Synergistic Microstructures, Mechanical Properties, and Piezoresistive Performance Improvement of Nanoengineered Cementitious Composites by CNT and GNP

Abstract

1. Introduction

2. Materials and Experiments

2.1. Materials

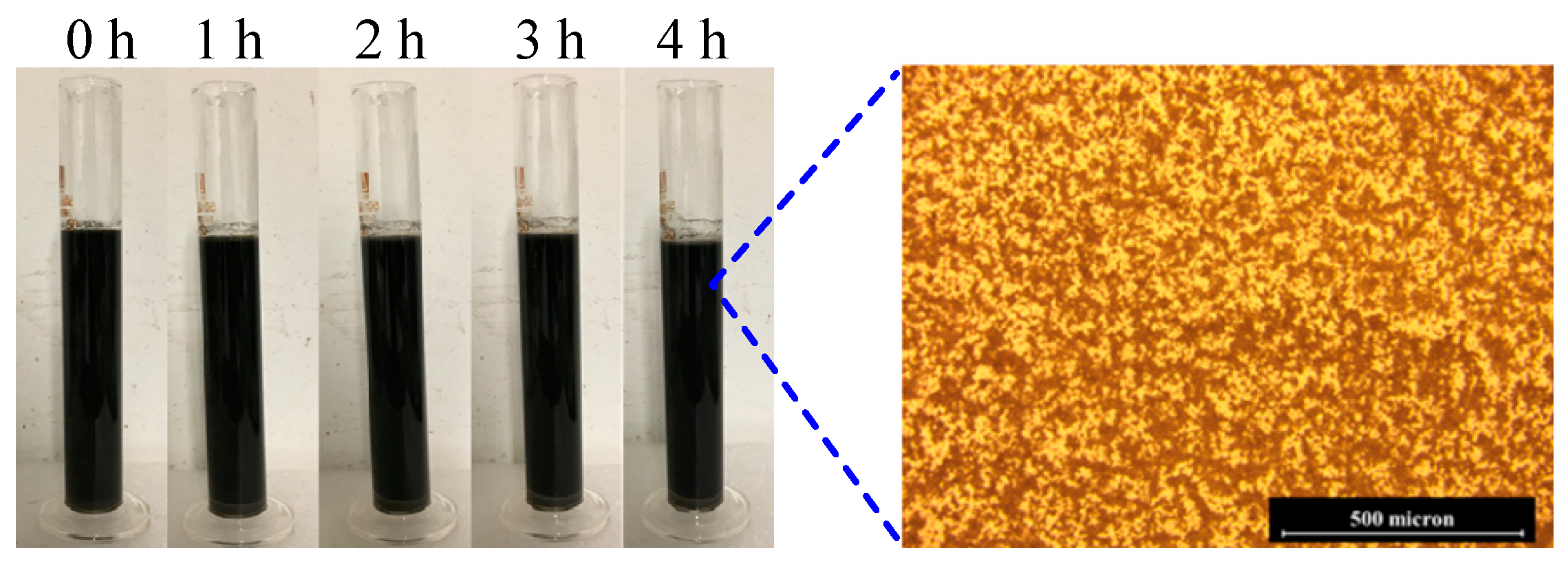

2.2. Sample Preparation

2.3. Tests and Methods

2.3.1. Mechanical Properties Test

2.3.2. Piezoresistive Test

2.3.3. Microstructure Test

3. Results and Discussion

3.1. Mechanical Properties

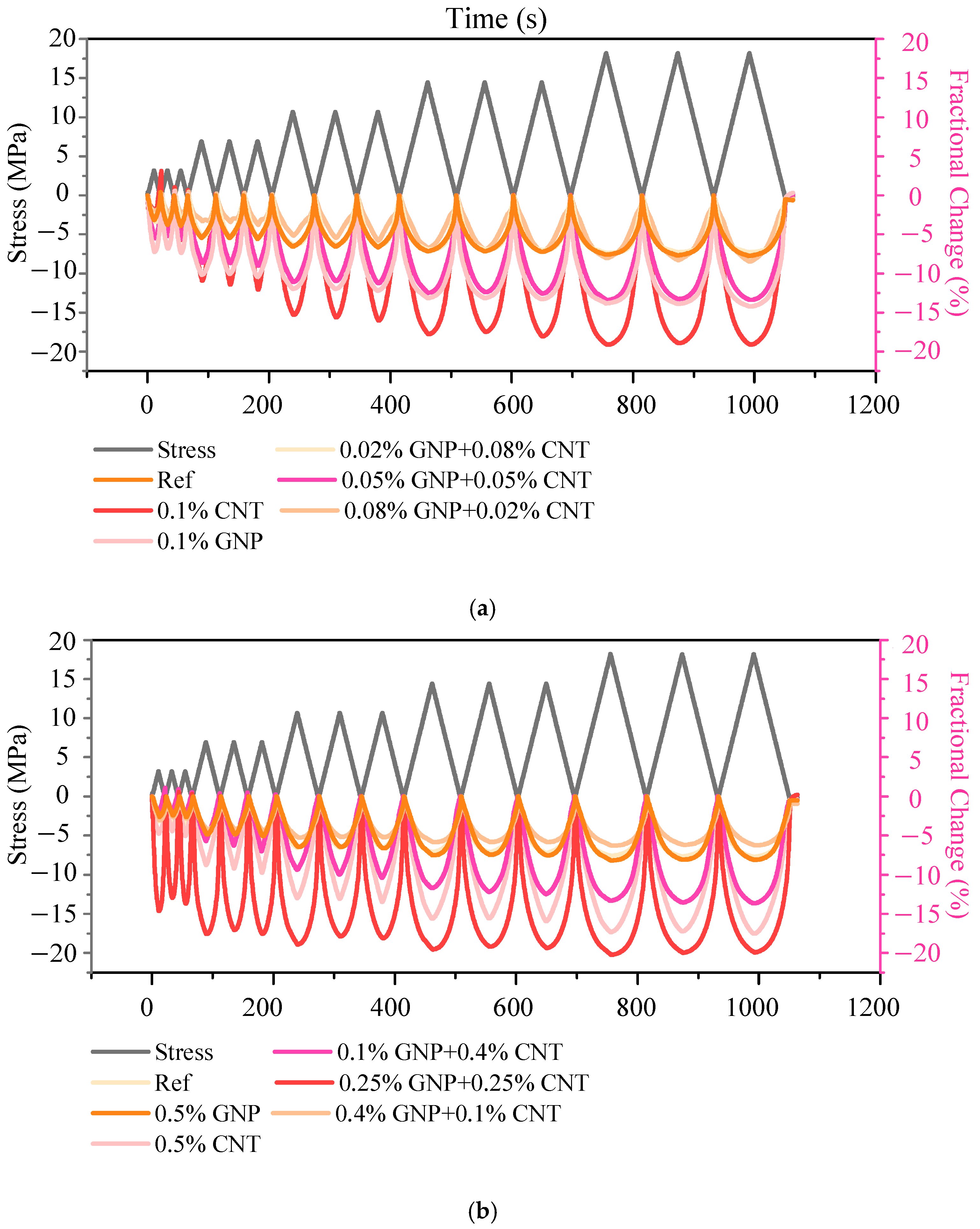

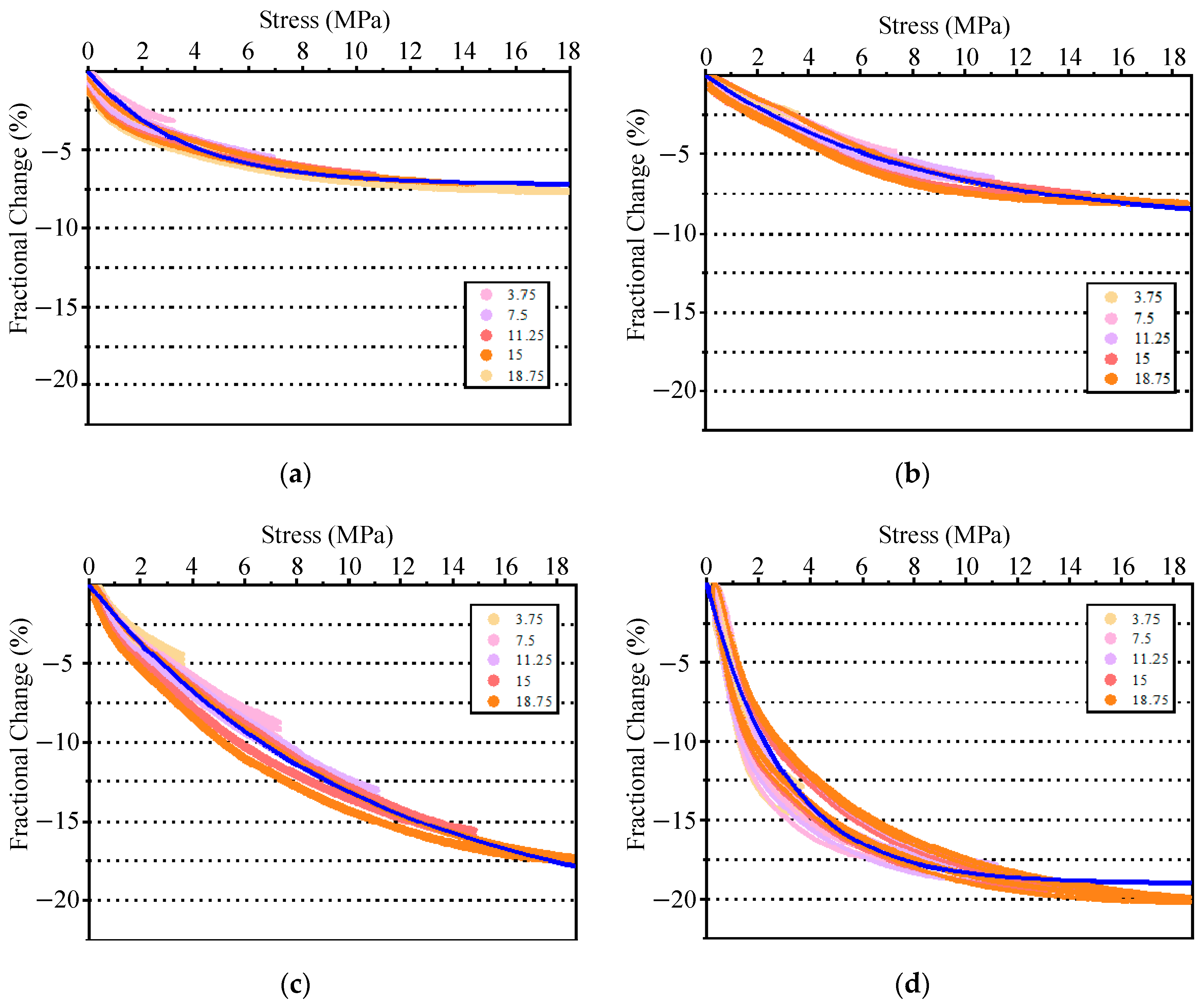

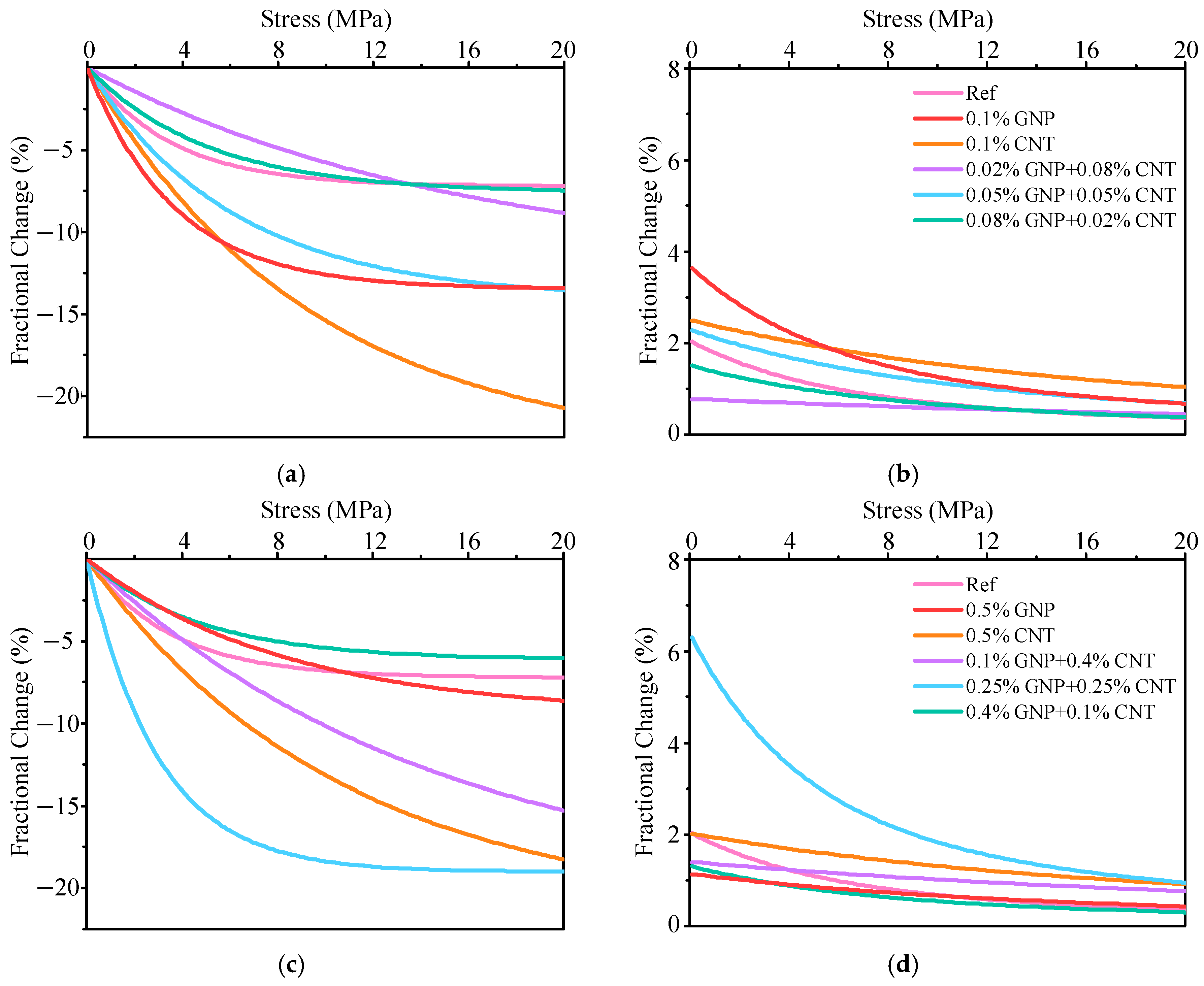

3.2. Piezoresistive Performance

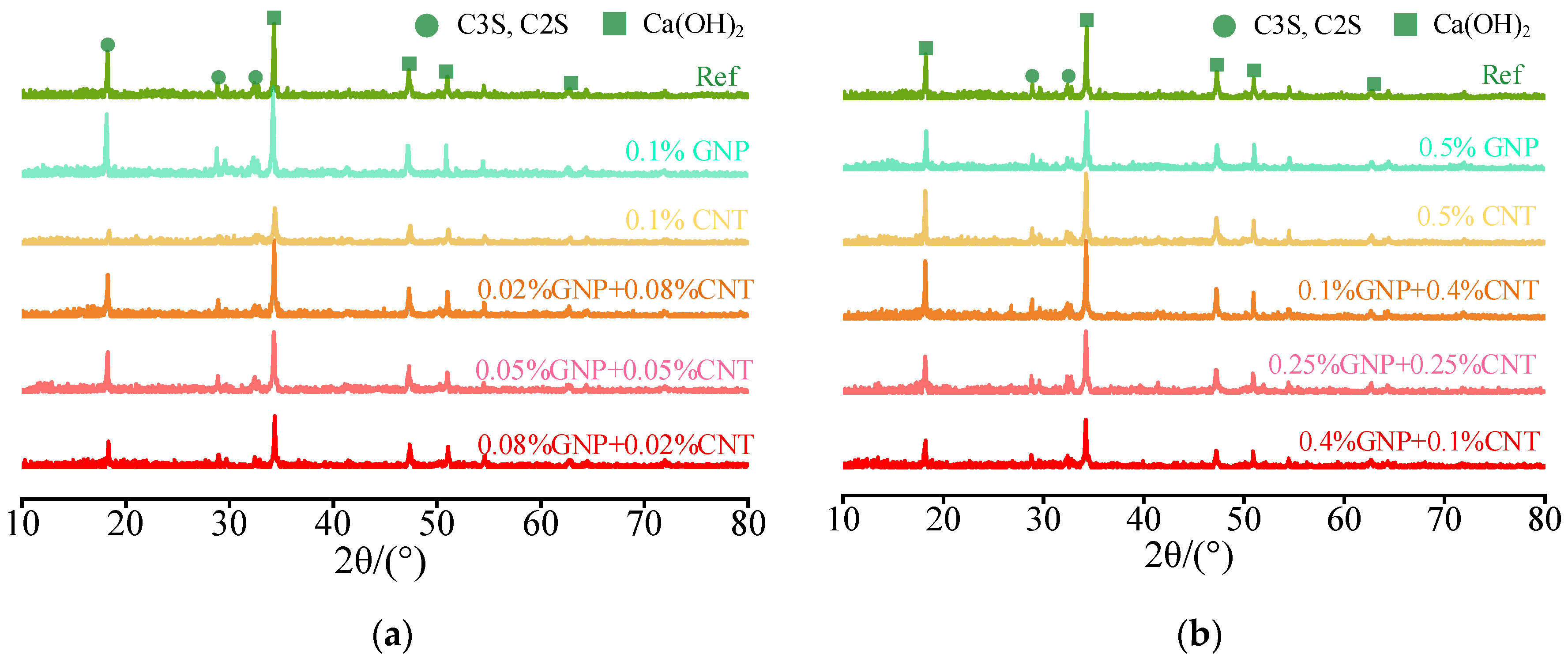

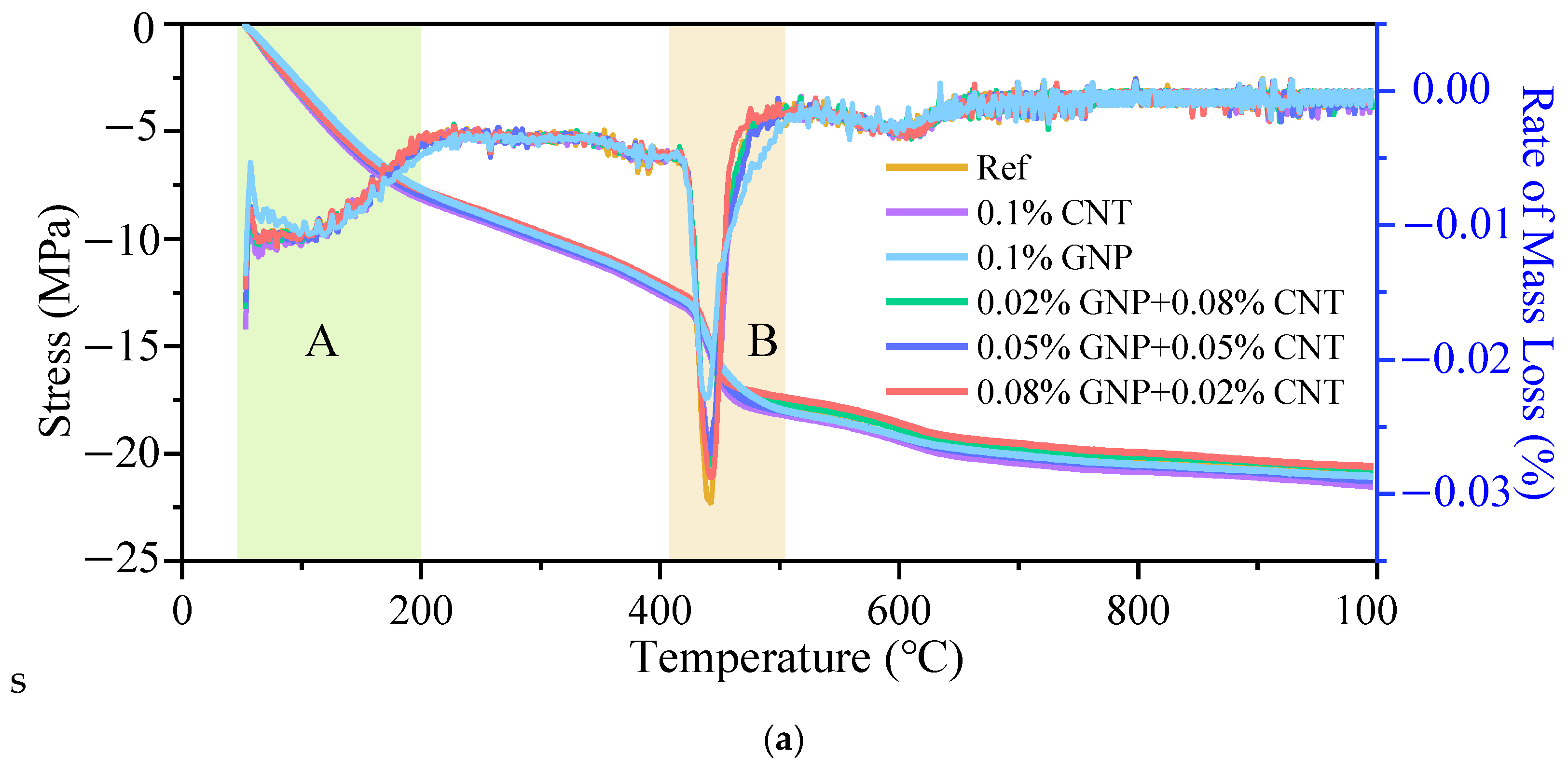

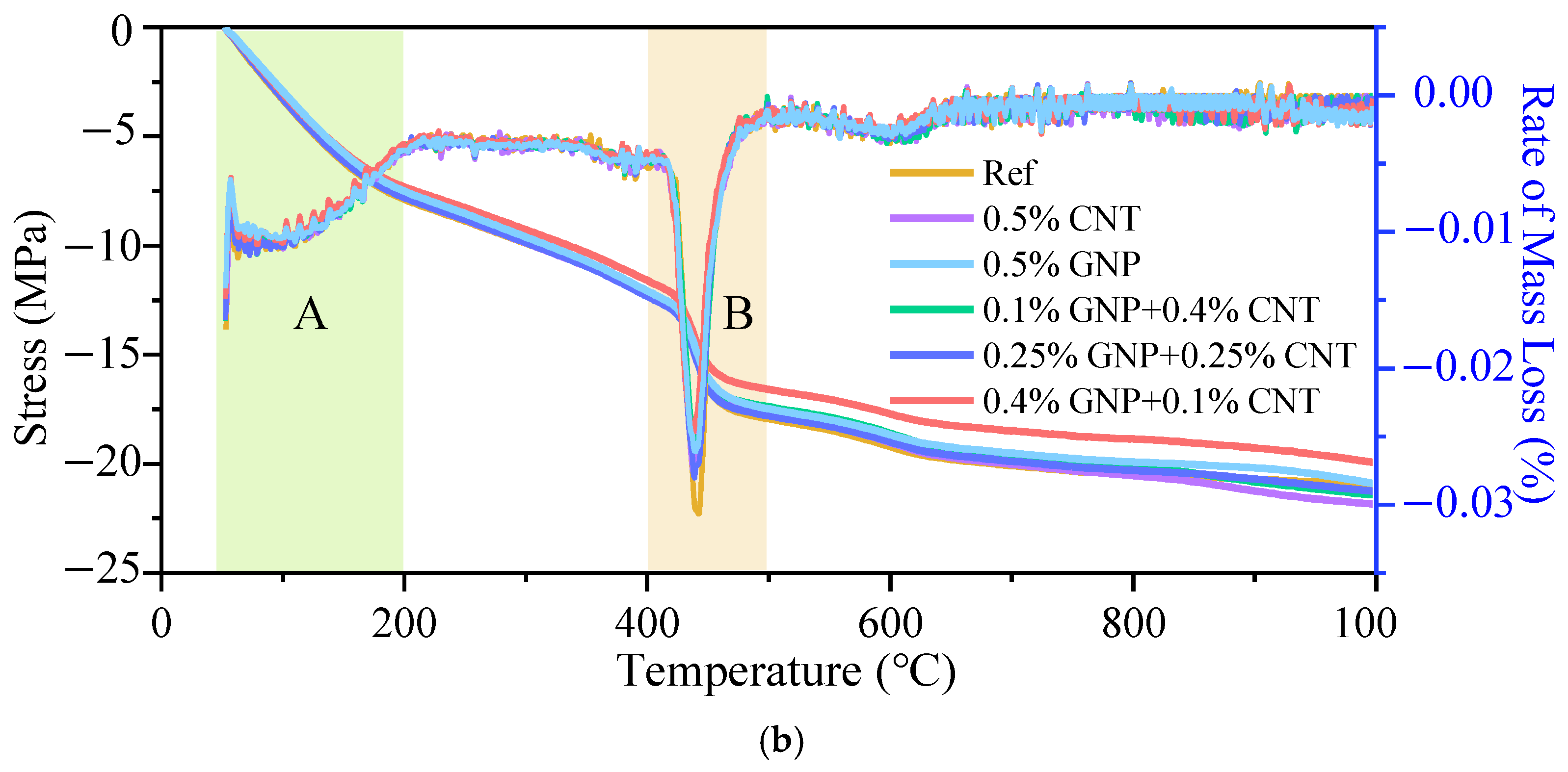

3.3. Chemical Analysis

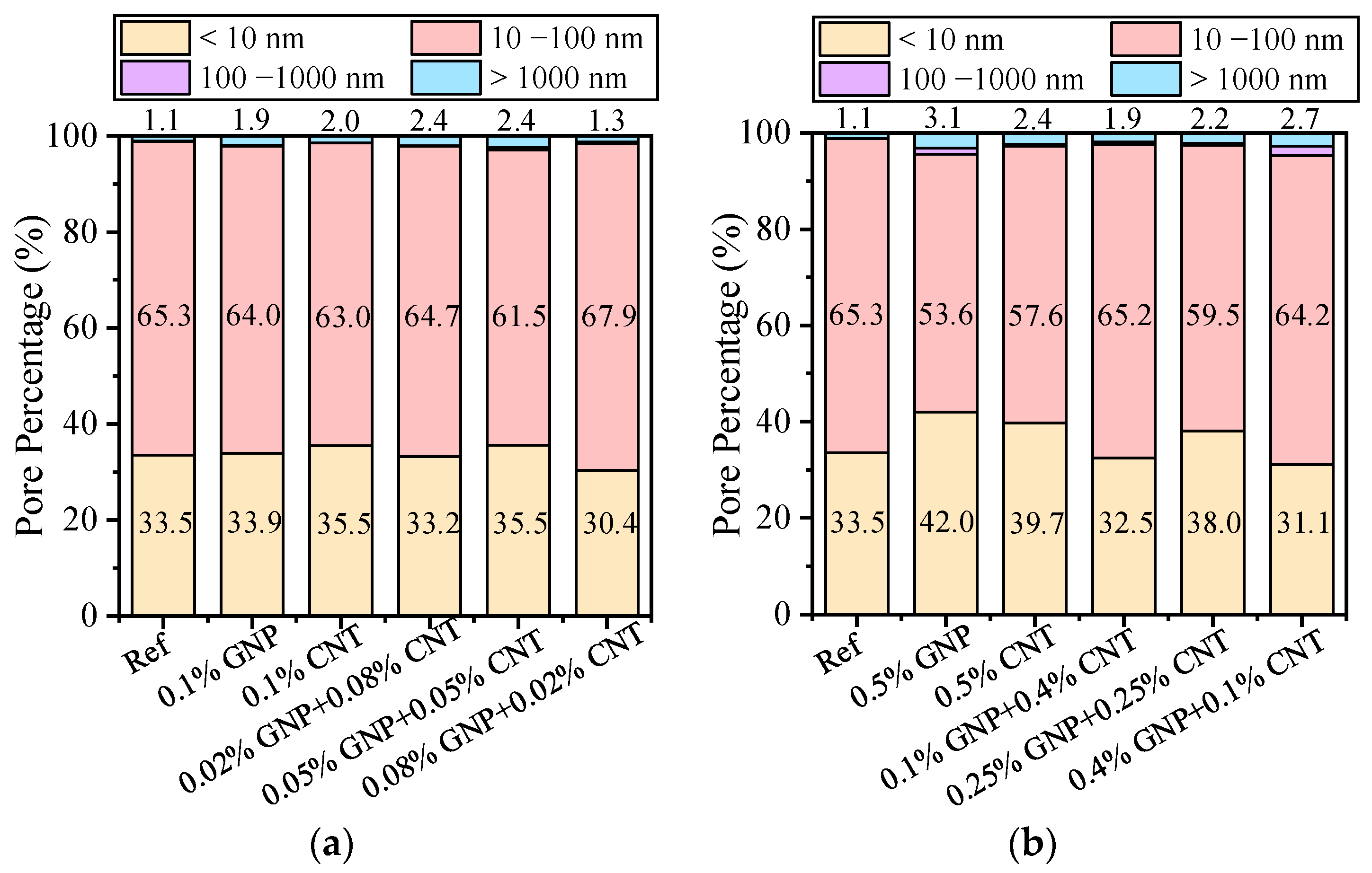

3.4. Pore Structure Analysis

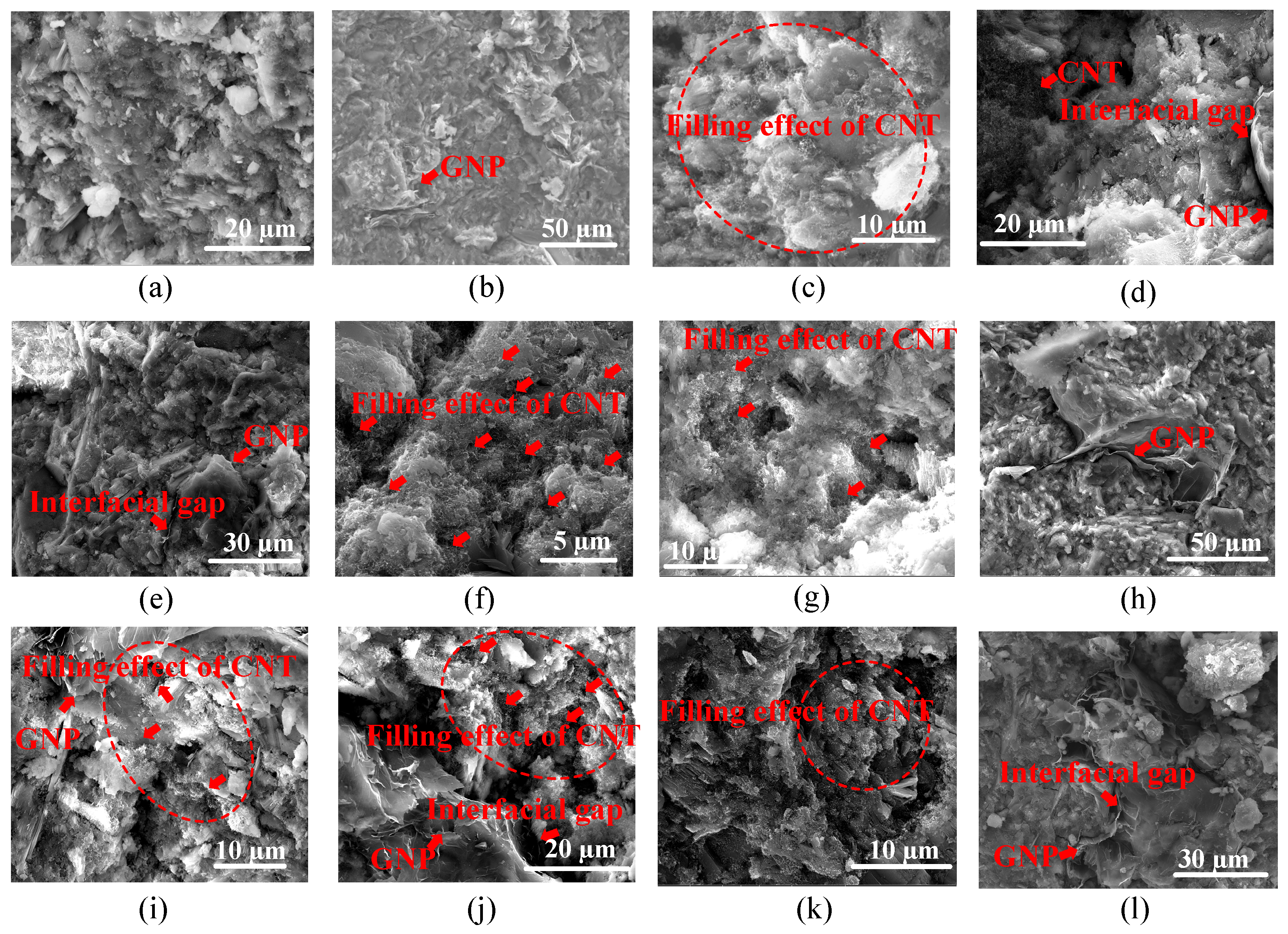

3.5. Microstructure

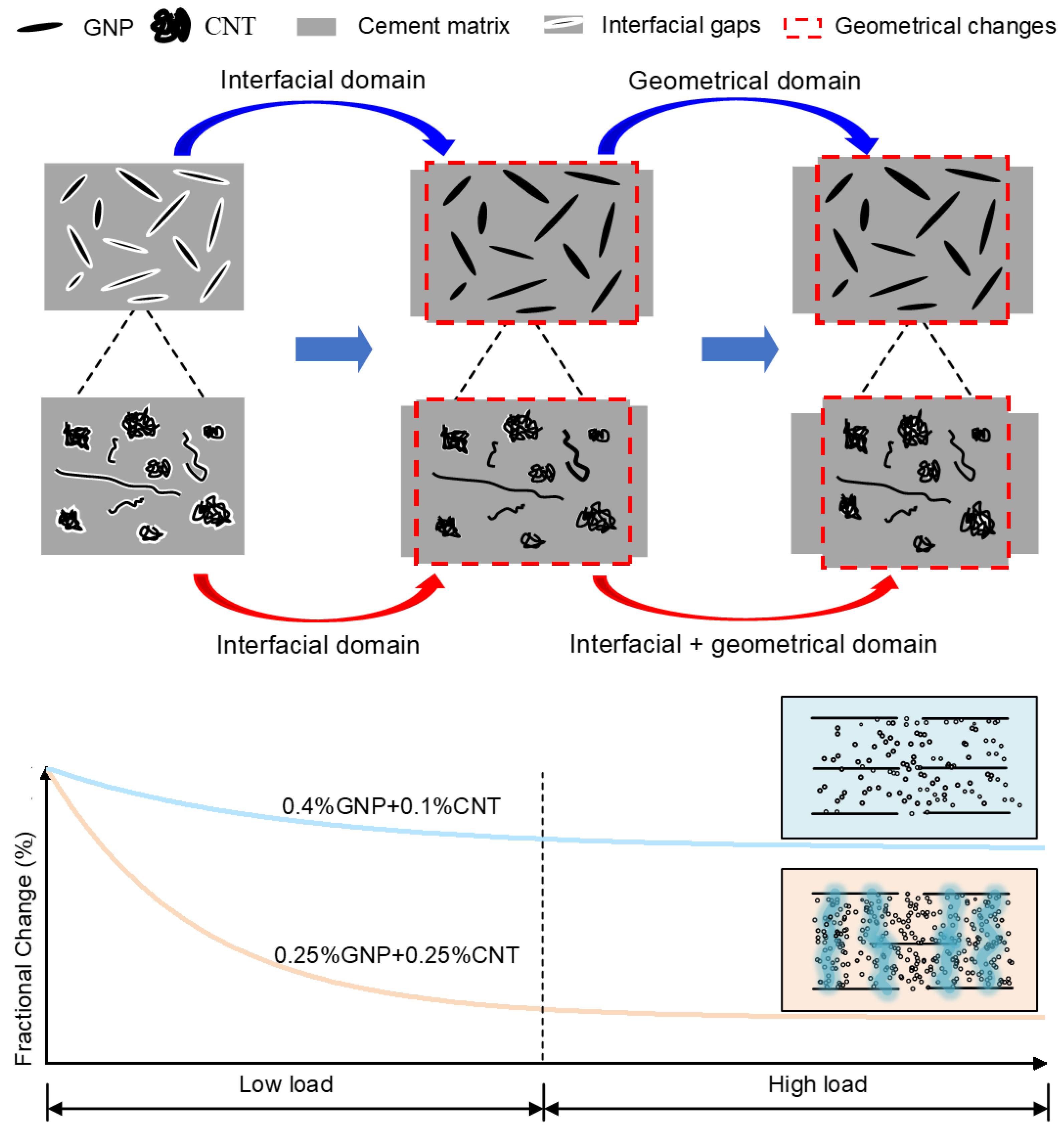

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Han, B.; Guan, X.; Ou, J. Electrode design, measuring method and data acquisition system of carbon fiber cement paste piezoresistive sensors. Sens. Actuators A-Phys. 2007, 135, 360–369. [Google Scholar] [CrossRef]

- Wen, S.; Chung, D.D.L. Carbon fiber-reinforced cement as a strain-sensing coating. Cem. Concr. Res. 2001, 31, 665–667. [Google Scholar] [CrossRef]

- Taha, M.M.R.; Shrive, N.G. Enhancing fracture toughness of high-performance carbon fiber cement composites. ACI Mater. J. 2001, 98, 168–178. [Google Scholar] [CrossRef] [PubMed]

- Wen, S.; Chung, D.D.L. Partial replacement of carbon fiber by carbon black in multifunctional cement–matrix composites. Carbon 2007, 45, 505–513. [Google Scholar] [CrossRef]

- Soroushia, P.; Nagi, M.; Okwuegbu, A. Freeze-thaw durability of lightweight carbon fiber reinforced cement composites. ACI Mater. J. 1992, 89, 491–494. [Google Scholar] [CrossRef]

- Sanchez, F.; Zhang, L.; Ince, C. Multi-scale performance and durability of carbon nanofiber/cement composites. In Nanotechnology in Construction 3; Springer: Berlin/Heidelberg, Germany, 2009; pp. 345–350. [Google Scholar]

- Chung, D.D.L. Cement reinforced with short carbon fibers: A multifunctional material. Compos. Part B-Eng. 2000, 31, 511–526. [Google Scholar] [CrossRef]

- Wijesinghe, K.A.P.; Lanarolle, G.; Gunasekara, C.; Hidallana-Gamage, H.D.; Law, D.W.; Wang, L.; Gamage, N.; Gunathilaka, H.M.B.I. Thermal insulation and acoustic absorption performance of textile fibre-reinforced cement mortars. J. Build. Eng. 2025, 111, 113128. [Google Scholar] [CrossRef]

- Akbar, A.; Kodur, V.K.R.; Liew, K.M. Microstructural changes and mechanical performance of cement composites reinforced with recycled carbon fibers. Cem. Concr. Compos. 2021, 121, 104069. [Google Scholar] [CrossRef]

- Balandin, A.A.; Ghosh, S.; Bao, W.; Bao, W.; Calizo, I.; Teweldebrhan, D.; Miao, F.; Lau, C. Superior Thermal Conductivity of Single-Layer Graphene. Nano Lett. 2008, 8, 902–907. [Google Scholar] [CrossRef] [PubMed]

- Toutanji, H.A.; Elkorchi, T.; Katz, R.N. Strength and reliability of carbon-fiber-reinforced cement composites. Cem. Concr. Compos. 1994, 16, 15–21. [Google Scholar] [CrossRef]

- Banthia, N.; Djeridane, S.; Pigeon, M. Electrical resistivity of carbon and steel micro-fiber reinforced cements. Cem. Concr. Res. 1992, 22, 804–814. [Google Scholar] [CrossRef]

- Zhu, Y.; Murali, S.; Cai, W.; Li, X.; Suk, J.W.; Potts, J.R.; Ruoff, R.S. Graphene and Graphene Oxide: Synthesis, Properties, and Applications. Adv. Mater. 2010, 22, 3906–3924. [Google Scholar] [CrossRef]

- Stoller, M.D.; Park, S.; Zhu, Y.; An, J.; Ruoff, R.S. Graphene-Based Ultracapacitors. Nano Lett. 2008, 8, 3498–3502. [Google Scholar] [CrossRef]

- Varillas, J.; Lukeš, J.; Manikas, A.; Maňák, J.; Dluhoš, J.; Melníková, Z.; Kalbáč, M.; Galiotis, C.; Frank, O. Mechanical response of monolayer graphene via a multi-probe approach. Int. J. Mech. Sci. 2024, 273, 109208. [Google Scholar] [CrossRef]

- Sevim, O.; Jiang, Z.; Ozbulut, O.E. Effects of graphene nanoplatelets type on self-sensing properties of cement mortar composites. Constr. Build. Mater. 2022, 359, 129488. [Google Scholar] [CrossRef]

- Win, T.T.; Raengthon, N.; Prasittisopin, L. Advanced cement composites: Investigating the role of graphene quantum dots in improving thermal and mechanical performance. J. Build. Eng. 2024, 96, 110556. [Google Scholar] [CrossRef]

- Abedi, M.; Fangueiro, R.; Correia, A. Development of a Novel Multifunctional Cementitious-Based Geocomposite by the Contribution of CNT and GNP. Nanomaterials 2021, 11, 961. [Google Scholar] [CrossRef]

- Tufail, R.; Naeem, M.; Ahmad, J.; Waheed, H.; Majdi, A.; Farooq, D.; Maqsoom, A.; Butt, F. Evaluation of the fresh and mechanical properties of nano-engineered self compacting concrete containing graphite nano/micro platelets. Case Stud. Constr. Mater. 2022, 17, e01165. [Google Scholar] [CrossRef]

- Wang, B.; Jiang, R.; Wu, Z. Investigation of the Mechanical Properties and Microstructure of Graphene Nanoplatelet-Cement Composite. Nanomaterials 2016, 6, 200. [Google Scholar] [CrossRef]

- Massion, C.; Lu, Y.; Crandall, D.; Bunger, A.; Radonjic, M. Graphene nanoplatelets reinforced cement as a solution to leaky wellbores reinforcing weak points in hydrated Portland cement with graphene nanoparticles improves mechanical and chemical durability of wellbore cements. Cem. Concr. Compos. 2022, 133, 104726. [Google Scholar] [CrossRef]

- Du, H.; Pang, S.D. Enhancement of barrier properties of cement mortar with graphene nanoplatelet. Cem. Concr. Res. 2015, 76, 10–19. [Google Scholar] [CrossRef]

- Kishore, K.; Pandey, A.; Wagri, N.K.; Saxena, A.; Patel, J.; Al-Fakih, A. Technological challenges in nanoparticle-modified geopolymer concrete: A comprehensive review on nanomaterial dispersion, characterization techniques and its mechanical properties. Case Stud. Constr. Mater. 2023, 19, e02265. [Google Scholar] [CrossRef]

- Tao, J.; Wang, X.; Wang, Z.; Zeng, Q. Graphene nanoplatelets as an effective additive to tune the microstructures and piezoresistive properties of cement-based composites. Constr. Build. Mater. 2019, 209, 665–678. [Google Scholar] [CrossRef]

- Fan, Y.; Ni, Z.; Mu, S.; Hang, Z.; Wang, Y.; Feng, C.; Su, Y.; Weng, G.J. Hybrid micromechanical modelling and experiments on electrical conductivity of graphene reinforced porous and saturated cement composites. Cem. Concr. Compos. 2023, 141, 105148. [Google Scholar] [CrossRef]

- Amiryaghoubi, N.; Fathi, M.; Barar, J.; Omidian, H.; Omidi, Y. Recent advances in graphene-based polymer composite scaffolds for bone/cartilage tissue engineering. J. Drug Deliv. Sci. Technol. 2022, 72, 103360. [Google Scholar] [CrossRef]

- Zeng, Y.; Peng, L.; Ma, B.; Sun, W.; Shi, X.; Zou, Z.; Chen, W. Influence of multi-walled carbon nanotubes on the performance of nano-silica enhanced lightweight cement-based composites under cyclic action of freeze-thaw and erosion. Constr. Build. Mater. 2025, 493, 143132. [Google Scholar] [CrossRef]

- Xu, S.; Liu, J.; Li, Q. Mechanical properties and microstructure of multi-walled carbon nanotube-reinforced cement paste. Constr. Build. Mater. 2015, 76, 16–23. [Google Scholar] [CrossRef]

- Jiříčková, A.; Pavlík, Z.; Pavlíková, M.; Pivák, A.; Záleská, M.; Lauermannová, A.M.; Jankovský, O. Impact of oxidized carbon nanotubes on the mechanical, thermal, and hygric properties of Portland cement- and magnesium oxychloride cement-based mortars: A route to advanced building composites. Case Stud. Constr. Mater. 2025, 22, e04902. [Google Scholar] [CrossRef]

- Han, B.; Yu, X.; Kwon, E. A self-sensing carbon nanotube/cement composite for traffic monitoring. Nanotechnology 2009, 20, 445501. [Google Scholar] [CrossRef]

- Li, W.W.; Ji, W.M.; Wang, Y.C.; Liu, Y.; Shen, R.X.; Xing, F. Investigation on the Mechanical Properties of a Cement-Based Material Containing Carbon Nanotube under Drying and Freeze-Thaw Conditions. Materials 2015, 8, 8780–8792. [Google Scholar] [CrossRef]

- Elena, C.P.; Rosalía, P.T.; Fernando, V. Effect of Multi-Walled Carbon Nanotubes on Strength and Electrical Properties of Cement Mortar. Materials 2021, 14, 79. [Google Scholar]

- Cui, H.; Yang, S.; Memon, S. Development of Carbon Nanotube Modified Cement Paste with Microencapsulated Phase-Change Material for Structural–Functional Integrated Application. Int. J. Mol. Sci. 2015, 16, 8027–8039. [Google Scholar] [CrossRef]

- Habib, A.; Maalej, M.; Dirar, S.; Junaid, M.T.; Altoubat, S. Sensitive Analysis on the Compressive and Flexural Strength of Carbon Nanotube-Reinforced Cement Composites Using Machine Learning. SDHM Struct. Durab. Health Monit. 2025, 19, 789–817. [Google Scholar] [CrossRef]

- Jia, X.; Anna Lushnikova, A.; Plé, O. Use of Carbon Nanotubes for the Functionalization of Concrete for Sensing Applications. Sensors 2025, 25, 3755. [Google Scholar] [CrossRef]

- Saafi, M. Wireless and embedded carbon nanotube networks for damage detection in concrete structures. Nanotechnology 2009, 20, 395502. [Google Scholar] [CrossRef]

- Zhou, L.; Li, J.; Xing, C. MXene–polymer nanocomposites for precise structural and functional applications. Chem. Eng. J. 2025, 506, 159868. [Google Scholar] [CrossRef]

- Tjong, S.C. Recent progress in the development and properties of novel metal matrix nanocomposites reinforced with carbon nanotubes and graphene nanosheets. Mater. Sci. Eng. R 2013, 74, 281–350. [Google Scholar] [CrossRef]

- GB/T 17671-1999; Method of Testing Cement Mortar Strength. China Building Materials Press: Beijing, China, 1999.

- Mironov, V.S.; Kim, J.K.; Park, M.; Lim, S.; Cho, W.K. Comparison of electrical conductivity data obtained by four-electrode and four-point probe methods for graphite-based polymer composites. Polym. Test. 2007, 26, 547–555. [Google Scholar] [CrossRef]

- Islam, I.; Chng, H.K.; Yap, A.U. X-ray diffraction analysis of mineral trioxide aggregate and Portland cement. Int. Endod. J. 2010, 39, 220–225. [Google Scholar] [CrossRef]

- Zuaiter, M.; Al-Rub, R.K.A.; Banat, F.; Kim, T.Y. Bio-derived sustainable graphene alternative for enhancing the mechanical properties of cement mortars. Constr. Build. Mater. 2025, 489, 142245. [Google Scholar] [CrossRef]

- Zhang, Q.; Zeng, Q.; Zheng, D.; Wang, J.; Xu, S. Oven dying kinetics and status of cement-based porous materials for in-lab microstructure investigation. Adv. Cem. Res. 2018, 30, 204–215. [Google Scholar] [CrossRef]

- Hughes, T.L.; Methven, C.M.; Jones, T.G.J.; Pelham, S.E.; Fletcher, P.; Hall, C. Determining cement composition by Fourier transform infrared spectroscopy. Adv. Cem. Based Mater. 1995, 2, 91–104. [Google Scholar] [CrossRef]

- Kim, G.; Suh, H.; Cho, S.; Im, S.; Nezhad, E.; Seok, S.; Choi, C.; Bae, S. Synergistic strengthening mechanism of Portland cement paste reinforced by a triple hybrid of graphene oxide, functionalized carbon nanotube, and nano-silica. Constr. Build. Mater. 2022, 352, 129017. [Google Scholar] [CrossRef]

- Qin, X.; Zhu, S.; Zhang, R. Evaluation of Stabilized Graphite Nanoplatelets: Dispersion Quality and Mechanical Properties of Cement Composites. J. Test. Eval. 2019, 47, 20180482. [Google Scholar] [CrossRef]

- Zaheer, M. Mechanical Performance of Cementitious Composites by MWCNTs Addition for Structural Applications. J. Civ. Eng. Constr. 2020, 9, 51–62. [Google Scholar] [CrossRef]

- Huang, H.; Teng, L.; Gao, X.; Khayat, K.H.; Wang, F.; Liu, Z. Effect of carbon nanotube and graphite nanoplatelet on composition, structure, and nano-mechanical properties of C-S-H in UHPC. Cem. Concr. Res. 2022, 154, 106713. [Google Scholar] [CrossRef]

- Konsta-Gdoutos, M.S.; Metaxa, Z.S.; Shah, S.P. Multi-scale mechanical and fracture characteristics and early-age strain capacity of high performance carbon nanotube/cement nanocomposites. Cem. Concr. Compos. 2010, 32, 110–115. [Google Scholar] [CrossRef]

- Liu, Y.F.; Hu, Y.G. Piezoresistive behavior of Graphene Oxide/Graphite-modified cement-based composites under combined thermal and tensile effects. Constr. Build. Mater. 2025, 481, 141618. [Google Scholar] [CrossRef]

- Dong, W.; Li, W.; Shen, L.; Sun, Z.; Sheng, D. Piezoresistivity of smart carbon nanotubes (CNTs) reinforced cementitious composite under integrated cyclic compression and impact. Compos. Struct. 2020, 241, 112106. [Google Scholar] [CrossRef]

- Jing, G.; Ye, Z.; Lu, X.; Hou, P. Effect of graphene nanoplatelets on hydration behaviour of Portland cement by thermal analysis. Adv. Cem. Res. 2016, 29, 63–70. [Google Scholar] [CrossRef]

- Zeng, Q.; Mao, T.; Li, H.; Peng, Y. Thermally insulating lightweight cement-based composites incorporating glass beads and nano-silica aerogels for sustainably energy-saving buildings. Energy Build. 2018, 174, 97–110. [Google Scholar] [CrossRef]

- Pan, R.; Chen, F.; Feng, Q.; Zeng, Q.; Zhang, Z.; Xu, R. Study on the performance of graphene-enhanced cementitious piezoresistive sensors in self-sensing concrete members. Sens. Actuators A-Phys. 2025, 395, 117050. [Google Scholar] [CrossRef]

- Zhang, J.; Wei, S.; Shang, C.; Duan, Y.; He, Z.; An, H.; Yu, X.; Peng, Z. Modeling and experimental analysis of piezoresistive behavior in conductive porous elastomer under significantly large deformation. Int. J. Eng. Sci. 2024, 201, 104091. [Google Scholar] [CrossRef]

- Cai, J.; Chawla, S.; Naraghi, M. Piezoresistive effect of individual electrospun carbon nanofibers for strain sensing. Carbon 2014, 77, 738–746. [Google Scholar] [CrossRef]

- Goutier, M.; Hilbig, K.; Vietor, T.; Böl, M. Process Parameters and Geometry Effects on Piezoresistivity in Additively Manufactured Polymer Sensors. Polymers 2023, 15, 2159. [Google Scholar] [CrossRef]

- Lebedev, O.V.; Ozerin, A.N.; Abaimov, S.G. Multiscale Numerical Modeling for Prediction of Piezoresistive Effect for Polymer Composites with a Highly Segregated Structure. Nanomaterials 2021, 11, 162. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, T.; Zhang, B.; Williams, T.; Lin, Y.T.; Li, L.; Zhou, Y.; Lu, W.; Kim, S.H.; Chen, L.Q.; et al. Structural Insight in the Interfacial Effect in Ferroelectric Polymer Nanocomposites. Adv. Mater. 2020, 32, e2005431. [Google Scholar] [CrossRef]

- Sun, Q.; Luo, S.; Lin, Y.; Yan, X.; Huang, R.; Liu, Q.; Yan, S.; Lin, X. Interfacial electric field effects enhance the kinetics and stability of magnesium metal anodes for rechargeable magnesium batteries. Adv. Powder Mater. 2025, 4, 100335. [Google Scholar] [CrossRef]

- Romain, M.; Roman, P.; Saviot, L.; Millot, N.; Boireau, W. Inferring the Interfacial Reactivity of Gold Nanoparticles by Surface Plasmon Resonance Measurements. Langmuir 2023, 39, 13058–13067. [Google Scholar] [CrossRef]

- Zhang, Y.; Xia, W.; Wang, D.; Jiang, Z.; Wang, X.; Dong, M.; Chen, K. Highly stretchable, self-healing, anti-freezing, and moisturizing hydrogel with efficient conductive pathways for self-powered sensing skin electronics. Chem. Eng. J. 2025, 520, 165986. [Google Scholar] [CrossRef]

| Chemical Composition | Percentage | Mineral Composition | Percentage |

|---|---|---|---|

| SiO2 | 22.15 | C3S | 56.54 |

| Al2O3 | 4.51 | C2S | 20.87 |

| Fe2O3 | 3.39 | C3A | 6.22 |

| CaO | 65.36 | C4AF | 10.31 |

| MgO | 2.31 | ||

| SO3 | 0.46 | ||

| NaOeq | 0.488 | ||

| f-CaO | 0.95 |

| Material | GNP | Material | CNT |

|---|---|---|---|

| Diameter | 5–10 μm | Purity | >95% |

| Thickness | 3–10 nm | External diameter, Internal diameter | 8–15 nm, 3–5 nm |

| Specific surface area | 31.657 m2/g | Length | ~50 μm |

| Tap density | 0.075 g/cm3 | Specific surface area | >140 m2/g |

| Apparent density | 0.050 g/cm3 | Color | Black |

| Carbon content | >99.5% | Tap density | 0.15 g/cm3 |

| Appearance | Black powder | Real density | ~2.1 g/cm3 |

| Electrical conductivity | 500–1000 S/cm | Electrical conductivity | >100 S/cm |

| Purity | 99.5% |

| Material | Melamine |

|---|---|

| Appearance | White powder |

| Bulk density | 0.5–0.8 g/cm3 |

| Drying loss | <4% |

| pH | 9–11.4 (20 °C 20% solution) |

| Number | GNP (%) | CNT (%) | Dispersant (g) | Cement (g) | Water (g) |

|---|---|---|---|---|---|

| Ref | 0 | 0 | 0 | 2700 | 945 |

| 0.1% GNP | 0.1 (2.7) | 0 | 1.35 | ||

| 0.1% CNT | 0 | 0.1(2.7) | |||

| 0.02% GNP + 0.08% CNT | 0.02 (0.54 g) | 0.08 (2.16 g) | |||

| 0.05% GNP + 0.05% CNT | 0.05 (1.35 g) | 0.05 (1.35 g) | |||

| 0.08% GNP + 0.02% CNT | 0.08 (2.16 g) | 0.02 (0.54 g) | |||

| 0.5% GNP | 0.5 (13.5) | 0 | 6.75 | ||

| 0.5% CNT | 0 | 0.5 (13.5) | |||

| 0.1% GNP + 0.4% CNT | 0.1 (2.7 g) | 0.4 (10.8 g) | |||

| 0.25% GNP + 0.25% CNT | 0.25 (6.75 g) | 0.25 (6.75 g) | |||

| 0.4% GNP + 0.1% CNT | 0.4 (10.8 g) | 0.1 (2.7 g) |

| Number | Porosity (%) | Mean Pore Size (nm) | Threshold Pore Size (nm) |

|---|---|---|---|

| Ref | 15.5 | 12.2 | 17.1 |

| 0.1% GNP | 15.2 | 12.5 | 17.1 |

| 0.1% CNT | 15.6 | 12.2 | 17.1 |

| 0.02% GNP + 0.08% CNT | 16.1 | 13.4 | 40.3 |

| 0.05% GNP + 0.05% CNT | 15.8 | 12.1 | 17.1 |

| 0.08% GNP + 0.02% CNT | 16.4 | 13.9 | 40.3 |

| 0.5% GNP | 14.9 | 10.8 | 13.7 |

| 0.5% CNT | 15.2 | 10.7 | 13.7 |

| 0.1% GNP + 0.4% CNT | 15.8 | 13.6 | 40.3 |

| 0.25% GNP + 0.25% CNT | 14.7 | 10.7 | 13.7 |

| 0.4% GNP + 0.1% CNT | 14.5 | 14.6 | 40.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tu, K.; Zhang, Y.; Wang, J.; Yang, H.; Tao, J.; Zeng, Q. Synergistic Microstructures, Mechanical Properties, and Piezoresistive Performance Improvement of Nanoengineered Cementitious Composites by CNT and GNP. Buildings 2025, 15, 4104. https://doi.org/10.3390/buildings15224104

Tu K, Zhang Y, Wang J, Yang H, Tao J, Zeng Q. Synergistic Microstructures, Mechanical Properties, and Piezoresistive Performance Improvement of Nanoengineered Cementitious Composites by CNT and GNP. Buildings. 2025; 15(22):4104. https://doi.org/10.3390/buildings15224104

Chicago/Turabian StyleTu, Kebiao, Yeqing Zhang, Junjian Wang, Haiyan Yang, Jin Tao, and Qiang Zeng. 2025. "Synergistic Microstructures, Mechanical Properties, and Piezoresistive Performance Improvement of Nanoengineered Cementitious Composites by CNT and GNP" Buildings 15, no. 22: 4104. https://doi.org/10.3390/buildings15224104

APA StyleTu, K., Zhang, Y., Wang, J., Yang, H., Tao, J., & Zeng, Q. (2025). Synergistic Microstructures, Mechanical Properties, and Piezoresistive Performance Improvement of Nanoengineered Cementitious Composites by CNT and GNP. Buildings, 15(22), 4104. https://doi.org/10.3390/buildings15224104