Abstract

In the present context of mitigating greenhouse gas emissions, interground portland-limestone cement (PLC) with elevated limestone filler (LF) replacement ratios (exceeding 15%) presents a feasible sustainable alternative, capable of diminishing clinker content. While LFs are known to modify the microstructure of concrete, the influence on ASR development has yet to be fully understood and requires further investigation. In this context, this work evaluates the effect of LFs replacement ratios between 15% and 25% on ASR development in concrete mixtures incorporating PLC. Analysis of expansion from accelerated mortar bar tests (AMBT) and concrete prism tests (CPT) indicate that increasing LF content from 15% to 25% does not substantially affect ASR-induced expansion. These findings underscore the viability of PLC as a sustainable construction material that does not compromise durability concerning ASR.

1. Introduction

The construction industry, responsible for 8% of global greenhouse gas emissions [], faces increasing pressure to adopt environmentally sustainable methods. Portland-limestone cement (PLC), produced by partially substituting clinker with up to 15% interground limestone fillers (LFs), has emerged as a viable solution owing to its extensive availability and capacity to preserve essential engineering properties (e.g., 28-day compressive strength and initial slump), comparable to traditional concrete [,]. However, the 15% reduction in clinker can still not meet the demand for sustainability targets. In Canada, the average clinker content in cement reached 89% by 2020, which should be further decreased to 60% to achieve a reduction of 1.6 million tonnes of CO2 and meet the net-zero goal by 2050 []. This goal requires a minimum of 20% clinker replacement by limestone, exceeding the limits allowed in current standards []. However, the performance of PLC, especially when limestone content surpasses 15%, raises concerns regarding both short-term and long-term behavior [,,,,]. Compromises in compressive strength and long-term performance, such as carbonation, have been documented in comparison to conventional portland cement. Nevertheless, while both the engineering properties and the resistance against the ingress of harmful substances can be enhanced by optimizing the particle packing of the concrete system [], the influence of the interground LFs on internal swelling mechanisms is primarily unknown. This is especially critical in scenarios prone to ASR, where proper cement selection is one of the most effective strategies to prevent or minimize induced deterioration [].

The use of LFs can enhance the pore structure of concrete through the filler effect, potentially reducing moisture transport within the concrete and inhibiting ASR development []. Conversely, because LFs lack cementitious or pozzolanic qualities, the dilution effect resulting from a reduced quantity of hydration products (i.e., calcium silicate hydrate) and increased porosity may outweigh the benefits of void filling. The fineness of LFs can also markedly affect the pore structure of PLC concrete []. Consequently, examining the viability of PLC with elevated interground LFs content (i.e., beyond 15%) as a sustainable substitute for conventional cement, especially regarding ASR, warrants additional study. This work applies two accelerated laboratory setups (i.e., AMBT and CPT) to assess the overall impact of elevated interground limestone content in PLC on ASR. The main objective of this work is to explore the influence of limestone content and the fineness of PLC on ASR-induced expansion.

2. Background

2.1. Alkali–Silica Reaction

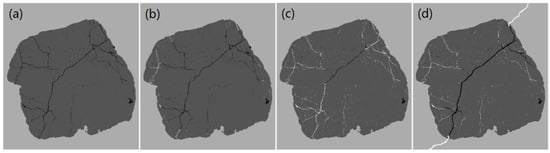

The alkali–silica reaction (ASR) occurs when hydroxyl ions (OH−) in the concrete’s pore solution react with metastable silica phases in aggregates. The highly alkaline environment in moist concrete promotes silica dissolution from reactive aggregate particles into the pore solution, leading to the precipitation of secondary products (i.e., ASR gel). The formed gel absorbs moisture, expanding and generating internal pressure that ultimately causes microcracking within aggregates and surrounding cement paste, as illustrated in Figure 1. Although the reaction does not directly involve alkalis, the concentration of OH− in the pore solution is largely influenced by sodium (Na+) and potassium ions (K+) [], which are primarily released during clinker hydration. Recent studies have also indicated that alkalis may increase the solubility of amorphous silica and consume aluminium in the aqueous phase, thereby accelerating the initiation of ASR [,,,].

Figure 1.

An illustrated sequence of ASR with an aggregate particle (dark grey) embedded in the cement paste (light grey) of a concrete: (a) aggregate particle with pre-existing micro-cracks, (b) precipitation of ASR products (white) starting close to the interface with the cement paste, (c) continuous precipitation towards the interior of the aggregate particle, and (d) cracking of the aggregate and adjacent cement paste with the diffusion of alkali–silica solution into the cement paste and its precipitation along the crack [].

ASR progression is influenced by the reactivity of aggregates, the type of binders, and the moisture content of the environment []. Once initiated, mitigating ASR remains a challenge, emphasizing the importance of selecting appropriate materials during mix design as a preventive strategy. With the advancement in low-carbon concrete, it is necessary to examine the influence brought by the cement alternatives through accelerated laboratory techniques, such as the accelerated mortar bar test (AMBT) and the concrete prism test (CPT), which remain essential for evaluating ASR kinetics.

2.2. The Effect of Limestone Addition on ASR

Depending on the amount and particle size distribution, intergrinding limestone and clinker directly alters cement’s chemical composition and hydration mechanism []. Four principal effects, such as filler, nucleation, dilution, and chemical effects, explain the hydration process and mechanical properties of PLC concrete []. Nevertheless, the influence of LFs on ASR is primarily unknown, as ASR is a complex internal swelling reaction that cannot be only deduced from mechanical indicators such as compressive strength.

2.2.1. Filler Effect

The filler effect largely depends on the limestone’s particle size distribution (PSD). When LFs are finer than cement particles, they act as physical fillers, occupying small voids between cement particles and reducing porosity. As a result, the compressive strength and penetrability resistance of concrete can be enhanced []. In the case of accelerated laboratory ASR testing, this effect (i.e., reduced porosity) can limit moisture ingress, suppressing ASR development. However, the extent of this effect depends on the amount and fineness of LFs, which is unclear and requires further investigation.

2.2.2. Nucleation Effect

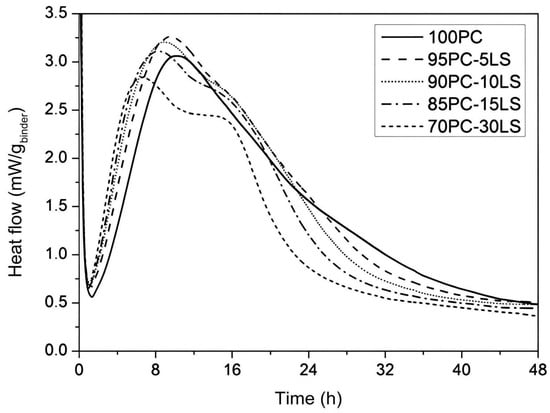

Besides the physical filler effect caused by the fine limestone, LFs provide preferential places for the precipitation of C-S-H [], accelerate the hydration reaction [], and improve the degree of hydration []. Notably, the nucleation effect primarily influences hydration within the first 48 h [], as shown in Figure 2. Given that ASR is a long-term issue, the nucleation effect is likely to have minimal significance for ASRs. However, further research is needed to establish a correlation between this effect and ASR kinetics.

Figure 2.

Heat of hydration of PC and PC + limestone [].

2.2.3. Dilution Effect

The dilution effect occurs when LFs replace clinker, reducing the availability of cementitious materials. Therefore, it is mainly influenced by the amount of LFs. Moreover, this effect is most pronounced when coarser particles (i.e., maximum particle size = 20 μm) [] are used, as they contribute minimally to packing density and nucleation site. Reducing clinker content can result in fewer hydration products, less refined pore structure, and potentially increased moisture penetration, exacerbating ASR. Similar to the filler effect, the significance of LFs content and fineness for the dilution effect remains unclear and requires further study.

2.2.4. Chemical Effect

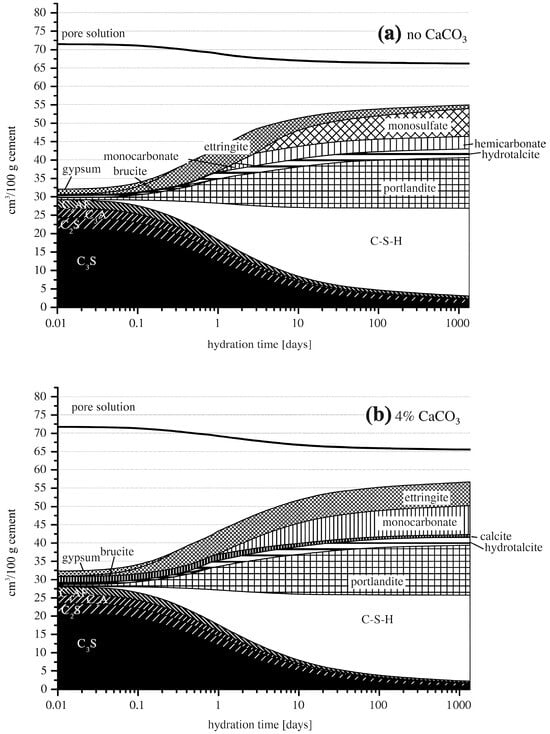

Besides the three major effects, the chemical effect of limestone on hydration has been well documented through thermodynamic models and experimental studies []. Although limestone lacks cementitious or pozzolanic properties, part of the interground limestone is not inert and will react with alumina phases (i.e., alumina hydroxyl) in the pore solution. As illustrated by Figure 3, the addition of 4% limestone does not significantly impact portlandite or C-S-H but reacts to form hemi-carbo aluminate (Hc), which transitions to mono-carbo aluminate (Mc) at later stages instead of mono-sulphate.

Figure 3.

Modelled changes during the hydration of (a) PC, without additional limestone and (b) PC4, with 4 wt.% limestone. Volume expressed as cm3/100 g unhydrated cement [].

The formation of Mc, which stabilizes the ettringite, reduces the solid volume in the mixture and may restrict the penetration of moisture into concrete. However, consuming alumina hydroxyl can exacerbate ASR damage by covering the surface of the reactive silica and limiting contact with OH− [,]. As discussed in the literature [], neither the fineness nor the amount of LFs appears to mitigate ASRs when alumina depletion is significant. Notably, alumina’s positive influence is primarily observed when alumina-rich supplementary cementitious materials (SCMs) are incorporated. The implications of further reducing alumina content in the concrete matrix without alumina-rich SCMs are yet to be explored.

3. Scope of Work

Two sources of PLCs (i.e., A and B) with high limestone contents (i.e., 13.34% and 24.54%) and different particle size distributions (PSD) were used to investigate the influence of PLC properties (i.e., LFs content and fineness) on ASR development. Six standardized mortar bars and concrete cylinders were prepared in accordance with ASTM 1260 [] and ASTM 1293 []. The mixtures were proportioned using water-to-cement (w/c) ratios of 0.47 and 0.45, respectively.

In addition, six companion concrete families were fabricated using the same w/c ratio to assess the effect of LFs addition on pore structure properties, as indicated by compressive strength. The contributions of LFs content and fineness to ASR kinetics were appraised. Finally, a two-way analysis of variance (ANOVA) was used for data validation.

4. Experimental Program

4.1. Raw Materials

Six different types of PLC obtained from two milling facilities (A and B) with distinct fineness were assessed. Each was interground with three nominal limestone ratios (i.e., 15%, 20%, and 25%) and provided similar PSD. The combination of these materials with non-reactive and ultra-highly reactive aggregates was evaluated through the accelerated mortar bar test (AMBT) and concrete prism test (CPT). The actual limestone contents were characterized by combustion analysis, and a summary of the oxide components and mineralogical phases is presented in Table 1.

Table 1.

Chemical composition, mineralogical phases, and limestone contents of portland-limestone cements.

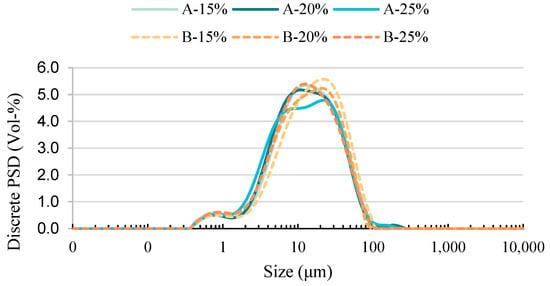

The specific surface area (SSA) of the materials was measured through the Blaine air permeability test, as well as the Brunauer-Emmett-Teller (BET) technique, which provides higher-accuracy data to help in the cement hydration study, especially in the case of PLC, where the fineness of LFs is of high importance. The specific gravity of the materials was obtained using Le Chatelier flasks, following ASTM C188 []. The physical properties of the PLCs are presented in Table 2. Finally, laser diffraction spectroscopy was employed to retrieve the PSD of each material used, and the results are presented in Figure 4.

Table 2.

Physical Characterization of the PLCs.

Figure 4.

Particle size distribution of the PLCs.

An ultra-highly reactive polymictic sand from Jobe Materials, El Paso, TX, USA and a non-reactive limestone coarse aggregate from Ottawa, ON, Canada are used in this research. Table 3 provides information on the aggregates used in this study. The reactivity levels are determined by testing the aggregates from the same laboratory but with OPC [].

Table 3.

Information on aggregates used in study.

4.2. Test Methods

4.2.1. Accelerated Mortar Bar Test

The accelerated mortar bar test (AMBT), as per ASTM 1260 [], is a 16-day short-term test used to evaluate the aggregate reactivity potential for ASR-induced expansion.

The w/c is fixed at 0.47. Fine aggregates are sieved and graded to obtain designated proportions for different sizes, as shown in Table 4.

Table 4.

Grading requirements of AMBT [].

Prism-shaped mortar bars (25 mm × 25 mm × 285 mm) were cast and moisture-cured for one day, followed by immersion in 1M NaOH solution at 80 °C to accelerate the ASR development. The length of mortar bars was then periodically measured for computing the expansion after a 14-day period.

4.2.2. Concrete Prism Test

The 1-year concrete prism test (CPT), as per ASTM 1293 [], is widely accepted to examine the potential alkali reactivity of concrete aggregates []. The mixture is formulated at a fixed coarse-to-fine ratio of 60:40, and a total cement content of 420 kg/m3 is adopted. The total alkali content is boosted by adding sodium hydroxide during batching to achieve 1.25% NaOeq by mass of cement for all the mixes. The detailed mix proportioning is presented in Table 5.

Table 5.

Mix-proportioning of CPT specimens.

In this study, CPT was performed using cylinders (100 mm × 200 mm) instead of prisms to monitor the expansion [] and facilitate future research on damage assessment through mechanical testing (i.e., stiffness damage test []). The cylinders were maintained at 38 °C in plastic pails with relative humidity exceeding 95% to monitor ASR-induced expansion.

4.2.3. Compression Test

Compressive strength testing was performed according to ASTM C-39 [], with a 2000 N/s loading rate. According to the ACI method [], the mix is designed with a 0.45 w/c ratio to obtain 35 MPa, and the detailed mix proportioning is presented in Table 6.

Table 6.

Mix-proportioning of specimens for compression test.

Samples were demolded 24 h after casting and cured in a moist curing tank (i.e., 95% relative humidity and 25 °C) until testing at 28 days. For each mixture, three cylinders were tested to allow statistical validation.

5. Results

5.1. ASR Kinetics in AMBT and CPT

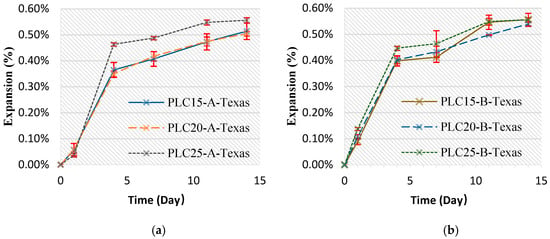

Figure 5 illustrates the expansion behavior for the PLC-A (Figure 5a) and PLC-B (Figure 5b) for the AMBT test. Both families exhibited rapid expansion in the first three days, followed by a more gradual expansion rate at later ages.

Figure 5.

ASR kinetics (expansion vs. time) of mortar bars (AMBT) from PLC from different sources: (a) A and (b) B.

For PLC-A (Figure 5a), mixes with 15% and 20% limestone content showed similar trends and results throughout the test duration, each reaching about 0.51% ± 0.03% expansion by day 14. Conversely, the 25% limestone mix displayed evident higher expansion starting from day 3, leading to 0.56% ± 0.01% expansion by the end of the test period.

Figure 5b reveals that PLC15-B and PLC20-B exhibit similar kinetics during the initial seven days. However, PLC15-B exhibited a sharp increase in expansion between days 7 and 11, eventually aligning with the expansion level of PLC25-B. By day 14, all mixes within the PLC-B group achieved similar expansion levels, averaging 0.55% ± 0.02%. Notably, PLC25-B consistently led in expansion throughout the test period.

According to ASTM C1778 [], all PLC mixtures tested with Texas sand are classified as “very highly reactive”, with expansion beyond 0.45% after 14 days in 1M NaOH solution.

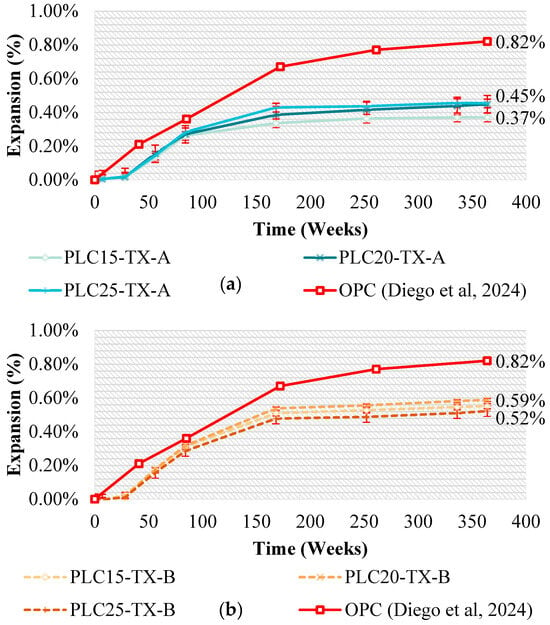

Figure 6 illustrates the kinetic behavior of the ASR-induced concrete cylinders under CPT evaluation. As seen in Figure 6a,b, ASR-induced expansion becomes noticeable after 28 days for both PLC-A and PLC-B, showing similar expansion levels up to 56 days (0.16% ± 0.02%). Afterwards, a significant discrepancy is witnessed until the end of the test, where a lower expansion level is obtained for all the PLC-A (from 0.37% to 0.45%) compared to the PLC-B (from 0.52% to 0.59%) families.

Figure 6.

ASR kinetics (expansion vs. time) of mortar bars (CPT) from PLC from different sources: (a) A and (b) B [].

In the PLC-A group, the expansion results of PLC bearing 20% and 25% LFs are the same, reaching 0.45%, whereas PLC15-A shows a marginally lower expansion of 0.37%. However, the same trend is not observed for the PLC-B group, with PLC20-B reaching the highest expansion level of 0.59%, followed by PLC15-B (0.55%) and PLC25-B (0.52%). There is no direct correlation between the limestone content and the degree of expansion.

Nevertheless, all PLC families demonstrate slower and milder ASR development compared to the results using OPC in the literature, with 0.82% expansion at 1 year []. It is also worth mentioning that the turning point of ASR development for both PLC and OPC is 6 months, when the expansion starts to level off. However, the slopes for PLC families are significantly steadier, with an average of a 0.04% increment from 6 months to 1 year.

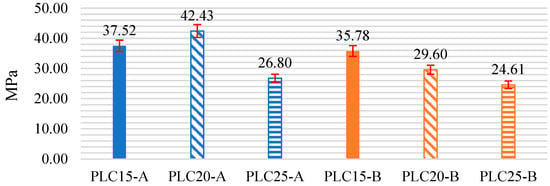

5.2. Compressive Strength

The 28-day compressive strength results for the PLC concrete mixes with varying LFs contents are presented in Figure 7, showing the differences among PLC15, PLC20, and PLC25. PLC15, with 15% LF replacement, achieved compressive strengths of 37.52 MPa (PLC15-A) and 35.78 MPa (PLC15-B), closely aligning with the target strength of 35 MPa, making it comparable to OPC. However, opposite trends are observed for PLC20, with 20% LF replacement. PLC20-A achieved the highest compressive strength of all mixes at 42.43 MPa, a 13% improvement compared to PLC15-A. Conversely, PLC20-B experienced a 17% reduction in strength compared to PLC15-B, dropping to 29.6 MPa. Finally, at the highest replacement level of 25%, both PLC25 mixes exhibited notable strength reductions. PLC25-A reached 26.8 MPa, while PLC25-B was further reduced to 24.61 MPa, representing approximately a 30% drop in strength relative to the PLC15 group.

Figure 7.

Compressive strength of the PLC concrete.

This indicates that while moderate LF replacement levels (i.e., 15–20%) can maintain or even enhance compressive strength, higher LF contents (i.e., 25%) compromise mechanical performance regardless of the source.

6. Discussion

This section evaluates the impact of varying limestone contents in PLCs on ultimate expansion results from the ASR testing setups (i.e., AMBT and CPT). A summary of the statistical analysis is provided in Table 7.

Table 7.

Statistical analysis appraises the influence of source and LFs contents.

6.1. Influence of Limestone Contents

The AMBT results indicate no statistically significant differences among the three LFs replacement ratios, with p = 0.143 (>0.05). Similarly, the CPT results at 1 year were analyzed, showing a higher significance level compared to the AMBT results (p = 0.06). However, this value is still too low to confirm that there is a significant difference between PLC15, 20, and 25. Nevertheless, the amount of LFs was found to have a significant influence on the compressive strength, within p < 0.001, highlighting its influence on the mechanical properties of PLC mixtures.

As widely addressed in the literature [], the pore structure of PLC is strongly linked to the physical filler effect and dilution effect. Variations observed in compression tests across different LFs ratios (Figure 7) can largely be attributed to the interplay between these effects. One study suggested that in concrete mixtures with a fixed water-to-cement ratio, porosity decreases with limestone content up to 15% but increases beyond 20–25% [], which appears to be the case for PLC-B families since there is a decrease in compressive strength with the increase in LFs content. Conversely, PLC concretes with up to 20% LFs show little porosity change or compressive strength in other studies [,], and this explains the trend of PLC-A families, where PLC20-A obtains the highest compressive strength. These findings suggest that, depending on the amount, the addition of LFs can result in either refinement or coarsening of the pore structure.

From the experimental results of the ultimate expansion, the extent of modification caused by LFs amount does not exert the same impact on ASR development as compressive strength when the LFs content is increased from 15% to 25%. A considerable improvement in ASR resistance is observed when comparing PLC with OPC, which bears up to 5% LFs []. This reflects that the initial 10% rise in LFs content is more influential than any further addition regarding the ASR resistance, which matches most of the conclusions in the research and the industrial report that the optimum amount of LFs content is 15% for the mechanical properties of PLC concrete [,,]. When the LFs are increased above 20%, discrepancies start to occur in the previous research [,,,,], which might indicate that the impact of the LFs amount is becoming minor and thus, other factors (e.g., fineness) are also affecting the results. Nevertheless, the dilution effect of high limestone content does not outweigh the benefits of the filler effect, since PLC25 from both A and B sources demonstrates significantly lower CPT expansion than OPC (i.e., 0.755% from []). In this context, PLC, despite containing up to 25% limestone, has enhanced resistance to ASR relative to OPC. This observation underscores the possibilities of PLC as a more resilient alternative to conventional OPC, particularly in environments susceptible to ASR.

Fine limestone fillers also serve as nucleation sites, expediting the initial hydration kinetics. The nucleation effect is evident in AMBT (Figure 2), as PLC (A and B)-25 demonstrate accelerated expansion during the initial three days, while not being reflected in the long-term CPT due to the first measurement occurring after one week. This swift initial expansion can be ascribed to enhanced hydration resulting from elevated limestone content, leading to the formation of more portlandite in a reduced timeframe. This process generates a surplus of hydroxide ions, initiating the ASR. Consequently, the stability of hydration and alkaline conditions results in a more progressive expansion over a period of 3 to 14 days. These findings align with prior studies demonstrating an increased calcium hydroxide concentration in PLCs with elevated limestone content during the initial hydration phases []. An alternate explanation for the increased expansion in the AMBT results may be attributed to the increased porosity and accelerated penetration of NaOH.

6.2. Influence of Limestone Fineness

A comparative investigation of sources A and B for PLCs containing identical amounts of limestone was conducted. It was found that PLCs show significant variance between sources in both AMBT and CPT. Based on variance analysis (ANOVA), these conclusions highlight the influence of fineness on PLC properties.

A previous study of the hydration and strength development of PLC concrete suggested that increased LFs fineness could compensate for the negative dilution effect on the mechanical properties caused by excessive clinker replacement [], especially in the early hydration process (i.e., the first 7 days), where the surface of finer LFs provides more nucleation sites for the precipitation of hydration products, thus promoting hydration and enhancing the early strength []. In the long term, the use of LFs of finer PSD as physical filler can fill more voids between cement particles, leading to denser packing and thus increasing the compressive strength, which is well-reflected in the compressive strength results, where the strength of PLC-A concrete is significantly higher than PLC-B. Based on the results, the PLCs with the same LFs content but exhibiting higher fineness could strengthen the filler effect and allow more LFs addition (e.g., from 15% to 20%) without diminishing performance.

The disadvantage of LFs addition was raised by Lothenbach et al. [] through thermodynamic modelling; they suggest that the stabilization of monocarbonate and ettringite caused by limestone addition can result in higher porosity in the cement matrix. Additionally, previous research also reported that the finer the LFs, the higher the reactivity of LFs []. The elevated consumption of alumina phases with finer LFs addition is even worse in the case of ASR, where alumina phases can limit the dissolution of silica and thus mitigate ASR []. Nevertheless, this predicted chemical side effect from thermodynamic modelling, which can be exacerbated with the increase in fineness, does have less impact on experimental permeability measurements [] and does not overwhelm the benefit of void-filling in this research. Although pore solution measurements on the concrete samples are required to provide robust validation, the higher fineness of PLC remains a benefit, as evidenced by the CPT results for ultimate ASR expansion and kinetics, which show significant differences between the two sources, with PLC-A families (higher fineness) demonstrating lower and slower expansion. While no direct microstructural validation (e.g., SEM, XRD) or transport property measurements (e.g., porosity, permeability, sorptivity) were conducted to validate the speculative interpretations, this work serves as the initial stage of the study aiming at understanding ASR kinetics in PLC systems. Future phases of this research, incorporating comprehensive microstructural and transport analyses, are required to validate and refine the conclusions.

7. Conclusions

From the research presented, the following main conclusions can be drawn:

- Comparative results of AMBT and CPT indicate that PLCs limit ASR-induced expansion from 0.755% and 0.82%, reported in the literature with OPC, to below 0.55% and 0.59% in this study, utilizing identical ultra-highly reactive Texas sand. Although still beyond the limitations specified in ASTM C1778 [], the reduced expansion highlights the impact on the test outcome and thus the potential impact of PLC in evaluating reactive aggregates []. Nevertheless, longer tests (i.e., real-site monitoring) will be required to verify if the reduced expansion is really a mitigation or just a delay.

- Statistical analysis of both the AMBT and CPT results concludes that increasing limestone content from 15% to 25% in PLC does not significantly influence ASR expansion, regardless of the fineness. However, microscopic analysis (i.e., damage rating index []) is required in the future for microstructural validation.

- With the sole addition of interground limestone, the fineness of PLC significantly influences the ASR-induced expansion within one year of testing through the refinement of pore structure (i.e., filler effect), which is more pronounced than the modifications to hydration kinetics and pore solution compositions (i.e., nucleation and chemical effects). Significantly, PLCs of higher fineness (Source A) obtain lower ultimate expansion, indicating that the defects of high LFs content (i.e., dilution effect) on ASR development can be partially compensated by higher fineness of PLC. Nevertheless, this interpretation is based substantially on expansion kinetics and compressive strength and requires further microstructural investigation (e.g., SEM) for validation.

- The expedited initiation and propagation of ASR during the initial three days of AMBT may be attributed to the nucleation effect. However, it may also be ascribed to the increased porosity resulting from a rising amount of LFs. Additional research is required to elucidate the primary issue, such as the mercury intrusion porosity test.

- The results of the compression test demonstrate different significance compared to the AMBT and CPT results, which reveal that compressive strength is not a proper indicator of transportation properties (e.g., permeability, sorptivity, etc.). Further measurements still need to be made to confirm the conclusions.

- Without any improvement in the mix-design, increasing the LFs content from 15% to 25% results in a significant reduction in compressive strength, which indicates that advanced mix-design techniques are required to facilitate the use of PLC25 in real structures.

Author Contributions

Conceptualization, Z.X. and L.S.; methodology, Z.X.; investigation, Z.X.; resources, Z.X. and L.S.; data curation, Z.X.; writing—original draft preparation, Z.X.; writing—review and editing, Z.X., A.B. and L.S.; visualization, Z.X. and A.B.; supervision, L.S.; project administration, L.S.; funding acquisition, L.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Mitacs Accelerate.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Petroche, D.M.; Ramirez, A.D. The Environmental Profile of Clinker, Cement, and Concrete: A Life Cycle Perspective Study Based on Ecuadorian Data. Buildings 2022, 12, 311. [Google Scholar] [CrossRef]

- Scrivener, K.L. Options for the future of cement. Indian Concr. J. 2014, 88, 11–21. [Google Scholar]

- Garcia, J.E.; Tiburzi, N.B.; Folliard, K.J.; Drimalas, T. Mechanical properties and electrical resistivity of portland limestone cement concrete systems containing greater than 15% limestone and supplementary cementitious materials. Cement 2022, 8, 100026. [Google Scholar] [CrossRef]

- Cement Association of Canada. Roadmap to Net-Zero Carbon Concrete by 2050. 2022. Available online: https://ised-isde.canada.ca/site/clean-growth-hub/en/cement-and-concrete-canada/roadmap-net-zero-carbon-concrete-2050 (accessed on 1 May 2025).

- CSA A3000-23; Cementitious Materials Compendium. Canadian Standards Association: Toronto, ON, Canada, 2023.

- Tsivilis, S.; Chaniotakis, E.; Badogiannis, E.; Pahoulas, G.; Ilias, A. A study on the parameters affecting the properties of Portland limestone cements. Cem. Concr. Compos. 1999, 21, 107–116. [Google Scholar] [CrossRef]

- Cost, V.T.; Howard, I.L.; Shannon, J. Improving Concrete Sustainability and Performance with Use of Portland–Limestone Cement Synergies. Transp. Res. Rec. J. Transp. Res. Board 2013, 2342, 26–34. [Google Scholar] [CrossRef]

- Elgalhud, A.A.; Dhir, R.K.; Ghataora, G. Chloride ingress in concrete: Limestone addition effects. Mag. Concr. Res. 2018, 70, 292–313. [Google Scholar] [CrossRef]

- Elgalhud, A.A.; Dhir, R.K.; Ghataora, G.S. Carbonation resistance of concrete: Limestone addition effect. Mag. Concr. Res. 2017, 69, 84–106. [Google Scholar] [CrossRef]

- De Grazia, M.T.; Sanchez, L.F.M.; Romano, R.; Pileggi, R. Evaluation of the fresh and hardened state properties of low cement content systems. Mag. Concr. Res. 2020, 72, 232–245. [Google Scholar] [CrossRef]

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties, and Materials, 4th ed.; McGraw-Hill Education: New York, NY, USA, 2014. [Google Scholar]

- Fournier, B.; Bérubé, M.-A. Alkali–aggregate reaction in concrete: A review of basic concepts and engineering implications. Can. J. Civ. Eng. 2000, 27, 167–191. [Google Scholar] [CrossRef]

- Wang, D.; Shi, C.; Farzadnia, N.; Shi, Z.; Jia, H.; Ou, Z. A review on use of limestone powder in cement-based materials: Mechanism, hydration and microstructures. Constr. Build. Mater. 2018, 181, 659–672. [Google Scholar] [CrossRef]

- Diamond, S. Cement and Concrete Research; Pergamon Press, Inc.: Elmsford, NY, USA, 1975; Volume 5, pp. 329–346. [Google Scholar]

- Leemann, A.; Katayama, T.; Fernandes, I.; Broekmans, M.A.T.M. Types of alkali–aggregate reactions and the products formed. Proc. Inst. Civ. Eng.—Constr. Mater. 2016, 169, 128–135. [Google Scholar] [CrossRef]

- Heisig, A.; Urbonas, L.; Beddoe, R.E.; Heinz, D. Ingress of NaCl in concrete with alkali reactive aggregate: Effect on silicon solubility. Mater. Struct. 2016, 49, 4291–4303. [Google Scholar] [CrossRef]

- Huenger, K.-J.; Kositz, M.; Danneberg, M. Influence of alkali supply from outside on the dissolution behavior of aggregates. In Proceedings of the 16th International Conference on Alkali-Aggregate Reaction in Concrete, Lisbon, Portugal, 31 May–2 June 2022. [Google Scholar]

- Giebson, C.; Seyfarth, K.; Ludwig, H.M. Aggregate dissolution kinetics. Mag. Concr. Res. 2023, 75, 734–746. [Google Scholar] [CrossRef]

- Leemann, A.; Góra, M.; Lothenbach, B.; Heuberger, M. Alkali silica reaction in concrete—Revealing the expansion mechanism by surface force measurements. Cem. Concr. Res. 2024, 176, 107392. [Google Scholar] [CrossRef]

- Lindgård, J.; Andiç-Çakır, Ö.; Fernandes, I.; Rønning, T.F.; Thomas, M.D.A. Alkali–silica reactions (ASR): Literature review on parameters influencing laboratory performance testing. Cem. Concr. Res. 2012, 42, 223–243. [Google Scholar] [CrossRef]

- Moon, G.D.; Oh, S.; Jung, S.H.; Choi, Y.C. Effects of the fineness of limestone powder and cement on the hydration and strength development of PLC concrete. Constr. Build. Mater. 2017, 135, 129–136. [Google Scholar] [CrossRef]

- Irassar, E.F. Sulfate attack on cementitious materials containing limestone filler—A review. Cem. Concr. Res. 2009, 39, 241–254. [Google Scholar] [CrossRef]

- Craeye, B.; De Schutter, G.; Desmet, B.; Vantomme, J.; Heirman, G.; Vandewalle, L.; Cizer, Ö.; Aggoun, S.; Kadri, E. Effect of mineral filler type on autogenous shrinkage of self-compacting concrete. Cem. Concr. Res. 2010, 40, 908–913. [Google Scholar] [CrossRef]

- Cyr, M.; Lawrence, P.; Ringot, E. Efficiency of mineral admixtures in mortars: Quantification of the physical and chemical effects of fine admixtures in relation with compressive strength. Cem. Concr. Res. 2006, 36, 264–277. [Google Scholar] [CrossRef]

- Thongsanitgarn, P.; Wongkeo, W.; Chaipanich, A.; Poon, C.S. Heat of hydration of Portland high-calcium fly ash cement incorporating limestone powder: Effect of limestone particle size. Constr. Build. Mater. 2014, 66, 410–417. [Google Scholar] [CrossRef]

- Lothenbach, B.; Le Saout, G.; Gallucci, E.; Scrivener, K. Influence of limestone on the hydration of Portland cements. Cem. Concr. Res. 2008, 38, 848–860. [Google Scholar] [CrossRef]

- Chappex, T.; Scrivener, K.L. The Effect of Aluminum in Solution on the Dissolution of Amorphous Silica and its Relation to Cementitious Systems. J. Am. Ceram. Soc. 2013, 96, 592–597. [Google Scholar] [CrossRef]

- Wei, S.; Zheng, K.; Zhou, J.; Prateek, G.; Yuan, Q. The combined effect of alkalis and aluminum in pore solution on alkali-silica reaction. Cem. Concr. Res. 2022, 154, 106723. [Google Scholar] [CrossRef]

- Briki, Y.; Zajac, M.; Haha, M.B.; Scrivener, K. Impact of limestone fineness on cement hydration at early age. Cem. Concr. Res. 2021, 147, 106515. [Google Scholar] [CrossRef]

- ASTM C1260; Standard Test Method for Potential Alkali Reactivity of Aggregates (Mortar-Bar Method). ASTM International: West Conshohocken, PA, USA, 2022. [CrossRef]

- ASTM C1293; Standard Test Method for Determination of Length Change of Concrete Due to Alkali-Silica Reaction. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM C188; Test Method for Density of Hydraulic Cement. ASTM International: West Conshohocken, PA, USA, 2017. [CrossRef]

- De Souza, D.J.; Sanchez, L.F.M.; Biparva, A. Influence of engineered self-healing systems on ASR damage development in concrete. Cem. Concr. Compos. 2024, 147, 105440. [Google Scholar] [CrossRef]

- Drolet, C.; Duchesne, J.; Fournier, B. Validation of the alkali contribution by aggregates to the concrete pore solution. Cem. Concr. Res. 2017, 98, 10–23. [Google Scholar] [CrossRef]

- Sinno, N.; Shehata, M.H. Effect of sample geometry and aggregate type on expansion due to alkali-silica reaction. Constr. Build. Mater. 2019, 209, 738–747. [Google Scholar] [CrossRef]

- Sanchez, L.F.M.; Drimalas, T.; Fournier, B.; Mitchell, D.; Bastien, J. Comprehensive damage assessment in concrete affected by different internal swelling reaction (ISR) mechanisms. Cem. Concr. Res. 2018, 107, 284–303. [Google Scholar] [CrossRef]

- ASTM C-39; Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2024. [CrossRef]

- Kosmatka, S.H.; Kerkhoff, B.; Panarese, W.C. Design and Control of Concrete Mixtures; Portland Cement Association: Skokie, IL, USA, 2002. [Google Scholar]

- ASTM C1778; Guide for Reducing the Risk of Deleterious Alkali-Aggregate Reaction in Concrete. ASTM International: West Conshohocken, PA, USA, 2022. [CrossRef]

- Tsivilis, S.; Tsantilas, J.; Kakali, G.; Chaniotakis, E.; Sakellariou, A. The permeability of Portland limestone cement concrete. Cem. Concr. Res. 2003, 33, 1465–1471. [Google Scholar] [CrossRef]

- Elgalhud, A.A.; Dhir, R.K.; Ghataora, G. Limestone addition effects on concrete porosity. Cem. Concr. Compos. 2016, 72, 222–234. [Google Scholar] [CrossRef]

- Tennis, P.D.; Thomas, M.D.A.; Weiss, W.J. State-of-the-Art Report on Use of Limestone in Cements at Levels of up to 15%; Portland Cement Association: Skokie, IL, USA, 2011. [Google Scholar]

- Dhir, R.K.; Limbachiya, M.C.; McCarthy, M.J.; Chaipanich, A. Evaluation of Portland limestone cements for use in concrete construction. Mater. Struct. 2007, 40, 459–473. [Google Scholar] [CrossRef]

- Palm, S.; Proske, T.; Rezvani, M.; Hainer, S.; Müller, C.; Graubner, C.-A. Cements with a high limestone content—Mechanical properties, durability and ecological characteristics of the concrete. Constr. Build. Mater. 2016, 119, 308–318. [Google Scholar] [CrossRef]

- Panesar, D.K.; Zhang, R. Performance comparison of cement replacing materials in concrete: Limestone fillers and supplementary cementing materials—A review. Constr. Build. Mater. 2020, 251, 118866. [Google Scholar] [CrossRef]

- Tsivilis, S.; Chaniotakis, E.; Kakali, G.; Batis, G. An analysis of the properties of Portland limestone cements and concrete. Cem. Concr. Compos. 2002, 24, 371–378. [Google Scholar] [CrossRef]

- Leemann, A.; Bernard, L.; Alahrache, S.; Winnefeld, F. ASR prevention—Effect of aluminum and lithium ions on the reaction products. Cem. Concr. Res. 2015, 76, 192–201. [Google Scholar] [CrossRef]

- Xia, Z.; Bergmann, A.; Sanchez, L. Assessment of Alkali-Silica Reaction Development in High Limestone Replacement Portland-Limestone Mortar and Concrete. In Proceedings of the 17th International Conference on Alkali-Aggregate Reaction in Concrete, Ottawa, ON, Canada, 18–24 May 2024; Volume 50, pp. 710–717. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).