Nano-Scale and Macro-Scale Characterizations of the Effects of Recycled Plastics on Asphalt Binder Properties

Abstract

1. Introduction

2. Objectives

3. Materials and Methods

3.1. Materials

3.1.1. Asphalt Binder

3.1.2. Hydrothermal Recycling of PETE

3.2. Mixing Procedure

3.3. Rheological Testing

3.3.1. Dynamic Shear Rheometer (DSR) Testing

3.3.2. Bending-Beam Rheometer (BBR) Testing

3.3.3. Asphalt Binder Cracking Device (ABCD) Testing

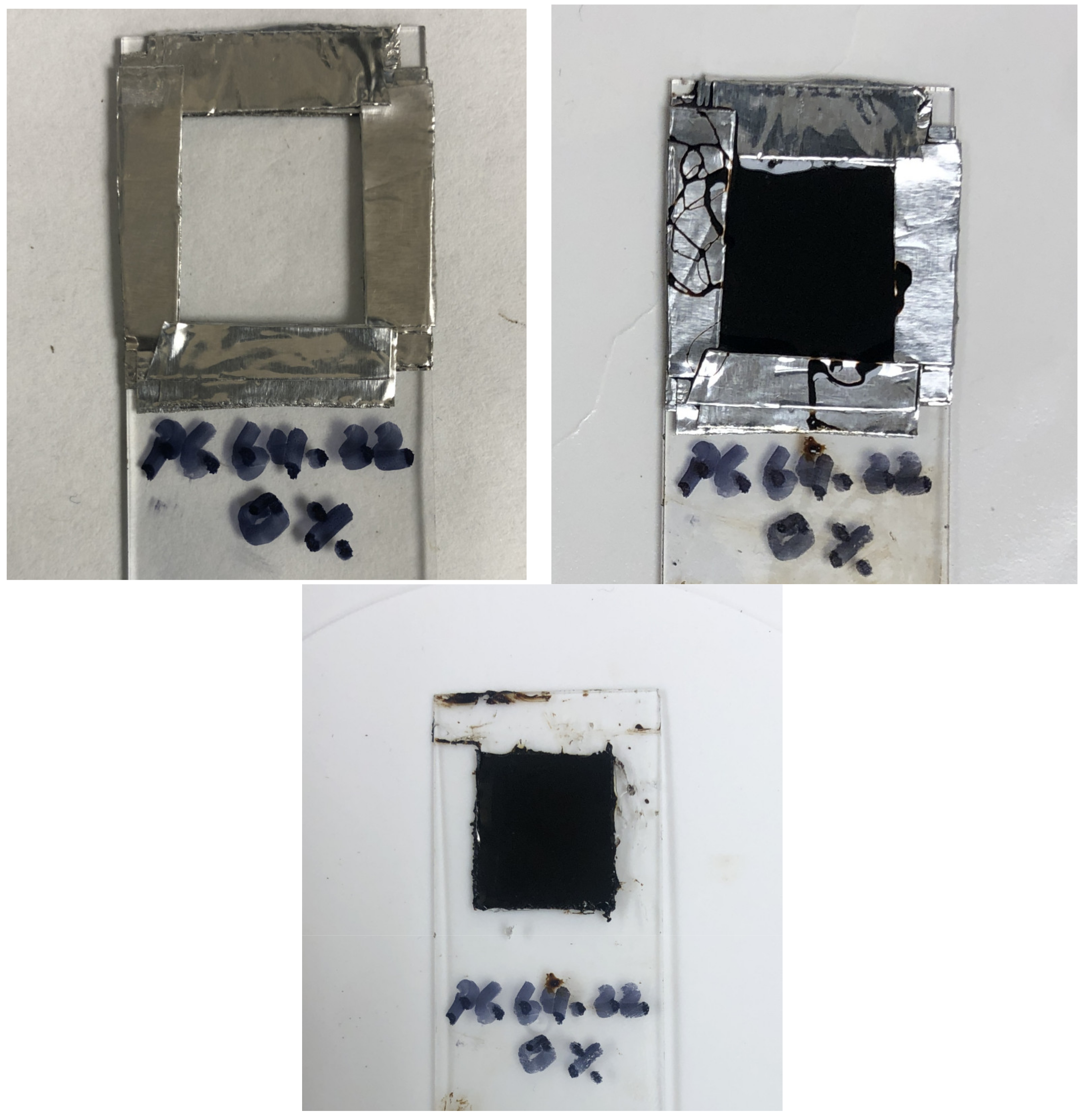

3.4. AFM Nano-Scale Testing

3.4.1. Sample Preparation

3.4.2. AFM Techniques

4. Results and Analysis

4.1. Results of Rheological Testing

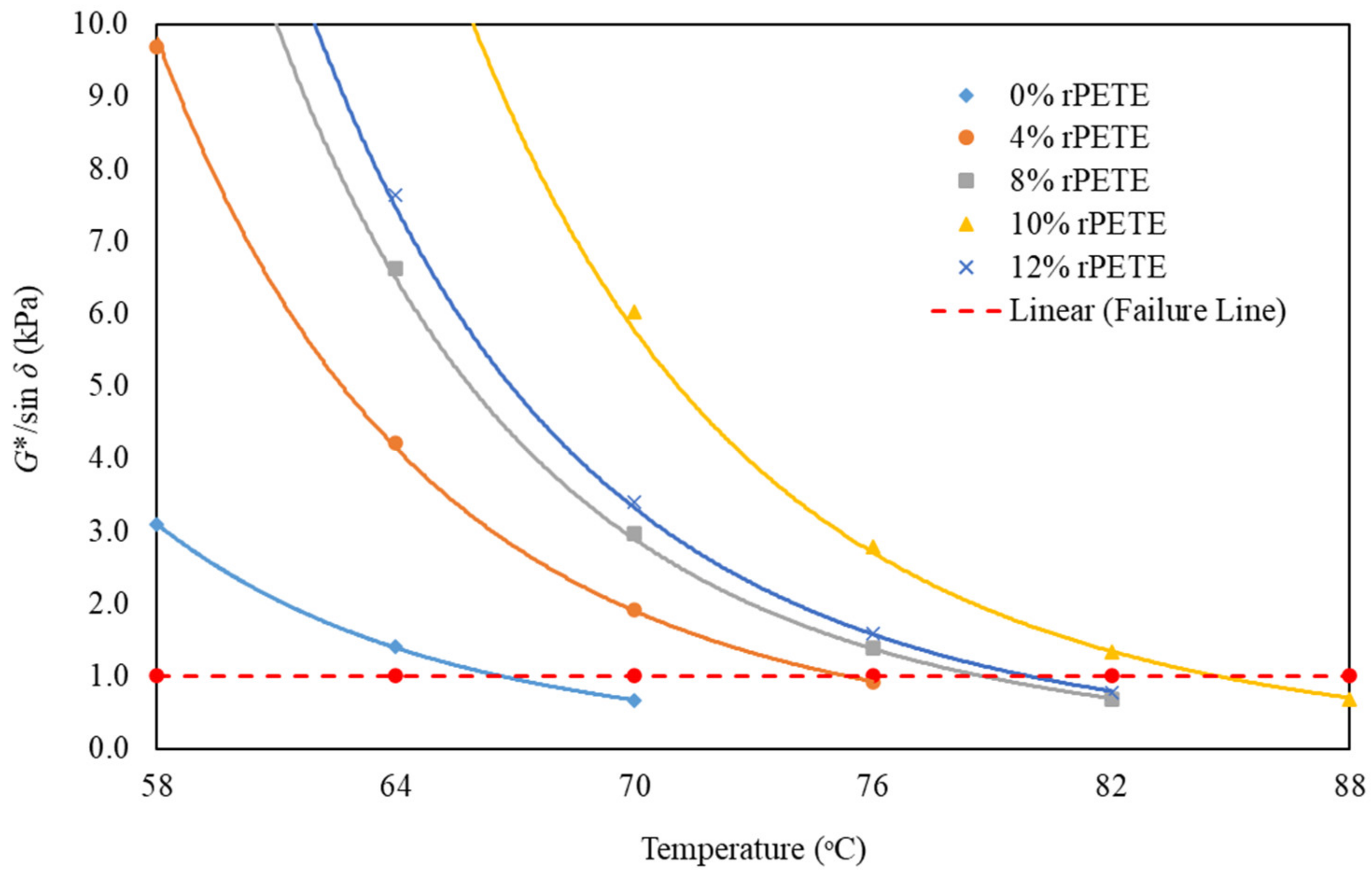

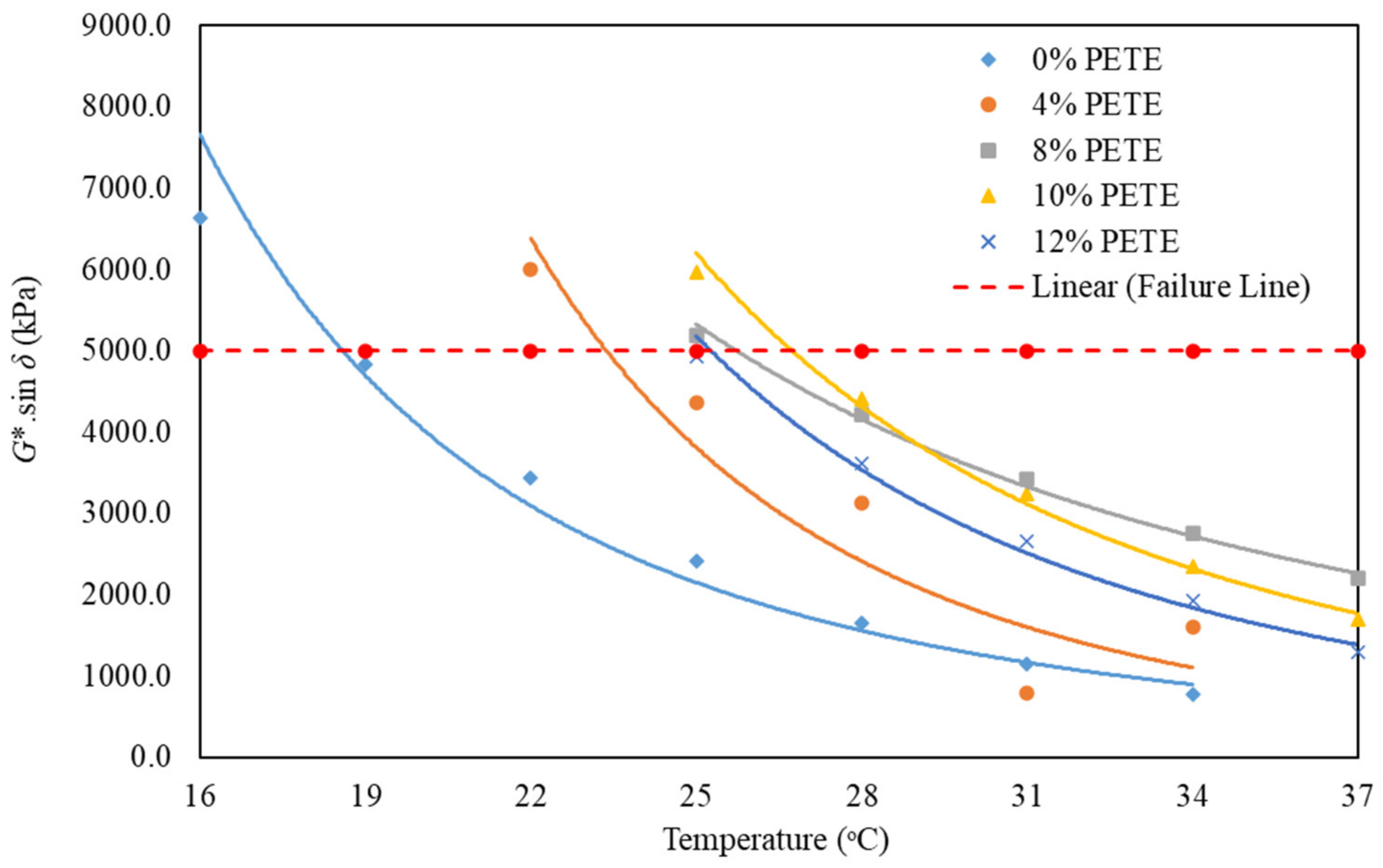

4.1.1. Results of DSR Testing

4.1.2. Results of BBR Testing

- : The critical low temperature of the asphalt binder at S60 is exactly equal to the specification value of 300 MPa;

- : The critical low temperature of the asphalt binder at the m-value is exactly equal to the specification value of 0.3.

| rPETE Content (%) | T (°C) | S60 (MPa) | m-Value | Pass/Fail (m-Value ≥ 0.3 and S ≤ 300 MPa) | Stiffness Continuous Grade (°C) | m-Value Continuous Grade (°C) | ΔTc (°C) |

|---|---|---|---|---|---|---|---|

| 0 | −6 | 68.7 | 0.36 | Pass | −30.60 | −22.28 | −10.32 |

| −12 | 163.7 | 0.303 | Pass | ||||

| 4 | −6 | 79.4 | 0.337 | Pass | −30.75 | −22.1 | −8.65 |

| −12 | 169.1 | 0.301 | Pass | ||||

| 8 | −6 | 81.6 | 0.328 | Pass | −30.73 | −19.86 | −10.87 |

| −12 | 172.4 | 0.284 | Fail | ||||

| 10 | −6 | 84.1 | 0.327 | Pass | −28.48 | −19.64 | −8.84 |

| −12 | 187.9 | 0.283 | Fail | ||||

| 12 | −6 | 85.1 | 0.314 | Pass | −26.85 | −17.57 | −8.46 |

| −12 | 204.7 | 0.26 | Fail |

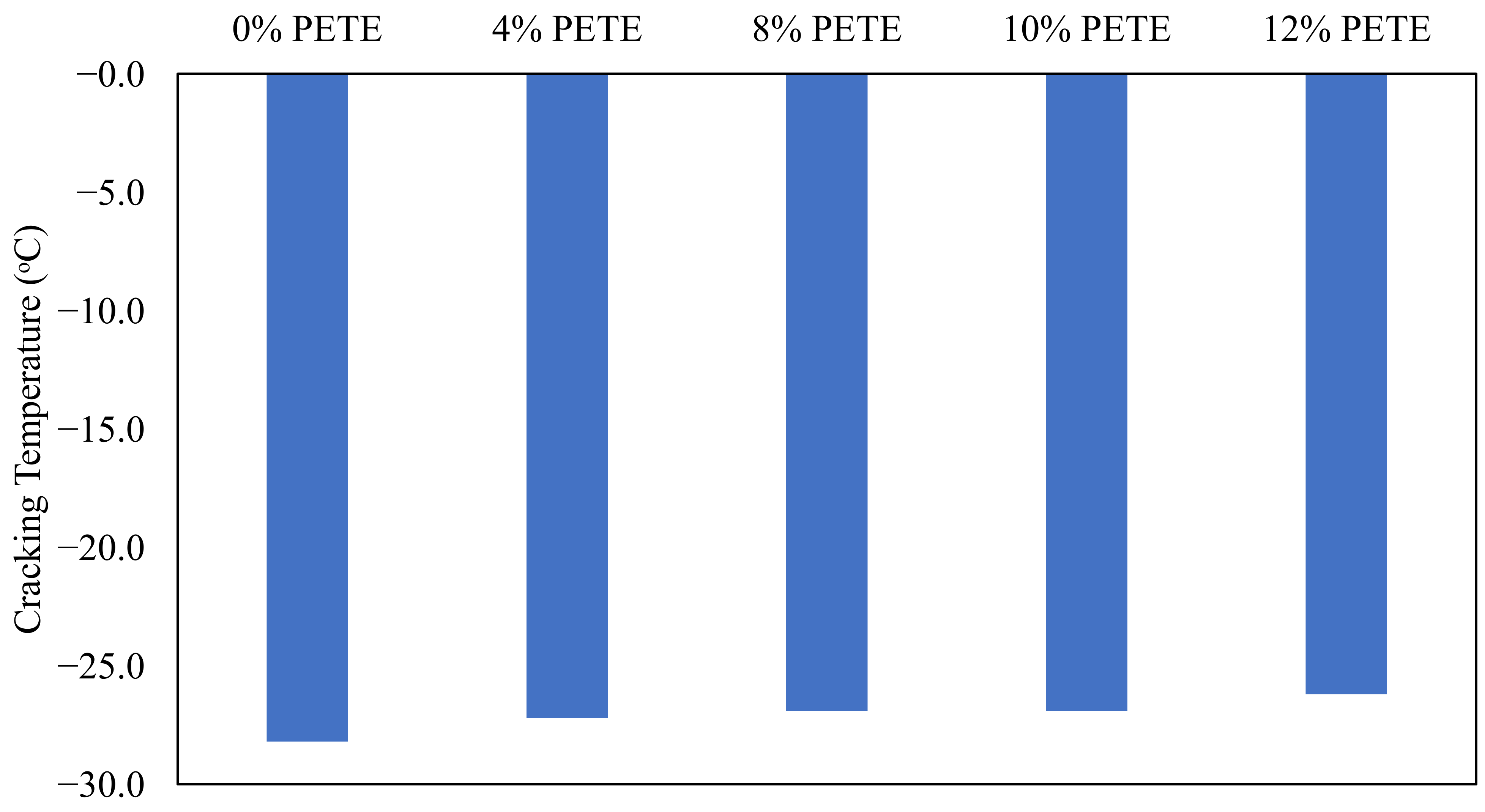

4.1.3. Results of ABCD Testing

4.1.4. Summary of Asphalt Binder Performance-Grading Tests

4.2. Results for AFM Nano-Scale Testing

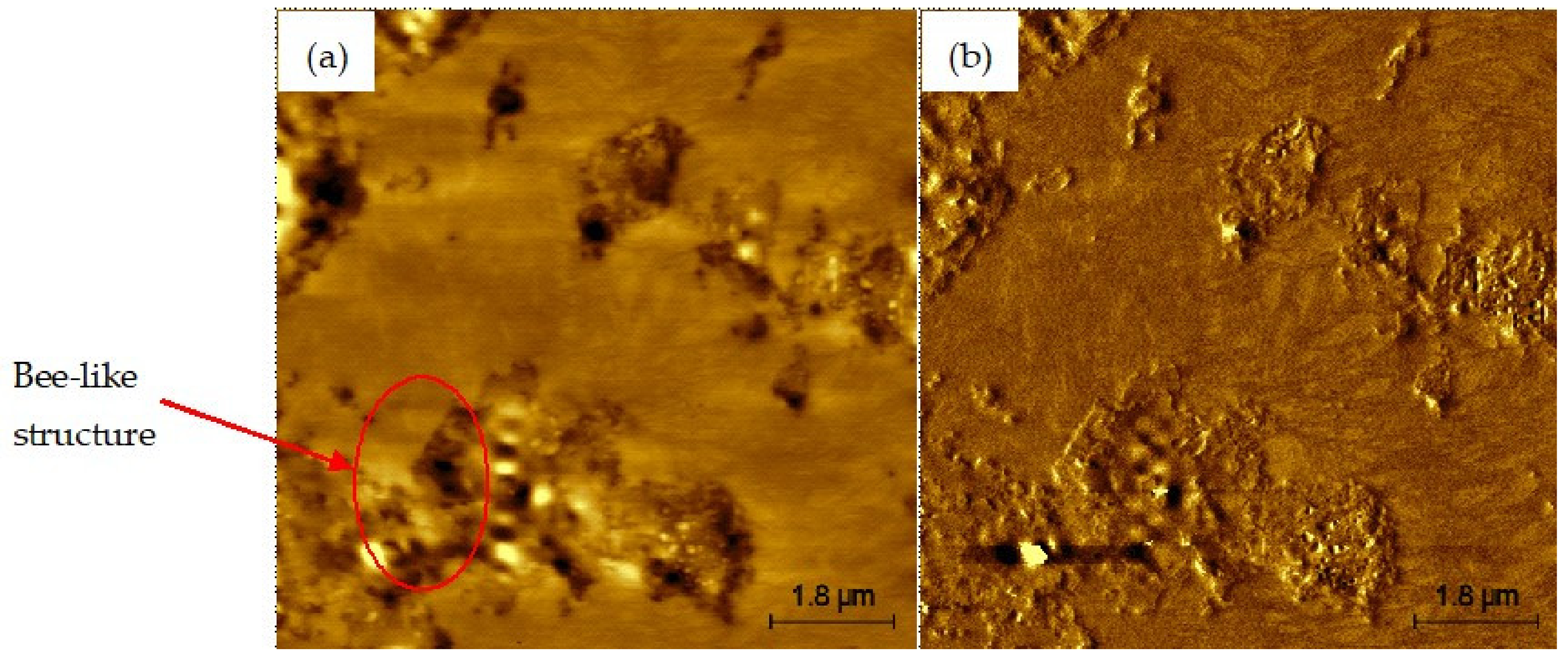

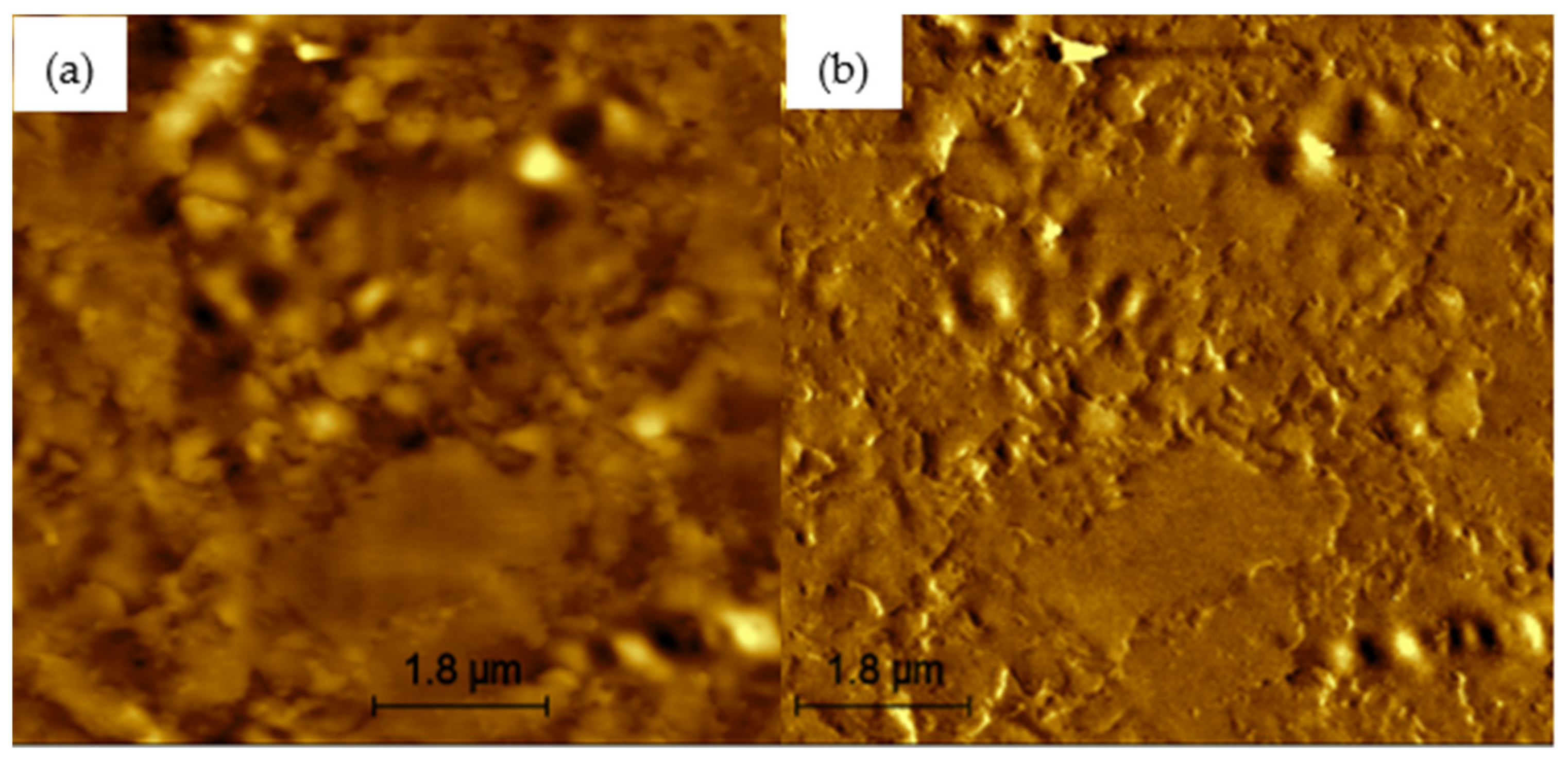

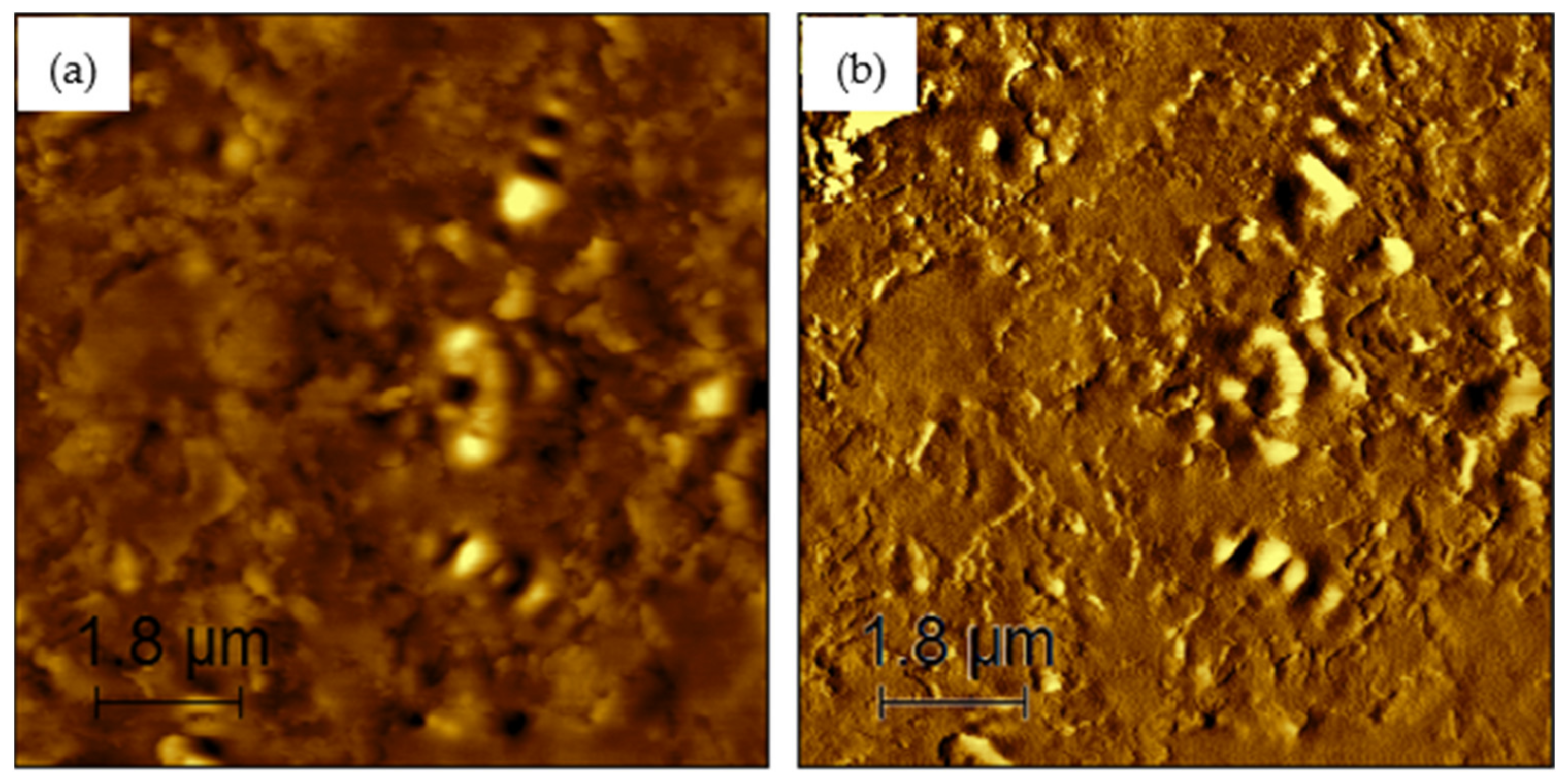

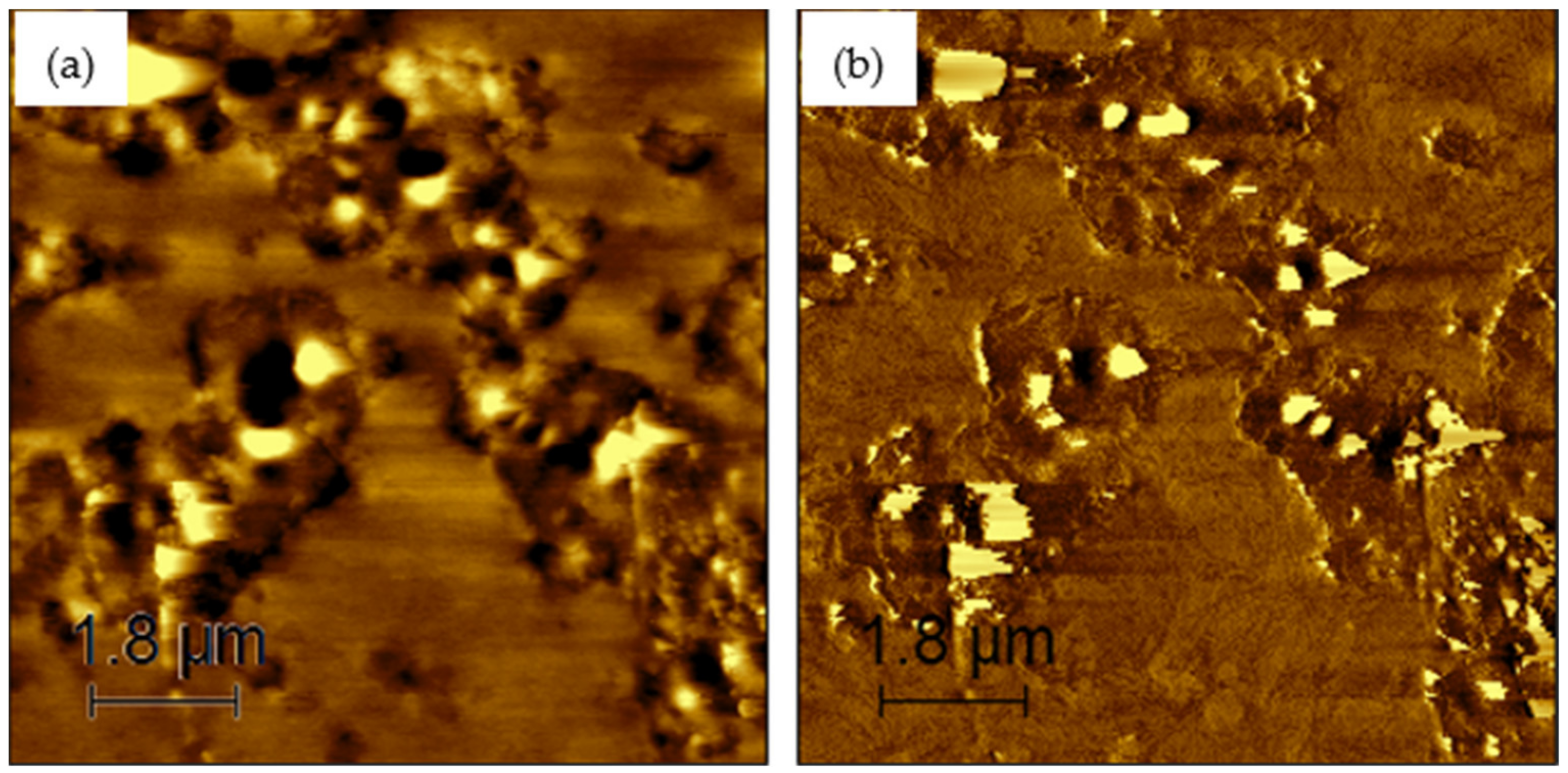

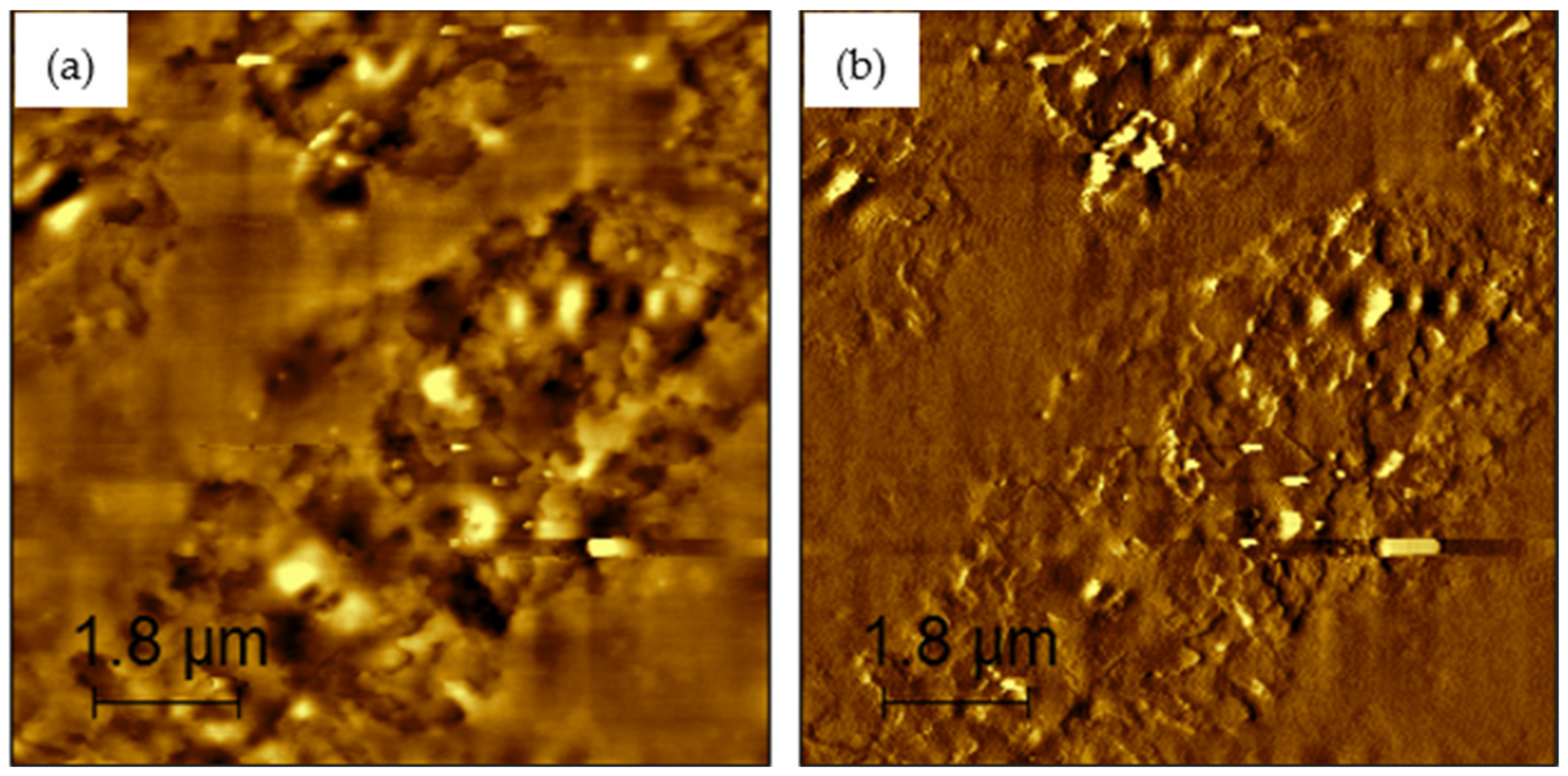

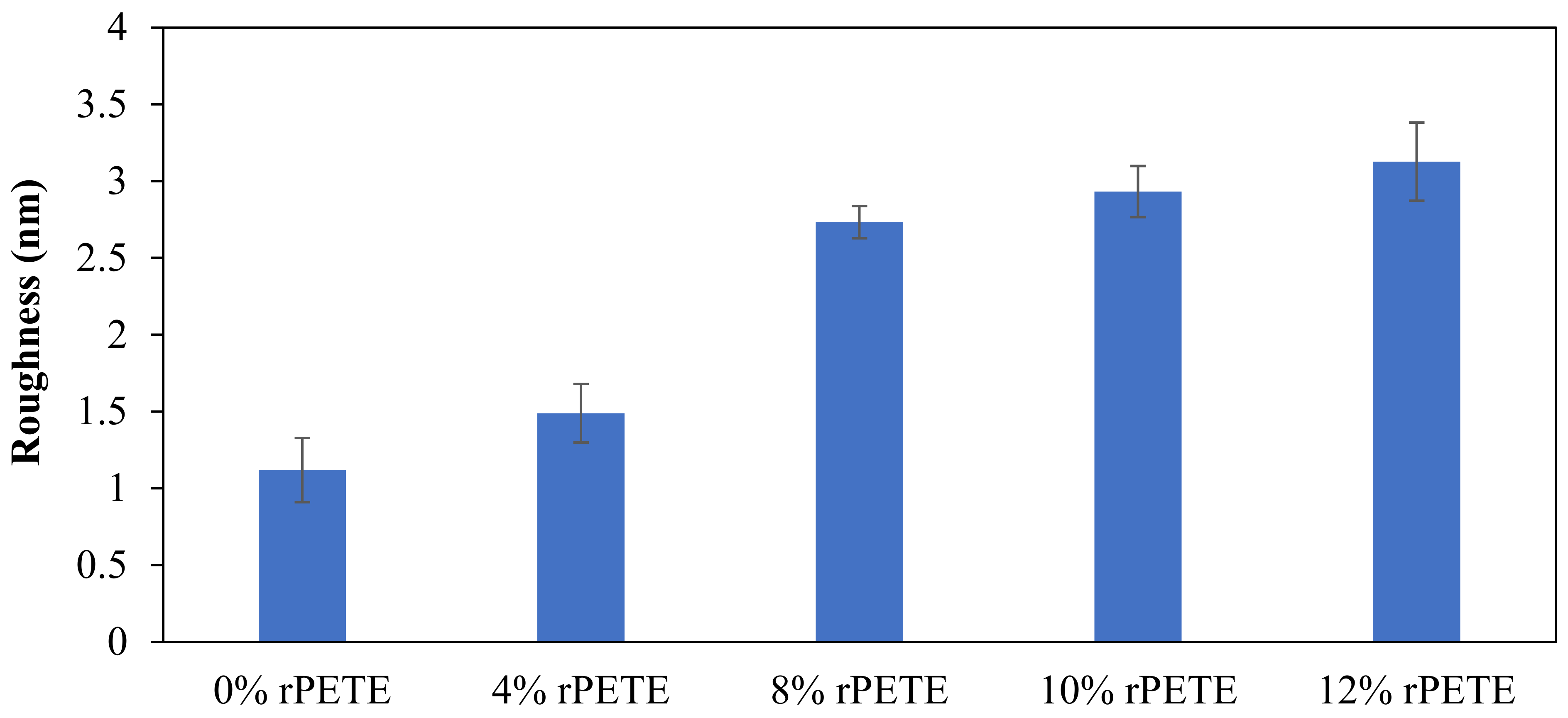

4.2.1. Results for AFM Tapping Mode

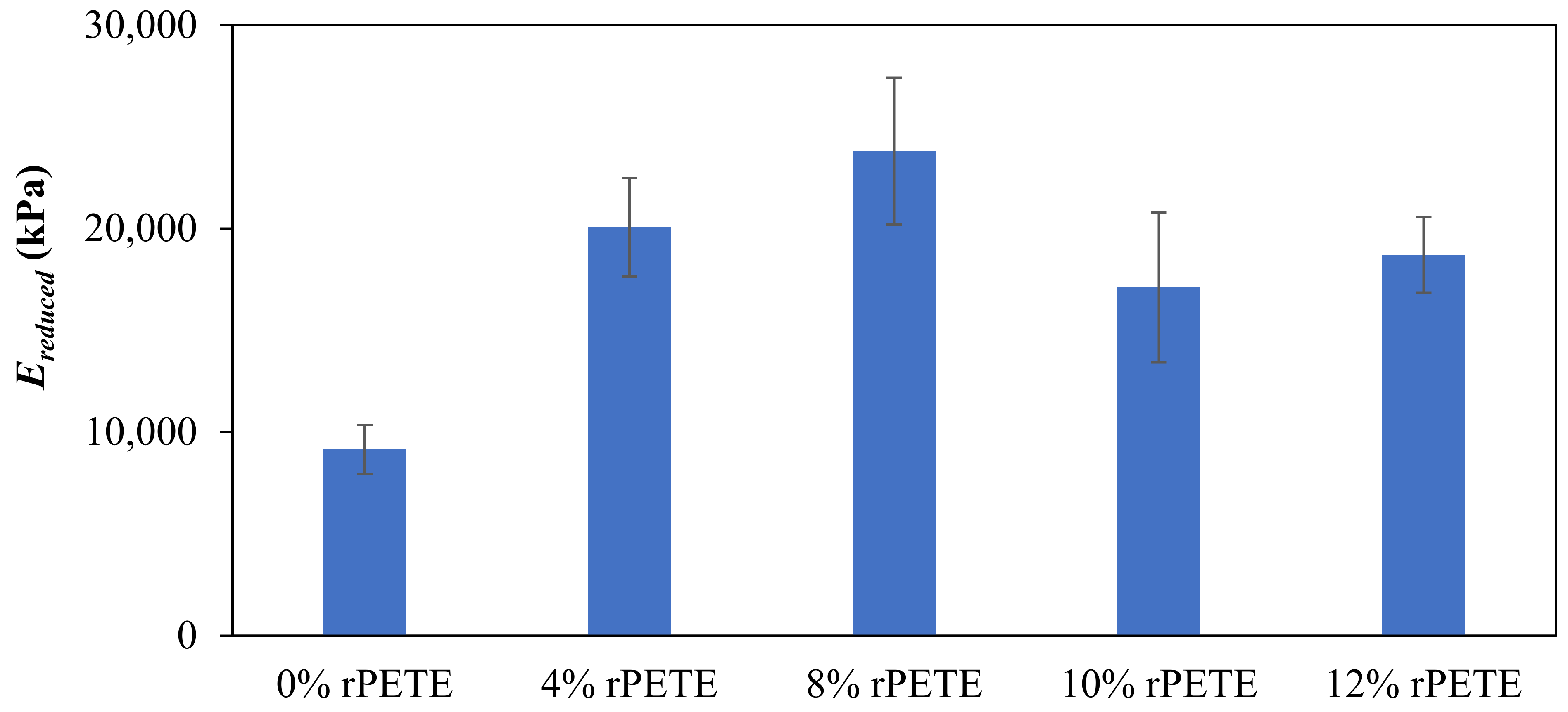

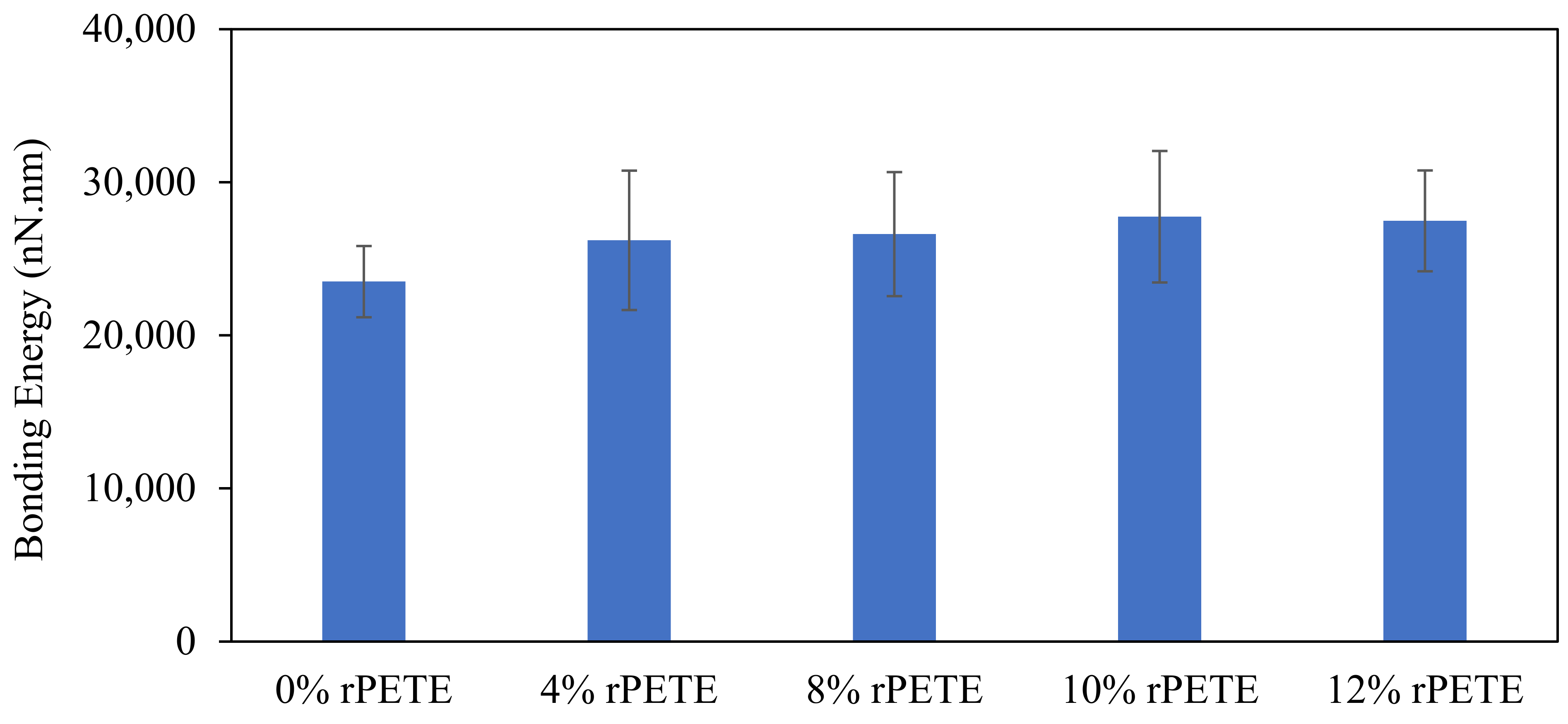

4.2.2. Results of AFM Force Spectroscopy Mode

4.2.3. Statistical Analysis of the Results for AFM Testing

5. Conclusions

- The addition of the rPETE enhanced the high- and intermediate-temperature rheological properties and slightly reduced the low-temperature rheological properties of the modified PG 64-22 binder;

- The results from the AFM testing indicated that the inclusion of rPETE in the asphalt binder improved the stiffness properties of the modified binder as compared with those of the control asphalt binder. In addition, the rPETE-modified binders showed rougher surfaces and remarkably higher values of the reduced modulus than the control binder;

- As seen from the results of the AFM bonding energy, the rPETE-modified binders showed higher bonding energy values compared with those of the control binder. This improvement in the bonding energy increased with increasing rPETE content. The addition of the 10% rPETE content resulted in the highest bonding energy among all the binders;

- The mixture with the 10% rPETE content resulted in the best high- and intermediate-temperature binder performances. Although the 4% rPETE binder showed improved high- and intermediate-temperature properties without reducing the low-temperature grade of the modified binder, 4% can be considered as the optimal content of rPETE as a modifier for the asphalt binder.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shahnawaz, M.; Sangale, M.K.; Ade, A.B. Plastic Waste Disposal and Reuse of Plastic Waste. In Bioremediation Technology for Plastic Waste; Springer: Singapore, 2019. [Google Scholar] [CrossRef]

- Jamshidi, A.; Hamzah, M.O.; Aman, M.Y. Effects of Sasobit® content on the rheological characteristics of unaged and aged asphalt binders at high and intermediate temperatures. Mater. Res. 2012, 15, 628–638. [Google Scholar] [CrossRef]

- Kök, B.V.; Yılmaz, M.; Akpolat, M. Evaluation of the conventional and rheological properties of SBS+Sasobit modified binder. Constr. Build. Mater. 2014, 63, 174–179. [Google Scholar] [CrossRef]

- Tarefder, R.A.; Yousefi, S.S. Rheological Examination of Aging in Polymer-Modified Asphalt. J. Mater. Civ. Eng. 2016, 28, 04015112. [Google Scholar] [CrossRef]

- Ghuzlan, K.A.; Al Assi, M.O. Sasobit-Modified Asphalt Binder Rheology. J. Mater. Civ. Eng. 2017, 29, 04017142. [Google Scholar] [CrossRef]

- Al-Omari, A.; Taamneh, M.; Khasawneh, M.A.; Al-Hosainat, A. Effect of crumb tire rubber, microcrystalline synthetic wax, and nano silica on asphalt rheology. Road Mater. Pavement Des. 2020, 21, 757–779. [Google Scholar] [CrossRef]

- Abuaddous, M.; Taamneh, M.M.; Rabab’ah, S.R. The potential use of recycled polyethylene terephthalate (RPET) plastic waste in asphalt binder. Int. J. Pavement Res. Technol. 2021, 14, 579–587. [Google Scholar] [CrossRef]

- Becker, Y.; Mendez, M.P.; Rodriguez, Y. Polymer modified asphalt. Vis. Tecnol. 2001, 9, 39–50. [Google Scholar] [CrossRef]

- Behnood, A.; Gharehveran, M.M. Morphology, rheology, and physical properties of polymer-modified asphalt binders. Eur. Polym. J. 2019, 112, 766–791. [Google Scholar] [CrossRef]

- Ma, F.; Jin, Y.; Fu, Z.; Dai, J.; Zhang, P.; Zhang, C.; Wen, Y. Influencing factors and evaluation methods of reinforcement effect of fiber-modified asphalt binder. Polym. Compos. 2022, 43, 8986–8999. [Google Scholar] [CrossRef]

- White, G.; Reid, G. Recycled waste plastic for extending and modifying asphalt binders. In Proceedings of the 8th Symposium on Pavement Surface Characteristics (SURF 2018), Brisbane, QLD, Australia, 2–4 April 2018; pp. 2–4. [Google Scholar]

- Ahmad, A.F.; Razali, A.R.; Razelan, I.S.M. Utilization of polyethylene terephthalate (PET) in asphalt pavement: A review. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; Volume 203, p. 012004. [Google Scholar]

- Khedaywi, T.; Haddad, M.; Bataineh, H. Effect of waste plastic polyethylene terephthalate on properties of asphalt cement. Innov. Infrastruct. Solut. 2023, 8, 232. [Google Scholar] [CrossRef]

- Chen, S. An Evaluation of Waste Plastic in Asphalt Pavement towards a Circular Economy. Ph.D. Thesis, University of Missouri–Columbia, Columbia, MO, USA, 2020. [Google Scholar]

- Wu, S.; Montalvo, L. Repurposing waste plastics into cleaner asphalt pavement materials: A critical literature review. J. Clean. Prod. 2021, 280, 124355. [Google Scholar] [CrossRef]

- Vorobyev, D.; Borisenko, Y.; Shvachev, D.; Rudak, S. Effective Polymer-Modified Bitumen Based on PET Waste. In Proceedings of the FORM 2022: Construction the Formation of Living Environment, Moscow, Russia, 20–22 April 2022; Springer International Publishing: Cham, Switzerland, 2022; pp. 417–427. [Google Scholar]

- Rotimi, A. Reuse of Waste Plastic as an Additive in Asphalt Concrete. ATBU J. Sci. Technol. Educ. 2022, 10, 49–59. [Google Scholar]

- Leng, Z.; Padhan, R.K.; Sreeram, A. Production of a sustainable paving material through chemical recycling of waste PET into crumb rubber modified asphalt. J. Clean. Prod. 2018, 180, 682–688. [Google Scholar] [CrossRef]

- Majka, T.M.; Ostrowski, K.A.; Piechaczek, M. Research on the Development of a Way to Modify Asphalt Mixtures with PET Recyclates. Materials 2023, 16, 6258. [Google Scholar] [CrossRef]

- Kawai, F.; Kawabata, T.; Oda, M. Current State and Perspectives Related to the Polyethylene Terephthalate Hydrolases Available for Biorecycling. ACS Sustain. Chem. Eng. 2020, 8, 8894–8908. [Google Scholar] [CrossRef]

- Bhanderi, K.K.; Joshi, J.R.; Patel, J.V. Recycling of polyethylene terephthalate (PET or PETE) plastics—An alternative to obtain value added products: A review. J. Indian Chem. Soc. 2023, 100, 100843. [Google Scholar] [CrossRef]

- Reza, M.T.; Wirth, B.; Lüder, U.; Werner, M. Behavior of selected hydrolyzed and dehydrated products during hydrothermal carbonization of biomass. Bioresour. Technol. 2014, 169, 352–361. [Google Scholar] [CrossRef] [PubMed]

- Saha, N.; McGaughy, K.; Reza, M.T. Elucidating hydrochar morphology and oxygen functionality change with hydrothermal treatment temperature ranging from subcritical to supercritical conditions. J. Anal. Appl. Pyrolysis 2020, 152, 104965. [Google Scholar] [CrossRef]

- Fang, C.; Liu, P.; Yu, R.; Liu, X. Preparation process to affect stability in waste polyethylene-modified bitumen. Constr. Build. Mater. 2014, 54, 320–325. [Google Scholar] [CrossRef]

- Mohammed, D.T.; Hussein, Z.H. Evaluation of pyrolisis PET utilization in asphalt binder. Evaluation 2014, 3, 114–121. [Google Scholar]

- Ghuzlan, K.A.; Al-Khateeb, G.G.; Qasem, Y. Rheological Properties of Polyethylene-Modified Asphalt Binder. Athens J. Technol. Eng. 2015, 2, 75–88. [Google Scholar] [CrossRef]

- Silva, J.d.A.A.e.; Lucena, L.C.d.F.L.; Rodrigues, J.K.G.; Carvalho, M.W.; Costa, D.B. Use of Micronized Polyethylene Terephthalate (Pet) Waste in Asphalt Binder. Pet. Sci. Technol. 2015, 33, 1508–1515. [Google Scholar] [CrossRef]

- Ameri, M.; Nasr, D. Properties of asphalt modified with devulcanized polyethylene terephthalate. Pet. Sci. Technol. 2016, 34, 1424–1430. [Google Scholar] [CrossRef]

- Nazzal, M.D.; Abu-Qtaish, L.; Kaya, S.; Powers, D. Using Atomic Force Microscopy to Evaluate the Nanostructure and Nanomechanics of Warm Mix Asphalt. J. Mater. Civ. Eng. 2015, 27, 04015005. [Google Scholar] [CrossRef]

- Abu Qtaish, L.; Nazzal, M.D.; Abbas, A.; Kaya, S.; Akinbowale, S.; Arefin, M.S.; Kim, S.-S. Micromechanical and Chemical Characterization of Foamed Warm-Mix Asphalt Aging. J. Mater. Civ. Eng. 2018, 30, 04018213. [Google Scholar] [CrossRef]

- Obaid, A.; Nazzal, M.D.; Abu Qtaish, L.; Kim, S.S.; Abbas, A.; Arefin, M.; Quasem, T. Effect of RAP Source on Cracking Resistance of Asphalt Mixtures with High RAP Contents. J. Mater. Civ. Eng. 2019, 31, 04019213. [Google Scholar] [CrossRef]

- Nazzal, M.D.; Abu Qtaish, L.; Al-Hosainat, A.; Abu Talha, S.; Kaya, S.; Abbas, A.R. Evaluation of Moisture Damage in Asphalt Mixtures at Macro- and Nanoscales. J. Mater. Civ. Eng. 2021, 33, 04021369. [Google Scholar] [CrossRef]

- AASHTO T 240; Standard Method of Test for Effect of Heat and Air on a Moving Film of Asphalt Binder (Rolling Thin-Film Oven Test). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2023.

- AASHTO T R28; Standard Practice for Accelerated Aging of Asphalt Binder Using a Pressurized Aging Vessel (PAV). American Association of State Highway Transportation Officials: Washington, DC, USA, 2023.

- AASHTO T 315-22; Standard Method of Test for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer (DSR). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2022.

- AASHTO T 313-22; Standard Method of Test for Determining the Flexural Creep Stiffness of Asphalt Binder Using the Bending Beam Rheometer (BBR). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2022.

- AASHTO T PP42; Standard Practice for Determination of Low-Temperature Performance Grade (PG) of Asphalt Binders. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2007.

- AASHTO TP 92–14; Standard Method of Test for Determining the Cracking Temperature of Asphalt Binder Using the Asphalt Binder Cracking Device (ABCD). Standard by American Association of State and Highway Transportation Officials: Washington, DC, USA, 2014.

- Binnig, G.; Quate, C.F.; Gerber, C. Atomic Force Microscope. Phys. Rev. Lett. 1986, 56, 930–933. [Google Scholar] [CrossRef]

- Das, P.K.; Baaj, H.; Tighe, S.; Kringos, N. Atomic force microscopy to investigate asphalt binders: A state-of-the-art review. Road Mater. Pavement Des. 2016, 17, 693–718. [Google Scholar] [CrossRef]

- Blanchard, C.R. Atomic Force Microscopy. Chem. Educ. 1996, 1, 1–8. [Google Scholar] [CrossRef]

- Nazzal, M.D.; Qtaish, L.A. The Use of Atomic Force Microscopy to Evaluate Warm Mix Asphalt (No. FHWA/OH-2012/19); Ohio Department of Transportation: Columbus, OH, USA, 2013.

- Tarefder, R.A.; Zaman, A.M. Nanoscale Evaluation of Moisture Damage in Polymer Modified Asphalts. J. Mater. Civ. Eng. 2010, 22, 714–725. [Google Scholar] [CrossRef]

- AbuQtaish, L.; Nazzal, M.D.; Kaya, S.; Kim, S.-S.; Abbas, A.; Abu Hassan, Y. AFM-Based Approach to Study Blending between RAP and Virgin Asphalt Binders. J. Mater. Civ. Eng. 2018, 30, 04017300. [Google Scholar] [CrossRef]

- Fischer-Cripps, A.C. Critical review of analysis and interpretation of nanoindentation test data. Surf. Coat. Technol. 2006, 200, 4153–4165. [Google Scholar] [CrossRef]

- Pauli, T.; Grimes, W.; Cookman, A.; Huang, S.-C. Adherence Energy of Asphalt Thin Films Measured by Force-Displacement Atomic Force Microscopy. J. Mater. Civ. Eng. 2014, 26, 04014089. [Google Scholar] [CrossRef]

- Asphalt Institute Technical Advisory Committee. Use of the Delta Tc Parameter to Characterize Asphalt Binder Behavior; Asphalt Institute: Lexington, KY, USA, 2019; ISBN 978-1-934154-77-9. [Google Scholar]

- Elwardany, M.; Planche, J.-P.; King, G. Universal and practical approach to evaluate asphalt binder resistance to thermally-induced surface damage. Constr. Build. Mater. 2020, 255, 119331. [Google Scholar] [CrossRef]

- Loeber, L.; Sutton, O.; Morel, J.; Valleton, J.-M.; Muller, G. New direct observations of asphalts and asphalt binders by scanning electron microscopy and atomic force microscopy. J. Microsc. 1996, 182, 32–39. [Google Scholar] [CrossRef]

- Jäger, A.; Lackner, R.; Eisenmenger-Sittner, C.; Blab, R. Identification of four material phases in bitumen by atomic force microscopy. Road Mater. Pavement Des. 2004, 5 (Suppl. 1), 9–24. [Google Scholar] [CrossRef]

- Masson, J.-F.; Leblond, V.; Margeson, J. Bitumen morphologies by phase-detection atomic force microscopy. J. Microsc. 2006, 221, 17–29. [Google Scholar] [CrossRef] [PubMed]

- Kringos, N.; Schmets, A.; Scarpas, A.; Pauli, T. Towards an understanding of the self-healing capacity of asphaltic mixtures. Heron 2011, 56, 45–74. [Google Scholar]

- Nazzal, M.D.; Kaya, S.; Gunay, T.; Ahmedzade, P. Fundamental Characterization of Asphalt Clay Nanocomposites. J. Nanomech. Micromech. 2013, 3, 1–8. [Google Scholar] [CrossRef]

- Holcombe, E.W.; Nazzal, M.D.; Mogawer, W.; Austerman, A.J.; Kaya, S. Evaluating Asphalt Binders Prepared with Different Processes to Meet the Same Performance Grade: Use of Atomic Force Microscope. Transp. Res. Rec. 2017, 2632, 99–109. [Google Scholar] [CrossRef]

- Loeber, L.; Muller, G.; Morel, J.; Sutton, O. Bitumen in colloid science: A chemical, structural and rheological approach. Fuel 1998, 77, 1443–1450. [Google Scholar] [CrossRef]

- Horcas, I.; Fernández, R.; Gómez-Rodríguez, J.M.; Colchero, J.; Gómez-Herrero, J.; Baro, A.M. WSXM: A software for scanning probe microscopy and a tool for nanotechnology. Rev. Sci. Instrum. 2007, 78, 013705. [Google Scholar] [CrossRef] [PubMed]

| Property | Specification | Sample Results |

|---|---|---|

| Original (Unaged) Binder | ||

| Dynamic Shear, 10 rad/s; G*/sinδ, kPa | ≥1.00 at 64 °C | 1.3993 at 64 °C |

| Pressure-Aging Vessel Residue | ||

| Dynamic Shear, 10 rad/s; G* · sinδ, kPa, 28 °C | ≤5000 at 28 °C | 1659.5 at 28 °C |

| Bending-Beam Creep Slope, m-value, −12 °C | ≥0.300 at −12 °C | 0.303 At −12 °C |

| Cracking Device PG Grade, °C | N/A | −22.9 |

| Property | Value |

|---|---|

| Specific Gravity at 25 °C | 1.38 |

| Average Molecular Weight (g/mol) | 228.199 |

| Average Melting Point (°C) | 260 |

| Glass-Transition Temperature (°C) | 67–81 |

| Average Modulus of Elasticity (GPa) | 3.25 |

| Average Yield Tensile Strength (MPa) | 73.7 |

| rPETE Content (%) | Continuous High-Temperature PG Grade (°C) |

|---|---|

| 0% | 66.70 |

| 4% | 75.27 |

| 8% | 78.73 |

| 10% | 84.53 |

| 12% | 79.83 |

| rPETE Content (%) | ABCD Cracking Temperature (°C) | ABCD PG Grade (°C) |

|---|---|---|

| 0 | −28.2 | −22.9 |

| 4 | −27.2 | −22.1 |

| 8 | −26.9 | −21.8 |

| 10 | −26.9 | −21.8 |

| 12 | −26.2 | −21.3 |

| rPETE Content (%) | BBR Temperature at Critical Stiffness (S = 300 MPa) (°C) | ABCD Cracking Temperature (°C) | Binder Failure Index (°C) |

|---|---|---|---|

| 0 | −30.60 | −28.20 | −2.40 |

| 4 | −30.75 | −27.20 | −3.55 |

| 8 | −30.73 | −26.90 | −3.83 |

| 10 | −28.48 | −26.90 | −1.58 |

| 12 | −26.85 | −26.20 | −0.65 |

| Parameter | Control Binder | 4% rPETE | 8% rPETE | 10% rPETE | 12% rPETE | Criteria |

|---|---|---|---|---|---|---|

| DSR Temperature for Unaged Binder (°C) | 64 | 70 | 76 | 82 | 76 | G*/sinδ ≥ 1.0 kPa |

| DSR Temperature for PAV Residue (°C) | 25 | 28 | 34 | 31 | 31 | G* · sinδ ≤ 5000 kPa |

| DSR PG Continuous Grade (°C) | 66.70 | 75.27 | 78.73 | 84.53 | 79.83 | |

| BBR PG Continuous Grade (°C) | −22.28 | −22.1 | −19.86 | −19.64 | −17.57 | S ≤ 300 MPa m-value ≥ 0.3 |

| BBR PG Grade for PAV Residue (°C) | −22 | −22 | −16 | −16 | −16 | |

| ABCD PG Continuous Grade (°C) | −22.9 | −22.1 | −21.8 | −21.8 | −21.3 | |

| PG Grade | PG 64-22 | PG 70-22 | PG 76-16 | PG 82-16 | PG 70-16 |

| Type 3 Tests of Fixed Effects | |||||

|---|---|---|---|---|---|

| Effect | Parameter | Num DF | Den DF | F-Value | p-Value |

| rPETE Content | Bonding Energy | 4 | 50 | 2.392 | 0.064 |

| Ereduced | 4 | 45 | 29.185 | <0.0001 | |

| Roughness | 4 | 14 | 67.734 | <0.0001 | |

| rPETE Content | Bonding Energy | Letter Group | rPETE Content | Ereduced | Letter Group | rPETE Content | Roughness | Letter Group |

|---|---|---|---|---|---|---|---|---|

| 10% | 27,749.7 | A | 8% | 23,799.2 | A | 12% | 3.127 | A |

| 12% | 27,483.2 | A | 4% | 20,067.1 | AB | 10% | 2.932 | A |

| 8% | 26,609.3 | AB | 12% | 18,707.5 | B | 8% | 2.733 | A |

| 4% | 26,211.2 | B | 10% | 17,104.7 | B | 4% | 1.489 | B |

| 0% | 23,513.5 | C | 0% | 9022.6 | C | 0% | 1.119 | B |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Hosainat, A.; Nazzal, M.D.; Kaya, S.; Reza, T. Nano-Scale and Macro-Scale Characterizations of the Effects of Recycled Plastics on Asphalt Binder Properties. Buildings 2024, 14, 642. https://doi.org/10.3390/buildings14030642

Al-Hosainat A, Nazzal MD, Kaya S, Reza T. Nano-Scale and Macro-Scale Characterizations of the Effects of Recycled Plastics on Asphalt Binder Properties. Buildings. 2024; 14(3):642. https://doi.org/10.3390/buildings14030642

Chicago/Turabian StyleAl-Hosainat, Ahmad, Munir D. Nazzal, Savas Kaya, and Toufiq Reza. 2024. "Nano-Scale and Macro-Scale Characterizations of the Effects of Recycled Plastics on Asphalt Binder Properties" Buildings 14, no. 3: 642. https://doi.org/10.3390/buildings14030642

APA StyleAl-Hosainat, A., Nazzal, M. D., Kaya, S., & Reza, T. (2024). Nano-Scale and Macro-Scale Characterizations of the Effects of Recycled Plastics on Asphalt Binder Properties. Buildings, 14(3), 642. https://doi.org/10.3390/buildings14030642