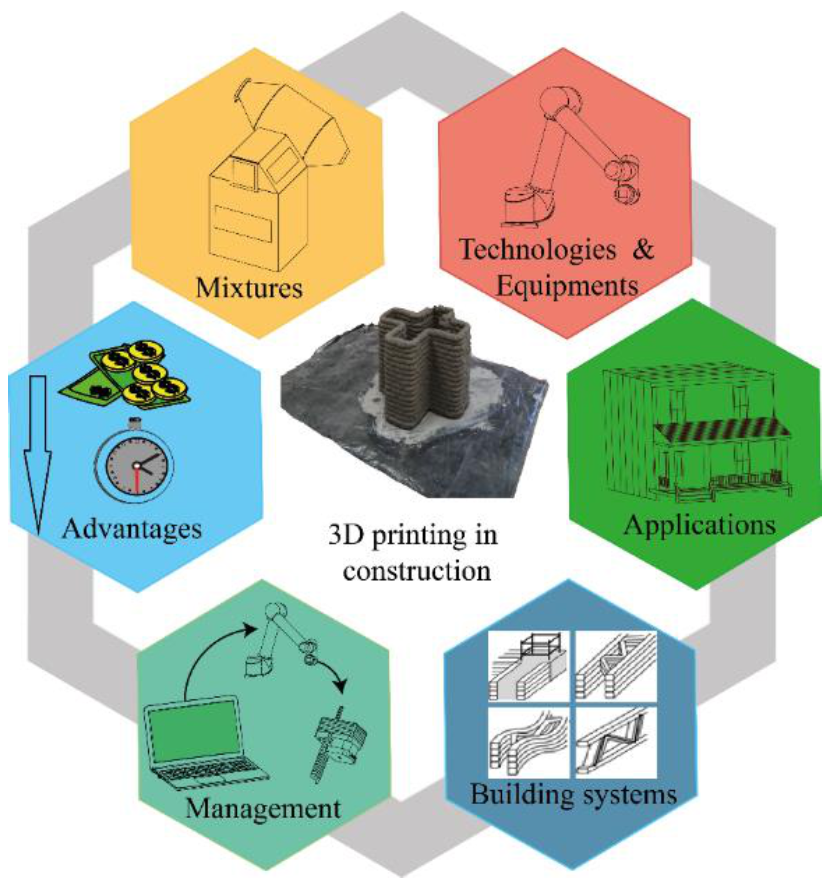

Recent Developments and Challenges of 3D-Printed Construction: A Review of Research Fronts

Abstract

1. Introduction

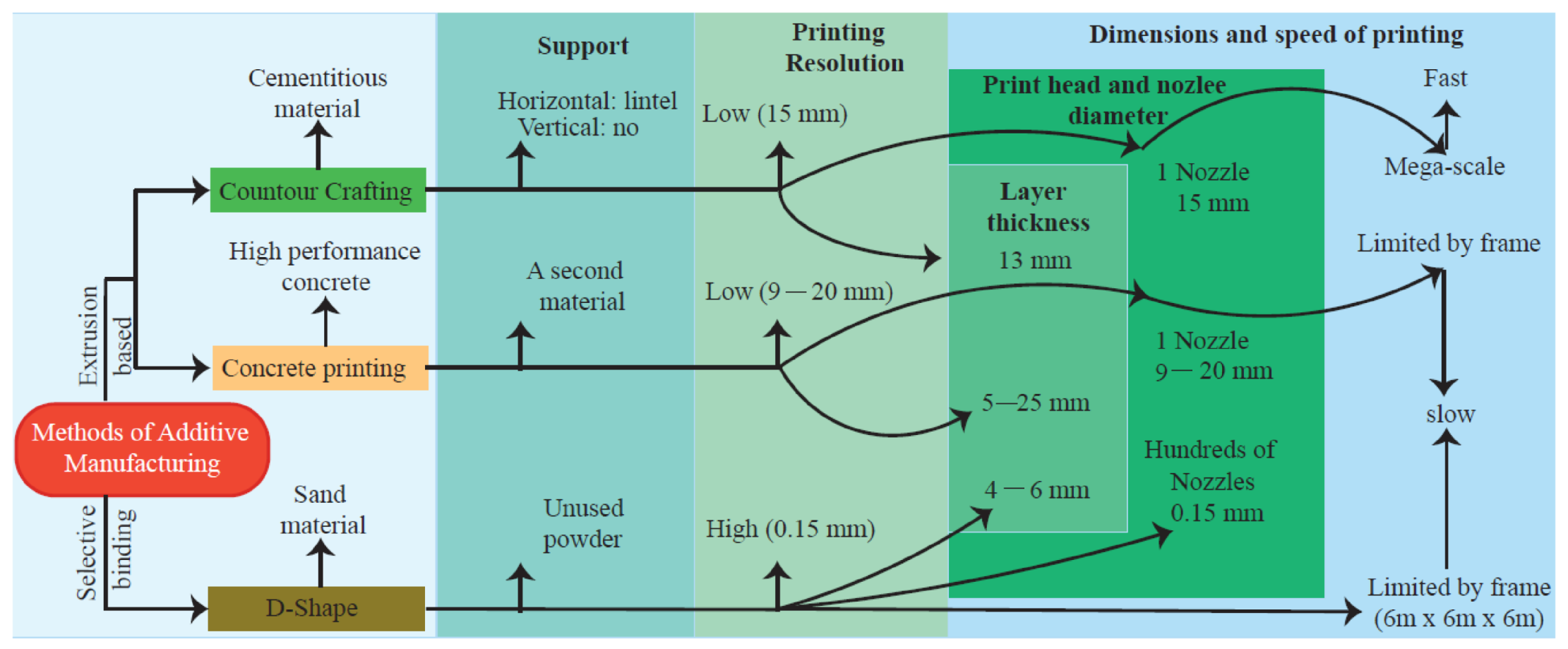

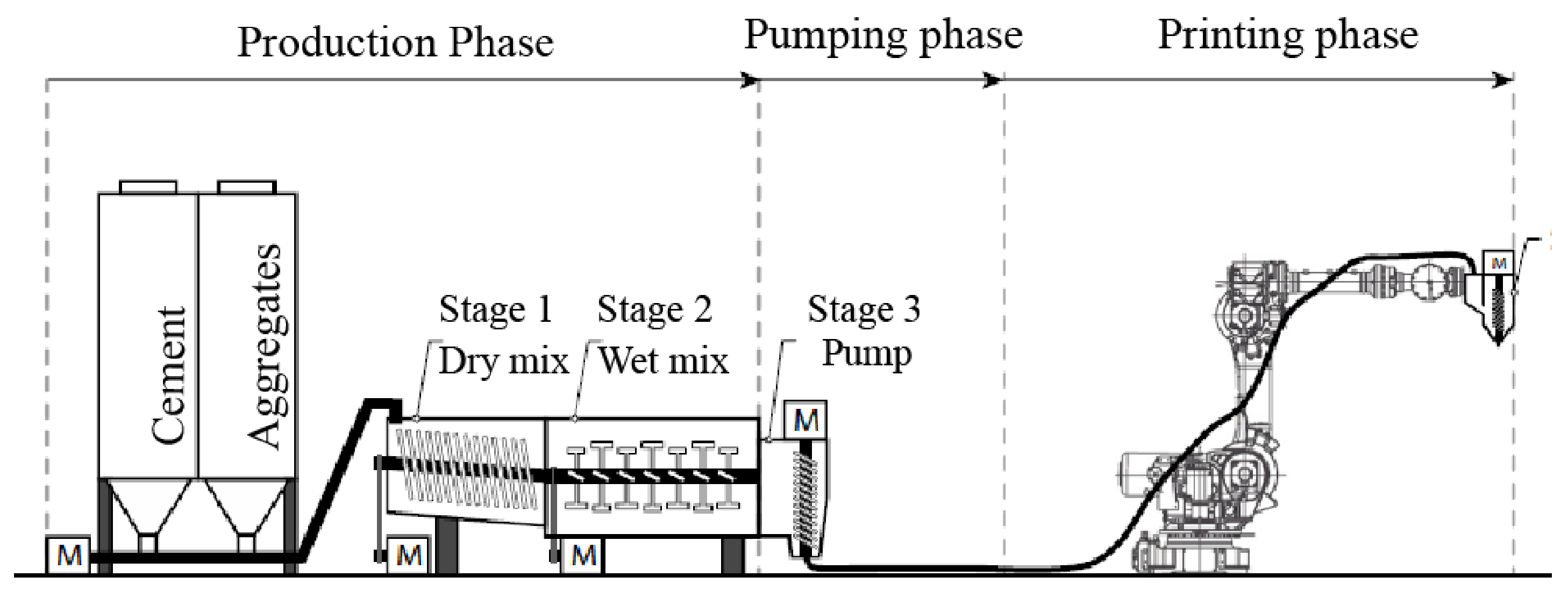

2. Mixtures

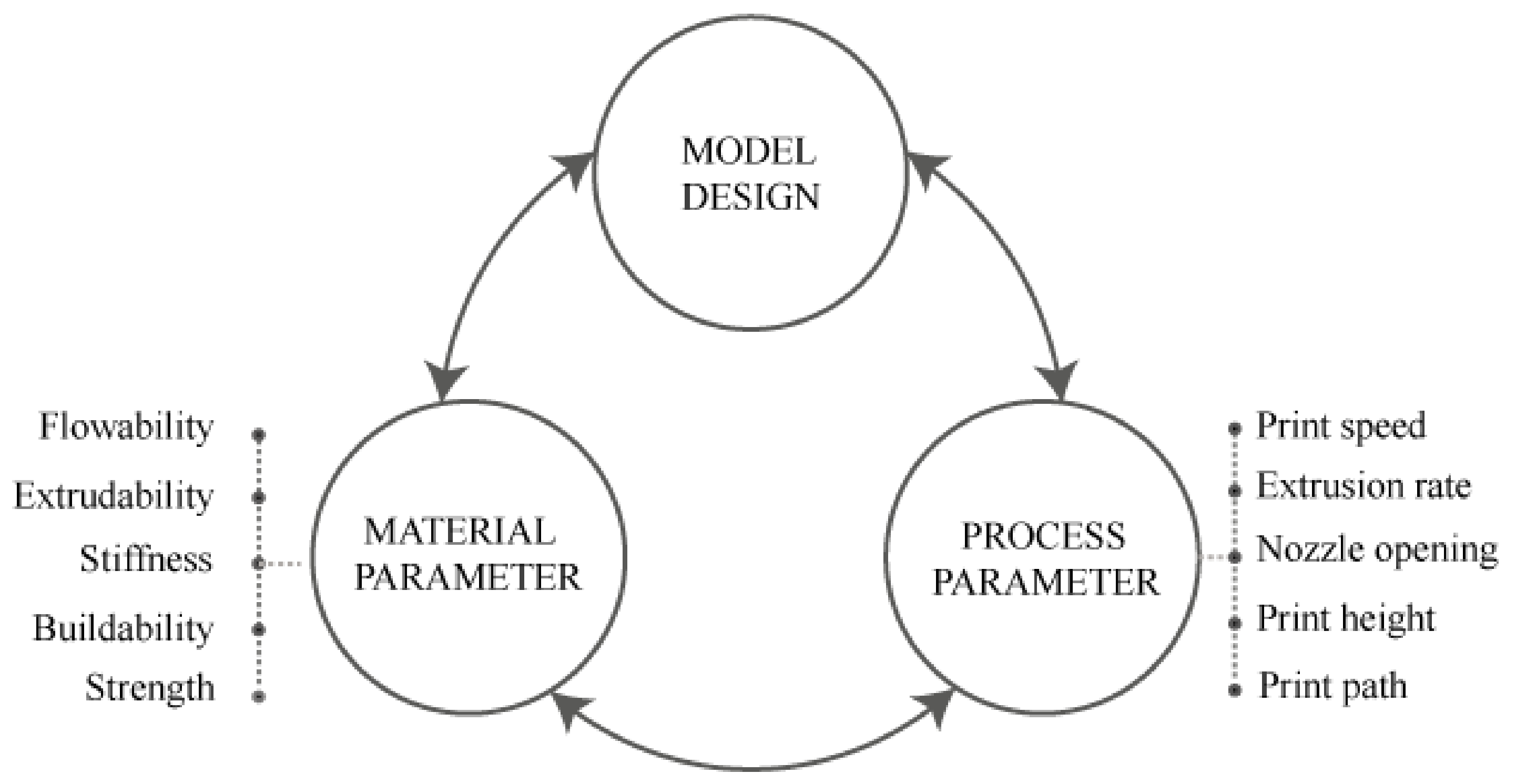

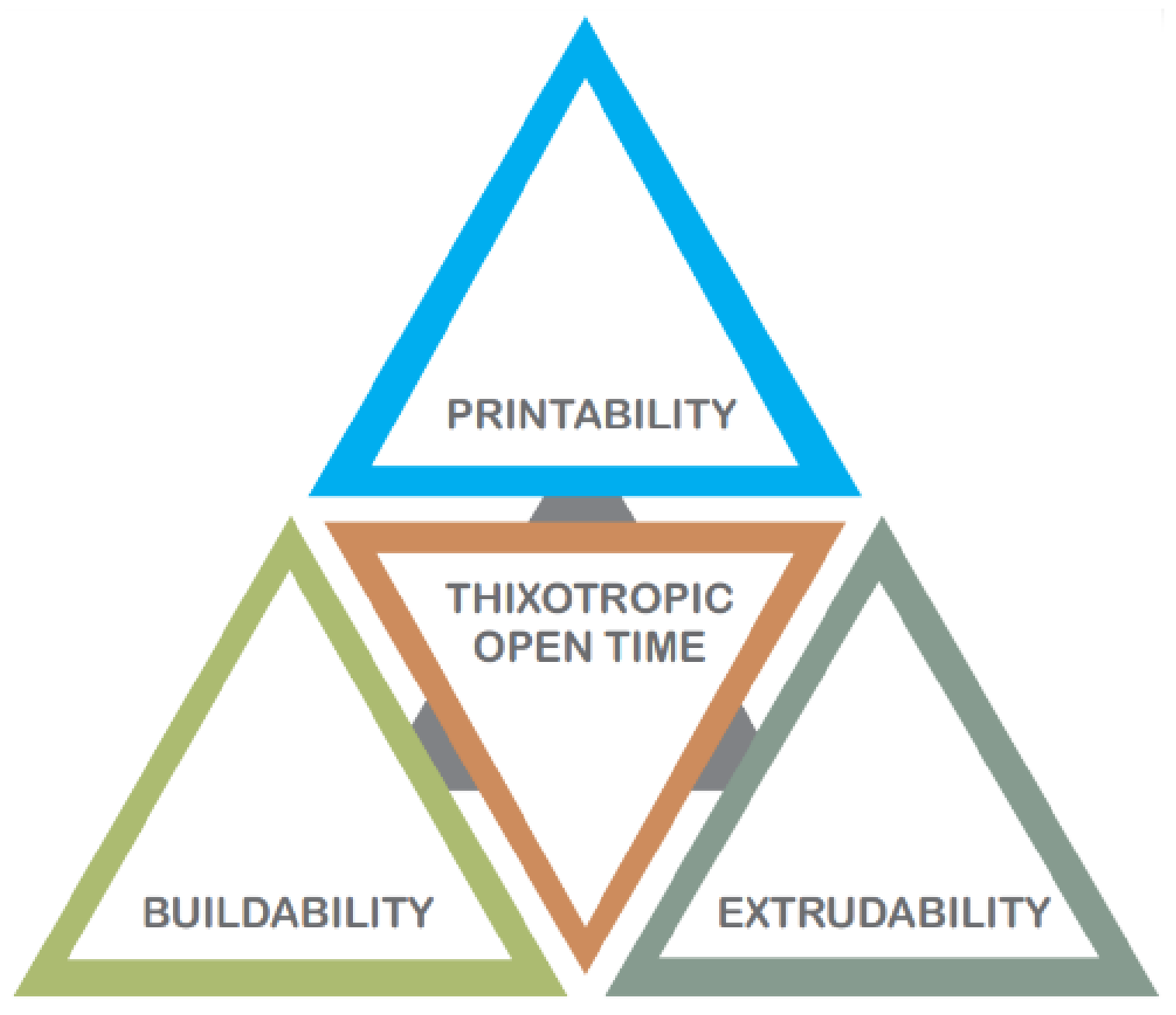

2.1. Critical Variables of the Concrete Printing Process

2.1.1. Extrudability

2.1.2. Open Time

2.1.3. Buildability

2.1.4. Shape Retention Factor (SRF)

2.1.5. Contraction Control

2.2. Dosages

2.3. Mixture Design

2.4. Addition of Fibers

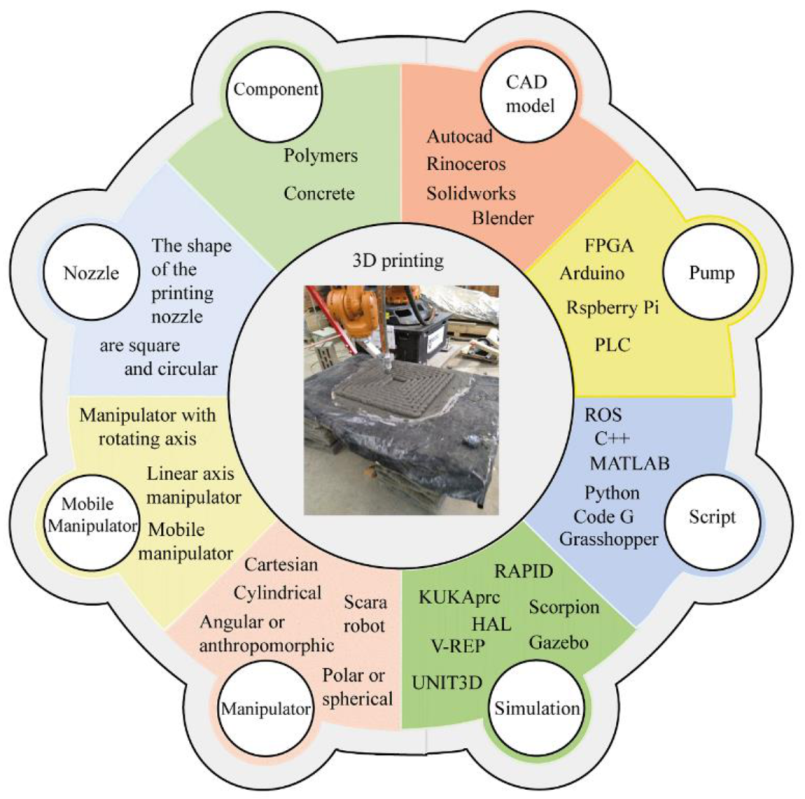

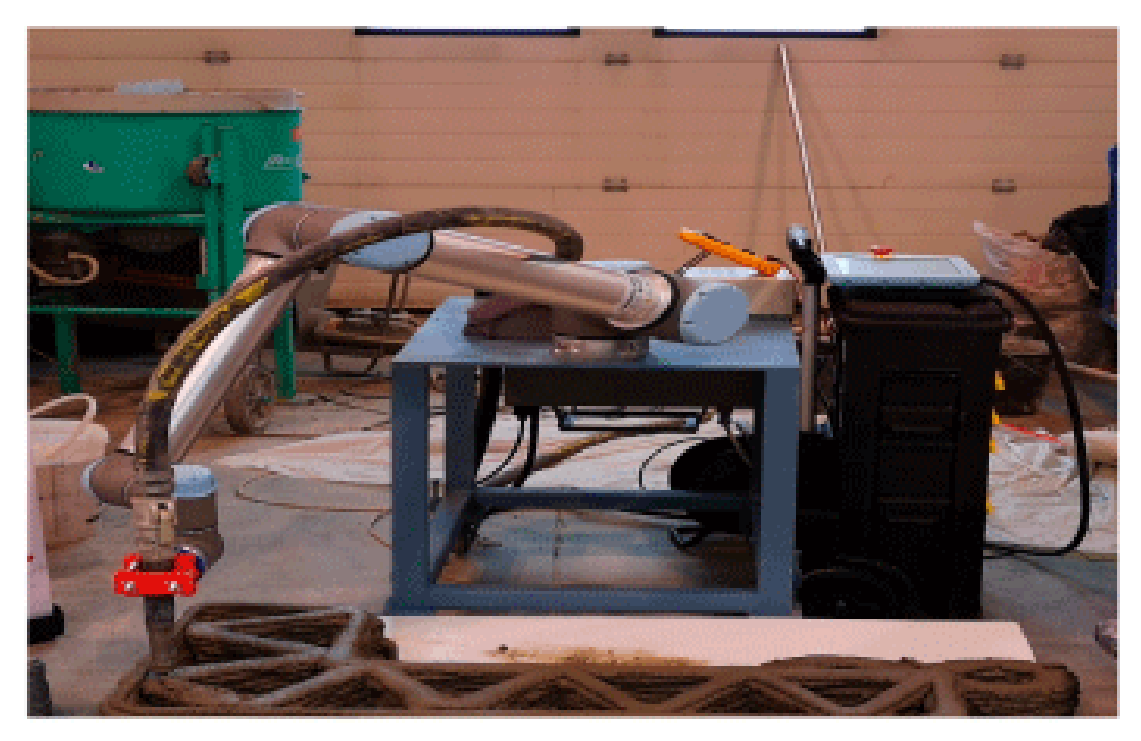

3. Technologies and Equipment

- Multidirectional AM: The control of direction between layers reduces the ladder effect and avoids the use of supports in conventional AM [41,42]. Furthermore, the degrees of freedom of the multi-directional configuration are assigned to the extrusion tool or the equipment’s base, thus allowing efficient printing of 3D models.

- Conformal AM: The strength of an element printed with AM techniques depends on the method of material deposition and the consistency between layers. The parameters to be considered are time, use of support structure, and printing direction, which can be efficiently managed through path generation algorithms [43].

- Assembling prefabricated components in AM: The integration of components during printing requires interaction between the process, the robot, and workers. Combining assemblies with human assistance generates orientation and positioning errors. To avoid these errors, the use of autonomous robots with a high degree of freedom allows efficient maneuverability within the workspace [41].

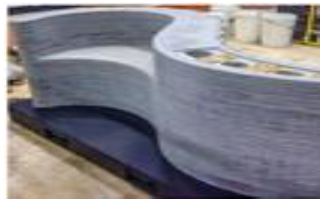

- Formwork-less AM: Improving the efficiency of the construction industry is one of the main challenges today. The use of formwork to produce concrete elements is a problem that generates delays and economic costs. Printing by extrusion makes it possible to eliminate the use of formwork. However, the model’s printing efficiency depends on how efficient the control is between the printing tool and the equipment base [41].

- Large-Scale: Printing systems in AM are usually gantry systems, robotic arms, and mobile manipulators. The challenge of these systems is to achieve large-scale printing. Based on this, gantry systems and robotic arms have a limited printing volume. Furthermore, the difference between these systems is that the robotic arm makes better use of its workspace. Despite mobile manipulators covering a larger workspace, these have low accuracy and low repeatability due to the use of a mobile base [41].

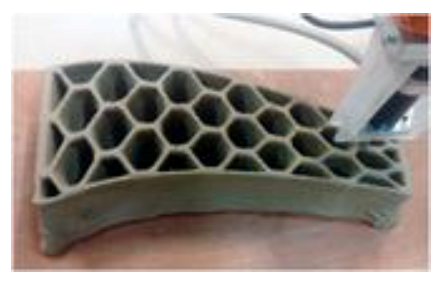

4. Applications

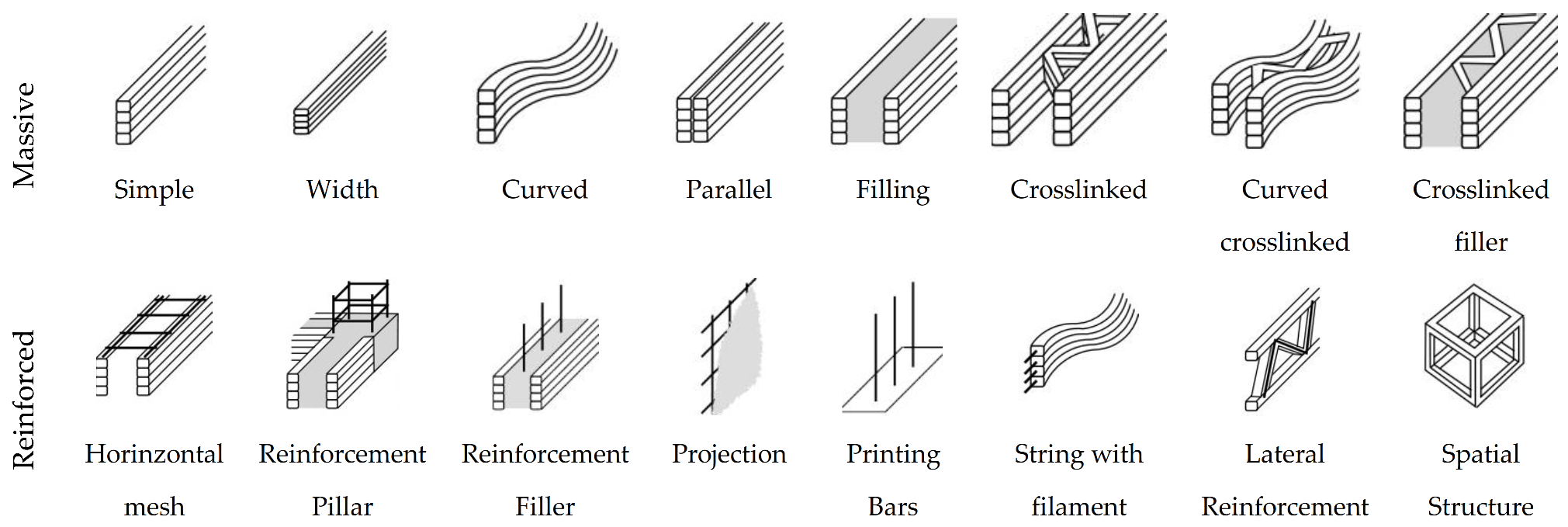

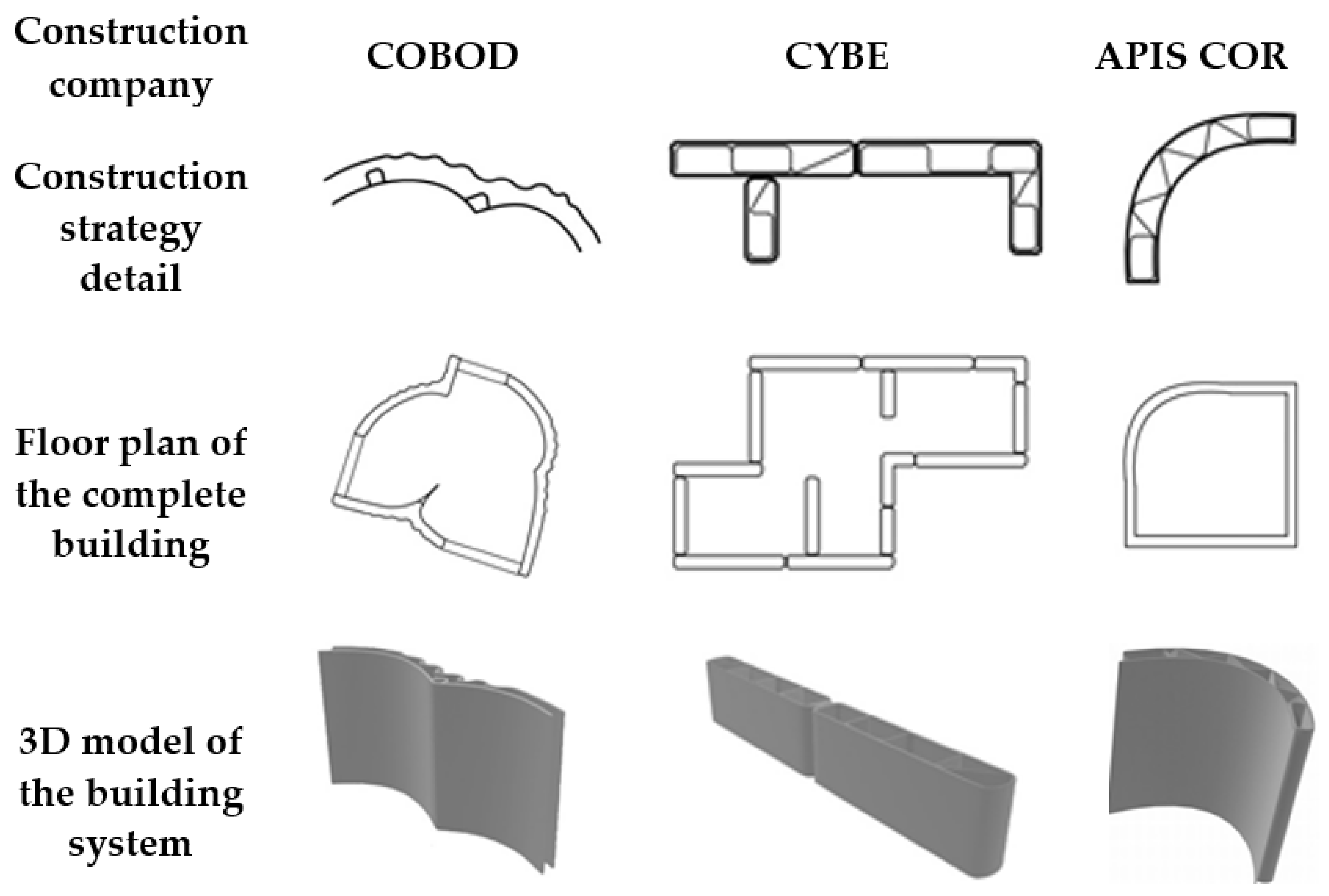

5. Building Systems

6. Management

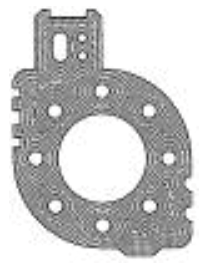

6.1. Programming

6.2. Print Nozzle

6.3. Short Description of Path Optimization Techniques in 3D-Printing Applications

6.4. Pump

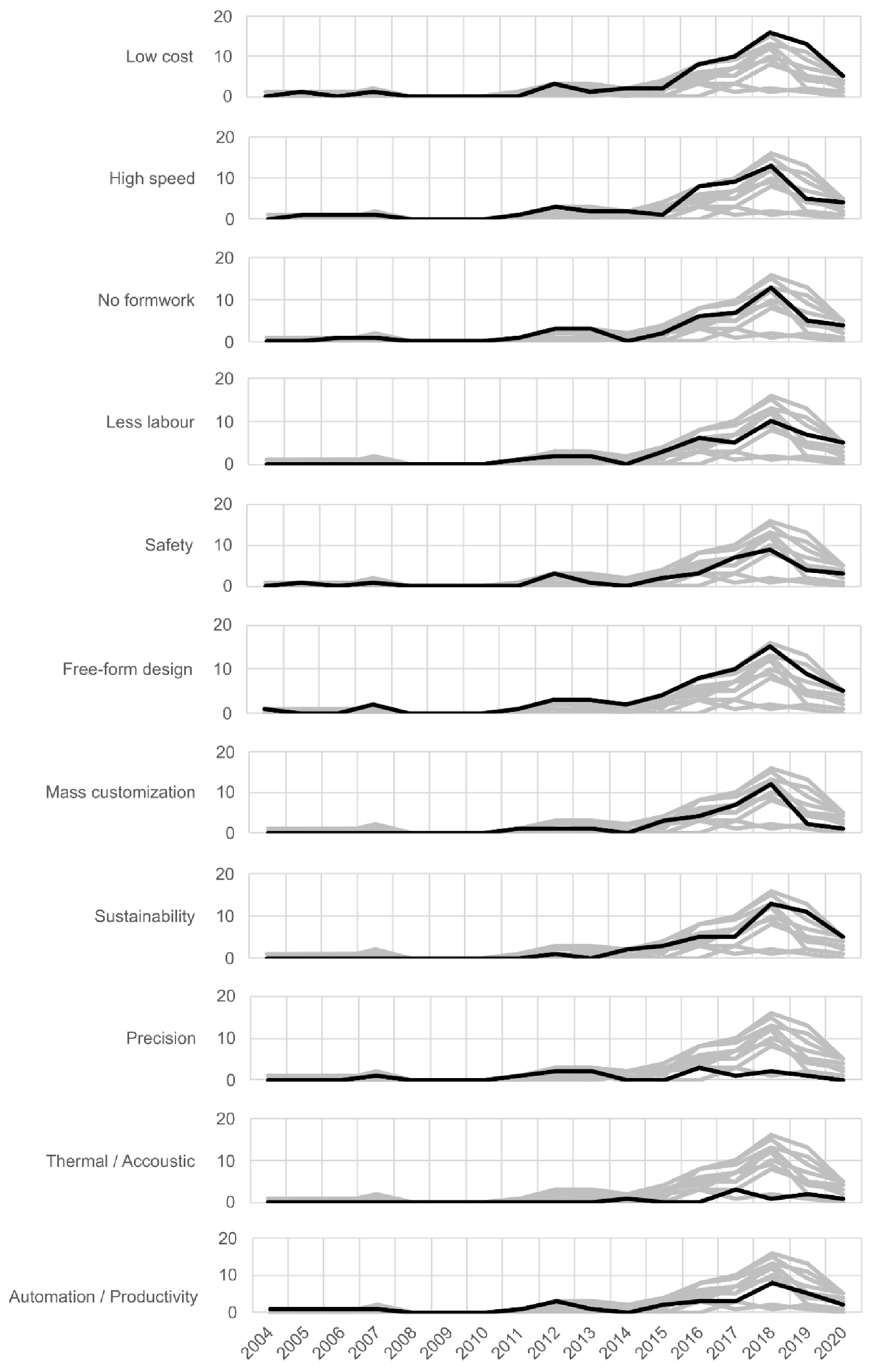

7. Advantages

8. Conclusions and Future Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Bogue, R. What are the prospects for robots in the construction industry? Ind. Rob. 2018, 45, 1–6. [Google Scholar] [CrossRef]

- Buchli, J.; Giftthaler, M.; Kumar, N.; Lussi, M.; Sandy, T.; Dörfler, K.; Hack, N. Digital in situ fabrication—Challenges and opportunities for robotic in situ fabrication in architecture, construction, and beyond. Cem. Concr. Res. 2018, 112, 66–75. [Google Scholar] [CrossRef]

- Sasson, A.; Johnson, J.C. The 3D printing order: Variability, supercenters and supply chain reconfigurations. Int. J. Phys. Distrib. Logist. Manag. 2016, 46, 82–94. [Google Scholar] [CrossRef]

- Chan, H.K.; Griffin, J.; Lim, J.J.; Zeng, F.; Chiu, A.S.F. The impact of 3D Printing Technology on the supply chain: Manufacturing and legal perspectives. Int. J. Prod. Econ. 2018, 205, 156–162. [Google Scholar] [CrossRef]

- Tahmasebinia, F.; Niemelä, M.; Sepasgozar, S.M.E.; Lai, T.Y.; Su, W.; Reddy, K.R.; Shirowzhan, S.; Sepasgozar, S.; Marroquin, F.A. Three-dimensional printing using recycled high-density polyethylene: Technological challenges and future directions for construction. Buildings 2018, 8, 165. [Google Scholar] [CrossRef]

- Sobotka, A.; Pacewicz, K. Mechanisation and automation technologies development in work at construction sites. IOP Conf. Ser. Mater. Sci. Eng. 2017, 251, 12046. [Google Scholar] [CrossRef]

- Gosselin, C.; Duballet, R.; Roux, P.; Gaudillière, N.; Dirrenberger, J.; Morel, P. Large-scale 3D printing of ultra-high performance concrete—A new processing route for architects and builders. Mater. Des. 2016, 100, 102–109. [Google Scholar] [CrossRef]

- Makul, N. Advanced smart concrete—A review of current progress, benefits and challenges. J. Clean. Prod. 2020, 274, 122899. [Google Scholar] [CrossRef]

- El-Sayegh, S.; Romdhane, L.; Manjikian, S. A critical review of 3D printing in construction: Benefits, challenges, and risks. Arch. Civ. Mech. Eng. 2020, 20, 34. [Google Scholar] [CrossRef]

- Labonnote, N.; Rønnquist, A.; Manum, B.; Rüther, P. Additive construction: State-of-the-art, challenges and opportunities. Autom. Constr. 2016, 72, 347–366. [Google Scholar] [CrossRef]

- Jain, P.; Kuthe, A.M. Feasibility study of manufacturing using rapid prototyping: FDM approach. Procedia Eng. 2013, 63, 4–11. [Google Scholar] [CrossRef]

- ASTM Standard. Standard Terminology for Additive Manufacturing Technologies; Astm International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- Kosmatka, S.H.; Kerkhoff, B.; Panarese, W.C. Design and Control Design and Control of Concrete Mixtures, 17th ed.; Portland Cement Association: Portland, OR, USA, 2008; ISBN 0893122173. [Google Scholar]

- Caron, J.F.; Demont, L.; Ducoulombier, N.; Mesnil, R. 3D printing of mortar with continuous fibres: Principle, properties and potential for application. Autom. Constr. 2021, 129, 103806. [Google Scholar] [CrossRef]

- Bautista-Gutierrez, K.P.; Herrera-May, A.L.; Santamaría-López, J.M.; Honorato-Moreno, A.; Zamora-Castro, S.A. Recent progress in nanomaterials for modern concrete infrastructure: Advantages and challenges. Materials 2019, 12, 3548. [Google Scholar] [CrossRef]

- Le, T.T.; Austin, S.A.; Lim, S.; Buswell, R.A.; Gibb, A.G.F.; Thorpe, T. Mix design and fresh properties for high-performance printing concrete. Mater. Struct. Constr. 2012, 45, 1221–1232. [Google Scholar] [CrossRef]

- Bos, F.; Wolfs, R.; Ahmed, Z.; Salet, T. Additive manufacturing of concrete in construction: Potentials and challenges of 3D concrete printing. Virtual Phys. Prototyp. 2016, 11, 209–225. [Google Scholar] [CrossRef]

- Kazemian, A.; Yuan, X.; Cochran, E.; Khoshnevis, B. Cementitious materials for construction-scale 3D printing: Laboratory testing of fresh printing mixture. Constr. Build. Mater. 2017, 145, 639–647. [Google Scholar] [CrossRef]

- Lim, S.; Buswell, R.A.; Le, T.T.; Austin, S.A.; Gibb, A.G.F.; Thorpe, T. Developments in construction-scale additive manufacturing processes. Autom. Constr. 2012, 21, 262–268. [Google Scholar] [CrossRef]

- Ma, G.; Li, Z.; Wang, L. Printable properties of cementitious material containing copper tailings for extrusion based 3D printing. Constr. Build. Mater. 2018. [Google Scholar] [CrossRef]

- Weng, Y.; Li, M.; Tan, M.J.; Qian, S. Design 3D printing cementitious materials via Fuller Thompson theory and Marson-Percy model. Constr. Build. Mater. 2018, 163, 600–610. [Google Scholar] [CrossRef]

- Panda, B.; Mohamed, N.A.N.; Paul, S.C.; Singh, G.V.P.B.; Tan, M.J.; Šavija, B. The effect of material fresh properties and process parameters on buildability and interlayer adhesion of 3D printed concrete. Materials 2019, 12, 2149. [Google Scholar] [CrossRef]

- Rubio, M.; Sonebi, M.; Amziane, S. Fresh and Rheological Properties of 3D Printing Bio-Cement-Based Materials. J. Civ. Eng. 2017, 35, 283–290. [Google Scholar]

- Ma, G.; Wang, L. A critical review of preparation design and workability measurement of concrete material for largescale 3D printing. Front. Struct. Civ. Eng. 2018, 12, 382–400. [Google Scholar] [CrossRef]

- Chen, Y.; Veer, F.; Copuroglu, O.; Schlangen, E. Feasibility of Using Low CO2 Concrete Alternatives in Extrusion-Based 3D Concrete Printing; Springer International Publishing: Berlin/Heidelberg, Germany, 2019; Volume 19, ISBN 9783319995199. [Google Scholar]

- Antoni, M.; Rossen, J.; Martirena, F.; Scrivener, K. Cement substitution by a combination of metakaolin and limestone. Cem. Concr. Res. 2012, 42, 1579–1589. [Google Scholar] [CrossRef]

- Lu, B.; Weng, Y.; Li, M.; Qian, Y.; Leong, K.F.; Tan, M.J.; Qian, S. A systematical review of 3D printable cementitious materials. Constr. Build. Mater. 2019, 207, 477–490. [Google Scholar] [CrossRef]

- Pan, M.; Linner, T.; Pan, W.; Cheng, H.; Bock, T. A framework of indicators for assessing construction automation and robotics in the sustainability context. J. Clean. Prod. 2018, 182, 82–95. [Google Scholar] [CrossRef]

- Hambach, M.; Volkmer, D. Properties of 3D-printed fiber-reinforced Portland cement paste. Cem. Concr. Compos. 2017, 79, 62–70. [Google Scholar] [CrossRef]

- Bos, F.P.; Ahmed, Z.Y.; Jutinov, E.R.; Salet, T.A.M. Experimental exploration of metal cable as reinforcement in 3D printed concrete. Materials 2017, 10, 1314. [Google Scholar] [CrossRef]

- Wolfs, R.J.M.; Bos, F.P.; Salet, T.A.M. Early age mechanical behaviour of 3D printed concrete: Numerical modelling and experimental testing. Cem. Concr. Res. 2018, 106, 103–116. [Google Scholar] [CrossRef]

- Craveiro, F.; Nazarian, S.; Bartolo, H.; Bartolo, P.J.; Pinto Duarte, J. An automated system for 3D printing functionally graded concrete-based materials. Addit. Manuf. 2020, 33, 155–173. [Google Scholar] [CrossRef]

- Rane, K.; Strano, M. A comprehensive review of extrusion-based additive manufacturing processes for rapid production of metallic and ceramic parts. Adv. Manuf. 2019, 7, 155–173. [Google Scholar] [CrossRef]

- Khoshnevis, B. Toward Total Automation of On-Site Construction—An Integrated Approach Based on Contour Crafting. In Proceedings of the 20th ISARC, Eindhoven, The Netherlands, 21–24 September 2003; pp. 61–66. [Google Scholar] [CrossRef]

- Wu, X.; Huang, Y. Adaptive fractional-order non-singular terminal sliding mode control based on fuzzy wavelet neural networks for omnidirectional mobile robot manipulator. ISA Trans. 2021; in press. [Google Scholar] [CrossRef]

- Neythalath, N.; Søndergaard, A.; Bærentzen, J.A. Adaptive robotic manufacturing using higher order knowledge systems. Autom. Constr. 2021, 127, 103702. [Google Scholar] [CrossRef]

- Perkins, I.; Skitmore, M. Three-dimensional printing in the construction industry: A review. Int. J. Constr. Manag. 2015, 15, 1–9. [Google Scholar] [CrossRef]

- Tibaut, A.; Rebolj, D.; Nekrep Perc, M. Interoperability requirements for automated manufacturing systems in construction. J. Intell. Manuf. 2013, 27, 251–262. [Google Scholar] [CrossRef]

- Craveiro, F.; Duarte, J.P.; Bartolo, H.; Bartolo, P.J. Additive manufacturing as an enabling technology for digital construction: A perspective on Construction 4.0. Autom. Constr. 2019, 103, 251–267. [Google Scholar] [CrossRef]

- Lim, J.H.; Weng, Y.; Pham, Q.C. 3D printing of curved concrete surfaces using Adaptable Membrane Formwork. Constr. Build. Mater. 2020, 232, 117075. [Google Scholar] [CrossRef]

- Ma, G.; Wang, L.; Ju, Y. State-of-the-art of 3D printing technology of cementitious material—An emerging technique for construction. Sci. China Technol. Sci. 2018, 61, 475–495. [Google Scholar] [CrossRef]

- Bhatt, P.M.; Malhan, R.K.; Shembekar, A.V.; Yoon, Y.J.; Gupta, S.K. Expanding capabilities of additive manufacturing through use of robotics technologies: A survey. Addit. Manuf. 2020, 31, 100933. [Google Scholar] [CrossRef]

- Song, X.; Pan, Y.; Chen, Y. Development of a low-cost parallel kinematic machine for multidirectional additive manufacturing. J. Manuf. Sci. Eng. Trans. ASME 2015, 137, 021005. [Google Scholar] [CrossRef]

- Zhang, G.Q.; Mondesir, W.; Martinez, C.; Li, X.; Fuhlbrigge, T.A.; Bheda, H. Robotic additive manufacturing along curved surface—A step towards free-form fabrication. In Proceedings of the 2015 IEEE Conference on Reobotics and Biomimetics, Zhuhai, China, 6–9 December 2015; pp. 721–726. [Google Scholar] [CrossRef]

- Al Rashid, A.; Khan, S.A.; Al-Ghamdi, S.G.; Koç, M. Additive manufacturing: Technology, applications, markets, and opportunities for the built environment. Autom. Constr. 2020, 118, 103268. [Google Scholar] [CrossRef]

- Bhatt, P.M.; Kabir, A.M.; Peralta, M.; Bruck, H.A.; Gupta, S.K. A robotic cell for performing sheet lamination-based additive manufacturing. Addit. Manuf. 2019, 27, 278–289. [Google Scholar] [CrossRef]

- Jeong, W.; Kwon, Y.S.; Kim, D. Three-dimensional printing of tungsten structures by directed energy deposition. Mater. Manuf. Process. 2019, 34, 986–992. [Google Scholar] [CrossRef]

- Bhatt, P.M.; Peralta, M.; Bruck, H.A.; Gupta, S.K. Robot assisted additive manufacturing of thin multifunctional structures. In Proceedings of the 13th International Manufacturing Science and Engineering Conference, College Station, TX, USA, 18–22 June 2018. [Google Scholar] [CrossRef]

- Cullen, A.T.; Price, A.D. Fabrication of 3D conjugated polymer structures via vat polymerization additive manufacturing. Smart Mater. Struct. 2019, 28, 104007. [Google Scholar] [CrossRef]

- Wu, P.; Wang, J.; Wang, X. A critical review of the use of 3-D printing in the construction industry. Autom. Constr. 2016, 68, 21–31. [Google Scholar] [CrossRef]

- Carneau, P.; Mesnil, R.; Roussel, N.; Baverel, O. Additive manufacturing of cantilever—From masonry to concrete 3D printing. Autom. Constr. 2020, 116, 103184. [Google Scholar] [CrossRef]

- Vantyghem, G.; Ooms, T.; de Corte, W. VoxelPrint: A Grasshopper plug-in for voxel-based numerical simulation of concrete printing. Autom. Constr. 2021, 122, 103469. [Google Scholar] [CrossRef]

- Özalp, F.; Yilmaz, H.D. Fresh and Hardened Properties of 3D High-Strength Printing Concrete and Its Recent Applications. Iran. J. Sci. Technol.-Trans. Civ. Eng. 2020, 44, 319–330. [Google Scholar] [CrossRef]

- Jovanović, M.; Raković, M.; Tepavčević, B.; Borovac, B.; Nikolić, M. Robotic fabrication of freeform foam structures with quadrilateral and puzzle shaped panels. Autom. Constr. 2017, 74, 28–38. [Google Scholar] [CrossRef]

- Kontovourkis, O.; Tryfonos, G. Robotic 3D clay printing of prefabricated non-conventional wall components based on a parametric-integrated design. Autom. Constr. 2020, 110, 103005. [Google Scholar] [CrossRef]

- El Sakka, F.; Hamzeh, F. 3D concrete printing in the service of lean construction. In Proceedings of the 25th Annual Conference of the International Group for Lean Construction, Heraklion, Greece, 9–12 July 2017; pp. 781–788. [Google Scholar] [CrossRef]

- Malé-Alemany, M. The Potential of Additive Manufacturing in Architecture: Towards a New Paradigm for Design and Construction, UPC-ETSAB; Universitat Politècnica de Catalunya: Barcelona, Spain, 2015. [Google Scholar]

- Tay, Y.W.D.; Panda, B.; Paul, S.C.; Noor Mohamed, N.A.; Tan, M.J.; Leong, K.F. 3D printing trends in building and construction industry: A review. Virtual Phys. Prototyp. 2017, 12, 261–276. [Google Scholar] [CrossRef]

- Al Jassmi, H.; Al Najjar, F.; Mourad, A.H.I. Large-Scale 3D Printing: The Way Forward. IOP Conf. Ser. Mater. Sci. Eng. 2018, 324, 012088. [Google Scholar] [CrossRef]

- Delgado Camacho, D.; Clayton, P.; O’Brien, W.J.; Seepersad, C.; Juenger, M.; Ferron, R.; Salamone, S. Applications of additive manufacturing in the construction industry—A forward-looking review. Autom. Constr. 2018, 89, 110–119. [Google Scholar] [CrossRef]

- Ghaffar, S.H.; Corker, J.; Fan, M. Additive manufacturing technology and its implementation in construction as an eco-innovative solution. Autom. Constr. 2018, 93, 1–11. [Google Scholar] [CrossRef]

- Wangler, T.; Lloret, E.; Reiter, L.; Hack, N.; Gramazio, F.; Kohler, M.; Bernhard, M.; Dillenburger, B.; Buchli, J.; Roussel, N.; et al. Digital Concrete: Opportunities and Challenges. RILEM Tech. Lett. 2016, 1, 67. [Google Scholar] [CrossRef]

- Doely, P.K. 3D Printing: A New Dimension in Construction. Available online: http://fwhtlaw.com/briefing-papers/3d-printing-new-dimension-construction/ (accessed on 9 February 2022).

- Duballet, R.; Baverel, O.; Dirrenberger, J. Classification of building systems for concrete 3D printing. Autom. Constr. 2017, 83, 247–258. [Google Scholar] [CrossRef]

- Marijnissen, M.P.A.; van der Zee, A. 3D Concrete Printing in Architecture. Mater. Stud. Methodol. 2016, 2, 299–308. [Google Scholar]

- Salet, T.A.M.; Ahmed, Z.Y.; Bos, F.P.; Laagland, H.L.M. Design of a 3D printed concrete bridge by testing*. Virtual Phys. Prototyp. 2018, 13, 222–236. [Google Scholar] [CrossRef]

- Xu, J.; Ding, L.; Love, P.E.D. Digital reproduction of historical building ornamental components: From 3D scanning to 3D printing. Autom. Constr. 2017, 76, 85–96. [Google Scholar] [CrossRef]

- Furet, B.; Poullain, P.; Garnier, S. 3D printing for construction based on a complex wall of polymer-foam and concrete. Addit. Manuf. 2019, 28, 58–64. [Google Scholar] [CrossRef]

- Vantyghem, G.; de Corte, W.; Shakour, E.; Amir, O. 3D printing of a post-tensioned concrete girder designed by topology optimization. Autom. Constr. 2020, 112, 103084. [Google Scholar] [CrossRef]

- Cohen, Z.; Carlson, N. Piling and pressing: Towards a method of 3D printing reinforced concrete columns. Constr. Robot. 2020, 4, 61–73. [Google Scholar] [CrossRef]

- Lublasser, E.; Adams, T.; Vollpracht, A.; Brell-Cokcan, S. Robotic application of foam concrete onto bare wall elements—Analysis, concept and robotic experiments. Autom. Constr. 2018, 89, 299–306. [Google Scholar] [CrossRef]

- Kwon, H. Experimentation and Analysis of Contour Crafting (CC) Process Using Uncured Ceramic Materials; University of Southern California: Los Angeles, CA, USA, 2002; p. 213. [Google Scholar]

- Lafhaj, Z.; Rabenantoandro, A.Z.; el Moussaoui, S.; Dakhli, Z.; Youssef, N. Experimental approach for printability assessment: Toward a practical decision-making framework of printability for cementitious materials. Buildings 2019, 9, 245. [Google Scholar] [CrossRef]

- Zhang, X.; Li, M.; Lim, J.H.; Weng, Y.; Tay, Y.W.D.; Pham, H.; Pham, Q.C. Large-scale 3D printing by a team of mobile robots. Autom. Constr. 2018, 95, 98–106. [Google Scholar] [CrossRef]

- Rivera, R.G.; Alvarado, R.G.; Martínez-Rocamora, A.; Cheein, F.A. A comprehensive performance evaluation of different mobile manipulators used as displaceable 3D printers of building elements for the construction industry. Sustainanility 2020, 12, 4378. [Google Scholar] [CrossRef]

- Nerella, V.N.; Mechtcherine, V. Studying the Printability of Fresh Concrete for Formwork-Free Concrete Onsite 3D Printing Technology (CONPrint3D); Elsevier Inc.: Amsterdam, The Netherlands, 2019; ISBN 9780128154816. [Google Scholar]

- Mathur, R. 3D Printing in Architecture. IJISET-Int. J. Innov. Sci. Eng. Technol. Impact Factor 2016, 3, 583–591. [Google Scholar]

- Duballet, R.; Baverel, O.; Dirrenberger, J. Space Truss Masonry Walls With Robotic Mortar Extrusion. Structures 2019, 18, 41–47. [Google Scholar] [CrossRef]

- Wolfs, R.J.M.; Bos, F.P.; Van Strien, E.C.F. A Real-Time Height Measurement and Feedback System for 3D Concrete Printing. In High Tech Concrete: Where Technology and Engineering Meet; Springer: Berlin/Heidelberg, Germany, 2018; Volume 1, pp. 1–10. ISBN 978-3-319-59470-5. [Google Scholar]

- De Schutter, G.; Lesage, K.; Mechtcherine, V.; Nerella, V.N.; Habert, G.; Agusti-Juan, I. Vision of 3D printing with concrete—Technical, economic and environmental potentials. Cem. Concr. Res. 2018, 112, 25–36. [Google Scholar] [CrossRef]

- Krimi, I.; Lafhaj, Z.; Ducoulombier, L. Prospective study on the integration of additive manufacturing to building industry—Case of a French construction company. Addit. Manuf. 2017, 16, 107–114. [Google Scholar] [CrossRef]

- Buswell, R.A.; Leal de Silva, W.R.; Jones, S.Z.; Dirrenberger, J. 3D printing using concrete extrusion: A roadmap for research. Cem. Concr. Res. 2018, 112, 37–49. [Google Scholar] [CrossRef]

- Malaeb, Z.; AlSakka, F.; Hamzeh, F. 3D Concrete Printing; Elsevier Inc.: Amsterdam, The Netherlands, 2019; ISBN 9780128154816. [Google Scholar]

- Allouzi, R.; Al-azhari, W.; Allouzi, R. Conventional Construction and 3D Printing: A Comparison Study on Material Cost in Jordan. J. Eng. 2020, 2020, 1424682. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Grafe, J.; Nerella, V.N.; Spaniol, E.; Hertel, M.; Füssel, U. 3D-printed steel reinforcement for digital concrete construction—Manufacture, mechanical properties and bond behaviour. Constr. Build. Mater. 2018, 179, 125–137. [Google Scholar] [CrossRef]

- Cesaretti, G.; Dini, E.; de Kestelier, X.; Colla, V.; Pambaguian, L. Building components for an outpost on the Lunar soil by means of a novel 3D printing technology. Acta Astronaut. 2014, 93, 430–450. [Google Scholar] [CrossRef]

- Bedarf, P.; Dutto, A.; Zanini, M.; Dillenburger, B. Foam 3D printing for construction: A review of applications, materials, and processes. Autom. Constr. 2021, 130, 103861. [Google Scholar] [CrossRef]

- Asprone, D.; Auricchio, F.; Menna, C.; Mercuri, V. 3D printing of reinforced concrete elements: Technology and design approach. Constr. Build. Mater. 2018, 165, 218–231. [Google Scholar] [CrossRef]

- Taha, N.; Walzer, A.N.; Ruangjun, J.; Lloret-fritschi, E.; Gramazio, F.; Kohler, M. Robotic AeroCrete A novel robotic spraying and surface treatment technology for the production of slender reinforced concrete elements. In Proceedings of the 37 Education and Research in Computer Aided Architectural Design in Europe and XXIII Iberoamerican Society of Digital Graphics, Joint Conference (N. 1), Porto, Portugal, 11–13 September 2019; Volume 3, pp. 245–254. [Google Scholar]

- Kreiger, E.L.; Kreiger, M.A.; Case, M.P. Development of the construction processes for reinforced additively constructed concrete. Addit. Manuf. 2019, 28, 39–49. [Google Scholar] [CrossRef]

- Ji, G.; Ding, T.; Xiao, J.; Du, S.; Li, J.; Duan, Z. A 3D printed ready-mixed concrete power distribution substation: Materials and construction technology. Materials 2019, 12, 1540. [Google Scholar] [CrossRef]

- Banda-Pérez, P.; García-Alvarado, R.; Muñoz-Sanguinetti, C. Architectural Digital Design for 3D Printing Housing: Search for 3D Printing in Construction Trends for a Design Methodology. In Proceedings of the XXV International Conference of the Iberoamerican Society of Digital Graphics, São Paulo, Brazil, 8–12 November 2021; pp. 1409–1422. [Google Scholar]

- Collado, R.; Valencia, P.; Luis, J.; Rodríguez, M.; Montes, M.; Guillermo, J. Investigación Sobre Construcción 3d y Sus Aplicaciones; Universitat Politècnica de València: Valencia, Spain, 2018; pp. 190–197. [Google Scholar] [CrossRef]

- Wolfs, R.J.M.; Salet, T.A.M. 3D Printing of Concrete Structures. Master’s Thesis, Eindhoven University of Technology, Eindhoven, The Netherlands, 2015. [Google Scholar]

- Dritsas, S.; Soh, G.S. Building robotics design for construction. Constr. Robot. 2018, 3, 1–10. [Google Scholar] [CrossRef]

- González Böhme, L.F.; Quitral Zapata, F.; Maino Ansaldo, S. Roboticus tignarius: Robotic reproduction of traditional timber joints for the reconstruction of the architectural heritage of Valparaíso. Constr. Robot. 2017, 1, 61–68. [Google Scholar] [CrossRef]

- Eversmann, P.; Gramazio, F.; Kohler, M. Robotic prefabrication of timber structures: Towards automated large-scale spatial assembly. Constr. Robot. 2017, 1, 49–60. [Google Scholar] [CrossRef]

- Stumm, S.; Devadass, P.; Brell-Cokcan, S. Haptic programming in construction. Constr. Robot. 2018, 2, 3–13. [Google Scholar] [CrossRef]

- Siddika, A.; Al Mamun, M.A.; Ferdous, W.; Saha, A.K.; Alyousef, R. 3D-printed concrete: Applications, performance, and challenges. J. Sustain. Cem. Mater. 2020, 9, 127–164. [Google Scholar] [CrossRef]

- Więckowski, A. “JA-WA”—A wall construction system using unilateral material application with a mobile robot. Autom. Constr. 2017, 83, 19–28. [Google Scholar] [CrossRef]

- Paul, S.C.; van Zijl, G.P.A.G.; Gibson, I. A review of 3D concrete printing systems and materials properties: Current status and future research prospects. Rapid Prototyp. J. 2018, 24, 784–798. [Google Scholar] [CrossRef]

- Khatri, N.R.; Islam, M.N.; Cao, P.-F.; Advincula, R.C.; Choi, W.; Jiang, Y. Integrating helicoid channels for passive control of fiber alignment in direct-write 3D printing. Addit. Manuf. 2021, 48, 102419. [Google Scholar] [CrossRef]

- Barnett, E.; Gosselin, C. Large-scale 3D printing with a cable-suspended robot. Addit. Manuf. 2015, 7, 27–44. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Nerella, V.N.; Will, F.; Näther, M.; Otto, J.; Krause, M. Large-scale digital concrete construction—CONPrint3D concept for on-site, monolithic 3D-printing. Autom. Constr. 2019, 107, 102933. [Google Scholar] [CrossRef]

- Keating, S.J.; Leland, J.C.; Cai, L.; Oxman, N. Toward site-specific and self-sufficient robotic fabrication on architectural scales. Sci. Robot. 2017, 2, 15. [Google Scholar] [CrossRef]

- Demont, L.; Ducoulombier, N.; Mesnil, R.; Caron, J.F. Flow-based pultrusion of continuous fibers for cement-based composite material and additive manufacturing: Rheological and technological requirements. Compos. Struct. 2021, 262, 113564. [Google Scholar] [CrossRef]

- Classen, M.; Ungermann, J.; Sharma, R. Additive manufacturing of reinforced concrete-development of a 3D printing technology for cementitious composites with metallic reinforcement. Appl. Sci. 2020, 10, 3791. [Google Scholar] [CrossRef]

- Bong, S.H.; Nematollahi, B.; Nazari, A.; Xia, M.; Sanjayan, J. Method of optimisation for ambient temperature cured sustainable geopolymers for 3D printing construction applications. Materials 2019, 16, 902. [Google Scholar] [CrossRef]

- Paul, S.C.; Tay, Y.W.D.; Panda, B.; Tan, M.J. Fresh and hardened properties of 3D printable cementitious materials for building and construction. Arch. Civ. Mech. Eng. 2018, 18, 311–319. [Google Scholar] [CrossRef]

- Cho, S.; Kruger, J.; Zeranka, S.; van Zijl, G. 3D Printable Concrete Technology and Mechanics. Concr. Bet. 2019, 158, 11–18. [Google Scholar]

- Le, T.T.; Austin, S.A.; Lim, S.; Buswell, R.A.; Law, R.; Gibb, A.G.F.; Thorpe, T. Hardened properties of high-performance printing concrete. Cem. Concr. Res. 2012, 42, 558–566. [Google Scholar] [CrossRef]

- Feng, P.; Meng, X.; Chen, J.-F.; Ye, L. Mechanical properties of structures 3D printed with cementitious powders. Constr. Build. Mater. 2015, 93, 486–497. [Google Scholar] [CrossRef]

- Van Dijk, N.P.; Maute, K.; Langelaar, M.; van Keulen, F. Level-set methods for structural topology optimization: A review. Struct. Multidiscip. Optim. 2013, 48, 437–472. [Google Scholar] [CrossRef]

- Sigmund, O.; Maute, K. Topology optimization approaches: A comparative review. Struct. Multidiscip. Optim. 2013, 48, 1031–1055. [Google Scholar] [CrossRef]

- Jin, Y.; Du, J.; Ma, Z.; Liu, A.; He, Y. An optimization approach for path planning of high-quality and uniform additive manufacturing. Int. J. Adv. Manuf. Technol. 2017, 92, 651–662. [Google Scholar] [CrossRef]

- Jin, G.Q.; Li, W.D.; Gao, L. An adaptive process planning approach of rapid prototyping and manufacturing. Robot. Comput. Integr. Manuf. 2013, 29, 23–38. [Google Scholar] [CrossRef]

- Zhao, H.; Gu, F.; Huang, Q.X.; Garcia, J.; Chen, Y.; Tu, C.; Benes, B.; Zhang, H.; Cohen-Or, D.; Chen, B. Connected fermat spirals for layered fabrication. ACM Trans. Graph. 2016, 35, 1–10. [Google Scholar] [CrossRef]

- Jin, Y.A.; He, Y.; Fu, J.Z.; Gan, W.F.; Lin, Z.W. Optimization of tool-path generation for material extrusion-based additive manufacturing technology. Addit. Manuf. 2014, 1, 32–47. [Google Scholar] [CrossRef]

- Giberti, H.; Sbaglia, L.; Urgo, M. A path planning algorithm for industrial processes under velocity constraints with an application to additive manufacturing. J. Manuf. Syst. 2017, 43, 160–167. [Google Scholar] [CrossRef]

- Thompson, B.; Yoon, H. Efficient path planning algorithm for additive manufacturing systems. IEEE Trans. Compon. Packag. Manuf. Technol. 2014, 4, 1555–1563. [Google Scholar] [CrossRef]

- Ganganath, N.; Cheng, C.T.; Fok, K.Y.; Tse, C.K. Trajectory planning for 3D printing: A revisit to traveling salesman problem. In Proceedings of the 2016 2nd International Conference on Control, Automation and Robotics (ICCAR), Hong Kong, China, 28–30 April 2016; pp. 287–290. [Google Scholar] [CrossRef]

- Xie, F.; Chen, L.; Li, Z.; Tang, K. Path smoothing and feed rate planning for robotic curved layer additive manufacturing. Robot. Comput. Integr. Manuf. 2020, 65, 101967. [Google Scholar] [CrossRef]

- Li, B.; Zhang, H.; Ye, P.; Wang, J. Trajectory smoothing method using reinforcement learning for computer numerical control machine tools. Robot. Comput. Integr. Manuf. 2020, 61, 101847. [Google Scholar] [CrossRef]

- Yang, J.; Li, D.; Ye, C.; Ding, H. An analytical C3 continuous tool path corner smoothing algorithm for 6R robot manipulator. Robot. Comput. Integr. Manuf. 2020, 64, 101947. [Google Scholar] [CrossRef]

- Calleja, A.; Tabernero, I.; Ealo, J.A.; Campa, F.J.; Lamikiz, A.; de Lacalle, L.N.L. Feed rate calculation algorithm for the homogeneous material deposition of blisk blades by 5-axis laser cladding. Int. J. Adv. Manuf. Technol. 2014, 74, 1219–1228. [Google Scholar] [CrossRef]

- He, S.; Yan, C.; Deng, Y.; Lee, C.H.; Zhou, X. A tolerance constrained G2 continuous path smoothing and interpolation method for industrial SCARA robots. Robot. Comput. Integr. Manuf. 2020, 63, 101907. [Google Scholar] [CrossRef]

- Chen, C.S.; Chen, S.K. Synchronization of tool tip trajectory and attitude based on the surface characteristics of workpiece for 6-DOF robot manipulator. Robot. Comput. Integr. Manuf. 2019, 59, 13–27. [Google Scholar] [CrossRef]

- Fok, K.Y.; Cheng, C.T.; Ganganath, N.; Iu, H.H.C.; Tse, C.K. Accelerating 3D Printing Process Using an Extended Ant Colony Optimization Algorithm. In Proceedings of the 2018 IEEE International Symposium on Circuits and Systems (ISCAS), Florence, Italy, 27–30 May 2018. [Google Scholar] [CrossRef][Green Version]

- Fok, K.Y.; Ganganath, N.; Cheng, C.T.; Iu, H.H.C.; Tse, C.K. A Nozzle Path Planner for 3-D Printing Applications. IEEE Trans. Ind. Inform. 2020, 16, 6313–6323. [Google Scholar] [CrossRef]

- Chalvin, M.; Campocasso, S.; Hugel, V.; Baizeau, T. Layer-by-layer generation of optimized joint trajectory for multi-axis robotized additive manufacturing of parts of revolution. Robot. Comput. Integr. Manuf. 2020, 65, 101960. [Google Scholar] [CrossRef]

- Li, S.; Liu, L.; Peng, C. A review of performance-oriented architectural design and optimization in the context of sustainability: Dividends and challenges. Sustainability 2020, 12, 1427. [Google Scholar] [CrossRef]

- Lim, S.; Buswell, R.A.; Valentine, P.J.; Piker, D.; Austin, S.A.; de Kestelier, X. Modelling curved-layered printing paths for fabricating large-scale construction components. Addit. Manuf. 2016, 12, 216–230. [Google Scholar] [CrossRef]

- Farouki, R.T.; Koenig, T.; Tarabanis, K.A.; Korein, J.U.; Batchelder, J.S. Path planning with offset curves for layered fabrication processes. J. Manuf. Syst. 1995, 14, 355–368. [Google Scholar] [CrossRef]

- Reiter, L.; Wangler, T.; Roussel, N.; Flatt, R.J. The role of early age structural build-up in digital fabrication with concrete. Cem. Concr. Res. 2018, 112, 86–95. [Google Scholar] [CrossRef]

- Bard, J.; Cupkova, D.; Washburn, N.; Zeglin, G. Robotic concrete surface finishing: A moldless approach to creating thermally tuned surface geometry for architectural building components using Profile-3D-Printing. Constr. Robot. 2018, 2, 53–65. [Google Scholar] [CrossRef]

- Nematollahi, B.; Xia, M.; Sanjayan, J. Current Progress of 3D Concrete Printing Technologies. In Proceedings of the ISARC2017—34th International Symposium on Automation and Robotics in Construction, Taipei, Taiwan, 1 July 2017. [Google Scholar]

- Anjum, T.; Dongre, P.; Misbah, F.; Nanyam, V.P.S.N. Purview of 3DP in the Indian Built Environment Sector. Procedia Eng. 2017, 196, 228–235. [Google Scholar] [CrossRef]

- Bos, F.; Ahmed, Z.; Wolfs, R.; Salet, T. 3D Printing Concrete with Reinforcement. In High Tech Concrete: Where Technology and Engineering Meet; Springer: Berlin/Heidelberg, Germany, 2018; Volume 1, ISBN 978-3-319-59470-5. [Google Scholar]

- Jagoda, J.; Diggs-McGee, B.; Kreiger, M.; Schuldt, S. The viability and simplicity of 3D-Printed construction: A military case study. Infrastructures 2020, 5, 35. [Google Scholar] [CrossRef]

- Alwi, A.; Karayiannis, S.; Starkey, B.; Gardner, M.; Reodique, K.; Varley, T. Contrucktion: MegaScale 3D Printing—Group 1; University of Surrey: Guildford, UK, 2013. [Google Scholar]

- García de Soto, B.; Agustí-Juan, I.; Hunhevicz, J.; Joss, S.; Graser, K.; Habert, G.; Adey, B.T. Productivity of digital fabrication in construction: Cost and time analysis of a robotically built wall. Autom. Constr. 2018, 92, 297–311. [Google Scholar] [CrossRef]

- Bosscher, P.; Williams, R.L.; Bryson, L.S.; Castro-Lacouture, D. Cable-suspended robotic contour crafting system. Autom. Constr. 2007, 17, 45–55. [Google Scholar] [CrossRef]

- Martínez-Rocamora, A.; García-Alvarado, R.; Casanova-Medina, E.; González-Böhme, L.F.; Auat-Cheein, F. (Forthcoming) Parametric programming of 3D printed curved walls for cost-efficient building design. J. Constr. Eng. Manag. 2020, 146, 04020039. [Google Scholar] [CrossRef]

- Wolfs, R.J.M.; Suiker, A.S.J. Structural failure during extrusion-based 3D printing processes. Int. J. Adv. Manuf. Technol. 2019, 104, 565–584. [Google Scholar] [CrossRef]

- Diggs-McGee, B.N.; Kreiger, E.L.; Kreiger, M.A.; Case, M.P. Print time vs. elapsed time: A temporal analysis of a continuous printing operation for additive constructed concrete. Addit. Manuf. 2019, 28, 205–214. [Google Scholar] [CrossRef]

- Carneau, P.; Baverel, O.; Mesnil, R.; Roussel, N. An exploration of 3d printing design space inspired by masonry. In Proceedings of the IASS Annual Symposium 2019—Structural Membranes 2019, Barcelona, Spain, 6–10 October 2019; pp. 1–10. [Google Scholar]

- Agustí-Juan, I.; Habert, G. Environmental design guidelines for digital fabrication. J. Clean. Prod. 2017, 142, 2780–2791. [Google Scholar] [CrossRef]

- Gomaa, M.; Carfrae, J.; Goodhew, S.; Jabi, W.; Veliz Reyes, A. Thermal performance exploration of 3D printed cob. Archit. Sci. Rev. 2019, 62, 230–237. [Google Scholar] [CrossRef]

- Ibrahim, M.M. 3D printed architecture. A new practical frontier in construction methods. In Proceedings of the ASCAAD 2016—Parametricism vs. Materialism: Evolution of Digital Technologies for Development, London, UK, 7–8 November 2016; pp. 169–178. [Google Scholar]

- Fischer, T.; Herr, C.M. Parametric customisation of a 3D concrete printed pavilion. In Proceedings of the CAADRIA 2016, 21st International Conference on Computer-Aided Architectural Design Research in Asia—Living Systems and Micro-Utopias: Towards Continuous Designing, Melbourne, Australia, 30 March–2 April 2016; pp. 549–558. [Google Scholar]

- Davtalab, O.; Kazemian, A.; Khoshnevis, B. Perspectives on a BIM-integrated software platform for robotic construction through Contour Crafting. Autom. Constr. 2018, 89, 13–23. [Google Scholar] [CrossRef]

- Nadal, A.; Pavón, J.; Liébana, O. 3D printing for construction: A procedural and material-based approach. Inf. La Constr. 2017, 69, 193. [Google Scholar] [CrossRef]

- Hwang, D.; Khoshnevis, B. An Innovative Construction Process-Contour. In Proceedings of the 22nd ISARC, Ferrara, Italy, 11–14 September 2005. [Google Scholar]

- Bukkanatnam, S.; Clark, B. Dynamic modeling and monitoring of contour crafting—An extrusion-based layered manufacturing process. J. Manuf. Sci. Eng. Trans. ASME 2007, 129, 135–142. [Google Scholar] [CrossRef]

- Khoshnevis, B.; Carlson, A.; Leach, N.; Thangavelu, M. Contour crafting simulation plan for lunar settlement infrastructure buildup. In Proceedings of the Thirteenth ASCE Aerospace Division Conference on Engineering, Science, Construction, and Operations in Challenging Environments, and the 5th NASA/ASCE Workshop On Granular Materials in Space Exploration, Pasadena, CA, USA, 15–18 April 2012; pp. 1458–1467. [Google Scholar] [CrossRef]

- Jeon, K.-H.; Park, M.-B.; Kang, M.-K.; Kim, J.-H. Development of an automated freeform construction system and its construction materials. In Proceedings of the ISARC—International Symposium on Automation and Robotics in Construction, Montréal, QC, Canada, 11–15 August 2013; pp. 1–7. [Google Scholar]

- Leach, N.; Carlson, A.; Khoshnevis, B.; Thangavelu, M. Robotic Construction by Contour Crafting: The Case of Lunar Construction. Int. J. Archit. Comput. 2012, 10, 423–438. [Google Scholar] [CrossRef]

- Feng, L.; Yuhong, L. Study on the Status Quo and Problems of 3D Printed Buildings in China. Glob. J. Hum.-Soc. Sci. 2014, 14, 1–4. [Google Scholar]

- Perrot, A.; Rangeard, D.; Pierre, A. Structural built-up of cement-based materials used for 3D-printing extrusion techniques. Mater. Struct. Constr. 2016, 49, 1213–1220. [Google Scholar] [CrossRef]

- Hager, I.; Golonka, A.; Putanowicz, R. 3D Printing of Buildings and Building Components as the Future of Sustainable Construction? Procedia Eng. 2016, 151, 292–299. [Google Scholar] [CrossRef]

- Raspall, F.; Bañón, C. vMESH: How to print Architecture? Blucher Des. Proc. 2016, 3, 394–398. [Google Scholar] [CrossRef]

- Marchment, T.; Xia, M.; Dodd, E.; Sanjayan, J.; Nematollahi, B. Effect of delay time on the mechanical properties of extrusion-based 3D printed concrete. In Proceedings of the 34rd ISARC, Taipei, Taiwan, 28 June–1 July 2017; pp. 240–245. [Google Scholar] [CrossRef]

- Sakin, M.; Kiroglu, Y.C. 3D Printing of Buildings: Construction of the Sustainable Houses of the Future by BIM. Energy Procedia 2017, 134, 702–711. [Google Scholar] [CrossRef]

- Anton, A.; Abdelmahgoub, A. Ceramic Components—Computational Design for Bespoke Robotic 3D Printing on Curved Support. In Proceedings of the 36th eCAADe Conference, Lodz, Poland, 19–21 September 2018; Volume 2, pp. 71–78. [Google Scholar]

- Grassi, G.; Lupica Spagnolo, S.; Paoletti, I. Fabrication and durability testing of a 3D printed façade for desert climates. Addit. Manuf. 2019, 28, 439–444. [Google Scholar] [CrossRef]

- Kruger, J.; Zeranka, S.; van Zijl, G. 3D concrete printing: A lower bound analytical model for buildability performance quantification. Autom. Constr. 2019, 106, 102904. [Google Scholar] [CrossRef]

- Shakor, P.; Nejadi, S.; Paul, G. A study into the effect of different nozzles shapes and fibre-reinforcement in 3D printed mortar. Materials 2019, 12, 1708. [Google Scholar] [CrossRef]

- Paolini, A.; Kollmannsberger, S.; Rank, E. Additive manufacturing in construction: A review on processes, applications, and digital planning methods. Addit. Manuf. 2019, 30, 100894. [Google Scholar] [CrossRef]

- Tay, Y.W.D.; Li, M.Y.; Tan, M.J. Effect of printing parameters in 3D concrete printing: Printing region and support structures. J. Mater. Process. Technol. 2019, 271, 261–270. [Google Scholar] [CrossRef]

- Xu, J.; Ding, L.; Cai, L.; Zhang, L.; Luo, H.; Qin, W. Volume-forming 3D concrete printing using a variable-size square nozzle. Autom. Constr. 2019, 104, 95–106. [Google Scholar] [CrossRef]

- Marchment, T.; Sanjayan, J. Mesh reinforcing method for 3D Concrete Printing. Autom. Constr. 2020, 109, 102992. [Google Scholar] [CrossRef]

- Nerella, V.N.; Krause, M.; Mechtcherine, V. Direct printing test for buildability of 3D-printable concrete considering economic viability. Autom. Constr. 2020, 109, 102986. [Google Scholar] [CrossRef]

- Panda, B.; Paul, S.C.; Mohamed, N.A.N.; Tay, Y.W.D.; Tan, M.J. Measurement of tensile bond strength of 3D printed geopolymer mortar. Meas. J. Int. Meas. Confed. 2018, 113, 108–116. [Google Scholar] [CrossRef]

- Khoshnevis, B.; Hwang, D.; Yao, K.-T.; Yeh, Z. Mega-scale fabrication by contour crafting Behrokh Khoshnevis. Int. J. Ind. Syst. Eng. 2006, 1, 301–306. [Google Scholar]

- Duarte, J.; Shadi, N.; Negar, A. Designing Shelters for 3D-printing. In Proceedings of the Ecaade 2018: Virtual & Physical Prototyping, Lodz, Poland, 17–21 September 2018; Volume 2, pp. 31–38. [Google Scholar]

- Yin, H.; Qu, M.; Zhang, H.; Lim, Y.C. 3D Printing and Buildings: A Technology Review and Future Outlook. Technol. Archit. Des. 2018, 2, 94–111. [Google Scholar] [CrossRef]

- Krause, M.; Otto, J.; Bulgakov, A.; Sayfeddine, D. Strategic optimization of 3D concrete printing using the method of CONPrint3D®. In Proceedings of the 35th ISARC, Berlin, Germany, 20–25 July 2018. [Google Scholar]

- Pascal, M.; Mathot, M.; Bos, F.; Coenders, J. Optimising 3D Printed Concrete Structures Using Topology Optimisation; Springer: Berlin/Heidelberg, Germany, 2018; ISBN 9783319594705. [Google Scholar]

- Lim, S.; Buswell, R.; Le, T.; Wackrow, R.; Austin, S.; Gibb, A.; Thorpe, T. Development of a viable concrete printing process. In Proceedings of the ISARC2011—28th International Symposium on Automation and Robotics in Construction, Seoul, Korea, 29 June–2 July 2011; Volume 2, pp. 665–670. [Google Scholar]

- Shakor, P.; Nejadi, S.; Paul, G.; Malek, S. Review of emerging additive manufacturing technologies in 3d printing of cementitious materials in the construction industry. Front. Built Environ. 2019, 4, 85. [Google Scholar] [CrossRef]

- Nan, C. A new machinecraft. Architectural robots. In Proceedings of the 20th International Conference of the Association for Computer-Aided Architectural Design Research in Asia (CAADRIA 2015), Daegu, Korea, 20–22 May 2015; pp. 745–754. [Google Scholar]

- Ahmed, Z.Y.; Bos, F.P.; Wolfs, R.J.M.; Salet, T. Design considerations due to scale effects in 3d concrete printing. In Proceedings of the 8th ASCAAD Conference, London, UK, 7–8 November 2016; pp. 1–10. [Google Scholar]

- Kashani, A.; Ngo, T.D. Optimisation of mixture properties for 3D printing of geopolymer concrete. In Proceedings of the 35th ISARC, Berlin, Germany, 20–25 July 2018. [Google Scholar] [CrossRef]

- Asprone, D.; Menna, C.; Bos, F.P.; Salet, T.A.M.; Mata-Falcón, J.; Kaufmann, W. Rethinking reinforcement for digital fabrication with concrete. Cem. Concr. Res. 2018, 112, 111–121. [Google Scholar] [CrossRef]

- Khoshnevis, B. Automated construction by contour crafting—Related robotics and information technologies. Autom. Constr. 2004, 13, 5–19. [Google Scholar] [CrossRef]

- Gomaa, M.; Jabi, W.; Veliz Reyes, A.; Soebarto, V. 3D printing system for earth-based construction: Case study of cob. Autom. Constr. 2021, 124, 103577. [Google Scholar] [CrossRef]

| Reference | Contents of Binder Materials |

|---|---|

| [18] | Portland cement (90%) and silica fume (10%) |

| [16,19] | Portland cement (70%), fly ash (20%), and silica fume (10%) |

| [25] | Portland cement (55%), fly ash (22%), and silica fume (23%) |

| [7] | Portland Cement (60–67%), limestone filler (17–20%), and silica fume (17–20%) |

| Component Type | Dosage (kg/m3) |

|---|---|

| Cement | 430 |

| Fly ash | 170 |

| Dispersed micra silica (solid content 50%) | 180 |

| Combined sand (0.06–2 mm) | 1240 |

| Water | 180 |

| Superplasticizer | 10 |

| AM Category | Manipulator | Mobile Manipulator | Gantry System | References |

|---|---|---|---|---|

| Sheet lamination | * | [45,47] | ||

| VAT photopolymerization | * | * | [48] | |

| Direct energy deposition | * | * | [46] | |

| Material extrusion | * | * | * | [17] |

| Automated Platforms | Applications | Advantages | Disadvantages | |

|---|---|---|---|---|

| Gantry System |  | Construction of a bridge whose size is 25.1 m [56]. | Large-scale printing | Size of the structure |

| Test printing of concrete arches without formwork [52]. | Efficient use of workspace | Assembly time | ||

| Construction of custom designs using 3D printing to model complex geometries [57]. | Specific print designs | |||

| 3D printing of concrete structures. Gantry sytem [58]. | ||||

| Industrial Manipulator |  | Construction of a house [59,60]. | ||

| Design of a post-tensioned concrete slab post-tensioned [61]. | Easy transport | Workspace | ||

| Construction of complex structures [32,51,54,55]. | Complex print designs | Limitations on manipulator movement | ||

| On-site construction of a mesh mold [62]. | Lower printing complexity | |||

| Reinforced concrete columns printed with 3D technology [63]. | ||||

| Design and printing of a double-curved facade prototype [64,65]. | ||||

| Industrial manipulator [66]. | ||||

| Mobile Manipulator |  | Construction of concrete facades [64]. | Customized printing designs workspace | Higher printing complexity |

| Construction of complex concrete geometries [67,68]. | Integration of a linear or circular axis and a mobile robot | |||

| Mobile manipulator [67]. | Integration of a linear or circular axis and a mobile robot |

| Attribute | Values | References |

|---|---|---|

| Location | On-site—Off-site | [70,77] |

| Safety | Harsh—Common | [14] |

| Existence | New—Repair | [38] |

| Structure | Regular—Optimized | [14,69] |

| Indoor performance | Regular—Optimized | [29,78] |

| Reproduction | Regular—Customized | [69] |

| Precision | Regular—Tolerance | [79] |

| Shape | Regular—Complex | [14,69] |

| Material | Homogenous—Multiple | [38,69] |

| System | Homogenous—Hybrid | [14] |

| Resources | New—Recycled | [69] |

| Management | Fragmented—Digital flow | [69] |

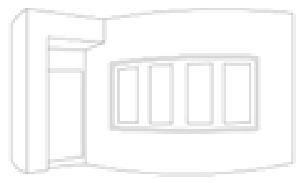

| Element | Description | Data | References |

|---|---|---|---|

| Wall | Double wall with an internal structure | Height: 1.8 m; by University of Southern California, USA | [17,19,37,57] |

| Bench | Free-form bench | 2 × 0.9 × 0.8 m; by the University of Loughborough, UK | [17,19,37,39,41,59,64] |

| Rebar wall | Wall with steel bars reinforcement | By Win Sun, China | [80,81] |

| Truss with reinforcement | Truss built with components and steel reinforcement | [38,74] | |

| Concrete wall | Rebar wall | Height: 0.6 m; length 1.52 m; by Khoshnevis | [41,58,82] |

| Democrite | Structural frame for a wall or partition | By James Gardiner | [69,74] |

| Curved wall | Double-curved slab component | By the University of Loughborough, UK | [41,58,82] |

| Acoustic damping wall | Wall built with round components to optimize acoustic behavior | 0.3 × 0.65 × 0.65 m; by Gosselin | [40] |

| Furniture | Sculpture | Component | Wall | Building | |

|---|---|---|---|---|---|

| Shapes |  |  |  |  |  |

| Applications |  Wonder Bench, University of Loughborough, UK |  Radiolaria, Enrico Dini, D-Shape—Monolite |  A Panel horizontally printed. TU Delft, Netherlands |  Double wall, Gosselin, France |  Full Printed House, Italy |

| References | Courtesy of [22] | Courtesy of [22] | Courtesy of [81] | Courtesy of [81] | Courtesy of [85] |

| Dimension | Minimum (cm) | Maximum (cm) | Mean (cm) |

|---|---|---|---|

| Cord width | 2 | 15 | 4 |

| Cord height | 1.5 | 5 | 2.5 |

| Wall thickness | 10 | 50 | 20 |

| Section length | 40 | 600 | 200 |

| Wall height | 200 | 300 | 240 |

| Crosslinked | 30 | 80 | 45 |

| Nozzle Type | Nozzle Type | ||

|---|---|---|---|

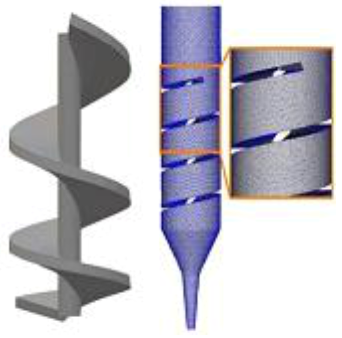

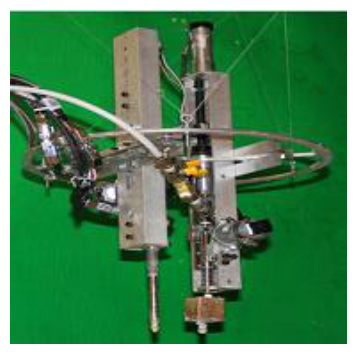

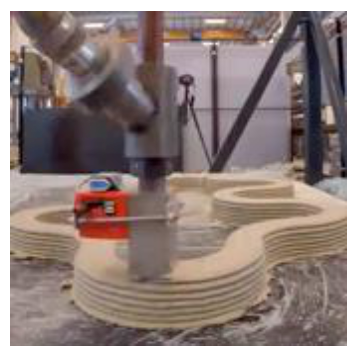

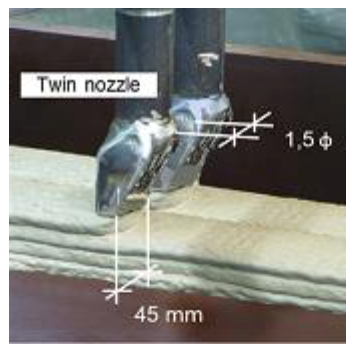

| Nozzle linked to a robotic system that moves on a rail [97]. |  | Nozzle with a helical system for injecting the material [99]. |

| Circular nozzle operated by a gantry system [98]. |  | Multi-nozzle system allowing different impression materials to be mixed [60,100]. |

| System consisting of a double rectangular nozzle system, mounted on a gantry robot [88]. |  | Rotating nozzle with rectangular cross-sections [101]. |

| Injection system with a foam extruder mounted on a mobile manipulator [102]. |  | Single round opening nozzle for printing circular profiles [101]. |

| Rectangular shaped nozzle operated by a gantry system, sinusoidal profile printing test [103]. |  | On-site printing tests using a rectangular nozzle [31]. |

| Small circular-shaped nozzle mounted on a robotic arm [103]. |  | Test printing of a multi-nozzle system, whose final effector has a material-cutting cross section [104]. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guamán-Rivera, R.; Martínez-Rocamora, A.; García-Alvarado, R.; Muñoz-Sanguinetti, C.; González-Böhme, L.F.; Auat-Cheein, F. Recent Developments and Challenges of 3D-Printed Construction: A Review of Research Fronts. Buildings 2022, 12, 229. https://doi.org/10.3390/buildings12020229

Guamán-Rivera R, Martínez-Rocamora A, García-Alvarado R, Muñoz-Sanguinetti C, González-Böhme LF, Auat-Cheein F. Recent Developments and Challenges of 3D-Printed Construction: A Review of Research Fronts. Buildings. 2022; 12(2):229. https://doi.org/10.3390/buildings12020229

Chicago/Turabian StyleGuamán-Rivera, Robert, Alejandro Martínez-Rocamora, Rodrigo García-Alvarado, Claudia Muñoz-Sanguinetti, Luis Felipe González-Böhme, and Fernando Auat-Cheein. 2022. "Recent Developments and Challenges of 3D-Printed Construction: A Review of Research Fronts" Buildings 12, no. 2: 229. https://doi.org/10.3390/buildings12020229

APA StyleGuamán-Rivera, R., Martínez-Rocamora, A., García-Alvarado, R., Muñoz-Sanguinetti, C., González-Böhme, L. F., & Auat-Cheein, F. (2022). Recent Developments and Challenges of 3D-Printed Construction: A Review of Research Fronts. Buildings, 12(2), 229. https://doi.org/10.3390/buildings12020229