1. Introduction

Food security is the foundation of national security and is closely associated with sustainable development. In China, government departments and the Food and Agriculture Organization (FAO) attach great importance to food security issues and have established a relatively complete food reserve system [

1]. Good food reserves are paramount to ensuring food supply. In this regard, grain depots are important infrastructure for ensuring the safety of national grain reserves, mainly including large warehouses, squat silos, and vertical silos [

2,

3,

4,

5].

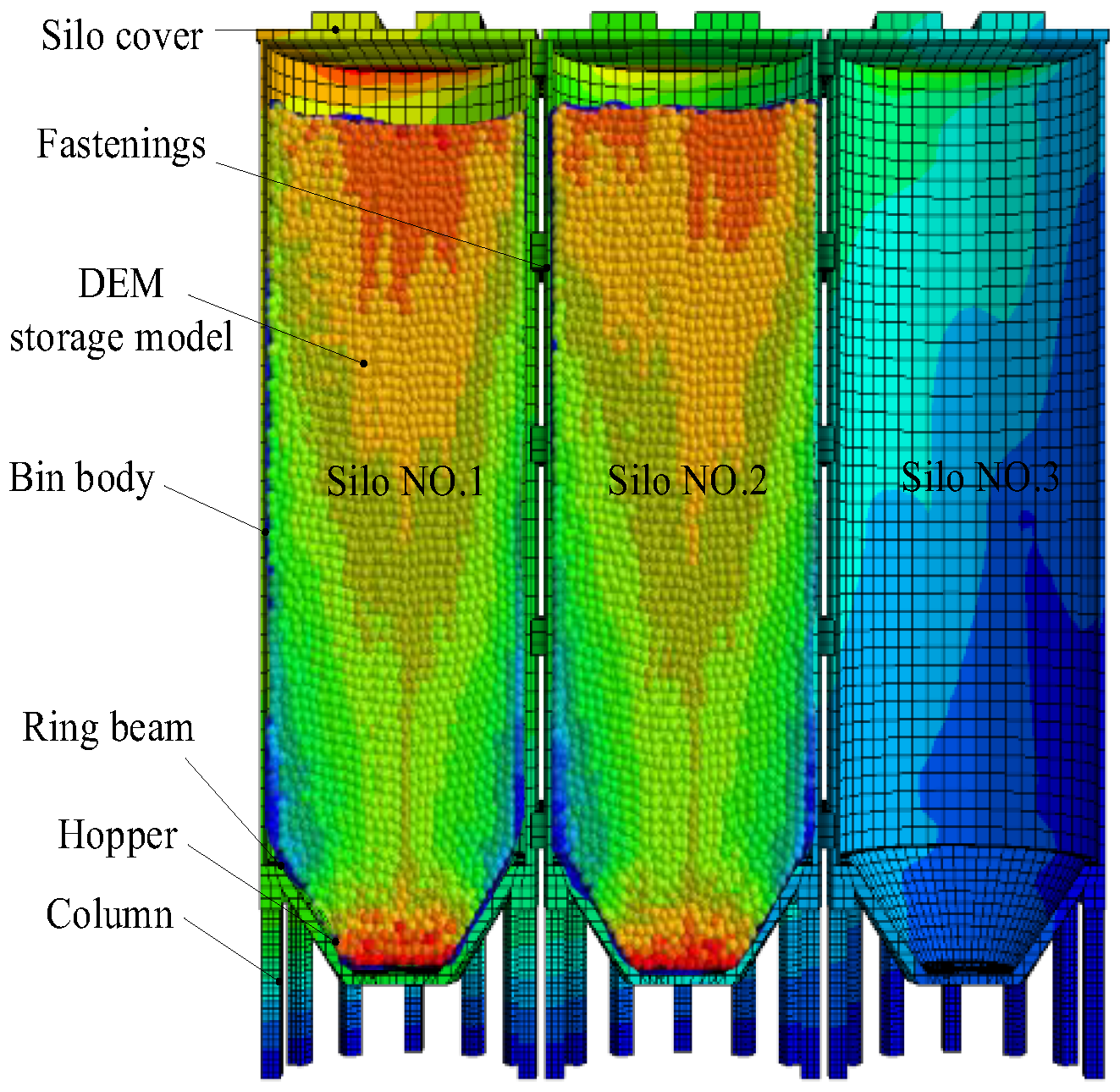

Based on the combination form, silos can be mainly divided into single and group silos. A group silo is suitable for the selection of a single row of multi-connected or multi-row multi-connected arrangement. Based on the type of support structural component, silos can be divided into column-supported silos, cylinder-supported silos, and a cylinder with column-supported silos [

5,

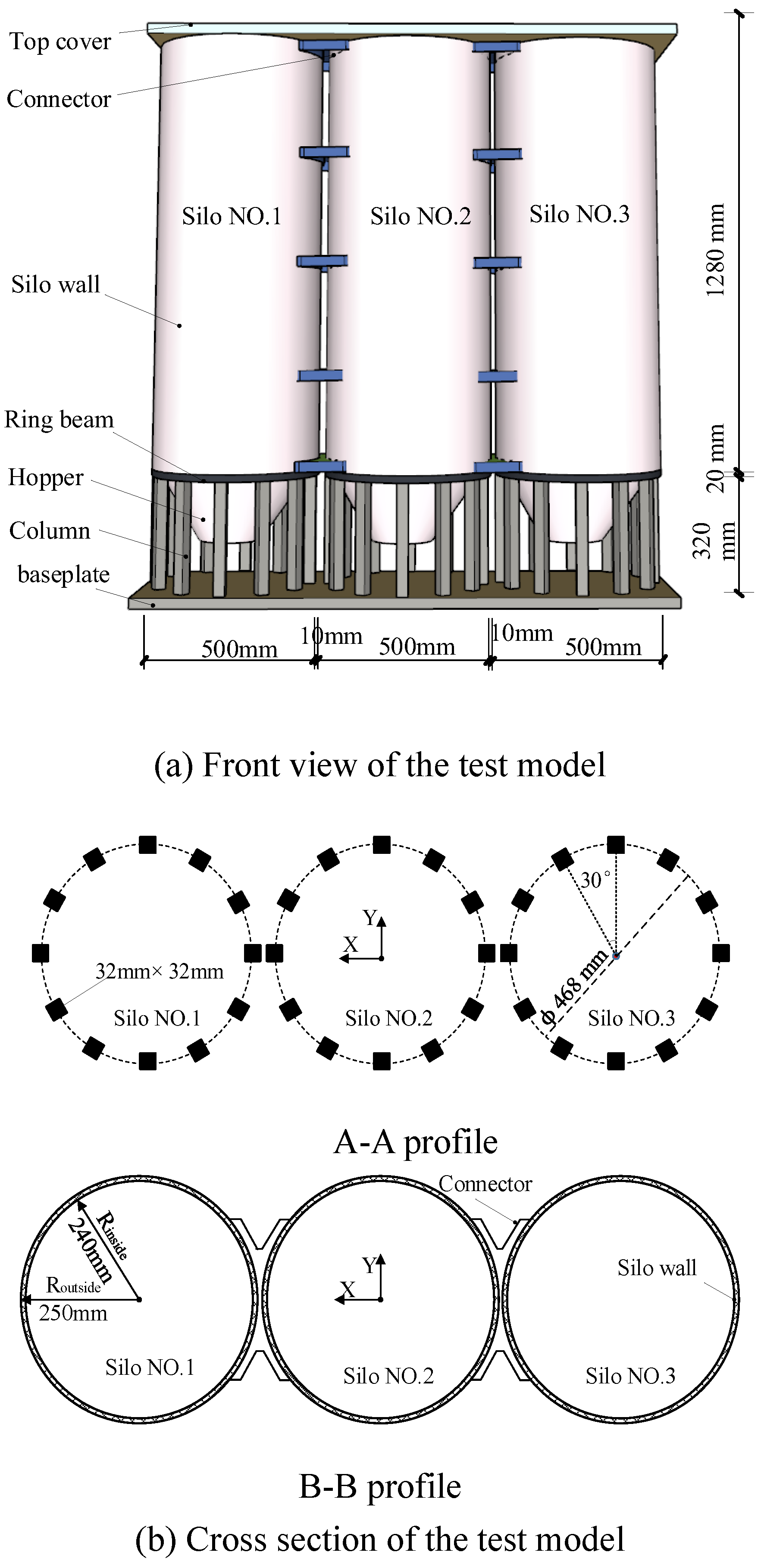

6]. Among them, the column-supported vertical-group silo has advantages, such as a small footprint, high storage capacity, and a high degree of mechanical automation, making it the main type of silo for grain storage and logistics transfer. The column-supported vertical-group silo is mostly constructed with reinforced concrete materials, presenting a unique structure comprising upper storage and lower columns, which allows for a large space and flexible use in the lower part of the structure while meeting the requirements of grain depots to a significant extent. Owing to these advantages, the column-supported vertical-group silo has become one of the main types of silos in the construction of grain depots, as shown in

Figure 1.

In the past three decades, column-supported vertical-group silo structures have been widely used in grain depots in China [

7,

8,

9,

10,

11,

12]. However, these structures have seen a large number of ruptures under the action of earthquakes. Earthquake disaster investigations have shown that the probability of loss of use due to damage to column-supported vertical silo structures is much higher than that in the case of general storage structures [

13,

14,

15]. Therefore, it is necessary to perform seismic research on storage structures, particularly silo structures.

Currently, scholars are conducting some research on silo structures. Ding et al. [

16] proposed a method for calculating the effective mass coefficient of column-supported silos under earthquake action based on experiments. Shi et al. [

17] conducted a shaking table test on a reinforced-concrete circular silo model to simulate earthquake vibrations. Jiang et al. [

18] studied the dynamic response of a column-supported circular silo structure under seismic action using actual engineering examples. Through a finite element numerical analysis, it was found that the weak positions in the structure are mainly the intersection between the ring beam top and the silo wall and the connection between the column and the ring beam. The upper silo and lower support exhibited inconsistent motion. Ding et al. [

19] conducted experimental research on the dynamic lateral pressure of a column-supported silo wall under seismic action. The research showed that the comprehensive correction factor used in the current code is too low, and the silo wall within the upper third of the silo produces a torsional effect, which enhances the dynamic response of the upper part of the structure. Ma et al. [

20] believed that in addition to material storage, structural asymmetry and differences in the silo volume and material density can form and exacerbate eccentric effects, causing torsional effects in column-supported storage structures. Through a finite element modal analysis of column-supported vertical silos and group silos, Zhang [

21] found that both single and group silos undergo torsional effects under empty conditions, accompanied by column bending or torsion. When only some of the single silos in a group silo are filled with material, asymmetric loading occurs, resulting in torsional vibration modes in the structure, and the impact of material storage on higher-order vibration modes is significant.

The storage materials in a column-supported vertical-group silo structure often undergo rapid loading and unloading, frequent turnover, and constantly changing quality and distribution due to market fluctuations, emergency material allocation, and other reasons [

22,

23,

24]. The storage quality and distribution of each individual silo constantly vary, often resulting in complex situations, such as the uneven distribution of stored materials and inconsistent storage heights. The structural center of mass and the center of rigidity deviate from each other, and under the action of earthquakes, the silo group, particularly single-row multi-column column-supported vertical silo structures, may experience spatial torsional effects, resulting in structural damage or even collapse, which seriously threatens the safety and stability of grain storage [

25,

26,

27,

28,

29,

30]. Hence, it is necessary to explore the seismic dynamic response laws of column-supported vertical-group silo structures and the spatial torsional effect mechanism of structures under nonuniform storage conditions.

However, there remain several significant gaps in the existing investigations. Most previous studies have concentrated on the dynamic behavior of single silos or symmetrically arranged group silos under uniform loading conditions, often neglecting the irregular torsional responses caused by mass eccentricity in column-supported vertical-group silo structures [

31,

32,

33,

34,

35,

36]. The dynamic response and torsional behavior under nonuniform grain storage conditions have rarely been addressed. Additionally, prior research has seldom examined the influence of different combination forms (e.g., 1 × 3, 2 × 3, 3 × 3) and varying mass distributions on the torsional displacement response [

37,

38,

39,

40]. Few studies have combined shaking table tests with FEM–DEM coupled modeling to comprehensively analyze the spatial torsion effects under seismic excitation. This study aims to bridge these gaps by experimentally and numerically investigating the seismic response and torsional characteristics of column-supported group silos under various eccentric mass distributions and structural layouts.

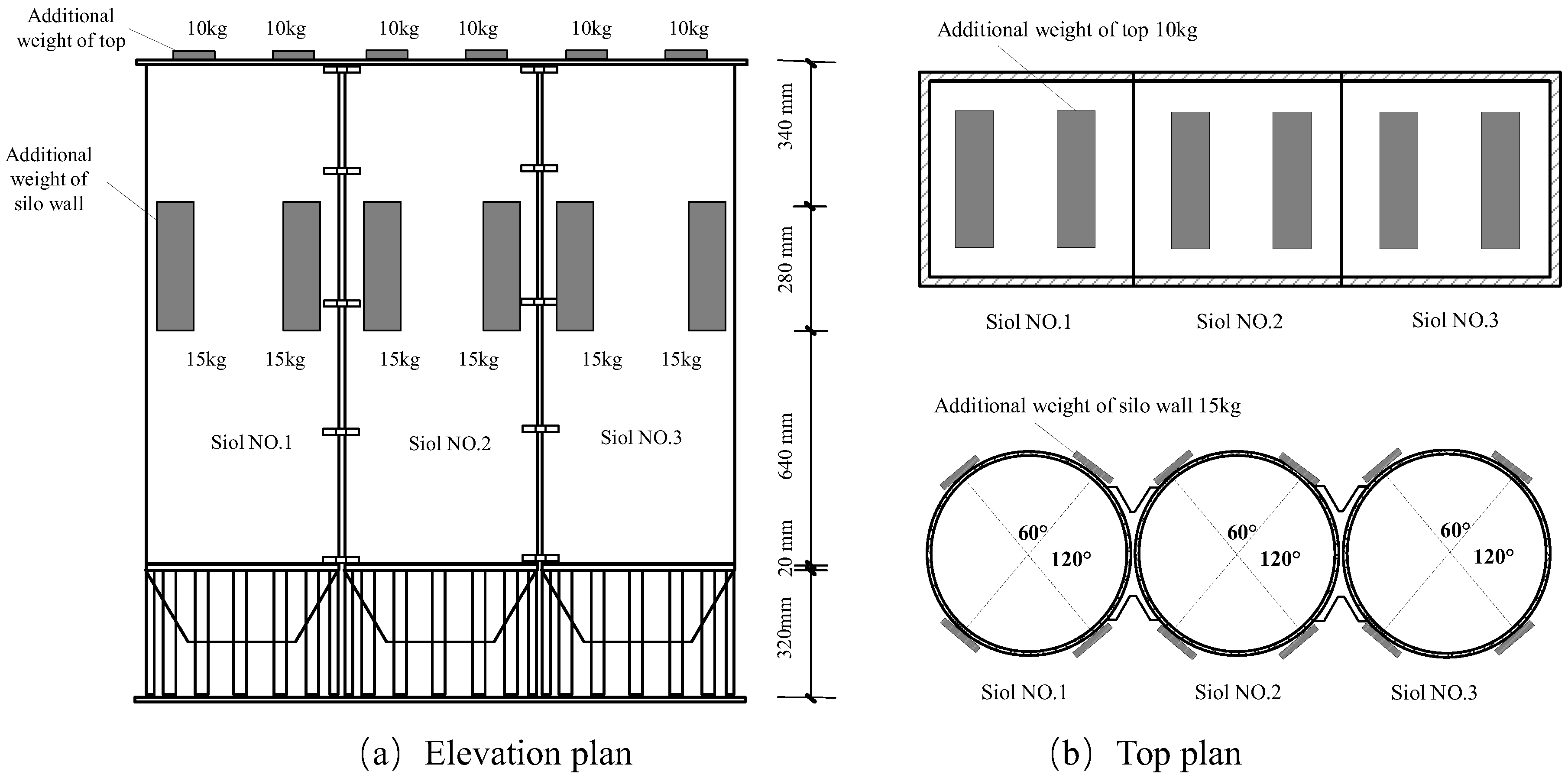

3. Experimental Phenomena

The displacement responses of the supporting structure and the silo body deviated significantly during the test as the displacement response of the silo increased with higher peak values of the input acceleration. Consequently, there was a more noticeable relative movement between the silo wall and the top layer storage. The link between the silo body and supporting column was where the displacement reaction in the model structure was primarily concentrated. The top of the column also experienced an abrupt rise in seismic reaction, leading to a maximum absolute displacement. Moreover, the supporting columns near the borders of the silos exhibited the greatest torsional deformation. A progressive amplification of the displacement response of the upper silo body relative to the lower supporting columns occurred with an increase in the peak values of the input acceleration; this caused discernible bending and shaking deformation in some sections of these columns. When subjected to the Wenchuan wave excitation, the overall torsional response of the silo under the FEE storage condition was pronounced, and the empty silo No. 3 had a more significantly delayed response than the others.

During the loading process, the storage material could be seen through the plexiglass to move with the silo; however, there was a slight delay, and when the input was large, the storage material at the top of the silo appeared to exhibit a thrown-up phenomenon. From the beginning to the end of the loading for each storage condition, the storage material was gradually compacted, and the storage material in the silo showed different degrees of sinking. At the end of the test, the storage material level appeared to exhibit a more evident sinking behavior, and the greater the amount of storage material was, the greater the sinking height. In the three silos with a full state (FFF), the height of the decline was slightly different, with a maximum distance of sinking of up to 21 mm, as shown in

Figure 7. With the exception of the two symmetric storage states, FFF and EEE, the structure underwent large displacement and torsional reactions during the other storage states. Most of the maximum values of the acceleration and displacement responses of the structural model occurred at the position of silo No. 1, and there was a large difference between silo No. 1 and silo No. 3. With an increase in the peak input acceleration, the transverse displacement difference between the silos gradually increased with an increase in the mass of the stored material.

Figure 8 shows the experimental phenomena of each structural model under each storage condition.

4. Analysis of the Test Results

4.1. Dynamic Characteristics

The natural frequency and mode of the model were determined through a transfer function analysis based on the white noise sweeping results; the damping ratio of the structure was determined using the half-power broadband approach. The damping ratio describes the relationship between the damping coefficient and the critical damping coefficient, which illustrates the amount of energy dissipated by the model structure during vibration.

Table 4 presents the model structural damping under various storage conditions. The storage of the model structure trembles and tosses with an increase in the peak value of the earthquake acceleration record. Moreover, both the dissipated energy of the structure and the damping ratio increase with the increasing height (mass) of the storage material.

4.1.1. Natural Frequency

Table 5 presents the frequency sweep results of the silo model. Clearly, there is a non-proportional relationship between the mass of the filling stored in the structure before the earthquake and the fundamental natural frequency of the structure in alignment, which gradually decreases with the mass. The natural frequency of the model essentially remains constant when the input wave peak acceleration increases. This suggests that the stiffness of the model did not degrade during testing and that the structure could continue to function elastically even after the input wave reached a peak acceleration of 0.4 g, as shown in

Figure 9.

4.1.2. Damping Ratio

The damping ratio describes the relationship between the damping coefficient and the critical damping coefficient, which illustrates the amount of energy dissipated by the model structure during vibration.

Table 4 presents the model structural damping under various storage conditions. The storage of the model structure trembles and tosses with the increasing peak value of the earthquake wave acceleration. Moreover, the dissipated energy of the structure and the damping ratio increase with the increasing height (mass) of the storage material. Under the storage conditions HEE and FHE, the increase in the damping ratio of the modeled structure was lower than that under the FFF storage condition.

4.2. Acceleration Response

The acceleration amplification factor

β was defined as the ratio of the peak acceleration response of each layer of the modeled structure to the peak input acceleration of the table. Since the dynamic response of the structural model at an input acceleration of 0.4 g was significantly higher than that of the structure at input accelerations ranging from 0.1 g to 0.3 g, the acceleration response of the structure at an input peak acceleration of 0.40 g was selected for silo No. 1 of the column-supported vertical-group silo structure, considering the influence of the storage filling mass and the distribution of the filling space on the structure. Based on the results obtained from the accelerometer tests on the shaking table, the top of the support column and the top of the silo were selected.

Figure 10 shows the distribution of the acceleration amplification factor

β of the modeled structure under the action of the three earthquake waves.

Figure 10 shows that under the action of the three earthquake waves, the peak acceleration of the supporting column of the No. 1 silo is greater than that of the upper silo body, which is primarily due to the sudden stiffness change in the pillar-supported silo model structure along the height direction.

A comparison of the acceleration peaks of silo No. 1 at different acceleration levels revealed that the acceleration peak of silo No. 1 under the El-Centro earthquake conditions alternated between FFE, FHE, and FEE; the maximum acceleration peak of silo No. 1 under the artificial earthquake conditions alternated between FHE and FEE; the acceleration peak of the maximum peak of silo No. 1 under the Wenchuan earthquake conditions alternated between FHE and FEE. This shows that although different earthquake waves and their spectral characteristics have some influence on the peak acceleration response, FFE, FHE, and FEE may be the most unfavorable storage conditions under the action of the three earthquake waves due to the existence of mass eccentricity. Therefore, in the design of column-supported vertical-group silos, the seismic performance of the unfavorable conditions under the mass eccentricity condition should not only be calculated for the FFF storage condition but also for the other conditions.

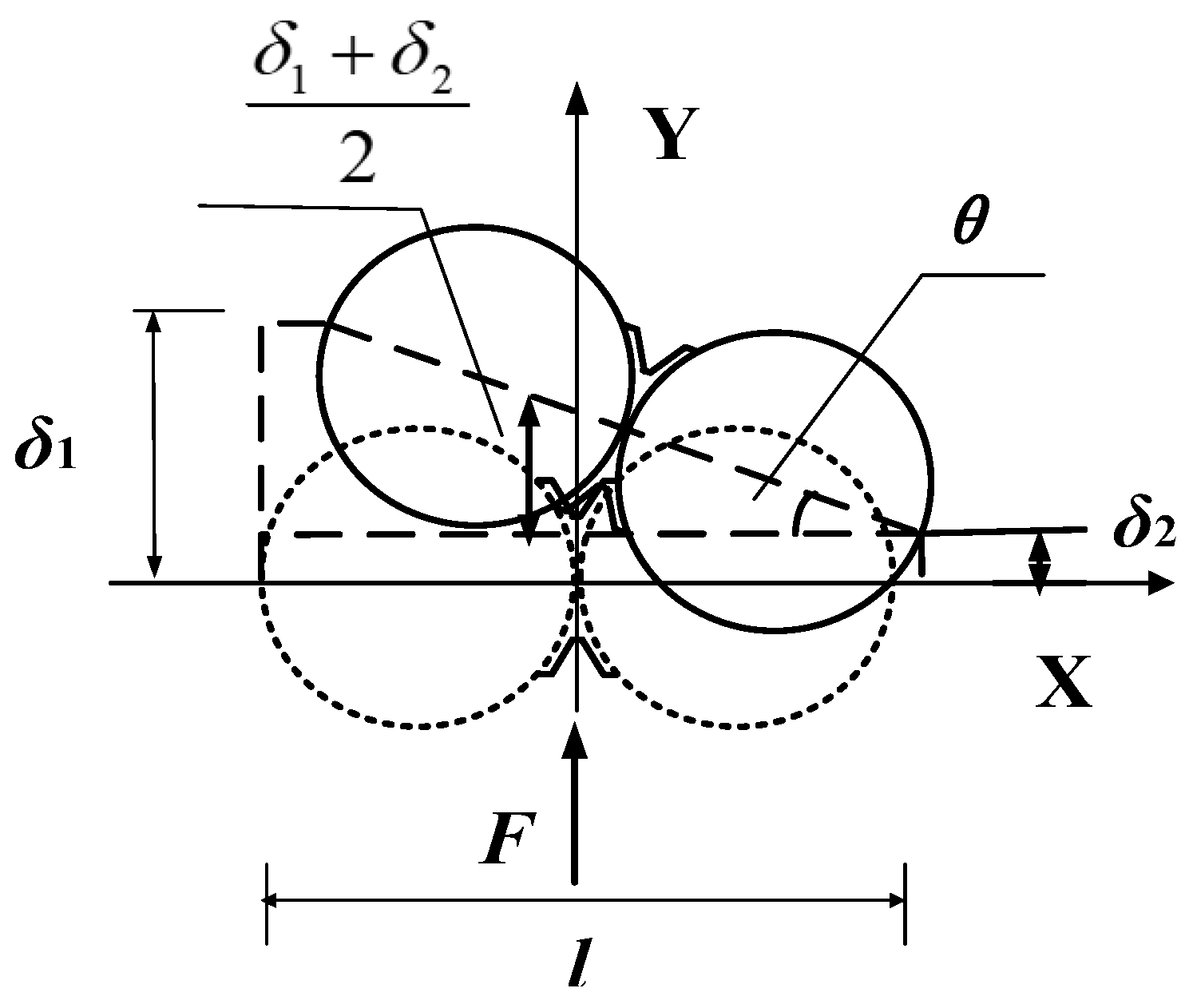

4.3. Displacement Response and the Torsional Displacement Ratio

The torsional displacement ratio is the ratio of the maximum and average elastic horizontal displacement of members resisting lateral forces at both ends of the structural layer under the application of eccentric horizontal forces. It is a crucial factor in determining whether a structure exhibits torsional irregularity as well as the degree of irregularity. It is determined using Equation (1), as shown in

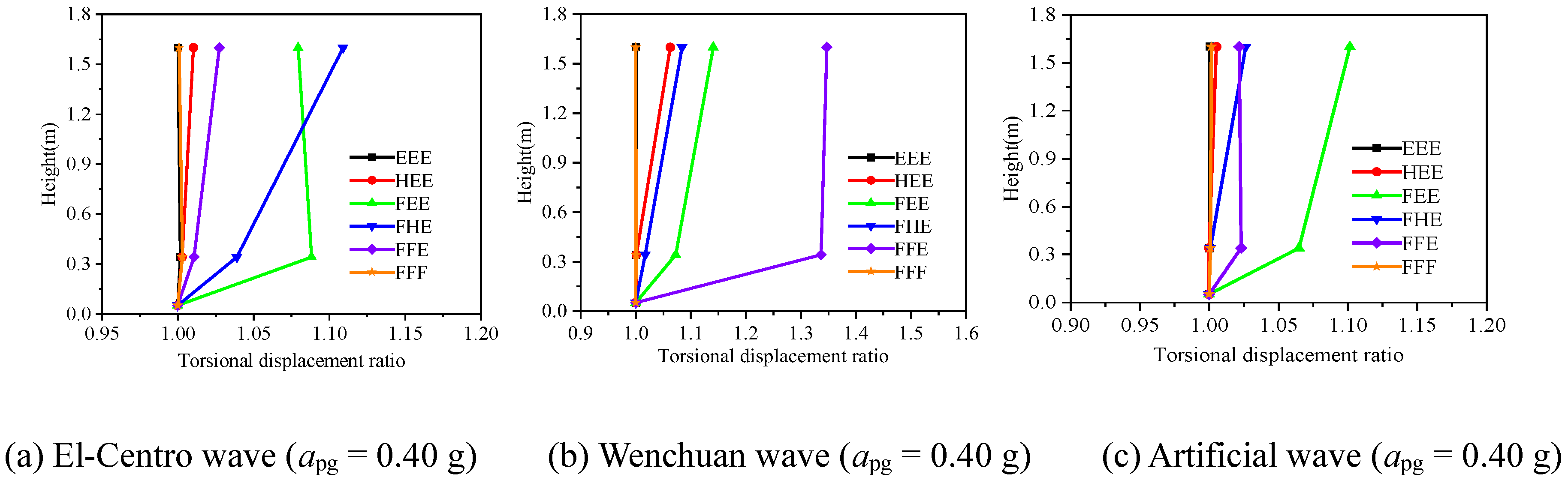

Figure 11. For the special structural form of the column-supported vertical-group silo, this study analyzed the displacement response of the structure with the torsional displacement ratio as a parameter, taking the torsional displacement ratio of the structure at an input peak acceleration of 0.40 g as an example, as shown in

Figure 12.

In Equation (1), λi is the torsional displacement ratio of the ith layer of the row of silos; δi1 and δi2 are the elastic horizontal relative displacements at the two ends of the ith layer of the row of silos in the vertical direction, calculated by subtracting the basal horizontal displacement from the absolute horizontal displacement of the measurement points at the two ends; δi1 is greater than δi2.

The distribution line is bent at the top of the model column, and the distribution of the torsional displacement ratio is bent along the height due to the effect of various earthquake records. Under the same waveform and loading grade, the torsional displacement ratios in the various storage states vary significantly, and the displacement ratio increases with the increasing nonuniform distribution of the storage material. These differences suggest that the storage state is the primary cause of torsion. Under identical storage conditions and loading grades, there is a minor variation in the displacement ratio. This suggests that the variation in the torsional effect is due to the sensitivity of the dispersion in the probability distribution of the seismic response spectrum.

Under the three seismic waves, the torsional displacement ratios of silos No. 2 and No. 3 under the EEE and FFF conditions were in the vicinity of that of silo No. 1, indicating a lack of significant torsional response in the structure when the storage material is symmetrically distributed among the silos within the structure. The maximum torsional displacement ratio of the structure under the El-Centro wave alternated between the FFE and FEE conditions, the maximum torsional displacement ratio under the artificial wave was significantly higher under the FEE condition than under the other conditions, and the maximum torsional displacement ratio under the Wenchuan wave was greater under the FEE condition than under the other conditions. This indicates that different seismic waves and their spectral characteristics have some influence on the peak acceleration response; however, due to the existence of mass eccentricity, the torsional effect is caused by the different distributions of the storage material in each internal silo. FFE and FEE may be considered the most unfavorable storage conditions under the three seismic waves, and the seismic design should focus on the calculation of the mass eccentricity condition.

The torsional displacement ratios of the structure under the El-Centro wave were not greater than 1.2 under any of the loading conditions. The torsional displacement ratios in the FEE displacement case were greater than 1.2 for the artificial wave. Under the action of the Wenchuan wave, the torsional displacement ratios under both the FEE and FFE displacement conditions were greater than 1.2, indicating that the different earthquake records and their spectral characteristics affected the peak acceleration response and that irregular torsional effects occurred in the case of the artificial and Wenchuan waves under different storage conditions.

6. Parametric Analysis of the Spatial Torsional Effects of the Structure

6.1. Surplus-Space Distribution

In contrast to the standard building structure system, the filling ratio and distribution of the group silo structure primarily influence the separation between the stiffness center and the center of mass. To ascertain the irregularity of the column-supported vertical-group silo structure, the mass and stiffness distributions in the group silo structure system must be first ascertained. Following this, the eccentricity of the structure and its corresponding displacement ratio under various working conditions must be computed. Finally, the eccentricity limit can be ascertained from the displacement ratio limit.

Figure 16 shows how the torsional displacement ratio of each silo structure increases with increasing eccentricity. The fitting formulas for each combination of curves in

Figure 16 are shown in

Table 7.

If the eccentricity falls between 0 and 150 mm and the torsional displacement ratio of the group silo structure is less than 1.2, every combination structure is considered free of the torsional effect. As the number of silos increases in the single-row direction, the displacement ratio progressively increases, as indicated by the trend lines for the 1 × 2, 1 × 3, 1 × 4, and 1 × 5 combinations. This is because the number of silos increases in the joint direction, shifting the center of rigidity in the joint direction, and increasing the eccentricity.

In summary, each combination form has a different eccentricity and displacement ratio. Thus, the silo-type combination should be used to determine the seismic design. This is because when the storage state distribution in the silo varies, the eccentricity of each combination structure gradually increases, thus increasing the torsional radius and ultimately the torque produced by the same earthquake activity.

6.2. Mass Surplus-to-Space Ratio

The void-to-fill ratio, which is the ratio of the reaction storage mass to the total mass, is the primary factor causing the eccentricity of the silo, as follows:

The variation trend chart of the void ratio under various storage conditions is plotted in

Figure 17. The fitting formulas for each combination of curves in

Figure 17 are shown in

Table 8.

The trend lines of the torsional displacement ratio of each silo-type structure, shown in

Figure 17, are normally distributed, with the symmetry axis of the positive distribution of the trend lines of each combination structure being the mass void-to-space ratio of 0.5. The displacement ratio increases from 0.25 to 0.5 and decreases from 0.5 to 0.75, suggesting that an increase in the mass somewhat reduces the likelihood of torsion.

According to the analysis, the mass void-to-space ratio and displacement ratio vary for each combination form. They should be determined in the seismic design based on the silo-type combination. Simultaneously, the torsional irregular design is included when the mass void-to-space ratio falls between 0.3 and 0.7, with the most detrimental operating condition occurring at a mass void-to-space ratio of 0.5. This is due to the maximum product of the seismic action and eccentricity generated by the mass. Specifically, the highest additional torque occurs when the mass of the combined structure for storage is half the total.

6.3. Combination Form of Vertical Silos

The “one-full and many-empty row” storage conditions were selected for each combination, i.e., the 1 × 2 combination FE storage condition, the 1 × 3 combination FEE storage condition, the 1 × 4 combination FEEE storage condition, the 1 × 5 combination FEEEE storage condition, the 2 × 3 combination FEE–FEE storage condition, and the 3 × 3 combination FEE–FEE–FEE storage condition. Subsequently, a comparative analysis was made, as shown in

Figure 18.

As shown in

Figure 18, the torsional displacement ratios under the “one-full and many-empty row” combination forms show a generally increasing trend. The torsional displacement ratio for the 1 × 2 and 1 × 3 combination forms reached 1.2. The ratio for the 1 × 4 and 1 × 5 combination forms was greater than 1.2 and less than 1.5. The ratio for the 2 × 3 and 3 × 3 combination forms was greater than 1.5. These results show that the vertical-group silo structure under the combination form of “one-full and many-empty rows” has a torsional reaction, and there is torsional irregularity.

The combination forms, ranging from the 1 × 2 combination to the 1 × 5 combination, show that the displacement ratio increases gradually with the increase in silo mass in the joint direction. This is due to the fact that when the material stored in the outermost silo is constant, the silo is subjected to a constant seismic action, while the increase in the silo mass in the joint direction causes an increase in the eccentricity between the center of rigidity and the center of mass. In other words, the torsional radius increases, which in turn causes the torque generated by the seismic action to increase, at which time the additional displacement generated by the torque increases, thereby increasing the torsional displacement ratio.

When the silo body and storage state are constant in the joint direction, the torsional displacement ratio increases with an increase in the number of rows. The difference between the single-row and two-row arrangements is significant, and the displacement ratio with the addition of more than two rows is not significantly different. This is evident when comparing the 1 × 3 combination with the 2 × 3 and 3 × 3 combinations. The displacement ratios of the 2 × 3 and 3 × 3 combinations are 1.35 and 1.36 times that of the 1 × 3 combination, respectively. This is because when two rows are compared with one row, an increase in the structural mass can enhance the inertial force more than the resistance effect of increasing the lateral stiffness on the inertial force, whereas the increase in the structural mass and lateral stiffness is typically constant. As a result, in the actual manufacturing process, the condition of having all the storage materials on the same side of the silo should be avoided as much as possible.

7. Discussion

The finite element–discrete element (FEM-DEM) coupled model in this article considers the particle structure interaction and provides a more detailed representation of the torsional effect caused by mass eccentricity. Compared to traditional single methods, this hybrid approach more realistically captures the interactions between stored particulate materials and structural components. In addition, this article presents six different nonuniform storage scenarios, which more accurately reflect real operating conditions. The effectiveness and credibility of the proposed model were verified through comparison with experiments. The research results provide useful guidance for the seismic design and safety assessment of column-supported vertical-group silo structures. Analysis shows that asymmetric storage conditions, especially configurations such as FEE and FFE, significantly increase the torsional response of the structure. These configurations should be carefully considered in design specifications and engineering practices. In addition, the torsional displacement ratio is related to the eccentricity and combination form of the silo group. Therefore, in the layout planning process, designers should avoid placing all the full silos on one side of the structure.

However, the research has some limitations, such as constructing a proportional model using organic glass to study the response of the structure within the elastic range, without considering elastic–plastic changes. In addition, in numerical simulations, although the FEM-DEM coupling method effectively captures the interaction between solid structures and granular media, simplified methods such as uniform particle size and ideal contact behavior are adopted. These may not fully reflect the heterogeneity of actual particulate materials.

8. Conclusions

The dynamic characteristics and seismic response of a column-supported vertical-group silo structure were analyzed by establishing an FEM–DEM numerical model, including the influence of the silo arrangement form, the number of silos, and the distribution and state of the stored materials in each single silo on the seismic response and torsional effect of the silo. The specific conclusions are as follows:

- (1)

The acceleration and displacement responses of the model structure of the group silo exhibited a folding trend, and there was a sudden change in the curve at the top of the column. The degree of bending of the folding line strengthened with the increase in the loading level and amount of storage material. The uneven storage mass and different surplus distributions of each single silo in the group silo had a greater influence on the dynamic characteristics and torsional effect of the model structure. Moreover, the degree of its influence increased with the uneven distribution of the storage material, and the torsional effect of the model structure of the group silo was enhanced. With the increase in the storage mass, the natural frequency of the silo model structure decreased, the damping ratio increased, and the storage material had a certain damping effect.

- (2)

The experimental model showed little difference in acceleration under the EEE or FFF storage conditions. The peak acceleration difference was greater under different storage heights, and the acceleration of the internal silos gradually increased as the storage state changed from empty to full. This indicates that when the storage material is unevenly distributed, the center of mass of the model will move toward the silo along with the storage material; therefore, the center of mass and the center of rigidity of the model will no longer be coincident, and a torsional response is generated under seismic action, leading to the inconsistent acceleration responses of the silo with and without the storage material. The acceleration response of the silo with the larger mass was higher, and the internal acceleration of the silo with the material was approximately 1.5 times the acceleration of the silo without the material.

- (3)

The results indicated that torsional displacement ratios exceeded 1.2, or even 1.5 under FFE and FEE conditions, confirming that these asymmetric storage scenarios are among the most unfavorable for seismic performance. The center of mass shifted away from the stiffness center due to unequal grain distribution, leading to torsional irregularities and differential displacement responses between silos. These findings highlight the inadequacy of current design practices that assume uniform loading or treat silos as independent entities.

In the current specification, it is unreasonable to use the seismic characteristics of independent single silos to replace column-supported vertical-group silos for dynamic calculations and seismic design. The displacement response mechanism of the column-supported group silo structure under seismic action and the differences and intrinsic connections of each silo in the silo group were elaborated in this paper. The findings can provide a reference and experimental basis for the research and engineering seismic design of column-supported vertical-group silos.