3D Printing in Facilities Management: A Systematic Review Toward Smart and Sustainable Building Operations

Abstract

1. Introduction

1.1. Background and Context

1.2. Literature Review

1.2.1. The Evolution of Facilities Management

1.2.2. Contemporary FM Challenges and Digital Innovation

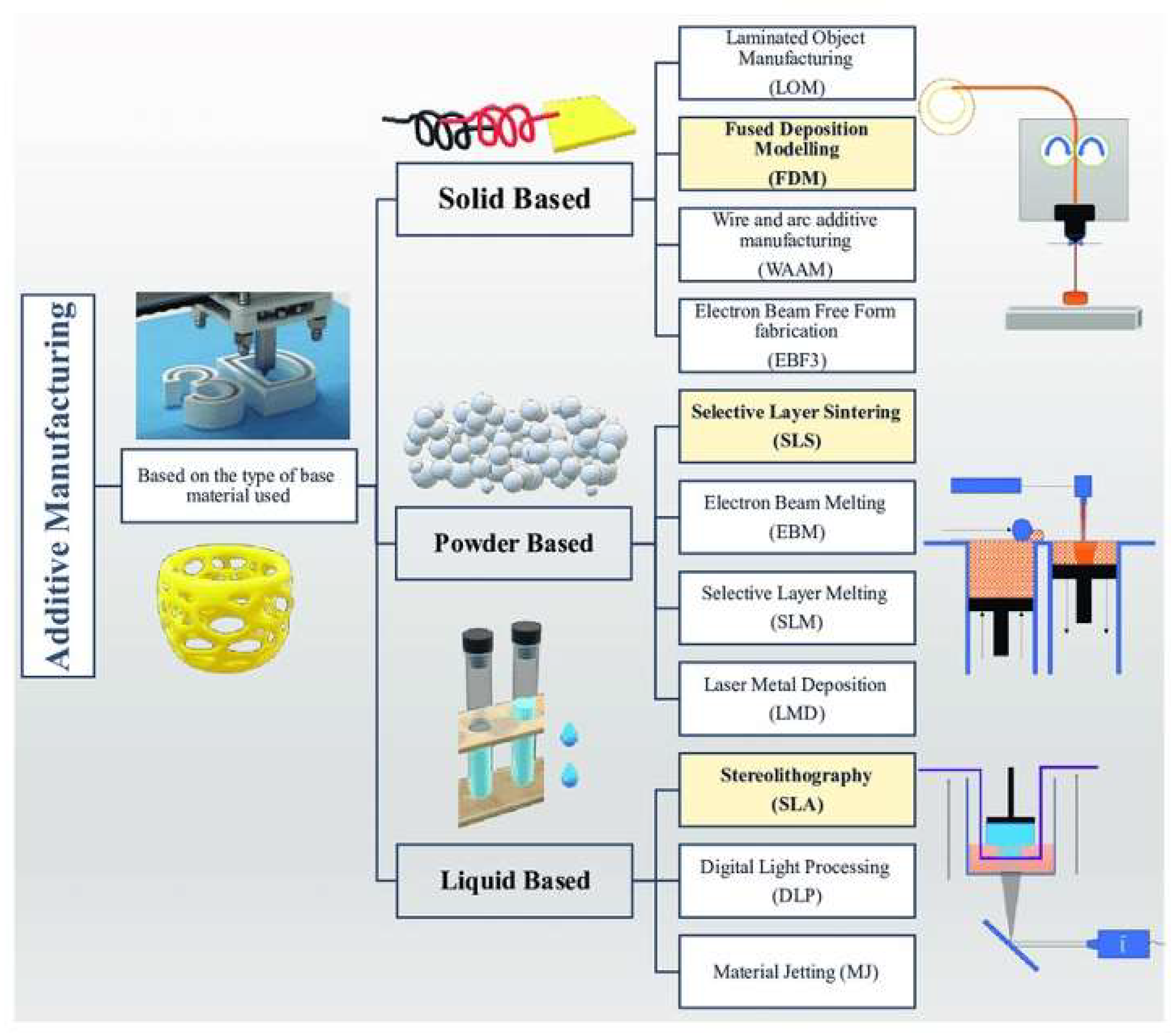

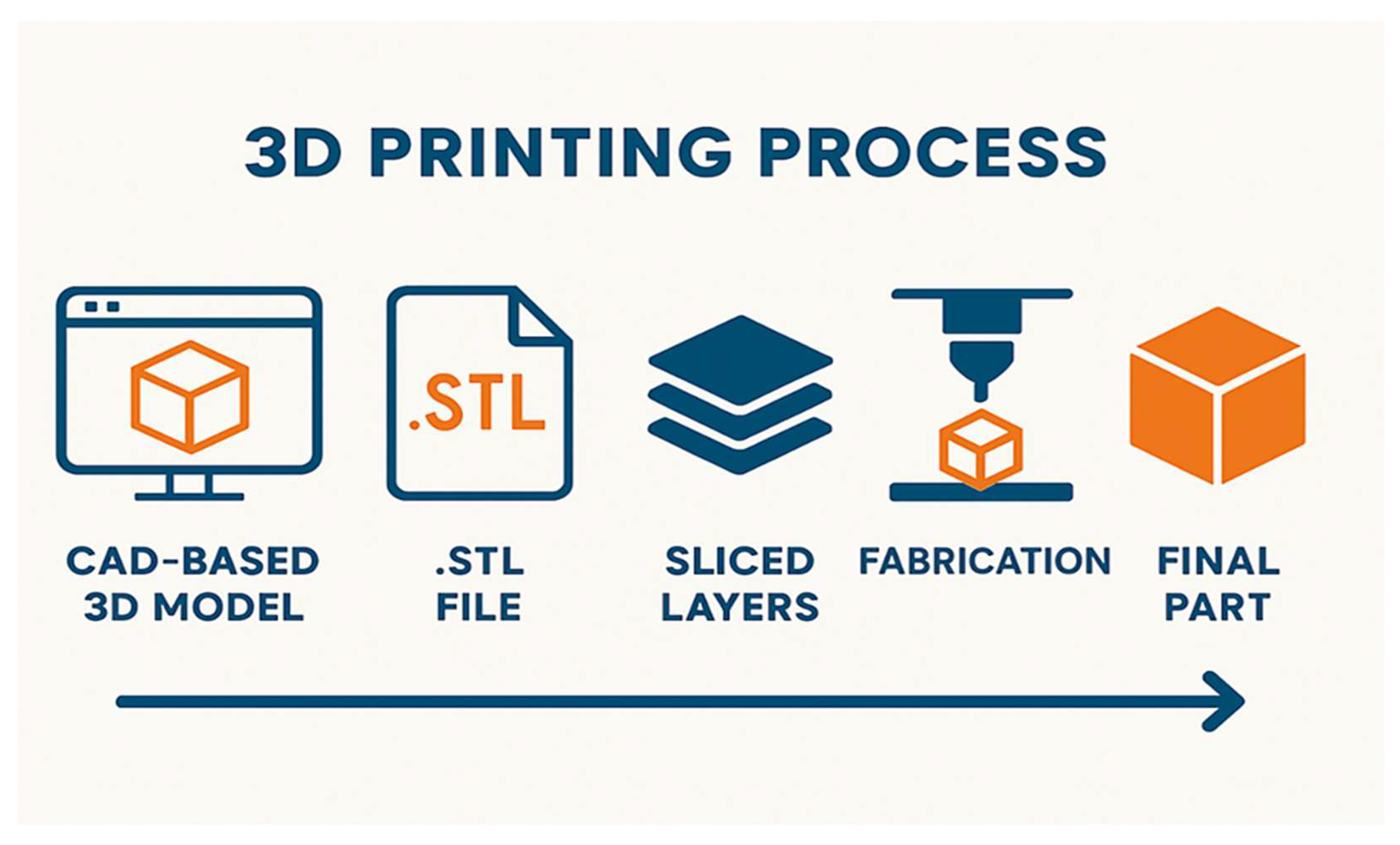

1.2.3. Overview of 3DP

1.2.4. Limitations and Challenges of 3DP Technology

1.3. Scope of Review

1.4. Problem Statement

1.5. Objectives

- Map and critically assess current 3DP applications in FM domains such as construction, maintenance, and supply chains.

- Evaluate key benefits, including on-demand, localized fabrication, reduced downtime, and sustainability gains, and major barriers to adoption, such as workforce readiness, material limitations, regulatory uncertainty, and standardization issues.

- Propose actionable recommendations for integrating 3DP with digital FM tools (e.g., BIM, digital twins) and outline a future research agenda to guide evidence-based, effective deployment.

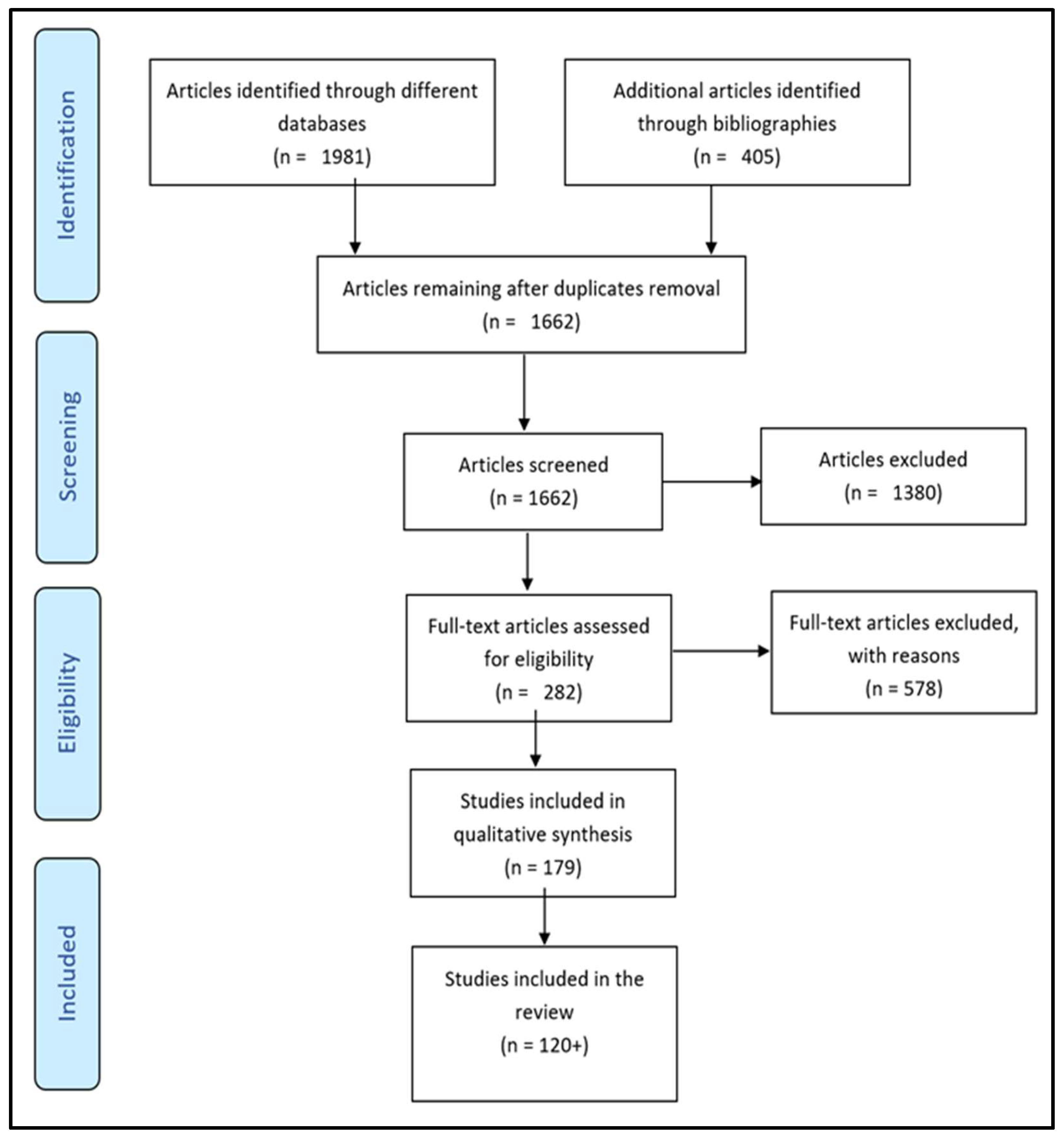

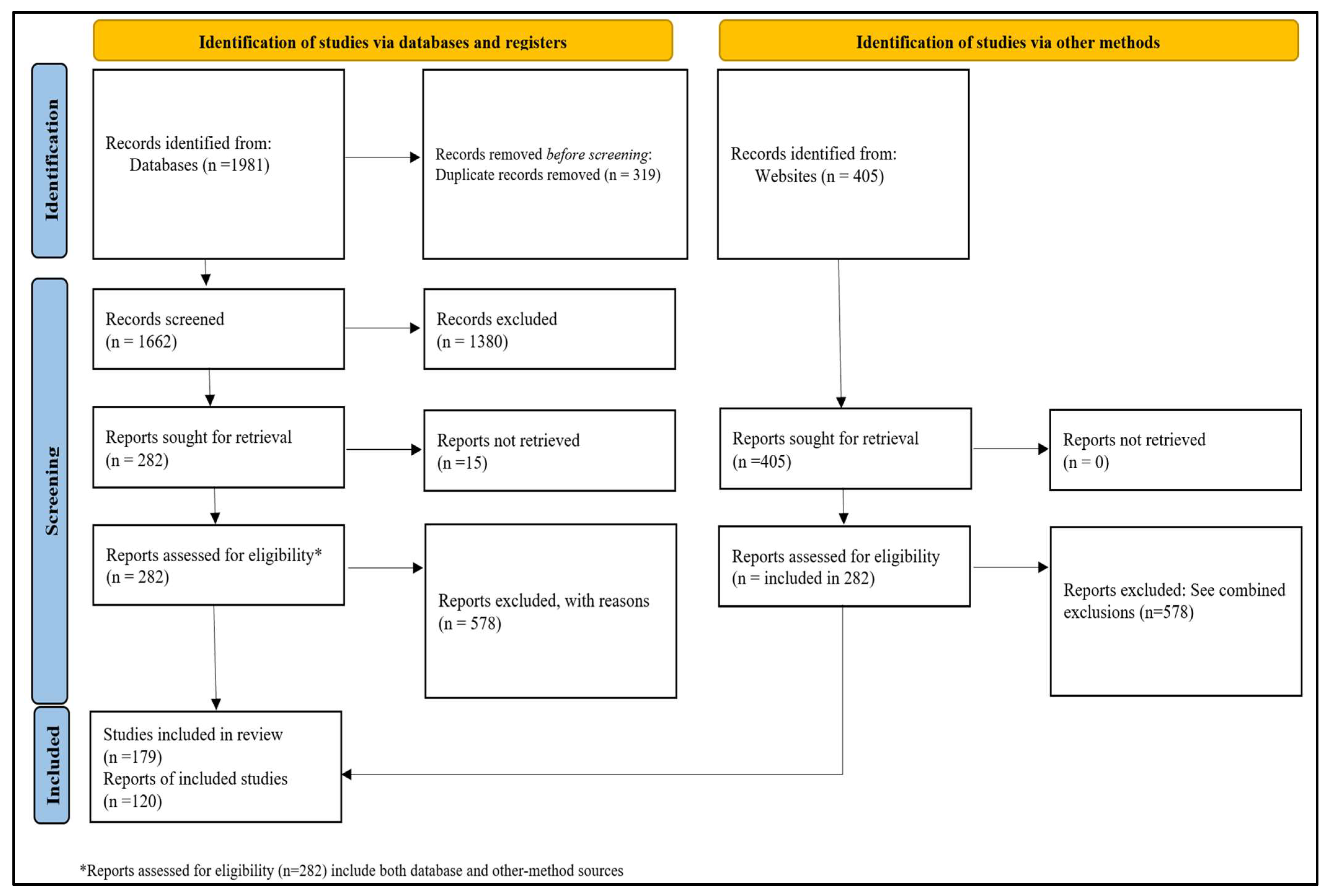

2. Methodology

2.1. Review Design

2.2. Data Collection Strategy

2.3. Screening, Inclusion, and Exclusion Criteria

- Inclusion:

- ○

- Articles focusing explicitly on 3DP/AM applications in FM-related construction, building operations, maintenance, and FM-related supply chains.

- ○

- Empirical studies, case reports, systematic reviews, and high-impact conference contributions.

- ○

- Studies published in English, post-2010.

- Exclusion:

- ○

- Duplicate records, non-English publications, and sources lacking substantive methodological description or sectoral relevance.

- ○

- Non-peer-reviewed or commercial/promotional articles.

2.4. Data Extraction and Thematic Categorization

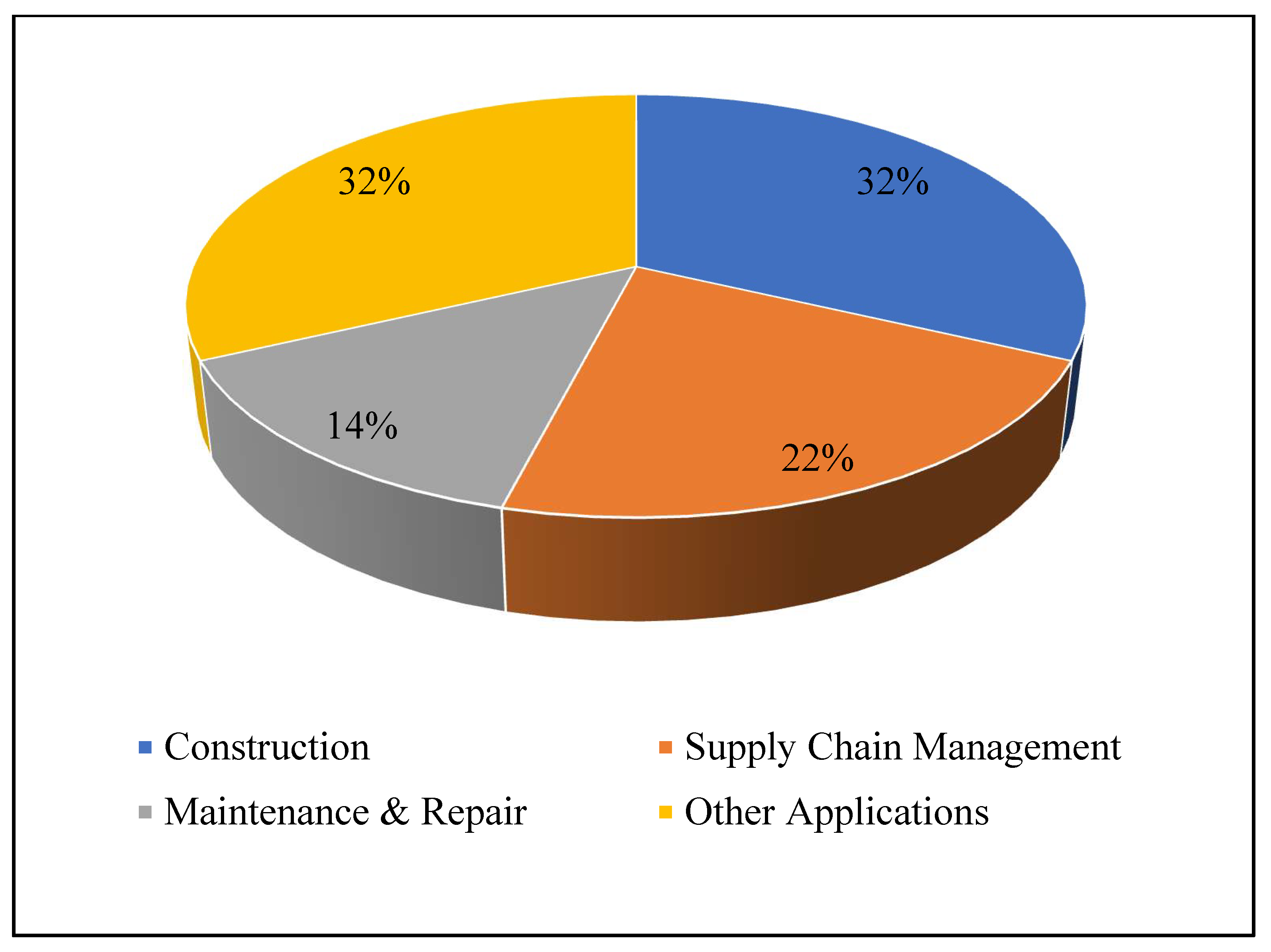

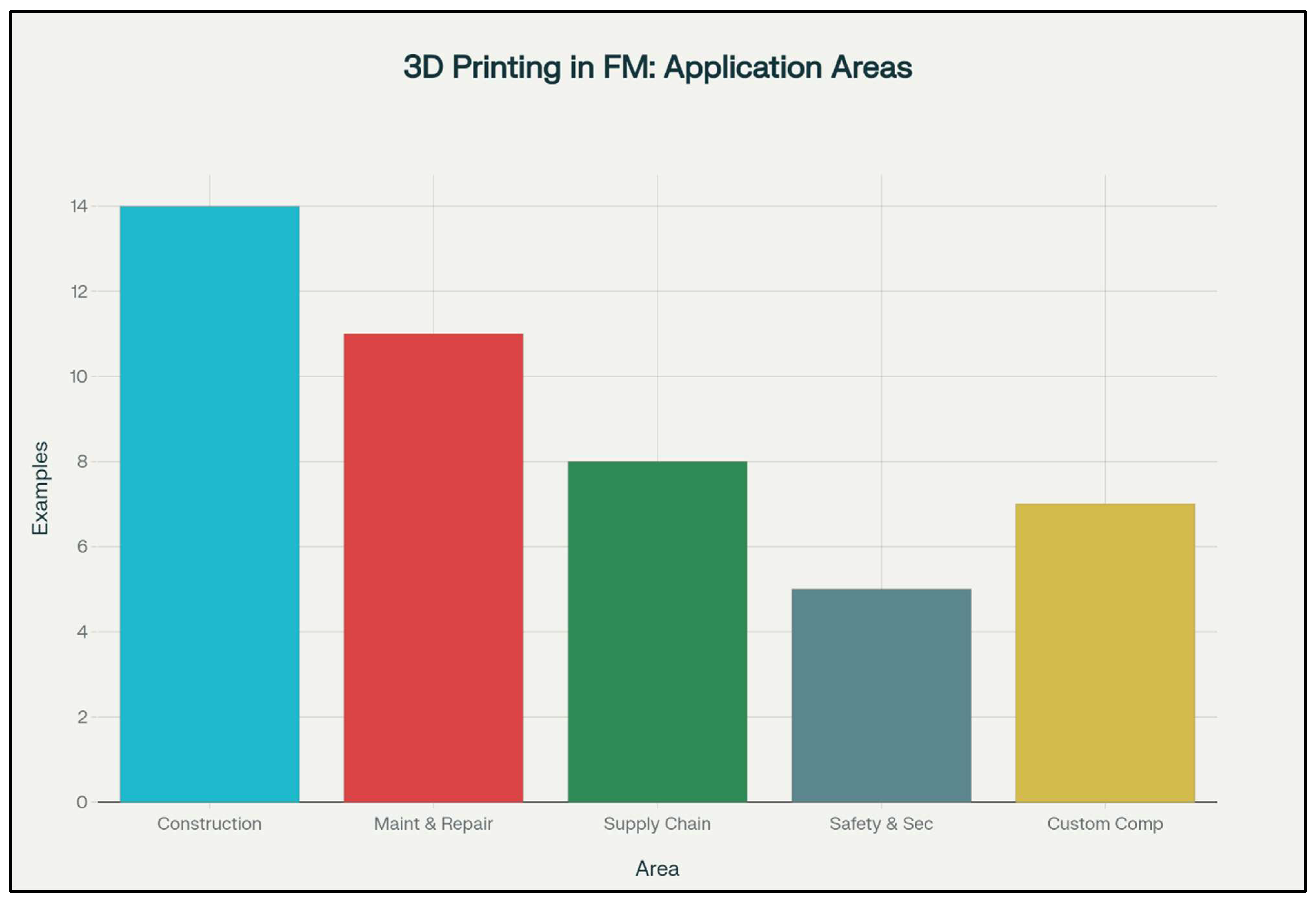

2.5. Sector Domain Distribution

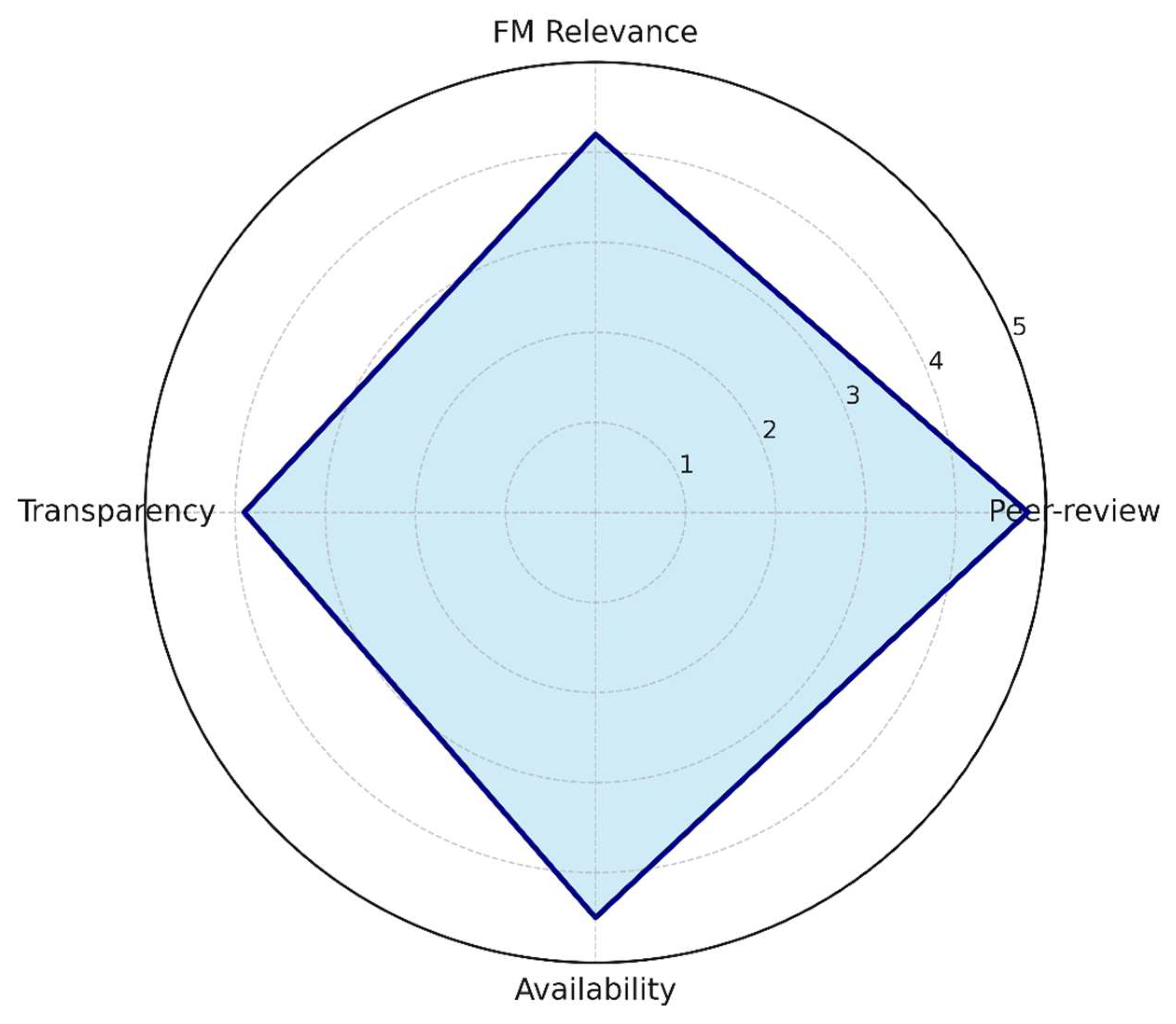

2.6. Quality Assurance and Study Assessment

3. Applications and Results

3.1. Summary of Representative Studies

3.2. Construction Applications

3.2.1. Role and Advantages

3.2.2. Case Studies and Key Innovations

3.2.3. Comparative Evaluation

3.3. Supply Chain Management (SCM)

3.3.1. Role and Advantages

3.3.2. Sectoral Examples

3.3.3. Synthesis

3.4. Maintenance and Repairs

3.4.1. Role and Advantages

- Rapid prototyping and replacement for bespoke or obsolete parts.

- Localized, in situ repair, critical for minimizing downtime in essential services.

- Environmental improvements by reducing resource needs for replacement cycles.

3.4.2. Cases and Results

| Sr. No. | Researcher | 3DP Process | M&R Specific Area | Comments |

|---|---|---|---|---|

| 1 | Wits et al. [62] | Different AM processes | Optimization of MRO | AM enables rapid customization and replacement of parts, reducing dependency on external suppliers and enhancing facility operational efficiency. |

| 2 | Kim et al. [37] | Metal AM with steel material | On-site maintenance of gaskets and O-rings using 3DP | Proposal of a part library-based information retrieval and inspection framework to support the maintenance of damaged gaskets and O-rings, validated through prototype systems |

| 3 | Kim et al. [38] | Metal AM SCS13 material | On-site repair of partially damaged parts (Ball) using 3DP technology | Proposal of a user-friendly maintenance framework including a parts catalog, automated part identification, and shape comparison for validating repairs, demonstrated with a damaged ball from a valve. |

| 4 | Yeon [40] | Concrete 3DP | Application of 3DP technology for spall repair | Proposal and environmental assessment of 3DP spall repair method as a more sustainable and efficient alternative to traditional partial-depth repair method |

| 5 | Nicolau [41] | FDM | Furniture manufacturing | 3DP connectors enhance furniture assembly efficiency and customization, offering significant benefits for FM |

| 6 | Lastra et al. [63] | Various AM processes | Preventive maintenance spare parts | Demonstrated improved maintenance strategies through AM-produced spare parts, reducing downtime and inventory costs while extending equipment lifecycles. |

| 7 | Infrastructure case study [64] | FDM/SLA | Rapid infrastructure maintenance | Real-world application showing 3DP enabling faster repair responses, particularly beneficial for remote locations and critical infrastructure systems |

| 8 | Alzahmi, Shamayleh & Stefancich [61] | Various AM technologies (systematic review) | Spare parts management (multi-sector synthesis) | Consolidated evidence across 77 studies shows AM reduces lead times, costs, and inventory, while enhancing flexibility and resilience. Identifies gaps in sustainability, quality control, and regulatory frameworks. |

3.4.3. Implementation Gaps

3.5. Summary Chart

| Facility Type | 3D Printed Part | Purpose and Description | References |

|---|---|---|---|

| Manufacturing Plants | Custom Tooling and Fixtures | Parts are tailored for specific manufacturing processes or tasks, highlighting the adaptability of 3D printing. | [69,70] |

| Prototypes | Rapidly created models for testing and validation before mass production crucial for product development. | [71,72] | |

| Replacement Parts | Components are no longer in production and are costly to store, so they are essential for machinery or vehicle maintenance. | [73] | |

| Personalized Components | Highly customized parts such as ergonomic handles or interfaces demonstrate 3D printing’s customization scope. | [51,74] | |

| Medical Facilities | Biomedical Implants and Prosthetics | Tailored to individual patient needs, including custom implants and prosthetic devices. | [75,76] |

| Architectural Firms | Architectural Models | Detailed models of buildings for planning and client presentations, aiding in visualization and planning. | [77] |

| Educational Institutions (Research/Arts & Design) | Educational Models | Scaled or abstracted models, such as anatomical models, are used in schools or universities for educational purposes. | [78,79] |

| Custom Laboratory Equipment | Tailored components for experiments such as custom Petri dishes, microscope parts, or fluidic channels. | [80] | |

| Robotics Components | Custom parts for student projects or research in robotics, including gears casings and structural elements. | [81] | |

| Engineering Prototypes | Functional prototypes for projects like vehicle parts, drones, or renewable energy solutions. | [82] | |

| Art and Design Projects | Custom sculptures jewelry or architectural models for student projects showcasing artistic applications. | [83] | |

| Theater and Film Props | Custom props for university productions ranging from historical replicas to fantastical objects. | ||

| Campus Infrastructure Parts | Small replacement parts such as custom fittings, brackets, glide components of the floor box cover, or different coverings/skirtings are needed to maintain campus facilities. | [84] | |

| Desk and Chair Components | Durable parts like chair arms, arm pads, and desk legs are often replaced due to breakage or wear. | [85] | |

| Shelving Brackets and Supports | Custom supports for heavy loads are especially useful in libraries or labs. | [84] | |

| Campus Maintenance | Handle and Knob Replacements | Replacements for broken handles and knobs on doors, drawers, and cabinets throughout campus buildings. | |

| Custom Light Fixture Parts | Unique components for light fixtures in specific areas or older buildings where replacements are hard to find. | [83] | |

| Equipment Mounts and Housing | Parts to mount or house various equipment in labs, such as camera mounts, projector housings, or computer stands. | [83] | |

| Decorative Elements | Custom elements to enhance the aesthetics of campus spaces or for specific events. | [85] | |

| Lab Fixture Components | Specific parts like clamps, stands, or holders are tailored for various laboratory setups. | [83] | |

| Chair Wheel/Caster | A tiny wheeled device is attached to the bottom of the chair legs for more effortless movement. | [86,87] | |

| Drawer Handles | Handles attached to drawers for opening and closing. | [83] |

4. Discussions

4.1. Synthesis of Findings

4.1.1. Sectoral Impact of 3D Printing in Facilities Management

4.1.2. Barriers and Bottlenecks in Implementation

- Economic and Practical Feasibility: Cost–benefit assessments remain context-dependent; initial investments in hardware, training, and digital infrastructure may be substantial.

- Regulatory and Safety Concerns: Compliance with industry, health, and safety standards lags behind technical advances; regulatory reform is needed for broad deployment, especially in healthcare and mission-critical infrastructures [90].

- Overcoming these barriers will require focused research, sector-specific pilot projects, workforce upskilling, and development of evidence-based decision-making frameworks, as highlighted in both the previous gaps section and throughout this review.

4.1.3. Synthesis with Broader Industry Trends

4.1.4. Limitations of Current Literature

4.1.5. Strategic Recommendations

4.2. Identified Research Gaps

- Lack of practical, science-based decision frameworks: There is no validated, operational model to help FM professionals systematically determine when and how to adopt 3DP over traditional methods, hindering evidence-based implementation and scaling.

- Limited economic and real-world feasibility studies: Few comprehensive cost–benefit analyses or longitudinal studies exist to quantify the long-term operational, financial, and sustainability impacts of 3DP integration in FM contexts. While recent studies have begun examining economic feasibility across different organizational scales [97], strategic cost–benefit frameworks for supply chain applications [101], and maturity models for systematic adoption [102], FM-specific economic assessments remain sparse and fragmented.

- Underexplored integration with digital FM tools: Empirical evidence and best-practice guidelines for seamless interoperability between 3DP and platforms such as BIM, IoT, and digital twins are still underdeveloped, creating barriers to digital FM transformation.

- Sector-specific barriers to standardization and certification: The establishment of industry-wide quality, safety, and regulatory standards for 3D-printed components in FM remains an unresolved challenge, especially for critical infrastructure and public-sector buildings.

- Workforce readiness and upskilling gaps: Systematic approaches for building digital and technical skills among FM staff, including hands-on training for 3DP operation and integration—are scarce, impeding broad-based adoption.

4.3. Comparative Synthesis by FM Area

| FM Application | Key Benefits | Challenges/Barriers | Evidence Strength |

|---|---|---|---|

| Construction | Complex geometries, reduced timelines [111] | Upfront CAPEX, standards, scalability [112] | Moderate |

| Maintenance/Repair | Downtime reduction, on-demand parts [113,114] | Skills, part libraries, regulatory gaps [113] | Moderate |

| Supply Chain | Localized production, lower inventory, Reduced Lead times [115,116,117] | Integration, cost, industry uptake [116,117] | Moderate |

| Furniture/Interior | Customization, improved repairs, Reduced Lead times [118,119] | Limited adoption, standards, tooling [119] | Limited/Emerging |

4.4. Comparative Cost–Benefit Insights of 3DP Applications in FM

| FM Domain | Application/Case Study | Reported Benefits | Reported Costs/Barriers | Quantified Value | Reference |

|---|---|---|---|---|---|

| Construction | CSA Cement Binder Jetting | Rapid prototype structures | High material cost; scalability concerns | Compressive strength 5.9–6.7 MPa | [36] |

| Construction | Inkjet Cement Mix | Durability improvements | High printer setup cost | Compressive strength 8.26 MPa; 49% porosity reduction | [42] |

| Sand Casting | Foundry Operations | Complex geometries, rapid production | Equipment CAPEX | 75% Cost reduction ($3960 → $990/batch) | [120] |

| Medical Models | Surgery Planning | Reduced operating time | Setup and training costs | $1500–3700 saved/case; 62 min time savings | [121] |

| Supply Chain | Spare Parts (Aerospace) | Lead time reduction weeks → hours; fleet readiness | Machine automation costs; limited throughput | Annual savings $97,900/year | [39,122] |

| Supply Chain | Space Operations (NASA/ISS) | On-demand tool fabrication in orbit | Transportation of AM hardware to space | Eliminated Earth resupply dependency | [54] |

| Maintenance | Spall Repair (Concrete 3DP | Faster repairs, reduced waste, eco-friendly | Regulatory approval pending | 30–60% inventory cost savings | [40,122,123] |

| Maintenance | Metal AM Gaskets/O-Rings | Avoided downtime, extended component life | Requires CAD libraries; technical skills | On-demand fulfillment (hours vs. weeks) | [37,120] |

4.5. Implications for Policy and Practice

4.6. Limitations of the Review

5. Future Scope and Evolution

5.1. Development and Empirical Testing of FM-Specific Decision-Support Frameworks

5.2. Comprehensive Techno-Economic and Longitudinal Assessments

5.3. Standardization, Certification, and Regulatory Adaptation for FM-Embedded 3DP

5.4. Workforce Upskilling and Targeted Educational Program Design

5.5. Digital Integration with Core FM Platforms

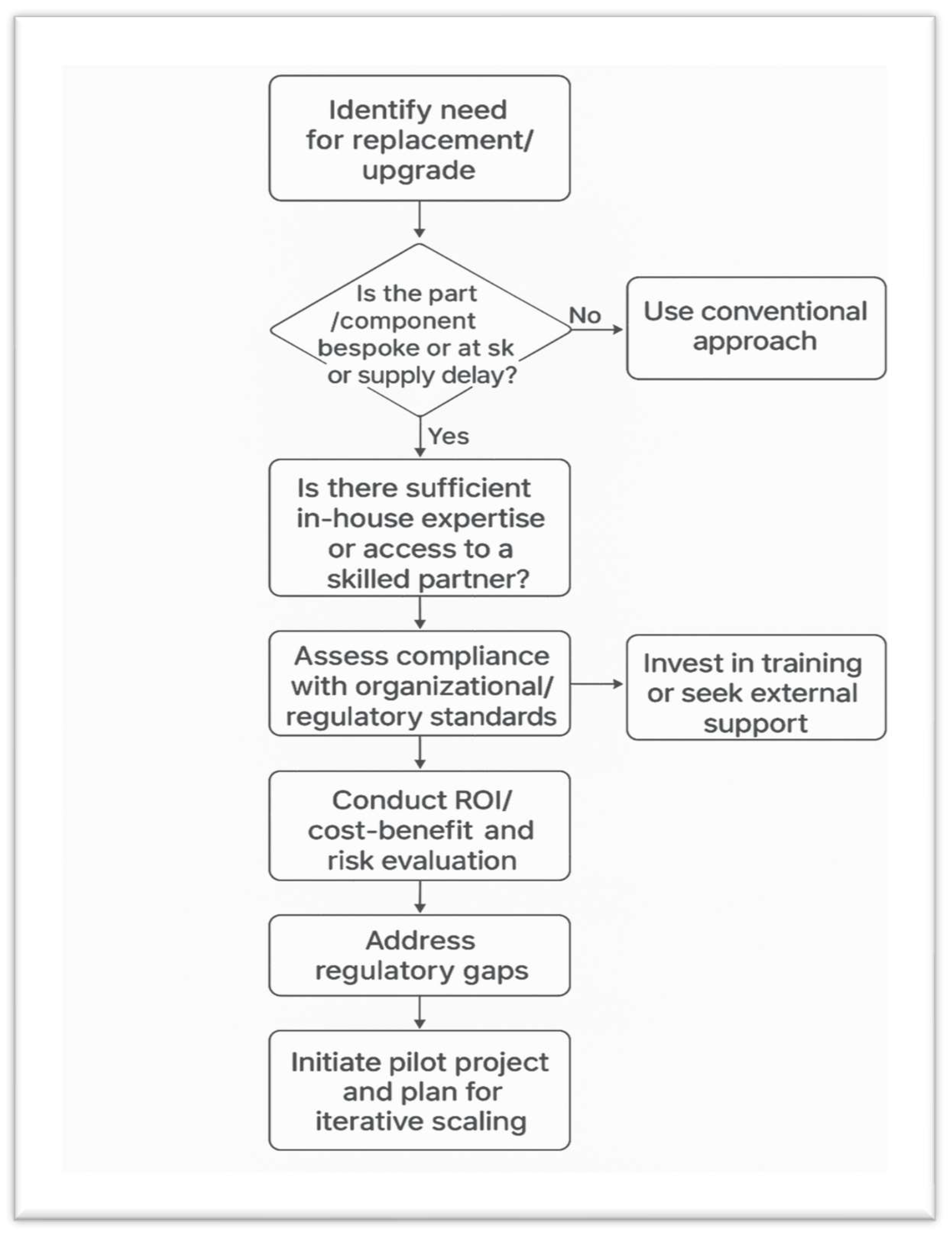

5.6. Conceptual Decision Framework for 3DP Adoption in FM

- Is the part or component adapted, or at risk of supply chain delay?

- Does the organization have sufficient in-house technical or digital expertise, or access to qualified partners?

- Are relevant regulatory or organizational standards met or achievable?

- Is there a strong business case in terms of cost, sustainability, or operational resilience?

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chotipanich, S. Positioning facility management. Facilities 2004, 22, 364–372. [Google Scholar] [CrossRef]

- Alfalah, G.; Zayed, T. A review of sustainable facility management research. Sustain. Cities Soc. 2020, 55, 102073. [Google Scholar] [CrossRef]

- Shaw, C.; Pereira, F.d.A.; McNally, C.; O’donnell, J. Facilities management domain review: Potential contributions towards digitalisation. In Proceedings of the European Conference on Computing in Construction, Online, 26–28 July 2021; pp. 123–130. [Google Scholar] [CrossRef]

- Strategic Facilities Management Framework. Available online: https://www.rics.org/profession-standards/rics-standards-and-guidance/sector-standards/real-estate-standards/strategic-facilities-management-framework (accessed on 31 October 2024).

- Adapting, Evolving, Leading: A Resilient Approach to Modern Facility Management. MEFMA. Available online: https://mefma.org/adapting-evolving-leading-a-resilient-approach-to-modern-facility-management/ (accessed on 30 August 2025).

- Alrubaidi, M. Evaluating the Effects of Digital Transformation on Facilities Management Projects in Saudi Arabia: Overcoming Challenges and Seizing Opportunities. Open J. Civ. Eng. 2024, 14, 536–569. [Google Scholar] [CrossRef]

- Moshood, T.D.; Rotimi, J.O.; Shahzad, W.; Bamgbade, J.A. Infrastructure digital twin technology: A new paradigm for future construction industry. Technol. Soc. 2024, 77, 102519. [Google Scholar] [CrossRef]

- Rynk, R.; Koerting, N.; Ziegenbein, J.; Hardin, J.; Oshins, C.; Brown, N.J.; Lilkas-Rain, D. Facility management. In The Composting Handbook; Academic Press: Cambridge, MA, USA, 2022; Available online: https://compostfoundation.org/composting-handbook/ (accessed on 25 August 2025).

- ISO 41011:2024(en); Facility Management—Vocabulary. ISO: Geneva, Switzerland, 2024. Available online: https://www.iso.org/obp/ui/#iso:std:iso:41011:ed-2:v1:en (accessed on 28 October 2024).

- What Is Facility Management? Available online: https://www.ifma.org/about/what-is-fm/ (accessed on 28 October 2024).

- Wang, T.; Ali, A.S.; Au-Yong, C.P. Exploring a body of knowledge for promoting the building information model for facility management. Ain Shams Eng. J. 2022, 13, 101717. [Google Scholar] [CrossRef]

- Pinti, L.; Codinhoto, R.; Bonelli, S. A Review of Building Information Modelling (BIM) for Facility Management (FM): Implementation in Public Organisations. Appl. Sci. 2022, 12, 1540. [Google Scholar] [CrossRef]

- Atkin, B.; Bildsten, L. A future for facility management. Constr. Innov. 2017, 17, 116–124. [Google Scholar] [CrossRef]

- Atta, N.; Talamo, C. Digital transformation in facility management (FM). IoT and big data for service innovation. In Digital Transformation of the Design, Construction and Management Processes of the Built Environment; Research for Development; Springer: Cham, Switzerland, 2020; pp. 267–278. [Google Scholar] [CrossRef]

- Motamedi, A.; Hammad, A.; Asen, Y. Knowledge-assisted BIM-based visual analytics for failure root cause detection in facilities management. Autom. Constr. 2014, 43, 73–83. [Google Scholar] [CrossRef]

- Dehghanghadikolaei, A.; Emamian, S.S.; Fotovvati, B.; Gisario, A.; Mehrpouya, M.; Vosooghnia, A. The potential of additive manufacturing in the smart factory industrial 4.0: A review. Appl. Sci. 2019, 9, 3865. [Google Scholar] [CrossRef]

- Hilal, M.; Maqsood, T.; Abdekhodaee, A. A hybrid conceptual model for BIM in FM. Constr. Innov. 2019, 19, 531–552. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Iftekar, S.F.; Aabid, A.; Amir, A.; Baig, M. Advancements and Limitations in 3D Printing Materials and Technologies: A Critical Review. Polymers 2023, 15, 2519. [Google Scholar] [CrossRef] [PubMed]

- Kafle, A.; Luis, E.; Silwal, R.; Pan, H.M.; Shrestha, P.L.; Bastola, A.K. 3D/4D Printing of Polymers: Fused Deposition Modelling (FDM), Selective Laser Sintering (SLS), and Stereolithography (SLA). Polymers 2021, 13, 3101. [Google Scholar] [CrossRef] [PubMed]

- Kanishka, K.; Acherjee, B. Revolutionizing manufacturing: A comprehensive overview of additive manufacturing processes, materials, developments, and challenges. J. Manuf. Process 2023, 107, 574–619. [Google Scholar] [CrossRef]

- Su, J.; Ng, W.L.; An, J.; Yeong, W.Y.; Chua, C.K.; Sing, S.L. Achieving sustainability by additive manufacturing: A state-of-the-art review and perspectives. Virtual Phys. Prototyp. 2024, 19, e2438899. [Google Scholar] [CrossRef]

- Bozkurt, Y.; Karayel, E. 3D printing technology; methods, biomedical applications, future opportunities and trends. J. Mater. Res. Technol. 2021, 14, 1430–1450. [Google Scholar] [CrossRef]

- de Sousa Alves, B.A.; Kontziampasis, D.; Soliman, A.H. The Quest for the Holy Grail Of 3D Printing: A Critical Review of Recycling in Polymer Powder Bed Fusion Additive Manufacturing. Polymers 2024, 16, 2306. [Google Scholar] [CrossRef]

- Vaidya, R.; Anand, S. Image Processing Assisted Tools for Pre- and Post-processing Operations in Additive Manufacturing. Procedia Manuf. 2016, 5, 958–973. [Google Scholar] [CrossRef]

- Dörfler, K.; Dielemans, G.; Leutenegger, S.; Jenny, S.E.; Pankert, J.; Sustarevas, J.; Lachmayer, L.; Raatz, A.; Lowke, D. Advancing construction in existing contexts: Prospects and barriers of 3d printing with mobile robots for building maintenance and repair. Cem. Concr. Res. 2024, 186, 107656. [Google Scholar] [CrossRef]

- Digital Skills: How Employers Can Respond to Future Demand. World Economic Forum. Available online: https://www.weforum.org/stories/2022/11/digital-skills-labour-market-future/ (accessed on 31 August 2025).

- Tofail, S.A.M.; Koumoulos, E.P.; Bandyopadhyay, A.; Bose, S.; O’Donoghue, L.; Charitidis, C. Additive manufacturing: Scientific and technological challenges, market uptake and opportunities. Mater. Today 2018, 21, 22–37. [Google Scholar] [CrossRef]

- Manufacturing Study Shows Both Growth and Looming Talent Gap. Manufacturing News Desk|Advancedmanufacturing.org. Available online: https://www.advancedmanufacturing.org/news-desk/study-amid-growth-a-looming-gap-of-manufacturing-talent/article_d5ac43ac-fe7b-11ee-8e9f-dfc9469f7ff2.html (accessed on 31 August 2025).

- Rios, L.M.H.; Campaña, W.; Orobio, A. Insights into the Convergence of Bim and 3D Printing in Construction. Heliyon 2024. [Google Scholar] [CrossRef]

- Ivkić, I.; Buhmann, T.; List, B. A Cost-Benefit Analysis of Additive Manufacturing as a Service. In Proceedings of the International Conference on Cloud Computing and Services Science CLOSER, Porto, Portugal, 1–3 April 2025; pp. 219–230. [Google Scholar] [CrossRef]

- Ultimaker. 3D Printing: The Total Cost of Ownership; Ultimaker: Utrecht, The Netherland, 2020. [Google Scholar]

- Thomas, D.S.; Gilbert, S.W. Costs and Cost Effectiveness of Additive Manufacturing; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2014. [Google Scholar] [CrossRef]

- Shahrubudin, N.; Koshy, P.; Alipal, J.; Kadir, M.H.A.; Lee, T.C. Challenges of 3D printing technology for manufacturing biomedical products: A case study of Malaysian manufacturing firms. Heliyon 2020, 6, e03734. [Google Scholar] [CrossRef] [PubMed]

- Shakor, P.; Nejadi, S.; Paul, G.; Malek, S. Review of emerging additive manufacturing technologies in 3d printing of cementitious materials in the construction industry. Front. Built Environ. 2019, 4, 427880. [Google Scholar] [CrossRef]

- Ingaglio, J.; Fox, J.; Naito, C.J.; Bocchini, P. Material characteristics of binder jet 3D printed hydrated CSA cement with the addition of fine aggregates. Constr. Build. Mater. 2019, 206, 494–503. [Google Scholar] [CrossRef]

- Kim, H.; Cha, M.; Kim, B.C.; Kim, T.; Mun, D. Part library-based information retrieval and inspection framework to support part maintenance using 3D printing technology. Rapid Prototyp. J. 2019, 25, 630–644. [Google Scholar] [CrossRef]

- Kim, H.; Cha, M.; Kim, B.C.; Lee, I.; Mun, D. Maintenance framework for repairing partially damaged parts using 3D printing. Int. J. Precis. Eng. Manuf. 2019, 20, 1451–1464. [Google Scholar] [CrossRef]

- Khajavi, S.H.; Partanen, J.; Holmström, J. Additive manufacturing in the spare parts supply chain. Comput. Ind. 2014, 65, 50–63. [Google Scholar] [CrossRef]

- Yeon, J.; Rew, Y.; Choi, K.; Kang, J. Environmental Effects of Accelerated Pavement Repair Using 3D Printing: Life Cycle Assessment Approach. J. Manag. Eng. 2020, 36. [Google Scholar] [CrossRef]

- Nicolau, A.; Pop, M.A.; Coșereanu, C. 3D printing application in wood furniture components assembling. Materials 2022, 15, 2907. [Google Scholar] [CrossRef]

- Shakor, P.; Sanjayan, J.; Nazari, A.; Nejadi, S. Modified 3D printed powder to cement-based material and mechanical properties of cement scaffold used in 3D printing. Constr. Build. Mater. 2017, 138, 398–409. [Google Scholar] [CrossRef]

- El-Mahdy, D.; Gabr, H.S.; Abdelmohsen, S. SaltBlock as a 3D printed sustainable construction material in hot arid climates. J. Build. Eng. 2021, 43, 103134. [Google Scholar] [CrossRef]

- Keating, S.; Oxman, N. Compound fabrication: A multi-functional robotic platform for digital design and fabrication. Robot. Comput. Integr. Manuf. 2013, 29, 439–448. [Google Scholar] [CrossRef]

- Furet, B.; Poullain, P.; Garnier, S. 3D printing for construction based on a complex wall of polymer-foam and concrete. Addit. Manuf. 2019, 28, 58–64. [Google Scholar] [CrossRef]

- Lublasser, E.; Adams, T.; Vollpracht, A.; Brell-Cokcan, S. Robotic application of foam concrete onto bare wall elements-Analysis concept and robotic experiments. Autom. Constr. 2018, 89, 299–306. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Nerella, V.N.; Will, F.; Näther, M.; Otto, J.; Krause, M. Large-scale digital concrete construction–CONPrint3D concept for on-site, monolithic 3D-printing. Autom. Constr. 2019, 107, 102933. [Google Scholar] [CrossRef]

- Li, L.; Xiao, B.; Fang, Z.; Xiong, Z.; Chu, S.; Kwan, A. Feasibility of glass/basalt fiber reinforced seawater coral sand mortar for 3D printing. Addit. Manuf. 2021, 37, 101684. [Google Scholar] [CrossRef]

- Le, T.T.; Austin, S.A.; Lim, S.; Buswell, R.A.; Gibb, A.G.F.; Thorpe, T. Mix design and fresh properties for high-performance printing concrete. Mater. Struct. Mater. Constr. 2012, 45, 1221–1232. [Google Scholar] [CrossRef]

- Corsini, L.; Aranda-Jan, C.B.; Moultrie, J. The impact of 3D printing on the humanitarian supply chain. Prod. Plan. Control 2022, 33, 692–704. [Google Scholar] [CrossRef]

- MacDonald, E.; Wicker, R. Multiprocess 3D printing for increasing component functionality. Science 2016, 353, aaf2093. [Google Scholar] [CrossRef]

- Scott, A.; Harrison, T.P. Additive manufacturing in an end-to-end supply chain setting. 3D Print. Addit. Manuf. 2015, 2, 65–77. [Google Scholar] [CrossRef]

- Jia, F.; Wang, X.; Mustafee, N.; Hao, L. Investigating the feasibility of supply chain-centric business models in 3D chocolate printing: A simulation study. Technol. Forecast. Soc. Change 2016, 102, 202–213. [Google Scholar] [CrossRef]

- Harbaugh, J. Space Station 3-D Printer Builds Ratchet Wrench to Complete First Phase of Operations. NASA. 2017. Available online: https://www.nasa.gov/mission_pages/station/research/news/3Dratchet_wrench (accessed on 25 August 2025).

- Knofius, N.; van der Heijden, M.C.; Zijm, W.H.M. Moving to additive manufacturing for spare parts supply. Comput. Ind. 2019, 113, 103134. [Google Scholar] [CrossRef]

- Sirichakwal, I.; Conner, B. Implications of Additive Manufacturing for Spare Parts Inventory. 3D Print. Addit. Manuf. 2016, 3, 56–63. [Google Scholar] [CrossRef]

- Ryan, M.J.; Eyers, D.R.; Potter, A.T.; Purvis, L.; Gosling, J. 3D printing the future: Scenarios for supply chains reviewed. Int. J. Phys. Distrib. Logist. Manag. 2017, 47, 992–1014. [Google Scholar] [CrossRef]

- Mecheter, A.; Pokharel, S.; Tarlochan, F. Additive Manufacturing Technology for Spare Parts Application: A Systematic Review on Supply Chain Management. Appl. Sci. 2022, 12, 4160. [Google Scholar] [CrossRef]

- Feldmann, C.; Pumpe, A. A holistic decision framework for 3D printing investments in global supply chains. Transp. Res. Procedia 2017, 25, 677–694. [Google Scholar] [CrossRef]

- Eyers, D.R.; Potter, A.T.; Gosling, J.; Naim, M.M. The flexibility of industrial additive manufacturing systems. Int. J. Oper. Prod. Manag. 2018, 38, 2313–2343. [Google Scholar] [CrossRef]

- Alzahmi, W.; Shamayleh, A.; Stefancich, M. The Role of Additive Manufacturing in Spare Parts Management: A Systematic Review. Clean. Eng. Technol. 2025, 27, 101029. [Google Scholar] [CrossRef]

- Wits, W.W.; García, J.R.R.; Becker, J.M.J. How additive manufacturing enables more sustainable end-user maintenance, repair and overhaul (MRO) strategies. Procedia CIRP 2016, 40, 693–698. [Google Scholar] [CrossRef]

- Lastra, R.; Pereira, A.; Díaz-Cacho, M.; Acevedo, J.; Collazo, A. Spare Parts Made by Additive Manufacturing to Improve Preventive Maintenance. Appl. Sci. 2022, 12, 10564. [Google Scholar] [CrossRef]

- 3D Printing for Rapid Maintenance. Available online: https://www.gihub.org/infrastructure-technology-use-cases/case-studies/3d-printing-for-rapid-maintenance/?utm_source=chatgpt.com (accessed on 30 August 2025).

- Ergene, B.; İnci, Y.E.; Çetintaş, B.; Daysal, B. An experimental study on the wear performance of 3D printed polylactic acid and carbon fiber reinforced polylactic acid parts: Effect of infill rate and water absorption time. Polym. Compos. 2025, 46, 372–386. [Google Scholar] [CrossRef]

- Zheng, H.; Zhu, S.; Chen, L.; Wang, L.; Zhang, H.; Wang, P.; Sun, K.; Wang, H.; Liu, C. 3D Printing Continuous Fiber Reinforced Polymers: A Review of Material Selection, Process, and Mechanics-Function Integration for Targeted Applications. Polymers 2025, 17, 1601. [Google Scholar] [CrossRef]

- Dojan, C.F.; Ziaee, M.; Masoumipour, A.; Radosevich, S.J.; Yourdkhani, M. Additive manufacturing of carbon fiber-reinforced thermoset composites via in-situ thermal curing. Nat. Commun. 2025, 16, 4691. [Google Scholar] [CrossRef]

- Lee, C.; Choi, J.Y.; Lee, H.; Ok, K.; Ahn, S.H.; Jeon, J.H. Interdependent influence of additive manufacturing parameters and material hybridization with optimization for impact resistance. Manuf. Lett. 2025, 44, 847–856. [Google Scholar] [CrossRef]

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Wang, C.C.L.; Shin, Y.C.; Zhang, S.; Zavattieri, P.D. The status, challenges, and future of additive manufacturing in engineering. CAD Comput. Aided Des. 2015, 69, 65–89. [Google Scholar] [CrossRef]

- Petrovic, V.; Gonzalez, J.V.H.; Ferrando, O.J.; Gordillo, J.D.; Puchades, J.R.B.; Grinan, L.P. Additive layered manufacturing: Sectors of industrial application shown through case studies. Int. J. Prod. Res. 2011, 49, 1061–1079. [Google Scholar] [CrossRef]

- Wohlers, T.; Gornet, T.; Mostow, N.; Campbell, I.; Diegel, O.; Kowen, J.; Huff, R.; Stucker, B.; Fidan, I.; Doukas, A.; et al. History of Additive Manufacturing. Wohlers Report 2016–2022. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=4474824 (accessed on 30 August 2025).

- Lindemann, C.; Reiher, T.; Jahnke, U.; Koch, R. Towards a sustainable and economic selection of part candidates for additive manufacturing. Rapid Prototyp. J. 2015, 21, 216–227. [Google Scholar] [CrossRef]

- Holmström, J.; Partanen, J.; Tuomi, J.; Walter, M. Rapid manufacturing in the spare parts supply chain: Alternative approaches to capacity deployment. J. Manuf. Technol. Manag. 2010, 21, 687–697. [Google Scholar] [CrossRef]

- Vlasceanu, D.; Baciu, F.; Popescu, D.; Hadar, A.; Marinescu, R. Development and 3D Printing of an ABS Ergonomic Handle for Medical Use A case study. Mater. Plast. 2018, 55, 630–633. [Google Scholar] [CrossRef]

- Ventola, C.L. Medical Applications for 3D Printing: Current and Projected Uses. Pharm. Ther. 2014, 39, 704. Available online: https://pmc.ncbi.nlm.nih.gov/articles/PMC4189697/ (accessed on 30 November 2024).

- Chia, H.N.; Wu, B.M. Recent advances in 3D printing of biomaterials. J. Biol. Eng. 2015, 9, 4. [Google Scholar] [CrossRef]

- Huang, Y.; Leu, M.; Mazumder, J.; Donmez, A. Additive Manufacturing: Current State, Future Potential. Gaps & Needs, and Recommendations 137 (2015). Available online: https://www.nist.gov/publications/additive-manufacturing-current-state-future-potential-gaps-needs-and-recommendations (accessed on 30 November 2024).

- Sun, Y.; Li, Q. The application of 3D printing in mathematics education. In Proceedings of the ICCSE 2017—12th International Conference on Computer Science and Education, Houston, TX, USA, 22–25 August 2017; pp. 47–50. [Google Scholar] [CrossRef]

- Sun, Y.; Li, Q. Visualization of Mathematical Education by 3D Printer. In Proceedings of the 1st IEEE International Conference on Knowledge Innovation and Invention, Jeju, Republic of Korea, 23–27 July 2018; pp. 266–269. [Google Scholar] [CrossRef]

- Tri, H.N.N.; Thanh, T.N. Exploring the potential benefits of 3D printing technology in laboratory equipment: Case studies on custom lab equipment and components. J. Mater. Constr. 2023, 13, 4–7. [Google Scholar] [CrossRef]

- Chen, W. Additive Manufacturing for Fabrication of Robotic Components. Adv. Robot. Mech. Eng. 2020, 169–171. [Google Scholar] [CrossRef]

- Singh, R.; Bhavar, V.; Kattire, P.; Thakare, S.; Patil, S.; Singh, R.K.P. A Review on Functionally Gradient Materials (FGMs) and Their Applications. IOP Conf. Ser. Mater. Sci. Eng. 2017, 229, 012021. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing, 2nd ed.; Springer: New York, NY, USA, 2015; pp. 1–498. [Google Scholar] [CrossRef]

- Pradel, P.; Zhu, Z.; Bibb, R.; Moultrie, J. Investigation of design for additive manufacturing in professional design practice. J. Eng. Des. 2018, 29, 165–200. [Google Scholar] [CrossRef]

- Chua, C.K.; Leong, K.F. 3D Printing and Additive Manufacturing: Principles and Applications, 5th ed.; World Scientific Publishing: Singapore, 2017; pp. 1–426. [Google Scholar] [CrossRef]

- Huang, S.H.; Liu, P.; Mokasdar, A.; Hou, L. Additive manufacturing and its societal impact: A literature review. Int. J. Adv. Manuf. Technol. 2013, 67, 1191–1203. [Google Scholar] [CrossRef]

- Manufacturing, A. Wohlers Report 2021 Finds 7. Available online: https://search.worldcat.org/title/1248723503 (accessed on 30 November 2024).

- Quality Assurance of 3D Printing-Ensure the Quality of Your Parts-Danish Technological Institute. Available online: https://www.dti.dk/services/quality-assurance-of-3d-printing/ensure-the-quality-of-your-parts/42960 (accessed on 30 August 2025).

- ISO/ASTM TS 52930:2021; Additive Manufacturing—Qualification Principles—Installation, Operation and Performance (IQ/OQ/PQ) of PBF-LB Equipment. ISO: Geneva, Switzerland, 2021. Available online: https://www.iso.org/standard/79527.html?utm_source=chatgpt.com (accessed on 30 August 2025).

- Beitler, B.G.; Abraham, P.F.; Glennon, A.R.; Tommasini, S.M.; Lattanza, L.L.; Morris, J.M.; Wiznia, D.H. Interpretation of regulatory factors for 3D printing at hospitals and medical centers, or at the point of care. 3D Print. Med. 2022, 8, 7. [Google Scholar] [CrossRef]

- UL Solutions Helps Build Safety with 3D Printed Technology|UL Solutions. Available online: https://www.ul.com/resources/ul-helps-build-safety-3d-printed-technology?utm_source=chatgpt.com (accessed on 30 August 2025).

- 3D Printing Safety: Potential Hazards, Protection and Practices–Raise3D: Reliable, Industrial Grade 3D Printer. Available online: https://www.raise3d.com/blog/3d-printing-safety/ (accessed on 30 August 2025).

- Kirchain, R.; Moore, E.; Field, F. Preparing the Advanced Manufacturing Workforce: A Study of Occupation and Skills Demand in the 3D/Additive Manufacturing Industry. 2022. Available online: https://dspace.mit.edu/handle/1721.1/143871 (accessed on 30 August 2025).

- Sector Skills Strategy in Additive Manufacturing [SAM]. CEDEFOP. Available online: https://www.cedefop.europa.eu/en/project-fiches/sector-skills-strategy-additive-manufacturing-sam?etransnolive=1&utm_source=chatgpt.com (accessed on 30 August 2025).

- Tsay, G.S.; Staub-French, S.; Poirier, É. BIM for Facilities Management: An Investigation into the Asset Information Delivery Process and the Associated Challenges. Appl. Sci. 2022, 12, 9542. [Google Scholar] [CrossRef]

- Advancing Facilities Management with a Digital Thread-White Paper-Technology Community Technology Community. Available online: https://it.ifma.org/advancing-facilities-management-with-a-digital-thread-white-paper/ (accessed on 30 August 2025).

- Dhir, A.; Talwar, S.; Islam, N.; Alghafes, R.; Badghish, S. Different strokes for different folks: Comparative analysis of 3D printing in large, medium and small firms. Technovation 2023, 125, 102792. [Google Scholar] [CrossRef]

- Yamato, Y.; Fukumoto, Y.; Kumazaki, H. Proposal of Real Time Predictive Maintenance Platform with 3D Printer for Business Vehicles. Int. J. Inf. Electron. Eng. 2016, 6, 289–293. [Google Scholar] [CrossRef]

- 3D Printed Spare Parts—A Potential Risk? Available online: https://www.if-insurance.com/large-enterprises/insight/risk-consulting-magazine/risk-consulting-2018-1/3d-printed-spare-parts?utm_source=chatgpt.com (accessed on 30 August 2025).

- Niehues, S.; Berger, L.; Henke, M. Additive manufacturing in supply chains-the future of purchasing processes. TUHH Open Res. 2018, 25, 79–95. [Google Scholar] [CrossRef]

- Arbabian, M.E. Strategic Adoption of 3D Printing in Multi-Product Supply Chains: Cost and Capacity Considerations. 2025. Available online: https://arxiv.org/pdf/2506.10198 (accessed on 30 August 2025).

- Espadinha-Cruz, P.; Neves, A.; Matos, F.; Godina, R. Development of a maturity model for additive manufacturing: A conceptual model proposal. Heliyon 2023, 9, e16099. [Google Scholar] [CrossRef] [PubMed]

- Mecheter, A.; Tarlochan, F.; Kucukvar, M. A Review of Conventional versus Additive Manufacturing for Metals: Life-Cycle Environmental and Economic Analysis. Sustainability 2023, 15, 12299. [Google Scholar] [CrossRef]

- Chen, Z.; Han, C.; Gao, M.; Kandukuri, S.Y.; Zhou, K. A review on qualification and certification for metal additive manufacturing. Virtual Phys. Prototyp. 2022, 17, 382–405. [Google Scholar] [CrossRef]

- Joshi, S.C.; Sheikh, A.A. 3D-printing in aerospace and its long-term sustainability. Virtual Phys. Prototyp. 2015, 10, 175–185. [Google Scholar] [CrossRef]

- Wang, Y.C.; Chen, T.; Yeh, Y.L. Advanced 3D printing technologies for the aircraft industry: A fuzzy systematic approach for assessing the critical factors. Int. J. Adv. Manuf. Technol. 2019, 105, 4059–4069. [Google Scholar] [CrossRef]

- Sreehitha, V. Impact of 3D printing in automotive industry. Int. J. Mech. Prod. Eng. 2017, 5, 91–94. [Google Scholar]

- Petch, M. Audi Gives Update on Use of SLM Metal 3D Printing for the Automotive Industry, 3D Printing Industry. 2018. Available online: https://3dprintingindustry.com/news/audi-gives-update-use-slm-metal-3d-printing-automotive-industry-129376/ (accessed on 25 August 2025).

- Maghnani, R. An Exploratory Study: The impact of Additive Manufacturing on the Automobile Industry. Int. J. Curr. Eng. Technol. 2015, 5, 3407. Available online: https://inpressco.com/wp-content/uploads/2015/10/Paper563407-3410.pdf (accessed on 25 August 2025).

- Liu, Z.; Zhang, M.; Bhandari, B.; Wang, Y. 3D printing: Printing precision and application in food sector. Trends Food Sci. Technol. 2017, 69, 83–94. [Google Scholar] [CrossRef]

- Banihashemi, S.; Akbarnezhad, A.; Sheikhkhoshkar, M.; El Haouzi, H.B.; Rolfe, B. 3D printing in construction: Sustainable technology for building industry. Prog. Addit. Manuf. 2025. [Google Scholar] [CrossRef]

- Zhuang, Z.; Xu, F.; Ye, J.; Hu, N.; Jiang, L.; Weng, Y. A comprehensive review of sustainable materials and toolpath optimization in 3D concrete printing. npj Mater. Sustain. 2024, 2, 12. [Google Scholar] [CrossRef]

- Preventive Maintenance with A 3D Printing Option. Available online: https://www.researchgate.net/publication/331374681_Preventive_maintenance_with_a_3D_printing_option (accessed on 30 August 2025).

- Frastika, Y.; Pongoh, F.M.; Anwar, D.; Palapa, A.; Alamsya, J. Analysis of the Application of Additive Manufacturing for On-Demand Repair and Maintenance of Naval Equipment in Remote Maritime Operations. Int. J. Mech. Ind. Control Syst. Eng. 2025, 2, 46–61. [Google Scholar] [CrossRef]

- Attaran, M. The rise of 3-D printing: The advantages of additive manufacturing over traditional manufacturing. Bus. Horiz. 2017, 60, 677–688. [Google Scholar] [CrossRef]

- Jha, D.; Sawant, R.; Mukherjee, S.; Ashvinbhai, A.; Upadhyay, R.K. Redefining supply chain and related aspects through integration of 3D printing technology. Sustain. Manuf. Serv. Econ. 2025, 4, 100030. [Google Scholar] [CrossRef]

- Chan, H.K.; Griffin, J.; Lim, J.J.; Zeng, F.; Chiu, A.S.F. The impact of 3D Printing Technology on the supply chain: Manufacturing and legal perspectives. Int. J. Prod. Econ. 2018, 205, 156–162. [Google Scholar] [CrossRef]

- Liu, Y. Research on the Application and Optimization of 3D Printing in Interior Decoration. In ACM International Conference Proceeding Series; Association for Computing Machinery: New York, NY, USA, 2024; pp. 596–600. [Google Scholar] [CrossRef]

- Zhang, D.; Kantaros, A.; Ganetsos, T.; Kanetaki, Z.; Stergiou, C.; Pallis, E.; Papoutsidakis, M. Design and Fabrication of Customizable Urban Furniture Through 3D Printing Processes. Processes 2025, 13, 2492. [Google Scholar] [CrossRef]

- 75% Cost Savings with 3D Printing. Voxeljet. Available online: https://www.voxeljet.com/additive-manufacturing/case-studies/foundry/3d-printing-saves-costs-in-sand-casting/ (accessed on 31 August 2025).

- Ballard, D.H.; Mills, P.; Duszak, R.; Weisman, J.A.; Rybicki, F.J.; Woodard, P.K. Medical 3D Printing Cost-savings in Orthopedic and Maxillofacial Surgery: Cost Analysis of Operating Room Time Saved with 3D Printed Anatomic Models and Surgical Guides. Acad. Radiol. 2019, 27, 1103. [Google Scholar] [CrossRef] [PubMed]

- 4 Ways AM Helps You Cut Costs and Create More Complex Parts. Available online: https://www.materialise.com/en/inspiration/articles/cut-costs-solve-complexity-additive-manufacturing (accessed on 31 August 2025).

- European Patent Office. Innovation Trends in Additive Manufacturing: Patents in 3D Printing Technologies; European Patent Office: Munich, Germany, 2023. [Google Scholar]

| Author (Year) | FM Area | 3DP Technology | Main Findings | Noted Limitation |

|---|---|---|---|---|

| Ingaglio et al. [36] | Construction | Binder Jetting Cement | Achieves complex, load-bearing prototypes | Scalability, material cost |

| Kim et al. [37,38] | Maintenance | Metal AM, CAD Library | Enables fast, on-site part replacement | Technical skills required |

| Khajavi et al. [39] | Supply Chain | Metal AM | Distributed spare part manufacturing, lead time reduction | Machine automation needed |

| Yeon et al. [40] | Infrastructure | Concrete 3DP | Eco-friendly spall repair | Regulatory approval |

| Nicolau et al. [41] | Furniture | FDM (Plastic) | Custom furniture parts, improved repair | Limited industry standard |

| Researcher | 3DP Process | Material | Parts Made | Comments |

|---|---|---|---|---|

| Ingaglio et al. [36] | Binder jet cement-based printing. | Dry cementitious mix comprised of round-grain fine aggregates and calcium sulfoaluminate (CSA) cement | Tests samples (Cube, Dogbone, Prism) for mechanical characterization | It demonstrates the potential of binder jet printing in construction with CSA cement, achieving compressive strengths of 5.94–6.70 MPa and flexural strengths of 1.76–2.39 Mpa. |

| Shakor et al. [42] | standard inkjet printing | Portland cement (OPC) (Geelong cement) and calcium aluminate cement (CAC) (CIMENT FONDU, Kerneos). | Tests samples for compressive strength and porosity measurement | They developed a unique cement mix for 3DP, achieving a maximum compressive strength of 8.26 MPa and a minimum porosity of 49.28% at optimal saturation levels. |

| Mahdy et al. [43] | the robocasting/direct ink writing (RC/DIW) | salt and sand, Ethylene-vinyl acetate polymer (EVA) | SaltBlock prototype | Salt Block achieved 9.5 MPa compressive strength and 0.94 W/m2K thermal performance, demonstrating significant environmental and economic benefits for desert construction. |

| Keating and Oxman [44] | Robotic Spray Foam & Machining | PU | Dome prototype | Demonstrated the use of a 6-axis robotic arm for integrated 3DP, milling, and sculpting, highlighting its potential for multi-functional and efficient construction processes |

| Furel et al. [45] | Robotic Foam Printing | PU | lost formwork for a single-storey small house | Demonstrated Batiprint3D™, achieving 30–40% higher thermal performance in social housing constructed in just 54 h |

| Lublasser et al. [46] | Robotic Application of Foam Concrete on Walls | Foamed Concrete | Thermal reinforcement of existing walls | Lublasser et al. (2018) demonstrated the potential of robotic 3DP to apply highly insulating, recyclable foam concrete façades to existing buildings to meet energy-efficiency standards. |

| Mechtcherine et. al. [47] | Extrusion with robotic boom | Foamed Concrete | Monolithic thermo-structural walls | 3D-printed foamed concrete was used for monolithic, load-bearing, and insulating walls. |

| Li et al. [48] | Extrusion-based portable 3DP apparatus | local seawater and coral, Portland cement sand, glass fiber, and basalt fiber | Test specimens for bending and compression testing | Demonstrated the potential of using 3D printable fiber-reinforced seawater coral sand mortar, achieving high flexural and compressive strengths for sustainable construction in remote areas. |

| Le et al. [49] | Extrusion-based 3DP apparatus | Cement, Flyash, Silica fumes, polypropylene fibers | Test specimens for bending and compression testing | The optimized mix with a 3:2 sand-binder ratio and 1.2 kg/m3 of polypropylene fibers achieved 110 MPa compressive strength at 28 days. It was validated through the successful manufacture of full-scale freeform components. |

| Sr. No. | Researcher | 3DP Process | Supply Chain Area | Comments |

|---|---|---|---|---|

| 1 | Khajavi et al. [39] | Metal AM | Configuration of spare parts supply chains in the aeronautics industry using additive manufacturing. | Distributed production of spare parts using AM technology can lower costs and enhance flexibility but requires advancements in machine automation and production speed. |

| 2 | Corsini, Aranda-Jan & Moultrie [50] | Extrusion-based AM | Humanitarian supply chain logistics, distributed production of spare parts and essential goods for relief operations | 3DP reduces lead times and supplier dependency, enhances flexibility and resilience in emergencies, but faces barriers in quality control, scalability, and local capacity building. |

| 3 | Jia et al. [53] | Extrusion-based 3DP | Impact of 3DP on profitability and business models in the chocolate industry. | Early 3D printing technology adopters can gain a competitive advantage, disrupting traditional supply chains. |

| 4 | Harbaugh [54] | FDM | On-demand manufacturing and in-space production. | Demonstrated successful 3DP of a ratchet wrench on the ISS from a transmitter design file, highlighting the potential for reducing dependency on Earth-based resupply missions. |

| 5 | Knofius et al. [55] | AM in general | Part Consolidation and Spare Parts Management | Consolidation with AM often increases total costs due to replacing entire components instead of defective subcomponents. |

| 6 | Sirichakwal and Conner [56] | AM in general | Spare parts inventory management. | 3DP reduces holding costs and replenishment lead times, positively impacting total inventory costs and stock-out probabilities, especially for low-demand parts. |

| 7 | Ryan et al. [57] | Scenario-based AM (multiple technologies) | Strategic supply chain design, scenarios for AM integration | Identified four scenarios showing how AM can reshape inventory, production, and distribution models |

| Mecheter et al. [58] | AM in general | Systematic review of spare parts applications | Comprehensive analysis of AM benefits for spare parts supply chains, identifying key implementation factors and performance metrics across multiple industries. | |

| Feldmann & Pumpe [59] | Various AM processes | Holistic decision framework for global supply chains | Developed multi-criteria framework for 3DP investment decisions, addressing location, technology, and capacity planning considerations. | |

| 8 | NASA/ISS (Harbaugh [54]) | Tool production in orbit | Space operations | Rapid, remote, mission-critical production. |

| Stakeholder | Opportunities | Concerns | Needs | Reference/ Source |

|---|---|---|---|---|

| Facilities Managers | Potential for streamlining maintenance processes | Concerns about the learning curve and training requirements | Need for a clear return on investment (ROI) justification | [63,64,97] |

| Maintenance Technicians | Opportunities for skill development and job enrichment | Apprehensions about job security and the impact on traditional roles | Importance of user-friendly interfaces and adequate training | [93,98] |

| Procurement and Supply Chain Managers | Potential for reducing inventory costs and minimizing stock-outs | Concerns about the quality and reliability of 3D-printed parts | Need for establishing new supplier relationships and quality control processes | [58,59,99,100] |

| Senior Management | Strategic value in terms of cost savings and operational efficiency | Concerns about the initial investment and the maturity of the technology | Importance of aligning 3DP initiatives with organizational goals | [100,101,102] |

| Theme | Challenge | Action Needed | References |

|---|---|---|---|

| Cost-effectiveness | Varies by sector and scale | Field studies, lifecycle cost analysis | [55,103] |

| Quality assurance | Lack of clear standards | Develop certification and protocols | [88,89,104,105,106] |

| Workforce skills | Digital/operational gaps | Targeted training, professional development | [93,94,107,108] |

| Digital integration | Data fragmentation | Harmonize BIM/3DP standards, pilot studies | [95,96,109,110] |

| Regulatory compliance | Unclear safety, approval status | Partnership with regulators, pilots | [90,91,92] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abid, M.T.; Khan, S.A.; Koç, M. 3D Printing in Facilities Management: A Systematic Review Toward Smart and Sustainable Building Operations. Buildings 2025, 15, 4231. https://doi.org/10.3390/buildings15234231

Abid MT, Khan SA, Koç M. 3D Printing in Facilities Management: A Systematic Review Toward Smart and Sustainable Building Operations. Buildings. 2025; 15(23):4231. https://doi.org/10.3390/buildings15234231

Chicago/Turabian StyleAbid, Muhammad Tuskheer, Shoukat Alim Khan, and Muammer Koç. 2025. "3D Printing in Facilities Management: A Systematic Review Toward Smart and Sustainable Building Operations" Buildings 15, no. 23: 4231. https://doi.org/10.3390/buildings15234231

APA StyleAbid, M. T., Khan, S. A., & Koç, M. (2025). 3D Printing in Facilities Management: A Systematic Review Toward Smart and Sustainable Building Operations. Buildings, 15(23), 4231. https://doi.org/10.3390/buildings15234231