Abstract

Rubberized concrete is a novel green building material that enhances many features when rubber particles are incorporated into cement mortar, simultaneously yielding economic benefits through the recycling of waste tires. This study applies styrene–butadiene latex (SBL) for toughening treatment. The investigation delves into the mechanism by which SBL improves the interface between rubber and cement, encompassing macroscopic mechanical properties, microscopic structural characteristics, and nano-scale interfacial interactions. Macroscopic mechanical tests reveal a significant increase in flexural strength, shear strength, and compressive strength of the composite concrete upon the introduction of SBL and rubber. Specifically, the compressive strength improved by 8.8%, shear strength by 13.7%, and flexural strength by 18.9% at 28 days. Through electron microscopy observation of corresponding polymer cement concrete sections, observations reveal that SBL reinforces both interfaces and elucidates its bonding impact at the micro-level interface. Molecular dynamics (MD) modeling of SBL/rubber/CSH is employed at the nanoscale to compute and examine the local structure, dynamic behavior, and binding energy of the interface. The findings indicate that SBL mitigates interface impacts, enhances interface hydrogen bonds, van der Waals interactions,

coordination bonds, and stability, consequently improving interfacial adhesion and fortifying the feeble interface bonding between organic polymers (rubber) and inorganic silicates (CSH).

1. Introduction

Recycled rubber concrete involves integrating waste rubber particles into standard concrete as a constituent material, resulting in a specialized form of concrete. Contrasted with traditional concrete, the incorporation of recycled rubber can improve the performance of multiple materials and finds utility in sound insulation, lightweight construction, freeze–thaw resistance, and heat-resistant composite materials [1,2]. Through various experiments, Ehsan M et al. [3] discovered that integrating rubber enhances the ductility of concrete while reducing its density, rendering it suitable for lightweight concrete applications. Xianfeng P et al. [4] validated the high durability of rubber concrete through numerical simulations of fatigue life at a microscopic scale. Hence, rubber concrete holds vast prospects for application in civil engineering. However, substituting rubber for natural aggregates may diminish the strength of concrete, limiting its widespread adoption in structural engineering [5]. Therefore, enhancing its interface properties is imperative. Liu K et al. [6] replaced 5%, 10%, and 15% of sand in concrete with rubber particles and introduced basalt fibers into rubber concrete, resulting in varied improvements in mechanical and carbonation properties. Yong F et al. [7] conducted a multiscale analysis on the mechanical features of PVA fiber rubber concrete, which underwent modification with the KH-560 coupling agent. They revealed that the silane coupling agent (SCA) adeptly remedied interface imperfections between rubber and hydration products. Numerous studies have illustrated that additives possess the capability to enhance the mechanical attributes of rubber concrete. Yuan, BX’s [8] team explored the effects of SiO2/Na2O ratio and liquid–solid ratio on the properties of alkali-activated engineering waste (EM) base polymers and performed a life cycle assessment. The results show that when the SiO2/Na2O ratio is 1.5, the seven-day compressive strength reaches 42 MPa, which is the best performance.

Because of its well-established manufacturing process and economical price point, styrene–butadiene latex (SBL) has emerged as a prevalent binding agent in modified concrete. Research by Murat MM et al. [9] indicates a significant enhancement in load-bearing capacity and ductility of specimens after the addition of SBL. Zhe X et al. [10] immersed rubber particles in SBL and then incorporated them into cementitious mortar, resulting in a noticeable enhancement of the interfacial behavior of the mortar. B.A. K and colleagues found that SBL improves the bonding efficiency of base concrete [11]. Dong et al.’s [12] study demonstrates improvements in flexural strength, bending toughness, as well as the impact toughness of cement concrete modified with a styrene–butadiene emulsion. While the aforementioned experiments validate the potential of SBL to improve concrete’s mechanical properties, there remains a scarcity of research concerning the performance diversity of rubber concrete, and a thorough exploration of the interface is lacking in multiscale analysis.

Multiscale analysis can better elucidate the interface bonding behavior between polymers and cementitious materials, with the introduction of molecular dynamics (MD) simulation techniques providing an opportunity for this [13]. Lijuan L et al. [14] adopted an integrated approach combining experimentation and simulation. They utilized molecular dynamics simulations to reveal the modification mechanisms and validate the macro- and micro-scale test results. The research conducted by Na Z et al. [15] involved molecular dynamics simulation to examine both the adsorption and diffusion properties of ions at different concentrations, as well as the behavior of water molecules.

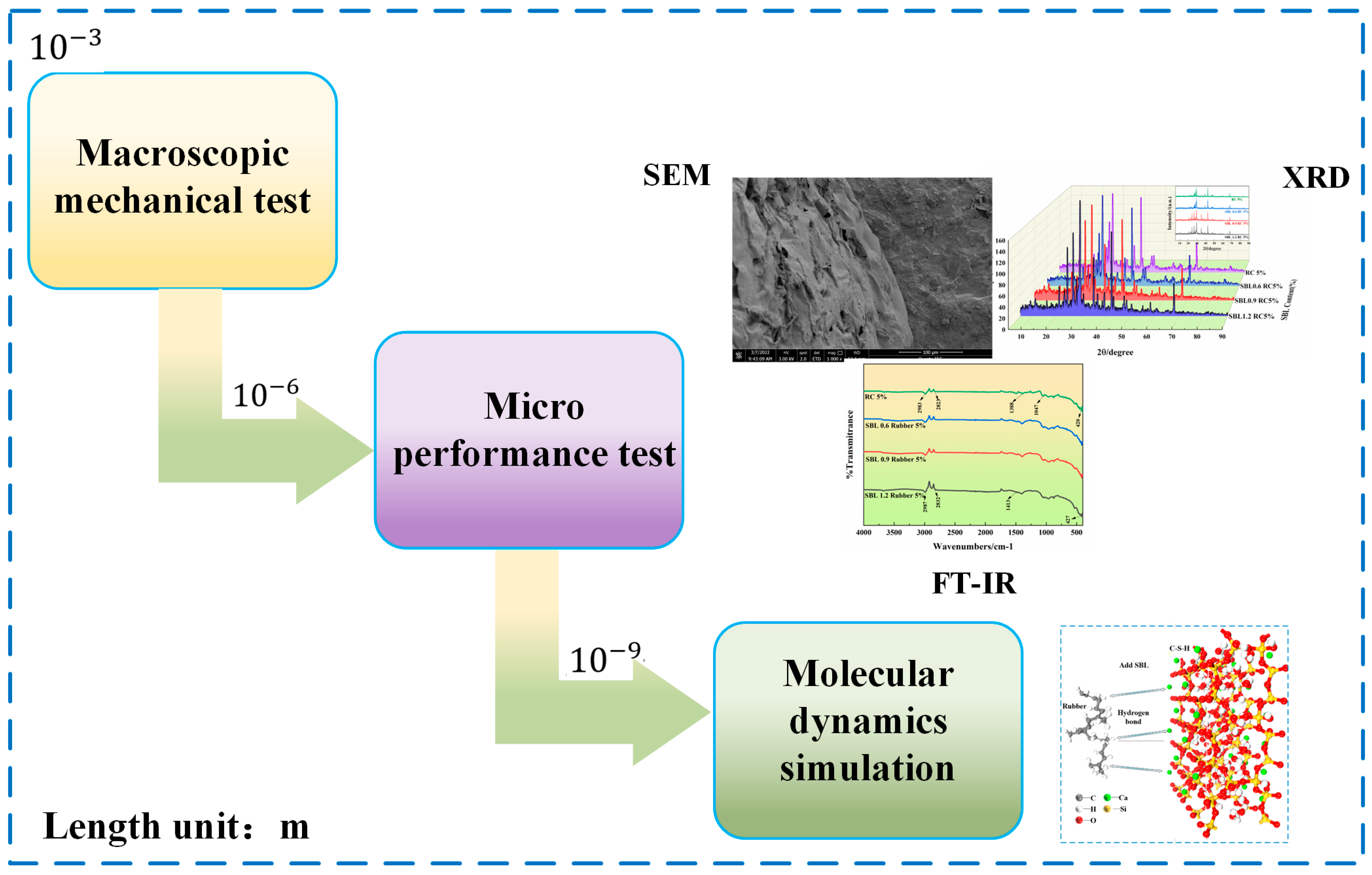

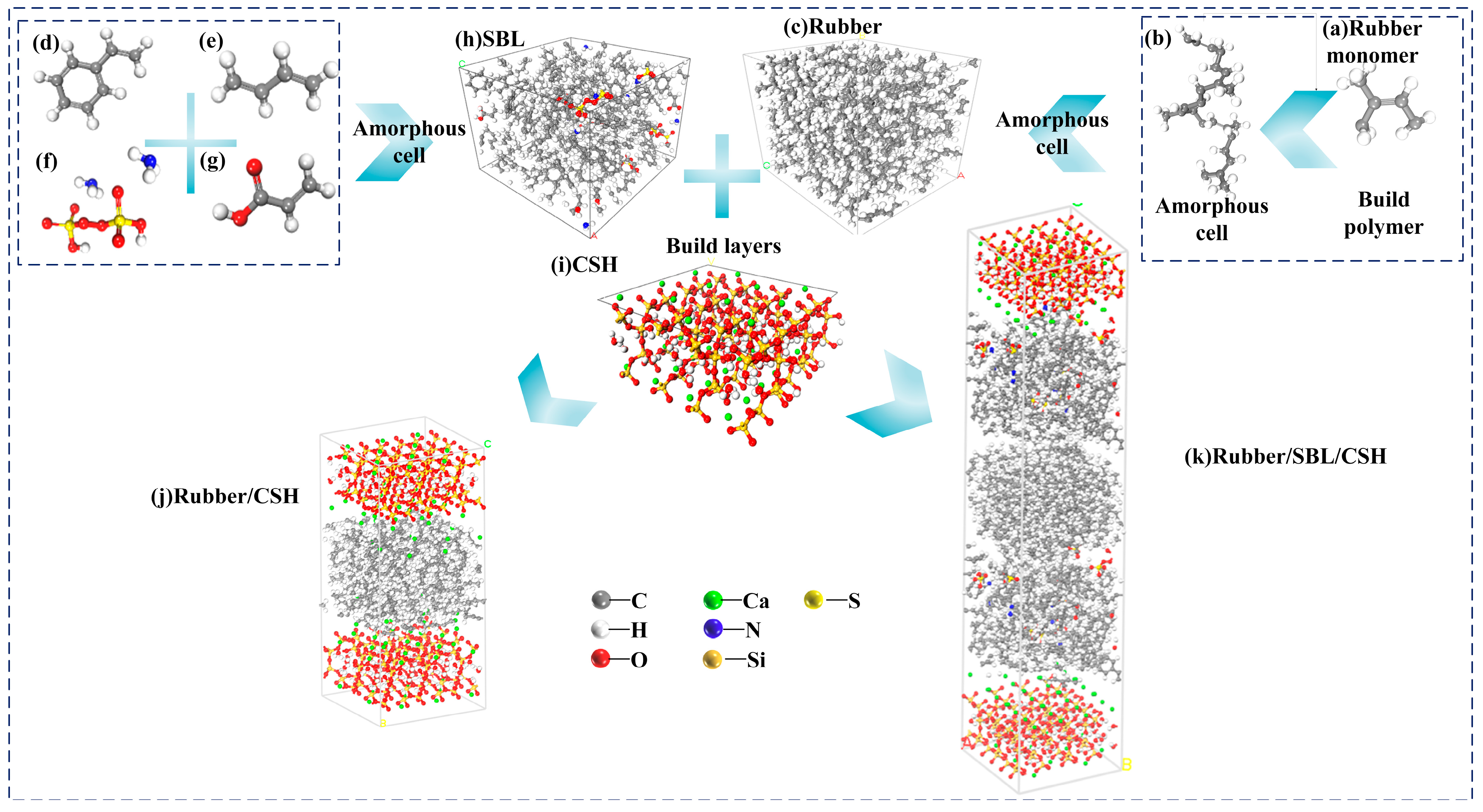

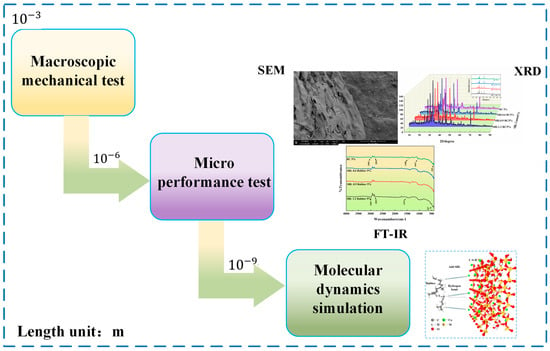

As depicted in Figure 1, this study applied SBL for the modification of rubber concrete and the assessment of mechanical properties in organic material composite concrete. Afterwards, SEM was utilized to characterize the interface structure between the SBL and rubber in conjunction with cementitious materials. Furthermore, the examination of chemical composition’s influence on reaction products was conducted through XRD and FT-IR. Ultimately, the molecular-scale investigation of SBL’s effect on interface properties in rubber concrete was conducted, providing theoretical insights for SBL’s application in concrete.

Figure 1.

Multiscale process.

2. Measure

2.1. Primary Materials

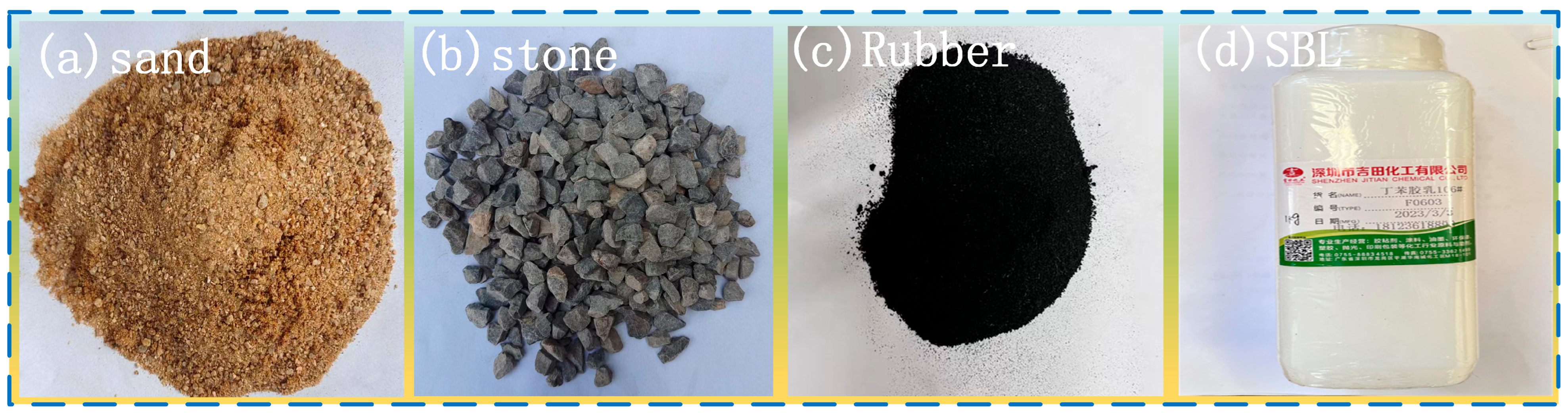

The fine aggregate used in this study is river sand (Figure 2a) with a fineness modulus of 2.6 and particle sizes between 0.25 and 0.40 mm. The coarse aggregate consists of gravel (Figure 2b), its maximum dimension is 19 mm, with a specific gravity of 2.6. The high strength rubber, depicted in Figure 2c, is sourced from Shanghai Chenqi Chemical Technology Co., Ltd. (Shanghai, China), with its physical and mechanical characteristics detailed in Table 1. The SBL utilized in this investigation, illustrated in Figure 2d, is supplied by Shenzhen Yoshida Chemical Co., Ltd. (Shenzhen, China), with its technical specifications outlined in Table 2. Portland cement (PO42.5), employed in this study, is furnished by China Hebei Cement Co., Ltd. (Shijiazhuang, China), boasting a design strength of 30 MPa.

Figure 2.

Test materials, where (a) fine aggregate, (b) coarse aggregate, (c) rubber, and (d) SBL.

Table 1.

Rubber parameters.

Table 2.

Styrene–butadiene latex parameters.

2.2. Treatment Method and Mechanism

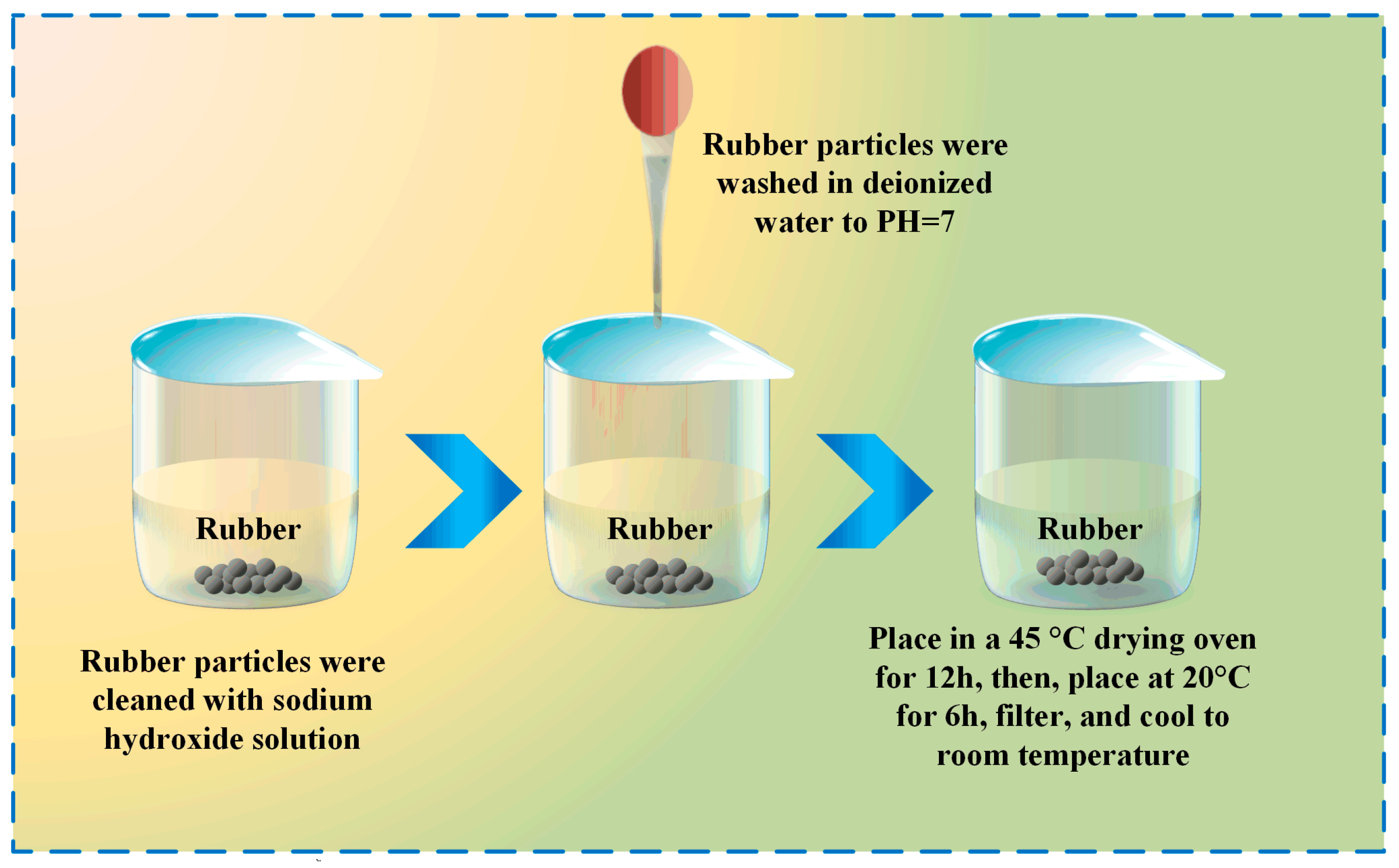

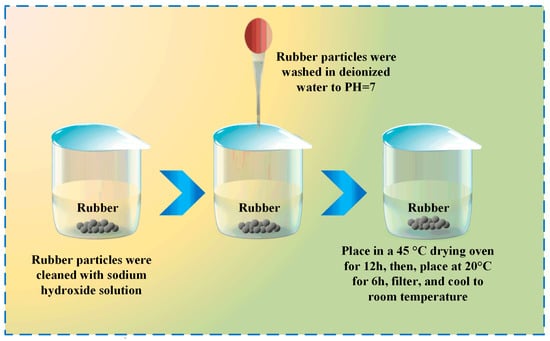

When rubber particles replace part of the fine aggregate in concrete, the weak bonding at the rubber–cement interface generally reduces compressive strength [16]. Surface pretreatment of rubber is considered the most effective strategy to mitigate this adverse effect [17,18]. Therefore, pre-treating rubber particles with sodium hydroxide to remove substances from the surface of rubber powder, reduce surface voids, and avoid untreated rubber surface roughness and porosity is essential. The entire process is illustrated in Figure 3 [19].

Figure 3.

Rubber pretreatment.

2.3. Mix Ratio Design

The concrete formula in the test referred to the “Common Concrete Mix Proportion Design Regulations” (JGJ55-2011), [20,21] and the water–cement ratio was 0.49. To form a controlled trial. Group A’s rubber replaced fine aggregate 5% rubber concrete (RC) as a blank control. In this study, 5%, 10%, and 15% of fine aggregate were replaced by equal volumes of rubber. The water parameters of SBL were 0.6%, 0.9%, and 1.2%. Table 3 shows the details of the compression test, shear test, and bending test that were carried out on specimens with different proportions, and three test blocks were designed for each test to ensure the accuracy of the experimental results.

Table 3.

Modified rubber concrete mix proportions.

2.4. Specimen Preparation

The study aimed to validate the macroscopic mechanical effects of SBL on rubber concrete. concrete was prepared in nine sets with different parameters, and each set underwent compressive, shear, and flexural tests at 7 and 28 days. Three samples were used for each mechanical test to calculate error values. SBL/rubber composite concrete was added to HJW-60 with specified quantities of coarse and fine aggregates, where they were blended for a duration of 1 min, followed by the addition of 3.9 kg of cement and stirring for 2 min. The appropriate weight proportions of SBL were mixed with 1.6 kg of water. Additionally, to ensure the uniform distribution of rubber particles in the cement mortar, rubber particles were added to the mixer in three equal parts, each time stirring for 1 min. Subsequently, all water and SBL mixtures were added and stirred for 2 min before pouring the mixture into molds coated with a releasing agent. The molds were vibrated on a vibrating table for 1 min while simultaneously smoothing the surface. Following a 24 h curing period at room temperature, all concrete test blocks were removed from the molds and subsequently transferred to a standard curing room for periods of 7 and 28 days.

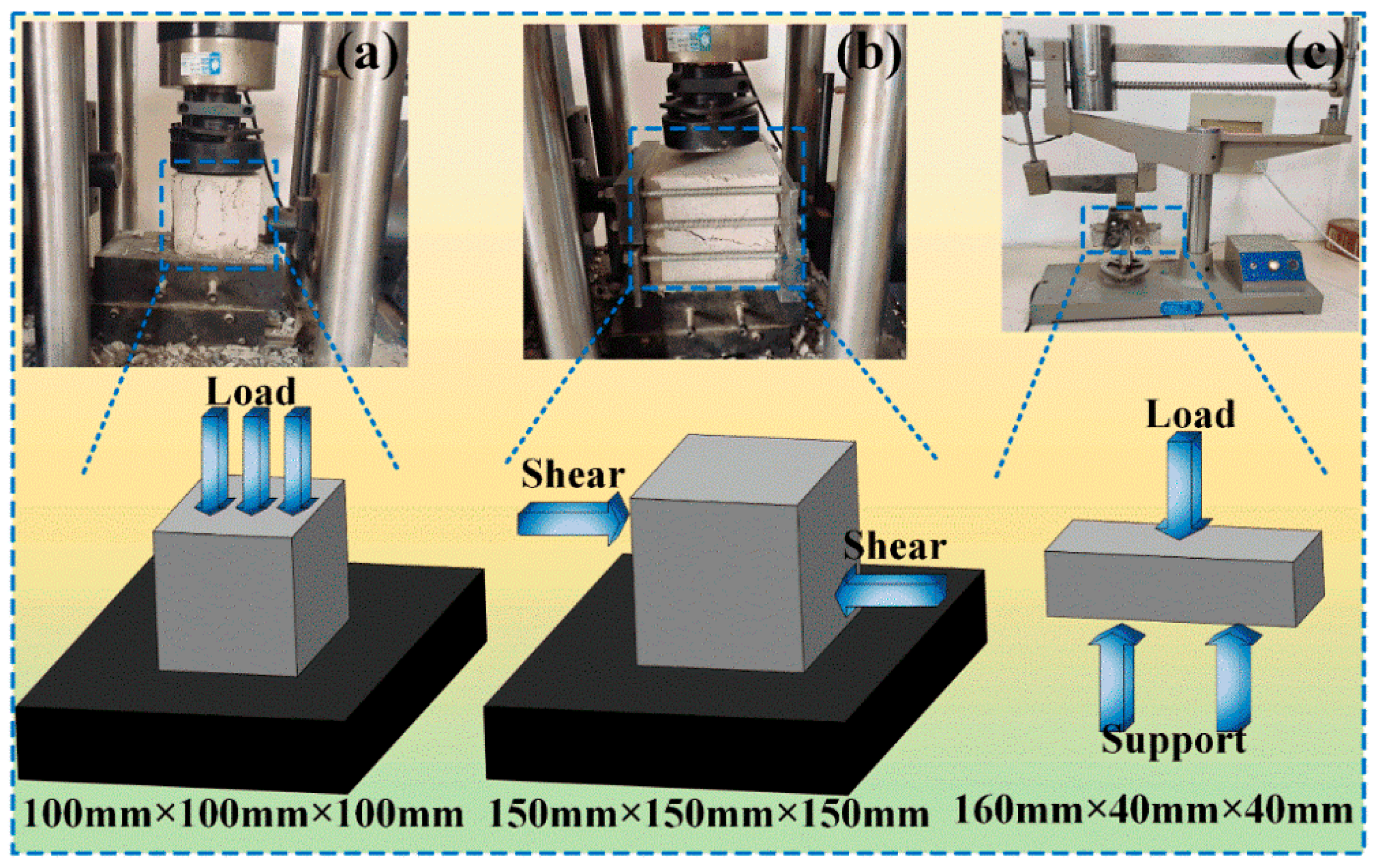

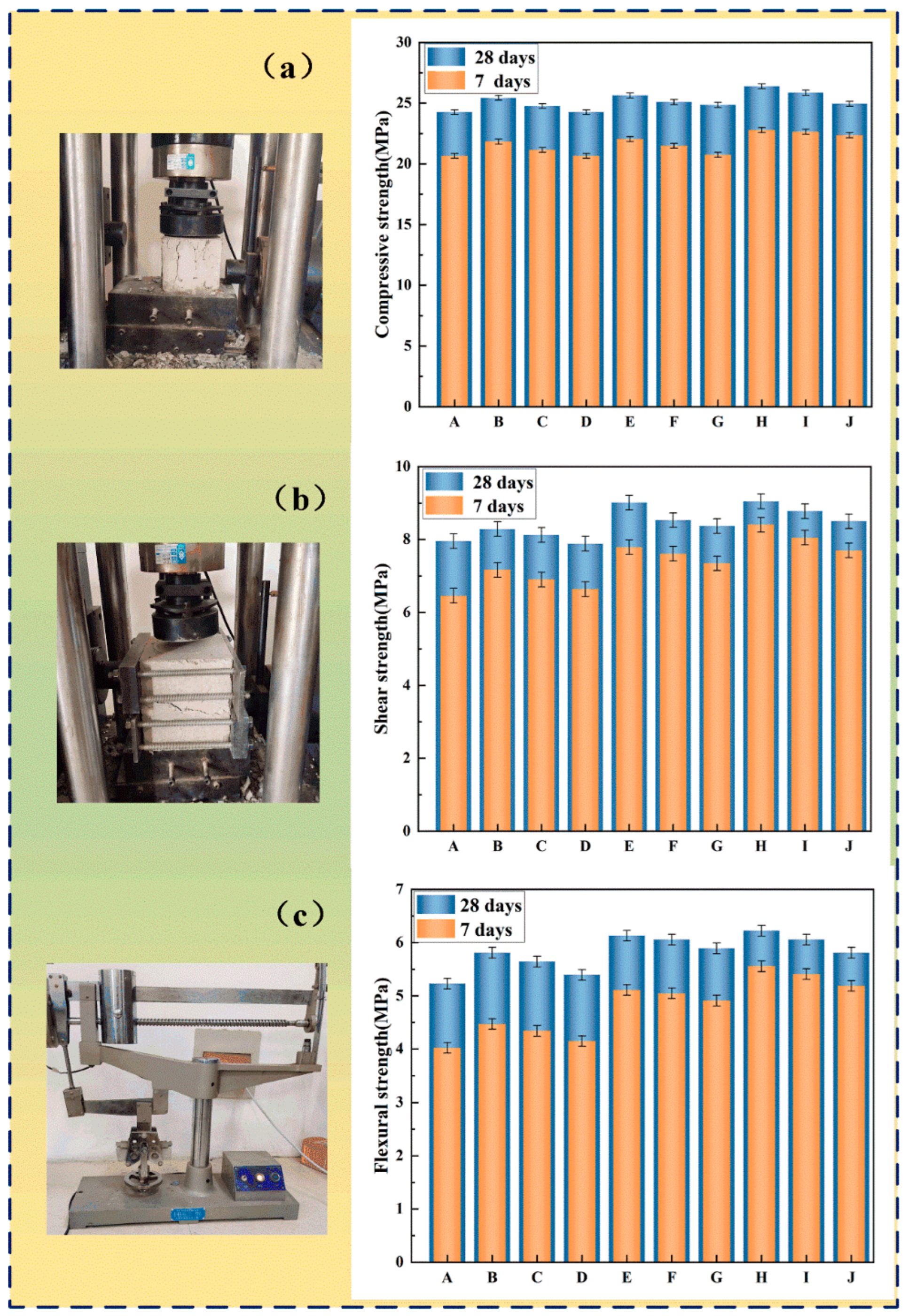

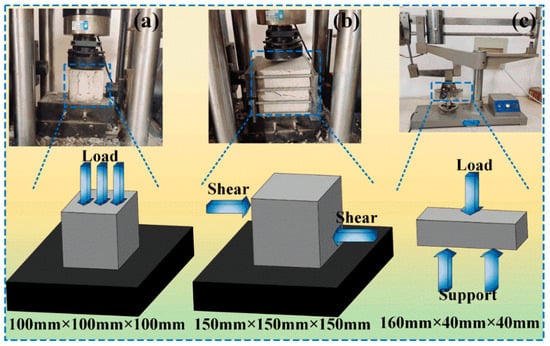

2.5. Mechanical Testing

To understand the mechanical properties of SBL/rubber composite concrete, researchers conducted mechanical tests on the composite samples at specified curing ages (7 and 28 days). These tests followed the guidelines stipulated in the “Standard for Test Methods of Concrete Physical and Mechanical Properties” (GB/T 50081-2019 [22]). The specimens used for compressive strength tests had dimensions of 100 mm × 100 mm × 100 mm, while those for shear strength tests were sized at 150 mm × 150 mm × 150 mm. The equipment used for shear strength tests was the Y250 digital stress-controlled direct shear tester. For flexural strength tests, the specimen dimensions were 40 mm × 40 mm × 160 mm and a DKZ-5000 electric bending testing machine was used (Wuxi Jianyi, Wuxi, China). The instruments and their operational principles are illustrated in Figure 4.

Figure 4.

Laboratory equipment, (a–c) are compressive, shear and flexural tests, respectively.

3. Microanalysis

3.1. Scanning Electron Microscope (SEM)

The experimental procedure was as follows: Specimens that had not cured to the specified time were cut into cubes of 10 mm × 10 mm × 10 mm. After being smoothed with 2000-grit sandpaper, Immersion in anhydrous ethanol was used to prevent further hydration of the specimens. Following this, they were subjected to 24 h of drying in a vacuum oven at 40 °C and then air dried. Lastly, the specimens were affixed to the sample stage for gold coating under vacuum conditions. Following modification, the SEM equipment was employed to analyze the microstructure of the interfaces between SBL/cement and rubber/cement, both before and after the process.

3.2. X-Ray Diffraction (XRD)

XRD analysis of samples stored for 28 days was performed to determine the phase composition and content of SBL and rubber composites. The experimental process proceeded in the following manner: chunks of rubber concrete (RC) devoid of direct stress, alongside those featuring a 5% rubber substitution, and exhibiting SBL parameters of 0.6%, 0.9%, and 1.2%, underwent immersion in anhydrous ethanol for 48 h to stop hydration reactions. Subsequently, it was ground into a powder. This was followed by a 24 h drying treatment conducted in a vacuum oven at 50 °C. The resulting powder was then shaped into a 15 mm × 15 mm flat surface for analysis in a diffractometer.

3.3. Fourier Transform Infrared Spectrometer (FT-IR)

Incorporating SBL into cementitious materials initiates a sequence of reactions with cement hydration products, prompting a need for additional investigation into the chemical interactions of SBL during the hydration process. For this purpose, damaged specimens of rubber concrete (RC) with 5% rubber substitution and SBL parameters of 0.6%, 0.9%, and 1.2% were selected. Following grinding into a suitable powder for infrared spectroscopy experiments, the specimens underwent 24 h of vacuum drying and then were subjected to infrared spectroscopic analysis using the equipment.

4. Molecular Simulation

4.1. Computational Model

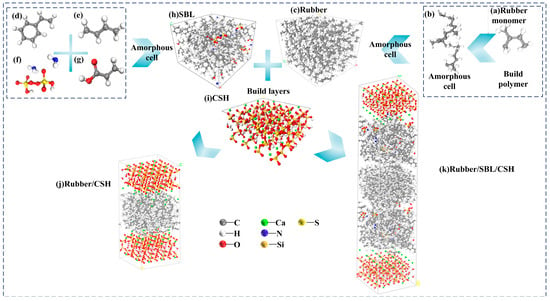

Given the predominant use of synthetic rubber in current production and applications, a unit cell with a density of 1.93 g/cm3 was selected for the rubber model based on the main components of hydrocarbons in the experimental materials. Five rubber monomers, as shown in Figure 5a, were assembled to form polymer chains in the build polymer step, depicted in Figure 5b. Subsequently, an amorphous cell was formed to create an indefinite unit cell (Figure 5c), with dimensions a = 20.20 Å, b = 20.20 Å, c = 20.87 Å, and τ = 90°. For the styrene–butadiene latex model, a unit cell with a density of 1.01 g/cm3 was chosen based on the main components of the experimental materials. Benzene monomers (Figure 5d), butadiene monomers (Figure 5e), ammonium persulfate monomers (Figure 5f), and acrylic acid monomers (Figure 5g) were combined in a ratio of 62:30:4:4 to form an amorphous cell (Figure 5h), with dimensions a = 20.20 Å, b = 20.20 Å, c = 20.87 Å, and τ = 90°. The primary binding phase in concrete materials is calcium silicate hydrate () gel, which accounts for 70% of cement hydration products and significantly influences the properties of cement and concrete [23,24]. Previous studies have demonstrated that the molecular structure model of Tobermorite can well match various parameters of actual [22]. Therefore, an initial model of Tobermorite with a size of 1.1 nm was derived from the inorganic crystal database. Subsequently, it was sliced, extended, and combined along the crystal plane [0 0 1] to form nanoscale pores, with a thickness of approximately 11.0 Å on one side of the substrate. Placed within a lattice with dimensions a = 20.20 Å, b = 20.20 Å, c = 11.00 Å, and τ = 90° and a vacuum layer thickness of , utilizing this configuration, the gel pore was fashioned to serve as the model for the cementitious substrate, illustrated in Figure 5i. To evaluate the effect of SBL on the adsorption behavior of at the interface, two initial models were formulated: one without SBL doping and one with SBL doping. The initial model without SBL doping was formed by building layers of rubber (Figure 5c) and (Figure 5i), resulting in the model (Figure 5j). On the other hand, the initial model with SBL doping was created by building layers of SBL (Figure 5h), rubber (Figure 5c), and (Figure 5i), leading to the model, as depicted in Figure 5k.

Figure 5.

(j) model and (k) model.

4.2. Force Field Simulation Details

Previous studies have demonstrated that the COMPASS force field provides good agreement with experimental results, enabling its application in simulating cement hydration products [25,26]. Hence, the molecular dynamics experiment in this study adopted the COMPASS force field. An isothermal–isobaric (NPT) ensemble was employed to simulate the interface model, and the time steps were set to 200 ps and 1 fs, respectively. In order to reduce the target volume, the system is stabilized at a density close to the actual value. Then, the molecular dynamics experiments were carried out by constant volume thermometry (NVT). Upon completion of dynamic simulation utilizing a time step of 1 fs and spanning a total duration of 1 ns, the final ballistic file was acquired. Throughout this sequence, maintenance of the target temperature and pressure within the system was ensured via the utilization of Nose–Hoover–Langevin (NHL) and Andersen methodologies. Under both NPT and NVT regimes, the stabilization of temperature and density occurred, validating the sufficiency of the relaxation interval [27].

5. Results and Discussion

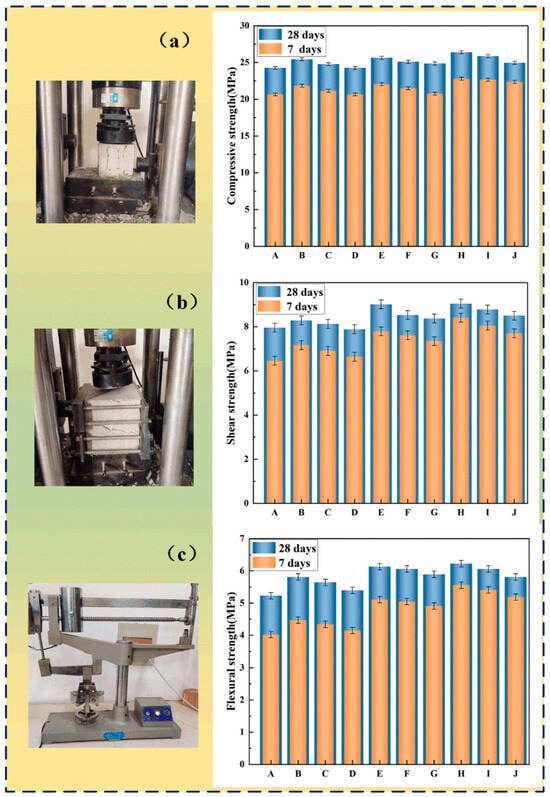

5.1. Mechanical Test Result

This article conducted classical macroscopic experiments by setting a blank control group (RC) and nine specimens with different mixing ratios to ensure the universality of the experimental results. In Figure 6a, the compressive strength test outcomes for SBL/rubber concrete with varying contents are depicted at both 7 and 28 days. A statistical examination was conducted to compare the mechanical properties of SBL/rubber concrete at different concentrations with those of group A, which represents regular rubber concrete. When fixing the SBL, the compressive strength of concrete decreased notably with higher rubber content at both 7 and 28 days. Conversely, at a constant rubber content, increasing SBL dosage led to a marked improvement in compressive strength. This suggests that incorporating SBL can counteract the decline in compressive strength observed in rubber concrete. Figure 6b shows the shear strength results of SBL/rubber concrete at 7 and 28 days. Compared with the RC group, the shear strength declined with increasing rubber content under constant SBL conditions, indicating the detrimental effect of rubber on shear performance. Correspondingly, Figure 6c presents the flexural performance of SBL/rubber concrete at 7 and 28 days, showing a trend similar to that of rubber concrete. While maintaining constant SBL parameters, an increase in rubber content led to a reduction in the flexural strength of concrete, suggesting that the incorporation of rubber decreases concrete’s flexural performance. Conversely, with fixed rubber content, enhancing the SBL parameters resulted in improved flexural strength for rubber concrete, highlighting SBL’s capacity to enhance rubber concrete’s flexural performance.

Figure 6.

Experimental results of macroscopic mechanics, (a–c) show the results of compressive, shear and flexural tests, respectively.

According to the statistical findings mentioned above, it is clear that the overall mechanical strength of rubber concrete rises as the SBL parameters increase. Specifically, when the SBL parameter is 1.2 and rubber replaces 5% of the fine aggregate, the comprehensive mechanical performance is maximally enhanced compared to 5% rubber concrete. The compressive, shear, and flexural performance of specimens cured for 7 days improved by 10.3%, 23.1%, and 27.5%, respectively, while those cured for 28 days improved by 8.8%, 13.7%, and 18.9%, respectively. This illustrates how SBL effectively reduces the brittle failure of rubber concrete while augmenting its toughness. Furthermore, SBL has the capability to fortify the interface bonding between the polymer and the cement matrix, thereby enhancing the mechanical characteristics of composite concrete. This hypothesis will be validated in the subsequent chapters through SEM, XRD, FT-IR, and MD.

5.2. Microscopic Test Result

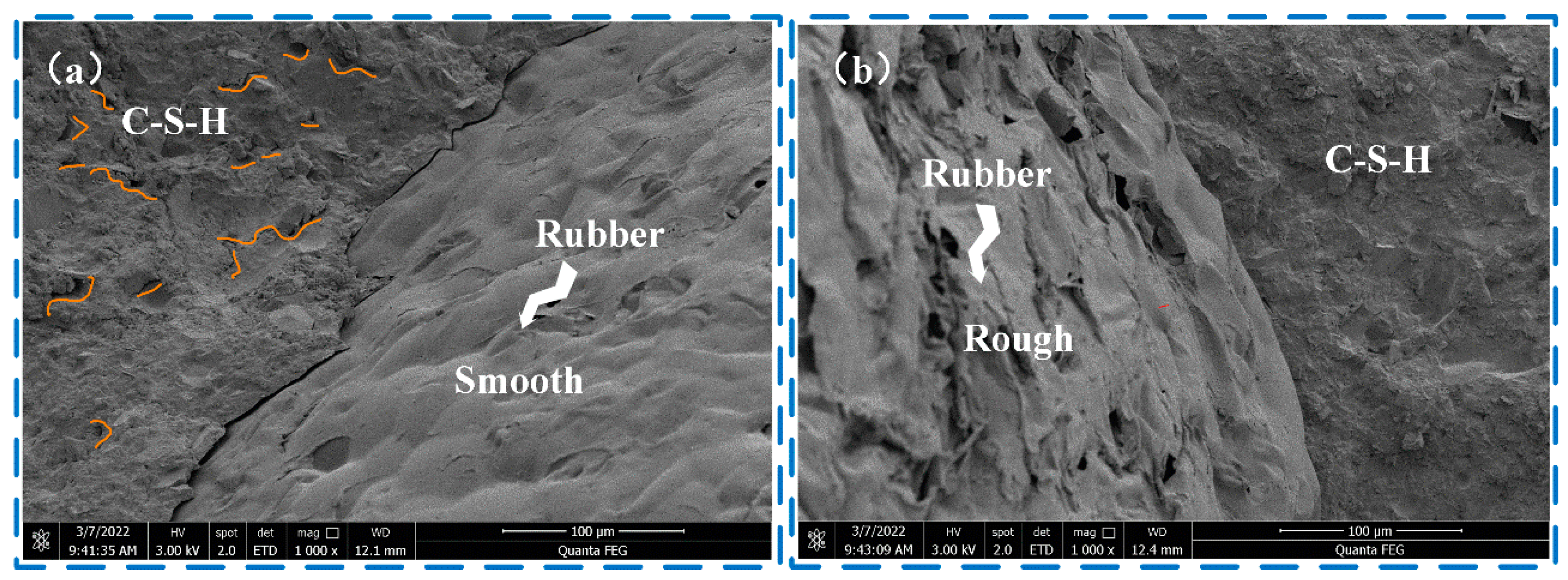

5.2.1. SEM

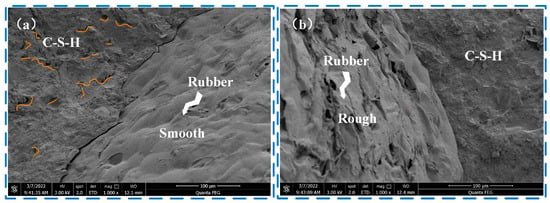

As shown in Figure 7a, after the destruction of low-parameter SBL/rubber concrete, the rubber surface leaves a smooth trace, and the cement-based surface has more holes and gaps. It can be seen in Figure 7b, that after the destruction of rubber concrete after adding SBL, the rubber surface is obviously rough, the cement-based surface is also more-dense, and the holes and gaps are greatly reduced. The bond strength and interfacial toughness are improved. The SBL fills the pores, enabling the rubber to establish a strong bond with the cement base, thus enhancing the bond strength between the components. The findings indicate that the interfacial bonding provided by SBL mitigates cracking in the composite concrete, while its incorporation enhances the adhesion between the rubber particles and the cement paste.

Figure 7.

(a) electron microscope results, (b) electron microscope results.

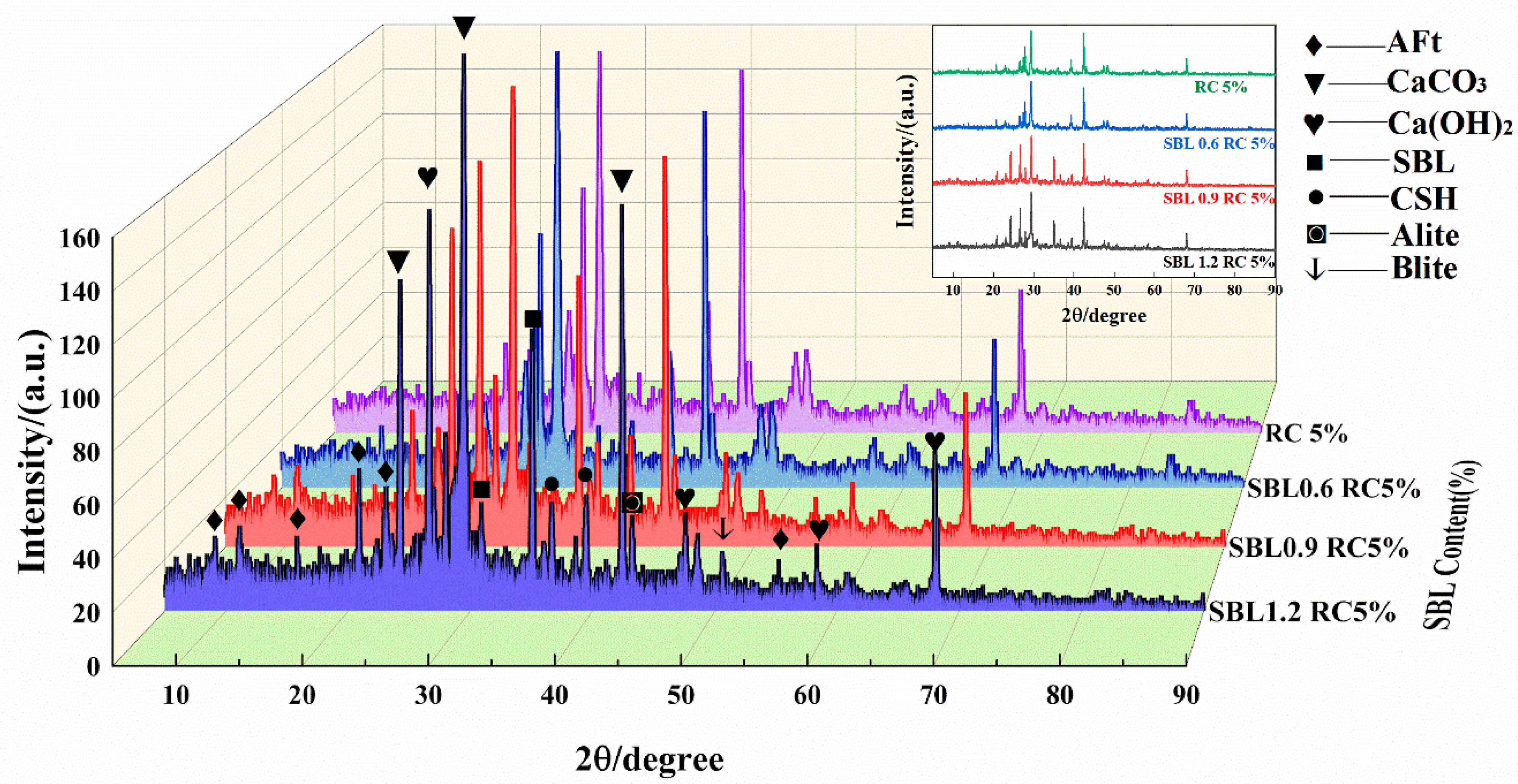

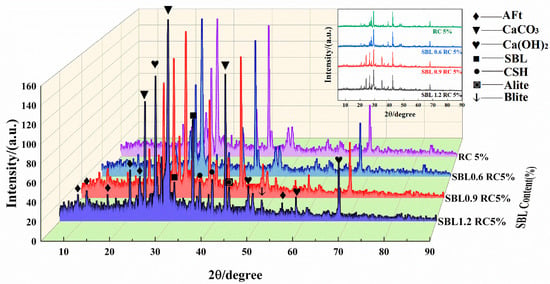

5.2.2. XRD

As depicted in Figure 8, short peaks emerge around 29° in rubber concrete following the addition of SBL, aligning closely with the profile of absorption peaks in other regions, albeit with alterations in intensity. These findings suggest that SBL likely impacts the content and crystallization of hydration products without altering the composition of composite hydration products. Furthermore, in rubber concrete powder containing SBL, the characteristic peaks of Alite and Belite exhibit increased prominence, indicating a delay in the cement’s chemical reaction induced by SBL [28]. A short peak at 38°, possibly representing gel with low crystallinity, suggests that adding SBL augments the quantity of gel [7], resulting in enhanced interfacial density, optimized the interfacial strength, and thus increased the properties of rubber concrete.

Figure 8.

XRD results.

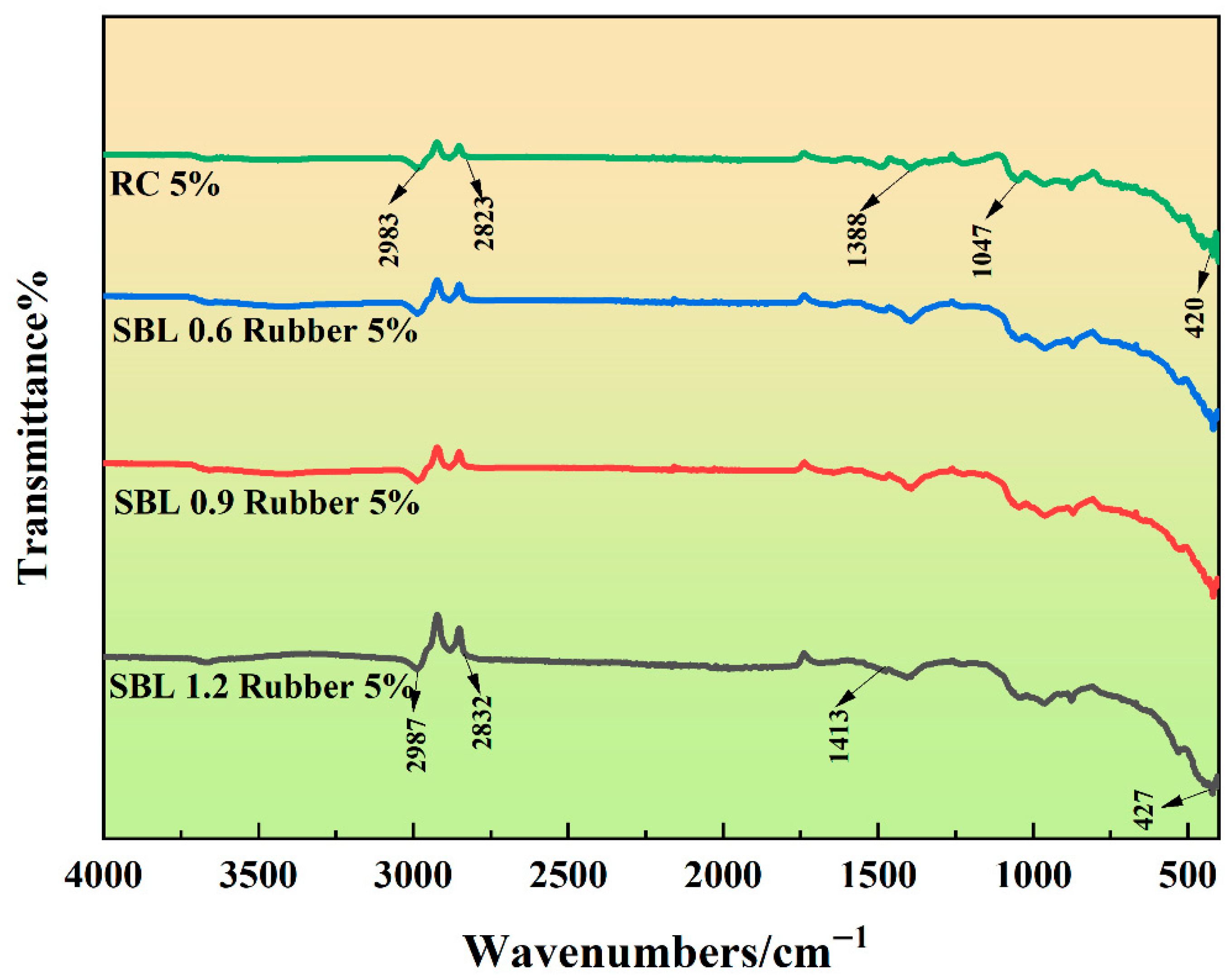

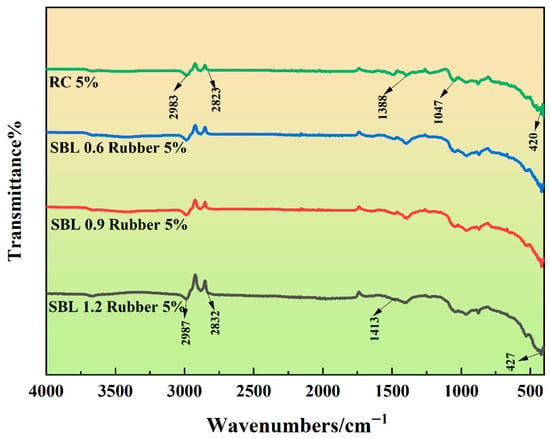

5.2.3. FT-IR

Observing Figure 9, it becomes evident that FT-IR results of rubber concrete after SBL addition resemble those of RC, suggesting the absence of a chemical reaction between SBL addition and rubber [22]. Notably, as the SBL content increases from 2832 cm−1 to 2987 cm−1 and from 427 cm−1 to 1413 cm−1, the strength of the vibration bands increases. This indicates that the addition of SBL reduces the hydration reaction of the cement matrix and increases the gel content at the same time, which aligns with previous findings [29]. The heightened gel quantity strengthens the bond between rubber and cement-based interfaces, thereby enhancing the properties of rubber concrete.

Figure 9.

FT-IR results.

5.3. Molecular Results

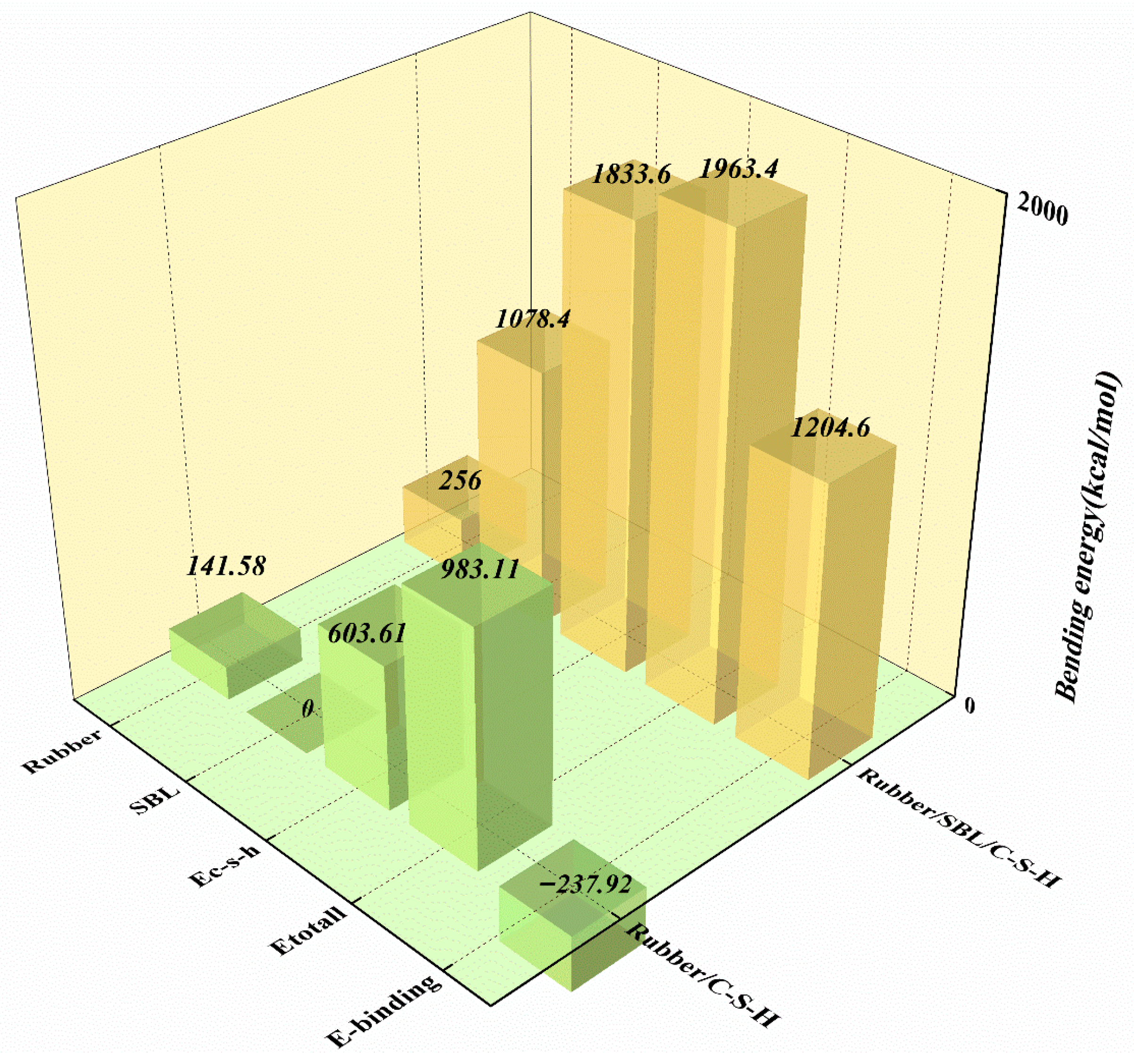

5.3.1. Binding Energy

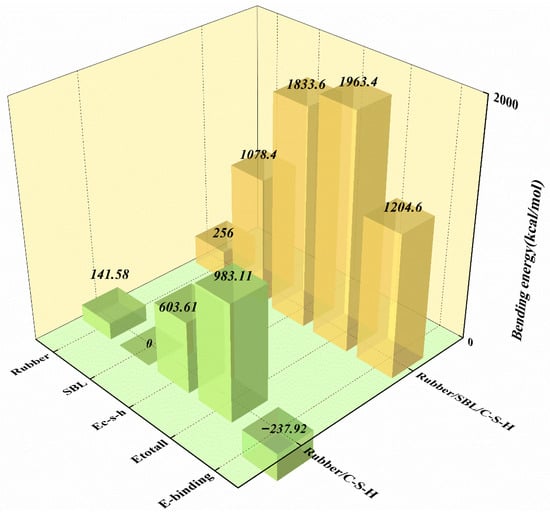

In MS software, binding energy plays a dual role: evaluating the interaction strength among different components within the interface model and serving as a pivotal measure of adsorption strength during the adsorption process [30]. A positive binding energy signifies attraction between the two systems, while a negative value suggests repulsion. Furthermore, the magnitude of the binding energy indicates the strength of interaction between the systems, correlating with system stability; a higher absolute value indicates a stronger interaction and greater stability [31].

As illustrated in Figure 10, the force module was employed to compute the binding energy of the rubber, , and , models separately for the model. Subsequently, the calculation outcomes were utilized in formula (1) [32] to determine the binding energy, yielding a value of −237.92

Figure 10.

Interaction of and interfaces.

The model and the energy of rubber, SBL, and models was calculated by the force module, and the results were brought to formula (2) [32], and the binding energy of was calculated as 1204.6 kcal/mol.

Upon the incorporation of SBL, there is a notable increase in the absolute binding energy of the system, suggesting enhanced stability in the structure.

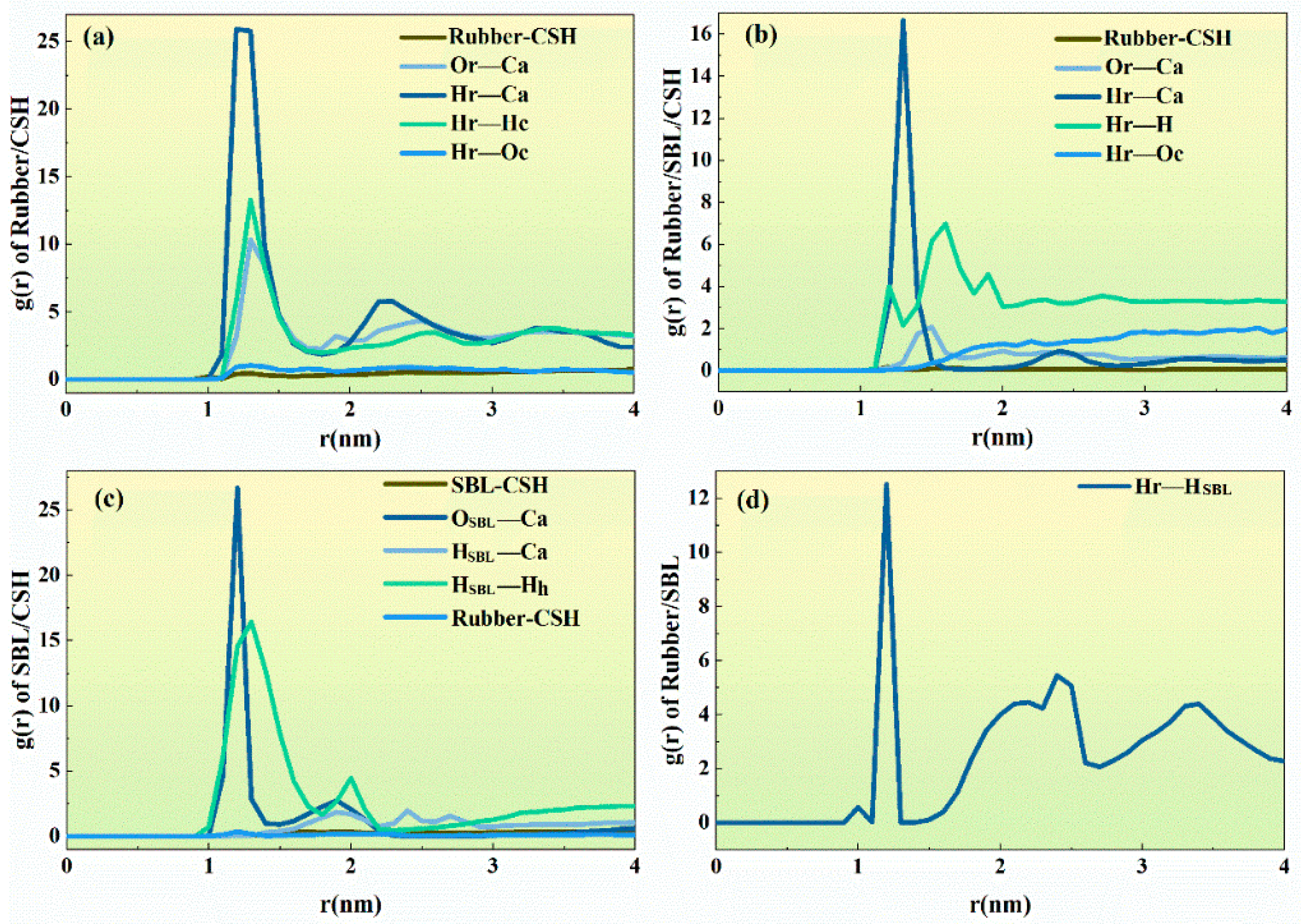

5.3.2. Radial Distribution Function (RDF)

RDF computed through formula (3), serves as a valuable tool for comprehending the interface structure and interaction dynamics between the polymer and matrix [33,34]. RDF, an abbreviation for radial distribution function, delineates the probability-based distance between particles relative to reference particles, shedding light on their interaction modes [35].

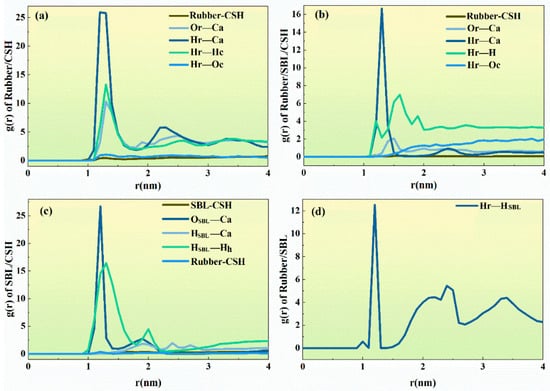

The intermolecular forces, comprising hydrogen bonding and van der Waals interactions, are at play. Through the force module, the radial distribution functions (RDFs) for both systems are calculated. Figure 11a,b illustrates that the primary interaction at the interface is a interaction. Notably, the peaks observed for and are significant, emphasizing the crucial role of the ionic bond formed by in enhancing the interface interactions between the polymer and . Contrasting with Figure 11a,b, Figure 11c,d show variations in the RDF values of and . This suggests that the addition of SBL promotes enhanced interface interactions between the polymer and cement base. Moreover, the increase in the peak in Figure 11d indicates that the introduction of SBL enhances the hydrogen bonding between rubber and CSH, thereby strengthening the interfacial interaction between them.

Figure 11.

(a) RDF of , (b) RDF of , (c) RDF of , and (d) RDF of - in .

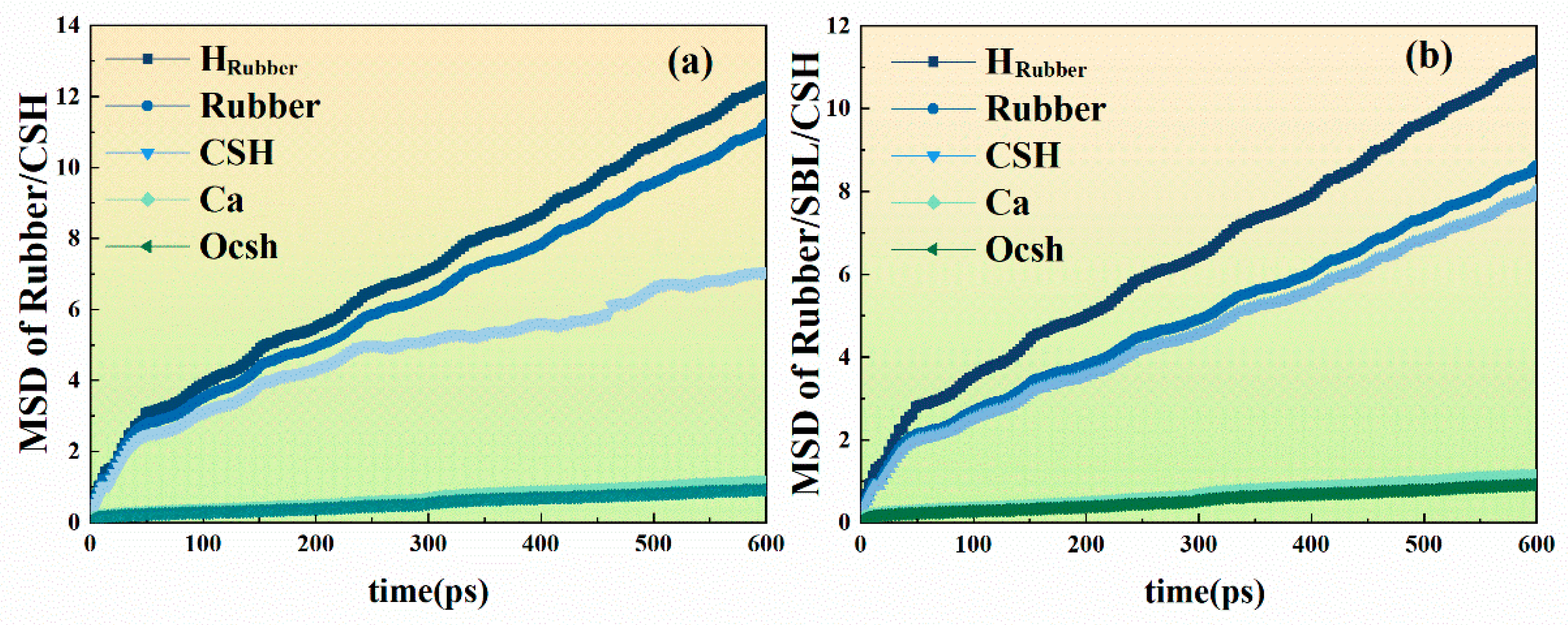

5.3.3. Mean Square Displacement (MSD)

Within molecular dynamics analysis, mean square displacement (MSD) stands as a significant parameter, denoting the average square displacement of particles, essential for assessing atomic motion characteristics [36]. A steeper slope of the MSD curve correlates with a higher molecular diffusion coefficient, which can be determined via formula (4) [37].

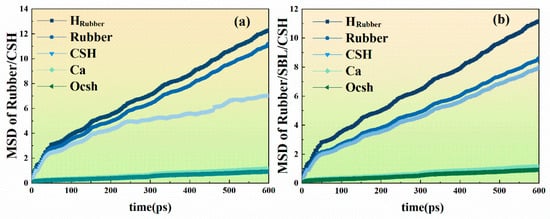

The calculation results of the mean square displacement of the two systems ( and ) are shown in Figure 12. Figure 12a,b reveal that the MSD value for rubber exceeds that of , indicating the latter’s superior structural stability. Additionally, the MSD curve for hydrogen atoms in rubber outstrips that of other atoms, indicating heightened activity at the interface. Conversely, both calcium and oxygen atoms in maintain consistently low MSD values, underscoring the stability of the structure. Noteworthy is the varying degrees of decline in MSD values within the curve of Figure 12b compared to Figure 12a, while the sequence of atomic MSD values remains largely unaltered. This suggests that the free mobility of H, Ca, and O within the channel experiences inhibition following the addition of SBL. However, this modification likely does not compromise the overall stability of the system. Instead, it strengthens the hydrogen bond interactions between and , thereby improving the interface bonding between rubber and CSH. As a result, the overall performance of the concrete is enhanced.

Figure 12.

The MSD of (a) , rubber, , Ca, and in the system, (b) , Rubber, , , and in system.

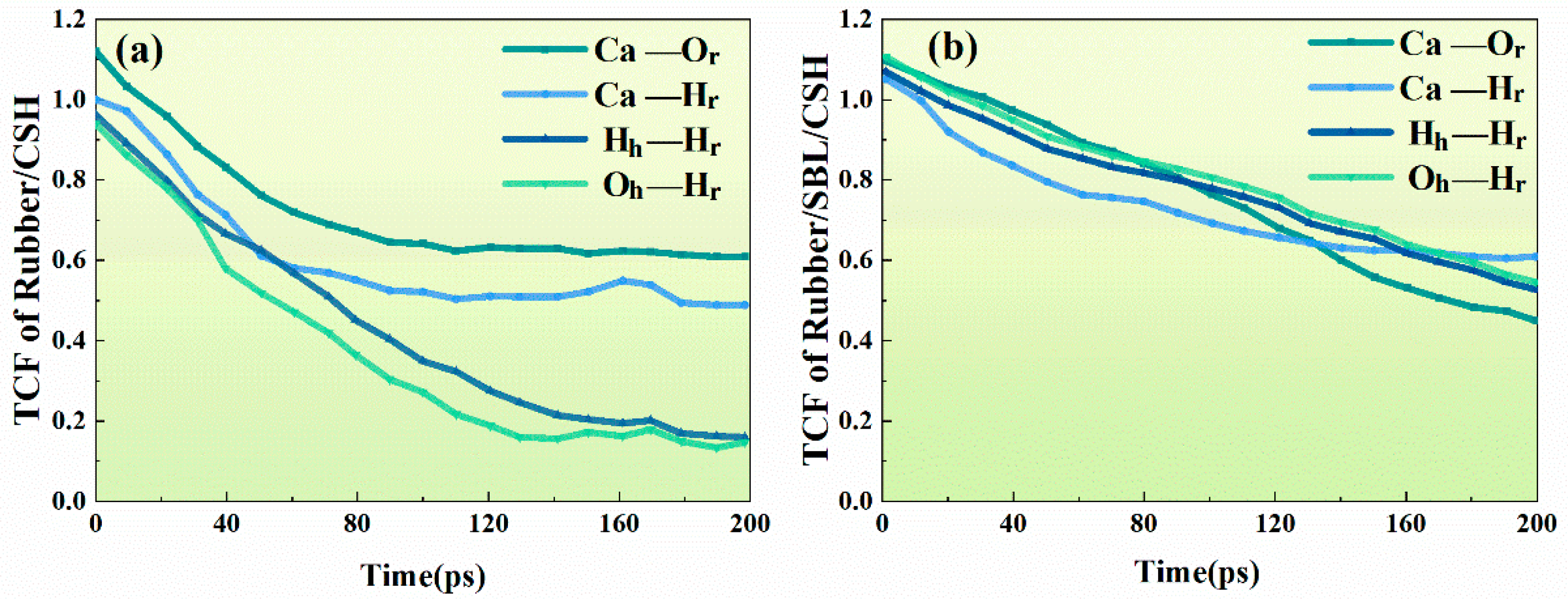

5.3.4. Time Correlation Function (TCF)

By delineating the stability of pivotal chemical bonds at the interface, the time correlation function offers insight into the strength, stability, and dynamic characteristics of these interface connections [36]. Over time, if the TCF value is continual at one, then the connection between the atoms is stable [38]. On the other hand, if the TCF value is 0 or disappears, the atomic connection is unstable. Consequently, the variation in the TCF value from one signifies the stability level of the atom pair connection. A larger deviation from one in the TCF value implies an increased probability of atomic connection disruption. This computation is conducted through the utilization of formula (5) [39].

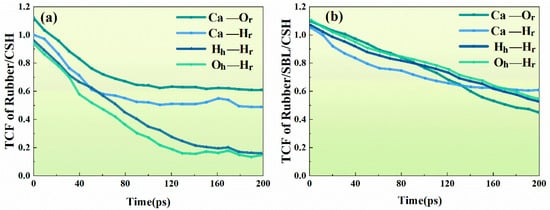

The TCF calculation results for the first 200 ps of the main atoms of the two systems are shown in the figure. The activity patterns of O and H atoms in water molecules are consistent in both systems. This alignment validates the model’s rationality. As shown in Figure 13a, the hydrogen bonding effect in the system shows a downward trend before 125 ps and then stabilizes at about 0.18 for a long time. Illustrated in Figure 13b, the TCF curve of the H bond in exhibits a slight initial decrease before stabilizing around 0.6. This suggests that SBL improves the hydrophilicity of the rubber surface. Moreover, when comparing the TCF values of and in the two systems, it is observed that the TCF value of experiences a rapid decline, reaching stability by 120 ps, whereas the TCF value of SBL decreases gradually throughout the calculation. This observation indicates that SBL delays the fracture of the two coordinate bonds, confirming its substantial influence on the interaction at the interface.

Figure 13.

(a) TCF of system, (b) TCF of system.

The variation trends of and in the two systems closely mirror each other, suggesting consistent activity patterns of oxygen and hydrogen atoms in water molecules. This alignment validates the model’s rationality. As illustrated in Figure 13a, the hydrogen bonding effect in the system initially declines before stabilizing around 0.18 for an extended period. Conversely, depicted in Figure 13b, the time correlation function (TCF) curve of hydrogen bonds in exhibits a slight decrease initially, followed by stabilization at approximately 0.6, confirming the role of SBL in imparting greater hydrophilicity to the rubber surface. Additionally, by comparing the TCF values of and in the two systems, it is observed that in the system, the TCF value begins to rapidly decline and stabilizes at 120 ps, while in the presence of SBL, the decrease is gradual throughout the calculation. This suggests that SBL prolongs the retention of the two coordinate bonds, underscoring its significant influence on the interface interaction between Rubber and .

6. Multiscale Analysis

6.1. Mechanism for Macroscopic Enhancement

When conducting compression, shear, and flexural tests on concrete materials, the chemical bonding force between mortar and mortar, as well as between mortar and aggregate, is evident, chiefly influenced by the composition properties of the mortar itself [40]. Nevertheless, as rubber replaces a portion of the fine aggregates and the adhesion between rubber and mortar is comparatively weaker, the mechanical characteristics of rubber concrete decline, while its deformability gradually rises. The incorporation of SBL not only enhances the concrete density but also reinforces the interfacial bonding between the rubber particles and the cement paste. Thus, on a macroscopic level, it is evident that SBL enhances the compressive, shear, and flexural properties of rubber concrete.

6.2. Mechanism for Microscopic Enhancement

The enhancement of macroscopic mechanical properties of rubber concrete by SBL is due to the chemical bonding between materials. SEM reveals a reduction in concrete bubbles and rougher bonding surfaces on the rubber upon the addition of SBL. This suggests that integrating SBL not only boosts the density of concrete but also reinforces the interfacial bonding strength between rubber and cement. The addition of SBL notably amplifies the interaction at the interfaces of rubber and cement, thus bolstering the strength of the composite material.

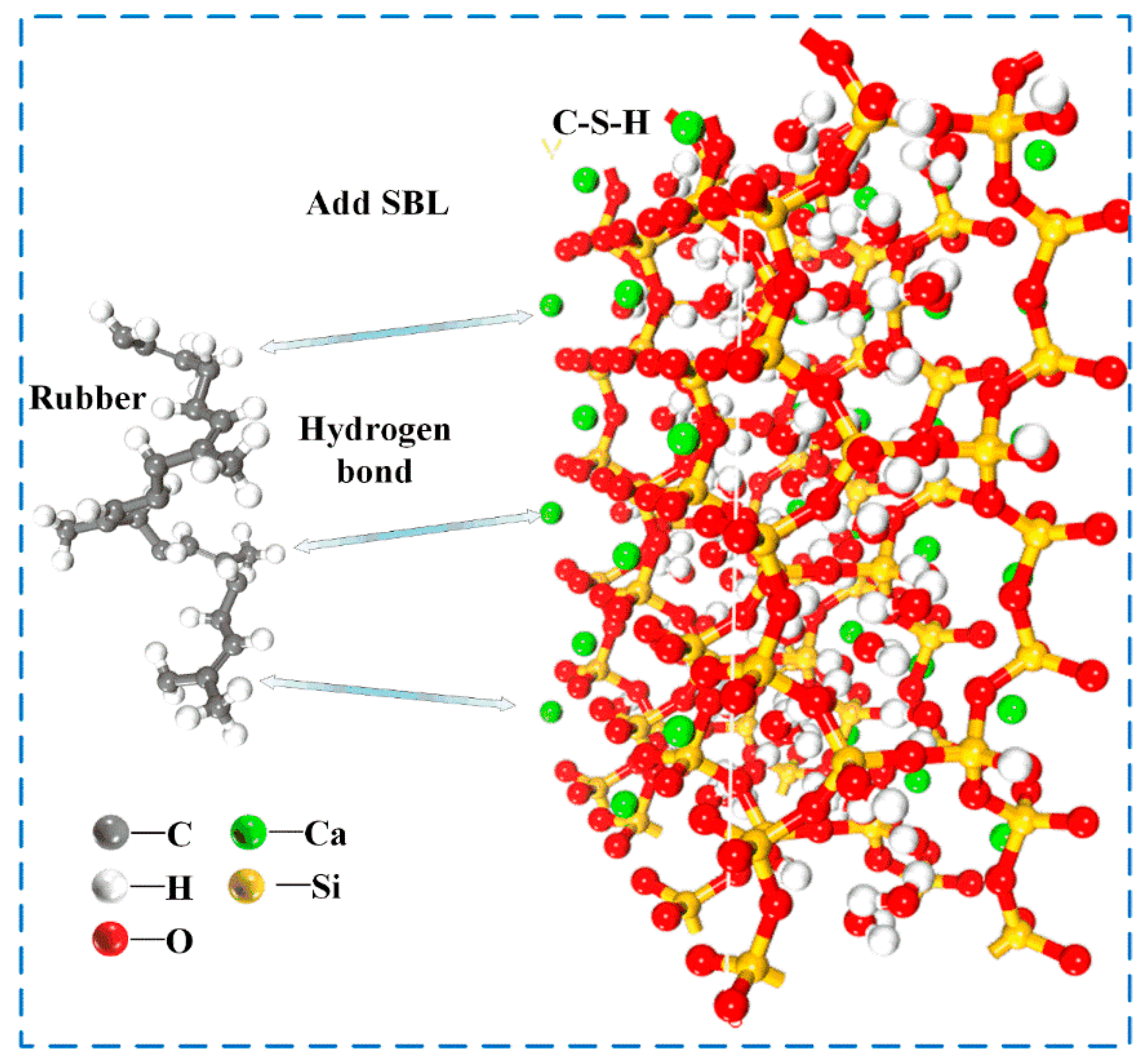

6.3. Mechanism for Nano Enhancement

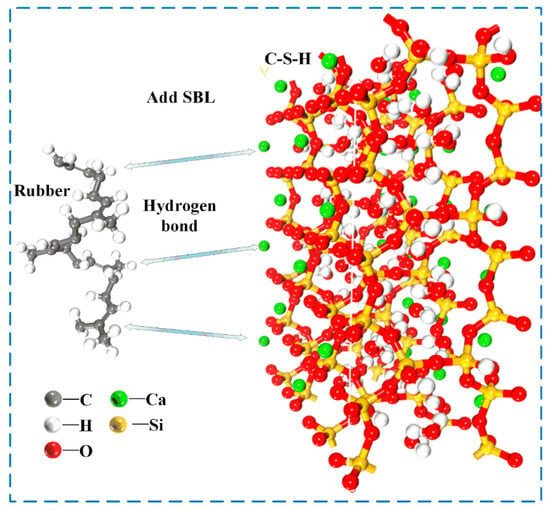

The pivotal bond between gels and various polymers at the interface is the ionic bond formed by hydrogen bonds with [23]. As shown in this study, molecular dynamics simulation results demonstrate that the addition of SBL promotes the formation of a hydrogen bond between the hydrogen atom of rubber and the calcium atom of CSH. This strengthens the interface bonding between rubber and CSH, thereby improving the overall properties of rubber concrete. This effect is illustrated in Figure 14.

Figure 14.

Nano improvement mechanism.

7. Conclusions

The study illustrated the strengthening influence of SBL on rubber concrete through macroscopic assessments. SEM was employed to investigate the microstructural changes in rubber, while XRD and FT-IR were utilized to characterize the modifications in rubber concrete products. Molecular dynamics analysis was performed to examine the interface structure. The findings derived from this comprehensive analysis are outlined as follows:

- Macroscopic mechanical tests reveal a significant increase in flexural strength, shear strength, and compressive strength of the composite concrete upon the introduction of SBL and rubber. Specifically, the compressive strength improved by 8.8%, shear strength by 13.7%, and flexural strength by 18.9% at 28 days.

- Based on SEM observations, it is evident that incorporating SBL enhances the density of the cementitious matrix and addresses the inadequate adhesion between rubber and cement, thereby augmenting the cohesion between rubber and concrete and ultimately enhancing the mechanical properties of the concrete.

- XRD and FTIR analyses show that SBL delays cement hydration, increases the quantity of gel, and optimizes the composition of interface cement hydration products, thereby enhancing the overall strength of rubber concrete.

- Molecular dynamics simulations revealed that styrene–butadiene latex promotes the creation of enduring H bonds between rubber’s hydrogen atoms and cement’s calcium ions, effectively linking rubber with the matrix, thereby bolstering interface bonding strength.

- Multiscale analysis shows that SBL significantly enhances rubber concrete’s performance and compactness, promoting high durability and performance. However, molecular dynamics currently only analyzes surface interactions and cannot accurately assess the impact of different parameters.

Author Contributions

Conceptualization, W.W., Y.F. and J.F.; methodology, W.W. and J.F.; software, W.W., Y.F. and J.F.; validation, W.W., Y.F. and J.F.; formal analysis, W.W.; investigation, Y.F.; resources, W.W. and J.F.; data curation, W.W., Y.F. and J.F.; writing—original draft preparation, W.W. and J.F.; writing—review and editing, Y.F. and J.F.; visualization, J.F.; supervision, Y.F.; project administration, Y.F.; funding, Y.F. All authors have read and agreed to the published version of the manuscript.

Funding

National Natural Science Foundation of China: 52578399.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Mei, J.; Xu, G.; Ahmad, W.; Khan, K.; Amin, M.N.; Aslam, F.; Alaskar, A. Promoting sustainable materials using recycled rubber in concrete: A review. J. Clean. Prod. 2022, 373, 133927. [Google Scholar] [CrossRef]

- Garcia-Troncoso, N.; Acosta-Calderon, S.; Flores-Rada, J.; Baykara, H.; Cornejo, M.H.; Riofrio, A.; Vargas-Moreno, K. Effects of Recycled Rubber Particles Incorporated as Partial Sand Replacement on Fresh and Hardened Properties of Cement-Based Concrete: Mechanical, Microstructural and Life Cycle Analyses. Materials 2022, 16, 63. [Google Scholar] [CrossRef]

- Ehsan, M.; Mahdi, K. Recycling of landfill waste tyre in construction materials: Durability of concrete made with chipped rubber. Constr. Build. Mater. 2023, 409, 134114. [Google Scholar] [CrossRef]

- Pei, X.; Huang, X.; Li, H.; Cao, Z.; Yang, Z.; Hao, D.; Min, K.; Li, W.; Liu, C.; Wang, S.; et al. Numerical Simulation of Fatigue Life of Rubber Concrete on the Mesoscale. Polymers 2023, 15, 2048. [Google Scholar] [CrossRef]

- Xu, Y.; Wang, J.; Zhang, P.; Guo, J.; Hu, S. Enhanced effect and mechanism of colloidal nano-SiO2 modified rubber concrete. Constr. Build. Mater. 2023, 378, 131203. [Google Scholar] [CrossRef]

- Liu, K.; Liu, H.X.; Liu, B.B.; Liu, Y.N. Mechanical performance and carbonation resistance of basalt fiber—Polypropylene fiber rubber concrete. Front. Mater. 2023, 10, 1229629. [Google Scholar] [CrossRef]

- Feng, Y.; Wang, W.; Wang, S.; Niu, Z.; Li, L. Multi-scale analysis of mechanical properties of KH-560 coupling agent modified PVA fiber-rubber concrete. Compos. Interfaces 2023, 30, 983–1010. [Google Scholar] [CrossRef]

- Yuan, B.; Huang, X.; Huang, Q.; Shiau, J.; Liang, J.; Zhang, B.; Zheng, J.; Fahimizadeh, M.; Sabri, M.M. Effects of particle size on properties of engineering muck-based geopolymers: Optimization through sieving treatment. Constr. Build. Mater. 2025, 492, 142967. [Google Scholar] [CrossRef]

- Muslum, M.M. Experimental behavior of injected geopolymer grout using styrene-butadiene latex for the repair and strengthening of masonry walls. Adv. Struct. Eng. 2021, 24, 2484–2499. [Google Scholar] [CrossRef]

- Xiong, Z.; Tang, Z.; He, S.; Fang, Z.; Chen, Z.; Liu, F.; Li, L. Analysis of mechanical properties of rubberised mortar and influence of styrene–butadiene latex on interfacial behaviour of rubber–cement matrix. Constr. Build. Mater. 2021, 300, 124027. [Google Scholar] [CrossRef]

- Khaleel, B.A.; Abed, J.M.; Abed, H.S. Enhancement of bonding efficiency between overlay and substrate concrete using styrene-butadiene rubber latex and different surface roughness methods. Eng. Appl. Sci. Res. 2021, 48, 33–39. [Google Scholar]

- Dong, F.; Mingkai, Z.; Deyong, J.; Qing, L. Investigation on the relationship between flexural strength, flexural toughness and impact toughness of styrene–butadiene rubber latex-modified cement concrete. Mater. Res. Innov. 2015, 19, S8-849–S8-854. [Google Scholar] [CrossRef]

- Aviral, S.; Sumit, S. Recent advances in experimental and molecular dynamics study of graphene-oxide/natural rubber composites: A review. J. Reinf. Plast. Compos. 2023, 42, 110–130. [Google Scholar]

- Li, L.; Wang, W.; Xu, Z.; Niu, Z.; Li, X.; Wang, Q. Mechanical Property Test and Finite Element Simulation Analysis of KH-560 Coupling Agent-Modified PVA Rubber Concrete. Geofluids 2022, 2022, 2839755. [Google Scholar] [CrossRef]

- Zhang, N.; Mao, Z.; Sun, Q.; Luo, Y.; Zhang, P.; Wang, Q.; Yang, R.; Zhang, M.; Wang, D. The influence of polymer powder on the ion transportation and antierosion mechanism of cement mortar: From experiments to molecular dynamics simulation. Constr. Build. Mater. 2023, 409, 134171. [Google Scholar] [CrossRef]

- Yuan, B.; Huang, Q.; Xu, W.; Han, Z.; Luo, Q.; Chen, G.; Yuan, J.; Zhang, Q.; Sabri, S.M.M. Study on the interaction between pile and soil under lateral load in coral sand. Geomech. Energy Environ. 2025, 42, 100674. [Google Scholar] [CrossRef]

- Maria da Silva, F.; Batista, L.S.; Gachet, L.A.; Lintz, R.C. The Effect of Tire-Rubber Pretreatment on the Physical–Mechanical Properties and Durability of High-Performance Concrete. J. Mater. Civ. Eng. 2022, 34, 04022354. [Google Scholar] [CrossRef]

- Youssf, O.; Swilam, A.; Tahwia, A.M. Performance of crumb rubber concrete made with high contents of heat pre-treated rubber and magnetized water. J. Mater. Res. Technol. 2023, 23, 2160–2176. [Google Scholar] [CrossRef]

- Shahzad, K.; Zhao, Z. Experimental study of NaOH pretreated crumb rubber as substitute of fine aggregate in concrete. Constr. Build. Mater. 2022, 358, 129448. [Google Scholar] [CrossRef]

- Jia, Y. Discussion on the revision significance of JGJ55-2011 “Ordinary Concrete Mix Design Regulations”. New Build. Mater. 2013, 40, 27–30. [Google Scholar]

- Yuan, B.; Liang, J.; Huang, X.; Huang, Q.; Zhang, B.; Yang, G.; Wang, Y.; Yuan, J.; Wang, H. Eco-efficient recycling of engineering muck for manufacturing low-carbon geopolymers assessed through LCA: Exploring the impact of synthesis conditions on performance. Acta Geotech. 2024, 20240915. [Google Scholar] [CrossRef]

- Feng, Y.; Wang, Q.; Li, L.; Ma, Y.; Li, X. Multiscale analysis of silane coupling agent modified rubber-fiber concrete interfaces. Mater. Today Commun. 2023, 35, 105960. [Google Scholar] [CrossRef]

- Wang, X.; Xie, W.; Ren, J.; Zhu, J.; Li, L.-Y.; Xing, F. Interfacial Binding Energy between Calcium-Silicate-Hydrates and Epoxy Resin: A Molecular Dynamics Study. Polymers 2021, 13, 1683. [Google Scholar] [CrossRef]

- Kim, G.; Im, S.; Jee, H.; Suh, H.; Cho, S.; Kanematsu, M.; Morooka, S.; Koyama, T.; Nishio, Y.; Machida, A.; et al. Effect of magnesium silicate hydrate (M-S-H) formation on the local atomic arrangements and mechanical properties of calcium silicate hydrate (C-S-H): In situ X-ray scattering study. Cem. Concr. Res. 2022, 159, 106869. [Google Scholar] [CrossRef]

- Tavakoli, D.; Tarighat, A. Molecular dynamics study on the mechanical properties of Portland cement clinker phases. Comput. Mater. Sci. 2016, 119, 65–73. [Google Scholar] [CrossRef]

- Alkhateb, H.; Al-Ostaz, A.; Cheng, A.H.-D.; Li, X. Materials Genome for Graphene-Cement Nanocomposites. J. Nanomechanics Micromechanics 2013, 3, 67–77. [Google Scholar] [CrossRef]

- Yuan, B.; Huang, X.; Li, R.; Luo, Q.; Shiau, J.; Wang, Y.; Yuan, J.; Sabri, S.M.M.; Huang, S.; Liao, C. Dynamic behavior and deformation of calcareous sand under cyclic loading. Soil Dyn. Earthq. Eng. 2025, 199, 109730. [Google Scholar] [CrossRef]

- Feng, Y.; Qin, D.; Zhao, C.; Li, Y. Multiscale Enhancement Mechanisms of EVA on EPS-Cement Composites. J. Mater. Civ. Eng. 2023, 35, 04023102. [Google Scholar] [CrossRef]

- Li, F.; Yang, Y.; Tao, M.; Li, X. A cement paste-tail sealant interface modified with a silane coupling agent for enhancing waterproofing performance in a concrete lining system. RSC Adv. 2019, 9, 7165–7175. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Cao, J. Interfacial heat transfer behavior of graphene-based filler and calcium-silicate-hydrate in cement composites. Int. J. Heat Mass Transf. 2021, 176, 121165. [Google Scholar] [CrossRef]

- Yu, C.; Hu, K.; Yang, Q.; Wang, D.; Zhang, W.; Chen, G.; Kapyelata, C. Analysis of the Storage Stability Property of Carbon Nanotube/Recycled Polyethylene-Modified Asphalt Using Molecular Dynamics Simulations. Polymers 2021, 13, 1658. [Google Scholar] [CrossRef]

- Feng, Y.; Li, Y.; Zhao, C.; Qin, D.; Wang, C.; Wang, P. Nano-CaCO3 enhances PVA fiber-matrix interfacial properties: An experimental and molecular dynamics study. Mol. Simul. 2022, 48, 1378–1392. [Google Scholar]

- Yu, C.; Hu, K.; Yang, Q.; Chen, Y. Multi–scale observation of oxidative aging on the enhancement of high–temperature property of SBS–modified asphalt. Constr. Build. Mater. 2021, 313, 125478. [Google Scholar] [CrossRef]

- Xu, G.; Wang, H. Diffusion and interaction mechanism of rejuvenating agent with virgin and recycled asphalt binder: A molecular dynamics study. Mol. Simul. 2018, 44, 1433–1443. [Google Scholar] [CrossRef]

- Zhao, C.; Li, L.; Li, X.; Chen, W.; Li, Y. Multi-scale analysis of the synergistic strengthening effect of silane coupling agent on PVA and cement interface. Front. Mater. 2023, 10, 1276785. [Google Scholar] [CrossRef]

- Lu, Z.; Yu, J.; Yao, J.; Hou, D. Experimental and molecular modeling of polyethylene fiber/cement interface strengthened by graphene oxide. Cem. Concr. Compos. 2020, 112, 103676. [Google Scholar] [CrossRef]

- Wang, W.; Feng, Y.; Li, X. EVA/KH560 synergistically modified recycled concrete mechanical properties—Experiment and molecular dynamics simulations. J. Mol. Graph. Model. 2024, 126, 108641. [Google Scholar] [CrossRef] [PubMed]

- Feng, Y.; Wang, W.; Wang, S. PVA fiber/cement-based interface in silane coupler KH560 reinforced high performance concrete—Experimental and molecular dynamics study. Constr. Build. Mater. 2023, 395, 132184. [Google Scholar] [CrossRef]

- Feng, Y.; Qin, D.; Zhao, C. The synergistic strengthening effect of silane coupling agent on the interface between PVA/EPS and cement: Experiment and molecular simulation. Compos. Interfaces 2023, 30, 21–41. [Google Scholar] [CrossRef]

- Yuan, B.; Liang, J.; Zhang, B.; Chen, W.; Huang, X.; Huang, Q.; Li, Y.; Yuan, P. Optimized reinforcement of granite residual soil using a cement and alkaline solution: A coupling effect. J. Rock Mech. Geotech. Eng. 2025, 17, 509–523. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).