Abstract

In sheet microforming processes, in-surface principal strain rates may be compressive such that the thickness of the sheet increases in the process of deformation. In general, the evolution of free surface roughness depends on the sense of the principal strain normal to the free surface. Therefore, in order to predict the evolution of free surface roughness in processes in which this normal principal strain is positive by means of empirical equations, it is necessary to carry out experiments in which the thickness of the sheet increases. Conventional experiments, such as the Marciniak test, do not provide such strain paths. In general, it is rather difficult to induce a sufficiently uniform state of strain in thin sheets of increasing thickness throughout the process of deformation because instability occurs at the very beginning of the process. The present paper proposes a compression test for thin sheets. Teflon sheets are placed between support jigs and the metallic sheet tested to prevent the occurrence of instability and significantly reduce the effect of the support jigs on the evolution of surface roughness. The test is used to determine the evolution of surface roughness in thin sheets made of C1220-O under three strain paths.

1. Introduction

Micro sheet metal forming for manufacturing thin structural parts has been applied in various fields of medical, information/communication and electrical devices. Especially, the further miniaturization of copper alloy parts widely used in electronic device parts such as micro connecter pins and terminals has been required with growing interest in the next-generation communication of 5G. Micro sheet metal forming is an attractive manufacturing method capable of mass production at high productivity. However, it is difficult to miniaturize the size of products using conventional sheet metal forming techniques, because various size effects [1,2] such as material properties, forming condition, heat transfer [3], friction [4], formability [5] and machine functions seriously influence the quality of products. As one of the size effects in micro sheet metal forming, the ratio of grain size [6] and surface roughness [7,8] to thickness becomes large relative to the scaling down of product size. The increasing ratio of surface roughness to thickness of material at the micro-scale causes decreasing ductility [7]. The effect of the number of grains through the thickness affects the formability of microforming [8]. In addition, it is well known that the surface roughness evolution on the free surface with the non-contact surface of the material occurs with increasing plastic deformation [9,10,11]. Thus, surface roughness evolution in micro sheet metal forming strongly effects not only surface appearance, but also tribological behavior [12] and formability [13].

In micro sheet metal forming processes, in-surface principal strain rates may be compressive such that the thickness of the sheet increases in the process of deformation. This mode of deformation occurs, for example, in flanges and side walls of some stamping processes [14,15]. Using conventional empirical equations for free surface roughness evolution, for example [16,17,18], it is in general possible to predict the evolution of free surface roughness in such processes without having experimental results in the domain of compressive in-surface principal strain rates, since these empirical equations do not account for the effect of the strain path on free surface roughness evolution. In particular, experimental data found by means of tests in which the thickness of the sheet decreases can be used to identify the empirical free surface roughness evolution equation. However, the accuracy of such predictions is questionable. In particular, in most cases the sense of the principal strain normal to the free surface, εn, has a significant effect on the evolution of free surface roughness. It has been shown in [19,20] using a great number of independent experimental data. In this paper, a qualitative dependence of the roughness parameters, Ra and Rz, on εn and the equivalent strain, εeq, has been proposed. This dependence is confirmed by numerical results reported in [21]. In this work, a model of crystallographic plasticity has been adopted to predict the evolution of free surface roughness. Several tests are available to identify the empirical equation for free surface roughness evolution proposed in [19,20] in the range εn < 0 (for example, uniaxial tension, equibiaxial tension, Marciniak test [22] and others). However, to the best of the authors’ knowledge, no test has been proposed to determine the evolution of free surface roughness in the range of εn > 0. The present paper concerns itself with such a test. The test is used to find the evolution of free surface roughness in thin sheets made of C1220-O for three values of the ratio εn/εeq.

2. Compression Test

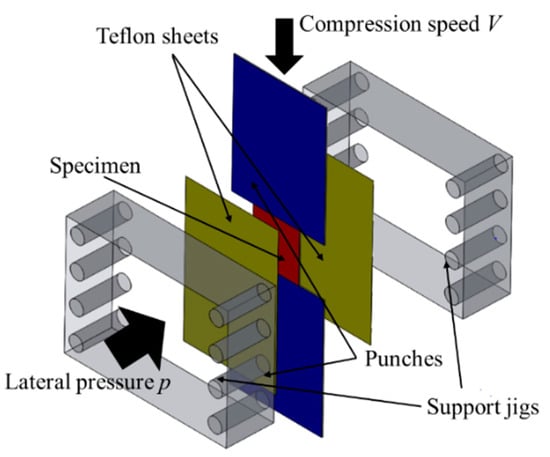

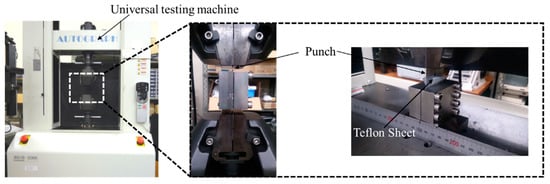

A number of compression tests for thin sheets have been proposed in the literature [23,24]. A distinguished feature of the test described in this section is that it is designed to prevent instability and significantly reduce the effect of support jigs on the evolution of surface roughness. A schematic diagram of the experimental setup is shown in Figure 1. A metallic sheet to be tested and two teflon sheets are placed between two support jigs to prevent the occurrence of instability. The teflon sheets are used to significantly reduce the effect of the support jigs on the evolution of surface roughness in the sample. The use of soft material for this purpose has been justified in [25]. It has been shown in this work that the evolution of roughness at the contact surface between the material tested and the rubber is practically the same as the evolution of free surface roughness at large plastic strains. Furthermore, it has been shown in [26] that a hydrostatic pressure of 405 MPa does not affect the evolution of surface roughness. Thus, it is believed that the teflon sheets and the contact pressure between these sheets and the material tested do not affect the evolution of surface roughness. Pressure (p) is applied to the support jigs to prevent wrinkling at early stages of the process. The metallic and teflon sheets are compressed by two punches. The speed of each punch is V. Grid lines should be applied on the surfaces of the metallic sheet to measure in-surface strains. Then, the through thickness strain can be found from the equation of incompressibility. The test may be interrupted several times to determine the dependence of roughness parameters on the equivalent strain and through thickness strain.

Figure 1.

Schematic diagram of the experimental setup of compression test for thin sheet metals.

3. Evolution of Surface Roughness in C1220-O Sheets in the Range εn > 0

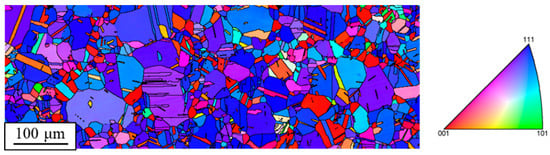

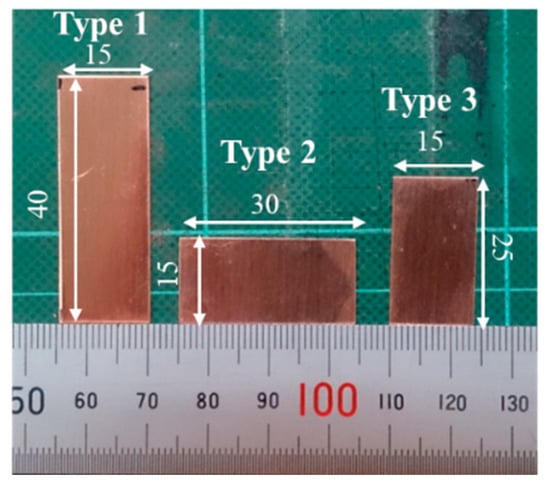

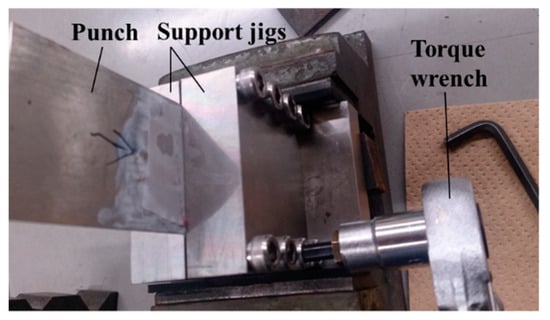

Samples for testing were cut from commercial phosphorous-deoxidized copper C1220-O (99.90 wt% or more of copper and 0.015–0.040 wt% Phosphorus) sheets of thickness t = 0.5 mm. For microstructure observation, the samples were mounted with resin and polished. After polishing, the surface treatment by ion milling SVM-721 (SANYU ELECTRON Co., Tokyo, Japan) was conducted. The microstructure was observed using a HITACHI S-3700N Scanning Electron Microscope (SEM) (HITACHI Ltd., Tokyo, Japan) with a Nordlys NL 04-2201-03 Electron Back-Scatter Diffraction (EBSD) system (Oxford Instruments plc., Abingdon, UK) The average grain size = 40 μm was found by Hyde’s method (Figure 2). In order to create different strain paths, three types of rectangular samples were used (type 1: 40 mm long × 15 mm wide; type 2: 30 mm long × 15 mm wide; type 3: 25 mm long × 15 mm wide). Three nominally identical samples of each type were cut using a milling machine. Samples of types 1 and 3 were compressed along the long side of the rectangular and samples of type 2 along the short side (Figure 3). The compression direction and the rolling direction are matched. The teflon sheets (Nitto Denko Corporation, NITOFLON No. 900UL) of thickness 0.05 mm, width 40 mm and length 50 mm were used in all tests. Fasteners were used to join two support jigs together (Figure 4). The torque applied to turn the fasteners was measured by using a torque wrench and this torque controlled the lateral pressure p (Figure 1). For each type of sample, the magnitude of the torque was chosen by trial-and-error to prevent wrinkling (1.5 Nm for type 1, 1.5 Nm for type 2, 4 Nm for type 3). The test jig of width 60 mm, height 50 mm and thickness 25 mm was made of carbon steel S45C. The test jig fitted in the test pieces is shown in Figure 5. The compression test was conducted using a SHIMAZU AUTOGRAPH AG-50kN universal testing machine with maximum load of 50 kN (SHIMAZU Co., Kyoto, Japan). The test pieces were each tested to ε1 = −0.24 under compression speed V = 1 mm/min (Figure 1). In order to measure in-surface principal strains, ε1 and ε2, grid lines were applied by a scriber on the free surface on each sample. To calculate ε1 and ε2, the dimensions of the initial 5 mm × 5 mm grids after deformation were measured using a KEYENCE VHX900 digital microscope (KEYENCE Co., Osaka, Japan). Figure 6 shows the typical shape of grids before and after deformation using a sample of type 1. The through thickness strain, ε3 ≡ εn, was calculated by means of the equation of incompressibility. The surface roughness in the area surrounded by grid lines was measured using KEYENCE VK-100 confocal laser microscope (KEYENCE Co., Osaka, Japan). The arithmetic average roughness Ra along the compression direction was evaluated. Assuming that strain paths are proportional, the von Mises equivalent strain was found as:

Figure 2.

Microstructure of pure copper C1220-O.

Figure 3.

Specimen size used in compression experiments.

Figure 4.

Torque controlled the lateral pressure using turning fasteners.

Figure 5.

Photo of compression test set up for thin sheet metal.

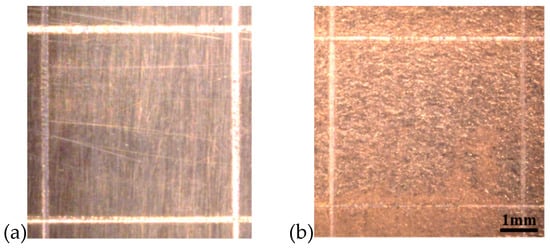

Figure 6.

Change in square grid (a) before and (b) after deformation for sample of type 1.

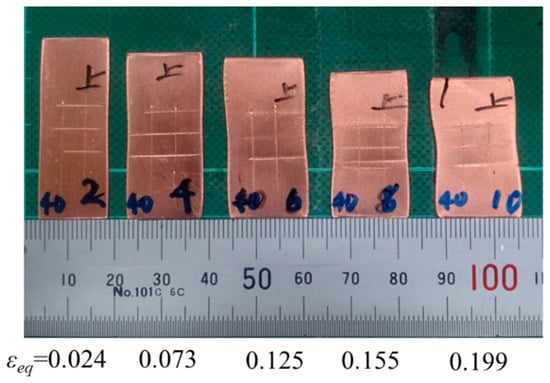

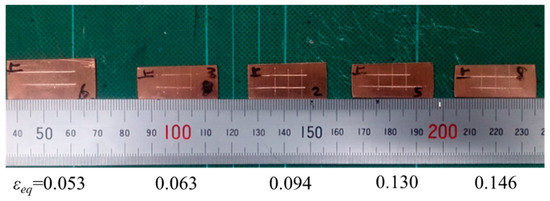

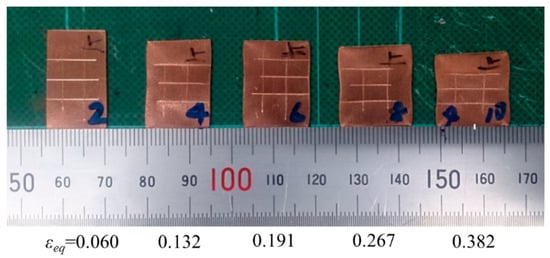

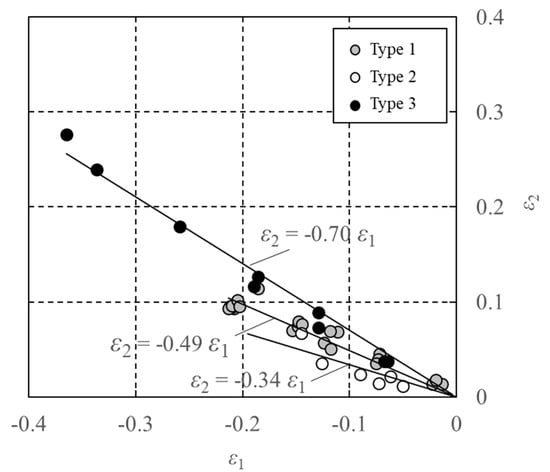

The shape of samples of type 1 at several values of the equivalent strain is shown in Figure 7. It is seen from this figure that deformation is practically uniform up to εeq = 0.199. The shape of samples of type 2 at several values of the equivalent strain is shown in Figure 8. It is seen from this figure that deformation is practically uniform up to εeq = 0.146. The shape of samples of type 3 at several values of the equivalent strain is shown in Figure 9. It is seen from this figure that deformation is practically uniform up to εeq = 0.382. The experimental dependence of ε2 on ε1 for all three types of samples is depicted in Figure 10. These experimental data were fitted to polynomials of the first degree. As a result,

where 1 ≤ i ≤ 3 and

Figure 7.

Shape of samples of type 1 at several values of the equivalent strain.

Figure 8.

Shape of samples of type 2 at several values of the equivalent strain.

Figure 9.

Shape of samples of type 3 at several values of the equivalent strain.

Figure 10.

Experimental dependence of of ε2 on ε1 for all three types of samples.

Here β1 corresponds to samples of type 1, β2 to samples of type 2, and β3 to samples of type 3. Equation (2) is illustrated in Figure 10. It is seen from this figure that the assumption that the strain paths are proportional is satisfied with a high degree of accuracy. Using Equation (2) and the equation of incompressibility, ε1 + ε2 + ε3 = 0, it is possible to transform Equation (1) to:

4. Results

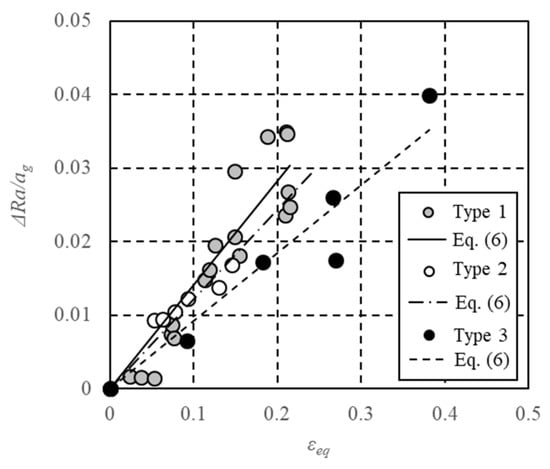

One of the main outputs of the test proposed is that the empirical equation for free surface roughness evolution proposed in [4] can be identified. In particular, this equation reads:

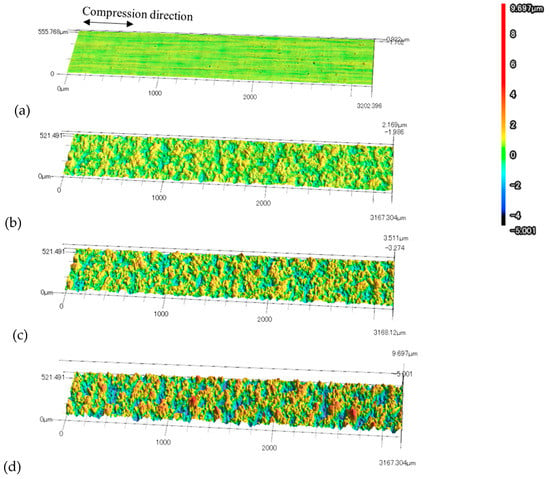

where R is the surface roughness parameter (Ra or Rz), R0 is its initial magnitude, and is a function of its argument. This function should be determined from experiment. Figure 11 shows the three-dimensional behavior of free surface roughness evolution with increasing for the sample of type 2. It is seen that the surface roughens with . Thus, the effectivity of the proposed compression method for thin sheets to evaluate free surface roughness evolution is verified. The variation of with found from the experiment is depicted in Figure 12. It is seen from Equation (4) that the ratio is constant along each strain path. Therefore, Equation (5) predicts that is a linear function of for each strain path. Figure 12 confirms this prediction. The experimental data shown in Figure 12 were fitted to polynomials of the first degree to give:

Figure 11.

Free surface roughness evolution with increasing εeq for the sample of type 2: (a) εeq = 0, (b) εeq = 0.053, (c) εeq = 0.063, (d) εeq = 0.094.

Figure 12.

Comparison of surface roughness evolution between predicted equation and experiments.

Substituting Equation (3) into Equation (4) one can get = 0.65 for samples of type 1, = 0.51 for samples of type 2 and = 0.29 for samples of type 3. Then, it follows from Equations (5) and (6) that

The domain of the function is . The Marciniak test (see, for example, [19,20]) can be adopted to produce various strain paths in the range . Then, the procedure for determining the function at given values of is the same as that used to arrive at Equation (7). In our previous study, the Marciniak test was carried out on C1220-O sheets for three strain paths [20]. As a result,

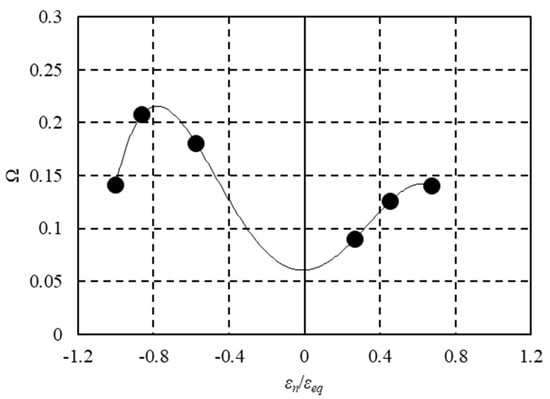

The experimental data given in Equations (7) and (8) are illustrated in Figure 13. The approximating curve is determined by the equation:

Figure 13.

Discrete and continuous functions Ω for C1220P-O sheets.

Both the experimental data and approximating curve suggest that the function has a local minimum in the vicinity of . The same conclusion has been drawn in [4] based on analysis of many independent experimental results. Thus, the surface roughness evolution is affected by the strain path and minimum surface roughness evolution is obtained under the strain path in which the ratio of is close to zero. Therefore, a crucial issue for determining an accurate approximation of the function . over its entire domain is to propose and carry out a test in which the ratio is close to zero.

5. Conclusions

A new experiment has been proposed to reveal the effect of the strain path on the evolution of surface roughness. The experiment consists of a compression test under lateral pressure. The latter is used to verify that the effect of the lateral pressure on the evolution of surface roughness is small. Therefore, the evolution of surface roughness in the compression test can be regarded as free surface roughness evolution. The compression test can be adopted for identifying the empirical equation for free surface roughness evolution proposed in [19,20] in the range . Both compression and tensile tests have been carried out on C1220-O sheets. As a result, the value of the function involved in the empirical equation has been found at three points (see Equation (7)). In addition, the Marciniak test has been conducted to determine the value of the function at three points in the range (see Equation (8)). It has been emphasized that an accurate approximation of the function over its entire domain requires a test in which . This will be the subject of a subsequent investigation. The conventional study on the evolution of surface roughness has been discussed mainly in the tension state (). In this study, the proposed test can evaluate the evolution of free surface roughness under the compression strain path (). The testing results will contribute to predict the evolution of surface roughness in flanges and side walls of some micro sheet metal forming processes with compressive modes such that the thickness of the sheet increases in the process of deformation. Therefore, it is concluded that the prediction range of the evolution of surface roughness can be expanded through a series of these studies.

Author Contributions

T.F. and S.A. made the experimental conceptual design and the theoretical framework, wrote the paper. K.A. carried out the experiments.

Funding

The main part of this work was done while S.A. was with Tokyo Metropolitan University as a visiting professor under the short-term program sponsored by Japan Society for the Promotion of Science (grant S16056). S.A. also acknowledges support from the Russian Ministry of Science and Higher Education (Project AAAA-A17-117021310373-3).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Geiger, M.; Kleiner, M.; Eckstein, R.; Tiesler, N.; Engel, U. Microforming. CIRP Annals 2001, 50, 445–462. [Google Scholar] [CrossRef]

- Vollertsen, F.; Biermann, D.; Hansen, H.N.; Jawahir, I.S.; Kuzman, K. Size effects in manufacturing of metallic components. CIRP Annals 2009, 58, 566–587. [Google Scholar] [CrossRef]

- Furushima, T.; Manabe, K. FE analysis of size effect on deformation and heat transfer behavior in microtube dieless drawing. J. Mater. Process. Technol. 2008, 201, 123–127. [Google Scholar] [CrossRef]

- Engel, U. Tribology in microforming. Wear 2006, 260, 265–273. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, W.; Gau, J.-T.; Shen, Z.; Ma, Y.; Zhang, G.; Wang, X. Feature Size Effect on Formability of Multilayer Metal Composite Sheets under Microscale Laser Flexible Forming. Metals 2017, 7, 275. [Google Scholar] [CrossRef]

- Kals, T.A.; Eckstein, R. Miniaturization in sheet metal working. J. Mater. Process. Technol. 2000, 103, 95–101. [Google Scholar] [CrossRef]

- Fu, M.W.; Chan, W.L. Geometry and grain size effects on the fracture behavior of sheet metal in micro-scale plastic deformation. Mater. Des. 2011, 32, 4738–4746. [Google Scholar] [CrossRef]

- Furushima, T.; Tsunezaki, H.; Manabe, K.I.; Alexsandrov, S. Ductile fracture and free surface roughening behaviors of pure copper foils for micro/meso-scale forming. Int. J. Mach. Tools Manuf. 2014, 76, 34–48. [Google Scholar] [CrossRef]

- Osakada, K.; Oyane, M. On the Roughening of Free Surface in Deformatio Process. Bull. JSME 1971, 14, 171–177. [Google Scholar] [CrossRef]

- Yamaguchi, K.; Mellor, P.B. Thickness and Grain Size Dependence of Limit Strains in Sheet Metal Stretching. Int. J. Mech. Sci. 1976, 18, 85–90. [Google Scholar] [CrossRef]

- Furushima, T.; Masuda, T.; Manabe, K.; Alexandrov, S. Inhomogeneous 3D Finite Element Model for Prediction of Free Surface Roughening. Adv. Mater. Res. 2012, 418–420, 1040–1043. [Google Scholar] [CrossRef]

- Shimizu, T.; Yang, M.; Manabe, K. Classification of mesoscopic tribological properties under dry sliding friction for microforming operation. Wear 2015, 330–331, 49–58. [Google Scholar] [CrossRef]

- Luo, L.; Jiang, Z.; Wei, D.; Manabe, K.I.; Zhao, X.; Wu, D.; Furushima, T. Effects of surface roughness on micro deep drawing of circular cups with consideration of size effects. Finite Elem. Anal. Des. 2016, 111, 46–55. [Google Scholar] [CrossRef]

- Hu, P.; Li, D.Y.; Li, Y.X. Analytical models of stretch and shrink flanging. Int. J. Machine Tools and Manuf. 2003, 43, 1367–1373. [Google Scholar] [CrossRef]

- Shimizu, T.; Ogawa, M.; Yang, M.; Manabe, K. Plastic anisotropy of ultra-thin rolled phosphor bronze foils and its thickness strain evolution in micro-deep drawing. Mater. Design 2014, 56, 604–612. [Google Scholar] [CrossRef]

- Klimczak, T.; Dautzenberg, J.H.; Kals, J.A.G. On the Roughening of a Free Surface During Sheet Metal Forming. CIRP Annals 1988, 37, 267–270. [Google Scholar] [CrossRef][Green Version]

- Parmar, A.; Mellor, P.B.; Chakrabarty, J. A New Model for the Prediction of Instability and Limit Strains in Thin Sheet Metal. Int. J. Mech. Sci. 1977, 19, 389–398. [Google Scholar] [CrossRef]

- Jain, M.; Lloyd, D.J.; Macewen, S.R. Hardening Laws, Surface Roughness and Biaxial Tensile Limit Strains of Sheet Aluminium Alloys. Int. J. Mech. Sci. 1996, 38, 219–232. [Google Scholar] [CrossRef]

- Alexandrov, S.; Manabe, K.; Furushima, T. A New Empirical Relation for Free Surface Roughening. Trans. ASME J. Manufact. Sci. Eng. 2011, 133, 014503. [Google Scholar] [CrossRef]

- Furushima, T.; Sato, H.; Manabe, K.; Alexandrov, S. Identification of an Empirical Equation for Predicting Free Surface Roughness Evolution in Thin Sheets of Aluminum Alloy and Pure Copper. J. Manuf. Sci. Eng. Trans. ASME 2018, 140, 034501. [Google Scholar] [CrossRef]

- Becker, R. Effects of Strain Localization on Surface Roughening During Sheet Forming. Acta Mater. 1998, 46, 1385–1401. [Google Scholar] [CrossRef]

- Marciniak, Z.; Kuczynski, K. Limit strains in the processes of stretch-forming sheet metal. Int. J. Mech. Sci. 1967, 9, 609–612. [Google Scholar] [CrossRef]

- Bae, G.H.; Huh, H. Tension/compression test of auto-body steel sheets with the variation of the pre-strain and the strain rate. WIT Trans. Eng. Sci. 2011, 72, 213–225. [Google Scholar]

- Piao, K.; Lee, J.K.; Kim, J.H.; Kim, H.Y.; Chung, K.; Barlat, F.; Wagoner, R.H. A sheet tension/compression test for elevated temperature. Int. J. Plast. 2012, 38, 27–46. [Google Scholar] [CrossRef]

- Fukuda, M.; Yamaguchi, K.; Takakura, N.; Sakano, Y. Roughening Phenomenon on Free Surface of Products in Sheet Metal Forming. J. Japan Soc. Technol. Plast. 1974, 15, 994–1002. [Google Scholar]

- Azushima, A.; Miyagawa, M. Effect of Working Factors and Metallurgical Factors on Roughening Phenomenon on Free Surface of Sheets—Investigation on Free Surface of Sheet Deformed I. J. Japan Soc. Technol. Plast. 1986, 27, 1261–1267. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).