Abstract

Experimental results from 109 flush end-plate (FEP) connections were analyzed to investigate the failure modes and damage index of FEP connections across various damage states. The present study was conducted in accordance with the performance design objectives specified in China’s GB50011-2010 Code for Seismic Design of Buildings. The observed rotation angles and corresponding rotation factors were systematically categorized using a probabilistic statistical approach, with the 95% confidence lower limit as the primary constraint. The damage states of FEP connections were classified as virtually undamaged, lightly damaged, moderately damaged, severely damaged, and joint failure. A minimum plate thickness of 12 mm and a minimum high-strength bolt diameter of 20 mm are recommended to be used for the FEP connections, in accordance with building codes in China, the United States, and Europe. Quasi-static tests of six FEP connections were conducted to validate the damage-state categorization. The results revealed that for connections undergoing moderate and severe damage, the mean rotation factor deviated from the theoretical values proposed in this study by 3.7% and 9.4%, respectively. Therefore, the damage state of FEP connections can be reliably predicted based on different rotation angles using the damage-state categorization presented herein.

1. Introduction

Prior to the 1990s, rigid connection in steel frames was commonly used due to the strong seismic performance [1]. Subsequent studies on seismic events, such as the 1994 Northridge earthquake in the United States and the 1995 Hanshin earthquake in Japan, revealed that many rigid connections had suffered brittle fractures, particularly at the welds in beam–column joints [2,3,4]. Notably, the Northridge earthquake revealed that damage to welded beam–column joints primarily occurred in the lower flange of the beam. This damage was mainly attributed to the formation of brittle cracks at the root of the weld. The propagation of these cracks varied, extending into either the base material or the heat-affected zone. However, beam–column joints with bolted end-plate connections experienced less severe damage.

Bolted end-plate connections can primarily be classified into the following types: flush end-plate (FEP) connection, extended end-plate connection, and recessed end-plate connection. Among these, FEP connections are more widely used than the other types of end-plate connections [5]. Coelho [6,7] varied the end-plate thickness, bolt diameter, and bolt material properties to investigate the mechanical performance of FEP and extended end-plate connections. The results showed that increasing the end-plate thickness led to higher initial rotational stiffness and flexural-load-carrying capacity of the connections. Additionally, the connections using high-strength Grade 12.9 bolts exhibited poor ductility, leading to a recommendation for using Grade 8.8 high-strength bolts. Factors such as the beam section dimensions, end-plate thickness, bolt diameter, and bolt grade were considered. Broderick [8] investigated the failure modes of FEP connections under monotonic and cyclic-loading conditions. Their results showed that the most common failure mode for these connections was thread stripping between the bolt and nut, consistent with the predictions of Eurocode 3 [9]. Faridmehr [10] experimentally validated the design methods for FEP connection in accordance with AISC 360-10 [11] and Eurocode 3 [9]. Both standards were deemed suitable for classifying the properties of FEP connections. However, the experimental values of the initial rotational stiffness were approximately half of those predicted by AISC 360-10 [11].

Qiang [12] conducted a comparative study on the mechanical performance of flush end-plate connection joints made of high-strength steel under fire and room temperature conditions. The results show that, with proper design, the bending capacity of joints with thinner high-strength steel end plates can achieve or even surpass that of joints with thicker regular steel end plates. Shi [13] studied the seismic performance of eight full-scale specimens with various beam–column section dimensions, end-plate configurations, and bolt diameters under cyclic loading, proposing the “strong connection, weak plate” design principle. Sun [14] conducted quasi-static tests on three flush end-plate joint specimens, one made of Q345 and two made of Q690 steel. By varying the end-plate thickness, column section size, and material, the mechanical performance of ordinary steel and high-strength steel joints was obtained. The results show that compared to ordinary steel joints, high-strength steel joints have an improved bending capacity but reduced rotational stiffness, as high-strength steel has a lower deformation resistance in the elastic phase, making high-strength bolts more prone to failure.

Existing research has primarily focused on how variations in component parameters affect the mechanical performance of FEP connections, with few studies exploring different damage states. The present work investigates the relationship between the rotation factors (calculated as the ratio of the rotation corresponding to each stage and the yield angle of the joint in the loading process) and the damage states to assess the condition of FEP connections. Guided by the GB50011-2010 Code for Seismic Design of Buildings [15] and JGJ 99-2015 Technical Specification for Steel Structure of Tall Buildings [16], damage states are categorized as virtually undamaged, lightly damaged, moderately damaged, severely damaged, and joint failure. This study addresses the research gap by assessing rotation factors and associated damage states and validating the categorized damage-state classifications through experiments.

2. Experimental Database

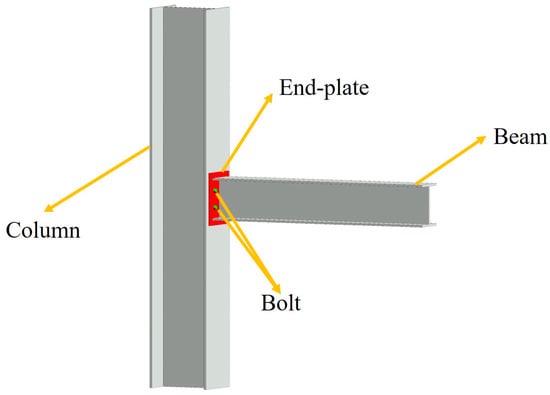

An FEP connection primarily comprises a beam, column, end plate, and bolts. In this setup, the beam is welded to the end plate, which are then connected to the column using high-strength bolts. Figure 1 provides a schematic representation of an FEP connection.

Figure 1.

Schematic diagram of flush end-plate connection.

Table 1 lists the specimen parameters from previous studies conducted by other researchers. These experiments are primarily focused on examining the effects of the end-plate thickness, bolt diameter, and the cross-sectional area of the beams and columns on the performance of FEP connections. The end-plate thickness ranged from 8 to 26 mm, and all specimens were equipped with high-strength bolts, categorized by diameter as M10, M16, M20, M24, and M27 (where numbers indicate the diameter in mm).

Table 1.

Data sources and main parameters.

3. Damage State of FEP Connections

Following the seismic performance recommendations from GB50011-2010 Code for Seismic Design of Buildings [15] and JGJ 99-2015 Technical Specification for Steel Structure of Tall Buildings [16], along with existing experimental studies, the rotation factor was chosen as the damage indicator. Based on the relationship between the rotation factor (i.e., the ratio of the actual rotation angle to the yield rotation angle of the joint), the damage states are classified as follows: virtually undamaged, lightly damaged, moderately damaged, severely damaged, and joint failure.

3.1. Rotation Factor

The rotation factor is the ratio of the real rotation angle to the yield rotation angle of the joint and can be calculated using the following equation:

where and are the real and yield rotation angles of the joint, respectively.

λ = θ/θy

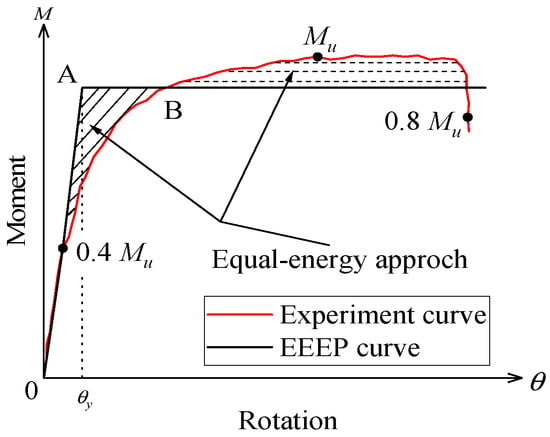

In this study, for specimens with a given yield rotation , the given value was based on clear to yield rotation references. For specimens without a given yield rotation, the yield rotation was calculated using the equivalent energy elastic–plastic (EEEP) method, a commonly used approach for determining the yield rotation angle [32,33]. Figure 2 illustrates the calculation process, where Mu represents the ultimate bending moment of the beam–column joints, and θy denotes the yield rotation of the beam–column joints. The red line represents the experimental curve and the black line represents the EEEP curve. When the integral areas above and below line AB are equal, a vertical line is drawn from point A to the X-axis. The intersection of this vertical line with the test curve represents the yield rotation angle of the joint.

Figure 2.

EEEP method schematic diagram.

3.2. Virtually Undamaged State

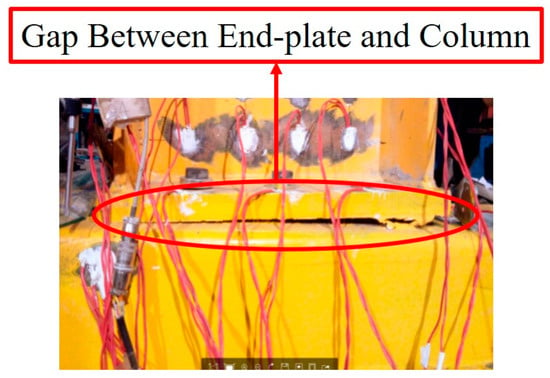

In the virtually undamaged state, the joint remains essentially intact, with only a minor gap beginning to form between the end plate and the column flange [20]. Therefore, no repairs or only minor repairs are needed to maintain continued use; Figure 3 shows the joint damage. Since the deformation remains elastic in this state, the rotation factor is set to 2/3, as referenced in EC3 [9].

Figure 3.

Gap between end plate and column [19].

3.3. Lightly Damaged State

In the lightly damaged state, the gap between the column flange and the end plate widens, and the end plate undergoes noticeable bending [13]. The joint requires general repair and can be safely used after implementing necessary safety measures. In this state, plastic deformation begins in the FEP connections, meaning that the rotation factor is 1.0 and the real rotation is equal to the yield rotation.

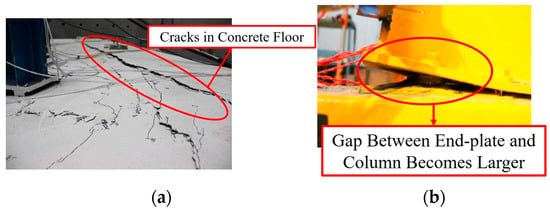

3.4. Moderately Damaged State

In the moderately damaged state, the end plate bends significantly, and the compression flange of the beam undergoes noticeable deformation. An overhaul, including local demolition, is required. Cracks in the concrete floor continue to spread, widening fissures, and the concrete at the column flange becomes crushed [20,22]. Figure 4 illustrates the joint damage. Based on the collected test data, the rotation factor at the 95% lower confidence limit is 1.77, with an average of 2.43 and a median of 2.49.

Figure 4.

Moderately damaged state. (a) Cracks in concrete floor [34]. (b) Gap between end plate and column becomes larger [19].

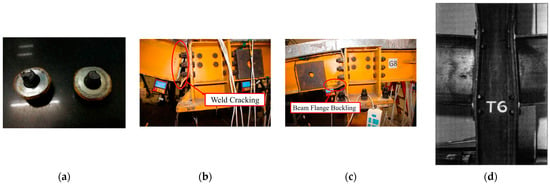

3.5. Severely Damaged State

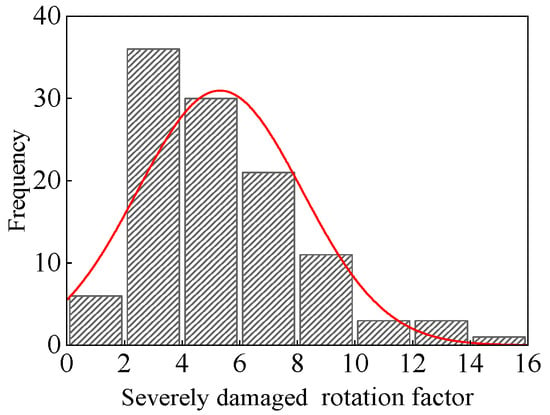

In the severely damaged state, the bolt may either be pulled apart or the threads may strip; alternatively, the weld seam between the end plate and the beam flange may fracture. In such cases, the joint should be demolished. Experimental observations indicate that the predominant damage modes of the joint in this state include bolt fracture or thread stripping, accounting for 46.79% of all specimens, as shown in Figure 5a; weld fracture between the end plate and beam flange, accounting for 13.76%, as shown in Figure 5b; and beam or column flange buckling, accounting for 7.34%, as shown in Figure 5c,d. Figure 5 shows the failure modes of the joint. As shown in Figure 6, the frequency distribution of rotation factors in this state follows a normal distribution, with a 95% lower confidence limit, average, and median of 4.77, 5.31, and 4.65, respectively. When the rotation factor exceeds the limit for severely damaged, the joint is considered to have failed.

Figure 5.

Severely damaged state. (a) Bolt fracture [19]. (b) Weld cracking [34]. (c) Beam flange buckling [34]. (d) Column flange buckling [35].

Figure 6.

Distribution of rotation factor for severely damaged state.

4. Effect of Different Parameters on Rotation Factor

4.1. Thickness of End Plate

Table 2 presents the calculated median and 95% confidence interval values of the rotation factor for different end-plate thicknesses. When the end-plate thickness is less than 12 mm, the rotation factor increases with the thickness of the end plate. However, when the end-plate thickness exceeds 12 mm, the rotation factor decreases when the end-plate thickness increases. This phenomenon can be explained as follows: When the end plate is relatively thin (thickness < 12 mm), the flexural-load-bearing capacity of the joint is primarily controlled by the end plate, which results in an end-plate buckling failure. When the end-plate thickness increases (>12 mm), the flexural-load-bearing capacity of the joint transitions from being end-plate-controlled to column-flange-controlled. The increase in the end-plate thickness continuously increases the flexural-load-bearing capacity until it surpasses the ultimate tensile-load-bearing capacity of the column flange. Consequently, the rotation factor of the joint decreases. To address this dilemma and ensure that the specimens simultaneously satisfy the requirements pertaining to the ductility and bearing capacity, a judicious selection of the appropriate end-plate thickness becomes imperative.

Table 2.

Rotation factor for different thicknesses of end plates.

4.2. Selection of End-Plate Thickness According to Different Codes

Different national standards have specified the value of the end-plate thickness. The Chinese code GB 51022-2015 Technical Code for Steel Structure of Light-Weight Building with Gabled Frames stipulates that the minimum end-plate thickness should be greater than 16 mm or 0.8 times the diameter of the bolt [36]. Similarly, CECS 260:2009 Technical Specification for Steel Structures With End-Plate Semi-Rigid Connection provides a formula to calculate the maximum end-plate thickness [37]. Although the GB 51022-2015 code for gabled frames emphasizes rigid connections at joints, the FEP connection falls under the category of semi-rigid connections, and its design is primarily guided by the specifications outlined in the CECS 260:2009 code.

In the EC3 [9] code, no explicit end-plate thickness values are specified, but it states that if the bearing capacity of the joint is controlled by the bending column flange or end plate, the end-plate thickness t should satisfy the following:

where d is the nominal diameter of the bolt, is the ultimate tensile strength of the bolts, and is the yield strength of the end plates.

Further, AISC Steel Design Guide Series 16 [38] specifies the minimum end-plate thicknesses tp,reqd as shown in Equations (3) and (4):

where ϕb = 0.9; γr is a factor greater than or equal to 1.0 and is used to modify the required factored moment to limit the connection rotation at the ultimate moment to 10% of the simple span rotation; Mu = ϕMnp is the connection strength with the bolt rupture limit state; Fpy is the end-plate material yield strength; Mu is the required flexural strength; and Y is the yield line.

In summary, to satisfy the requirements pertaining to the load-carrying capacity and the energy dissipation capacity of the joint, the minimum thickness of the FEP joint should be 12 mm.

4.3. Bolt Diameter

The bolt diameter is one of the most important factors affecting the bending capacity of FEP connections. Changes in the bolt diameter affect the structural rotation factor, load-carrying capacity, and energy dissipation capacity. As indicated in Table 3, when the bolt diameter is less than M20, the rotation factor of the joint increases with the bolt diameter. However, when the bolt diameter exceeds M20, the rotation factor of the joint decreases with the increase in the bolt diameter, because when the bolt diameter is relatively small, the bolts fail before other components. When the bolt diameter increases, the shear stiffness of the joint also increases, and the rotation factor is maximum for M20.

Table 3.

Rotation factor for different bolt diameters.

4.4. Selection of Bolt Diameters According to Different Codes

The use of high-strength bolts with diameters of 16–30 mm is recommended by various Chinese codes, including the GB51022-2015 [36], CECS 260:2009 [37], and GB50017-2017 Code for Design of Steel Structure [39].

AISC Steel Design Guide Series 16 [37] specifies a minimum bolt diameter db,reqd to be calculated as follows:

where is the required flexural strength, ϕ = 0.75; is the bolt material tensile strength; and is the distance from the centerline of the nth tension bolt row to the center of the compression flange.

In summary, to simultaneously satisfy the requirements pertaining to the load-bearing capacity and joint rotation capacity, the most suitable high-strength bolt is M20.

5. Experiment Verification

5.1. Introduction

In this section, the suitability of the proposed rotation factor for the joint is verified on the basis of experimental results. Table 4 lists the experimental and theoretical rotation factor values under damage states and confirms the effectiveness of the proposed rotation factor in predicting the failure modes of joints at various rotations. To ensure a certain safety margin for the joints, the 95% confidence lower limit value is the recommended threshold for the rotation factor.

Table 4.

Main parameters of specimens.

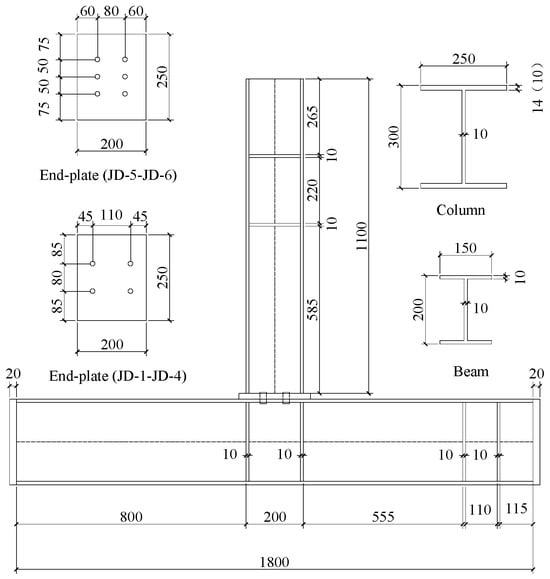

5.2. Experiment Overview

To validate the proposed rotation factor, six specimens were designed and fabricated based on the CECS 260:2009 code [37]. The specimens were numbered JD-1 to JD-6. By varying the end-plate thickness for specimens JD-1 and JD-2, column flange thickness for JD-3 and JD-4, and bolt diameter for JD-5 and JD-6, the damage modes of the connections under damage states were observed. The beams and columns of the specimens were constructed using welded H-beams. The cross-section dimensions of the beams were HM200 mm × 150 mm × 10 mm × 10 mm (height × width × web thickness × flange thickness). To investigate the effect of column flange thickness on the mechanical properties of FEP connections, the thickness of the column flange of specimen JD-4 was different from that of other specimens. The end-plate dimensions were 200 mm × 250 mm. Stiffening ribs were incorporated into the joint region, and 8.8 high-strength friction-type bolts were used for the connections. With the exception of the high-strength bolts, all specimens were composed of Q235 steel. Table 4 shows the main parameters of the specimens; material properties’ data of Q235 steel are as shown in Table 5. Figure 7 shows the detailed joint configuration.

Table 5.

Q235 steel material properties’ data.

Figure 7.

Details of specimens.

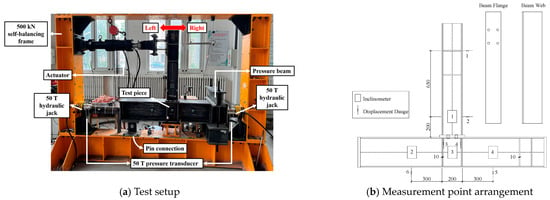

5.3. Experimental Setup and Loading System

The experimental setup consisted of seven components: a 500 kN self-balanced frame, an actuator, test specimens, a pressure beam, pin connections, a 50 T hydraulic jack, and a 50-ton pressure sensor. Figure 8a illustrates the arrangement of the test specimens, with the column placed horizontally and the beam oriented vertically. The axial load ratio for the specimens was 0.1, and axial pressure was applied at both ends of the column using a 50 T hydraulic jack. The actuator was connected to the bolt holes on the beam flange, and the height of the loading point center was consistent with the height of displacement gauge 1, as shown in Figure 8b.

Figure 8.

Test setup.

The arrangement of displacement gauges and inclinometers is shown in Figure 8b. Displacement gauges 1 and 2 measure the horizontal displacement of the beam, displacement gauges 3 and 4 measure the deformation of the joint area, and displacement gauges 5 and 6 measure the vertical displacement of the column. Four inclinometers are located at the web of the beam (inclinometer 1), the web of the column (inclinometers 2 and 4), and the joint area (inclinometer 3) to measure the relative rotation between the beam and column. The joint rotation angle θ is composed of the relative rotation between the axes of the beam and column, and the calculation method is shown in Equations (6)–(8).

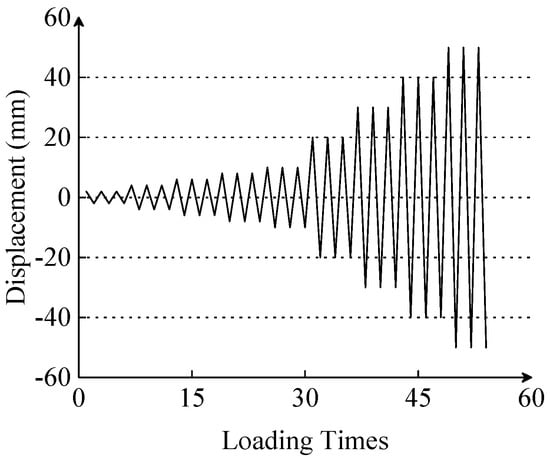

In the experiment, displacement-controlled loading was utilized. Up to 10 mm, the displacement load increment was 2 mm; after 10 mm was reached, the displacement load increment was set to 10 mm. Each stage was cyclically loaded three times. Figure 9 illustrates the loading protocol. The positive direction for specimen-loading displacement was defined as rightward, and the negative direction was leftward, as depicted in Figure 8.

Figure 9.

Loading system diagram.

5.4. Test Phenomena and Skeleton Curve

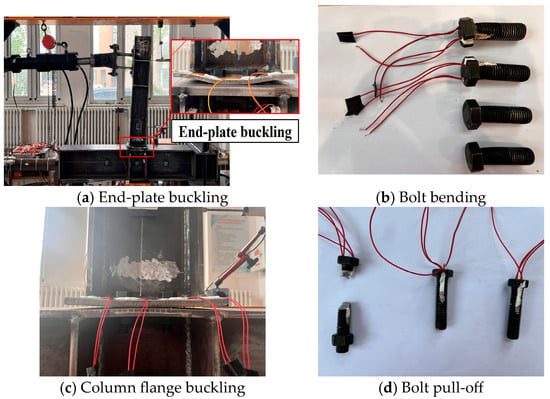

During the initial stages of the experiments, all specimens remained in the elastic phase with no significant changes. When the specimens entered the plastic deformation phase, several distinctive failure modes emerged with increasing load. Specimens JD-1 and JD-2 experienced excessive end-plate buckling deformation, so the loading was terminated. Figure 10a illustrates the end-plate buckling. In the case of specimen JD-3, noticeable bolt deformations simultaneously occurred with end-plate yielding, as shown in Figure 10b. Specimen JD-4 exhibited substantial column flange buckling with end-plate yielding, as depicted in Figure 10c. Specimens JD-5 and JD-6 experienced damage near the tension flange with bolt failure for JD-5, as shown in Figure 10d. Figure 7 shows the failure modes corresponding to the ultimate rotation, and Table 6 summarizes these failure modes.

Figure 10.

Failure modes of joints.

Table 6.

Specimen damage modes.

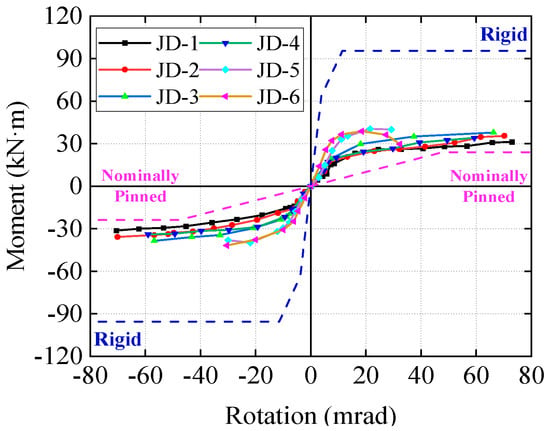

Figure 11 presents the skeleton curve for the joints and reveals that all joints are semi-rigid. Notably, specimens JD-5 and JD-6 exhibit significantly higher skeleton curves than other specimens. Thus, with six high-strength bolts (M14 or M16) and an appropriate arrangement, these joints exhibit a higher flexural-load-bearing capacity and initial rotational stiffness than those with four M20 high-strength bolts. This approach satisfies the design requirements while economizing on materials. Specimen JD-1 displays the lowest skeleton curve, and it is near the hinge limit, according to the EC3 standard. Thus, when the end plate is relatively thin, the material performance of other components is not fully realized, which leads to complete end-plate buckling on both ends. Hence, in joint design, the selection of an appropriate end-plate thickness is of paramount importance.

Figure 11.

Skeleton curves.

5.5. Comparison of Rotation Factors

The rotation factors of joints in damage states are analyzed, as shown in Table 7. The rotation factors of the joints with the virtually undamaged state and lightly damaged state are calculated according to the EC3 standard elastic stage rotation and yield rotation, respectively. The difference between the average rotation factor of moderately and severely damaged joints and the corresponding theoretical values is 3.7% and 9.4%, respectively, and the 95% confidence lower limit is 32.3% and 0.8%, respectively. Therefore, the rotation factor proposed in this study can predict the joint damage under different damage states, and therefore has security redundancy.

Table 7.

Comparison of specimen rotation factors.

6. Conclusions

By collecting 109 previous experimental data sets and introducing the rotation factor, the damage states of flush end-plate joints were classified into five categories—virtually undamaged, lightly damaged, moderately damaged, severely damaged, and joint failure—based on the seismic performance design requirements of the GB50011 code. This classification was validated through experiments. Additionally, by analyzing the rotation factor limits of flush end-plate connection joints with varying end-plate thicknesses and bolt diameters at the point of joint failure, and referencing the specifications for end-plate thickness and bolt diameter in Chinese, American, and European codes, relevant design recommendations were proposed. The main conclusions are as follows:

(1) The limits for the virtually undamaged and lightly damaged states of the joints are determined based on the European code EC3, which are set at 2/3 and 1, respectively. The rotation factors for the moderately damaged and severely damaged states are determined through experimental observations and the ratio of the corner angle to the yield angle, corresponding to their failure modes, which are set at 1.77 and 4.77, respectively. When the joint rotation exceeds 4.77, it is considered the joint failure stage. To ensure that the damage limit values have a certain safety reserve, the lower limit of the 95% confidence interval is taken as the limit value for the joint’s damage state.

(2) Thinner end plates in FEP joints exhibit a higher ductility but lower flexural-load-bearing capacity, while thicker end plates may decrease the energy dissipation capacity of the structure. Based on existing experimental data and industry specifications, this study successfully balances energy consumption and bearing capacity of structures with FEP connections. As such, this study recommends a minimum end-plate thickness of 12 mm.

(3) Experimental data indicate that high-strength M20 bolts exhibit high ductility. Based on these data and relevant specifications, M20 high-strength bolts are recommended for joint design.

(4) The predicated rotation factors show that for joints experiencing moderate and severe damages, the mean rotation factor deviates from the proposed theoretical values by 3.7% and 9.4%, respectively, with 95% lower confidence limits of 32.3% and 0.8%, respectively. These values enhance the accuracy of predicting the damage state of joints under damage states and can provide increased safety through redundancy.

Author Contributions

J.S.: Data curation. J.Z.: Investigation, Writing—original draft, Preparation. W.L.: Methodology, Validation. Y.L.: Experimental guidance. H.Y.: Supervision, Project administration. Q.L.: Conceptualization, Formal analysis. All authors have read and agreed to the published version of the manuscript.

Funding

This study was supported by the Hebei Province Natural Science Foundation Project (Nos. E2021208010, E2023208069, E2023208080), Central Government Guide Local Science and Technology Development Fund Project (No. 236Z5408G), and Hebei Province Higher Education Institutions Special Research Projects (Industry-University-Research Collaboration) (CXY2024045).

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

Author Jizhi Su was employed by the company State Grid Electric Power Co., Ltd., Economic and Technological Research Institute. Author Jinpu Zhou was employed by the company Hebei Airport Management Holding Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Gao, W.J.; Tang, G.W.; Lin, K. Earthquake Hazard to Steel Frame and Anti-earthquake Investigation. Technol. Highw. Transport. 2008, S2, 66–69. [Google Scholar]

- Gross, J.L. A connection model for the seismic analysis of welded steel moment frames. Eng. Struct. 1998, 20, 390–397. [Google Scholar] [CrossRef]

- Mahin, S.A. Lessons from damage to steel buildings during the Northridge earthquake. Eng. Struct. 1998, 20, 261–270. [Google Scholar] [CrossRef]

- Huang, B.S. Seismic Damage to Building Steel Structures in the Kobe Earthquake in Japan and Implications. Build. Struct. 2000, 9, 24–25. [Google Scholar] [CrossRef]

- Xiong, C.; Guo, Y.J.; Li, X. Research on mechanical properties of flush end plate semi-rigid beam-column joints. China Sci. Pap. 2019, 14, 1066–1071. [Google Scholar]

- Coelho, A.M.G.; Bijlaard, F.S. Experimental behaviour of high strength steel end-plate connections. J. Constr. Steel Res. 2006, 63, 1228–1240. [Google Scholar] [CrossRef]

- Coelho, A.M.G.; Bijlaard, F.S.; da Silva, L.S. Experimental assessment of the ductility of extended end plate connections. Eng. Struct. 2004, 26, 1185–1206. [Google Scholar] [CrossRef]

- Broderick, B.; Thomson, A. The response of flush end-plate joints under earthquake loading. J. Constr. Steel Res. 2002, 58, 1161–1175. [Google Scholar] [CrossRef]

- ENV 1993-1-8:2005; Eurocode 3: Design of Steel Structures—Part 1.8: Design of Joints. CEN: Brussels, Belgium, 2005.

- Faridmehr, I.; Tahir, M.M.; Lahmer, T. Classification System for Semi-Rigid Beam-to-Column Connections. Lat. Am. J. Solids Struct. 2016, 13, 2152–2175. [Google Scholar] [CrossRef]

- ANSI/AISC360-10; Specification for Structural Steel Buildings. American Institute of Steel Construction: Chicago, IL, USA, 2016.

- Qiang, X.H.; Ren, C.C.; Jiang, X.; Huang, Z. Experimental and Theoretical Study on Behavior of High Strength Steel Flush Endplate Connections under Fire Conditions. J. Tongji Univer. Nat. Sci. 2017, 45, 673–683. [Google Scholar] [CrossRef]

- Shi, G. Static and Seismic Behavior of Semirigid End-plate Connections in Steel Frames. Ph.D. Thesis, Tsinghua University, Beijing, China, 2004. [Google Scholar]

- Sun, F.F.; Sun, M.; Li, G.Q.; Xiao, Y.; Wei, M.; Liu, L. Experimental study on seismic behavior of high-strength steel beam-to-column end-plate connections. J. Build. Struct. 2014, 35, 116–124. [Google Scholar] [CrossRef]

- GB 50011-2010; Code for Seismic Design of Buildings. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2010.

- JGJ 99-2015; Technical Specification for Steel Structure of Tall Building. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2016.

- Thomson, A.W.; Broderick, B.M. Earthquake resistance of flush end-plate steel joints for moment frames. Proc. Inst. Civ. Eng. Struct. Build. 2002, 152, 157–165. [Google Scholar] [CrossRef]

- Abolmaali, A. Nonlinear Dynamic Finite Element Analysis of Steel Frames with Semi-Rigid Joints. Ph.D. Thesis, University of Oklahoma, Norman, OK, USA, 1999. [Google Scholar]

- Wang, Y.; Wang, Z.; Pan, J.; Wang, P. Seismic Behavior of a Novel Blind Bolted Flush End-Plate Connection to Strengthened Concrete-Filled Steel Tube Columns. Appl. Sci. 2020, 10, 2517. [Google Scholar] [CrossRef]

- Dong, S. Experimental Research on Behavior of Flush End-plate Composite Joints under Positive Moment. Master’s Thesis, Nanjing University of Technology, Nanjing, China, 2006. [Google Scholar]

- Shek, P.; Tahir, M.; Sulaiman, A.; Tan, C. Experimental Evaluation of Flush End—Plate Connection with Built-up Hybrid Beam Section. Adv. Struct. Eng. 2012, 15, 331–341. [Google Scholar] [CrossRef]

- Zheng, D.S. Experimental Study on Seismic Behaviours of Flush End-Plate Composite Joints. Master’s Thesis, Nanjing University of Technology, Nanjing, China, 2005. [Google Scholar]

- Lu, Y.; Zhang, L.; Jiang, Y.H. Bearing Capacity for Flush End-plated Connections Between Rectangular Tubular Columns and H-shaped Beams with Single Direction Bolts. J. Tongji Univ. Nat. Sci. 2018, 46, 162–169. [Google Scholar] [CrossRef]

- Lu, P.; Yang, J.; Ran, T.; Wang, W. Experimental study on flexural capacity and fire resistance of high strength Q690 steel flush end-plate connections. Thin-Walled Struct. 2023, 184, 110506. [Google Scholar] [CrossRef]

- Loh, H.; Uy, B.; Bradford, M. The effects of partial shear connection in composite flush end plate joints Part I—Experimental study. J. Constr. Steel Res. 2005, 62, 378–390. [Google Scholar] [CrossRef]

- Lin, R.D. Finite Element and Experiment Analysis on Flush End-plate Beam-column Joint of Portal Frame. Ind. Constr. 2012, 42, 128–132+138. [Google Scholar] [CrossRef]

- Aydın, A.C.; Maali, M.; Kılıç, M.; Sağıroğlu, M. Experimental investigation of sinus beams with end-plate connections. Thin-Walled Struct. 2015, 97, 35–43. [Google Scholar] [CrossRef]

- Keipour, N.; Valipour, H.; Bradford, M. Experimental study of steel-timber composite (STC) beam to steel column joints having a flush end-plate. Eng. Struct. 2018, 174, 906–918. [Google Scholar] [CrossRef]

- da Silva, L.S.; de Lima, L.R.; Vellasco, P.C.d.S.; de Andrade, S.A. Behaviour of flush end-plate beam-to-column joints under bending and axial force. Steel Compos. Struct. 2004, 4, 77–94. [Google Scholar] [CrossRef]

- Li, D.S. Research on Mechanical Behavior of Concrete Filled Steel Tubular Column-Steel Beam Blind Bolted Joints. Ph.D. Thesis, Fuzhou University, Fuzhou, China, 2016. [Google Scholar]

- Wang, J.-F.; Han, L.-H.; Uy, B. Hysteretic behaviour of flush end plate joints to concrete-filled steel tubular columns. J. Constr. Steel Res. 2009, 65, 1644–1663. [Google Scholar] [CrossRef]

- Mohamed, N.; Farghaly, A.S.; Benmokrane, B.; Neale, K.W. Drift Capacity Design of Shear Walls Reinforced with Glass Fiber-Reinforced Polymer Bars. ACI Struct. J. 2014, 111, 1397. [Google Scholar] [CrossRef]

- E2126-11; Standard Test Methods for Cyclic (Reversed) Load Test for Shear Resistance of Vertical Elements of the Lateral Force Resisting Systems for Buildings1. American Society for Testingand Materials International: West Conshohocken, PA, USA, 2011.

- Liu, H.-Y.; Yang, B.; Kang, S.-B. Testing and analysis of composite floor systems under peripheral column removal scenarios. Procedia Eng. 2017, 210, 261–268. [Google Scholar] [CrossRef]

- Youngson, G.K.; Wang, Z.M.; Bose, B. An appraisal of the design rules in eurocode 3 for bolted end-plate joints by comparison with experimental results. Proc. Inst. Civ. Eng. Struct. Build. 1996, 116, 221–234. [Google Scholar] [CrossRef]

- GB51022-2015; Technical Code for Steel Structure of Light-Weight Building with Gabled Frames. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2015.

- CECS 260:2009; Technical Specification for Steel Structures with End-Plate Semi-Rigid Connection. China Association for Engineering Construction: Beijing, China, 2009.

- Design Guide 16: Flush and Extended Multiple-Row Moment End-Plate Connections. American Institute of Steel Construction, Chicago. 2002. Available online: https://www.aisc.org/Design-Guide-16-Flush-and-Extended-Multiple-Row-Moment-End-Plate-Connections (accessed on 6 September 2023).

- GB 50017-2017; Standard for Design of Steel Structures. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2017.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).