Abstract

Energy piles are highly favored for their excellent, low energy consumption in providing heating for public residences. The temperature field changes the activity of the diffuse double electric layer (DEL) on the particle surface, thereby altering the distribution of the stress field in the soil and ultimately affecting the mechanical properties of the interface between the energy pile and the soil. Therefore, studying the influence of water content on the mechanical behavior of the soil–structure interface in the temperature field is crucial for energy pile safety. This study used a modified temperature-controlled direct shear apparatus to obtain the influence of water content and temperature on the shear behavior of the soil–structure interface. Then, the test results were analyzed and discussed. Finally, three results were obtained: (1) The water content of bentonite (wbent) had a significant impact on the shear stress–shear displacement curve of the soil–structure interface; when the wbent was less than the wp of the bentonite, the τ-l curve exhibited a softening response, then displayed a hardening response. (2) The shear strength of the soil–structure interface gradually decreased with the increase of wbent. (3) The shear strength of the soil–structure interface increased with increasing temperature under various wbent and vertical loads.

1. Introduction

With the increasing demand for quality of life, the energy consumption required for heating and cooling in public housing continues to increase. Due to the limitations of the current global environment and situation, a low-energy-consumption and low-carbon-emission method is more reasonable for future development. Energy piles are an effective and economic means of using geothermal energy resources for heating and cooling buildings, contributing to the future requirements for renewable energy in new construction [,,,,,]. Energy piles recycle geothermal energy by heat exchange, but the heat exchange can change the temperature and then induce the redistribution of soil stress [,]. In addition, the soil–structure interface serves as the main interface for load transfer and deformation coordination [,,,,]; the temperature changes make the mechanical properties of the interface between the soil and energy piles more complicated. Therefore, the mechanical properties of soil–structure interfaces under temperature fields have always been a research hotspot in underground engineering.

Di Donna et al. [] reported that temperature changes had no direct effect on the shear properties of sandy soil–concrete interfaces, while the shear strength and cohesion of the clay–concrete interface strengthened with increasing temperature. Yavari N et al. [] discovered that the interface between clay and concrete exhibited softening during the shear process, although the influence of temperature on the shear strength and friction angle of sand or the clay–concrete interface was low. Li et al. [] demonstrated that temperature influenced the cohesion of clay and the interface between clay and concrete structures, and the degree of influence depending on normal stress and stress history. Maghsoodi et al. [] observed that the cohesion of clay and the clay–concrete interface augmented with rising temperature, resulting in an increase in shear strength. By employing the hyperbolic tangent model of load transfer, Sun et al. [] established the thermo-mechanical coupling load transfer analysis approach for an energy pile. Golchin and Guo et al. [] indicated that the effect of thermal cycling on the shear strength of materials could be ignored, but shear displacement occurred during the application of thermal cycling, while shear stress did not increase, which confirmed the coupling between shear stress and temperature. Cui et al. [] developed a new thermomechanical model based on the boundary surface plasticity framework to predict the thermodynamic behavior of saturated and unsaturated interfaces. Through laboratory-scale studies, Yin et al. [] defined the shear behavior of the soil–structure interface of intermediate soils between sand and clay. It can be seen that although there have been many studies on the soil–structure interface of energy piles under temperature fields, there seems to be no consistent conclusion.

Water is mostly present at the pile–soil interface in nature, and water migration occurs with heat transmission. The heating process would induce the evaporation of pore water, causing water vapor to flow towards regions of lower vapor pressure in the soil []. Farouki et al. [] proposed that water movement might be important in fine-grained unsaturated soils. Then, Hellstrom [] claimed that the phenomena of water movement became obvious in high-porosity soils with low saturation when temperatures were above 25 °C. Fuentes and Pinyol et al. [] found that in low-permeability soils, increasing temperature might lead to an increase in pore water pressure, thus affecting the strength and stiffness of the soil, while for high-permeability soils, this effect was less related with pore water pressure. Abdelaziz and Ozudogru et al. [] declared that temperature changes could significantly affect the density, thermal diffusion and compressive strength of concrete due to changes in permeability and porosity. The effect of these assumptions was highlighted by Gawecka et al. [], who brought attention to the findings which increased the displacement of the pile head and reduced the time variation in the axial stress. Vieira and Alberdi-Pagola et al. [] discovered that heat loads could change pore water pressure and water flow regimes in soils, whereas hydraulic conditions would also affect the temperature field due to pore fluids’ conduct and transport heat.

In the study of energy piles, Bourne-Webb and Bodas Freitas et al. [] noted that ignoring hydraulic coupling would result in more significant pile movement and lower changes in pile response stress. Sailer and Taborda et al. [] suggested that the primary cause of excessive pore water pressure was attributed to the thermal-hydro-mechanics (THM) characteristics and conditions of the soil. According to Li and Lv et al. [], the water content significantly affected the hardening–softening behavior of the interface between silt and structure. During the shear test of the interface, the deformation of the soil gradually increased with decreasing water content and increasing interfacial roughness. The matrix suction of unsaturated silt significantly influenced the peak shear stress while exhibiting little impact on the residual shear stress. Lin and Wang et al. [] indicated that the cohesion and friction angle at the pile–soil interface were affected by pile surface roughness, soil density, water content, freeze–thaw cycles and stress level, but showed varying degrees of sensitivity. Kou et al. [] found the max shear stress was greatly affected by temperature changes, and the max shear stress at negative temperatures was 17% higher than that at positive temperatures. This was because the water in the soil freezes at negative temperatures, forming a concrete–ice–soil bonding interface, thereby increasing the peak strength of the interface.

The authors speculate that the temperature influenced not only the pore conditions and the evaporation and movement of water within the soil, but also the adsorbed water film and the diffuse double electric layer (DEL) on the surface of the particles [,], which had a direct impact on soil permeability, the transmission of force and deformation coordination among particles [,]. Consequently, it was crucial to investigate the effect of water on the mechanical properties of the soil–structure interface in temperature field in order to obtain a better understanding of the shear properties of the shear interface for energy piles. To verify this speculation, in the present study, a series of temperature-controlled direct shear tests were carried out on a fine-grained artificial sand–concrete interface under different water contents and temperature conditions. Then, the influence of water contents and temperatures on the mechanical properties of these shear surfaces was systematically investigated at the micro-level. The results can provide experimental support for further understanding of the thermal–mechanical coupling mechanism at the soil–structure interface of energy piles.

2. Materials and Methods

2.1. Test Materials and Test Apparatus

The present experiment mainly focused on the mechanical properties of the interface between soil and pile structures under temperature field. The literature research in the previous section showed that temperature changes have different effects on the soil–pile interface of sandy soil and clay soil. Meanwhile, soil in nature typically exists in a mixed state of clay and non-clay particles. In addition, the majority of the piles are composed of precast concrete. Considering the above factors, the sand with fine clay soil and concrete blocks were selected as the contacted soil and piles, respectively.

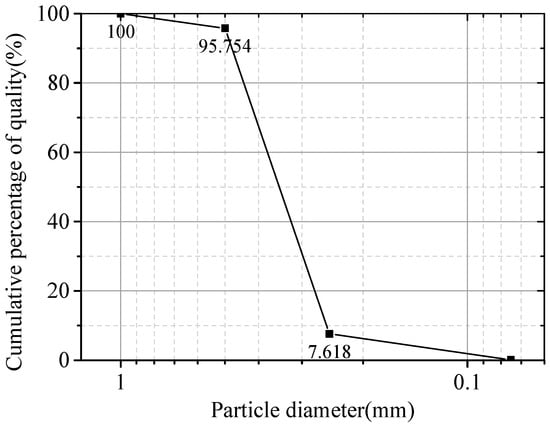

The fine-grained sandy soil was prepared by mixing sand with a specific amount of bentonite. In order to reduce the influence of other factors, a relatively uniform sand particle was used to prepare the sample. The sand had a non-uniformity coefficient (Cu) of 1.52 and a curvature coefficient (Cc) of 1.0. The distribution curve of the particle size of the sand is illustrated in Figure 1. In addition, the mineral content of bentonite is presented in Table 1. The prepared circular concrete block had a diameter of 61.8 mm and a thickness of 20 mm, and the strength grade of concrete was C30. The roughness of concrete blocks was analyzed through image analysis using Matlab (2023a), and the average peak valley distance on the surface of the concrete blocks was 0.1 mm.

Figure 1.

Particle size distribution curve of the sand.

Table 1.

Basic physical parameters of bentonite.

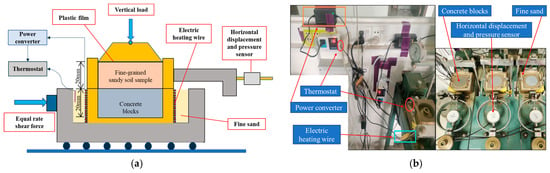

In this experiment, a self-improved temperature-controlled direct shear apparatus was employed as shown in Figure 2, and the accuracy of this equipment is 0.1 °C. This device was modified on the ZJ strain-controlled quadruple shear direct shear apparatus by an added temperature control system to acquire automatic heating and heat preservation. As illustrated in Figure 2a, sample heating is achieved by wrapping an electric heating wire around the outer surface of the copper shear box, while the fine sand filling the outside of the box is to achieve uniform heating and insulation. After connecting the power, the set temperature value is input on the temperature controller; then, the electric heating wire starts heating. When the temperature reaches the design value, the electric heating wire stops heating and enters the insulation state. At this time, the electric heating wire and fine sand ensure a constant temperature of the samples. The temperature range of the temperature control system is 20~70 °C. The physical image of the improved instrument is shown in Figure 2b.

Figure 2.

Self-improved temperature-controlled direct shear apparatus: (a) instrument schematic diagram; (b) physical image.

2.2. Experimental Scheme

This study investigated the effect of temperature on the shear properties between a concrete structure and fine-grained sandy soil with different water content. Therefore, the main control factors of this experiment were the water content and the temperature of the samples. According to the relevant literature, based on the temperature range around the world and the working conditions of energy piles, the commonly used temperature range for studying the mechanical properties of energy piles is 0–55 °C [,,]. Considering the above literature and experimental instrument conditions, the test temperatures were set at 20 °C, 30 °C, 40 °C, 50 °C and 60 °C, respectively. Clay particles have a significant adsorption effect on water, while sand particles absorb very little water. The surface properties of clay particles change significantly after absorbing water, which affects the properties of the interface in contact with it. Therefore, this article focuses on the effect of changes in the water content of clay particles on the characteristics of shear interfaces. The adsorbed water or DEL on the surface of clay particles is one way to explain the influence of water content and temperature on the shear behaviors of the soil–structure in this paper, so the water content of the bentonite was set near the plastic limit and the liquid limit, specifically at 40%, 55%, 70%, 85% and 100%. It should be noted that when the water content of the quartz sand was set at 3%, it mainly existed in a saturated condition, so the water content of the soil sample was presented by the water content of the bentonite, written as wbont. The design mass content of fine particles (bentonite) in the sample was generally 20%, and the cumulative porosity of the sample was 0.32. Tests have shown that after mixing, the water content of bentonite remains almost unchanged in the mixture of sand and moist bentonite. Considering that samples with higher water content have lower strength, the normal stresses were controlled at 12.5 kPa, 25 kPa, 37.5 kPa and 50 kPa. The experimental scheme is shown in Table 2.

Table 2.

Experiment scheme.

Before testing, the concrete block was wet and placed into the lower box of the shear box, ensuring that the shear surface of the shear box was exactly flush with the upper surface of the concrete block. Then, we continued to fill the box with the prepared soil samples. After the samples filled the box, the box was sealed with plastic film and a shear box cover, and then heated to the designated temperature and maintained for 90 min, which ensured the shear box and the soil sample evenly reached the designed temperature. The shear tests were carried out at a constant shear rate of 0.8 mm/min until the contact surface was destroyed and the ultimate shear strength was reached, or the shearing displacement reached 4 mm (ASTM D3080/D3080M-23 []). The test was stopped when the shearing displacement of the contact surface reached 6 mm. After the shear test, temperature detection was performed on the soil inside the shear box to ensure that the temperature remained constant throughout the entire shear process.

3. Results

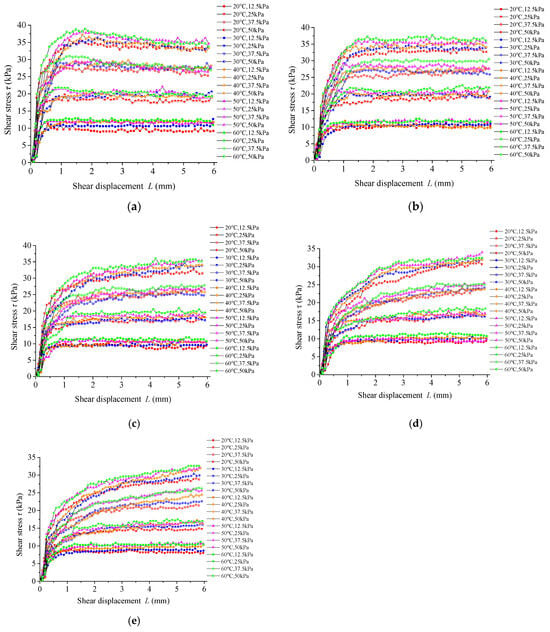

3.1. Effect of wbent on τ-l Relationship of Interface

The shear stress–shear displacement curves of the samples with different water contents are depicted in Figure 3. When wbent was below 55%, the τ-l curve exhibited a softening response. The shear softening phenomenon caused by low moisture content is consistent with the findings of other scholars [,]. Conversely, when wbent exceeded 55%, the τ-l curve displayed a hardening response. There were mainly two types of τ-l curves for hardened contact surfaces: the local hardening stable type, as illustrated in Figure 3b, and the full-process hardening type, as shown in Figure 3d. As shown in Figure 3, the peak point evidently showed that the wbent significantly influenced the elastic–plastic strengthening stage of the τ-l relationship curve, which developed with the increasing of wbent. For example, under a normal stress of 50 kPa, the strengthening stage concluded at the shear displacement of 0.8~1.0 mm when the water content was below 55%, while the strengthening stage ended at the shear displacement of 1.4~1.8 mm when the water content exceeded 55%. In addition, the residual strength in the residual sliding stage decreased with the increasing wbent, and this tendency became obvious with the increase in normal stress. The maximum reduction in residual strength was observed as the wbent increased from 55% to 70% under a normal stress of 50 kPa, resulting in a decrease of 4–6 kPa.

Figure 3.

The τ-l relationship curve of different temperatures at different moisture contents: (a) wbent = 40%; (b) wbent = 55%; (c) wbent = 70%; (d) wbent = 85%; (e) wbent = 100%.

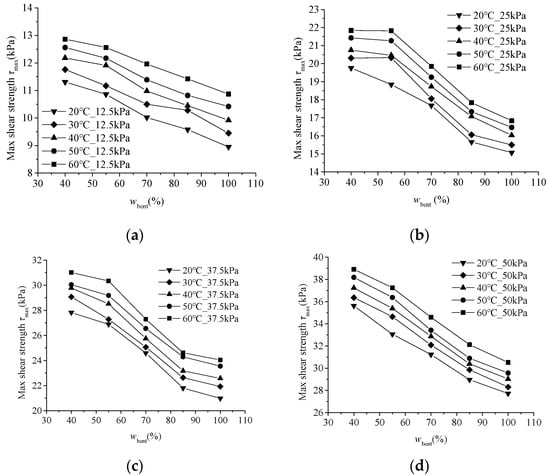

3.2. Effect of wbent on Shear Strength of Interface

Figure 4 presents the max shear strength distribution of the soil–structure interface with different wbent, different temperatures and different normal stress values. It shows that the shear strength of the soil–structure interface decreased with the increase in wbent; this is consistent with the research of many scholars [,,,,,]. In addition, under consistent wbent and temperature, the reduction in the max shear strength gradually increased with the rise in normal stress. Thus, the decrease in the max shear strength by the wbent became more obvious as the normal stress increased. This result has also been confirmed before [,,,]. Furthermore, the max shear strength of the soil–structure interface exhibited a nearly linear increase with increase in temperature [].

Figure 4.

τmax–wbent curve of soil–structure interface: (a) P = 12.5 kPa; (b) P = 25 kPa; (c) P = 37.5 kPa; (d) P = 50 kPa.

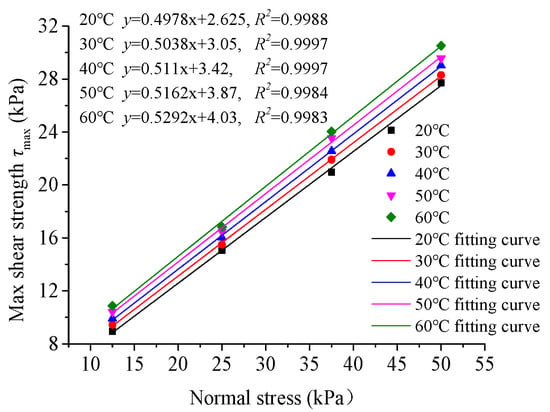

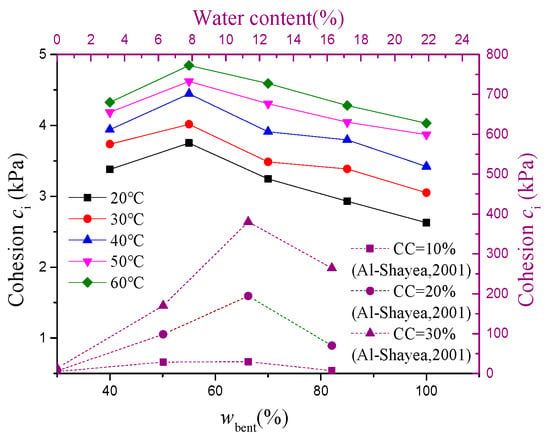

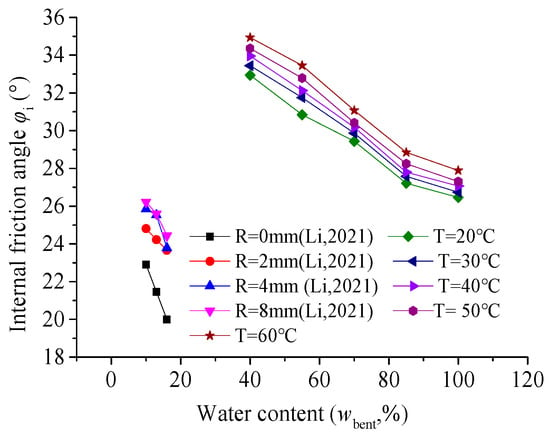

3.3. Effect of Water Content on Interface c and φ Values

To further investigate the shear behavior of the soil–structure interface influenced by wbent, according to the relevant literature [,,], the Mohr–Coulomb failure criterion was employed to define the shear response. The relationship between the max shear strength (τmax) and corresponding normal stress was subjected to linear fitting to obtain the interface shear envelope, from which the cohesion (ci) and internal friction angle (φi) of the soil–structure interface could be acquired as shown in Figure 5. Figure 6 and Figure 7 represent the effect of temperature on cohesion (ci) and the internal friction angle (φi) of the soil–structure interface with different wbent, respectively.

Figure 5.

Shear envelope of soil–structure interface (wbent = 100%).

Figure 6.

Relationship curve of ci–wbent of the soil–structure interface (CC = clay content).

Figure 7.

Relationship curve of φi–wbent of soil–structure interface (R = roughness; T = temperature).

As illustrated in Figure 6, as the wbent increased, the cohesion of the soil–structure interface at each temperature initially increased and subsequently decreased, peaking at a wbent of 55%; other scholars have also observed such phenomena [,,]. Figure 7 demonstrated that the internal friction angle of the soil–structure interface decreased with the increase in the wbent at various temperatures. Such phenomena have also observed by Li et al. [] Moreover, an increased wbent led to a lower reduction in the friction angle of the soil–structure interface. Consequently, the influence of wbent on the angle of the soil–structure interface was more significant than that of temperature.

4. Results Analysis and Discussions

4.1. Mechanistic Analysis of Shear Surface Properties Affected by wbent

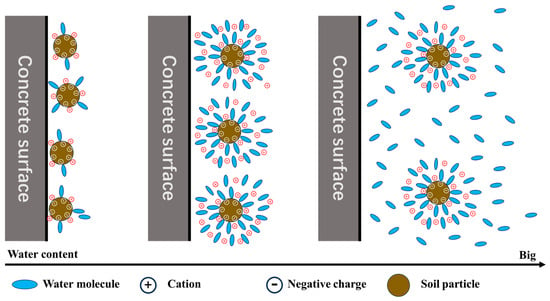

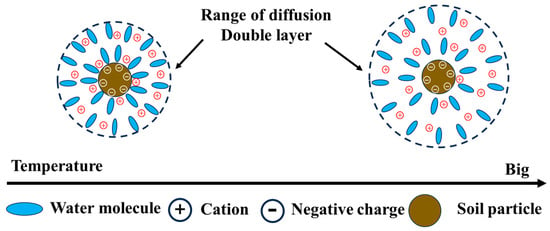

From the basic properties of mineralogy, it is clear that the surface of soil particles possesses negative charges. The attraction of water molecules and cations on the surface of the particles results in the formation of a diffuse double electric layer (DEL). The water closer to the particle surface in the DEL forms as strongly bound water with a certain shear strength, whereas the mixed liquid of water molecules and cations farther away has a certain viscosity []. The liquid with a certain viscosity and shear strength could affect the transfer of surface forces and the coordination of deformation on the particle surface, and this effect is more significant for clay particles than for non-clay particles [,]. The bentonite selected in this test contains 92% montmorillonite, which was a very reactive clay mineral with excellent water adsorption capacity, whereas the selected sand was mainly composed of the non-clay mineral quartz, which had a weak water adsorption capacity. Moreover, the particle size of bentonite was only 0.015 mm, exhibiting a large specific surface area and a high charge density on the surface. As a comparison, quartz sand had a particle size of 1.5 mm, characterized by a limited specific surface area and a small surface charge. Therefore, the mechanical property of the soil–structure interface was mainly affected by the change in the surface state of bentonite particles when the water content of bentonite changed. As the wbent in the sample gradually increased, the changes in the soil–structure interface were shown in Figure 8.

Figure 8.

Schematic diagram of the impact of wbent changes on interfaces.

There is only strongly bound water on the surface of clay particles when the water content is about 0.88 of the plastic limit. The plastic limit of bentonite in this test was 54.2%. When the wbent was below the plastic limit, such as 40%, adsorbed water on the surface of the bentonite particles was extremely thin and even could not form a completely adsorbed water film. At the micro-level, the contact between the soil and the shear surface of the concrete block was mainly the hard contact between quartz sand and concrete and the hard contact between clay mineral crystals and concrete. Therefore, the internal friction effect was obvious, and the internal friction angle was relatively large, as shown in Figure 7. This behavior was similar to that of pure sand shear without bonding, which was more prone to cause shear reduction. Therefore, strain softening is exhibited in the shear stress–shear displacement curve in Figure 3a. In addition, the contact slip time of the water film between particles during shearing was short due to the thin adsorbed water film. Consequently, the duration of the elastic–plastic strengthening phase in the curve depicted in Figure 3a was shorter.

As the wbent gradually increased (≤55%), the thickness of adsorbed water on the surface of bentonite particles changed from strongly bound water to weakly bound water, and then the DEL gradually formed []. At this point, the contact between the bentonite particles on the shear surface and the concrete gradually became the contact between the adsorbed water film or the DEL and the concrete. Therefore, the cohesive effect of the soil–structure interface progressively increased while the friction effect decreased. Macroscopically, the cohesive force gradually increased, and the internal friction angle gradually decreased, as shown in Figure 6 and Figure 7. Although the water film on the surface of the bentonite particles increased this time, the thickness was still limited, and the water film was easily damaged during the shear process. Consequently, there was still a certain softening phenomenon in the shear stress–shear displacement curve, which led to a shorter duration of the elastic–plastic strengthening stage, as shown in Figure 3b.

When the wbent increased above 55%, particularly beyond the plastic limit, the free water on the particle surface gradually increased, alongside the adsorbed water and the DEL. The contact area of the DEL and the adsorbed water film between the particles both reduced as the free water increased []. The free water filled between the interface of the clay particles and the concrete acted as a lubricant. The increased free water reducing the cohesion and internal friction angle of the shear surface, as illustrated in Figure 6 and Figure 7. During the shear process, the presence of adsorbed water on particle surfaces or an increase in the thickness of the DEL caused fine particles to be more susceptible to slipping and disengaging under shear force, resulting in a larger share of shear load on the sand particles. The strength of sand particles was significantly higher compared to that of bentonite particles; hence, the shear stress–shear displacement curves exhibited a hardening phenomenon, as depicted in Figure 3c–e. In addition, as the thickness of the adsorbed water film or DEL increased, the particle viscosity increased and the duration of the elastic–plastic strengthening stage also became longer, as illustrated in Figure 3c–e.

As the wbent increased, although the cohesion underwent a process of first increasing and then decreasing, the internal friction angle continued to decrease, but the strength of sand particles was significantly greater than that of bentonite particles. Therefore, under the comprehensive effect, the shear strength of the soil–structure interface gradually decreased with the increase in wbent, as shown in Figure 4 and Figure 5. These results are consistent with the research findings of some scholars [,,,,,].

4.2. Mechanistic Analysis of the Effect of Temperature Change on Interfacial Properties

At the microscopic level, temperature can affect the activity state of molecules. In this experiment, as the temperature gradually increased, the energy and activity of water molecules and cations on the surface of the particles increased, and the activity range of water molecules and ions also increased. Therefore, the area of adsorbed water layer or DEL on the surface of the particles increased, as shown in Figure 9. When the wbent was low, an increase in temperature led to an increase in the DEL, which increased the cohesive effect between particles. In addition, the increase in volume induced by the DEL squeezed the activity space of the sand particles, which augmented the contact normal force on the sand particle–concrete interface, leading to a larger friction effect. The combination of these two effects ultimately led to an increase in both the cohesion and friction of the soil–structure interface.

Figure 9.

The influence of temperature changes on the DEL.

As the wbent gradually increased, especially when there was a relatively high amount of free water, the increase in temperature accelerated the movement of water molecules at the interface between sand particles, clay particles and concrete. This resulted in a decrease in the shear strength of bound water and a decrease in the viscosity of the DEL. Therefore, the cohesion of the soil–concrete interface significantly decreased, as shown in Figure 7. However, for sand particles, the combined effect of volume expansion and water lubrication caused by the increasing temperature was only a slight increase in the internal friction angle.

At the macro-level, temperature changes could cause the expansion and contraction of objects. In this experiment, as the temperature increased, the water molecules, sand particles, bentonite particles in the soil sample and even the concrete all experienced a certain degree of volume expansion [,,,]. Under the constraints of the shear box, the volume of the sample became denser. At this point, the positive stress on the shear surface between sand particles, bentonite particles and concrete increased, and the cohesion and friction angle between particles under shear load also increased, as shown in Figure 5, Figure 6 and Figure 7. This effect was similar to the increasing vertical load during specimen shearing, as shown in Figure 4 and Figure 5. Under the same conditions, the greater the normal stress, the greater the shear strength of the specimen.

5. Conclusions

In addition to temperature, the water content also had a significant impact on the bearing capacity of energy piles. This paper speculated that water content and temperature would affect the thickness of the adsorbed water layer on the surface of clay particles, thereby altering the contact properties between the particles and the structural interaction surface, altering the shear behavior of the interface, and ultimately affecting the bearing capacity of the energy pile. This article verified the above speculation through temperature-controlled direct shear tests; finally, three results were obtained as follows:

(1) When the wbent was less than the plastic limit water content (wp) of the bentonite, the τ-l curve exhibited a softening response. Conversely, when wbent exceeded wp, the τ-l curve displayed a hardening response. At the same time, the strengthening stage duration of the curve increased with the increasing wbent.

(2) The shear strength of the soil–structure interface gradually decreased with the increase in wbent. With the increasing wbent, the cohesion underwent a process of first increasing (wbent ≤ 55) and then decreasing, while the internal friction angle continued to decrease, and the comprehensive effect was decrease.

(3) The shear strength of the soil–structure interface increased with increasing temperature under various wbent and vertical stresses. An increase in temperature enhanced the activity of molecules and increased the thickness of adsorbed water and DEL, causing expansion of the sample and concrete, resulting in an increase in normal stress at the contact surface, thus increasing the cohesion and internal friction angle.

This study has achieved the above research results. However, whether the increase in temperature will lead to an increase in the thickness of the water film and the expanded DEL on the surface of clay particles is only the authors’ speculation. Subsequent research can ultimately verify this speculation through microscopic testing methods. In addition, as suggested by the reviewers, further research on the influences of particle size distribution, external environmental factors on the interface shear property, and changes in pore water pressure during the experimental process may be conducted in the future.

Author Contributions

Conceptualization, J.C. and H.J.; methodology, J.C.; validation, H.J., X.Z. and Y.L.; formal analysis, J.C.; investigation, H.J.; resources, H.J.; data curation, Y.W.; writing—original draft preparation, H.J.; writing—review and editing, J.C.; supervision, W.P.; project administration, W.P.; funding acquisition, J.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Guangdong Basic and Applied Basic Research, grant number 2024A1515012795; Guangdong Basic and Applied Basic Research, grant number 2022A1515110793; Tertiary Education Scientific research project of Guangzhou Municipal Education Bureau, grant number 2024312504; Guangzhou Railway Polytechnic launches research project for newly introduced talents, grant number GTXYR2412; Guangdong Province Vocational College Industry Education Integration Innovation Platform, grant number 2023CJPT010; and Guangdong Province Special Project for Key Fields of Ordinary Universities, grant number 2024ZDZX4093.

Data Availability Statement

If readers need to access the data, they can directly contact the author to obtain them.

Conflicts of Interest

Author Hao Jiang was employed by the company Shanghai Municipal Engineering Design Institute (Group) Guangdong Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Guo, Y.; Wang, C.; Bouazza, A.; Kong, G.; Ding, X. Thermal performance of pipe-type energy piles with open-ended heat exchange tubes. Appl. Therm. Eng. 2025, 258, 124573. [Google Scholar] [CrossRef]

- Mohamad, Z.; Fardoun, F.; Meftah, F. A review on energy piles design, evaluation, and optimization. J. Clean. Prod. 2021, 292, 125802. [Google Scholar] [CrossRef]

- Laloui, L.; Sutman, M. Experimental investigation of energy piles: From laboratory to field testing. Géoméch. Energy Environ. 2021, 27, 100214. [Google Scholar] [CrossRef]

- Wu, D.; Liu, H.; Kong, G.; Li, C. Thermo-mechanical behavior of energy pile under different climatic conditions. Acta Geotech. 2019, 14, 1495–1508. [Google Scholar] [CrossRef]

- Amatya, B.L.; Soga, K.; Bourne-Webb, P.J.; Amis, T.; Laloui, L. Thermo-mechanical behaviour of energy piles. Géotechnique 2015, 62, 503–519. [Google Scholar] [CrossRef]

- Hamada, Y.; Saitoh, H.; Nakamura, M.; Kubota, H.; Ochifuji, K. Field performance of an energy pile system for space heating. Energy Build. 2007, 39, 517–524. [Google Scholar] [CrossRef]

- Bourne-Webb, P.; Burlon, S.; Javed, S.; Kürten, S.; Loveridge, F. Analysis and design methods for energy geostructures. Renew. Sustain. Energy Rev. 2016, 65, 402–419. [Google Scholar] [CrossRef]

- Laloui, L.; Moreni, M.; Vulliet, L. Comportement d’un pieu bi-fonction, fondation et échangeur de chaleur. Can. Geotech. J. 2003, 40, 388–402. [Google Scholar] [CrossRef]

- Wu, W.; Di, T.; Yang, X.; El Naggar, M.H.; Zhang, Y. Revised pile-pile mutual interaction factors for seismic analysis of end-bearing pile groups em-bedded in saturated stratum. Soil Dyn. Earthq. Eng. (1984) 2024, 182, 108745. [Google Scholar] [CrossRef]

- Zhang, Y.; Ji, H.; Zhang, L.; El Naggar, M.H.; Wu, W. Identification of bored pile defects utilizing torsional low strain integrity test: Theoretical basis and numerical analysis. J. Rock Mech. Geotech. Eng. 2024; in press. [Google Scholar] [CrossRef]

- Chen, J.; Yuan, J.; Tong, H.; Fang, Y.; Gu, R. Mechanism study on the soil mechanical behavior of the mixed soil based on energy multi-scale method. Front. Mater. 2023, 10, 1270865. [Google Scholar] [CrossRef]

- Kong, G.; Chang, H.; Wu, D.; Peng, H.; Shen, Y.; Abuel-Naga, H. Effects of pile configuration on the group behavior of semi-floating energy piles. J. Build. Eng. 2023, 77, 107487. [Google Scholar] [CrossRef]

- Li, M.; Li, Y.; Islam, R. Effects of water content and interface roughness on the shear strength of silt–cement mortar interface. Soils Found. 2021, 61, 1615–1629. [Google Scholar] [CrossRef]

- Di Donna, A.; Ferrari, A.; Laloui, L. Experimental investigations of the soil-concrete interface: Physical mechanisms, cyclic mobilisation and behaviour at different temperatures. Can. Geotech. J. 2016, 53, 659–672. [Google Scholar] [CrossRef]

- Yavari, N.; Tang, A.M.; Pereira, J.M.; Hassen, G. Effect of temperature on the shear strength of soils and the soil–structure interface. Can. Geotech. J. 2016, 53, 1186–1194. [Google Scholar] [CrossRef]

- Li, C.; Kong, G.; Liu, H.; Abuel-Naga, H. Effect of temperature on behaviour of red clay–structure interface. Can. Geotech. J. 2019, 56, 126–134. [Google Scholar] [CrossRef]

- Maghsoodi, S.; Cuisinier, O.; Masrouri, F. Thermal effects on mechanical behaviour of soil–structure interface. Can. Geotech. J. 2020, 57, 32–47. [Google Scholar] [CrossRef]

- Sun, M.; Wu, S.; Wang, T.; Xie, Y.; Xu, M.; Dong, Y.; Zhao, D.; Wu, W. Thermo-Mechanical Coupling Load Transfer Method of Energy Pile Based on Hyperbolic Tangent Model. Buildings 2024, 14, 3190. [Google Scholar] [CrossRef]

- Golchin, A.; Guo, Y.; Vardon, P.J.; Liu, S.; Zhang, G.; Hicks, M.A. Shear creep behaviour of soil–structure interfaces under thermal cyclic loading. Geotech. Lett. 2023, 13, 22–28. [Google Scholar] [CrossRef]

- Cui, S.; Zhou, C. A thermo-mechanical model for saturated and unsaturated soil–structure interfaces. Can. Geotech. J. 2024, 61, 2615–2631. [Google Scholar] [CrossRef]

- Yin, K.; Fauchille, A.-L.; Vasilescu, R.; Dano, C.; Kotronis, P.; Sciarra, G. Influence of clay fraction on the shear behavior of an interface between sand-clay mixture and concrete. Géoméch. Energy Environ. 2024, 38, 100543. [Google Scholar] [CrossRef]

- Vieira, A.; Alberdi-Pagola, M.; Christodoulides, P.; Javed, S.; Loveridge, F.; Nguyen, F.; Cecinato, F.; Maranha, J.; Florides, G.; Prodan, I.; et al. Characterisation of Ground Thermal and Thermo-Mechanical Behaviour for Shallow Geothermal Energy Applications. Energies 2017, 10, 2044. [Google Scholar] [CrossRef]

- Farouki, O.T. Thermal Properties of Soils; US Army Corps of Engineers, Cold Regions Research and Engineering Laboratory: Hanover, NH, USA, 1981. [Google Scholar]

- Hellström, G. Ground Heat Storage: Thermal Analyses of Duct Storage Systems. Ph.D Thesis, Lund University, Lund, Sweden, 1991. [Google Scholar]

- Fuentes, R.; Pinyol, N.; Alonso, E. Effect of temperature induced excess porewater pressures on the shaft bearing ca-pacity of geothermal piles. Geomech. Energy Environ. 2016, 8, 30–37. [Google Scholar] [CrossRef]

- Abdelaziz, S.; Ozudogru, T.Y. Non-uniform thermal strains and stresses in energy piles. Environ. Geotech. 2016, 3, 237–252. [Google Scholar] [CrossRef]

- Gawecka, K.A.; Taborda, A.D.M.G. Numerical modelling of thermo-active piles in London Clay. Geotech. Eng. 2017, 170, 201–219. [Google Scholar] [CrossRef]

- Bourne-Webb, P.J.; Bodas Freitas, T.M.; Freitas Assunção, R.M. A review of pile-soil interactions in isolated, thermally-activated piles. Comput. Geotech. 2019, 108, 61–74. [Google Scholar] [CrossRef]

- Sailer, E.; Taborda, D.M.; Zdravković, L.; Potts, D.M.; Cui, W. Thermo-hydro-mechanical interactions in porous media: Implications on thermo-active retaining walls. Comput. Geotech. 2021, 135, 104121. [Google Scholar] [CrossRef]

- Li, Y.-H.; Lv, M.-F.; Guo, Y.-C.; Huang, M.-S. Effects of the soil water content and relative roughness on the shear strength of silt and steel plate interface. Meas. J. Int. Meas. Confed. 2021, 174, 109003. [Google Scholar] [CrossRef]

- Lin, C.; Wang, G.; Guan, C.; Feng, D.; Zhang, F. Experimental study on the shear characteristics of different pile-soil interfaces and the in-fluencing factors. Cold Reg. Sci. Technol. 2023, 206, 103739. [Google Scholar] [CrossRef]

- Kou, H.; Sun, Y.; Chen, Q.; Huang, J.; Zhang, X. Shear behavior of cold region clay-concrete interface under temperature-controlled direct shear tests. J. Build. Eng. 2024, 98, 111203. [Google Scholar] [CrossRef]

- Azhar, M.; Mondal, S.; Tang, A.M.; Singh, A.K. Effect of temperature on the mechanical properties of fine-grained soils—A review. Geothermics 2024, 116, 102863. [Google Scholar] [CrossRef]

- Wei, S.; Abdelaziz, S.L. Temperature Effects on the Thickness of the Diffused Double Layer Using Molecular Dynamics. In Proceedings of the Geo-Congress 2022, Charlotte, NC, USA, 20–23 March 2022. [Google Scholar]

- Chen, J.; Tong, H.; Yuan, J.; Fang, Y.; Gu, R. Permeability Prediction Model Modified on Kozeny-Carman for Building Foundation of Clay Soil. Buildings 2022, 12, 1798. [Google Scholar] [CrossRef]

- Yuan, J.; Chen, Z.; Xiao, H.; Zheng, L.; Li, W.; Song, X. Thermal-mechanical behavior of deeply buried pipe energy pile group in sand obtained from model test. Appl. Therm. Eng. 2024, 261, 125078. [Google Scholar] [CrossRef]

- ASTM D3080/D3080M-23; Standard Test Method for Direct Shear Test of Soils Under Consolidated Drained Conditions. ASTM International: West Conshohocken, PA, USA, 2023.

- Wei, Y.; Wu, X.; Xia, J.; Miller, G.A.; Cai, C.; Guo, Z.; Hassanikhah, A. The effect of water content on the shear strength characteristics of granitic soils in South China. Soil Tillage Res. 2019, 187, 50–59. [Google Scholar] [CrossRef]

- Wang, X.; Qin, X.; Tan, J.; Yang, L.; Ou, L.; Duan, X.; Deng, Y. Effect of the moisture content and dry density on the shear strength parameters of collapsing walls in hilly granite areas of South China. Int. Soil Water Conserv. Res. 2024, 12, 697–713. [Google Scholar] [CrossRef]

- Fasinmirin, J.T.; Olorunfemi, I.E.; Olakuleyin, F. Strength and hydraulics characteristics variations within a tropical Alfisol in Southwestern Nigeria under different land use management. Soil Tillage Res. 2018, 182, 45–56. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, X.; Zou, X.; Tian, J.; Liu, B.; Li, J.; Kang, L.; Chen, H.; Wu, Y. Estimation of surface shear strength of undisturbed soils in the eastern part of northern China’s wind erosion area. Soil Tillage Res. 2018, 178, 1–10. [Google Scholar] [CrossRef]

- Alonso, E.; Pereira, J.-M.; Vaunat, J.; Olivella, S. A microstructurally based effective stress for unsaturated soils. Géotechnique 2010, 60, 913–925. [Google Scholar] [CrossRef]

- Horn, R. Stress—Strain effects in structured unsaturated soils on coupled mechanical and hydraulic processes. Geoderma 2003, 116, 77–88. [Google Scholar] [CrossRef]

- Al-Shayea, N.A. The combined effect of clay and moisture content on the behavior of remolded unsaturated soils. Eng. Geol. 2001, 62, 319–342. [Google Scholar] [CrossRef]

- Yang, Y.; Huang, S.; Yu, S.; Cai, H.; Zhai, J. Experimental investigation on the temperature-dependent shear strength of frozen coarse-grained soil-rock interfaces by considering three-dimensional roughness. Transp. Geotech. 2024, 49, 101434. [Google Scholar] [CrossRef]

- Zhou, J.; Liu, C.; Zhu, K.; Shen, P. Macroscopic behaviour and mesoscopic mechanism of shear strength characteristics of pile-soil interface under cyclic loading. Ocean Eng. 2024, 297, 116998. [Google Scholar] [CrossRef]

- Huang, Y.; Hu, G. Influence of normal stress on the shear strength of the structural plane considering the size effect. Front. Earth Sci. 2023, 11, 1116302. [Google Scholar] [CrossRef]

- Pan, W.; Jiang, H.; Chen, J. The effect of temperature on shear characteristics of interface between sand and concrete considering the fine-grained soil content. Arab. J. Geosci. 2022, 15, 1–11. [Google Scholar] [CrossRef]

- Shi, Y.; Li, S.; Zhang, T.; Liu, J.; Zhang, J. Compaction and shear performance of lime-modified high moisture content silty clay. Case Stud. Constr. Mater. 2024, 21, e3529. [Google Scholar] [CrossRef]

- Mitchell, J.K.; Soga, K. Fundamentals of Soil Behavior, 3rd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2005. [Google Scholar]

- Zhang, S.; Pei, H.; Plötze, M.; Ying, H. Molecular dynamics modeling of hydraulic conductivity of soil considering variable viscosity and adsorbed water. Appl. Clay Sci. 2022, 228, 106598. [Google Scholar] [CrossRef]

- Yin, Y.; Li, Q.; Qiao, L. Response of energy pile-soil structure and pile group effect: An indoor similarity simulation study. J. Build. Eng. 2022, 51, 104247. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).