3. Results and Discussions

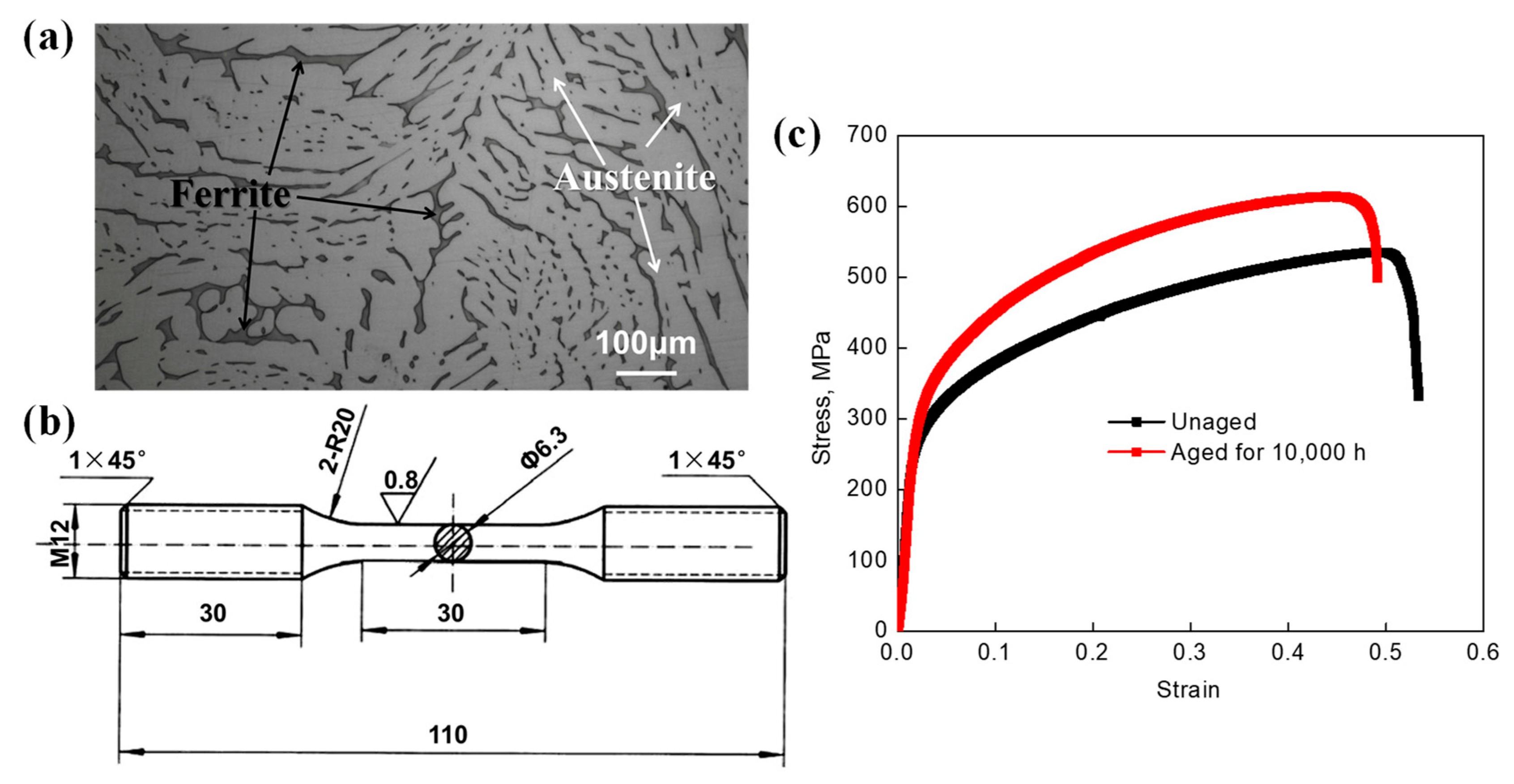

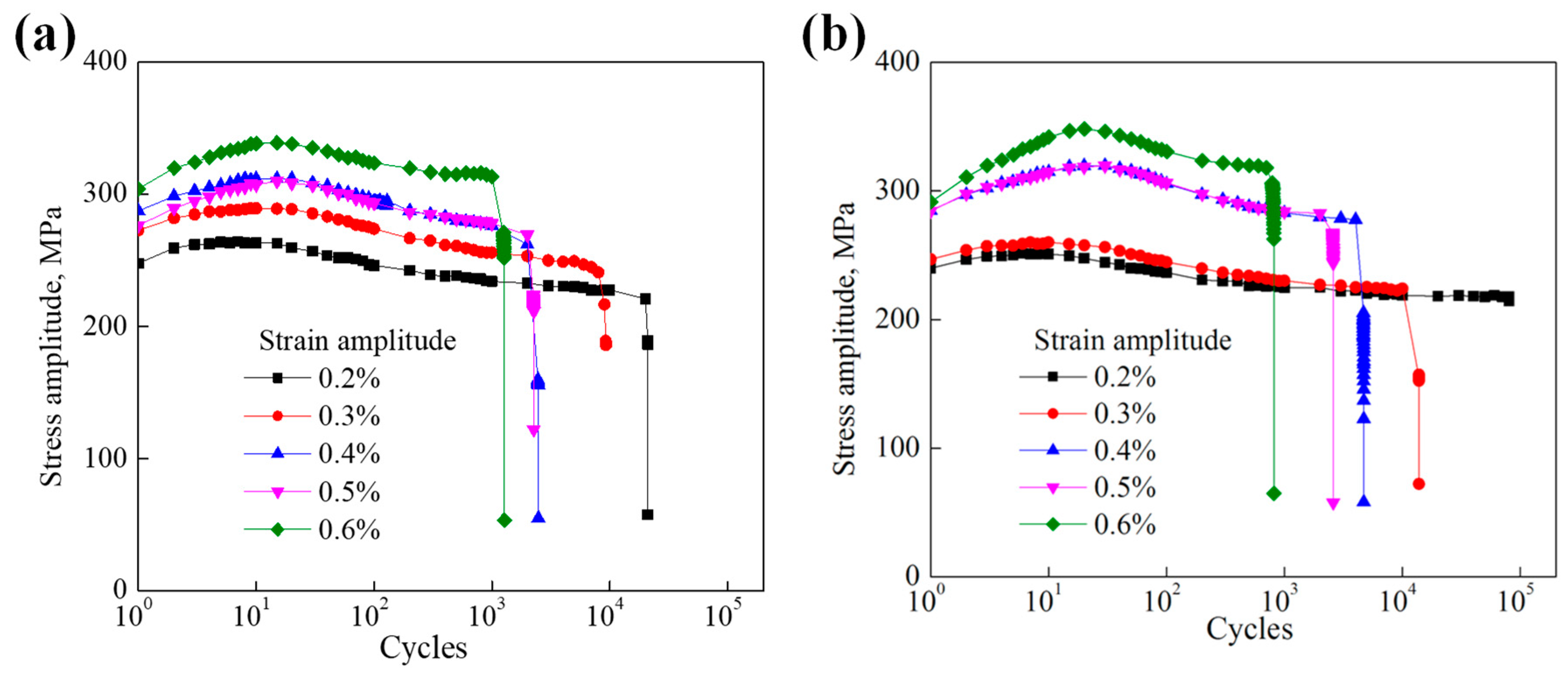

The cycle stress response curves of the unaged and aged CDSS are shown in

Figure 2. The variation of the stress amplitude of the material under cyclic loading can be divided into four stages: (1) The cyclic hardening stage, where the stress amplitude rapidly rises to the maximum stress amplitude in the first few cycles; (2) the slow cyclic softening stage, where the material begins to soften once the maximum stress amplitude was reached; (3) the cyclic saturation stage, where the stress amplitudes stay unchanged with cycles; (4) the rapid softening stage, where the material softens and eventually fractures. The cyclic stress response characteristics of the unaged and aged materials were closely related to the strain amplitude. Under low strain amplitude, cyclic softening occurred after initial short cyclic hardening, followed by the cyclic saturation stage, which accounted for more than half of the total life. While the cyclic saturation stage was much shorter under high strain amplitude, the cycle softening stage accounted for more than half of the total life. Compared with the unaged materials, the degree of cyclic hardening and softening of the aged materials was more pronounced, and the proportion of the cycle hardening stage in the total life was higher.

The values of both the maximum and saturated stress amplitudes of CDSS tested at high strain amplitude increased after thermal aging, while they had the opposite trend at low strain amplitude. The LCF lives of both the unaged and aged specimens gradually decreased with increasing strain amplitude from 0.2 to 0.6%. The effect of thermal aging on fatigue life was closely related to the strain amplitude. At low strain amplitudes, the fatigue life of the material increases significantly after thermal aging. Under the strain amplitude of 0.2%, the CDSS thermal aged at 400 °C for 10,000 h was still not broken after 80,000 cycles. At high strain amplitudes, the LCF life of the material decreased after thermal aging. Under the strain amplitude of 0.6%, the cyclic life of the aged CDSS reduced by 40% compared with the unaged CDSS.

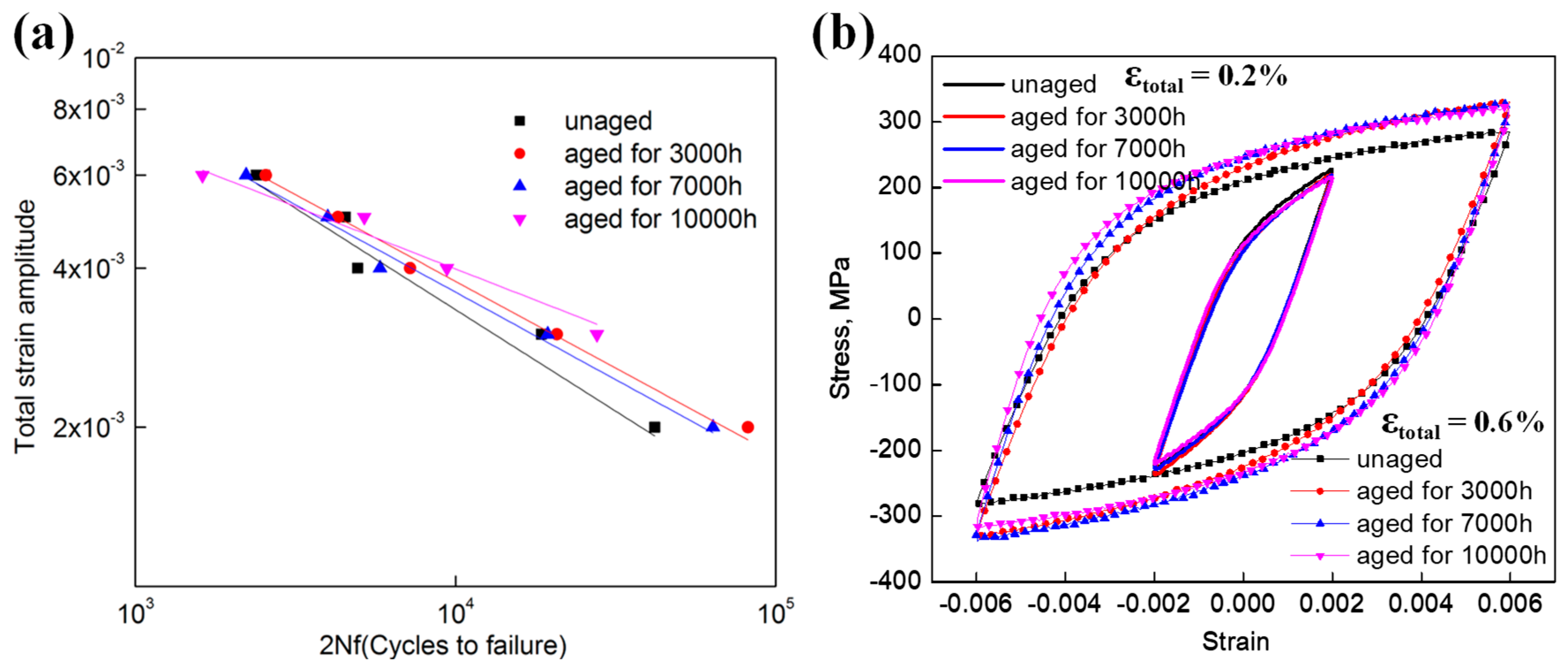

The Coffin–Manson model was used to fit the LCF experimental data at different aging states and

Table 2 lists all the parameters. In accordance with the determined parameters,

Figure 3a shows the variation of fatigue life with strain amplitude for the CDSS unaged and aged at 400 °C for 3000, 7000, and 10,000 h. For the same thermal aging state, the LCF life of the material decreased linearly with increasing strain amplitude. The stable hysteresis loops under 0.2 and 0.6% strain amplitudes (at half of the fatigue life) of specimens with different aging states are shown in

Figure 3b. Under low strain amplitude, thermal aging has no significant effect on the stable hysteresis loop of both the unaged and aged CDSS. The area of the stable stress-strain hysteresis loop of the aged CDSS under high strain amplitude was larger than that of the unaged material. With the increase of aging time, the increasing energy per cycle under high strain amplitude accelerated the damage of material, resulting in the decrease of fatigue life.

The fatigue fracture surfaces under all conditions in the present study include three regions: The crack initiation region, the fatigue crack growth region (with beach markings), and the rapid rupture region. Under low strain amplitude, only one crack origin forms on the fracture surface of the unaged and aged CDSS samples. While several sites of crack origin were observed on the surfaces of the unaged and aged samples under high strain amplitude. Dimple is the main feature of the rapid rupture region for all samples and some brittle fracture features were observed only on the surface of the aged sample under high strain amplitude. The difference in the fatigue fracture morphology caused by thermal aging and strain amplitude mainly occurred in the crack growth region. The morphologies of fatigue crack growth regions in the unaged and aged CDSS under 0.2 and 0.6% strain amplitudes are shown in

Figure 4. Both the ferritic and austenitic phases displayed fatigue fringes on the fatigue fracture surfaces of the fatigue crack growth regions in unaged CDSS under a strain amplitude of 0.2%, and the two phases could not be distinguished from each other. When the strain amplitude increased to 0.6%, the fatigue fringe spacing of the unaged CDSS significantly broadens. The fatigue fracture morphologies of CDSS after thermal aging for 10,000 h were significantly different from the unaged. The ferritic and austenitic phases on the fatigue fracture surface display different characteristics, and the fatigue fringes mainly appear in austenite. The fatigue fringes in the austenite of the aged CDSS under 0.6% strain amplitude were denser than those in the unaged material. Brittle cleavage characteristics and micro-cracks in ferrite were observed on the fracture surface of the aged CDSS under 0.6% strain amplitude. The micro-cracks in ferrite of the aged CDSS led to a significant decrease in fatigue life.

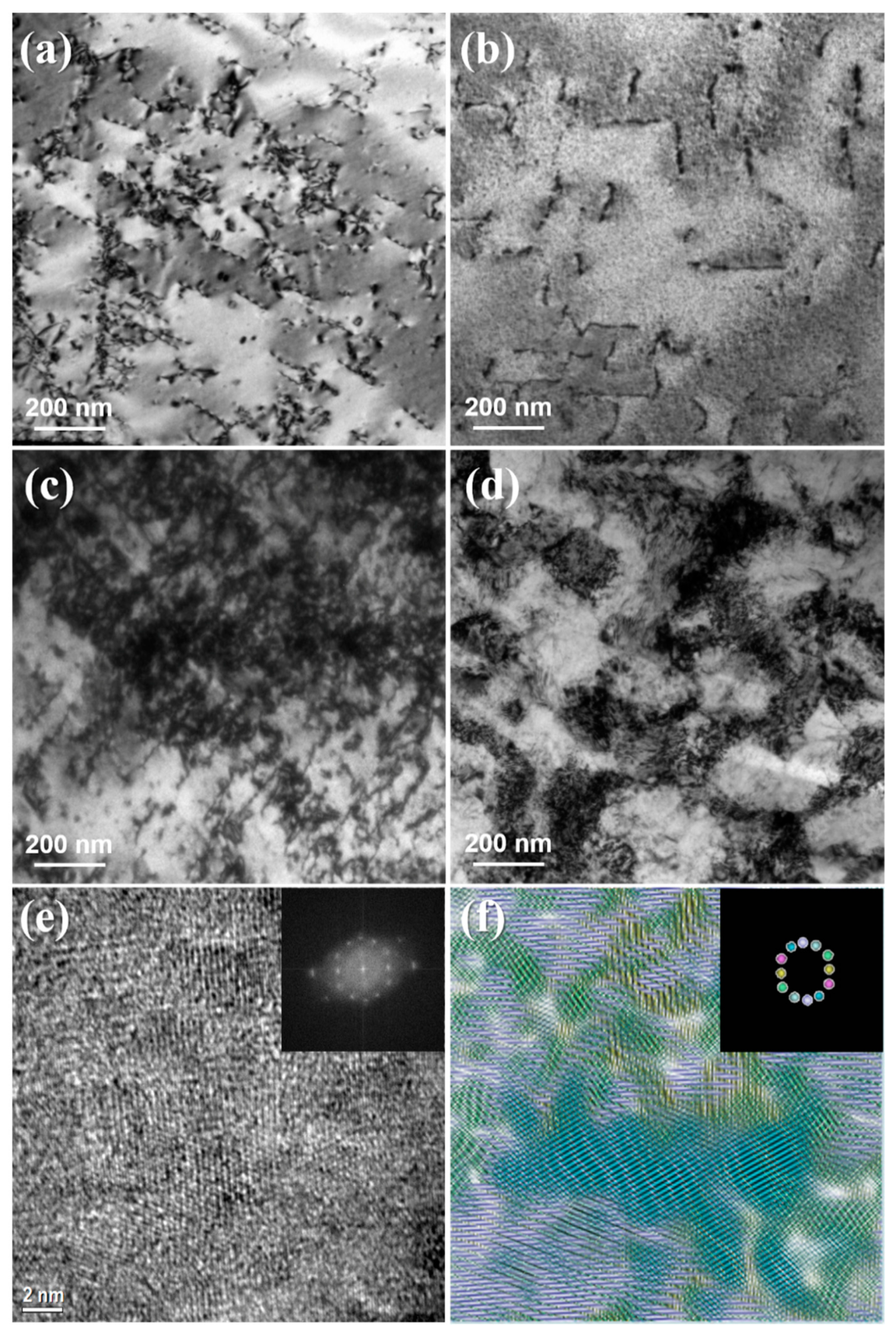

In order to investigate the deformation mechanism in the unaged and aged CDSS during cyclic loading under different strain amplitudes, the deformed microstructures were observed in TEM. A TEM sample was cut from the fatigue fracture surface of the unaged and aged CDSS under a strain amplitude of 0.3% and 0.6%. Our previous studies have shown that the mechanical property degradation of CDSS induced by thermal aging is mainly caused by the hardening and embrittlement in ferrite [

17,

18]. Thus, the observation of the deformed structures of the fatigued samples is focused on the dislocation structures in ferrite.

Figure 5a–d displays the TEM images of ferrite in the fatigued specimen of the unaged and aged under strain amplitude of 0.3% and 0.6%.

Under low strain amplitudes, the dislocation structure in ferrite of the unaged material is dominated by dislocation lines. In contrast, the dislocation density in the aged material is extremely low, and the mottled structure caused by spinodal decomposition can be observed. This indicated that a very low degree of plastic deformation occurs in ferrite of the aged material under low strain amplitudes. When the strain amplitude increased to 0.6%, the dislocation structures in the ferrite phase of the unaged and aged materials changed significantly. The dislocation density in ferrite of the unaged material was much higher than that under low strain amplitude. The vein dislocation structures formed in ferrite of the aged material under high strain amplitude, indicating that the ferrite phase underwent severe plastic deformation.

The high resolution transmission electron microscopy (HRTEM) image of ferrite in the fatigued aged specimen under 0.6% strain amplitude showed the lattice distortion (

Figure 5e), which is similar to the deformed microstructures of the aged CDSS after tensile deformation reported in our previous investigation [

25].

Figure 5f shows the corresponding orientation distribution of the HRTEM image, indicating that ferrite in the aged CDSS was divided into nanoscale regions with different orientations after deformation. These regions have a similar dimension as the Cr-enriched and Cr-depleted domains in ferrite induced by spinodal decomposition during thermal aging.

After thermal aging, the ferritic phase spinodally decomposed into Cr-enriched and Cr-depleted domains, which caused hardening and embrittlement in the ferrite. Severe plastic deformation in ferrite of the aged CDSS during cyclic loading under high strain amplitude caused the cleavage cracking in the hardened ferrite phases. The premature failure of ferrite in the aged CDSS accelerated the propagation of fatigue crack and thus shortens the LCF life.

Author Contributions

X.W. and Y.W. designed the research project; S.L. performed the experiments, analyzed the data, and wrote the manuscript; all the authors contributed to the discussions and commented on the manuscript.

Funding

This work was financially supported by the National Natural Science Foundation of China (NSFC) (Grant No. 51601013) and the State Key Laboratory for Advanced Metals and Materials (Grant No. 2018Z-25).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Chung, H.M. Aging and life prediction of cast duplex stainless steel components. Int. J. Pres. Ves. Pip. 1992, 50, 179–213. [Google Scholar] [CrossRef]

- Kawaguchi, S.; Sakamoto, N.; Takano, G.; Matsuda, F.; Kikuchi, Y.; Mráz, L. Microstructural changes and fracture behavior of CF8M duplex stainless steels after long-term aging. Nucl. Eng. Des. 1997, 174, 273–285. [Google Scholar] [CrossRef]

- Yamada, T.; Okano, S.; Kuwano, H. Mechanical property and microstructural change by thermal aging of SCS14A cast duplex stainless steel. J. Nucl. Mater. 2006, 350, 47–55. [Google Scholar] [CrossRef]

- Chung, H.M.; Leax, T.R. Embrittlement of laboratory and reactor aged CF3, CF8, and CF8M duplex stainless steels. Mater. Sci. Tech.-Lond. 1990, 6, 249–262. [Google Scholar] [CrossRef]

- Timofeev, B.T.; Nikolaev, Y.K. About the prediction and assessment of thermal embrittlement of Cr–Ni austenitic–ferritic weld metal and castings at the ageing temperatures 260–425 °C. Int. J. Pres. Ves. Pip. 1999, 76, 849–856. [Google Scholar] [CrossRef]

- Shiao, J.J.; Tsai, C.H.; Kai, J.J.; Huang, J.H. Aging embrittlement and lattice image analysis in a Fe-Cr-Ni duplex stainless steel aged at 400 °C. J. Nucl. Mater. 1994, 217, 269–278. [Google Scholar] [CrossRef]

- Chandra, K.; Kain, V.; Bhutani, V.; Raja, V.S.; Tewari, R.; Dey, G.K.; Chakravartty, J.K. Low temperature thermal aging of austenitic stainless steel welds: Kinetics and effects on mechanical properties. Mater. Sci. Eng. A 2012, 534, 163–175. [Google Scholar] [CrossRef]

- Pareige, C.; Novy, S.; Saillet, S.; Pareige, P. Study of phase transformation and mechanical properties evolution of duplex stainless steels after long term thermal ageing (>20 years). J. Nucl. Mater. 2011, 411, 90–96. [Google Scholar] [CrossRef]

- Zhang, B.; Xue, F.; Li, S.L.; Wang, X.T.; Liang, N.N.; Zhao, Y.H.; Sha, G. Non-uniform phase separation in ferrite of a duplex stainless steel. Acta Mater. 2017, 140, 388–397. [Google Scholar] [CrossRef]

- Brown, J.E.; Cerezo, A.; Godfrey, T.J.; Hetherington, M.G.; Smith, G.D.W. Quantitative atom probe analysis of spinodal reaction in ferrite phase of duplex stainless steel. Mater. Sci. Tech. 1990, 6, 293–300. [Google Scholar] [CrossRef]

- Soriano-Vargas, O.; Avila-Davila, E.O.; Lopez-Hirata, V.M.; Cayetano-Castro, N.; Gonzalez-Velazquez, J.L. Effect of spinodal decomposition on the mechanical behavior of Fe–Cr alloys. Mater. Sci. Eng. A 2010, 527, 2910–2914. [Google Scholar] [CrossRef]

- Danoix, F.; Auger, P. Atom probe studies of the Fe-Cr system and stainless steels aged at intermediate temperature: A review. Mater. Charact. 2000, 44, 177–201. [Google Scholar] [CrossRef]

- Pumphrey, P.H.; Akhurst, K.N. Aging kinetics of CF3 cast stainless steel in temperature range 300–400 °C. Mater. Sci. Tech.-Lond. 1990, 6, 211–220. [Google Scholar] [CrossRef]

- Bonnet, S.; Bourgoin, J.; Champredonde, J.; Guttmann, D.; Guttmann, M. Relationship between evolution of mechanical properties of various cast duplex stainless steels and metallurgical and aging parameters: Outline of current EDF programmes. Mater. Sci. Tech.-Lond. 1990, 6, 221–229. [Google Scholar] [CrossRef]

- Hale, G.E.; Garwood, S.J. Effect of aging on fracture behaviour of cast stainless steel and weldments. Mater. Sci. Tech.-Lond. 1990, 6, 230–236. [Google Scholar] [CrossRef]

- Tavares, S.A.C.S. Tensile properties of duplex UNS S32205 and lean duplex UNS S32304 steels and the influence of duration 475 ºC aging. Mater. Res. 2012, 15, 859–864. [Google Scholar] [CrossRef]

- Li, S.L.; Wang, Y.L.; Zhang, H.L.; Li, S.X.; Zheng, K.; Xue, F.; Wang, X.T. Microstructure evolution and impact fracture behaviors of Z3CN20-09M stainless steels after long-term thermal aging. J. Nucl. Mater. 2013, 433, 41–49. [Google Scholar] [CrossRef]

- Li, S.L.; Zhang, H.L.; Wang, Y.L.; Li, S.X.; Zheng, K.; Xue, F.; Wang, X.T. Annealing induced recovery of long-term thermal aging embrittlement in a duplex stainless steel. Mater. Sci. Eng. A 2013, 564, 85–91. [Google Scholar] [CrossRef]

- Chandra, K.; Singhal, R.; Kain, V.; Raja, V.S. Low temperature embrittlement of duplex stainless steel: Correlation between mechanical and electrochemical behavior. Mater. Sci. Eng. A 2010, 527, 3904–3912. [Google Scholar] [CrossRef]

- Li, S.; Wang, Y.; Li, S.; Zhang, H.; Xue, F.; Wang, X. Microstructures and mechanical properties of cast austenite stainless steels after long-term thermal aging at low temperature. Mater. Design 2013, 50, 886–892. [Google Scholar] [CrossRef]

- Chen, W.; Xue, F.; Tian, Y.; Yu, D.; Yu, W.; Chen, X. Effect of thermal aging on the low cycle fatigue behavior of Z3CN20.09M cast duplex stainless steel. Mater. Sci. Eng. A 2015, 646, 263–271. [Google Scholar] [CrossRef]

- Llanes, L.; Mateo, A.; Iturgoyen, L.; Anglada, M. Aging effects on the cyclic deformation mechanisms of a duplex stainless steel. Acta Mater. 1996, 44, 3967–3978. [Google Scholar] [CrossRef]

- Sahu, J.K.; Krupp, U.; Christ, H.J. Fatigue crack initiation behavior in embrittled austenitic–ferritic stainless steel. Int. J. Fatigue 2012, 45, 8–14. [Google Scholar] [CrossRef]

- Marrow, T.J.; King, J.E. Fatigue crack propagation mechanisms in a thermally aged duplex stainless steel. Mater. Sci. Eng. A 1994, 183, 91–101. [Google Scholar] [CrossRef]

- Li, S.; Wang, Y.; Wang, X. In situ observation of the deformation and fracture behaviors of Long-Term thermally aged cast duplex stainless steels. Metals 2019, 9, 258. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).