Abstract

The increasing urban population requires rapid housing construction. Rising global temperatures have led to more space cooling options inside buildings. There is a need to design new-age buildings with a sustainable, thermal comfort, and energy-efficiency approach. The present work integrates this approach into the design of prefabricated elements. Locally available co-fired ash, along with other sustainable alternates, are used in developing these elements. This study involves a performance evaluation and feasibility assessment of the proposed prefabricated system. A small-scale model house of one-third size is constructed using these elements for the purpose of functional evaluation. An average temperature variation of approximately 4 °C is observed upon comparison with the fly-ash brick model during the peak summer season. During energy assessment, a 12% and 52% decrease in embodied energy and peak cooling loads were observed. The time study resulted in 20% time savings over the conventional technique. The proposed system also includes a solar photo-voltaic panel, which compensates for 30% of the energy demand and reduces approximately 42% of the energy cost. Thus, the developed prefabricated system is found suitable for non-load bearing as well as functional applications. The performed studies determined the system to be sustainable, lightweight, quick, as well as energy efficient.

1. Introduction

Urbanization has led to many construction activities in developing countries. India’s urban population has increased to 35% by the end of 2020 from 30% in 2010. Being the second most populous country, the Indian government needs to accommodate this urban population, particularly the economically weaker sections (EWS), lower- and middle-income groups (LIG and MIG). The government has set a target of constructing 20 million houses in a span of 7 years, which translates to approximately 8000 houses per day as the construction rate [1]. To achieve this rate, various prefabrication techniques are being executed across different locations in the country. Global temperatures are also rising every year, with the last 9 years being in the top 10 warmest years as per records [2]. This increasing temperature led to the design of buildings with better space cooling options. Thus, there is a need to design new-age buildings with a sustainable, thermal comfort, and energy efficiency approach.

Prefabrication is a system of manufacturing building elements in controlled environments, transporting them, and assembling them on-site. These elements have better results than the conventional techniques. These elements have their application both in the structural as well as non-load bearing elements [3]. Inclusion of composite materials into the design for enhancing various properties was studied. Few of them enhanced the structural properties [4,5,6,7,8], whereas some improved the functional properties [9,10].

Prefabrication or prefab is majorly chosen in urban construction to overcome challenges related to space, time, and cost [11,12]. Some earlier studies mentioned prefabricated housing to be energy efficient as well as affordable for mass housing [13]. As 40% of energy consumption is solely due to building construction [14,15], the energy related to embodied energy (EE) and operational energy (OE) needs significant attention. EE is related to the individual production of raw materials and their transportation, whereas, OE deals with the application of end products in their final position and post-occupational phase [16].

An increase in construction activities exploits natural resources. Thus, sustainable alternatives for raw materials are necessary by including agro-industrial by-products into the mix designs. This further decreases the EE of the end-product. Many agro-industrial and construction wastes were used as alternative raw materials in earlier mix designs. Some of these alternates are fly ash, furnace slag [17], recycled paper-mill waste [18], briquette ash [19], blended ash [20,21,22], and construction and demolition wastes [23,24]. The physico-mechanical and functional test results of the novel end products were better in comparison with commercially available products.

Operational energy is mainly focused after the end-application, i.e., during the post-occupation phase of the end products. One of the main factors responsible for OE is space cooling, which has been observed to be increasing in the past few decades [25]. Maintaining thermal comfort during peak temperatures remains a critical task regarding space cooling. The inclusion of insulation materials is a potential solution that has been proven to reduce operational energy [26,27]. These materials of low thermal conductivity conserve the peak cooling load [28] by maintaining thermal comfort inside a building. Materials, such as expanded polystyrene (EPS), polyurethane foam (PUF), aerated concrete, and similar other materials, were added to the building products to enhance their thermal properties [26,29,30,31]. Along with this, the adoption of renewable energy techniques, such as utilisation of solar energy is a method to minimise OE demand. The application of solar photovoltaic panels in the building system encompasses energy efficiency [32,33].

Various techniques were developed to evaluate the performance of the products. The construction of a small-scale experimental model is one of the proven techniques to study the functional performance of the products [34,35]. Earlier literature studies highlighted the convergence of small-scale models to the actual buildings [4,35]. Building information modelling (BIM) has a variety of tools that involve modelling, orientation, and energy evaluation [36,37]. Results from this tool were extracted, analysed, and compared with conventional techniques, and were proven valid in the majority of the cases [38,39,40].

The reviewed literature presents the need for faster construction as well as energy-efficient housing. Integration of parameters, such as sustainability, building energy, and thermal comfort, with panelised building technology has given rise to the design and development of end-products. Sustainable alternates, such as agro-industrial by-products, are used as fine aggregates to reduce the embodied energy of the novel product. The application of insulation material in the mix design and solar photovoltaic panels in the prefabricated system were attempted to curtail the operational energy. Furthermore, the developed products are compared with conventional products and techniques.

2. Product Development and Methodology

2.1. Materials

An agro-industrial by-product, named co-fired ash (CFA) was acquired from a local industry in Nagpur, India (Figure 1). Upon various material characterisation tests and applications, this raw material was found suitable to be used as a construction material. Partial replacements of 20% and 10% CFA in fine aggregates for concrete (Figure 2) and lightweight (LW) prefabricated mix (Figure 3), respectively, were finalised. Expanded polystyrene (EPS) beads from waste packaging material were used as insulation materials in the prefabricated mix. This helps to reduce the density as well as the thermal conductivity of the developed end-product. Sustainable alternatives, such as fly ash and crushed sand, along with mineral and chemical admixtures were added to the mix to enhance its properties.

Figure 1.

CFA.

Figure 2.

CFA-based concrete.

Figure 3.

CFA-based LW mix.

2.2. Mix Design and Testing

Several trials of CFA-based end products were designed as per the Codal standards. The optimal mix trials were concluded for both concrete (Table 1) and LW mix (Table 2) [41], with a target of being superior to traditional construction products. Their respective physico-mechanical along with functional properties were compared to conventional products, as shown in Table 3.

Table 1.

Mix design of the CFA-based concrete.

Table 2.

Mix design of the CFA-based LW prefabricated mix.

Table 3.

Physico-mechanical and functional properties of materials.

2.3. Methodology

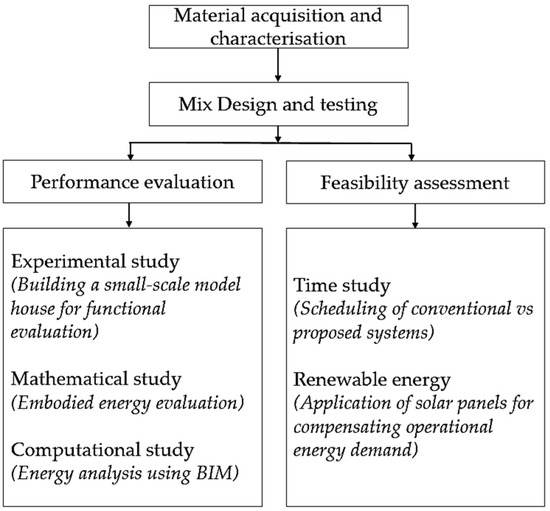

The current study involves a mix design of the proposed prefabricated elements. These elements are evaluated for both performance and feasibility. The workflow of the study is mentioned in Figure 4. Section 3 and Section 4 briefly discuss the performance of the evaluation of the developed products, whereas Section 5 discusses the feasibility of the assessment.

Figure 4.

Workflow diagram.

3. Development of Experimental Model

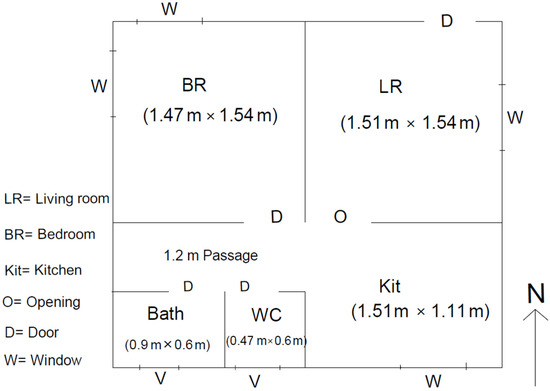

With the objective of evaluating the performance of the developed products, construction of the scaled-down model houses was found to be an established technique [34,35]. An indoor temperature assessment was also carried out that gave appropriate results regarding the thermal behaviour of walling materials. Thus, a small-scale experimental model house was planned for the performance evaluation of developed end products (Figure 5).

Figure 5.

Plan of the proposed model house.

Building of a Small-Scale Model House

The prefabrication technique was selected for the building of the model house, and the housing plan was scaled down to one-third of its original size. Precast structural elements (Figure 6) and prefabricated walling panels (Figure 7) were cast and cured as per the Codal standards [41]. The model house (Figure 8) was assembled with these elements in a shadow-free region at the Civil Engineering Department, Visvesvaraya National Institute of Technology, Nagpur, India. The orientation of the model house was towards the north direction. Another small-scale model house composed of fly-ash brickwork and concrete slab was also constructed for the purpose of a comparative study.

Figure 6.

Structural elements.

Figure 7.

Prefabricated Panels.

Figure 8.

Model house.

4. Performance Evaluation of the Developed Model

The performance of the model was studied by evaluating two parameters: functional and energy. Functional parameters were evaluated with the help of an experimental study that involved recording temperature data and observing the variation in thermal inertia, whereas energy assessment included the determination of the embodied energy and operational energy of the developed products.

4.1. Functional Evaluation

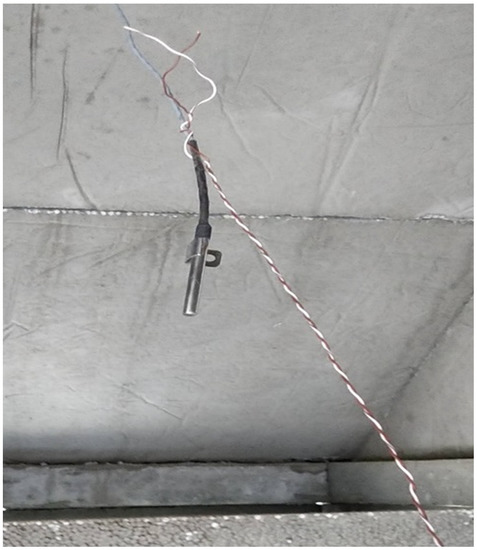

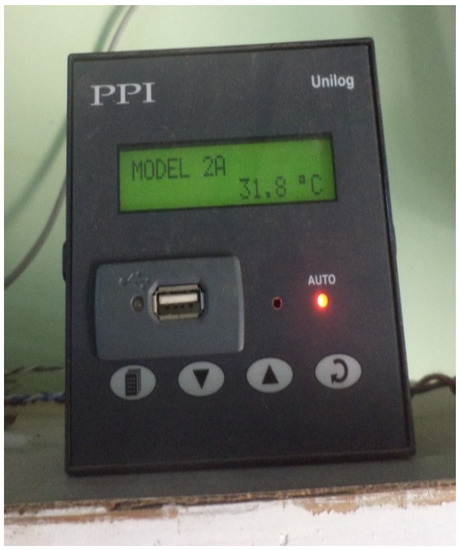

Two temperature sensors were fitted into each model house, as shown in Figure 9 and Figure 10. A data logger (Figure 11) that records the data from sensors over time was fitted into the study room. The study period for the temperature assessment was finalised as the summer of Nagpur (from March-end to mid-June), 2022. Hourly temperature data over the study period were collected for both models and further compared with the ambient outside temperature.

Figure 9.

Sensor in prefabricated model house.

Figure 10.

Sensor in fly-ash brick model house.

Figure 11.

Data Logger.

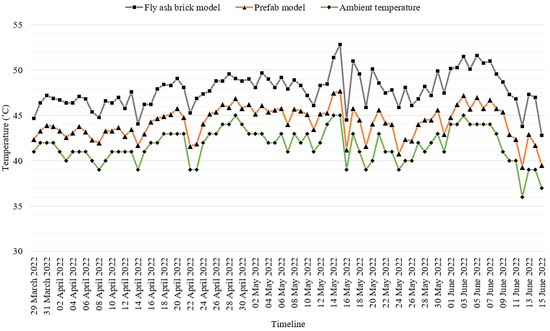

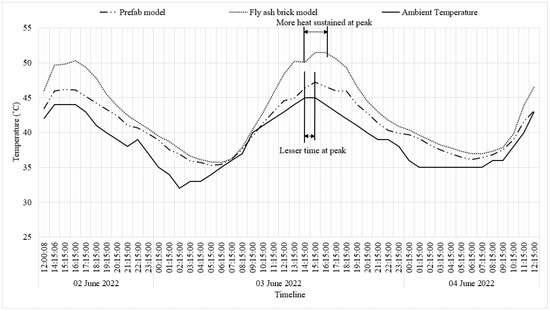

Over 1900 temperature data points were collected inside the model houses. The maximum daytime temperatures collected within this period were filtered, and a graph was plotted, as shown in Figure 12. Thermal inertia can be explained as the degree of slowness with which the temperature of an element advances towards its ambient conditions [42]. One of the hottest days was chosen, and a 48 h time interval was plotted on a graph with all the internal and external ambient temperatures. The thermal inertia can be observed from the graph, as shown in Figure 13.

Figure 12.

Comparison of maximum temperatures.

Figure 13.

Thermal inertia of developed models.

The thermal variation between the developed prefabricated model and the fly-ash brick model was studied and found to be approximately 4 °C. This proves that the developed prefabricated model has approximately 8% lower temperatures than the conventional technique. From Figure 13, it can be observed that the prefabricated model tends to cool down after it reaches its peak temperature, whereas, the fly-ash brick model sustains the heat for a longer duration than the developed model. The prefabricated panels involve materials created from lower thermal conductive materials than fly-ash bricks. This has a prominent effect on the thermal comfort provided by the two walling techniques.

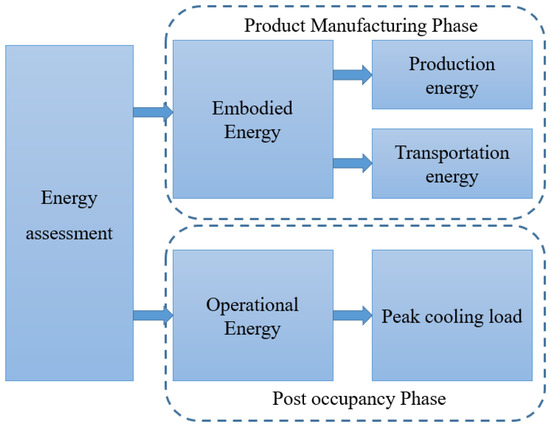

4.2. Energy Assessment

In order to evaluate the energy efficiency of a building, both embodied energy and operational energy have to be calculated. For the current study, EE was calculated mathematically for the materials during the product manufacturing and on-site execution phases. Operational energy was calculated by extracting the peak cooling loads during the post-occupancy phase through computational modelling (Figure 14).

Figure 14.

Flowchart for energy assessment.

4.2.1. Evaluation of Embodied Energy

Embodied energy comprises both the production and transportation energy of the raw materials [16,43,44,45] that were used during the product manufacturing and execution phases (Equation (1)).

Embodied energy = Production energy + Transportation energy

Production energy is the energy emitted while manufacturing or processing raw materials during manufacturing (Equation (2)). Electricity consumption is also considered in the calculation of production energy. The distance travelled by the raw material from its source to the end application is converted into transportation energy (Equation (3)).

Production energy = Weight of raw material × Thermal energy for producing one unit weight of raw material

Transportation energy = Distance travelled by raw material × Quantity of fuel × Density of fuel × Energy produced for one unit weight of fuel

Both these energies summed up for all the raw materials used in the end-product result in EE.

Two different building systems were considered in this evaluation: conventional fly-ash brick masonry system (fly-ash brickwork and reinforced cement concrete (RCC)); and developed prefabricated building system (CFA-based concrete prefabricated elements). EE was calculated and is presented in Table 4. The individual values for the brick masonry were opted from the earlier results [46]. The same method was followed for the developed prefabricated system.

Table 4.

Total EEs of conventional and proposed cases.

The end application of the prefabricated panels was for non-load bearing walls. However, the mix used for panels was more equivalent to concrete than the masonry product. The EE per cubic metre of the panels was 19% less than conventional concrete, whereas it was 40% more than the masonry product. The quantities played a key role in evaluating the EE of the whole system. The total quantity required for the wall panels was approximately 42% less than the masonry system. Hence, a 19% lower EE was observed for walling material, and an overall 12% lower EE was observed for the prefabricated system over the conventional system.

4.2.2. Operational Energy—Computational Modelling

One of the contributing factors to energy consumption in buildings is their location [27]. The Indian subcontinent has five climatic zones, as per NBC 2016 [47]. Sun path and weather conditions vary for each climatic zone. The consumption of household energy varies based on these conditions. Structures, similar in plan and size, differ in their operational energy demands and peak cooling loads based on the locality. The present study was conducted in Nagpur, India, with a latitude of 21.1232° N and a longitude of 79.0515° E. This region lies in the composite climatic zone, with maximum summer temperatures clocking between 48 and 49 °C.

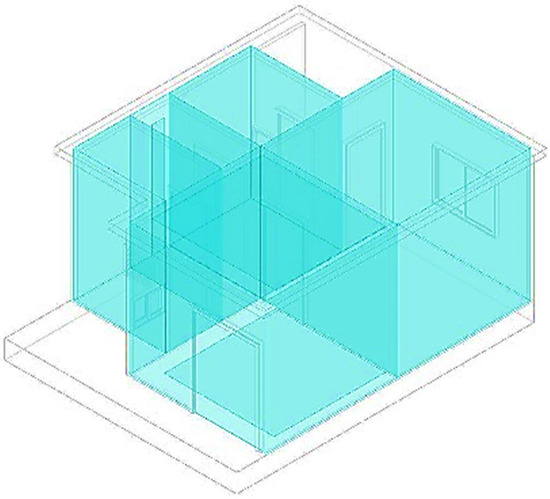

Computational modelling was considered for fly-ash brick masonry and developed prefabricated systems using the BIM tool, Revit. The location details, weather conditions, and properties of the end products (Table 5) were fed into the database. Models were oriented towards the north direction based on earlier experimental studies [35]. Energy models were prepared based on the given inputs (Figure 15). The thermal zones of walling members were identified based on the location, weather, and other parameters related to the construction products.

Table 5.

Material properties of end products.

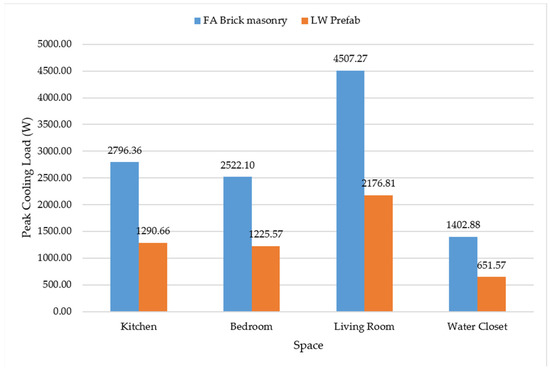

Figure 15.

Energy model.

The model includes individual spaces, such as a kitchen, bedroom, living room, and water closet. PCLs were extracted for these spaces and are presented in Figure 16. The functional properties, orientation, and locality have an impact on the operational energy demand. Since the locality and orientation are equivalent, the functional properties play a vital role in appropriate material selection. PCLs vary because of these properties, particularly thermal conductivity. The developed system has 50% and 62% less thermal conductivity for structural and walling elements, respectively. This resulted in a reduction of approximately 52% PCL for the developed system over the conventional system.

Figure 16.

Comparison of peak cooling loads of two systems.

5. Feasibility

The feasibility of the developed prefabricated system was checked for time and opting renewable energy. The time study was performed in order to find a feasible option in terms of quicker construction. Additionally, solar energy was used to run the electrical appliances in the model house. A feasibility check on replacing a part of energy consumption with solar energy was conducted.

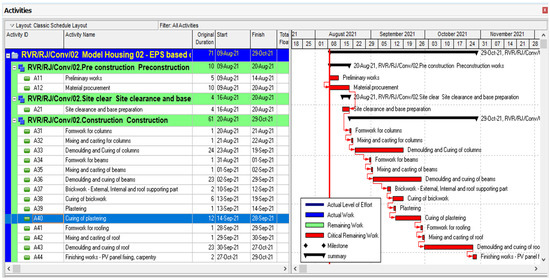

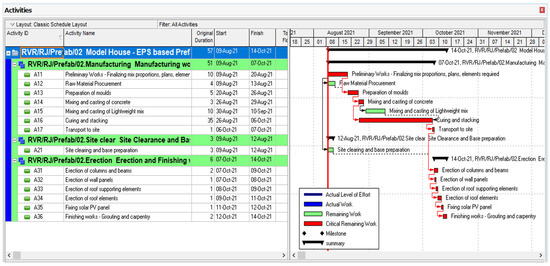

5.1. Time Study

Scheduling was carried out as part of the computational study. Two cases of comparison were considered in this study. Case A is a conventional construction with cast in situ concrete and fly-ash brickwork; case B is the proposed prefabricated system with pre-cast concrete elements and lightweight prefabricated walling panels. Sub-structure construction is considered the same for all the cases, and hence activities, such as material procurement, manufacturing, surface preparation, and on-site construction were considered. Upon executing the schedules, the overall duration of the projects was 71 days for case A, and 57 days for case B. The activity list and the Gantt chart are presented in Figure 17 and Figure 18.

Figure 17.

Schedule of Case A—complete conventional construction.

Figure 18.

Schedule of Case B—complete prefabricated construction.

The proposed prefabricated system turned out to be a better replacement for the conventional construction in terms of the total duration of the project. One of the major time-consuming activities is the curing period for elements. A complete prefabricated structure has a single stretch of curing where all its elements are cured in a single activity (Figure 18—case B). Whereas, a conventional case has multiple curing period activities which ultimately increases the total duration of the project. Thus, approximately 20% of the time savings are observed when opting for a complete prefabricated system over the conventional system.

5.2. Energy

The common household includes a few basic amenities, such as lighting, space cooling, and recreational activities. The most common appliances found in local households are lamps, tube-lights, ceiling fans, coolers, televisions (TVs), and refrigerators. The minimum number of these appliances required are estimated for the given plan. According to Indian climatic conditions, the seasons are divided into summer, monsoon, and winter. Summer season includes 3 months from March to May; monsoon is further divided as monsoon (June–September) and post monsoon (October and November); and winter is from December to February [35]. Working hours of the mentioned appliances are collected from the local residents. The average working hours of each appliance are presented in Table 6 based on the season.

Table 6.

Energy usage by a common household over the year.

The annual energy consumption of the given model is estimated to be approximately 1384 kWh. A solar photo-voltaic (PV) panel is fit into the model in order to generate the on-site energy and compensate a part of the energy consumption by the household. The annual energy generation of the PV panel is specified to be approximately 430 kWh (Table 7).

Table 7.

Annual energy generation from the solar PV panel.

A comparison of demand-supply management for operational energy resulted in 30% savings for the energy. By applying the local energy tariffs, approximately 42% of the cost savings were observed on the installation of the solar PV panel. Additionally, by comparing the initial investment for this PV panel (inclusive of the panel’s cost, transport, and installation) with the energy savings, a payback period of approximately 21 months was observed.

Application of climate-responsive design features, inclusion of sustainable building materials and installation of an on-site renewable energy unit are part of the green building criteria [48]. The proposed system contributes approximately 16% more energy generation than the mentioned criteria to attain certification in the green building category.

6. Discussion and Recommendations

Mix designs for concrete as well as lightweight walling materials were tested for suitability in on-site execution. The properties were compared with those of conventional products and found to be satisfactory for the application. As the post-occupancy parameters differed with the properties, performance evaluation, and feasibility assessment for reducing the energy demand were performed. The significant findings from the experimental, mathematical, and computational analyses are summarised below in Table 8. The values presented are all in terms of the percentage improvement over the conventional system.

Table 8.

Findings of the prefabricated system over the conventional system (in terms of %).

Walling contributes more surface area than the structural components. Ambient inside temperatures and peak cooling loads depend on the properties of these walling elements. In this study, CFA and EPS beads were used in the mixed design of walling members. The specific gravity and bulk density of the CFA were lower than those of conventional fine aggregates. Along with this, the presence of EPS beads in the prefabricated walling mix has made the end product much lighter than the brick. As the thermal conductivity of the walling element is less than the conventional one; the percentage reductions in ambient temperature as well as peak cooling load were observed. The inclusion of sustainable alternatives to conventional raw materials in the developed prefabricated system, its process, and the quantities have made the embodied energy optimal.

Buildings that have energy savings of approximately 20–30% are termed energy efficient by the Indian Green Building Council [48]. Energy efficiency leads to a reduction in greenhouse gas emissions from both fossil fuels as well as electricity-related emissions [49]. Reductions in EE and OE result in less usage of electricity. Thus, savings observed in energy ultimately contribute to reducing the carbon footprint of the material.

Sustainable and energy-efficient mass housing is a need of the hour in the Indian construction industry. The developed prefabricated elements suit these requirements as per the derived results. The panels were limited to a single-storeyed model. Hence, further studies could be extended to multi-storeyed buildings. The effect of various climatic conditions across the globe can also be studied, as the current study area is restricted to Nagpur, India.

7. Conclusions

The present study focused on the development of a construction product that could be applied as prefabricated elements. These elements include industrial by-products, such as fly ash and cofired ash as partial substitutes for cement and sand. Insulating materials were mixed to make the panels lightweight as well as thermally resistant. A combination of all these materials to produce a sustainable and energy-efficient construction product is a novel idea that was achieved. A small-scale model house was planned and constructed with the purpose of evaluating the functional performance of the end-products. Temperature sensors were placed in a prefabricated model and fly-ash brick model to assess and compare internal temperatures. This assessment resulted in the prefabricated system having an 8% lower inner temperature than the fly-ash brick model during the summer. During the peak temperatures, the prefabricated model recovered to its ambient temperature whereas, the conventional model sustained the peak temperature for longer duration. Embodied energy and peak cooling loads were evaluated and found to be 12% and 52% lower than the conventional system. Inclusion of the insulation material, such as expanded polystyrene beads, in the concrete played a major role in reducing the building energy of the product. Construction was quicker with the help of the proposed prefabricated system. Approximately 20% of the time savings were observed by opting for this prefabricated system over conventional. A solar photo-voltaic panel was placed over the roof of the prefabricated system with a view to compensate for the basic energy demand of the household. On compensating 30% of the energy requirement, approximately 42% of the conventional energy cost got reduced with a payback period of 21 months for the initial investment cost of a PV panel. Thus, the application of the proposed sustainable prefabricated system was found to be lightweight, energy efficient, and feasible in terms of energy and construction time.

Author Contributions

R.C.: Conceptualization, Methodology, Formal Analysis, Investigation, Data Curation, Writing—Original draft preparation; H.R.G.: Formal Analysis, Data Curation, Writing—Original draft preparation and reviewing; A.B.: Conceptualization, Methodology, Writing—Original draft preparation and reviewing; R.V.R.: Conceptualization, Methodology, Investigation, Writing—Original draft preparation and reviewing. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by funding under Liverpool John Moores University Global Challenge Research Fund 2018–2020 and the grant No. 271002/S0001/954FET/GCRFFET04.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available upon request from the corresponding author.

Acknowledgments

The experimentation and castings were conducted with the support of M/s. Apple Chemie India Pvt Ltd.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ministry of Housing & Urban Poverty Alleviation Government of India Pradhan Mantri Awas Yojana—Housing for All (Urban) —Credit Linked Subsidy Scheme. Gov. India New Delhi 2017, 2017, 1–62.

- Lindsey, R.; Dahlman, L. Climate Change: Global Temperature. Available online: https://www.climate.gov/news-features/understanding-climate/climate-change-global-temperature#:~:text=Earth%E2%80%99s%20temper-ature%20has%20risen%20by,%20based%20on%20NOAA%E2%80%99s%20temperature%20data (accessed on 10 October 2022).

- Chippagiri, R.; Bras, A.; Sharma, D.; Ralegaonkar, R.V. Technological and Sustainable Perception on the Advancements of Prefabrication in Construction Industry. Energies 2022, 15, 7548. [Google Scholar] [CrossRef]

- Aksoylu, C.; Kara, N. Strengthening of RC frames by using high strength diagonal precast panels. J. Build. Eng. 2020, 31, 101338. [Google Scholar] [CrossRef]

- Özkılıç, Y.O.; Aksoylu, C.; Arslan, M.H. Experimental and numerical investigations of steel fiber reinforced concrete dapped-end purlins. J. Build. Eng. 2021, 36, 102119. [Google Scholar] [CrossRef]

- Aksoylu, C.; Sezer, R. Investigation of precast new diagonal concrete panels in strengthened the infilled reinforced concrete frames. KSCE J. Civ. Eng. 2018, 22, 236–246. [Google Scholar] [CrossRef]

- Gemi, L.; Aksoylu, C.; Yazman, Ş.; Özkılıç, Y.O.; Arslan, M.H. Experimental investigation of shear capacity and damage analysis of thinned end prefabricated concrete purlins strengthened by CFRP composite. Compos. Struct. 2019, 229, 111399. [Google Scholar] [CrossRef]

- Özkılıç, Y.O.; Yazman, Ş.; Aksoylu, C.; Arslan, M.H.; Gemi, L. Numerical investigation of the parameters influencing the behavior of dapped end prefabricated concrete purlins with and without CFRP strengthening. Constr. Build. Mater. 2021, 275, 122173. [Google Scholar] [CrossRef]

- Einea, A.; Salmon, D.C.; Fogarasi, G.J.; Culp, T.D.; Tadros, M.K. State-of-the-art of Precast Concrete Sandwich Panels. PCI J. 1991, 36, 78–92. [Google Scholar] [CrossRef]

- O’Hegarty, R.; Kinnane, O. Review of precast concrete sandwich panels and their innovations. Constr. Build. Mater. 2020, 233, 117145. [Google Scholar] [CrossRef]

- Dave, M.; Watson, B.; Prasad, D. Performance and perception in prefab housing: An exploratory industry survey on sustainability and affordability. Procedia Eng. 2017, 180, 676–686. [Google Scholar] [CrossRef]

- Lopez, D.; Froese, T.M. Analysis of costs and benefits of panelized and modular prefabricated homes. Procedia Eng. 2016, 145, 1291–1297. [Google Scholar] [CrossRef]

- Chippagiri, R.; Gavali, H.R.; Ralegaonkar, R.V.; Riley, M.; Shaw, A.; Bras, A. Application of Sustainable Prefabricated Wall Technology for Energy Efficient Social Housing. Sustainability 2021, 13, 1195. [Google Scholar] [CrossRef]

- Bansal, D.; Singh, R.; Sawhney, R.L. Effect of construction materials on embodied energy and cost of buildings—A case study of residential houses in India up to 60 m2 of plinth area. Energy Build. 2014, 69, 260–266. [Google Scholar] [CrossRef]

- Ramesh, T.; Prakash, R.; Shukla, K.K. Life cycle energy analysis of buildings: An overview. Energy Build. 2010, 42, 1592–1600. [Google Scholar] [CrossRef]

- Venkatarama Reddy, B.V.; Jagadish, K.S. Embodied energy of common and alternative building materials and technologies. Energy Build. 2003, 35, 129–137. [Google Scholar] [CrossRef]

- Tembhurkar, S.; Ralegaonkar, R.; Azevedo, A.; Madurwar, M. Low cost geopolymer modular toilet unit for ODF India—A case study. Case Stud. Constr. Mater. 2022, 16, e00937. [Google Scholar] [CrossRef]

- Raut, S.P.; Sedmake, R.; Dhunde, S.; Ralegaonkar, R.V.; Mandavgane, S.A. Reuse of recycle paper mill waste in energy absorbing light weight bricks. Constr. Build. Mater. 2012, 27, 247–251. [Google Scholar] [CrossRef]

- Sakhare, V.V.; Ralegaonkar, R.V. Development and investigation of cellular light weight bio-briquette ash bricks. Clean Technol. Environ. Policy 2017, 19, 235–242. [Google Scholar] [CrossRef]

- Ram, S.; Ralegaonkar, R.V.; Pradhan, K. Use of co-fired blended ash in the development of sustainable construction materials. Proc. Inst. Civ. Eng. Eng. Sustain. 2017, 171, 425–432. [Google Scholar] [CrossRef]

- Gavali, H.R.; Bras, A.; Faria, P.; Ralegaonkar, R.V. Development of sustainable alkali-activated bricks using industrial wastes. Constr. Build. Mater. 2019, 215, 180–191. [Google Scholar] [CrossRef]

- Shelote, K.M.; Gavali, H.R.; Bras, A.; Ralegaonkar, R.V. Utilization of co-fired blended ash and chopped basalt fiber in the development of sustainable mortar. Sustainability 2021, 13, 1247. [Google Scholar] [CrossRef]

- Dakwale, V.A.; Ralegaonkar, R.V. Development of sustainable construction material using construction and demolition waste. Indian, J. Eng. Mater. Sci. 2014, 21, 451–457. [Google Scholar]

- Venkrbec, V.; Klanšek, U. Suitability of recycled concrete aggregates from precast panel buildings deconstructed at expired lifespan for structural use. J. Clean. Prod. 2020, 247, 119593. [Google Scholar] [CrossRef]

- IEA Final Residential Energy Use Covered by Labels, 2000–2021, IEA, Paris. Available online: https://www.iea.org/data-and-statistics/charts/final-residential-energy-use-covered-by-labels-2000-2021 (accessed on 30 April 2022).

- Kumar, D.; Alam, M.; Zou, P.X.W.; Sanjayan, J.G.; Memon, R.A. Comparative analysis of building insulation material properties and performance. Renew. Sustain. Energy Rev. 2020, 131, 110038. [Google Scholar] [CrossRef]

- Shoubi, M.V.; Shoubi, M.V.; Bagchi, A.; Barough, A.S. Reducing the operational energy demand in buildings using building information modeling tools and sustainability approaches. Ain Shams Eng. J. 2015, 6, 41–55. [Google Scholar] [CrossRef]

- Ralegaonkar, R.V.; Gavali, H.R.; Sakhare, V.V.; Puppala, A.J.; Aswath, P.B. Energy-efficient slum house using alternative materials. Proc. Inst. Civ. Eng. Energy 2017, 170, 93–102. [Google Scholar] [CrossRef]

- Naito, C.; Hoemann, J.; Beacraft, M.; Bewick, B. Performance and characterization of shear ties for use in insulated precast concrete sandwich wall panels. J. Struct. Eng. 2012, 138, 52–61. [Google Scholar] [CrossRef]

- Shams, A.; Stark, A.; Hoogen, F.; Hegger, J.; Schneider, H. Innovative sandwich structures made of high performance concrete and foamed polyurethane. Compos. Struct. 2015, 121, 271–279. [Google Scholar] [CrossRef]

- D’Orazio, M.; Stipa, P.; Sabbatini, S.; Maracchini, G. Experimental investigation on the durability of a novel lightweight prefabricated reinforced-EPS based construction system. Constr. Build. Mater. 2020, 252, 119134. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, Y.; He, B.J.; Xu, W.; Jin, G.; Zhang, X. Application and suitability analysis of the key technologies in nearly zero energy buildings in China. Renew. Sustain. Energy Rev. 2019, 101, 329–345. [Google Scholar] [CrossRef]

- Ralegaonkar, R.V.; Gupta, R. Design development of a static sunshade using small scale modeling technique. Renew. Energy 2005, 30, 867–880. [Google Scholar] [CrossRef]

- Raut, S.; Mandavgane, S.; Ralegaonkar, R. Thermal Performance Assessment of Recycled Paper Mill Waste–Cement Bricks Using the Small-Scale Model Technique. J. Energy Eng. 2014, 140, 04014001. [Google Scholar] [CrossRef]

- Sakhare, V.V.; Ralegaonkar, R.V. Strategy to control indoor temperature for redevelopment of slum dwellings. Indoor Built Environ. 2018, 27, 1203–1215. [Google Scholar] [CrossRef]

- Gavali, H.R.; Ralegaonkar, R.V. Application of information modelling for sustainable urban-poor housing in India. Proc. Inst. Civ. Eng. Eng. Sustain. 2018, 172, 68–75. [Google Scholar] [CrossRef]

- Ram, S.; Ralegaonkar, R.V.; Gavali, H.R. Assessment of energy efficiency in buildings using synergistic walling material. Proc. Inst. Civ. Eng. Energy 2018, 171, 182–189. [Google Scholar] [CrossRef]

- Abanda, F.H.; Byers, L. An investigation of the impact of building orientation on energy consumption in a domestic building using emerging BIM (Building Information Modelling). Energy 2016, 97, 517–527. [Google Scholar] [CrossRef]

- Li, H.X.; Ma, Z.; Liu, H.; Wang, J.; Al-Hussein, M.; Mills, A. Exploring and verifying BIM-based energy simulation for building operations. Eng. Constr. Archit. Manag. 2020, 27, 1679–1702. [Google Scholar] [CrossRef]

- Hilliaho, K.; Lahdensivu, J.; Vinha, J. Glazed space thermal simulation with IDA-ICE 4.61 software—Suitability analysis with case study. Energy Build. 2015, 89, 132–141. [Google Scholar] [CrossRef]

- Chippagiri, R.; Bras, A.; Ralegaonkar, R.V. Development of sustainable prefabricated housing system by small-scale experimental model. Proc. Inst. Civ. Eng.Eng. Sustain. 2022, 40, 1–14. [Google Scholar] [CrossRef]

- Merriam-Webster.com Dictionary Thermal Inertia. Available online: https://www.merriam-webster.com/dictionary/thermalinertia (accessed on 28 July 2022).

- Praseeda, K.I.; Reddy, B.V.V.; Mani, M. Embodied energy assessment of building materials in India using process and input-output analysis. Energy Build. 2015, 86, 677–686. [Google Scholar] [CrossRef]

- Chen, T.Y.; Burnett, J.; Chau, C.K. Analysis of embodied energy use in the residential building of Hong Kong. Energy 2001, 26, 323–340. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Barreneche, C.; Miró, L.; Morera, J.M.; Bartolí, E.; Inés Fernández, A. Low carbon and low embodied energy materials in buildings: A review. Renew. Sustain. Energy Rev. 2013, 23, 536–542. [Google Scholar] [CrossRef]

- Gavali, H.R.; Bras, A.; Ralegaonkar, R.V. Cleaner construction of social housing infrastructure with load-bearing alkali-activated masonry. Clean Technol. Environ. Policy 2021, 23, 2303–2318. [Google Scholar] [CrossRef]

- NBC National Building Code of India, Volume 2. Bur. Indian Stand. New Delhi India 2016, 2, 97.

- CII—IGBC IGBC Green New Buildings Rating System Version 3.0. 2014. Available online: https://igbc.in/igbc/html_pdfs/abridged/IGBC%20Green%20New%20Buildings%20Rating%20System%20(Version%203.0).pdf (accessed on 15 October 2022).

- IEA Emission Savings—Multiple Benefits of Energy Efficiency. Available online: https://www.iea.org/reports/multiple-benefits-of-energy-efficiency/emissions-savings (accessed on 15 October 2022).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).