Towards Sustainable Construction: Evaluating Thermal Conductivity in Advanced Foam Concrete Mixtures

Abstract

1. Introduction

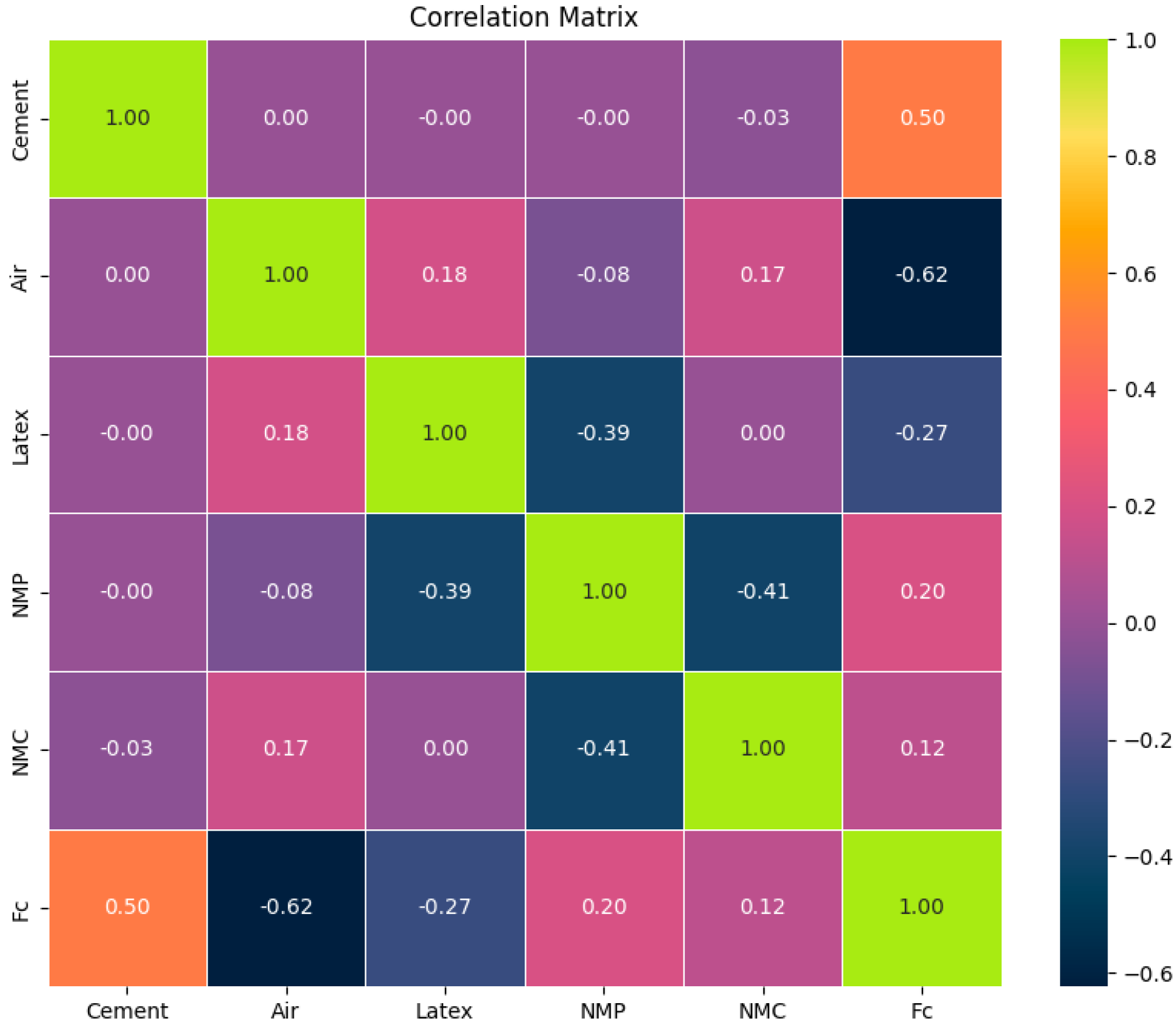

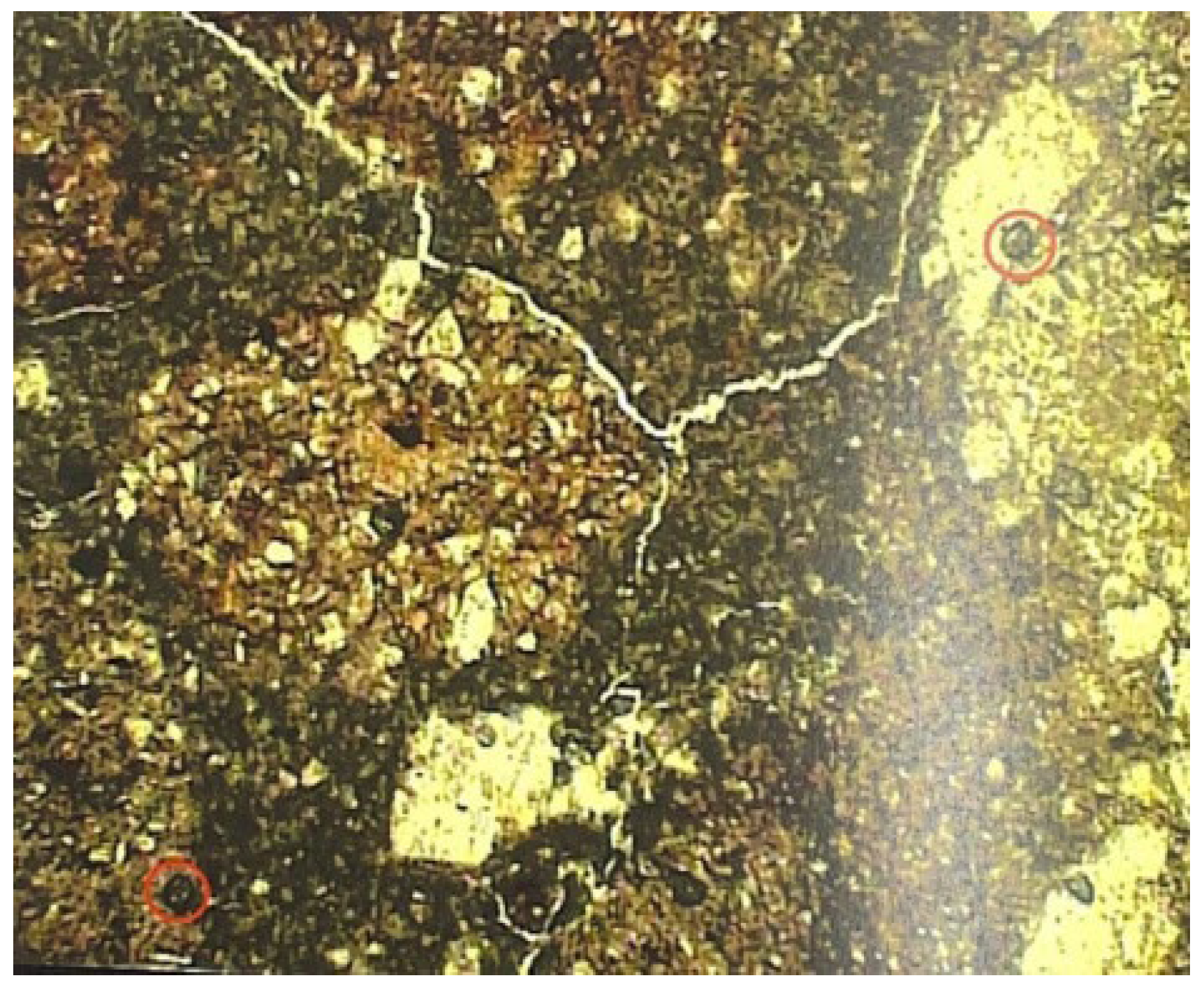

2. Experimental Design

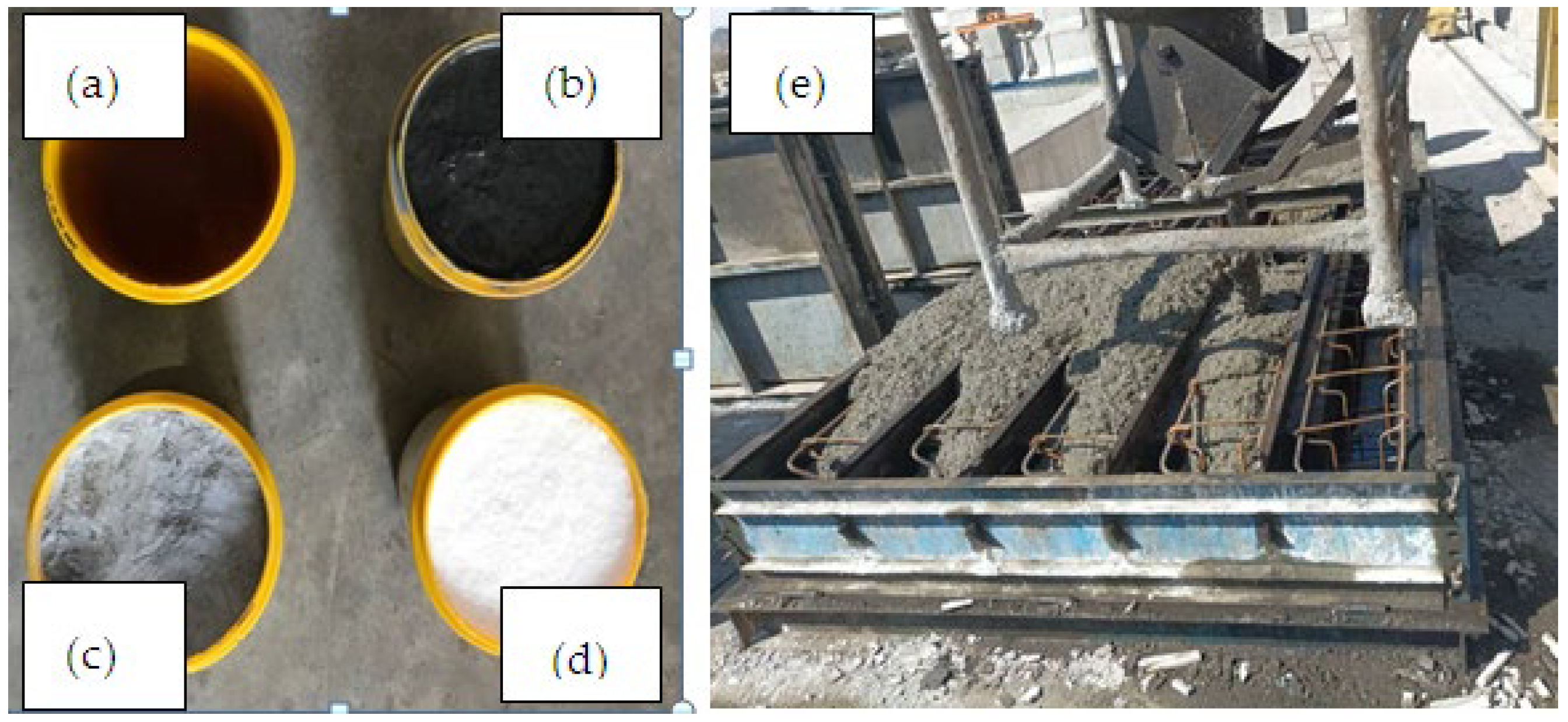

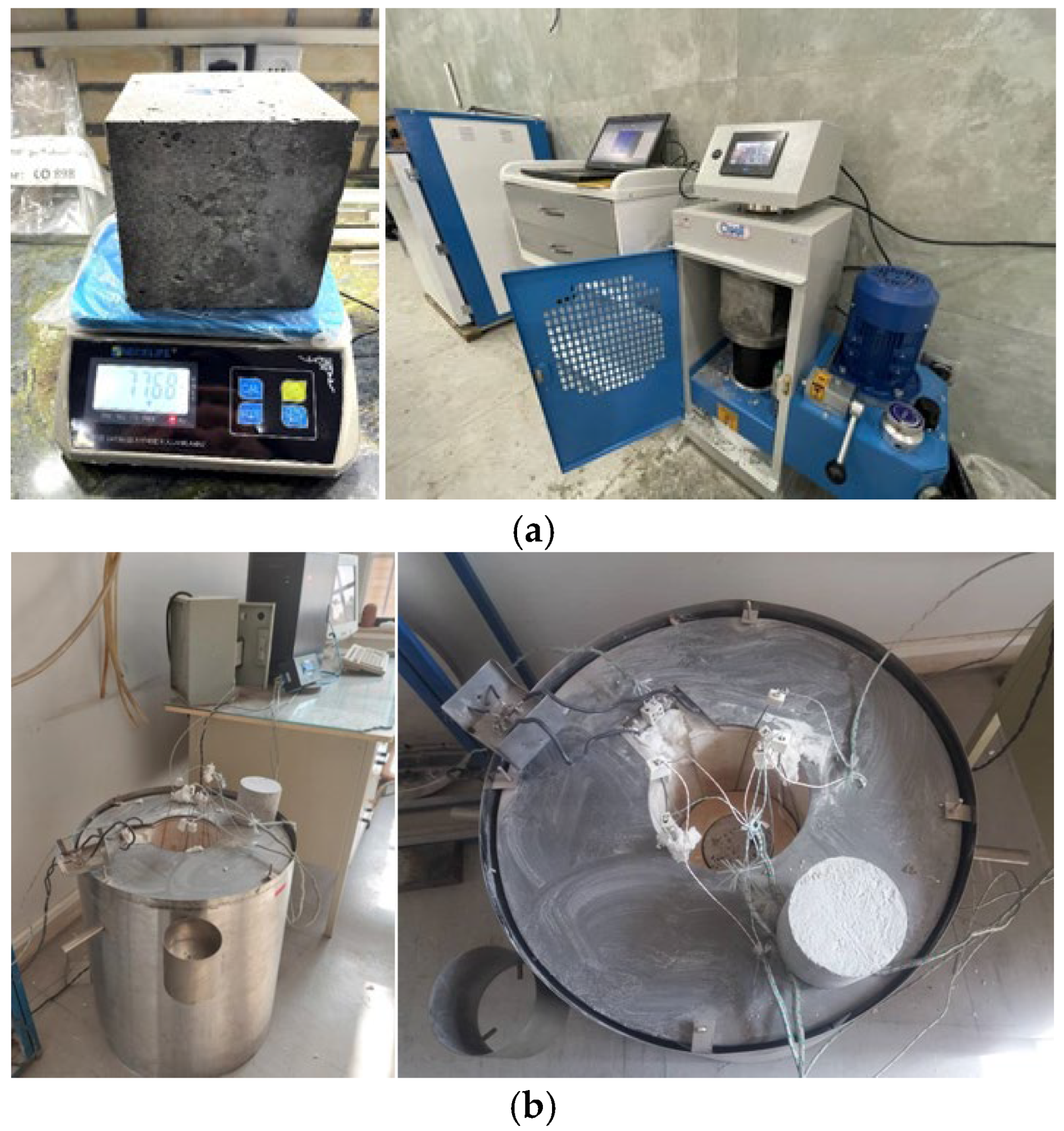

2.1. Used Materials and Testing Program

2.2. Implementation of Precast Concrete Panels for Interior Wall Systems

2.3. Test Standards

3. Results and Discussions

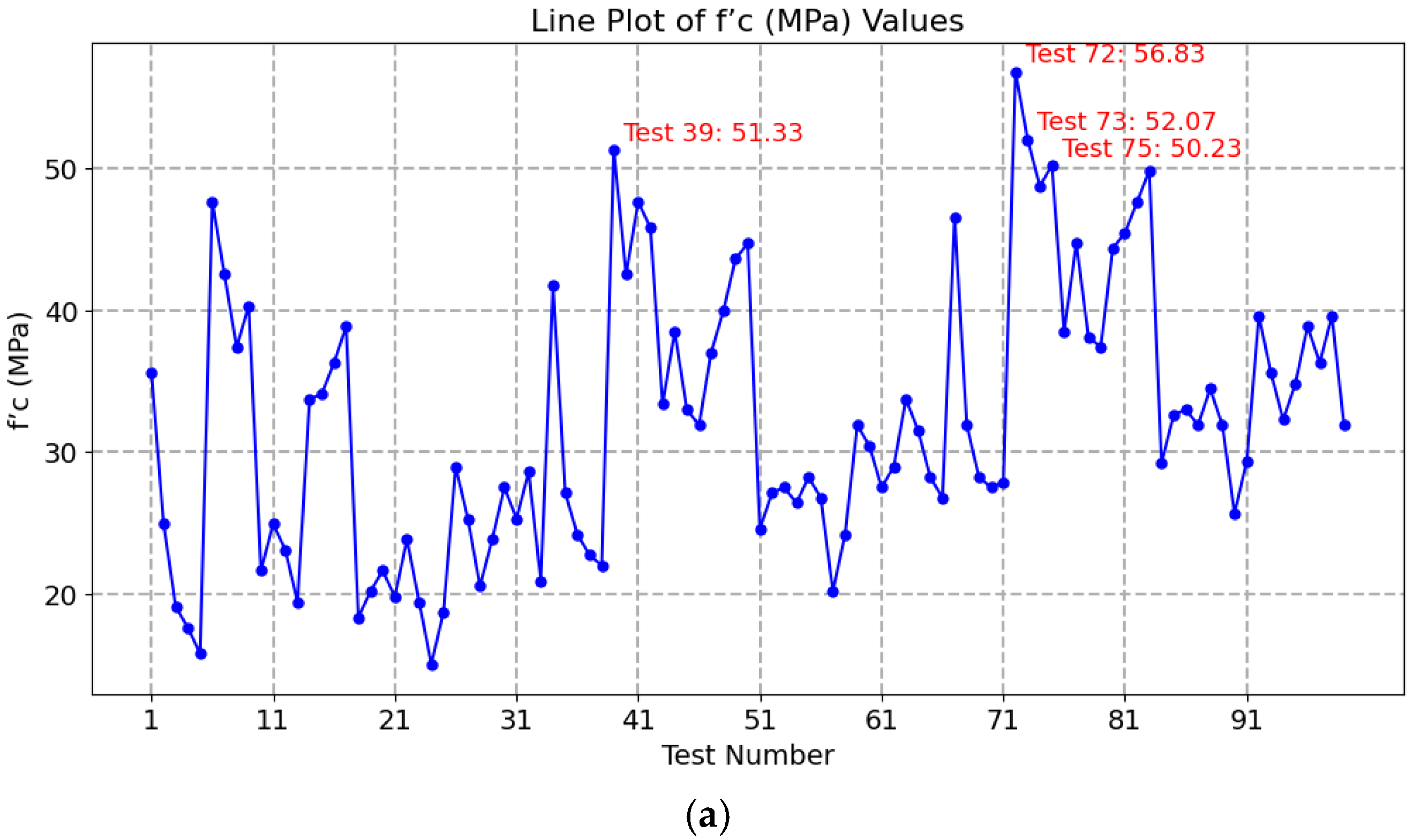

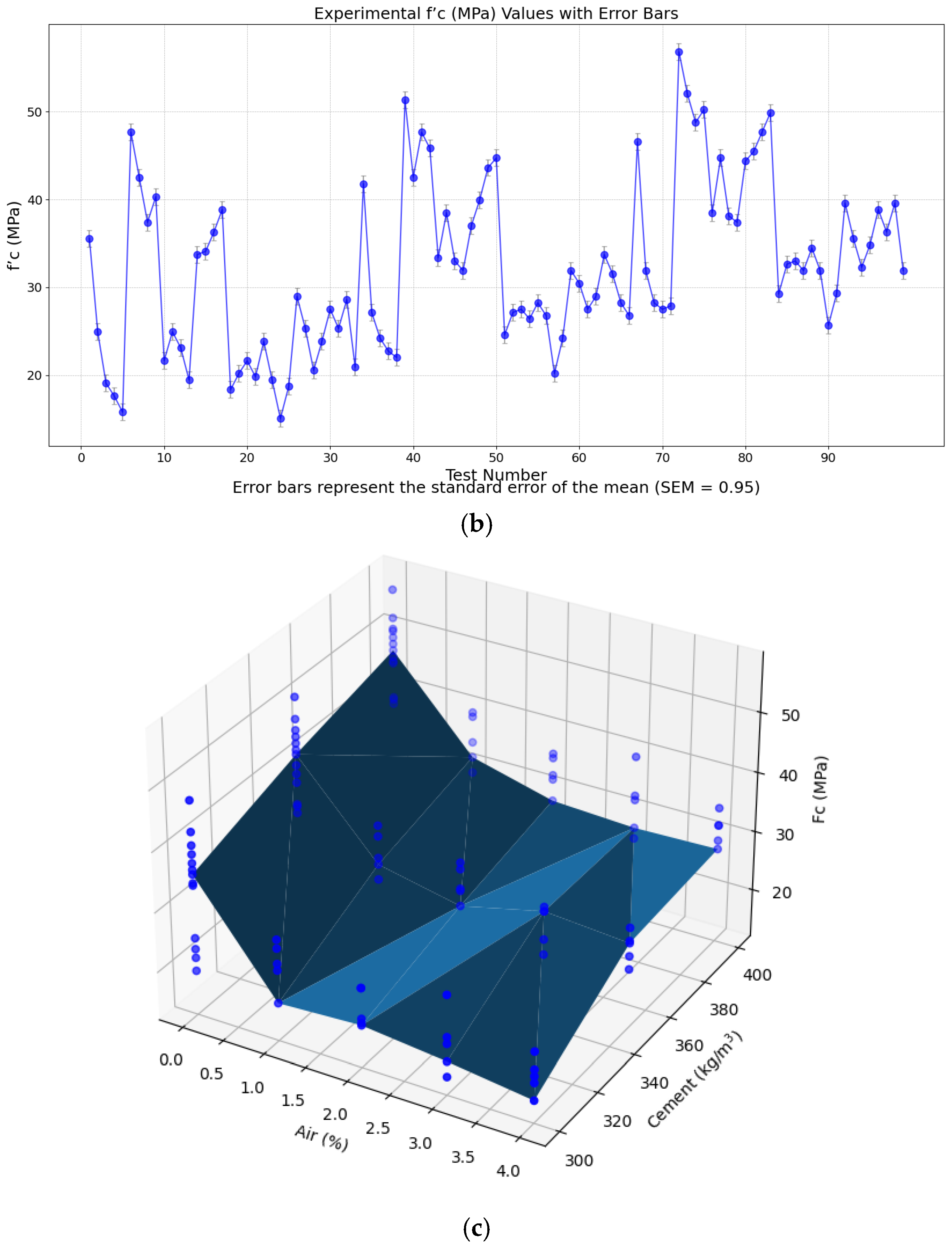

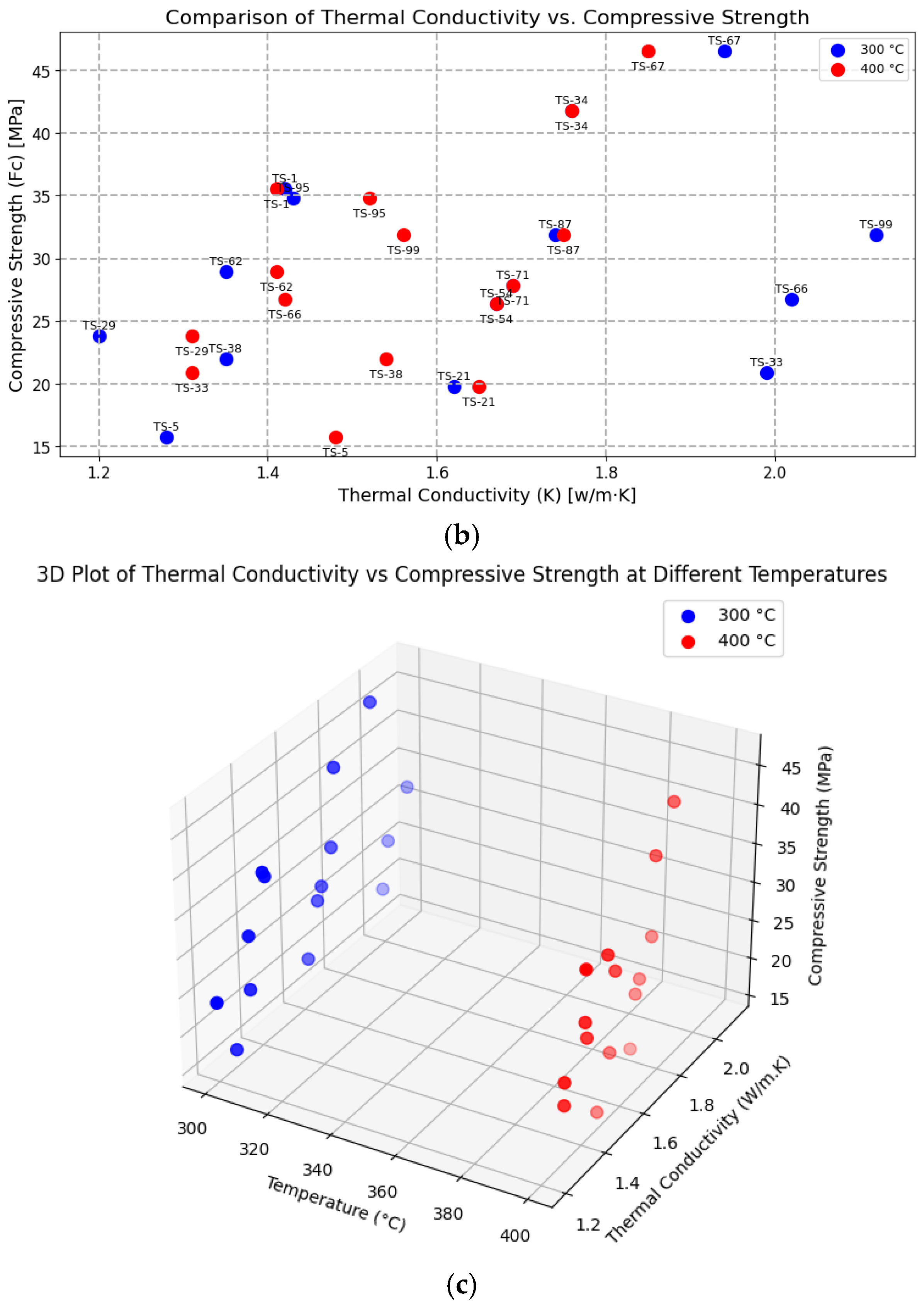

3.1. Compressive Strength Tests

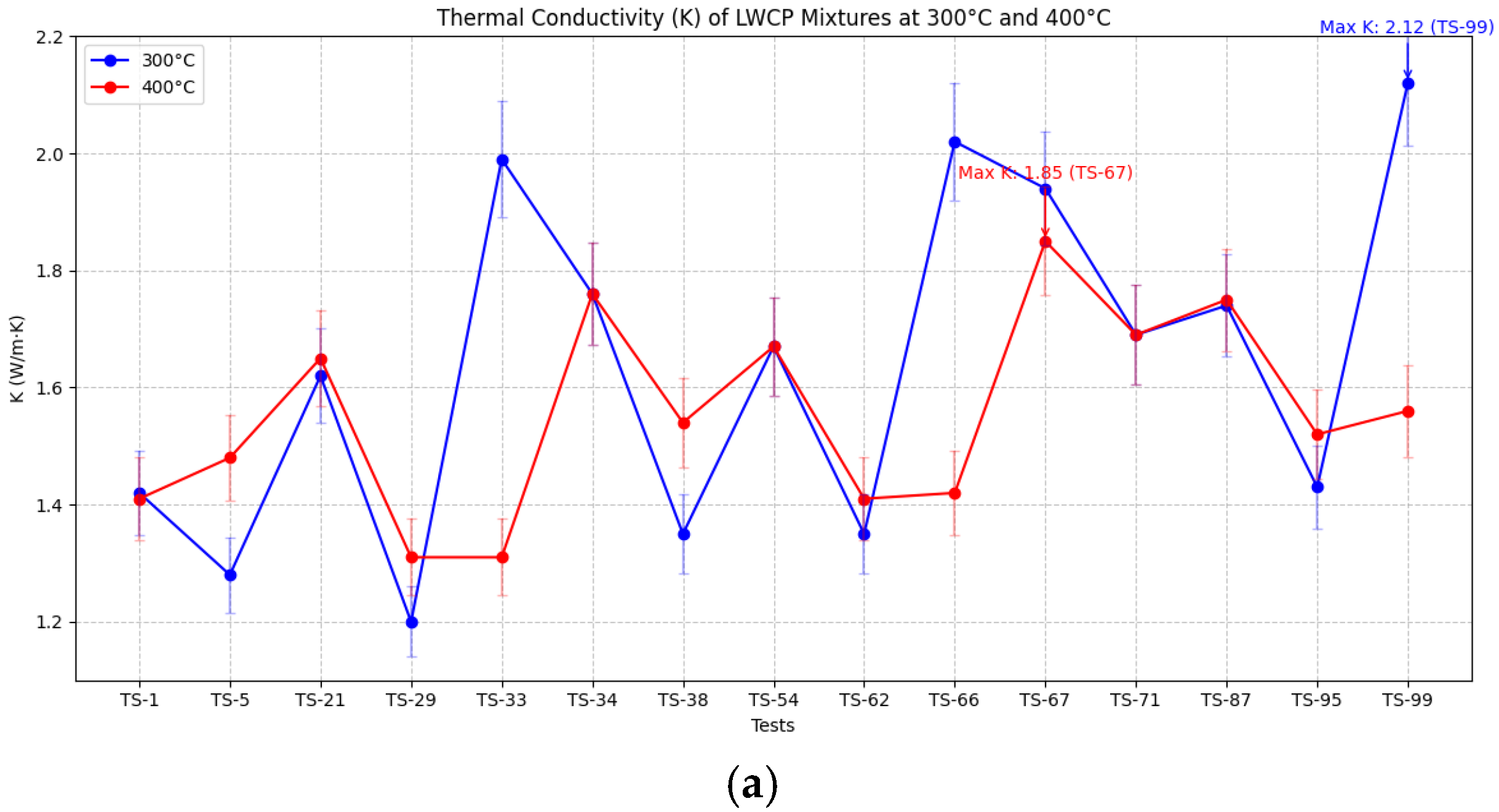

3.2. Thermal Conductivity Tests

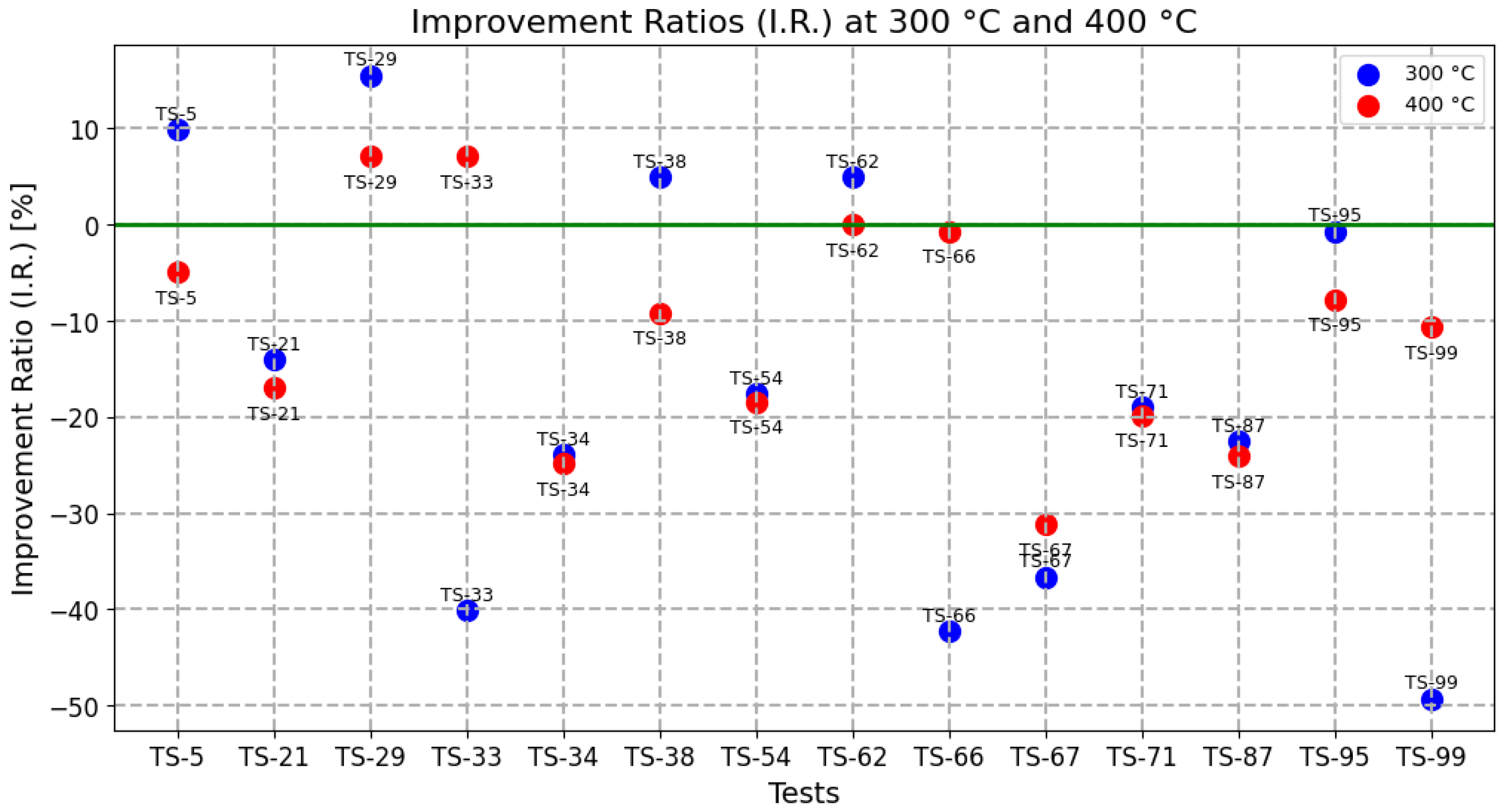

3.3. Improvement Ratio of the Thermal Conductivity Tests

3.4. Energy Saving Estimation

- Heat Transfer Equation: Q = k × A × (ΔT/d)

- Q = Heat transfer rate (W)

- k = Thermal conductivity (W/m·K)

- A = Surface area (m2)

- ΔT = Temperature difference (K)

- d = Wall thickness (m)

- Assumptions:

- Indoor temperature: 20 °C

- Average outdoor temperature during heating season: 0 °C

- Heating season duration: 180 days

- Comparison:

- (a)

- Standard concrete panel: k = 1.42 W/m·K (baseline value)

- (b)

- Optimized PCP (TS-29): k = 1.20 W/m·K

- Calculations:

- Heat transfer rate for standard panel:

- Q_std = 1.42 × 4000 × (20/0.15) = 756,800 W

- Heat transfer rate for optimized PCP:

- Q_opt = 1.20 × 4000 × (20/0.15) = 640,000 W

- Energy Savings:

- Daily energy saving: (756,800–640,000) × 24 h = 2,803,200 Wh = 2803.2 kWh

- Seasonal energy saving: 2803.2 kWh × 180 days = 504,576 kWh

- Cost Savings:

- Assuming an electricity cost of USD 0.12 per kWh:

- Annual cost saving: 504,576 kWh × USD 0.12 = USD 60,549.12

4. Conclusions

- The most effective mixture (TS-29) incorporated 4% air bubbles and 13% nano microsilica powder (NMP), achieving thermal conductivities of 1.31 W/m·K and 1.20 W/m·K at 300 °C and 400 °C, respectively. This represents a 7% and 15.5% improvement compared to the baseline, demonstrating significant potential for energy savings in building applications.

- While air entrainment effectively reduced thermal conductivity, it also lowered compressive strength. This highlights the importance of carefully balancing air content to achieve optimal performance in both areas.

- Latex addition, while beneficial for compressive strength, proved detrimental to thermal insulation, increasing conductivity. This suggests latex is unsuitable for PCP applications where thermal performance is a primary concern.

- Nano microsilica compound (NMC) additions exhibited a complex relationship with both thermal conductivity and compressive strength, generally increasing both. Further investigation is warranted to fully understand the influence of NMC on overall PCP performance.

5. Limitations of the Current Study and Recommendations for Future Research

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Test | Cement Dosage | Additives | Additive Percentage (%) |

|---|---|---|---|

| TS-1 | 300 | None | 0 |

| TS-2 | 300 | Air bubbles | 1 |

| TS-3 | 300 | Air bubbles | 2 |

| TS-4 | 300 | Air bubbles | 3 |

| TS-5 | 300 | Air bubbles | 4 |

| TS-6 | 300 | NMC | 5 |

| TS-7 | 300 | NMC | 6 |

| TS-8 | 300 | NMC | 7 |

| TS-9 | 300 | NMC | 8 |

| TS-10 | 300 | Latex | 2 |

| TS-11 | 300 | Latex | 3 |

| TS-12 | 300 | Latex | 4 |

| TS-13 | 300 | Latex | 5 |

| TS-14 | 300 | NMP | 10 |

| TS-15 | 300 | NMP | 11 |

| TS-16 | 300 | NMP | 12 |

| TS-17 | 300 | NMP | 13 |

| TS-18 | 300 | Air bubbles and NMC | 1–5 |

| TS-19 | 300 | Air bubbles and NMC | 2–6 |

| TS-20 | 300 | Air bubbles and NMC | 3–7 |

| TS-21 | 300 | Air bubbles and NMC | 3–8 |

| TS-22 | 300 | Air bubbles and Latex | 1–2 |

| TS-23 | 300 | Air bubbles and Latex | 2–3 |

| TS-24 | 300 | Air bubbles and Latex | 3–4 |

| TS-25 | 300 | Air bubbles and Latex | 4–5 |

| TS-26 | 300 | Air bubbles and NMP | 1–10 |

| TS-27 | 300 | Air bubbles and NMP | 2–11 |

| TS-28 | 300 | Air bubbles and NMP | 3–12 |

| TS-29 | 300 | Air bubbles and NMP | 4–13 |

| TS-30 | 300 | Air bubbles, NMC, and Latex | 1–5–2 |

| TS-31 | 300 | Air bubbles, NMC, and Latex | 2–6–3 |

| TS-32 | 300 | Air bubbles, NMC, and Latex | 3–7–4 |

| TS-33 | 300 | Air bubbles, NMC, and Latex | 4–8–5 |

| TS-34 | 350 | None | 0 |

| TS-35 | 350 | Air bubbles | 1 |

| TS-36 | 350 | Air bubbles | 2 |

| TS-37 | 350 | Air bubbles | 3 |

| TS-38 | 350 | Air bubbles | 4 |

| TS-39 | 350 | NMC | 5 |

| TS-40 | 350 | NMC | 6 |

| TS-41 | 350 | NMC | 7 |

| TS-42 | 350 | NMC | 8 |

| TS-43 | 350 | Latex | 2 |

| TS-44 | 350 | Latex | 3 |

| TS-45 | 350 | Latex | 4 |

| TS-46 | 350 | Latex | 5 |

| TS-47 | 350 | NMP | 10 |

| TS-48 | 350 | NMP | 11 |

| TS-49 | 350 | NMP | 12 |

| TS-50 | 350 | NMP | 13 |

| TS-51 | 350 | Air bubbles and NMC | 1–5 |

| TS-52 | 350 | Air bubbles and NMC | 2–6 |

| TS-53 | 350 | Air bubbles and NMC | 3–7 |

| TS-54 | 350 | Air bubbles and NMC | 3–8 |

| TS-55 | 350 | Air bubbles and Latex | 1–2 |

| TS-56 | 350 | Air bubbles and Latex | 2–3 |

| TS-57 | 350 | Air bubbles and Latex | 3–4 |

| TS-58 | 350 | Air bubbles and Latex | 4–5 |

| TS-59 | 350 | Air bubbles and NMP | 1–10 |

| TS-60 | 350 | Air bubbles and NMP | 2–11 |

| TS-61 | 350 | Air bubbles and NMP | 3–12 |

| TS-62 | 350 | Air bubbles and NMP | 4–13 |

| TS-63 | 350 | Air bubbles, NMC, and Latex | 1–5–2 |

| TS-64 | 350 | Air bubbles, NMC, and Latex | 2–6–3 |

| TS-65 | 350 | Air bubbles, NMC, and Latex | 3–7–4 |

| TS-66 | 350 | Air bubbles, NMC, and Latex | 4–8–5 |

| TS-67 | 400 | None | 0 |

| TS-68 | 400 | Air bubbles | 1 |

| TS-69 | 400 | Air bubbles | 2 |

| TS-70 | 400 | Air bubbles | 3 |

| TS-71 | 400 | Air bubbles | 4 |

| TS-72 | 400 | NMC | 5 |

| TS-73 | 400 | NMC | 6 |

| TS-74 | 400 | NMC | 7 |

| TS-75 | 400 | NMC | 8 |

| TS-76 | 400 | Latex | 2 |

| TS-77 | 400 | Latex | 3 |

| TS-78 | 400 | Latex | 4 |

| TS-79 | 400 | Latex | 5 |

| TS-80 | 400 | NMP | 10 |

| TS-81 | 400 | NMP | 11 |

| TS-82 | 400 | NMP | 12 |

| TS-83 | 400 | NMP | 13 |

| TS-84 | 400 | Air bubbles and NMC | 1–5 |

| TS-85 | 400 | Air bubbles and NMC | 2–6 |

| TS-86 | 400 | Air bubbles and NMC | 3–7 |

| TS-87 | 400 | Air bubbles and NMC | 3–8 |

| TS-88 | 400 | Air bubbles and Latex | 1–2 |

| TS-89 | 400 | Air bubbles and Latex | 2–3 |

| TS-90 | 400 | Air bubbles and Latex | 3–4 |

| TS-91 | 400 | Air bubbles and Latex | 4–5 |

| TS-92 | 400 | Air bubbles and NMP | 1–10 |

| TS-93 | 400 | Air bubbles and NMP | 2–11 |

| TS-94 | 400 | Air bubbles and NMP | 3–12 |

| TS-95 | 400 | Air bubbles and NMP | 4–13 |

| TS-96 | 400 | Air bubbles, NMC, and Latex | 1–5–2 |

| TS-97 | 400 | Air bubbles, NMC, and Latex | 2–6–3 |

| TS-98 | 400 | Air bubbles, NMC, and Latex | 3–7–4 |

| TS-99 | 400 | Air bubbles, NMC, and Latex | 4–8–5 |

References

- Zhang, Y.; Teoh, B.K.; Wu, M.; Chen, J.; Zhang, L. Data-Driven Estimation of Building Energy Consumption and GHG Emissions Using Explainable Artificial Intelligence. Energy 2023, 262, 125468. [Google Scholar] [CrossRef]

- Gursel, A.P.; Shehabi, A.; Horvath, A. Embodied Energy and Greenhouse Gas Emission Trends from Major Construction Materials of US Office Buildings Constructed After the Mid-1940s. Build. Environ. 2023, 234, 110196. [Google Scholar] [CrossRef]

- Osman, M.; Saad, M.M.; Ouf, M.; Eicker, U. From Buildings to Cities: How Household Demographics Shape Demand Response and Energy Consumption. Appl. Energy 2024, 356, 122359. [Google Scholar] [CrossRef]

- Miao, Y.; Ye, T.; Xiao, J.; Lau, S.S.Y.; Zhou, Z. Investigation on Alkali-Activated Insulation Mortar Containing High-Volume Recycled Concrete Powder for Energy-Efficient Buildings. Energy Build. 2024, 303, 113825. [Google Scholar] [CrossRef]

- O’Hegarty, R.; Amedeo, G.; Kinnane, O. The Impact of Compromised Insulation on Building Energy Performance. Energy Build. 2024, 316, 114337. [Google Scholar] [CrossRef]

- Mirnezami, S.; Hassani, A.; Baya, A. Evaluation of the Effect of Metallurgical Aggregates (Steel and Copper Slag) on the Thermal Conductivity and Mechanical Properties of Concrete in Jointed Plain Concrete Pavements (JPCP). Constr. Build. Mater. 2023, 367, 129532. [Google Scholar] [CrossRef]

- López-Rebollo, J.; Del Pozo, S.; Nieto, I.M.; Blázquez, C.S.; González-Aguilera, D. Experimental Study on the Thermal Properties of Pigmented Mortars for Use in Energy Efficiency Applications. J. Clean. Prod. 2023, 382, 135280. [Google Scholar] [CrossRef]

- Rashid, F.L.; Al-Obaidi, M.A.; Dulaimi, A.; Bernardo, L.F.A.; Eleiwi, M.A.; Mahood, H.B.; Hashim, A. A Review of Recent Improvements, Developments, Effects, and Challenges on Using Phase-Change Materials in Concrete for Thermal Energy Storage and Release. J. Compos. Sci. 2023, 7, 352. [Google Scholar] [CrossRef]

- Yan, L.; Yaghmour, E.; Scott, D.; Abu Qamar, M.I.; Fox, J.; Naito, C.; Neti, S.; Romero, C.E.; Sarunac, N.; Suleiman, M. Experimental Investigation of the Thermal Performance of Pervious Concrete Integrated with Phase Change Material for Dry Cooling Applications. Appl. Therm. Eng. 2024, 23, 121749. [Google Scholar] [CrossRef]

- Li, L.; Joseph, P.; Zhang, X.; Zhang, L. A Study of Some Relevant Properties of Concrete Incorporating Waste Ceramic Powder as a Cement Replacement Agent. J. Build. Eng. 2024, 87, 109106. [Google Scholar] [CrossRef]

- Haigh, R.; Sandanayake, M.; Sasi, S.; Yaghoubi, E.; Joseph, P.; Vrcelj, Z. Microstructural Attributes and Physiochemical Behaviours of Concrete Incorporating Various Synthetic Textile and Cardboard Fibres: A Comparative Review. J. Build. Eng. 2024, 86, 108690. [Google Scholar] [CrossRef]

- Chen, C.; Liu, X.; Liu, Z.; Shao, L.; Chang, H.; Liu, Q.; Miao, C.; Feng, P. Developing Heat-Conductive Concrete with Graphite-Modified Recycled Aggregates. Compos. Part B Eng. 2024, 284, 111721. [Google Scholar] [CrossRef]

- Gautam, A.; Tung, S. Advancing Sustainability in Concrete Construction: Enhancing Thermal Resilience and Structural Strength with Ground Granulated Blast Furnace Slag. Asian J. Civ. Eng. 2024, 25, 6119–6129. [Google Scholar] [CrossRef]

- Bai, Y.H.; Xie, Y.L.; Chen, Y. Innovative Multi-Functional Foamed Concrete Made from Rice Husk Ash: Thermal Insulation and Electromagnetic Wave Absorption. J. Mater. Sci. 2024, 59, 16112–16128. [Google Scholar] [CrossRef]

- Gedik, E.; Atmaca, A. An Experimental Study Investigating the Effects of Bentonite Clay on Mechanical and Thermal Properties of Concrete. Constr. Build. Mater. 2023, 383, 131279. [Google Scholar] [CrossRef]

- Lan, X.L.; Zhu, H.S.; Zeng, X.H.; Long, G.C.; Xie, Y.J. How Nano-Bubble Water and Nano-Silica Affect the Air-Voids Characteristics and Freeze-Thaw Resistance of Air-Entrained Cementitious Materials at Low Atmospheric Pressure? J. Build. Eng. 2023, 69, 106179. [Google Scholar] [CrossRef]

- Priyatham, B.; Lakshmayya, M.T.S.; Chaitanya, D. Review on Performance and Sustainability of Foam Concrete. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Xu, T.; Garrecht, H. Effects of Mixing Techniques and Material Compositions on the Compressive Strength and Thermal Conductivity of Ultra-Lightweight Foam Concrete. Materials 2024, 17, 2640. [Google Scholar] [CrossRef]

- Abdellatief, M.; Ahmed, Y.M.; Taman, M.; Elfadaly, E.; Tang, Y.; Abadel, A.A. Physico-Mechanical, Thermal Insulation Properties, and Microstructure of Geopolymer Foam Concrete Containing Sawdust Ash and Egg Shell. J. Build. Eng. 2024, 90, 109374. [Google Scholar] [CrossRef]

- Bong, S.H.; Du, H. Sustainable Additive Manufacturing of Concrete with Low-Carbon Materials. In Sustainable Concrete Materials and Structures; Woodhead Publishing: Sawston, UK, 2024; pp. 317–341. [Google Scholar] [CrossRef]

- Beytekin, H.E.; Kaya, Y.; Mardani, A.; Sezer, F.Ş. Effect of Fiber Type, Size, and Utilization Rate on Mechanical and Thermal Properties of Lightweight Concrete Facade Panels. Struct. Concr. 2024, 25, 3824–3840. [Google Scholar] [CrossRef]

- Nguyen-Van, V.; Tran, P.; San Ha, N.; Xie, Y.M.; Aslani, F. Blast Resistance of 3D-Printed Bouligand Concrete Panels Reinforced with Steel Fibers: Numerical Investigations. Compos. Struct. 2024, 348, 118481. [Google Scholar] [CrossRef]

- Ma, W.; Kolb, T.; Rüther, N.; Meinlschmidt, P.; Chen, H.; Yan, L. Physical, Mechanical, Thermal and Fire Behaviour of Recycled Aggregate Concrete Block Wall System with Rice Husk Insulation. Energy Build. 2024, 320, 114560. [Google Scholar] [CrossRef]

- Mohamed, A.M.; Tayeh, B.A.; Majeed, S.S.; Aisheh, Y.I.A.; Salih, M.N.A. Ultra-Light Foamed Concrete Mechanical Properties and Thermal Insulation Perspective: A Comprehensive Review. J. CO2 Util. 2024, 83, 102827. [Google Scholar] [CrossRef]

- Salehpour, B.; Ghobadi, M.; Ge, H.; Moore, T. Effects of Thermal Mass on Transient Thermal Performance of Concrete-Based Walls and Energy Consumption of an Office Building. J. Build. Phys. 2023, 47, 92–120. [Google Scholar] [CrossRef]

- Gbekou, F.K.; Belloum, R.; Chennouf, N.; Agoudjil, B.; Boudenne, A.; Benzarti, K. Thermal Performance of a Building Envelope Including Microencapsulated Phase Change Materials (PCMs): A Multiscale Experimental and Numerical Investigation. Build. Environ. 2024, 253, 111294. [Google Scholar] [CrossRef]

- Mendes, V.F.; Cruz, A.S.; Gomes, A.P.; Mendes, J.C. A Systematic Review of Methods for Evaluating the Thermal Performance of Buildings through Energy Simulations. Renew. Sustain. Energy Rev. 2024, 189, 113875. [Google Scholar] [CrossRef]

- Uribe, D.; Vera, S.; Perino, M. Development and Validation of a Numerical Heat Transfer Model for PCM Glazing: Integration to EnergyPlus for Office Building Energy Performance Applications. J. Energy Storage 2024, 91, 112121. [Google Scholar] [CrossRef]

- Ding, X.; Yu, J.; Lin, J.; Chen, Z.; Li, J. Experimental Investigations of Prefabricated Lightweight Self-Insulating Foamed Concrete Wall Panels. Structures 2024, 61, 106001. [Google Scholar] [CrossRef]

- Shi, J.; Zhang, M.; Zhu, X.; Yalçınkaya, Ç.; Çopuroğlu, O.; Liu, Y. Evaluation of Thermal Insulation Capacity and Mechanical Performance of a Novel Low-Carbon Thermal Insulating Foam Concrete. Energy Build. 2024, 323, 114744. [Google Scholar] [CrossRef]

- Nilimaa, J. Smart materials and technologies for sustainable concrete construction. Dev. Built Environ. 2023, 15, 100177. [Google Scholar] [CrossRef]

- Patel, B.; Rathore, P.K.S.; Gupta, N.K.; Sikarwar, B.S.; Sharma, R.; Kumar, R.; Pandey, A. Location optimization of phase change material for thermal energy storage in concrete block for development of energy efficient buildings. Renew. Energy 2023, 218, 119306. [Google Scholar] [CrossRef]

- Acar, M.C.; Çelik, A.I.; Kayabaşı, R.; Şener, A.; Özdöner, N.; Özkılıç, Y.O. Production of perlite-based-aerated geopolymer using hydrogen peroxide as eco-friendly material for energy-efficient buildings. J. Mater. Res. Technol. 2023, 24, 81–99. [Google Scholar] [CrossRef]

- Raja, P.; Murugan, V.; Ravichandran, S.; Behera, L.; Mensah, R.A.; Mani, S.; Kasi, A.; Balasubramanian, K.B.N.; Sas, G.; Vahabi, H.; et al. A Review of Sustainable Bio-Based Insulation Materials for Energy-Efficient Buildings. Macromol. Mater. Eng. 2023, 308, 2300086. [Google Scholar] [CrossRef]

- Cuce, E.; Cuce, P.M.; Alvur, E.; Yilmaz, Y.N.; Saboor, S.; Ustabas, I.; Linul, E.; Asif, M. Experimental performance assessment of a novel insulation plaster as an energy-efficient retrofit solution for external walls: A key building material towards low/zero carbon buildings. Case Stud. Therm. Eng. 2023, 49, 103350. [Google Scholar] [CrossRef]

- Nwokediegwu, Z.Q.S.; Ilojianya, V.I.; Ibekwe, K.I.; Adefemi, A.; Etukudoh, E.A.; Umoh, A.A. Advanced materials for sustainable construction: A review of innovations and environmental benefits. Eng. Sci. Technol. J. 2024, 5, 201–218. [Google Scholar] [CrossRef]

- Yu, K.; Jia, M.; Tian, W.; Yang, Y.; Liu, Y. Enhanced thermo-mechanical properties of cementitious composites via red mud-based microencapsulated phase change material: Towards energy conservation in building. Energy 2024, 290, 130301. [Google Scholar] [CrossRef]

- Abdellatief, M.; Elrahman, M.A.; Alanazi, H.; Abadel, A.A.; Tahwia, A. A state-of-the-art review on geopolymer foam concrete with solid waste materials: Components, characteristics, and microstructure. Innov. Infrastruct. Solut. 2023, 8, 230. [Google Scholar] [CrossRef]

- ASTM C260-86; Standard Specification for Air-Entraining Admixtures for Concrete. ASTM: West Conshohocken, PA, USA, 1995.

- BS EN 12390-3:2019; Testing Hardened Concrete. Compressive Strength of Test Specimens. BSI: London, UK, 2019.

- ISO 8301; Thermal Insulation–Determination of Steady-State Thermal Resistance and Related Properties–Heat Flow Meter Apparatus. ISO: Genève, Switzerland, 1991.

| Reference Mixture | Cement Dosage (kg/m3) | W/C | W (kg) | C (kg) | G (Natural Coarse) | S (Fine Coarse) |

|---|---|---|---|---|---|---|

| I | 300 | 0.5 | 150 | 300 | 1135 | 730 |

| II | 350 | 0.5 | 175 | 350 | 1140 | 745 |

| III | 400 | 0.5 | 200 | 400 | 1160 | 756 |

| Properties | NMC | NMP | Latex |

|---|---|---|---|

| Particle Size | 0.3 µm | 50 nm | 100 nm |

| Density | 2.2 g/cm3 | 2.4 g/cm3 | 1.1 g/cm3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohtadi, A.; Ghomeishi, M.; Dehghanbanadaki, A. Towards Sustainable Construction: Evaluating Thermal Conductivity in Advanced Foam Concrete Mixtures. Buildings 2024, 14, 3636. https://doi.org/10.3390/buildings14113636

Mohtadi A, Ghomeishi M, Dehghanbanadaki A. Towards Sustainable Construction: Evaluating Thermal Conductivity in Advanced Foam Concrete Mixtures. Buildings. 2024; 14(11):3636. https://doi.org/10.3390/buildings14113636

Chicago/Turabian StyleMohtadi, Alireza, Mohammad Ghomeishi, and Ali Dehghanbanadaki. 2024. "Towards Sustainable Construction: Evaluating Thermal Conductivity in Advanced Foam Concrete Mixtures" Buildings 14, no. 11: 3636. https://doi.org/10.3390/buildings14113636

APA StyleMohtadi, A., Ghomeishi, M., & Dehghanbanadaki, A. (2024). Towards Sustainable Construction: Evaluating Thermal Conductivity in Advanced Foam Concrete Mixtures. Buildings, 14(11), 3636. https://doi.org/10.3390/buildings14113636