Study of Mechanical and Fracture Properties of Concrete with Different Lengths of Polypropylene Fibers

Abstract

1. Introduction

2. Materials and Methods

2.1. Concrete Mixtures

2.2. Experimental Program

2.2.1. Workability

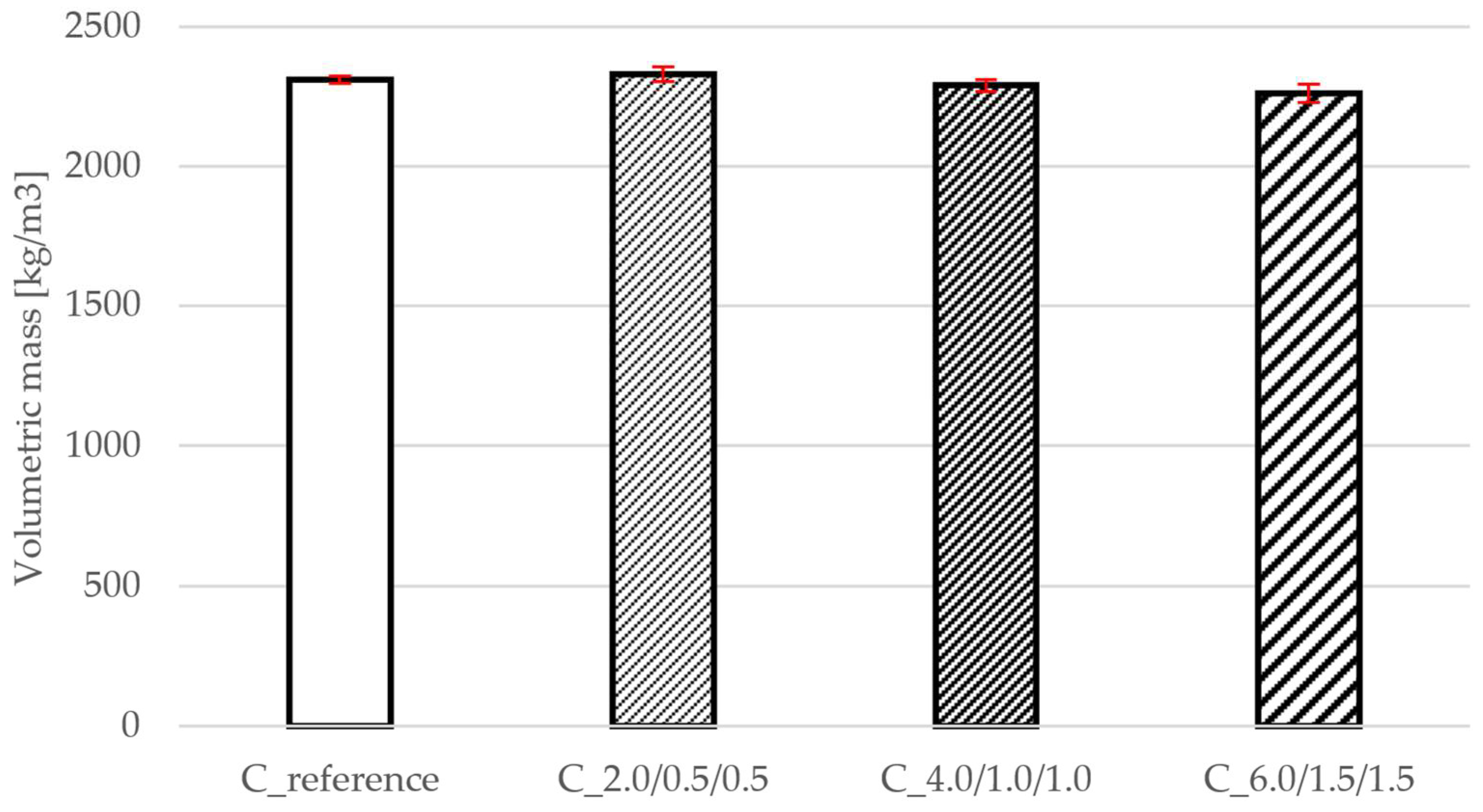

2.2.2. Volumetric Mass

2.2.3. Compressive Strength

2.2.4. Tensile Splitting Strength

2.2.5. Elastic Modulus

2.2.6. Fracture Mechanics

- (i)

- interpolation of a straight line through the initial ascending branch,

- (ii)

- iterative removal of outlier points until the correlation coefficient (R2) approached unity, and

- (iii)

- recalculation of fracture parameters using the adjusted curve.

3. Results

3.1. Mechanical Test

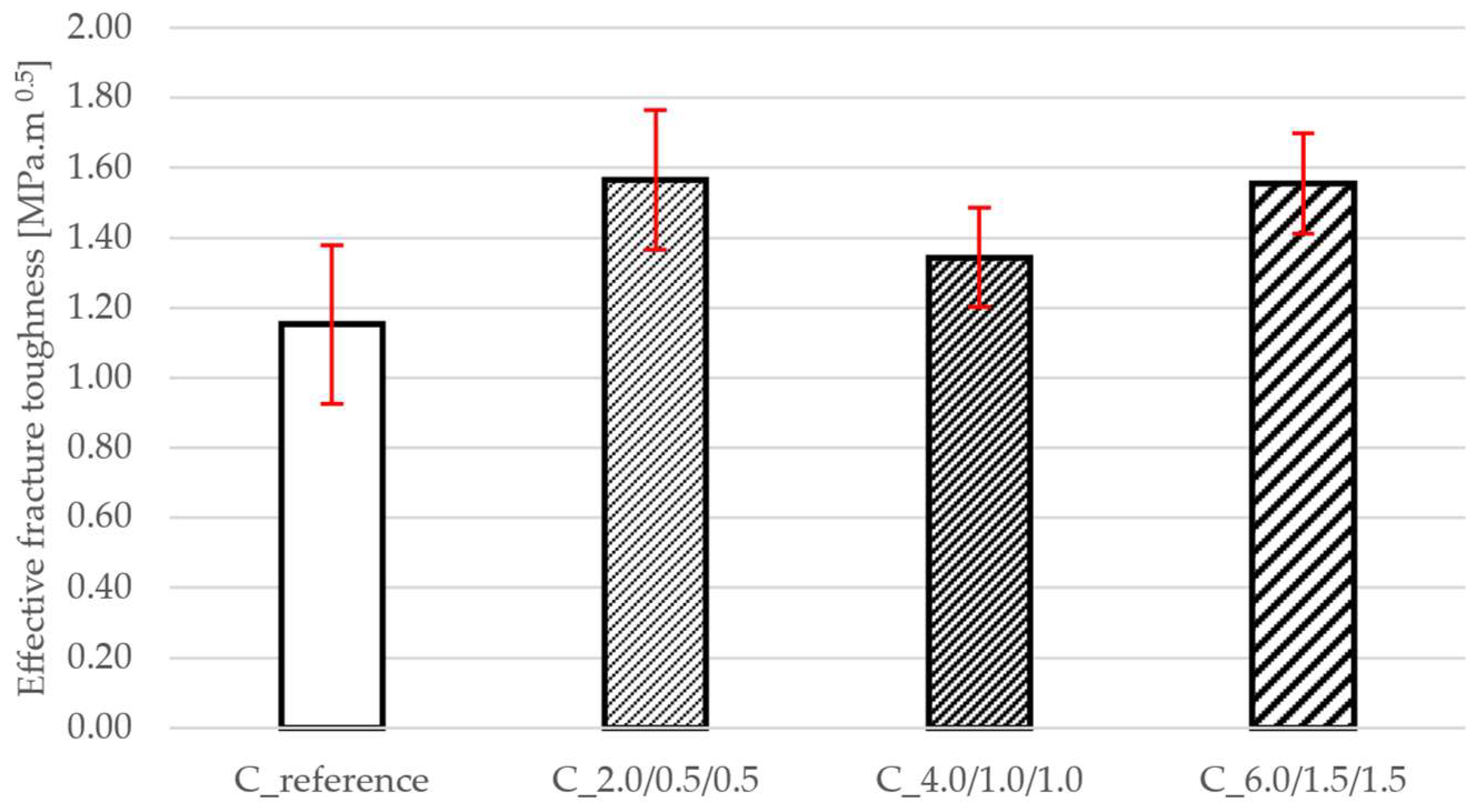

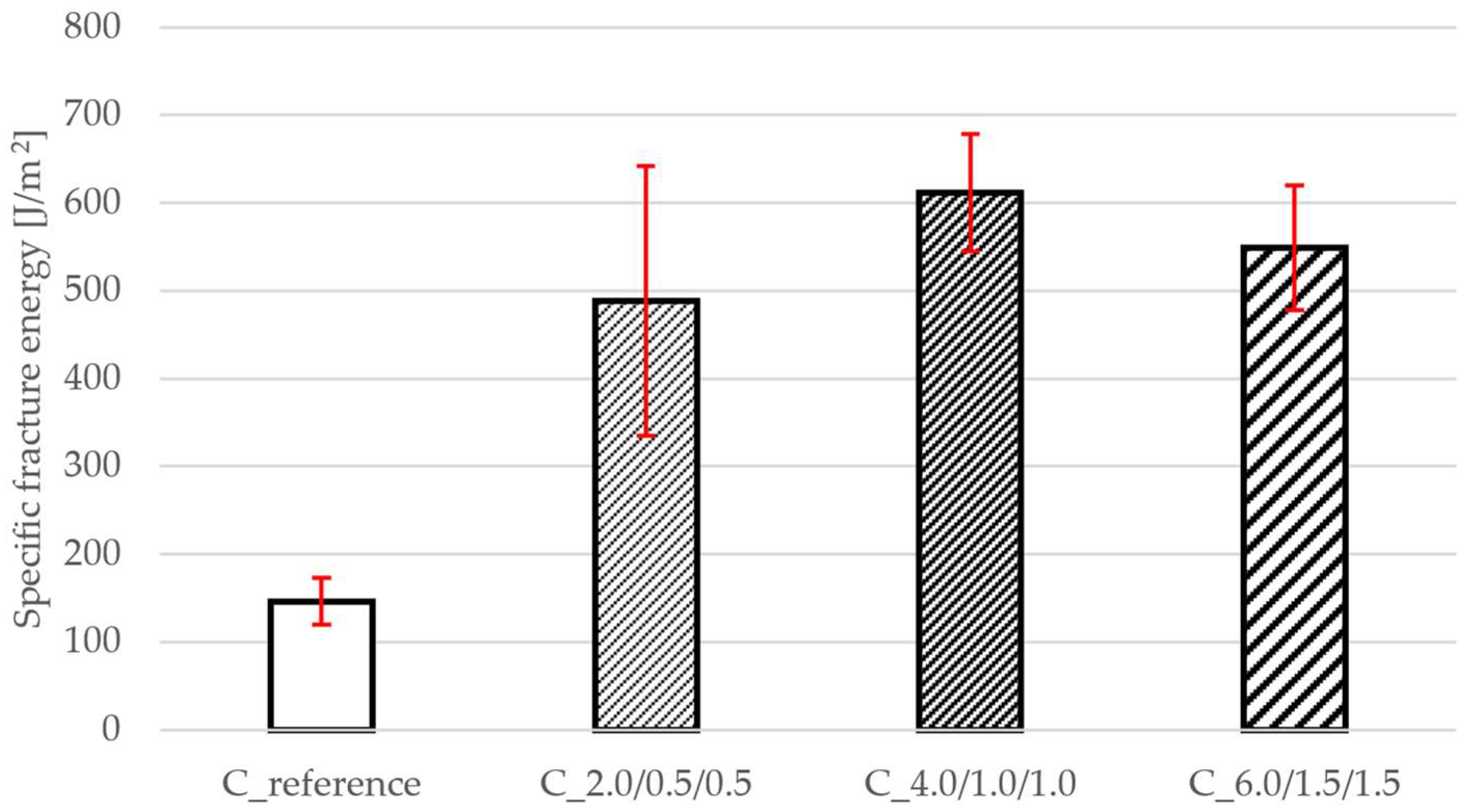

3.2. Fracture Properties

4. Summary and Discussion

5. Conclusions

- The addition of hybrid polypropylene fibers significantly improved the strength properties. The optimal mixture (2.0/0.5/0.5 kg/m3) increased compressive strength by 28.7% and splitting tensile strength by 30.1% compared with the reference concrete without fibers.

- The elastic modulus was only slightly affected, with changes within ±8% depending on fiber dosage.

- Fracture parameters were strongly influenced: fracture toughness and specific fracture energy were notably higher in fiber-reinforced mixtures. The hybridization provided a synergistic effect, where longer fibers bridged macrocracks and shorter fibers reduced microcrack propagation.

- Higher fiber contents (≥4.0/1.0/1.0 kg/m3) led to reduced workability and strength, likely due to fiber clustering and compaction difficulties, although fracture energy was still improved.

- The novelty of this work lies in the systematic evaluation of a fixed hybrid fiber ratio (4:1:1), combining macro- and microfibers in one mixture and simultaneously assessing mechanical and fracture properties.

- Limitations of this study include the use of only one commercial fiber type (Forta Ferro), the absence of microstructural validation (e.g., SEM or XCT), and the lack of long-term durability tests. Future research should therefore focus on different fiber brands, detailed microstructural analyses, and durability studies (e.g., freeze–thaw, chloride penetration, and carbonation).

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Konečný, P.; Ghosh, P.; Hrabová, K.; Lehner, P.; Teplý, B. Effective Methodology of Sustainability Assessment of Concrete Mixtures. Mater. Struct./Mater. Constr. 2020, 53, 98. [Google Scholar] [CrossRef]

- Nilimaa, J. Smart Materials and Technologies for Sustainable Concrete Construction. Dev. Built Environ. 2023, 15, 100177. [Google Scholar] [CrossRef]

- Yin, S.; Tuladhar, R.; Riella, J.; Chung, D.; Collister, T.; Combe, M.; Sivakugan, N. Comparative Evaluation of Virgin and Recycled Polypropylene Fibre Reinforced Concrete. Constr. Build. Mater. 2016, 114, 134–141. [Google Scholar] [CrossRef]

- Zhao, C.; Wang, Z.; Zhu, Z.; Guo, Q.; Wu, X.; Zhao, R. Research on Different Types of Fiber Reinforced Concrete in Recent Years: An Overview. Constr. Build. Mater. 2023, 365, 130075. [Google Scholar] [CrossRef]

- Rai, A.; Joshi, Y.P. Applications and Properties of Fibre Reinforced Concrete. J. Eng. Res. Appl. 2014, 4, 123–131. [Google Scholar]

- Wu, H.; Lin, X.; Zhou, A. A Review of Mechanical Properties of Fibre Reinforced Concrete at Elevated Temperatures. Cem. Concr. Res. 2020, 135, 106117. [Google Scholar] [CrossRef]

- Pham, L.; Tran, P.; Sanjayan, J. Steel Fibres Reinforced 3D Printed Concrete: Influence of Fibre Sizes on Mechanical Performance. Constr. Build. Mater. 2020, 250, 118785. [Google Scholar] [CrossRef]

- Abdalla, J.A.; Hawileh, R.A.; Bahurudeen, A.; Jyothsna, G.; Sofi, A.; Shanmugam, V.; Thomas, B.S. A Comprehensive Review on the Use of Natural Fibers in Cement/Geopolymer Concrete: A Step towards Sustainability. Case Stud. Constr. Mater. 2023, 19, e02244. [Google Scholar] [CrossRef]

- Zheng, Y.; Lv, X.; Hu, S.; Zhuo, J.; Wan, C.; Liu, J. Mechanical Properties and Durability of Steel Fiber Reinforced Concrete: A Review. J. Build. Eng. 2024, 82, 108025. [Google Scholar] [CrossRef]

- Fataar, H.; Combrinck, R.; Boshoff, W.P. An Experimental Study on the Fatigue Failure of Steel Fibre Reinforced Concrete at a Single Fibre Level. Constr. Build. Mater. 2021, 299, 123869. [Google Scholar] [CrossRef]

- Islam, M.S.; Ahmed, S.J. Influence of Jute Fiber on Concrete Properties. Constr. Build. Mater. 2018, 189, 768–776. [Google Scholar] [CrossRef]

- Li, B.; Chen, Z.; Wang, S.; Xu, L. A Review on the Damage Behavior and Constitutive Model of Fiber Reinforced Concrete at Ambient Temperature. Constr. Build. Mater. 2024, 412, 134919. [Google Scholar] [CrossRef]

- Gencel, O.; Ozel, C.; Brostow, W.; Martínez-Barrera, G. Mechanical Properties of Self-Compacting Concrete Reinforced with Polypropylene Fibres. Mater. Res. Innov. 2011, 15, 216–225. [Google Scholar] [CrossRef]

- Błaszczyński, T.; Przybylska-Fałek, M. Steel Fibre Reinforced Concrete as a Structural Material. Procedia Eng. 2015, 122, 282–289. [Google Scholar] [CrossRef]

- Lehner, P.; Horňáková, M.; Hrabová, K. Sensitivity Analysis of Stochastic Calculation of Scc Regarding Aggressive Environment. Materials 2021, 14, 6838. [Google Scholar] [CrossRef]

- Abousnina, R.; Premasiri, S.; Anise, V.; Lokuge, W.; Vimonsatit, V.; Ferdous, W.; Alajarmeh, O. Mechanical Properties of Macro Polypropylene Fibre-Reinforced Concrete. Polymers 2021, 13, 4112. [Google Scholar] [CrossRef]

- Çiftçioğlu, A.Ö.; Delikanlı, A.; Shafighfard, T.; Bagherzadeh, F. Machine Learning Based Shear Strength Prediction in Reinforced Concrete Beams Using Levy Flight Enhanced Decision Trees. Sci. Rep. 2025, 15, 27488. [Google Scholar] [CrossRef]

- He, F.; Biolzi, L.; Carvelli, V. Effect of Fiber Hybridization on Mechanical Properties of Concrete. Mater. Struct. 2022, 55, 195. [Google Scholar] [CrossRef]

- Zhu, H.; Wen, S.; Li, X.; Li, Y.; Fu, Z. Damage Evolution of Polypropylene–Basalt Hybrid Fiber Ceramsite Concrete under Chloride Erosion and Dry–Wet Cycle. Polymers 2023, 15, 4179. [Google Scholar] [CrossRef]

- Shafighfard, T.; Asgarkhani, N.; Kazemi, F.; Yoo, D.-Y. Transfer Learning on Stacked Machine-Learning Model for Predicting Pull-out Behavior of Steel Fibers from Concrete. Eng. Appl. Artif. Intell. 2025, 144, 111533. [Google Scholar] [CrossRef]

- Abbas, Y.M.; Khan, M.I. Efficacious Application of Data-Driven Machine Learning Models for Predicting and Optimizing the Flexural Tensile Strength of Fiber-Reinforced Concrete. Structures 2024, 64, 106574. [Google Scholar] [CrossRef]

- Nematzadeh, M.; Maghferat, A.; Zadeh Herozi, M.R. Mechanical Properties and Durability of Compressed Nylon Aggregate Concrete Reinforced with Forta-Ferro Fiber: Experiments and Optimization. J. Build. Eng. 2021, 41, 102771. [Google Scholar] [CrossRef]

- Fibres Ferro Forta. Available online: http://www.emzet.cz/vlakna-forta/vlakna-forta.htm (accessed on 29 September 2023).

- Liang, N.; You, X.; Yan, R.; Miao, Q.; Liu, X. Experimental Investigation on the Mechanical Properties of Polypropylene Hybrid Fiber-Reinforced Roller-Compacted Concrete Pavements. Int. J. Concr. Struct. Mater. 2022, 16, 3. [Google Scholar] [CrossRef]

- BSI BS EN 12390-2:2019; Testing Hardened Concrete. Part 2: Making and Curing Specimens for Strength Tests. BSI Standards Publication: London, UK, 2019.

- British Standards Institution BS EN 12390-7; Testing Hardened Concrete Part 7: Density of Hardened Concrete. BSI Standards Publication: London, UK, 2019.

- EN 12390-3; Testing Hardened Concrete Part 3: Compressive Strength of Test Specimens. BSI Standards Publication: London, UK, 2002.

- EN 12390-6; Testing Hardened Concrete—Part 6: Tensile Splitting Strength of Test Specimens. BSI Standards Publication: London, UK, 2009.

- EN 12390-13; Testing Hardened Concrete—Part 13: Determination of Secant Modulus of Elasticity in Compression. BSI Standards Publication: London, UK, 2013.

| C_reference | C_2.0/0.5/0.5 | C_4.0/1.0/1.0 | C_6.0/1.5/1.5 | |

|---|---|---|---|---|

| Portland Cement CEM I 42.5R [kg] | 340 | 340 | 340 | 340 |

| Fly ash [kg] | 80 | 80 | 80 | 80 |

| Fine aggregate 0/4 [kg] | 784 | 784 | 784 | 784 |

| Coarse aggregate 4/8 [kg] | 920 | 920 | 920 | 920 |

| Superplastificator [kg] | 5 | 6 | 6 | 6 |

| Water [L] | 180 | 162 | 166 | 165 |

| Mixture | C_2.0/0.5/0.5 | C_4.0/1.0/1.0 | C_6.0/1.5/1.5 |

|---|---|---|---|

| Relative difference | 0.9% | −0.9% | −2.2% |

| Mixture | C_2.0/0.5/0.5 | C_4.0/1.0/1.0 | C_6.0/1.5/1.5 |

|---|---|---|---|

| Relative difference | 28.7% | 9.3% | 14.7% |

| Mixture | C_2.0/0.5/0.5 | C_4.0/1.0/1.0 | C_6.0/1.5/1.5 |

|---|---|---|---|

| Relative difference | 30.1% | 27.4% | 23.3% |

| Mixture | C_2.0/0.5/0.5 | C_4.0/1.0/1.0 | C_6.0/1.5/1.5 |

|---|---|---|---|

| Relative difference | 4.7% | 7.8% | 0.0% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hrabová, K.; Láník, J.; Lehner, P. Study of Mechanical and Fracture Properties of Concrete with Different Lengths of Polypropylene Fibers. Buildings 2025, 15, 3041. https://doi.org/10.3390/buildings15173041

Hrabová K, Láník J, Lehner P. Study of Mechanical and Fracture Properties of Concrete with Different Lengths of Polypropylene Fibers. Buildings. 2025; 15(17):3041. https://doi.org/10.3390/buildings15173041

Chicago/Turabian StyleHrabová, Kristýna, Jaromír Láník, and Petr Lehner. 2025. "Study of Mechanical and Fracture Properties of Concrete with Different Lengths of Polypropylene Fibers" Buildings 15, no. 17: 3041. https://doi.org/10.3390/buildings15173041

APA StyleHrabová, K., Láník, J., & Lehner, P. (2025). Study of Mechanical and Fracture Properties of Concrete with Different Lengths of Polypropylene Fibers. Buildings, 15(17), 3041. https://doi.org/10.3390/buildings15173041