo Area, and Gangcheng Industrial Park. The line comprises nine stations, consisting of six underground stations, one semi-underground station, and two elevated stations, as illustrated in the route schematic (Figure 4). Line 4 initiated trial operations in January 2019, preceding Line 18’s December 2023 opening. Notably, all stations along Line 4 employed traditional construction methods for the installation of pipeline systems in both refrigeration plant rooms and fire pump rooms.

Figure 4.

The route diagram of the first phase project of Line 4.

3.2. Comparative Analysis of the Implementation Methods of Pipeline System Between Equipment Pipelines

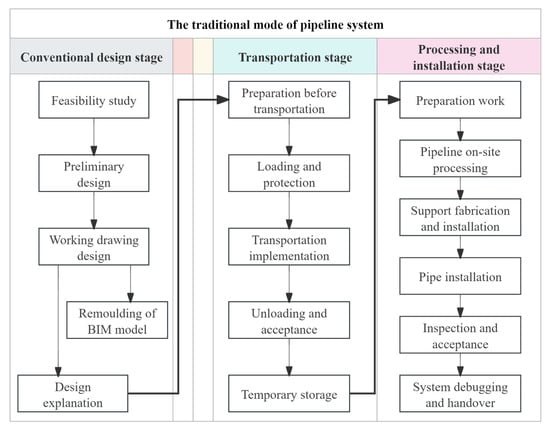

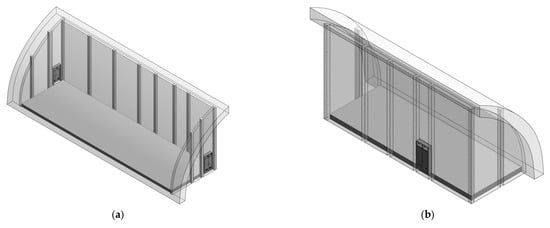

Figure 5 illustrates the implementation pathway of the conventional “on-site processing-centered” approach for pipeline systems. During the design phase, BIM models are merely utilized for the digital replication of design drawings to meet local policy requirements, without practical application in guiding construction, and without prefabrication-suitability optimization. In the transportation phase, the shipped items consist of raw pipeline materials and on-site processing equipment, with fundamental moisture and impact prevention measures as the primary protective strategies. All processing procedures (including pipe cutting and beveling) are completed on-site during the installation phase. This approach relies heavily on manual operations and experiential judgment, where quality and efficiency are significantly influenced by on-site conditions such as workspace limitations and weather factors.

Figure 5.

Flowchart of implementation process for pipeline systems: conventional mode.

Figure 6 delineates the implementation pathway of the prefabricated mode for pipeline systems, structured around the core principle of “prefabricated mode”. This framework expands upon the conventional approach by introducing two additional critical phases: model-optimized design and prefabrication processing. During the design phase, the initially developed BIM model undergoes a comprehensive transformation through a series of systematic procedures. These include preliminary compliance analysis and optimization, formulation of model decomposition rules, categorical model disassembly operations, and validation and refinement of disassembled models. This structured process enables the comprehensive transformation of the BIM model into a format deeply aligned with prefabrication requirements. In the prefabrication phase, all manufacturing activities (including precision cutting of pipe sections, modular integration and assembly, and non-destructive testing) are conducted within controlled factory environments. This setting ensures standardized quality control throughout the manufacturing process. In the installation stage, the segmented docking assembly method is used to realize industrial construction. This method significantly shortens the on-site operation time and reduces the requirements for the construction site area.

Figure 6.

Flowchart of implementation process for pipeline systems: prefabricated mode.

This study employs a systematic comparative analysis between Line 18 (implementing prefabricated mode) and Line 4 (utilizing conventional approach) as a core case study. Through comprehensive investigation across all project phases—design, prefabrication, transportation, and installation—coupled with field-measured data, we conduct a tripartite evaluation assessing schedule performance, technical implementation, and economic effectiveness. This methodological framework enables quantitative determination of operational distinctions between the two modes and systematic identification of the prefabricated approach’s contextual advantages.

3.2.1. Progress Dimension Comparison

Based on schedule data from six field investigations of Line 18 (prefabricated mode) and Line 4 (traditional mode), along with qualitative feedback from 12 interviewees on project duration pressure (e.g., the construction team noted traditional mode was constrained by mountainous terrain, causing process congestion), this section quantitatively compares core schedule control differences between the two modes across key stages: design optimization, prefabrication, transportation, and installation. The specific comparison is shown in Table 3.

Table 3.

Comparison of key indicators of progress dimension.

The core driving mechanism of the progress difference is that the prefabrication mode transforms the traditional on-site “serial process” (design → processing → installation) into “factory production and on-site preparation in parallel”. For example, the prefabrication of Line 18 is carried out simultaneously with the main construction of the station, and only the installation and docking work is retained on the site to avoid the internal friction of the on-site “transportation, processing and installation” after the completion of the traditional mode structure. In the traditional mode, all processes depend on the field space, and the multi-disciplinary cross-congestion between mountain equipment further prolongs the effective operation time.

Although the design phase in the prefabricated mode requires an additional 3–4 months compared to the conventional design cycle (averaging approximately six months), the core distinction lies in “change control and front-loaded detailing”. The prefabricated mode embeds mountainous working condition constraints in advance through BIM model optimization, resulting in zero post-release modifications after issuing prefabrication drawings. In contrast, the conventional approach, due to its failure to conduct topography and space-adapted detailed design proactively, necessitates repeated manual adjustments during the construction phase, ultimately leading to a longer effective project duration despite its ostensibly shorter initial design period.

The prefabricated mode transforms the traditional on-site “fabrication-installation” sequence into a synergistic process of “parallel factory prefabrication and on-site civil works”. For Line 18, prefabricated component manufacturing required only 18 days (consistent across both stations), representing a 49% reduction compared to the conventional on-site fabrication average of 35 days. This efficiency was further enhanced through “overlapping production and verification processes,” as demonstrated at Shipingqiao Station, where a 13-day overlap was achieved.

To address the spatial constraints of mountainous 1.2 m narrow passages, Line 18 decomposed prefabricated components into modules ≤ 1.2 m. By utilizing the brief window between track completion and operational commencement, the project implemented a combined “manual handling + track vehicle” transportation approach, completing the process within just 1–2 days. In contrast, the conventional method’s transportation of bulk raw materials required on-site cutting and segmentation due to dimensional incompatibility, compounded by limited storage space and multi-disciplinary interference, resulting in an average fragmented transportation cycle of approximately 15 days. This differential validates the prefabricated mode’s advantage in “topography-adapted transportation planning,” effectively eliminating the schedule inefficiencies inherent in the conventional “transportation–cutting–secondary transportation” sequence.

During the on-site installation phase, the prefabricated mode replaces the traditional complete sequence of “cutting-welding-installation” with modular splicing. Line 18 required only 7 days for prefabricated component splicing, representing an 84% reduction compared to the conventional mode’s average of 45 days. When calculating the total on-site duration from component/raw material delivery to debugging and acceptance, the prefabricated mode compressed the timeline from an average of 60 days to 18–23 days—a reduction exceeding 60%—thereby significantly alleviating on-site schedule pressure.

3.2.2. Comparison of Technical Dimensions

By tracking semi-automatic processing at Line 18’s prefabrication plant, observing BIM model applications across platform equipment rooms, and incorporating qualitative descriptions of construction quality from interviews with technicians (e.g., BIM engineers, prefabrication plant quality inspectors)—such as prefabrication staff noting factory standardized production reduces mountain humidity’s impact on welding quality—this section compares the two modes’ differences in technical adaptability and quality control across four dimensions: design, process, transportation, and installation technologies. The detailed comparative analysis is presented in Table 4.

Table 4.

Comparison of key indicators of technical dimension.

The fundamental technical distinction lies in the prefabricated mode’s proactive resolution of challenges: “BIM model optimization” preemptively resolves spatial conflicts in mountainous terrain, “standardized factory production” circumvents quality interference from on-site damp and confined environments, and “specialized mountainous solutions” address the adaptability shortcomings of the conventional one-size-fits-all approach. In contrast, the traditional mode’s reliance on manual experience allows all technical risks to materialize on-site, resulting in persistent rework and safety concerns.

The application of BIM in the design optimization phase of the prefabricated mode extends beyond mere model replication, utilizing specialized BIM plugins to achieve automated pipeline decomposition and automatic adaptation of supporting components such as flanges and support hangers. The core of this process lies in the classification of standardized pipe sections and free-form segments, which incorporates not only conventional factors like pipeline routing, elbows, and junctions but also integrates project-specific elements, including mountainous working conditions (e.g., 4.5 m tunnel height restrictions) and factory equipment parameters. Through this model optimization, 19 spatial interference issues were proactively identified (including insufficient clearance between pipes and structural beams, and transport pathway limitations). In contrast, the conventional mode employs BIM merely to satisfy policy review requirements without optimization procedures, causing all spatial conflicts to emerge during the construction phase and resulting in frequent rework.

The prefabricated mode leverages semi-automated factory equipment (including CNC cutting and pipe beveling machines, Chongqing, China) to achieve standardized production (see Figure 7), with all components undergoing pre-delivery quality inspections such as non-destructive testing and pressure testing. Despite potential limitations like “workers’ misinterpretation of drawings” and “semi-automated processes,” the method maintains a remarkably low rework rate of only 3.2–4.5%. In contrast, the conventional approach relies entirely on manual on-site fabrication, where processing precision is adversely affected by the damp and spatially constrained environments typical of mountain equipment rooms, resulting in a significantly higher rework rate of 18.7%.

Figure 7.

Semi-automatic processing schematic diagram of the preform factory. (a) Pipe docking on the pipe prefabrication platform; (b) semi-automatic welding.

During the transportation phase, Line 18 addressed the challenges of 1.2 m narrow passages and tunnel height restrictions (see Figure 8) by decomposing components into modular units (e.g., segmenting long pipes into 6–10 m sections) and implementing customized protective packaging. This approach resulted in a remarkably low damage rate of only 1.8–2.1%. In contrast, the conventional method, which transports bulk raw materials without specialized protection or adaptive design, suffered from collision deformation and bevel damage caused by mountain terrain vibrations, leading to a significantly higher damage rate of 9.3%.

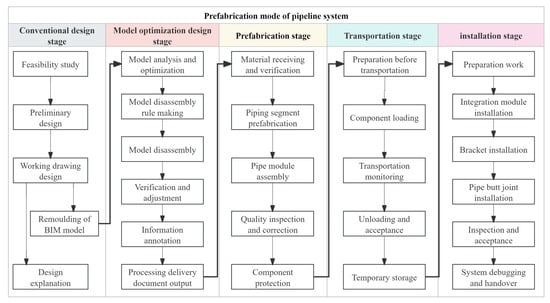

Figure 8.

BIM structure model diagram of equipment room in Shipingqiao station of No. 18 line. (a) Cold-water room structure model; (b) fire pump room structure model.

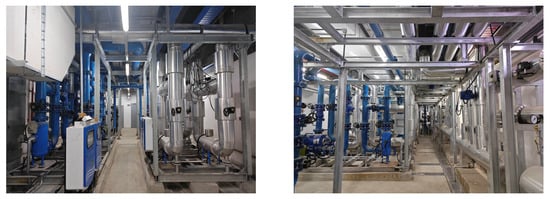

During the on-site installation phase, the prefabricated mode integrates 3D laser scanning technology for site verification and acceptance, replacing traditional welding with “flange docking and bolt fastening” (see Figure 9). This approach eliminates open flame operations, significantly reducing safety risks while leveraging the high precision of prefabricated components to shorten the commissioning and rectification period from an average of 5 days to just 2 days—virtually eliminating the repeated rework inherent in the traditional mode due to poor weld sealing integrity.

Figure 9.

Installation diagram of pipeline system between station equipment of Line 18.

3.2.3. Economic Dimension Comparison

Based on construction cost records (including materials, labor, and equipment rental details) of inter-equipment pipeline systems in Lines 18 and 4, coupled with qualitative feedback from cost engineers and operation/maintenance managers (e.g., operation teams emphasized high long-term leakage maintenance costs in the traditional mode), this section quantifies the economic performance differences between the two modes from short-term construction costs and 30-year long-term operation costs. Surveys and calculations indicate similar per-square-meter construction costs across different equipment rooms; thus, the economic comparison focuses on a single chilled water plant, excluding management costs, corporate profits, discount rates, and annual growth rates of labor operation/maintenance and equipment repair costs. Line 18, a PPP project with a 30-year concession period, has its comparative calculations presented in Table 5.

Table 5.

Comparison and calculation table of different modes of 30-year full cycle cost of single room equipment room of Line 18 (CNY 10,000).

During the construction phase, the prefabricated mode demonstrated significant labor cost savings of CNY 202,600 per equipment room pipeline system compared to the conventional approach. However, after offsetting additional expenses related to model optimization, materials (primarily increased flange connections for pipe segments), transportation (elevated handling complexity and trip frequency), and equipment rental (supplementary positioning and verification instruments), the prefabricated mode resulted in a marginal net increase of CNY 37,400. This outcome aligns with findings from multiple existing studies on similar prefabricated applications, confirming a nominal 1.8% cost increment that falls within expected parameters for initial implementation cycles [].

The pipeline system in chilled water rooms (including chiller connection pipes, valve assemblies, and flanges) demands higher welding precision and system sealing integrity than conventional pipelines. The prefabricated mode, with its standardized factory processing achieving 100% weld inspection qualification rate, significantly reduces leakage risks during the operation and maintenance phase. In contrast, the traditional mode’s reliance on manual on-site welding results in higher maintenance frequency, creating a cumulative 30-year maintenance cost differential of CNY 1.05 million. This further highlights the economic advantage of the prefabricated approach in chilled water room applications.

The project utilizes galvanized steel pipes with a typical service life of 30–40 years. According to project requirements, the pipeline system must be replaced before being transferred to the local government after 30 years of operation. The prefabricated mode allows for direct disassembly and replacement, achieving cost savings of approximately CNY 296,900 (a 35% reduction) compared to the conventional method. Overall, the prefabricated mode demonstrates a 30-year full-life-cycle cost of CNY 2.0841 million versus the traditional mode’s CNY 3.3936 million, realizing 38.6% savings and validating its economic superiority in long-term operation scenarios for mountain rail transit systems.

4. Discussion

Mountain rail transit systems, characterized by rugged terrain, significant elevation changes, and spatially constrained station equipment rooms, face compounded challenges from a shrinking skilled labor force and tight construction schedules. Within this context, traditional on-site construction methods for equipment room pipeline systems reveal pronounced limitations, including protracted project durations, inconsistent quality control, and multi-disciplinary coordination complexities. This study addresses these sector-wide challenges through a comparative analysis of two seminal cases: the prefabricated mode implemented in Line 18 versus the conventional construction approach utilized in Line 4. By systematically examining these contrasting methodologies, the research provides breakthrough insights into scene-specific adaptation for PPMRR. In response to the distinctive constraints of “spatial confinement, complex topography, and schedule intensity” endemic to mountainous regions, the study establishes an integrated technical framework encompassing “design optimization—prefabricated processing–mountain-area transportation–modular installation”. This holistic methodology rectifies the industry’s prevailing oversight of long-term value, which often leads to exaggerated emphasis on short-term construction costs associated with prefabrication. The proposed mountain-adapted prefabricated ecosystem effectively mitigates two fundamental pain points of traditional on-site construction: prolonged project timelines and quality variability. Nevertheless, several optimization opportunities remain in the implementation of the prefabricated mode for PPMRR, indicating pathways for further refinement.

4.1. Design Model Optimization

This section focuses on the core issues and optimization approaches of the prefabrication mode in the design stage, integrating two field surveys (covering model decomposition, prefabrication drawing issuance, and related links) during the design optimization phase of Line 18, common problems identified by the design team (including 3 MEP designers and 1 BIM engineer)—such as “the preliminary design does not incorporate mountain spatial constraints”—alongside differences in design schemes between the two lines and mountain adaptability in this study.

During the traditional construction drawing design phase for the equipment room pipeline systems at Line 18’s stations, key constraints related to prefabrication production, transportation, and on-site assembly were not adequately incorporated. Consequently, during the BIM model optimization and decomposition process, the prefabrication scheme exhibited mismatches with fabrication capabilities, incompatibility with transportation channel capacities, and insufficient consideration for on-site spatial limitations. Chongqing’s mountainous topography further severely exacerbated these construction constraints. Narrow construction access routes (with minimum widths of 1.2 m) and undulating site conditions restricted component handling paths, necessitating additional custom-designed adaptive connectors (such as multi-specification angled elbows) for prefabricated components.

The prefabricated mode in this project failed to reach its full potential due to a critical implementation gap: the absence of unified spatial planning for equipment rooms during the initial design phase of station construction drawings. This oversight resulted in significantly divergent pipeline room layouts across different stations within the same line, forcing model optimization into customized one-to-one approaches that frequently triggered model decomposition rework. Consequently, costs for BIM optimization, component refabrication, transportation, and project execution spiraled, ultimately undermining the economic viability of the prefabricated approach. This situation reveals a fundamental fragmentation in the current traditional construction drawing design process, particularly for MEP systems. The design optimization for prefabrication remains disconnected from the initial architectural design, often requiring implementation by third-party design teams at later stages, which inherently limits its effectiveness and integration.

In the interview, the design optimization team suggested that in the early stage of the project, the pipeline well, equipment room and transportation path planning should be integrated. In the construction drawing design or BIM model creation, the “prefabricated BIM model transformation connection list” should be formulated, and the six core parameters that need to be supplemented should be clarified: prefabricated factory parameters, transportation constraint parameters, material adaptation parameters, on-site space parameters, operation and maintenance reservation parameters, so as to ensure that the model disassembly scheme is compatible with the whole process of prefabrication, realize the standardized layout of pipeline system between equipment, reduce the amount of customized design work, and avoid potential conflicts on the construction site.

4.2. Information Chain and Collaborative Management Between Stages

Drawing on field observations of the BIM + GIS intelligent management platform application in Line 18 (documenting actual scenarios of the platform’s information transmission and multi-terminal collaboration functions), and integrating qualitative feedback from multi-department personnel (prefabrication plant leaders, construction team leaders, and design coordinators) on information collaboration efficiency in interviews (e.g., prefabrication plant personnel noted, “Offline meetings are required for module size adjustments, leading to a 3-day response delay”), this section analyzes the limitations and improvement directions of the prefabrication mode in information chain integration and inter-stage collaboration management.

Although the BIM + GIS intelligent management platform is used in Line 18, its information transmission and coordination functions are not fully utilized in the prefabricated construction of PPMRR. At the level of information transmission, although the platform integrates BIM models and GIS geographic data, it has not opened up the information links of design, prefabrication, and construction, which has repeatedly led to the disconnection between prefabrication production and the on-site construction rhythm.

At the level of collaborative efficiency, the multi-terminal function of the platform is not used for dynamic collaboration: the prefabricated factory finds the conflict between the component and the site space during the production process (such as the 1.2 m width limit of the underground channel), and needs to adjust the module size, but it cannot initiate the platform collaborative request in real time through the mobile terminal. It still needs to organize offline meetings, and the design change response time is extended from 1 day to 3 days.

In the interview, a number of high-level interviewees suggested that a full-cycle collaborative framework should be built with the platform as the core, and an information full-chain management system of “source planning-full chain connection-standard unification” should be established. In the project approval stage, the prefabricated factory and the transportation unit are included in the initial users of the platform, and it is clear that the design institute needs to share the BIM model through the platform in the scheme design stage, and cooperate with the prefabricated factory to determine the component splitting rules. The construction unit uploads the parameters of storage and hoisting equipment through the platform in advance, and plans the arrival rhythm of the components with the transportation team; standardize the two-dimensional code information of components (including processing parameters, quality inspection reports, operation and maintenance cycles), and install NFC chips in the underground area to realize offline information reading; regularly carry out platform collaborative training to improve information operation proficiency. The respondents agreed that if the potential of the prefabricated mode is fully utilized, the efficiency of departmental collaboration can be significantly improved, and the on-site construction period of PPMRR can be shortened to 14 days compared with the traditional mode.

4.3. The Supporting Professional Level of Prefabricated Mode

This section examines the supporting professional capabilities of the prefabrication mode across management, processing, transportation, and construction, drawing on field visits to the prefabrication plant (observing workers’ operation of semi-automatic equipment) and construction site (recording constructors’ component docking processes), and integrating qualitative feedback on professional capability gaps from managers and front-line operators (including 2 project managers, 3 prefabrication plant workers, and 2 on-site constructors) in interviews (e.g., project managers noted, “Insufficient experience in mountain terrain management tends to cause mismatches between components and transportation routes”).

The prefabrication mode has significant advantages over traditional construction, but it has higher professional requirements for managers: it is necessary for them to have the overall planning ability for mountain prefabrication and incorporate the constraints of mountain transportation and the narrow space characteristics between equipment into management; otherwise, mismatches between component size and transportation clearance, and conflicts between component stacking and construction movement paths are prone to occur. The management personnel’s ability to control the mountain scene is insufficient, and the whole process of prefabricated collaborative management and control cannot be realized.

At the factory processing stage, most prefabrication factories are converted from traditional industrial plants. Consequently, their processing staff—mostly former on-site welders or general technicians—lack expertise in specialized pipeline prefabrication for rail transit equipment rooms. There is insufficient understanding of the special process of pipeline prefabrication between rail transit equipment: there is a lack of precognition that the size of mountain components needs to be adapted to tunnel height limits and channel widths, and frequent deviations between design and finished products in the processing link; moreover, most of the prefabrication plants use semi-automatic processing equipment, and it is difficult to adapt the skills of transformation workers to such equipment, which aggravates the problems of low processing efficiency and fluctuation in the finished product qualification rate.

In the process of component transportation, there is no national or local standard for the whole process of “packaging–loading and unloading–transportation” (only supporting the standard of support and hanger components). This gap has a more significant impact on the mountain rail transit scene: mountain transportation has problems such as tunnel clearance and road bumps. The lack of uniform standards leads to different levels of component packaging protection, and some components have scratches in the anticorrosive layer and interface deformation due to insufficient packaging.

At the site construction end, the skills of traditional construction workers are not aligned with the needs of prefabricated modes: they are used to the long-term manual welding and assembly of parts on site, and have low adaptability to the “millimeter-level assembly accuracy” of prefabricated components; especially in mountainous areas, the clearance between equipment is narrow and the pipelines are dense. The components need to be accurately aligned in a limited amount of space. Traditional workers lack such refined operational experience, which means they are prone to docking deviation. In addition, workers have insufficient application ability with prefabricated information tools (two-dimensional code/NFC reading, BIM-assisted positioning). When the network of underground areas in mountainous areas is weak, obstacles to tool use aggravate low assembly efficiency, and even cause quality problems due to parameter misreading.

In the interview, many senior executives of the interviewed units suggested that managers should participate in the special training of mountain prefabrication and coordination, be familiar with terrain constraint management, optimize the mountain coordination function of the BIM + GIS platform, and shorten the response time of design changes. The factory side should customize special training for transformation workers, upgrade automatic processing equipment, and formulate process standards to reduce design-finished product deviations; the special standard of “packaging–loading and unloading–transportation” should be issued in the transportation link to promote RFID + GPS digital tracking. The construction side should build a 1:1 simulation scenario to train workers to use precision assembly and offline information tools, configure technical instructors, and establish a skill certification mechanism to improve on-site operation capabilities.

4.4. Limitations of This Study

This study acknowledges three primary limitations. First, the case scope remains relatively narrow, with core data sourced exclusively from Chongqing Line 18 and Line 4. The research does not incorporate projects from other mountainous cities (e.g., Guiyang, Kunming), and the impact of diverse mountain topographies (e.g., karst landscapes, deep canyons) on the prefabricated mode remains unaddressed, which may limit the geographical generalizability of the findings. Second, the full-life-cycle cost calculations do not account for the discount rate or fluctuations in raw material and labor costs, potentially leading to deviations from real-world scenarios. Third, while the study emphasizes schedule and economic dimensions, it does not analyze the long-term durability of prefabricated components, climatic impacts, or policy constraints, indicating that the research scope requires further expansion.

5. Conclusions

This study addresses the core industry challenges of strong topographic constraints, limited spatial resources, and difficulties in full-life-cycle management in PPMRR. Using Chongqing Rail Transit as an empirical context, it adopts a mixed-methods approach combining a case study, field investigation, and semi-structured interviews to systematically examine the transformative path of the prefabricated mode versus traditional construction methods, along with its mountain adaptation mechanisms, in terms of schedule, technical, and economic dimensions.

The research confirms that the prefabricated mode, through restructuring the entire workflow of “design optimization–factory prefabrication–mountain transportation–modular installation,” effectively adapts to mountainous constraints and resolves the pain points of traditional approaches. Schedule dimension: The prefabricated mode reduces the total project duration for PPMRR by 62–70% compared to the conventional approach. Economic dimension: The prefabricated mode achieves 38.6% savings in 30-year full-life-cycle costs relative to traditional methods. However, limitations persist, including inadequate incorporation of design constraints, information coordination gaps, and low workforce skill adaptability. The findings can be directly applied to equipment room pipeline projects in mountain urban rail transit, providing practical guidance for parameter integration during the design phase and collaborative management during construction. They also offer an empirical basis for skill development programs in construction enterprises and the formulation of local standards for transporting prefabricated components in mountainous areas. Subsequent studies may focus on developing standardized systems for mountain-specific prefabricated components, scenario-based iterations of digital collaboration platforms, and dynamic calculation models for full-life-cycle costs, thereby further promoting the scalable application of prefabricated technology in mountain rail transit.

Author Contributions

Conceptualization, J.W., H.C., and K.Z.; methodology, C.W. and Y.Z.; formal analysis, G.L., J.W., Q.L., and Z.L.; writing—review and editing, C.W., B.H., and Y.O.; Writing—original draft, B.H. and Y.O.; project administration, G.L. and Z.L.; resources, G.L. All authors have read and agreed to the published version of the manuscript.

Funding

The APC was funded by the Chongqing Construction Science and Technology Plan Project ‘Research on Low-carbon Rail Transit Modular Machine Room Product Line’ (Chengkezi 2022, No.5-12).

Institutional Review Board Statement

The study was conducted in accordance with the Declaration of Helsinki and approved by the Institutional Review Board of Chongqing University of Science and Technology (February 2023).

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

In this paper, due to some of the data not being disclosable, general language is used instead.

Acknowledgments

We thank Chongqing Rail Transit Line 18 Construction and Operation Co., Ltd., Chongqing Lizhi Technology Co., Ltd., Massey University of New Zealand, Chongqing University of Science and Technology, and T. Y. Lin International China for their support of the work of this thesis.

Conflicts of Interest

T. Y. Lin International China is the project contractor. Chongqing Rail Line 18 Construction and Operation Co., Ltd., is the main responsible unit of the project. Chongqing Lizhi Technology Co., Ltd., is a prefabricated manufacturer of pipeline systems between the engineering equipment of Chongqing rail transit line 18. When writing papers, the authors from these three institutions are responsible for the technical analysis.

Appendix A

Table A1.

Multi-stage semi-structured interview design table.

Table A1.

Multi-stage semi-structured interview design table.

| Correspondence Stage of Respondents | Core Research Direction | Semi-Structured Interview Questions |

|---|---|---|

| Design Phase (including BIM model optimization) |

1. Interdisciplinary collaboration and optimized disassembly;

2. Model-field precision matching; 3. Economic control in the modeling stage; | 1. Does the prefabrication mode impose limitations in your construction drawing design? If yes, what are they? 2. When optimizing the BIM model, what are the high-frequency difficulties and solutions of cross-disciplinary coordination? What are the standards and difficulties of pipe disassembly? 3. How do you align the fineness of the pipeline model between the platform equipment with the on-site accuracy? Has there ever been a case of rework due to precision deviation? If yes, can you share cases and improvements? 4. What are the main costs of the BIM phase? How much cost savings can be achieved through model optimization? |

| Pipeline Prefabrication Phase | 1. Prefabrication Process Bottlenecks and Precision Control; 2. Prefabrication Phase Cost Optimization; | 1. From prefabrication drawing review to component delivery, what is the most critical bottleneck process in the entire workflow? How would you recommend optimizing it? 2. Where do the main precision challenges lie in pipeline processing? If discrepancies between components and the BIM model are identified during re-inspection, how would you resolve them? 3. What proportion of total costs do raw materials account for in the prefabrication phase? What level of cost optimization could be achieved through procurement improvements and waste reduction? Is the current labor allocation appropriately aligned with the prefabrication schedule? |

| Prefabricated Component Transportation Phase | 1. Transportation-Warehousing Coordination and Risk Management; 2. Economic Optimization of Transportation and Warehousing; | 1. What specific transportation plan would you develop for prefabricated components (e.g., securing methods, route selection)? How would you mitigate risks such as impact damage? How should conflicts between transportation and on-site construction (e.g., storage area arrangements, hoisting operations) be coordinated? 2. Which factors significantly influence transportation costs (e.g., vehicle rental, reinforcement materials)? To what extent can transportation expenses be reduced through route optimization and shipment consolidation? How do storage methods impact component damage rates and the efficiency of secondary transportation? |

| On-site Prefabricated Installation and Construction Phase | 1. Model-On-site Matching and Rework Prevention; 2. Installation Process Optimization; 3. Installation Phase Cost Control and Management; | 1. When discrepancies are identified between BIM models and field conditions (e.g., structural dimensional deviations), how would you address them? What impact would such discrepancies have on installation efficiency? How are common rework issues identified during acceptance inspections (e.g., interface leakage) correlated with construction techniques and worker operations? 2. What are the key technical challenges in component assembly (e.g., flange sealing, pipeline slope control)? What specific improvements in construction techniques would you recommend? 3. What are the respective proportions of labor and equipment costs during the installation phase? To what extent could costs be reduced through shift scheduling optimization and equipment idle time reduction? |

| Post On-site Construction Acceptance | 1. Labor and Schedule Profiles: Prefabricated vs. Conventional Modes; 2. Comparative Evaluation of Full-Life-Cycle Economics; | 1. When comparing prefabricated installation with the conventional mode, what are the fundamental differences in personnel allocation (specialization of labor, skill requirements) and overall project timeline? What are the underlying reasons? How do these differences impact labor costs? 2. In which specific phases (design → prefabrication → transportation → installation → maintenance) are the most significant differences in full lifecycle costs manifested between the two modes? At what stage do the cost advantages of the prefabricated mode (such as maintenance savings) typically become apparent? 3. What is the return on investment for the upfront additional investments in the prefabricated mode (e.g., BIM software, prefabrication equipment)? What factors primarily support its economic advantages (e.g., benefits from shortened project durations)? |

References

- Shahtaheri, Y.; Rausch, C.; West, J.; Haas, C.; Nahangi, M. Managing risk in modular construction using dimensional and geometric tolerance strategies. Autom. Constr. 2017, 83, 303–315. [Google Scholar] [CrossRef]

- Jang, S.; Lee, G. Process, productivity, and economic analyses of BIM–based multi-trade prefabrication—A case study. Autom. Constr. 2018, 89, 86–98. [Google Scholar] [CrossRef]

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Guiding Opinions on Promoting the Collaborative Development of Intelligent Construction and Building Industrialization; Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2020. Available online: http://www.gov.cn/zhengce/zhengceku/2020-07/28/content_5530762.htm (accessed on 28 May 2025).

- Hu, R.; Chen, K.; Fang, W.; Zheng, L.; Xu, J. The technology-environment relationship revisited: Evidence from the impact of prefabrication on reducing construction waste. J. Clean. Prod. 2022, 341, 130883. [Google Scholar] [CrossRef]

- Liu, W. Practice of Prefabricated Mechanical and Electrical Installation in Urban Rail Transit. Build. Constr. 2021, 43, 2360–2363. [Google Scholar]

- Dong, C.; Wang, H.; Zhang, H.; Zhang, M.; Guan, J.; Zhang, Z.; Lin, Q.; Zuo, Z. Research on Fine Scheduling and Assembly Planning of Modular Integrated Building: A Case Study of the Baguang International Hotel Project. Buildings 2022, 12, 1892. [Google Scholar] [CrossRef]

- Baek, S.; Won, J.; Jang, S. Economic Integrated Structural Framing for BIM-Based Prefabricated Mechanical, Electrical, and Plumbing Racks. Appl. Sci. 2023, 13, 3677. [Google Scholar] [CrossRef]

- Banihashemi, S.; Tabadkani, A.; Hosseini, M.R. Integration of parametric design into modular coordination: A construction waste reduction workflow. Autom. Constr. 2018, 88, 1–12. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Fung, I.W.H.; Sing, M.C.P.; Ogunlana, S.O. Best practice of prefabrication implementation in the Hong Kong public and private sectors. J. Clean. Prod. 2015, 109, 216–231. [Google Scholar] [CrossRef]

- Sweis, G.; Sweis, R.; Hammad, A.; Shboul, A. Delays in construction projects: The case of Jordan. Int. J. Proj. Manag. 2008, 26, 665–674. [Google Scholar] [CrossRef]

- Li, Z.; Shen, G.Q.; Xue, X. Critical review of the research on the management of prefabricated construction. Habitat Int. 2014, 43, 240–249. [Google Scholar] [CrossRef]

- Zhang, W.; Lee, M.W.; Jaillon, L.; Poon, C.S. The hindrance to using prefabrication in Hong Kong’s building industry. J. Clean. Prod. 2018, 204, 70–81. [Google Scholar] [CrossRef]

- Li, X.; Li, Z.; Wu, G. Modular and Offsite Construction of Piping: Current Barriers and Route. Appl. Sci. 2017, 7, 547. [Google Scholar] [CrossRef]

- Khanzode, A.; Fischer, M.A.; Reed, D.A. Benefits and lessons learned of implementing building virtual design and construction (VDC) technologies for coordination of mechanical, electrical, and plumbing (MEP) systems on a large healthcare project. J. Inf. Technol. Constr. 2008, 13, 324–342. [Google Scholar]

- Zhang, Y.; Bai, X.; Dong, D.; Liu, C.; Li, B. Modular installation technology of MEP pipelines on the standard floor of super high-rise buildings. Installation 2019, 9, 53–56. [Google Scholar]

- Zhu, X.; Gao, Y. Discussion on modular design and construction of hospital data center computer room. Chin. J. Health Inf. Manag. 2022, 19, 551–555. [Google Scholar]

- Tommelein, I.D.; Gholami, S. Root causes of clashes in building information models. In Proceedings of the 20th Annual Conference of the International Group for Lean Construction, San Diego, CA, USA, 18–20 July 2012; pp. 1–10. [Google Scholar]

- Korman, T.M.; Simonian, L.; Speidel, E. Using Building Information Modeling to Improve the Mechanical, Electrical, and Plumbing Coordination Process for Buildings. J. Inf. Technol. Constr. 2008, 13, 1–10. [Google Scholar]

- Riley, D.R.; Varadan, P.; James, J.S.; Thomas, H.R. Benefit-Cost Metrics for Design Coordination of Mechanical, Electrical, and Plumbing Systems in Multistory Buildings. J. Constr. Eng. Manag. 2005, 131, 877–889. [Google Scholar] [CrossRef]

- Korman, T.M.; Fischer, M.A.; Tatum, C.B. Knowledge and Reasoning for MEP Coordination. J. Constr. Eng. Manag. 2003, 129, 627–634. [Google Scholar] [CrossRef]

- Yu, Y.; Zhang, J.; Yin, K. Application of modular MEP production and processing equipment in engineering. Installation 2022, 23, 23–25. [Google Scholar]

- Liu, S.; Zhang, N.; Chen, G.; Chen, H. Application of pipeline modular prefabrication and Prefabricated construction in large refrigeration room. Construction 2022, 44, 367–370. [Google Scholar]

- Bataglin, F.S.; Viana, D.D.; Formoso, C.T.; Bulhões, I.R. Model for planning and controlling the delivery and assembly of engineer-to-order prefabricated building systems: Exploring synergies between Lean and BIM. Can. J. Civ. Eng. 2020, 47, 165–177. [Google Scholar] [CrossRef]

- Said, H. Modeling and likelihood prediction of prefabrication feasibility for electrical construction firms. J. Constr. Eng. Manag. 2016, 142, 04015071. [Google Scholar] [CrossRef]

- Samarasinghe, T.; Gunaratna, M.M.M.P.; Feng, H.; Weerasuriya, T.U.; Yigitcanlar, T. Dependency Structure Matrix and Hierarchical Clustering based algorithm for optimum module identification in MEP systems. Autom. Constr. 2019, 104, 153–178. [Google Scholar] [CrossRef]

- Safa, M.; Shahi, A.; Nahangi, M.; Haas, C.; Noori, H. Automating measurement process to improve quality management for piping fabrication. Structures 2015, 3, 71–80. [Google Scholar] [CrossRef]

- Pan, Z.; Yang, R.; Yang, Z.; Liu, D.; Zhang, Y. Recovering building information model from 2D drawings for mechanical, electrical and plumbing systems of ageing buildings. Autom. Constr. 2023, 152, 104914. [Google Scholar] [CrossRef]

- Valkonen, T.; Alhava, O.; Viitanen, J.; Seppänen, O. Why do some projects prefabricate MEP while others do not? Lean Constr. J. 2025, 2025, 96–124. [Google Scholar] [CrossRef]

- Yan, G.; Liu, S.; Wang, H.; Ma, G.; Wang, L. A review of life cycle construction process and cutting-edge technology in prefabricated MEP installation engineering. Buildings 2024, 14, 630. [Google Scholar] [CrossRef]

- Antillón, E.I.; Morris, M.R.; Gregor, W. A value-based cost-benefit analysis of prefabrication processes in the healthcare sector: A case study. In Proceedings of the 22nd Annual Conference of the International Group for Lean Construction, Oslo, Norway, 25–27 June 2014; pp. 995–1006. [Google Scholar]

- McGraw Hill Construction. Prefabrication and Modularization: Increasing Productivity in the Construction Industry; McGraw Hill: New York, NY, USA, 2011; Available online: https://www.smacna.org/docs/default-source/resource-documents/prefabrication-modularization-in-the-construction-industry-smr-2011r.pdf?sfvrsn=e3b09a24_1 (accessed on 7 January 2025).

- Jaillon, L.; Poon, C.S. Sustainable construction aspects of using prefabrication in dense urban environment: A Hong Kong case study. Constr. Manag. Econ. 2008, 26, 953–966. [Google Scholar] [CrossRef]

- Yin, R.K. Case Study Research and Applications: Design and Methods, 6th ed.; SAGE Publications: Singapore, 2018. [Google Scholar]

- DBJ50/T-514-2025; Application Technical Standard of ASSEMBLED comprehensive Support and Hanger. Chongqing Housing and Urban-Rural Construction Committee: Chongqing, China, 2025.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).