Effects of Cerium on Weld Solidification Crack Sensitivity of 441 Ferritic Stainless Steel

Abstract

:1. Introduction

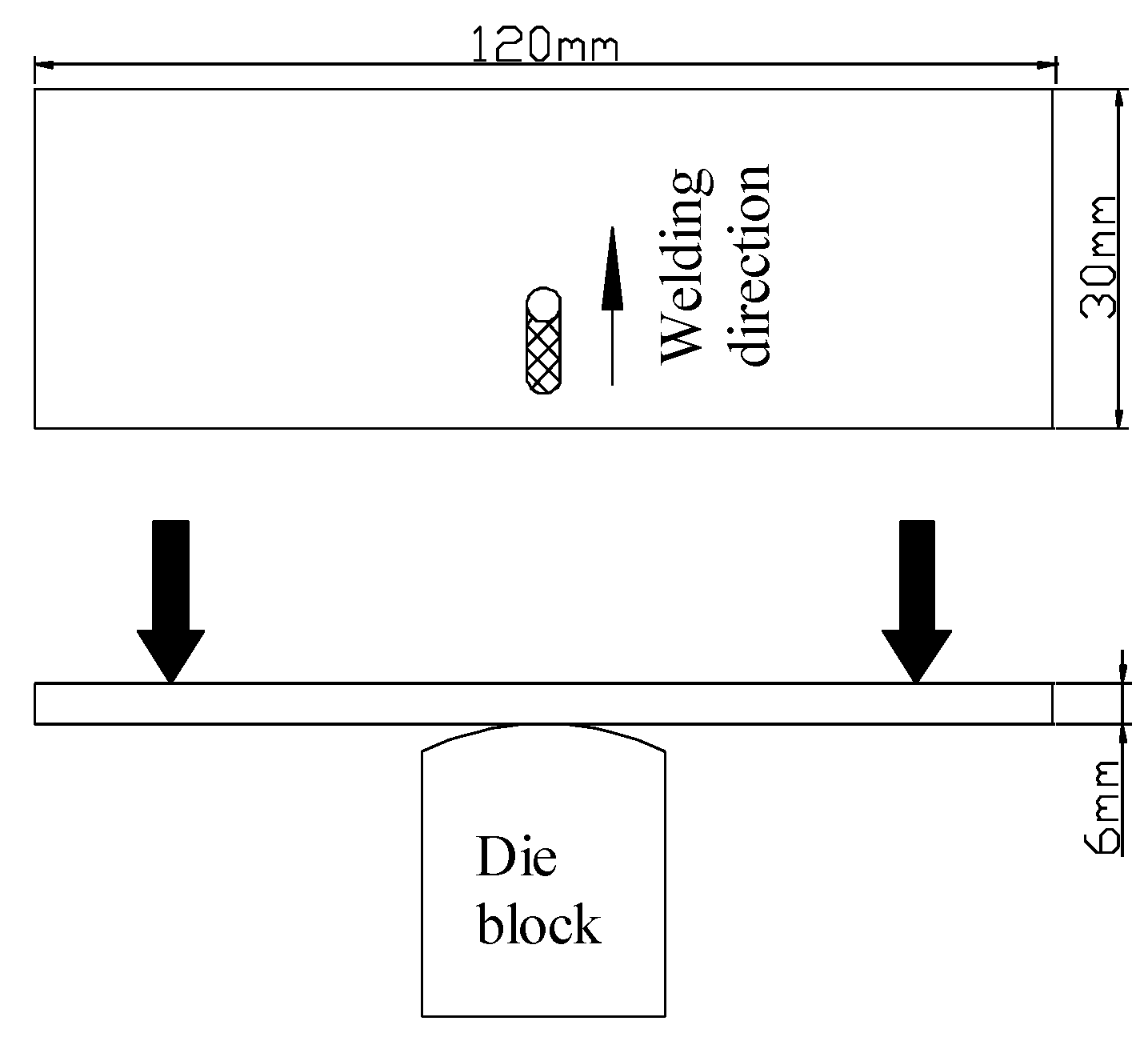

2. Materials and Methods

3. Results and Discussion

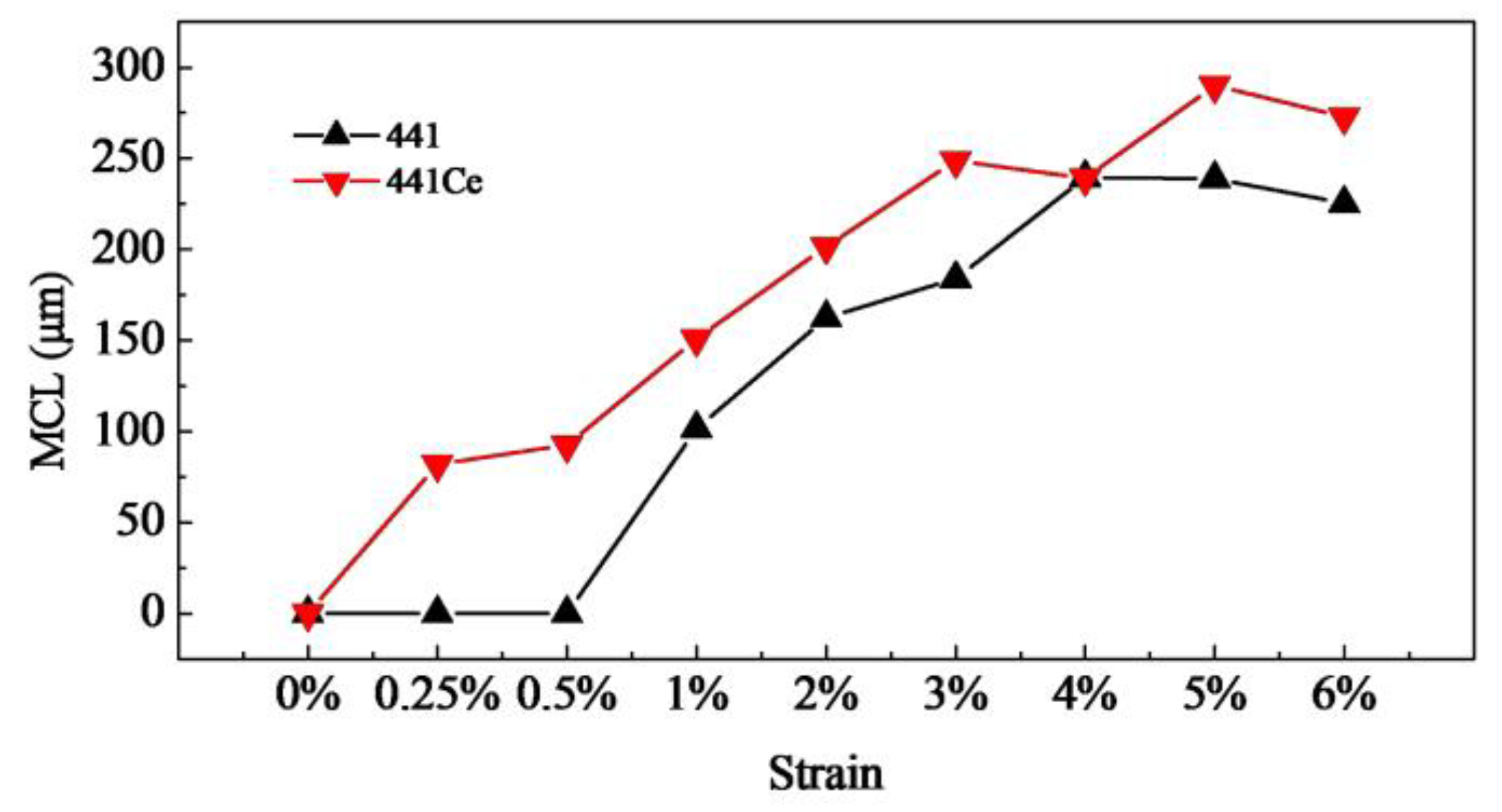

3.1. Threshold Strain and Maximum Crack Distance

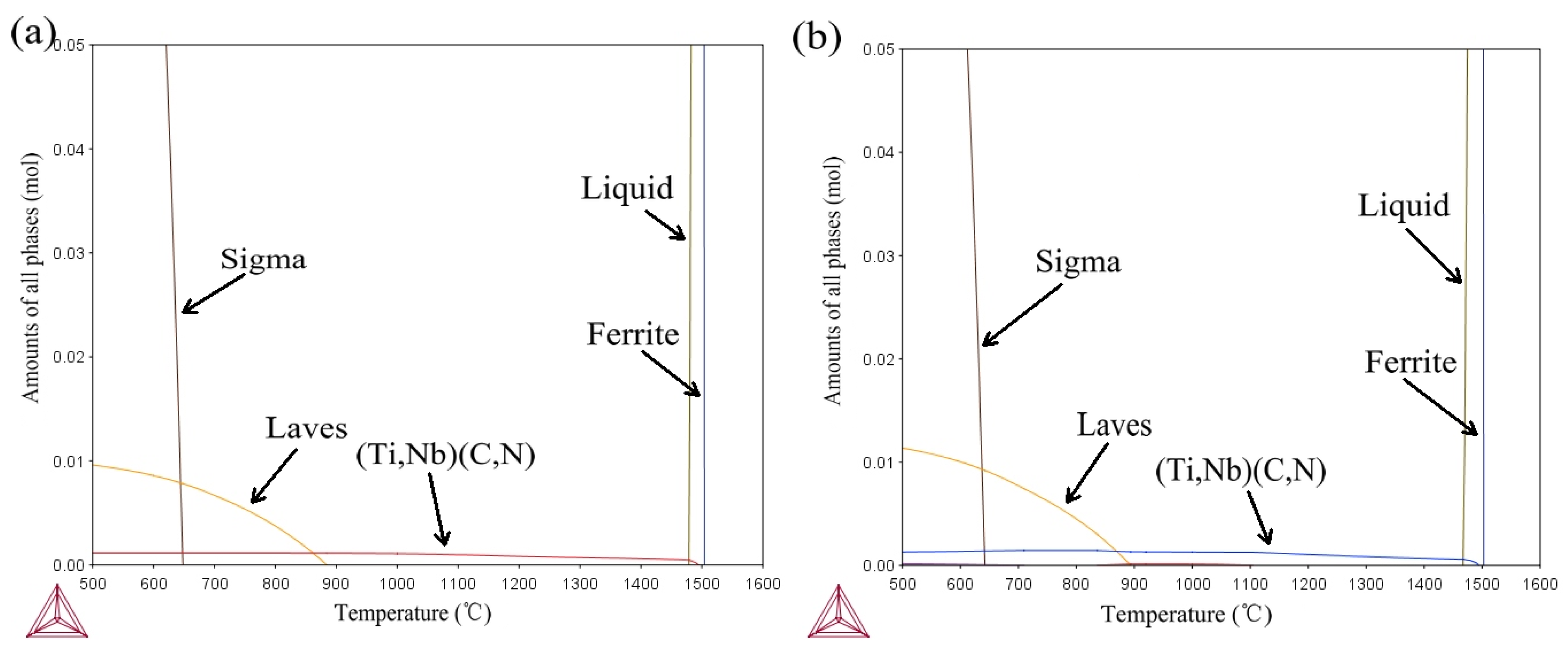

3.2. Thermodynamic Calculation of Solidification Process

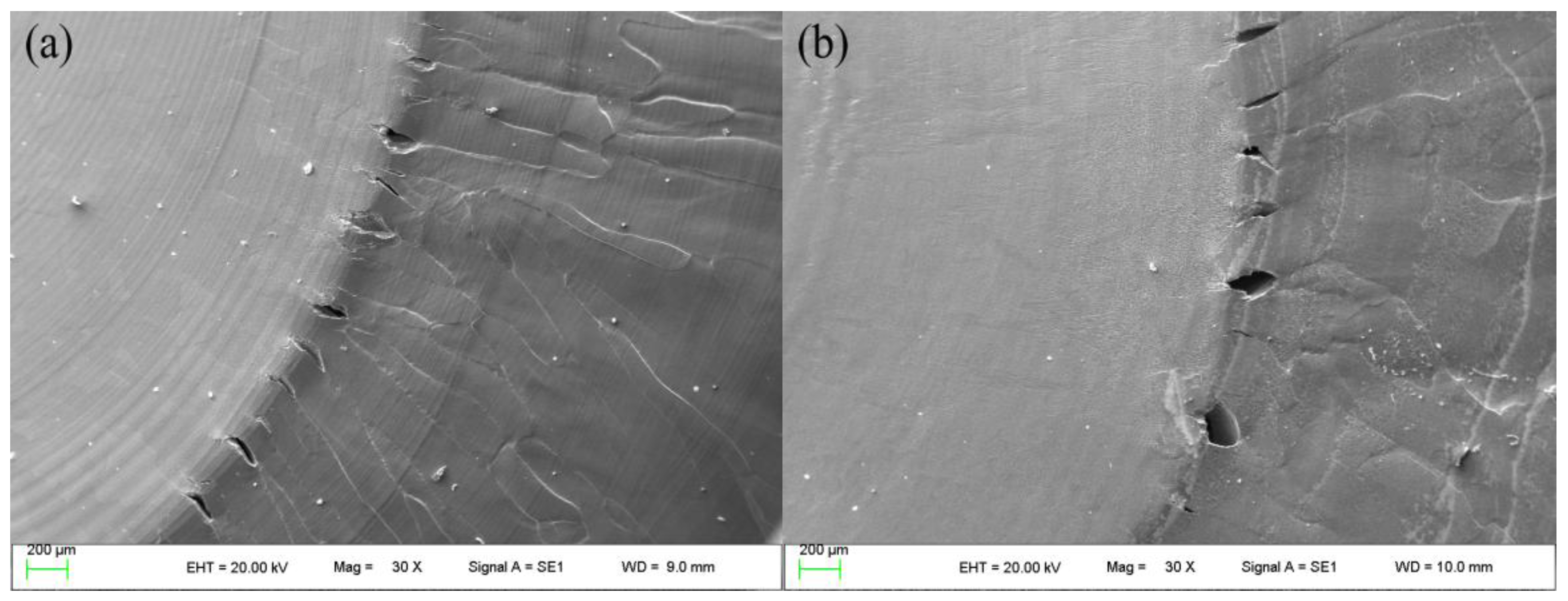

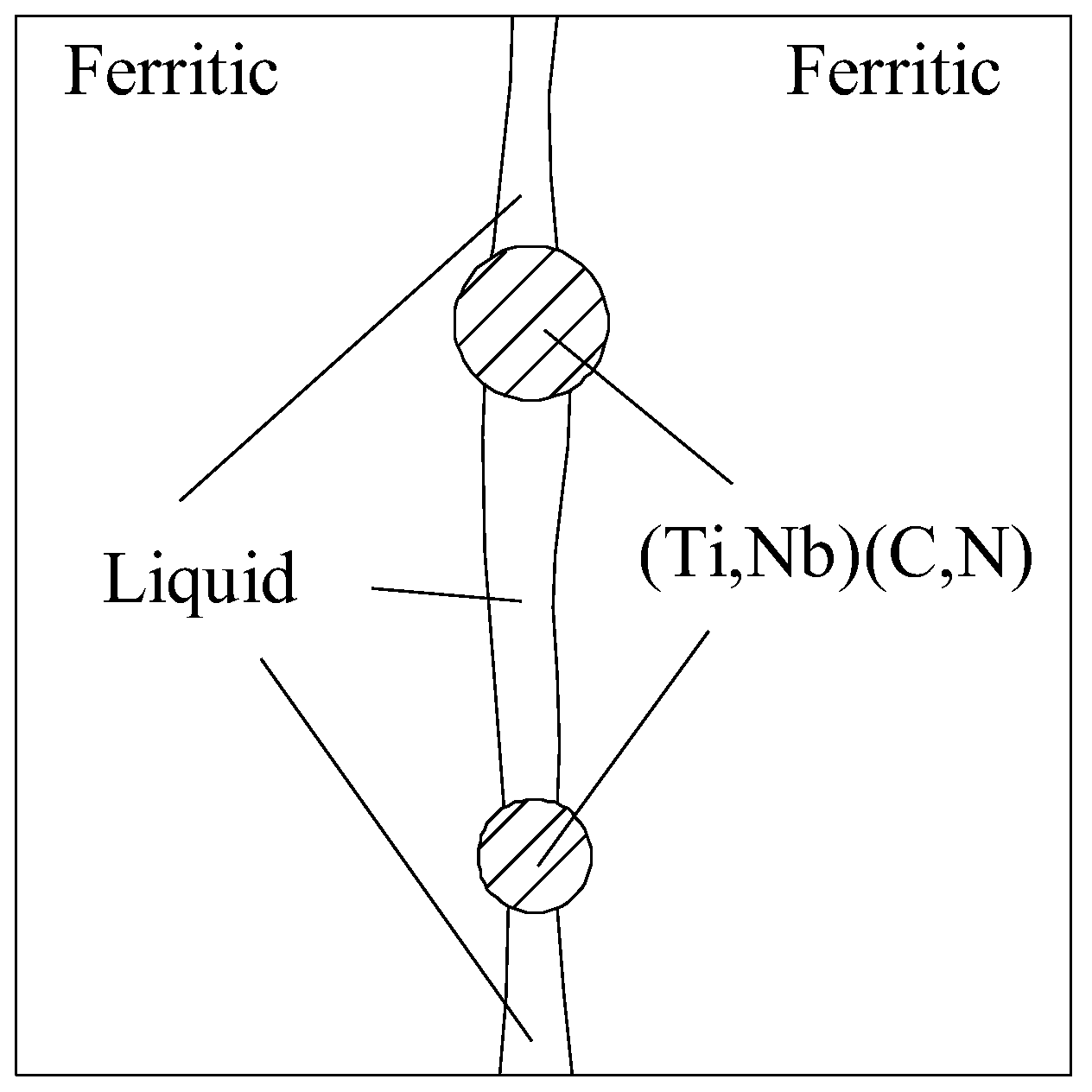

3.3. Solidification Crack Distribution and Morphology

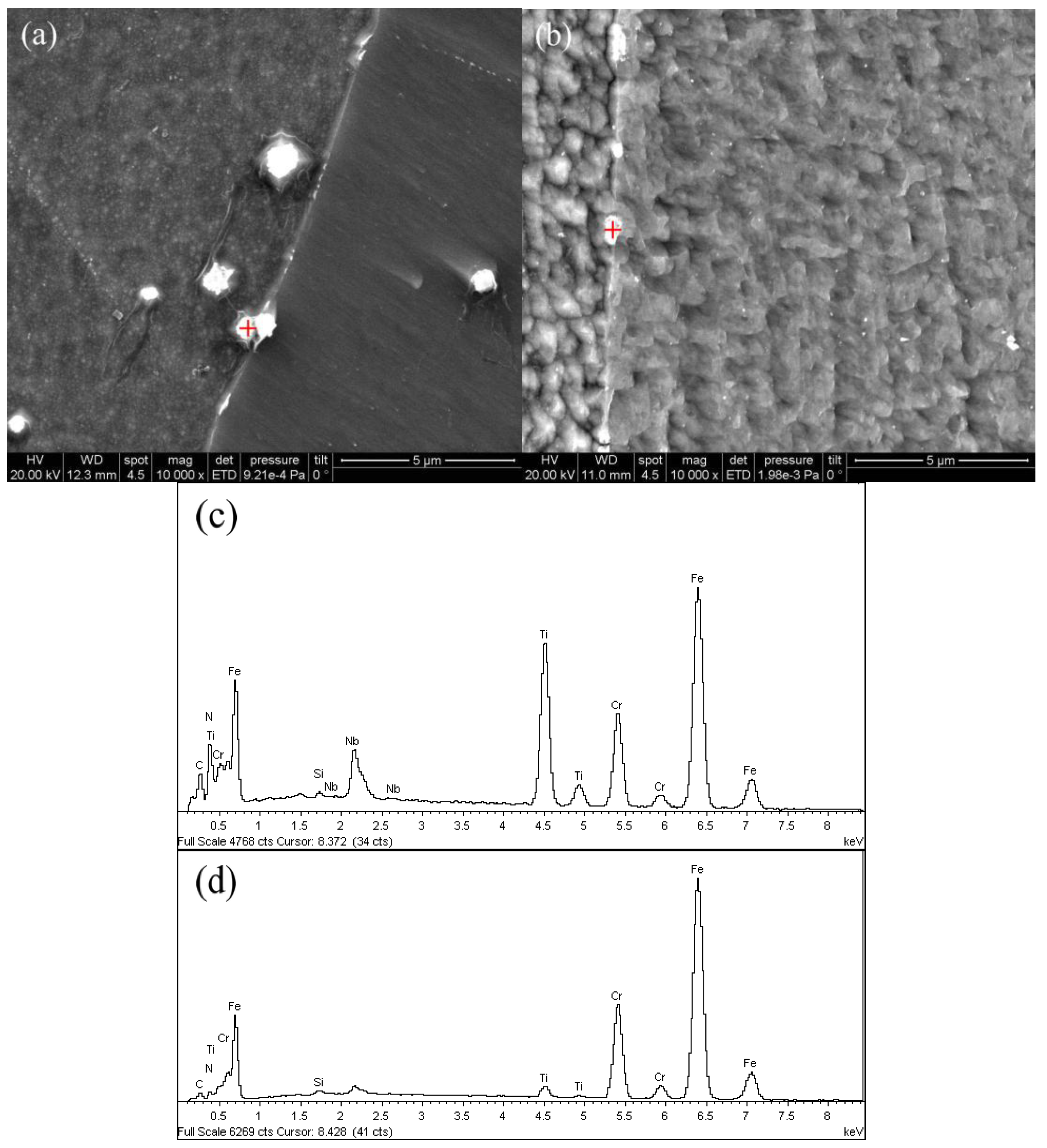

3.4. Precipitation

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bi, H.Y.; Wang, Z.Y.; Li, X.; Wang, B.S. Stainless steel for automotive exhaust system and pipes welding. World Iron Steel 2011, 5, 1–9. [Google Scholar] [CrossRef]

- Kim, J.K.; Kim, Y.H.; Uhm, S.H.; Lee, J.S.; Kim, K.Y. Intergranular corrosion of Ti-stabilized 11 wt% Cr ferritic stainless steel for automotive exhaust systems. Corros. Sci. 2009, 51, 2716–2723. [Google Scholar] [CrossRef]

- Ali-Löytty, H.; Jussila, P.; Valden, M. Optimization of the electrical properties of Ti–Nb stabilized ferritic stainless steel SOFC interconnect alloy upon high-temperature oxidation: The role of excess Nb on the interfacial oxidation at the oxide–metal interface. Int. J. Hydrogen Energy 2013, 38, 1039–1051. [Google Scholar] [CrossRef]

- Inoue, Y.; Kikuchi, M. Present and future trends of stainless steel for automotive exhaust system. Nippon Steel Tech. Rep. 2003, 88, 62–69. [Google Scholar]

- Sato, E.; Tanoue, T. Present and future trends of materials for automotive exhaust system. Nippon Steel Tech. Rep. 1995, 64, 13–19. [Google Scholar]

- Miyazaki, A.; Hirasawa, J.; Satoh, S. Advanced stainless steels for stricter regulations of automotive exhaust gas. Kawasaki Steel Tech. Rep. 2000, 43, 21–28. [Google Scholar]

- Li, X.; Bi, H.Y.; Zhang, Z.X. Development of ferritic stainless steels at Baosteel for the hot end of the exhaust system. Baosteel Technol. 2013, 5, 15–21. [Google Scholar] [CrossRef]

- Keming, F.; Ruiming, N. Research on determination of the rare earth content in metal phases of steel. Metall. Trans. A 1986, 17, 315–323. [Google Scholar] [CrossRef]

- Du, T. The effect and mechanism of rare earth elements in metals. Chin. J. Nonferrous Met. 1996, 6, 12–18. [Google Scholar] [CrossRef]

- Chen, Z.P.; Xu, Y.T.; Gu, L.M. Effect of Rare Earth on the Inclusions of Ultra Clean Ferritic Stainless Steel. In Proceedings of the 2012 National Conference on Metallurgical Physical Chemistry, Kunming, China, 15–17 August 2012; pp. 652–656. [Google Scholar]

- Wang, L.M. Application prospects and behavior of RE in new generation high strength steels with superior toughness. J. Chin. Rare Earth Soc. 2004, 22, 48–54. [Google Scholar]

- Zhang, S.H.; Yu, Y.C.; Li, H.; Ren, X.; Wang, S.B. Effect of cerium on solidification structure of SUS434 ferritic stainless steel. Foundry Technol. 2016, 37, 2641–2644. [Google Scholar] [CrossRef]

- Dong, F.; Zhao, X.H.; Yang, L. Effect of Ce on intergranular corrosion of 00Cr12 ferrite stainless steel. Chin. Rare Earths 2014, 35, 86–91. [Google Scholar] [CrossRef]

- Zheng, F.; Cheng, T.Y.; Zhang, Q.Y. Application and development of cerium in stainless steel. Nonferrous Met. 2011, 63, 78–80. [Google Scholar] [CrossRef]

- Sun, S.Y.; Yuan, S.Q.; Zhou, G.S.; Chai, D.L. Influence of rare earth element on the mechanical properties and microstructure of ferritic stainless steel. Trans. Mater. Heat Treat. 2007, 28, 22–24. [Google Scholar] [CrossRef]

- Zhu, J.X.; Chen, D.X.; Qi, G.P.; Ge, Q.; Chen, X.; Cai, Z.; Wang, L.M. Modifications on Resistance to High-Temperature-Oxidation of AISI430 Ferrite Stainless Steel by Addition of Rare Earth Elements. In Proceedings of the 2006 National Conference on Metallurgical Physical Chemistry, Jinan, China, 17–20 October 2006; pp. 490–496. [Google Scholar]

- Wei, L.L.; Zheng, J.H.; Chen, L.Q.; Misra, R.D.K. High temperature oxidation behavior of ferritic stainless steel containing W and Ce. Corros. Sci. 2018, 142, 79–92. [Google Scholar] [CrossRef]

- Wei, L.L.; Chen, L.Q.; Ma, M.Y.; Liu, H.L.; Misra, R.D.K. Oxidation behavior of ferritic stainless steels in simulated automotive exhaust gas containing 5 vol.% water vapor. Mater. Chem. Phys. 2018, 205, 508–517. [Google Scholar] [CrossRef]

- Lippold, J.C. Welding Metallurgy and Weldability; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2015; pp. 345–346. [Google Scholar]

- Lu, W.X.; Meng, Q.S.; Yang, S.J. The crystal crack form and the fracture character of austenitic weld under the Trans-varestraint hot crack test. J. Taiyuan Univ. Technol. 1986, 1, 21–27. [Google Scholar] [CrossRef]

- Peng, R.H.; Li, M.Z.; Sun, L.M. Investigation on the dendrites in weld metals of austenitic heat-resistant cast steels and on the fracture appearance of solidification cracks. J. Iron Steel Res. 1985, 5, 307–311. [Google Scholar] [CrossRef]

- Zhao, L.P.; Zhang, H.M.; Sun, X.S.; Cui, C.Y. Effect of adding methods and addition amount of Ce on microstructure of 2Cr13 stainless steel. Trans. Mater. Heat Treat. 2012, 33, 91–94. [Google Scholar] [CrossRef]

- Li, Y.B.; Wang, F.M.; Li, C.R. Effect of cerium on grain and carbide in low chromium ferritic stainless steels. J. Chin. Rare Earth Soc. 2009, 27, 123–127. [Google Scholar]

| Steel | C | Si | Mn | P | S | Cr | Nb | N | Ti | Ce |

|---|---|---|---|---|---|---|---|---|---|---|

| 441 | 0.005 | 0.380 | 0.340 | 0.008 | 0.002 | 18.630 | 0.430 | 0.008 | 0.140 | - |

| 441Ce | 0.008 | 0.360 | 0.310 | 0.008 | 0.001 | 18.440 | 0.460 | 0.008 | 0.190 | 0.024 |

| Steel | Solidification Start Temperature/°C | Solidification End Temperature/°C | Solidification Temperature Range/°C |

|---|---|---|---|

| 441 | 1504 | 1319 | 185 |

| 441Ce | 1502 | 1303 | 199 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, S.; Yan, B. Effects of Cerium on Weld Solidification Crack Sensitivity of 441 Ferritic Stainless Steel. Metals 2019, 9, 372. https://doi.org/10.3390/met9030372

Zhu S, Yan B. Effects of Cerium on Weld Solidification Crack Sensitivity of 441 Ferritic Stainless Steel. Metals. 2019; 9(3):372. https://doi.org/10.3390/met9030372

Chicago/Turabian StyleZhu, Shuangchun, and Biao Yan. 2019. "Effects of Cerium on Weld Solidification Crack Sensitivity of 441 Ferritic Stainless Steel" Metals 9, no. 3: 372. https://doi.org/10.3390/met9030372

APA StyleZhu, S., & Yan, B. (2019). Effects of Cerium on Weld Solidification Crack Sensitivity of 441 Ferritic Stainless Steel. Metals, 9(3), 372. https://doi.org/10.3390/met9030372