Three-Dimensional (3D) Microstructure-Based Modeling of a Thermally-Aged Cast Duplex Stainless Steel Based on X-ray Microtomography, Nanoindentation and Micropillar Compression

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

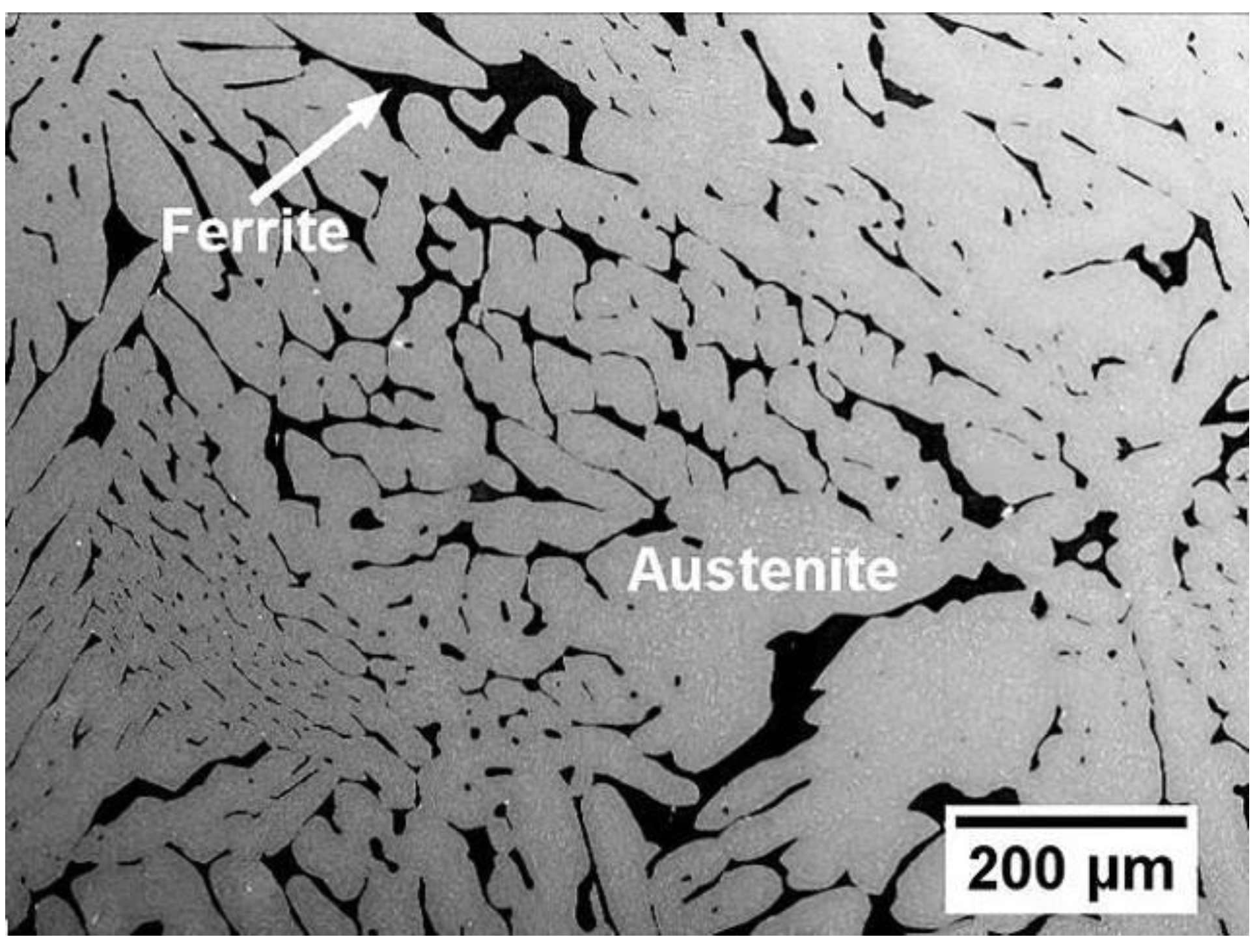

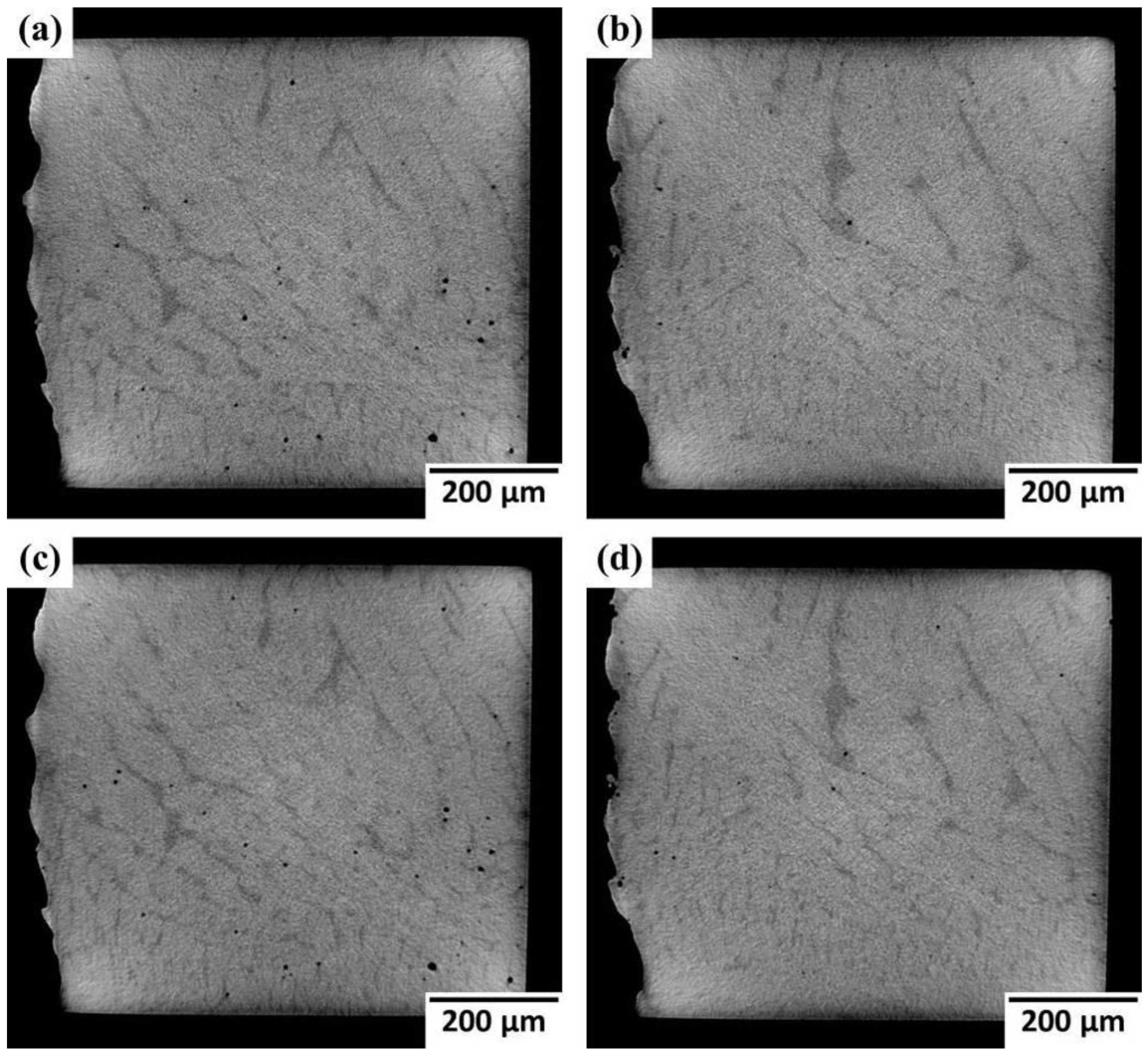

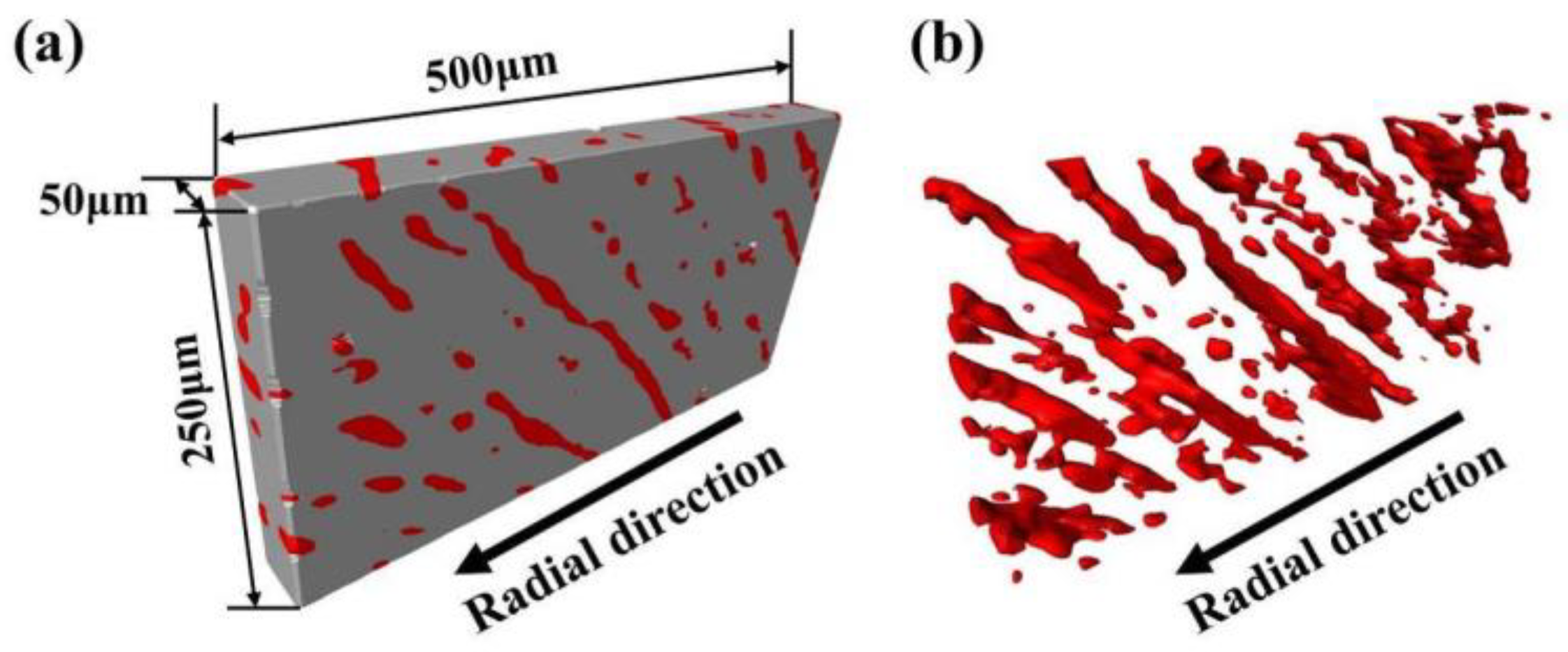

3.1. 3D Microstructural Evolution During Thermal Aging

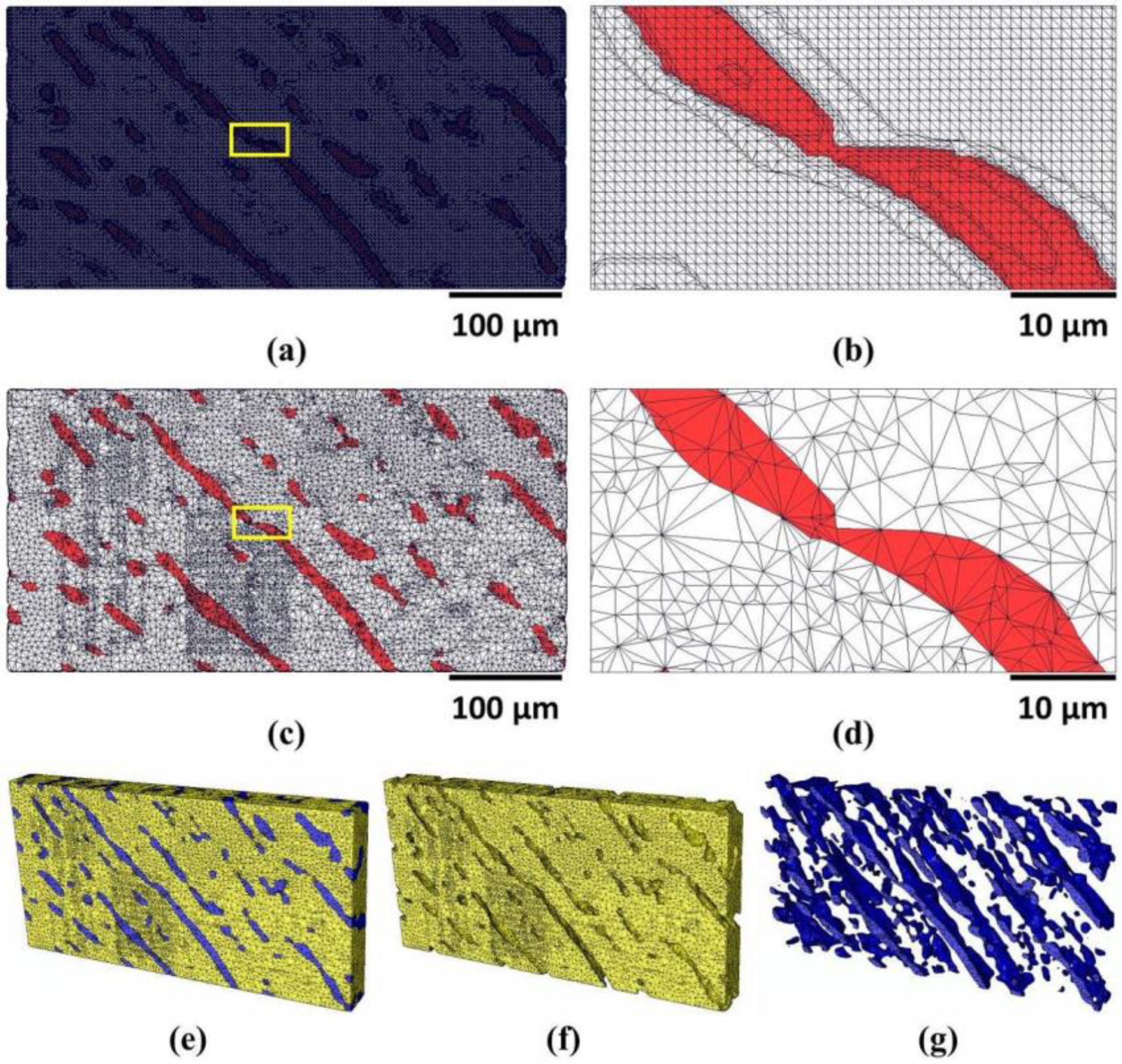

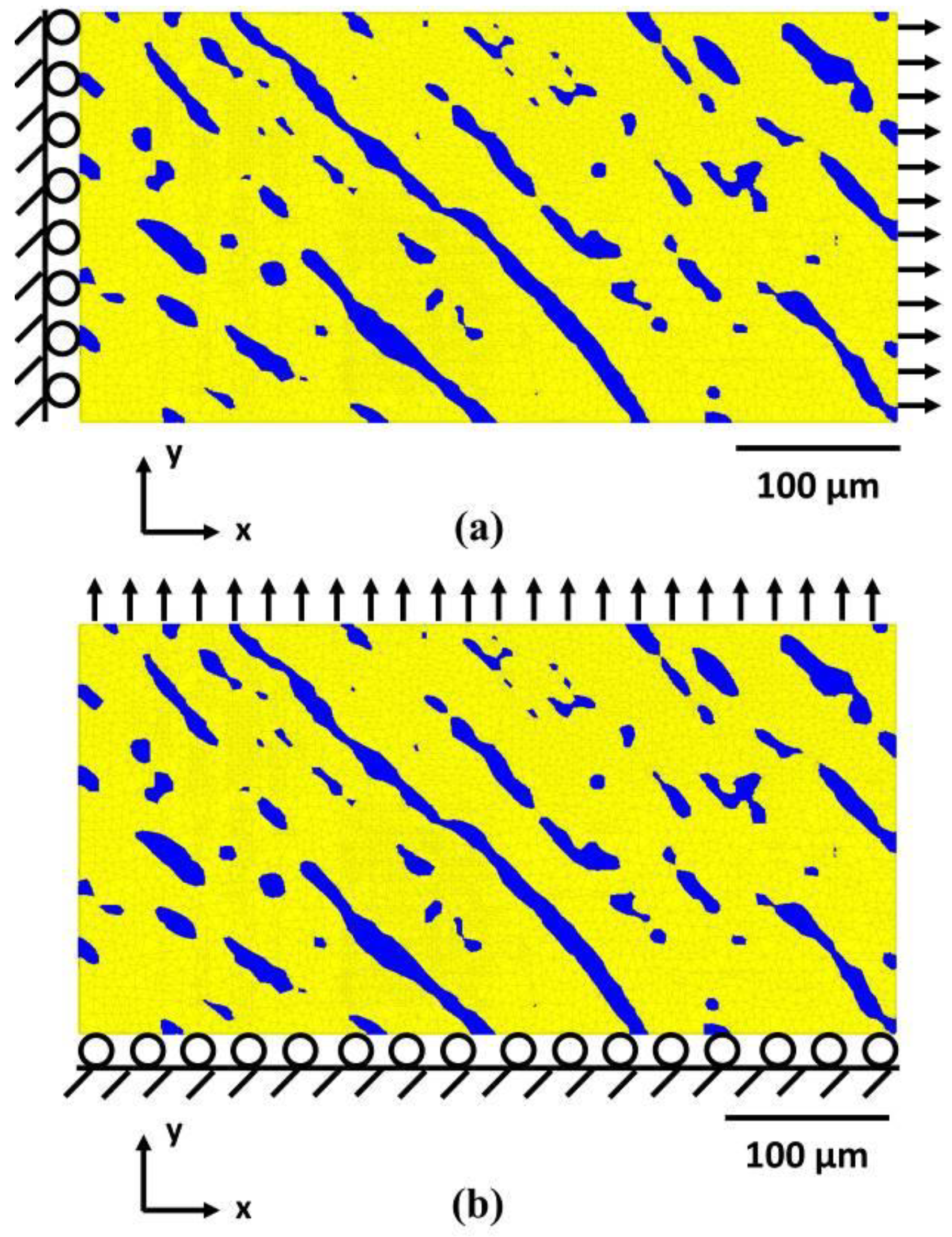

3.2. True Microstructure-Based Modeling

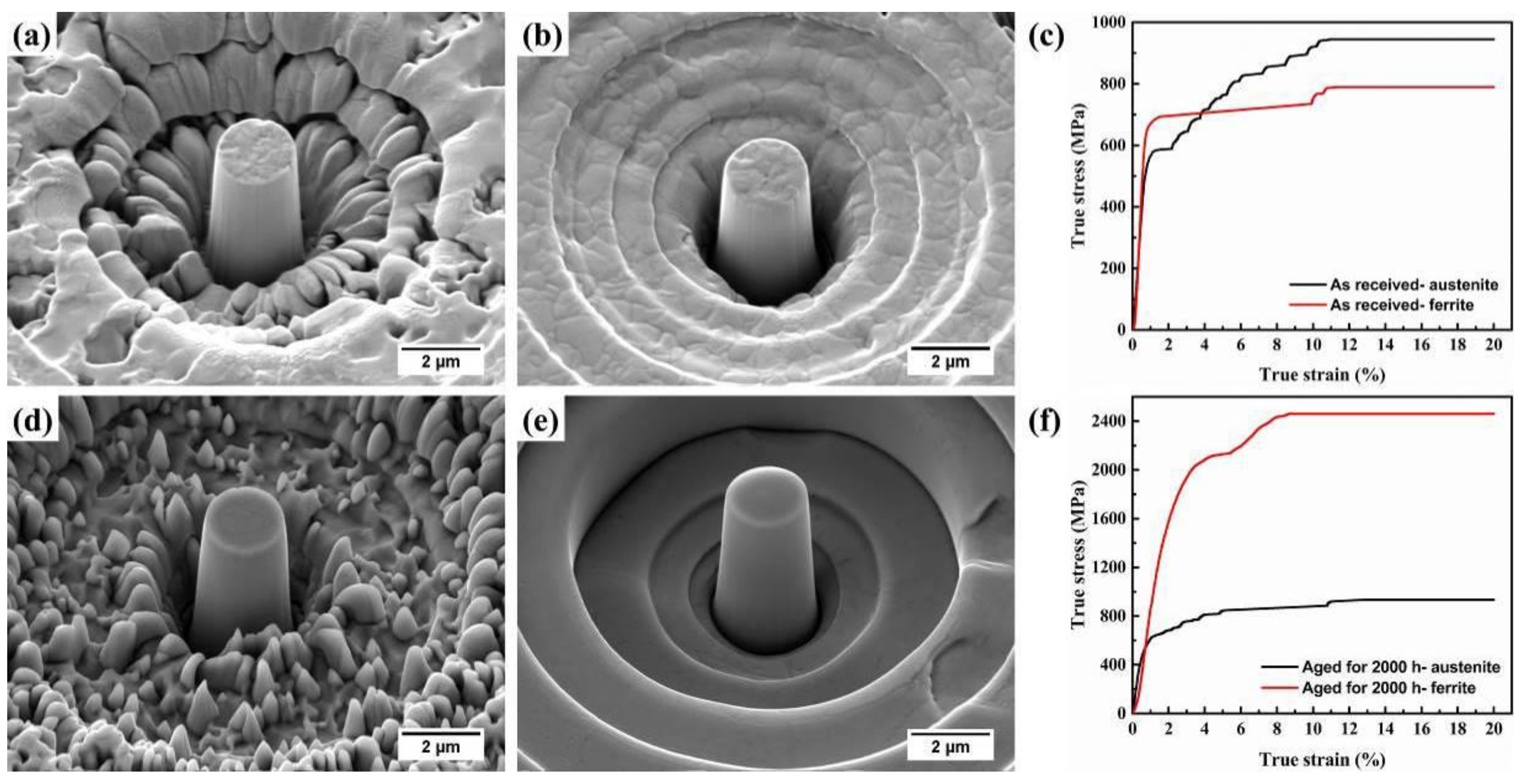

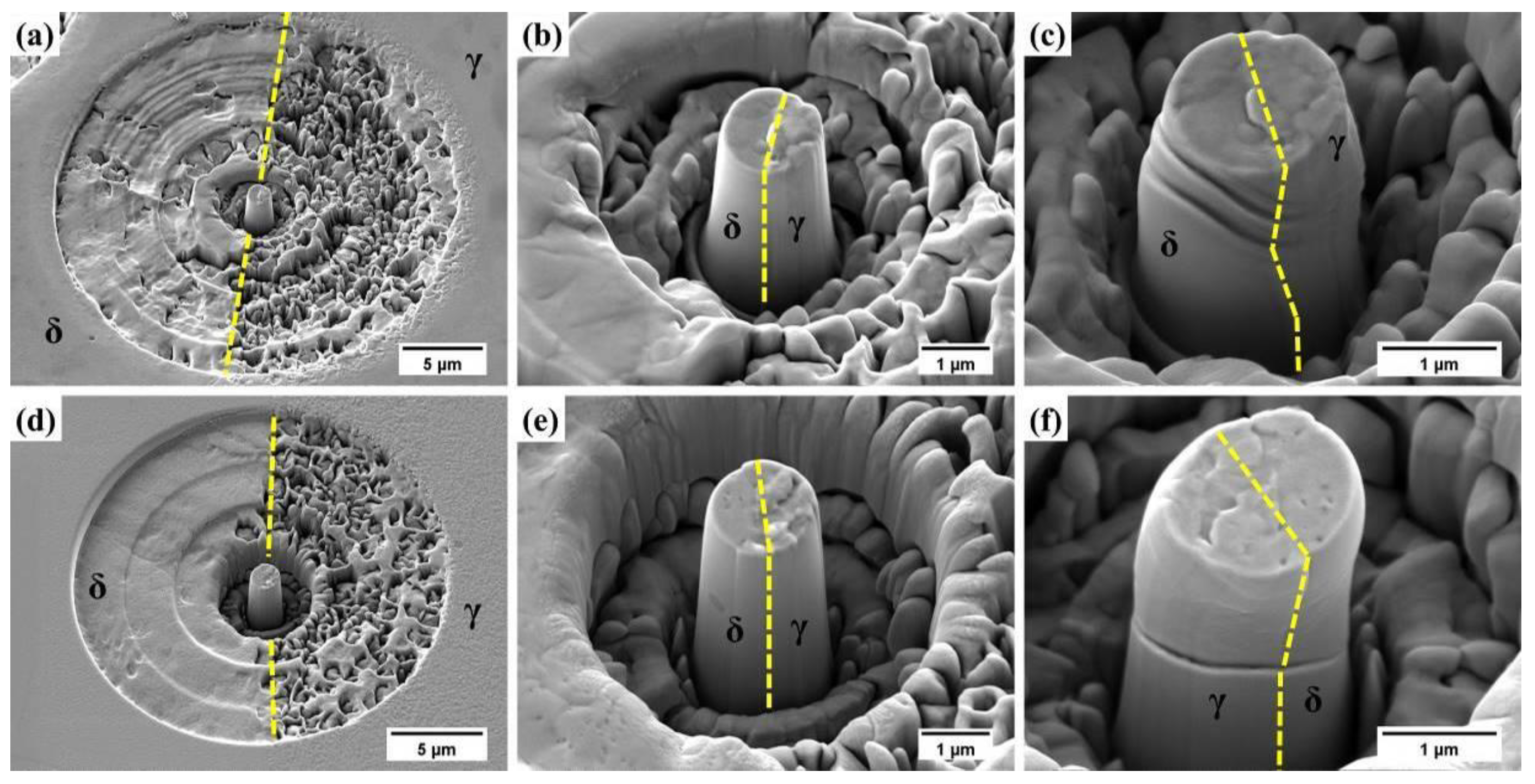

3.3. Constitutive Relationships of Austenite and Ferrite from Micropillar Compression

3.4. Simulation Results

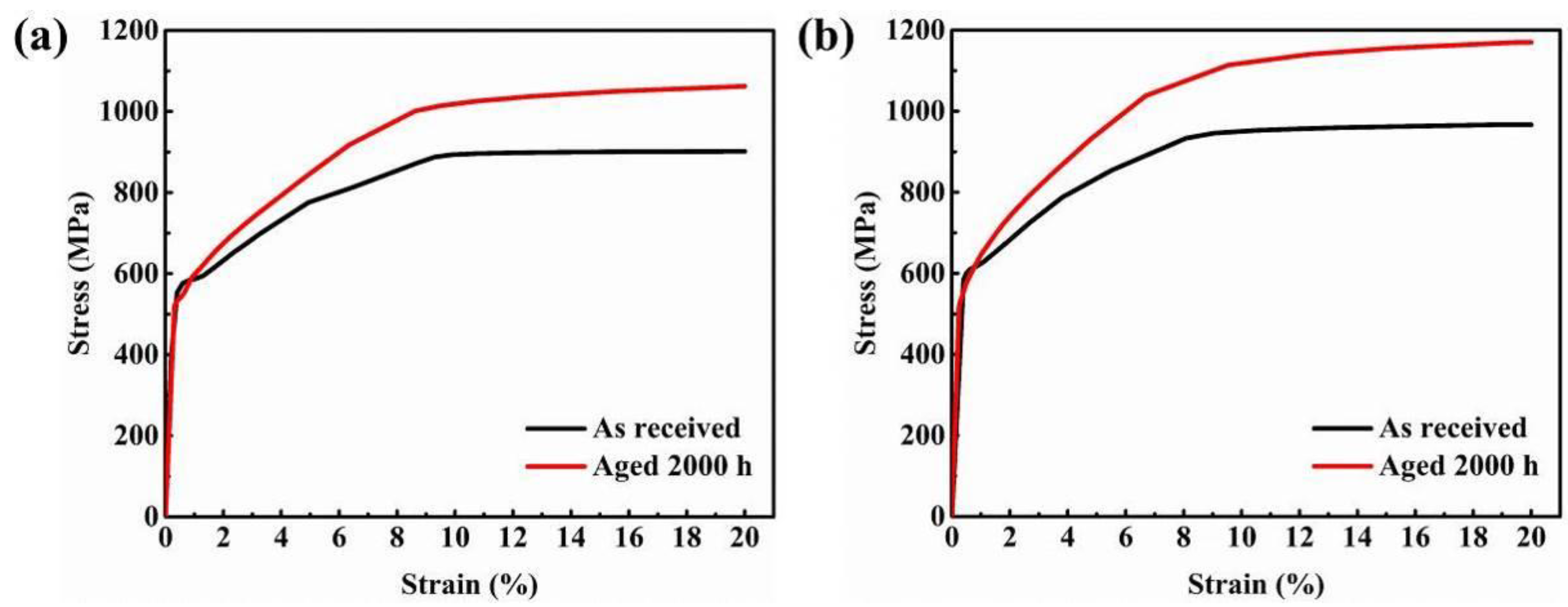

3.4.1. Stress–Strain Behavior

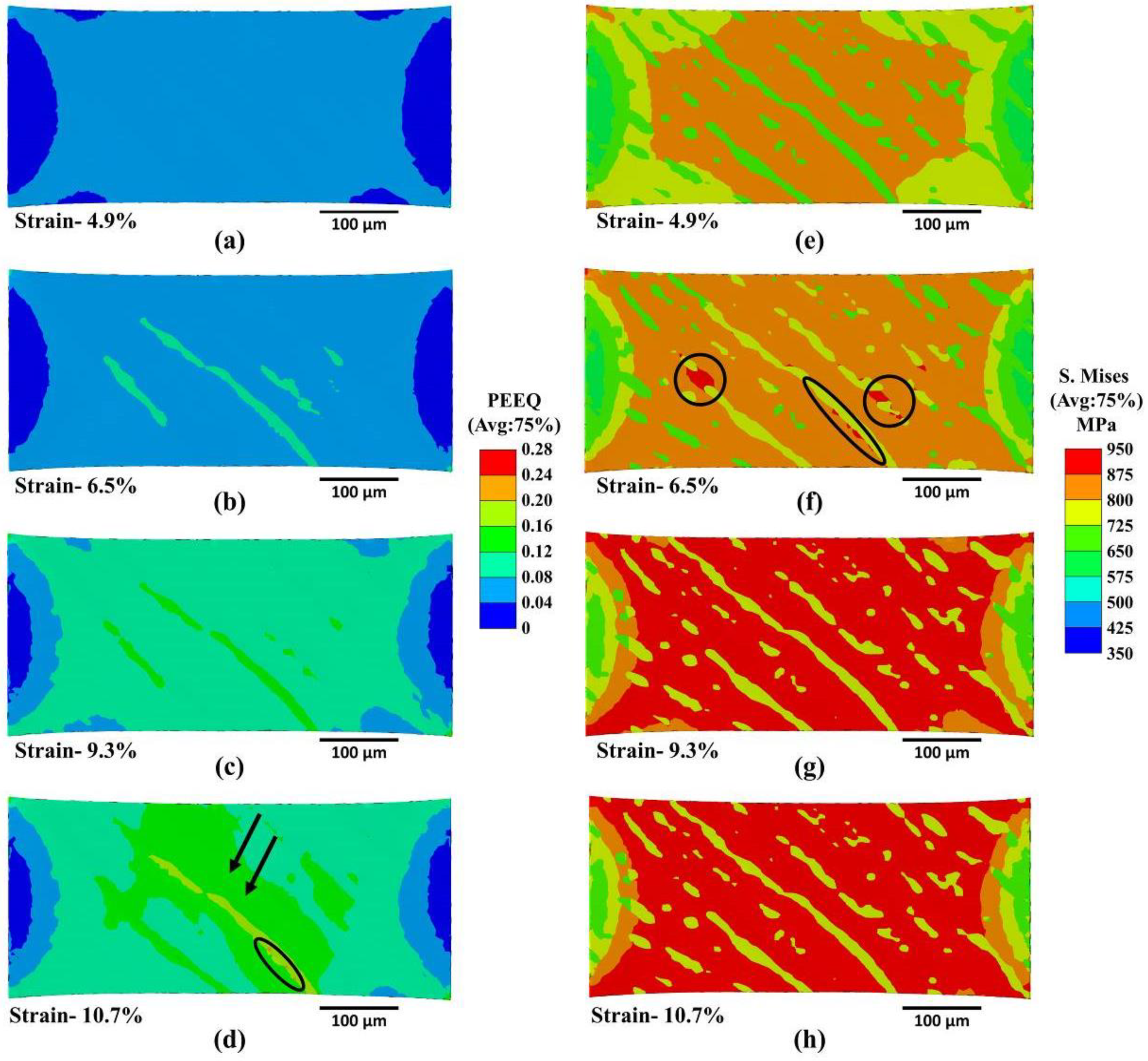

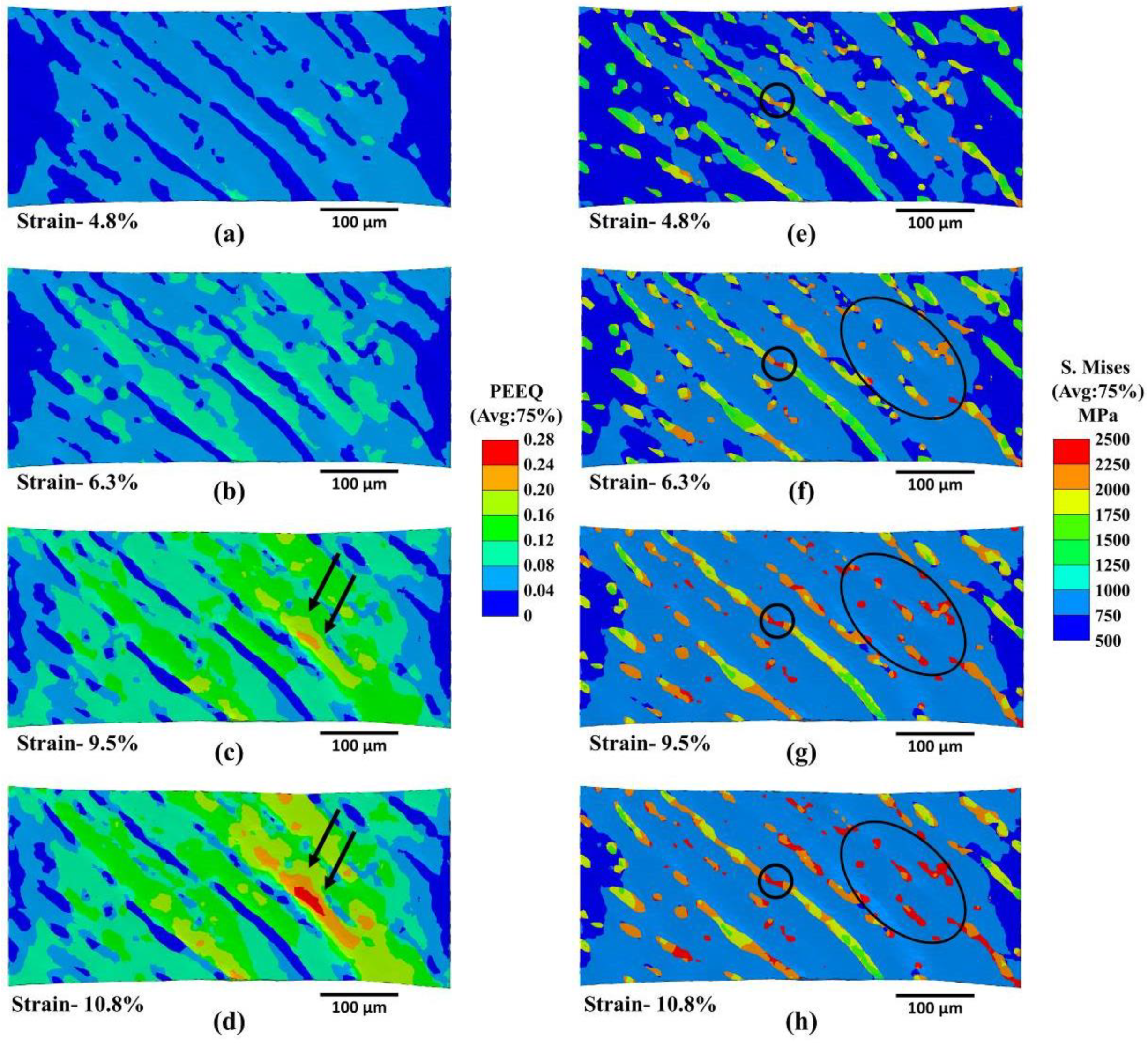

3.4.2. Tensile Deformation

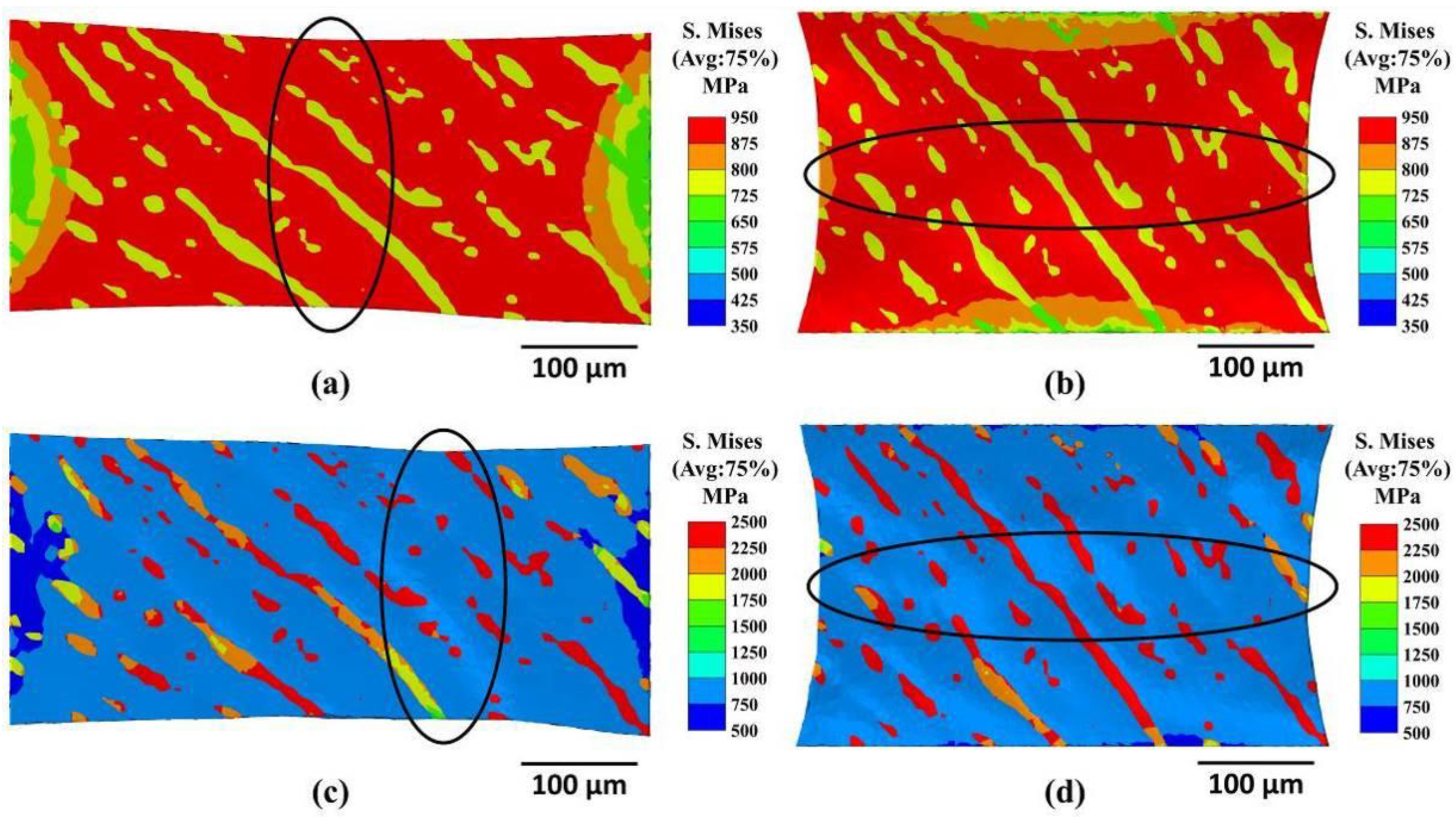

3.4.3. Necking Deformation

4. Conclusions

- 1)

- Aging at an intermediate temperature does not change the morphology of the two phases in Z3CN20.09M CDSS and the evolution on mechanical properties on CDSS among different aging conditions was caused by the precipitate phases formed during the aging process that strengthened the ferrite phase, such as the spinodal decomposition and the G-phase.

- 2)

- The compression of bicrystal micropillars with boundaries having a random orientation relationship shows that at the strain value of almost 20% the grain boundaries are still bonded well.

- 3)

- Finite element analysis based on the real 3D microstructure obtained for the X-ray microtomography and the mechanical properties of each individual phase achieved from the nanoindentation and micropillar compression tests is an appropriate numerical simulation method for CDSS, which can reveal some fascinating phenomena that cannot be directly observed by experiments.

- 4)

- The simulated stress–strain curve shows that the aged specimen has a higher tensile stress, which is caused by the hardening of ferrite during the aging process. While the increase rate is not as big as the ferrite phase itself, which can be explained by the ~20% volume fraction of ferrite.

- 5)

- The mechanical behaviors of this material are seriously affected by the mechanical properties of the individual phase. After the aging processes, the necking deformation tends to form in the area with the less large ferrite grains. The stress localization can form at the austenite/ferrite interface, the narrow region of ferrite grains and the small ferrite grains.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Park, Y.; Lee, Z. The effect of nitrogen and heat treatment on the microstructure and tensile properties of 25Cr–7Ni–1.5Mo–3W–xN duplex stainless steel castings. Mater. Sci. Eng. A 2001, 297, 78–84. [Google Scholar] [CrossRef]

- Pohl, M.; Storz, O.; Glogowski, T. Effect of intermetallic precipitations on the properties of duplex stainless steel. Mater. Charact. 2007, 58, 65–71. [Google Scholar] [CrossRef]

- Guo, E.; Singh, S.S.; Xie, H.; Williams, J.J.; Jing, T.; Chawla, N. Microstructure-Based Modeling of Deformation in Steels Based on Constitutive Relationships from Micropillar Compression. Steel Res. Int. 2014, 85, 946–953. [Google Scholar] [CrossRef]

- Li, S.L.; Wang, Y.L.; Wang, X.T. Effects of long term thermal aging on high temperature tensile deformation behaviours of duplex stainless steels. Mater. High Temp. 2015, 32, 524–529. [Google Scholar] [CrossRef]

- Guo, E.; Wang, M.; Jing, T.; Chawla, N. Temperature-dependent mechanical properties of an austenitic–ferritic stainless steel studied by in situ tensile loading in a scanning electron microscope (SEM). Mater. Sci. Eng. A 2013, 580, 159–168. [Google Scholar] [CrossRef]

- Weng, K.L.; Chen, H.R.; Yang, J.R. The low-temperature aging embrittlement in a 2205 duplex stainless steel. Mater. Sci. Eng. A 2004, 379, 119–132. [Google Scholar] [CrossRef]

- Yamada, T.; Okano, S.; Kuwano, H. Mechanical property and microstructural change by thermal aging of SCS14A cast duplex stainless steel. J. Nucl. Mater. 2006, 350, 47–55. [Google Scholar] [CrossRef]

- Zhang, Q.; Singaravelu, A.S.S.; Zhao, Y.; Jing, T.; Chawla, N. Mechanical properties of a thermally-aged cast duplex stainless steel by nanoindentation and micropillar compression. Mater. Sci. Eng. A 2019, 743, 520–528. [Google Scholar] [CrossRef]

- Zhang, Q.; Ma, S.; Jing, T. Mechanical Properties of a Thermally-aged Cast Duplex Stainless Steel by in Situ Tensile Test at the Service Temperature. Metals 2019, 9, 317. [Google Scholar] [CrossRef]

- Serre, I.; Salazar, D.; Vogt, J.B. Atomic force microscopy investigation of surface relief in individual phases of deformed duplex stainless steel. Mater. Sci. Eng. A 2008, 492, 428–433. [Google Scholar] [CrossRef]

- Avramovic-Cingara, G.; Ososkov, Y.; Jain, M.K.; Wilkinson, D.S. Effect of martensite distribution on damage behaviour in DP600 dual phase steels. Mater. Sci. Eng. A 2009, 516, 7–16. [Google Scholar] [CrossRef]

- Wang, Y.; Yao, Y.H.; Wang, Z.P.; Jin, Y.H.; Zhang, X.L.; Liu, J.N. Thermal ageing on the deformation and fracture mechanisms of a duplex stainless steel by quasi in-situ tensile test under OM and SEM. Mater. Sci. Eng. A 2016, 666, 184–190. [Google Scholar] [CrossRef]

- Li, S.; Wang, Y.; Wang, X. In Situ Observation of the Deformation and Fracture Behaviors of Long-Term Thermally Aged Cast Duplex Stainless Steels. Metals 2019, 9, 258. [Google Scholar] [CrossRef]

- Tavares, S.S.M.; Feijó, G.F.; Farneze, H.N.; Sandim, M.J.R.; Souza Filho, I.R.D. Influence of Microstructure on the Corrosion Resistance of AISI 317L (UNS S31703). Mater. Res. 2017, 20, 108–114. [Google Scholar] [CrossRef]

- Kamiya, O.; Kumagai, K.; Kikuchi, Y. Effects of delta ferrite morphology on low-temperature fracture toughness of austenitic stainless steel weld metal. Weld. Int. 1992, 6, 606–611. [Google Scholar] [CrossRef]

- Chen, T.H.; Weng, K.L.; Yang, J.R. The effect of high-temperature exposure on the microstructural stability and toughness property in a 2205 duplex stainless steel. Mater. Sci. Eng. A 2002, 338, 259–270. [Google Scholar] [CrossRef]

- Shiao, J.J.; Tsai, C.H.; Kai, J.J.; Huang, J.H. Aging embrittlement and lattice image analysis in a Fe-Cr-Ni duplex stainless steel aged at 400 °C. J. Nucl. Mater. 1994, 217, 269–278. [Google Scholar] [CrossRef]

- Timofeev, B.T.; Nikolaev, Y.K. About the prediction and assessment of thermal embrittlement of Cr–Ni austenitic–ferritic weld metal and castings at the ageing temperatures 260–425 °C. Int. J. Press. Vessel Pip. 1999, 76, 849–856. [Google Scholar] [CrossRef]

- Chéhab, B.; Bréchet, Y.; Véron, M.; Jacques, P.J.; Parry, G.; Mithieux, J.D.; Glez, J.C.; Pardoen, T. Micromechanics of high-temperature damage in dual-phase stainless steel. Acta Mater. 2010, 58, 626–637. [Google Scholar] [CrossRef]

- Li, S.; Wang, Y.; Zhang, H.; Li, S.; Wang, G.; Wang, X. Effects of prior solution treatment on thermal aging behavior of duplex stainless steels. J. Nucl. Mater. 2013, 441, 337–342. [Google Scholar] [CrossRef]

- Li, S.; Wang, Y.; Wang, X. Effects of ferrite content on the mechanical properties of thermal aged duplex stainless steels. Mater. Sci. Eng. A 2015, 625, 186–193. [Google Scholar] [CrossRef]

- Stewart, J.L.; Jiang, L.; Williams, J.J.; Chawla, N. Prediction of bulk tensile behavior of dual phase stainless steels using constituent behavior from micropillar compression experiments. Mater. Sci. Eng. A 2012, 534, 220–227. [Google Scholar] [CrossRef]

- Stewart, J.L.; Williams, J.J.; Chawla, N. Influence of Thermal Aging on the Microstructure and Mechanical Behavior of Dual-Phase, Precipitation-Hardened, Powder Metallurgy Stainless Steels. Metall. Mater. Trans. A 2012, 43, 124–135. [Google Scholar] [CrossRef]

- Chawla, N.; Deng, X. Microstructure and mechanical behavior of porous sintered steels. Mater. Sci. Eng. A 2005, 390, 98–112. [Google Scholar] [CrossRef]

- Prabu, S.B.; Karunamoorthy, L.; Kathiresan, S.; Mohan, B. Influence of stirring speed and stirring time on distribution of particles in cast metal matrix composite. J. Mater. Process. Technol. 2006, 171, 268–273. [Google Scholar] [CrossRef]

- Balasivanandha Prabu, S.; Karunamoorthy, L. Microstructure-based finite element analysis of failure prediction in particle-reinforced metal–matrix composite. J. Mater. Process. Technol. 2008, 207, 53–62. [Google Scholar] [CrossRef]

- Qin, S.; McLendon, R.; Oancea, V.; Beese, A.M. Micromechanics of multiaxial plasticity of DP600: Experiments and microstructural deformation modeling. Mater. Sci. Eng. A 2018, 721, 168–178. [Google Scholar] [CrossRef]

- Musienko, A.; Tatschl, A.; Schmidegg, K.; Kolednik, O.; Pippan, R.; Cailletaud, G. Three-dimensional finite element simulation of a polycrystalline copper specimen. Acta Mater. 2007, 55, 4121–4136. [Google Scholar] [CrossRef]

- Szlazak, K.; Vass, V.; Hasslinger, P.; Jaroszewicz, J.; Dejaco, A.; Idaszek, J.; Scheiner, S.; Hellmich, C.; Swieszkowski, W. X-ray physics-based CT-to-composition conversion applied to a tissue engineering scaffold, enabling multiscale simulation of its elastic behavior. Mater. Sci. Eng. C 2019, 95, 389–396. [Google Scholar] [CrossRef]

- Zhang, Q.; Niverty, S.; Singaravelu, A.S.S.; Williams, J.J.; Guo, E.; Jing, T.; Chawla, N. Microstructure and micropore formation in a centrifugally-cast duplex stainless steel via X-ray microtomography. Mater. Charact. 2019, 148, 52–62. [Google Scholar] [CrossRef]

- Zhang, H.; Schuster, B.E.; Wei, Q.; Ramesh, K.T. The design of accurate micro-compression experiments. Scr. Mater. 2006, 54, 181–186. [Google Scholar] [CrossRef]

- Danoix, F.; Auger, P. Atom Probe Studies of the Fe–Cr System and Stainless Steels Aged at Intermediate Temperature: A Review. Mater. Charact. 2000, 44, 177–201. [Google Scholar] [CrossRef]

- Li, S.L.; Wang, Y.L.; Zhang, H.L.; Li, S.X.; Zheng, K.; Xue, F.; Wang, X.T. Microstructure evolution and impact fracture behaviors of Z3CN20-09M stainless steels after long-term thermal aging. J. Nucl. Mater. 2013, 433, 41–49. [Google Scholar] [CrossRef]

- Li, S.L.; Zhang, H.L.; Wang, Y.L.; Li, S.X.; Zheng, K.; Xue, F.; Wang, X.T. Annealing induced recovery of long-term thermal aging embrittlement in a duplex stainless steel. Mater. Sci. Eng. A 2013, 564, 85–91. [Google Scholar] [CrossRef]

- Abaqus Analysis User’s Guide. Available online: http://dsk.ippt.pan.pl/docs/abaqus/v6.13/books/usb/default.htm (accessed on 20 April 2019).

- Liu, G.; Wang, Y.; Li, S.; Du, K.; Wang, X. Deformation behavior of thermal aged duplex stainless steels studied by nanoindentation, EBSD and TEM. Mater. High Temp. 2016, 33, 15–23. [Google Scholar] [CrossRef]

- Byun, T.S.; Hashimoto, N.; Farrell, K. Temperature dependence of strain hardening and plastic instability behaviors in austenitic stainless steels. Acta Mater. 2004, 52, 3889–3899. [Google Scholar] [CrossRef]

- Choudhary, B.K.; Samuel, E.I.; Sainath, G.; Christopher, J.; Mathew, M.D. Influence of Temperature and Strain Rate on Tensile Deformation and Fracture Behavior of P92 Ferritic Steel. Metall. Mater. Trans. A 2013, 44, 4979–4992. [Google Scholar] [CrossRef]

- Uchic, M.D.; Dimiduk, D.M. A methodology to investigate size scale effects in crystalline plasticity using uniaxial compression testing. Mater. Sci. Eng. A 2005, 400–401, 268–278. [Google Scholar] [CrossRef]

- Han, S.M.; Bozorg-Grayeli, T.; Groves, J.R.; Nix, W.D. Size effects on strength and plasticity of vanadium nanopillars. Scr. Mater. 2010, 63, 1153–1156. [Google Scholar] [CrossRef]

- Huang, L.; Li, Q.; Shan, Z.; Li, J.; Sun, J.; Ma, E. A new regime for mechanical annealing and strong sample-size strengthening in body centred cubic molybdenum. Nat. Commun. 2011, 2, 547. [Google Scholar] [CrossRef]

- Kaufmann, D.; Mönig, R.; Volkert, C.A.; Kraft, O. Size dependent mechanical behaviour of tantalum. Int. J. Plast. 2011, 27, 470–478. [Google Scholar] [CrossRef]

- Kim, J.; Jang, D.; Greer, J.R. Crystallographic orientation and size dependence of tension–compression asymmetry in molybdenum nano-pillars. Int. J. Plast. 2012, 28, 46–52. [Google Scholar] [CrossRef]

- Guo, E.; Xie, H.; Singh, S.S.; Kirubanandham, A.; Jing, T.; Chawla, N. Mechanical characterization of microconstituents in a cast duplex stainless steel by micropillar compression. Mater. Sci. Eng. A 2014, 598, 98–105. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Q.; Zhu, K.; Singaravelu, A.S.S.; Sun, W.; Jing, T.; Chawla, N. Three-Dimensional (3D) Microstructure-Based Modeling of a Thermally-Aged Cast Duplex Stainless Steel Based on X-ray Microtomography, Nanoindentation and Micropillar Compression. Metals 2019, 9, 688. https://doi.org/10.3390/met9060688

Zhang Q, Zhu K, Singaravelu ASS, Sun W, Jing T, Chawla N. Three-Dimensional (3D) Microstructure-Based Modeling of a Thermally-Aged Cast Duplex Stainless Steel Based on X-ray Microtomography, Nanoindentation and Micropillar Compression. Metals. 2019; 9(6):688. https://doi.org/10.3390/met9060688

Chicago/Turabian StyleZhang, Qingdong, Kai Zhu, Arun Sundar S. Singaravelu, Weizhao Sun, Tao Jing, and Nikhilesh Chawla. 2019. "Three-Dimensional (3D) Microstructure-Based Modeling of a Thermally-Aged Cast Duplex Stainless Steel Based on X-ray Microtomography, Nanoindentation and Micropillar Compression" Metals 9, no. 6: 688. https://doi.org/10.3390/met9060688

APA StyleZhang, Q., Zhu, K., Singaravelu, A. S. S., Sun, W., Jing, T., & Chawla, N. (2019). Three-Dimensional (3D) Microstructure-Based Modeling of a Thermally-Aged Cast Duplex Stainless Steel Based on X-ray Microtomography, Nanoindentation and Micropillar Compression. Metals, 9(6), 688. https://doi.org/10.3390/met9060688