Effect of a New Grain Refiner (Al–Ti–Mg–Ce) on Hardness, Tensile, and Impact Properties of Al–7Si Alloy

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

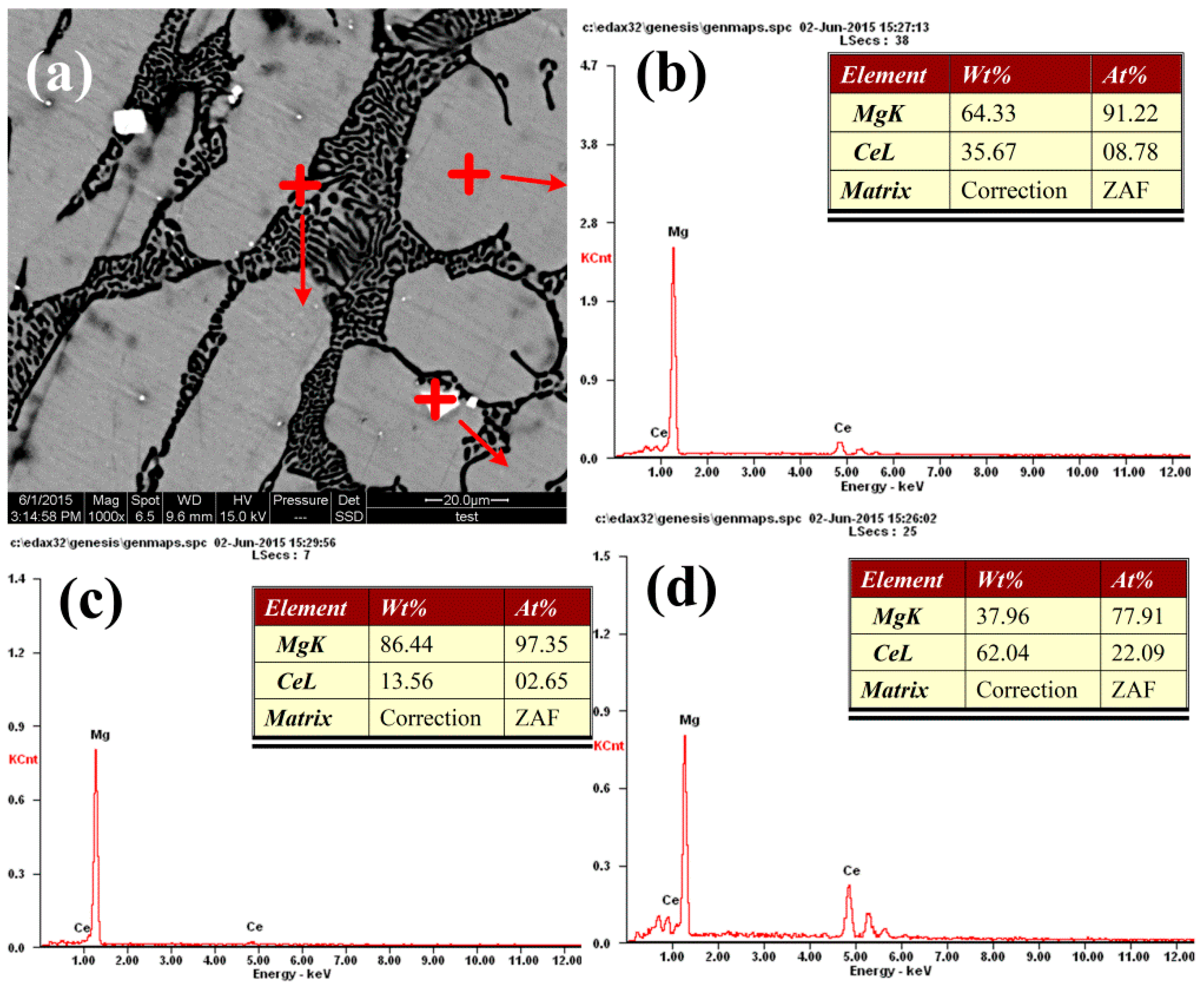

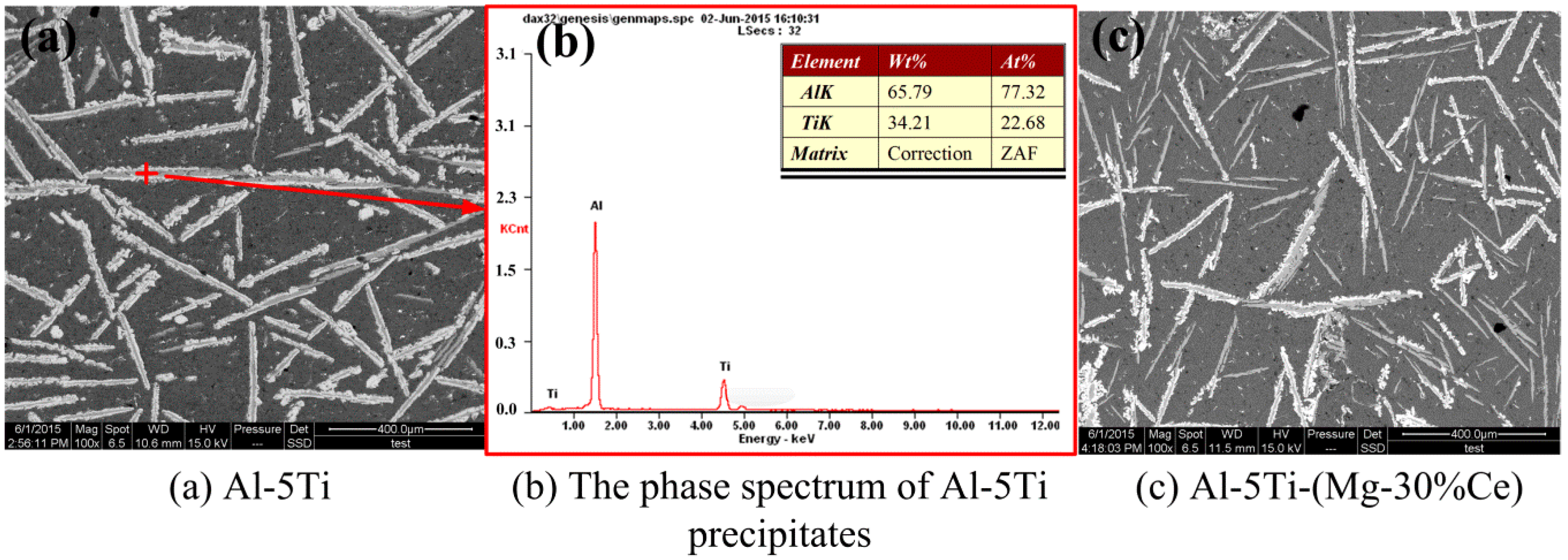

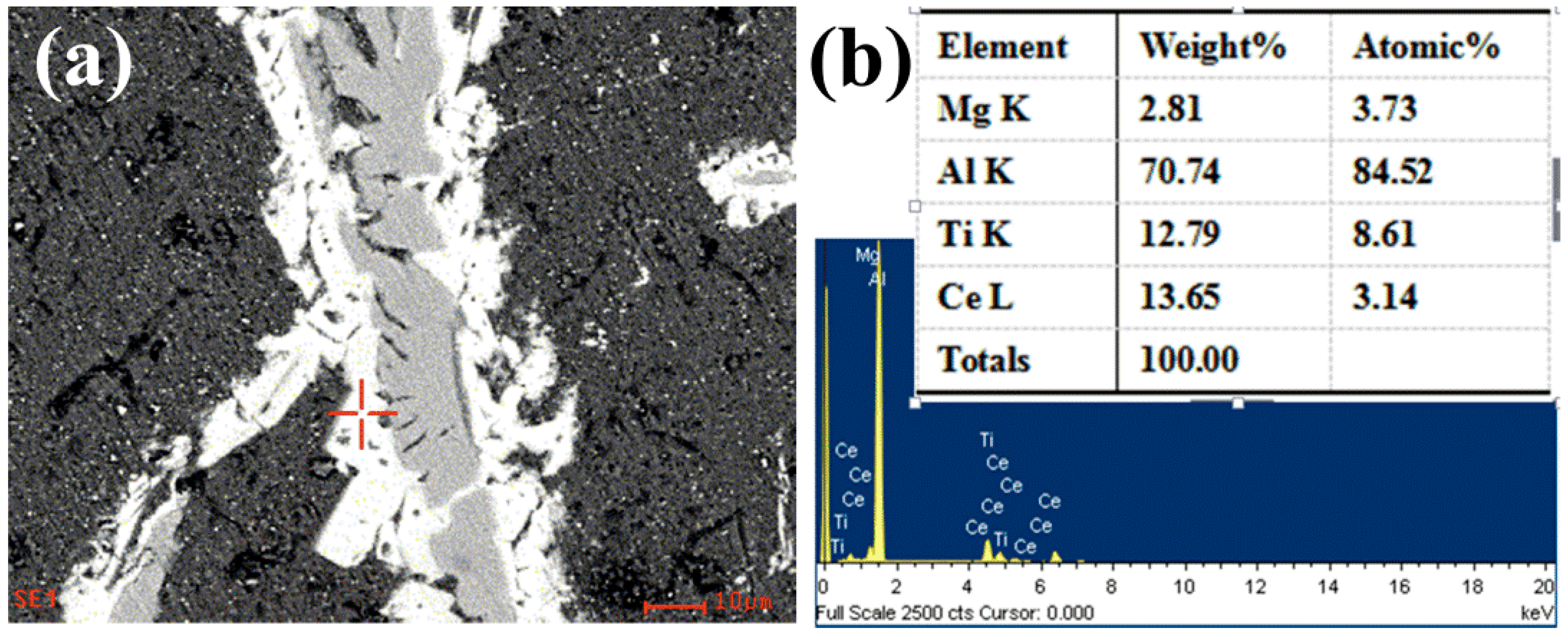

3.1. Energy Spectrum Analysis of Al–5Ti-(Mg–30%Ce)

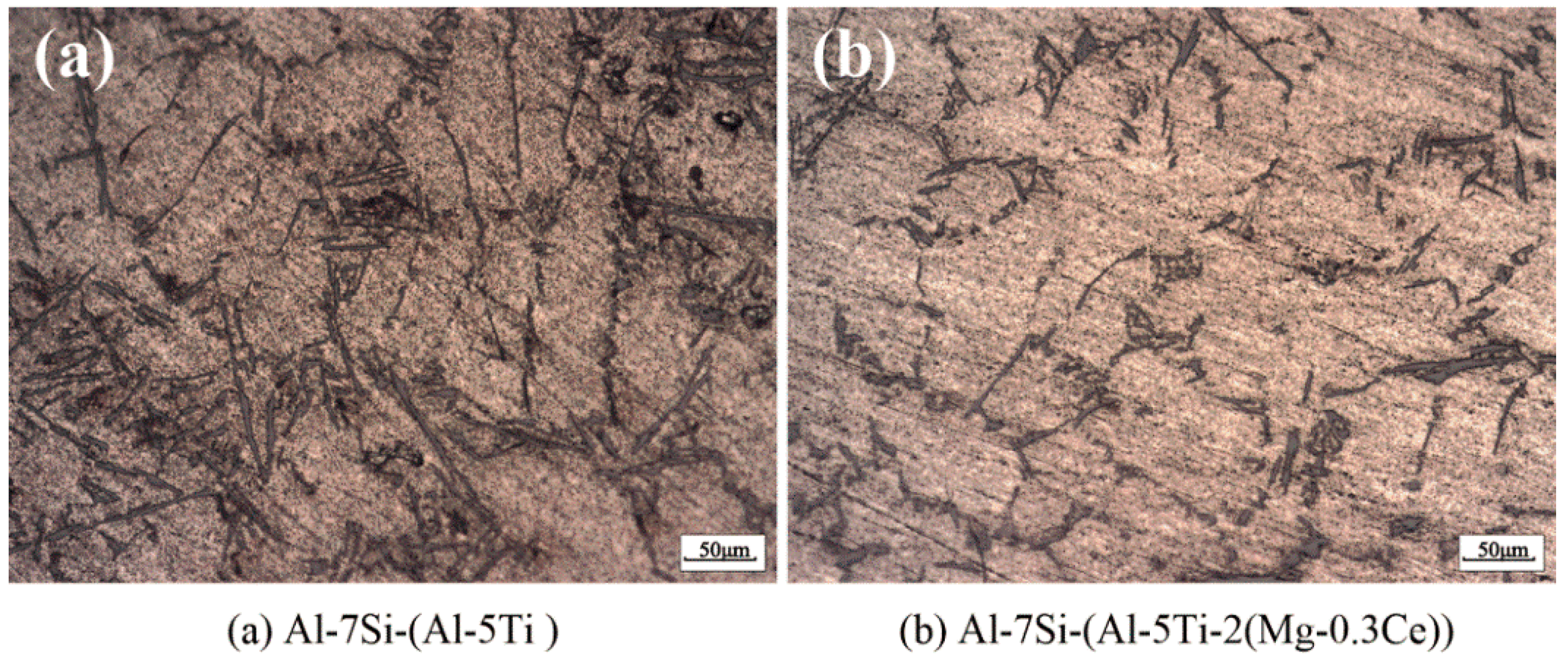

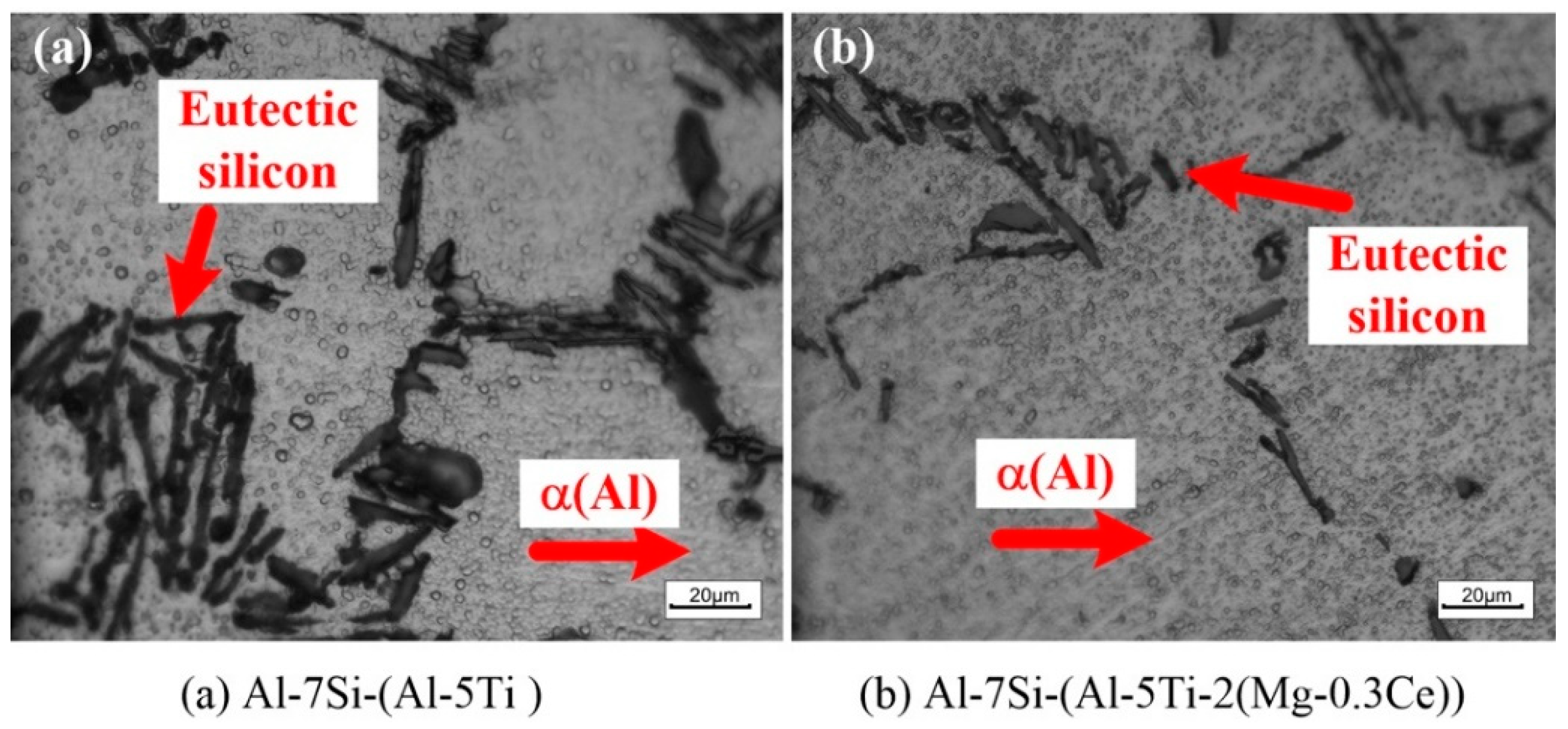

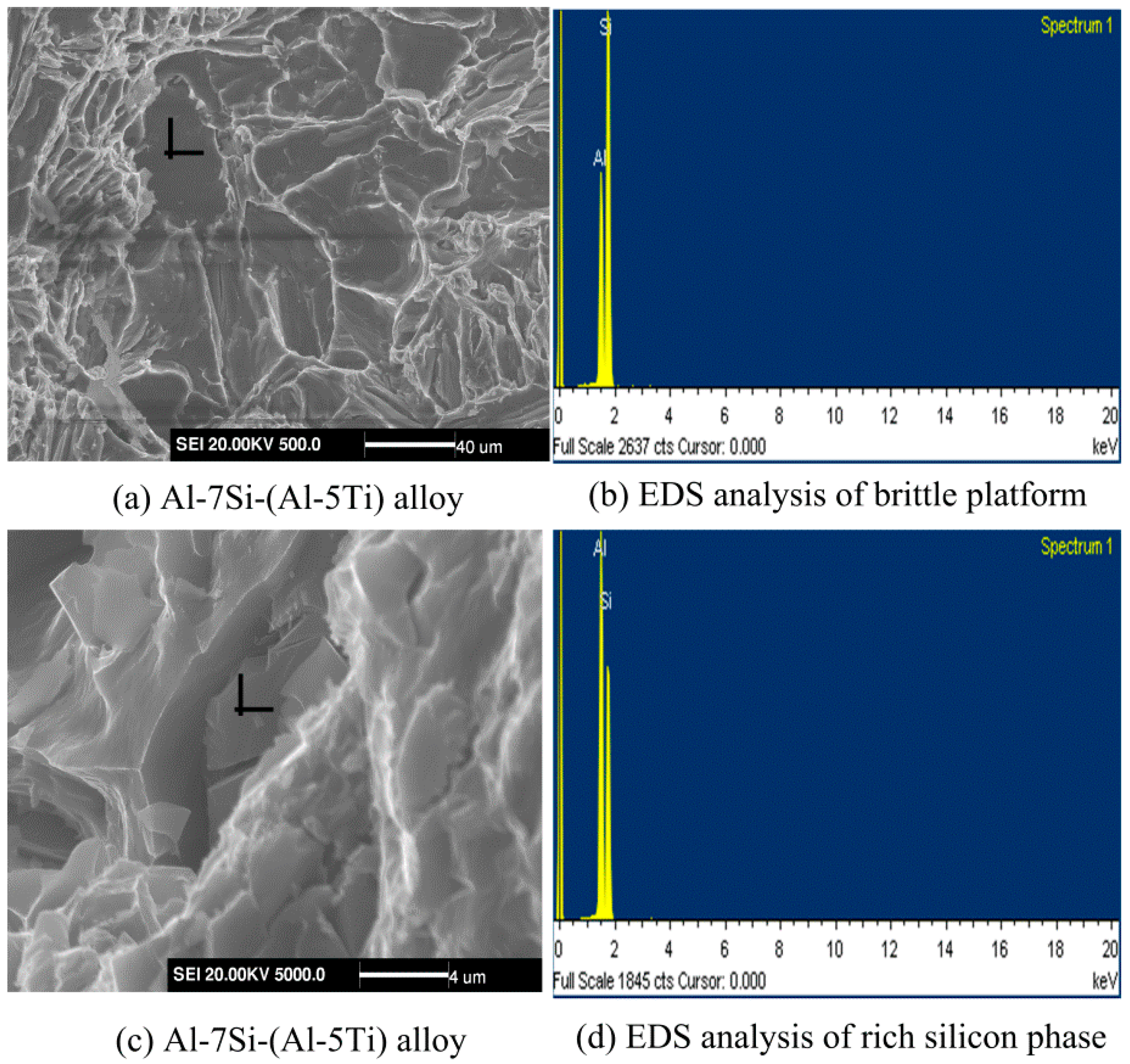

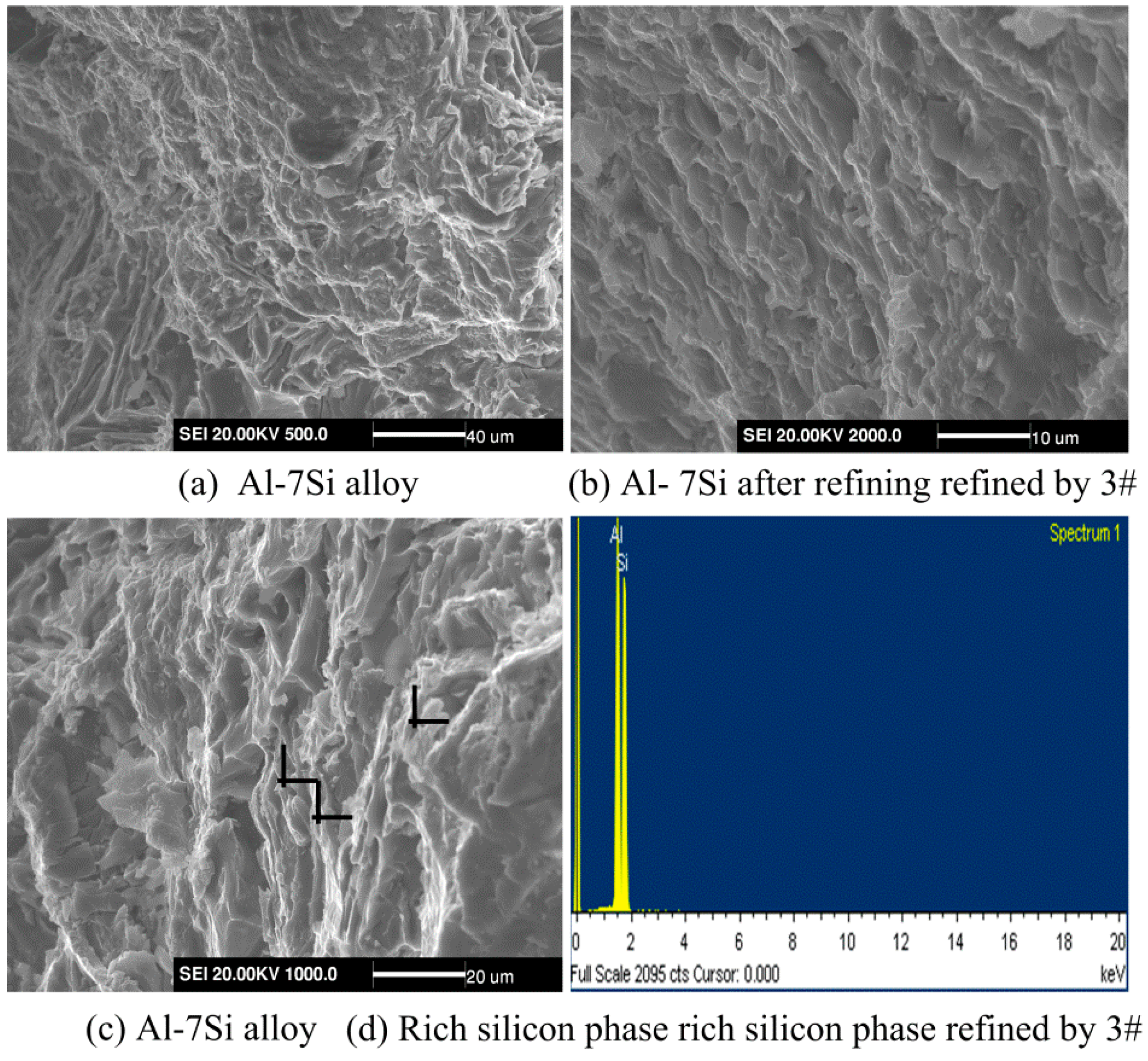

3.2. Microscopic Analysis of Al–Si Alloy

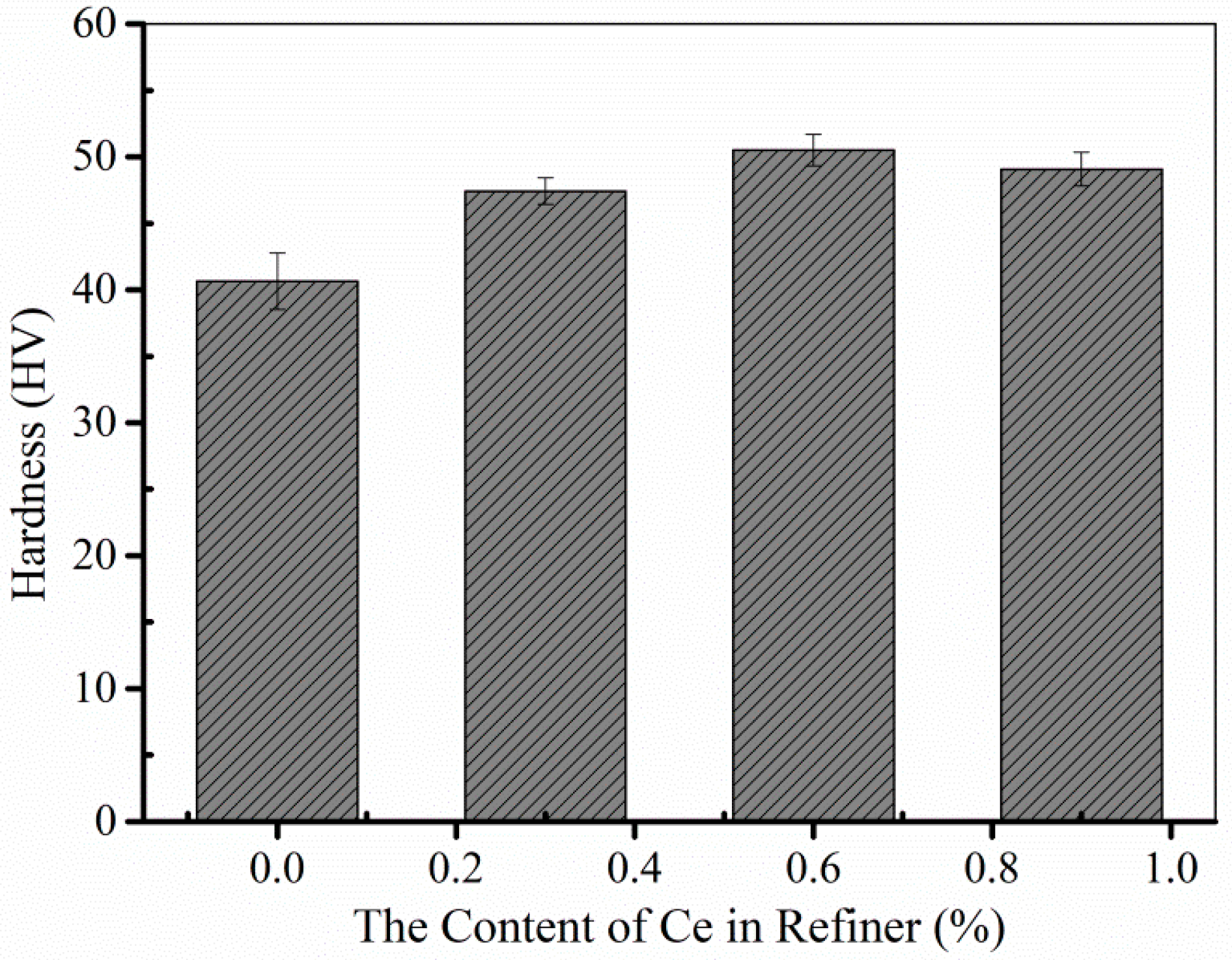

3.3. Microhardness of Al–Si Alloy

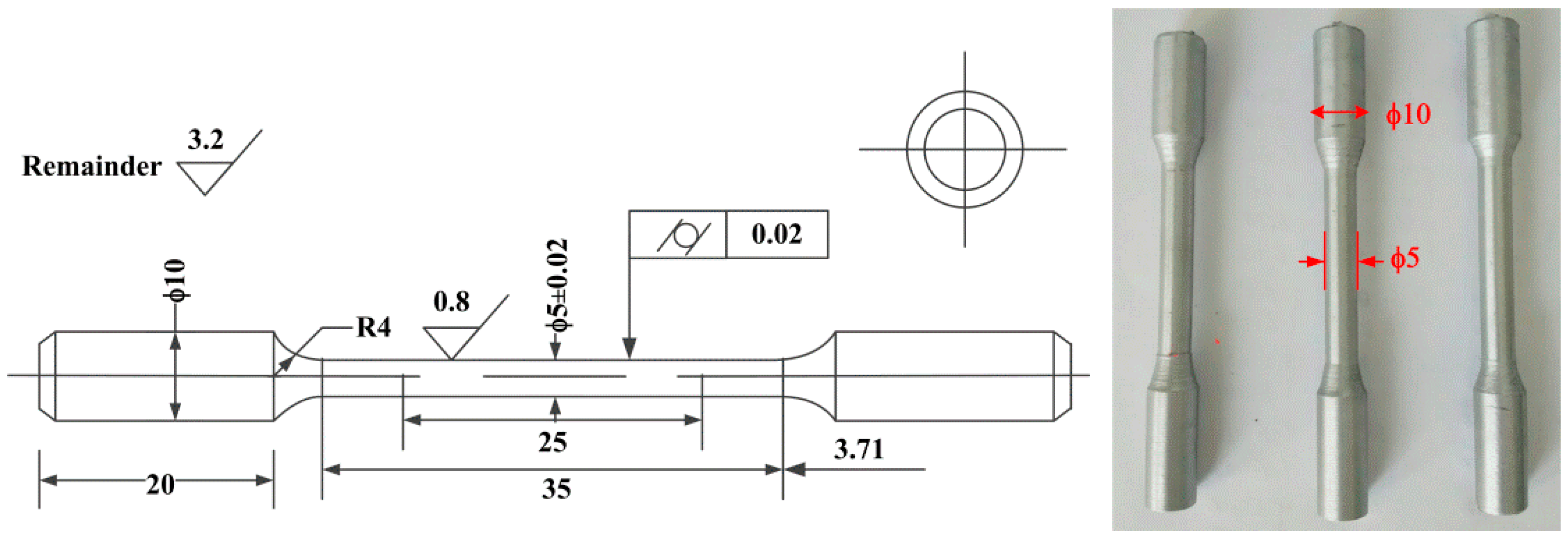

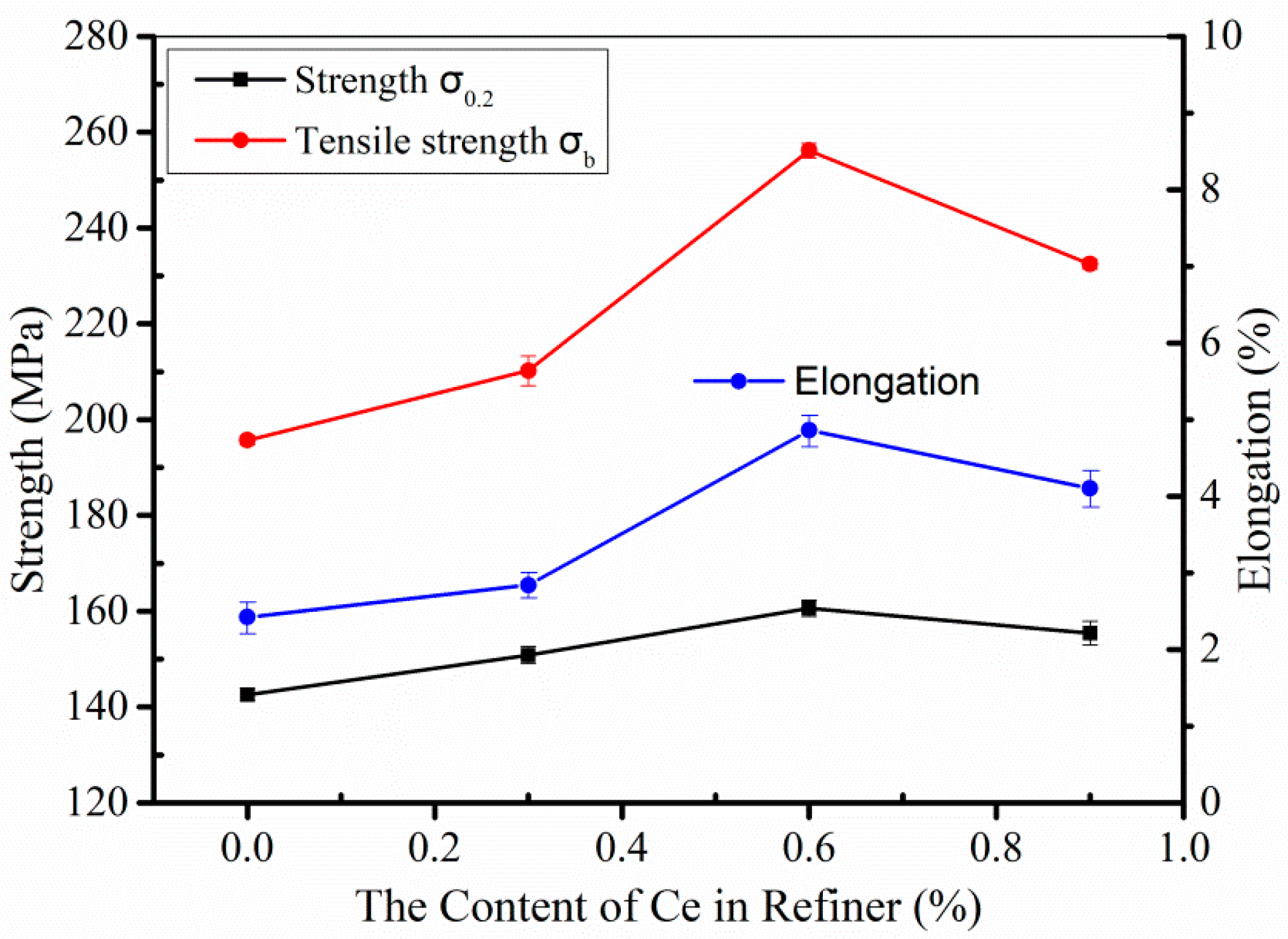

3.4. Tensile Properties of Al–Si Alloy

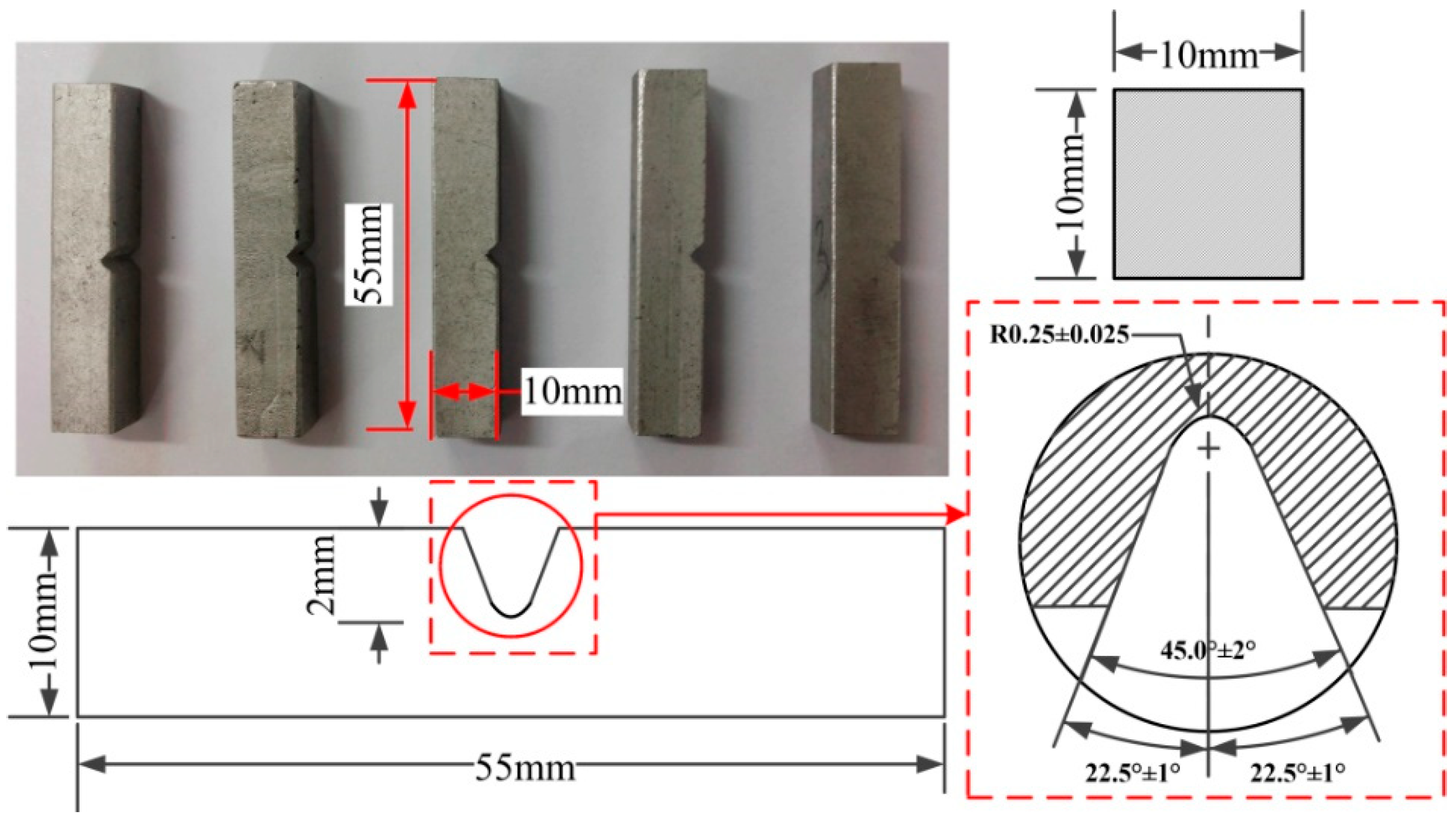

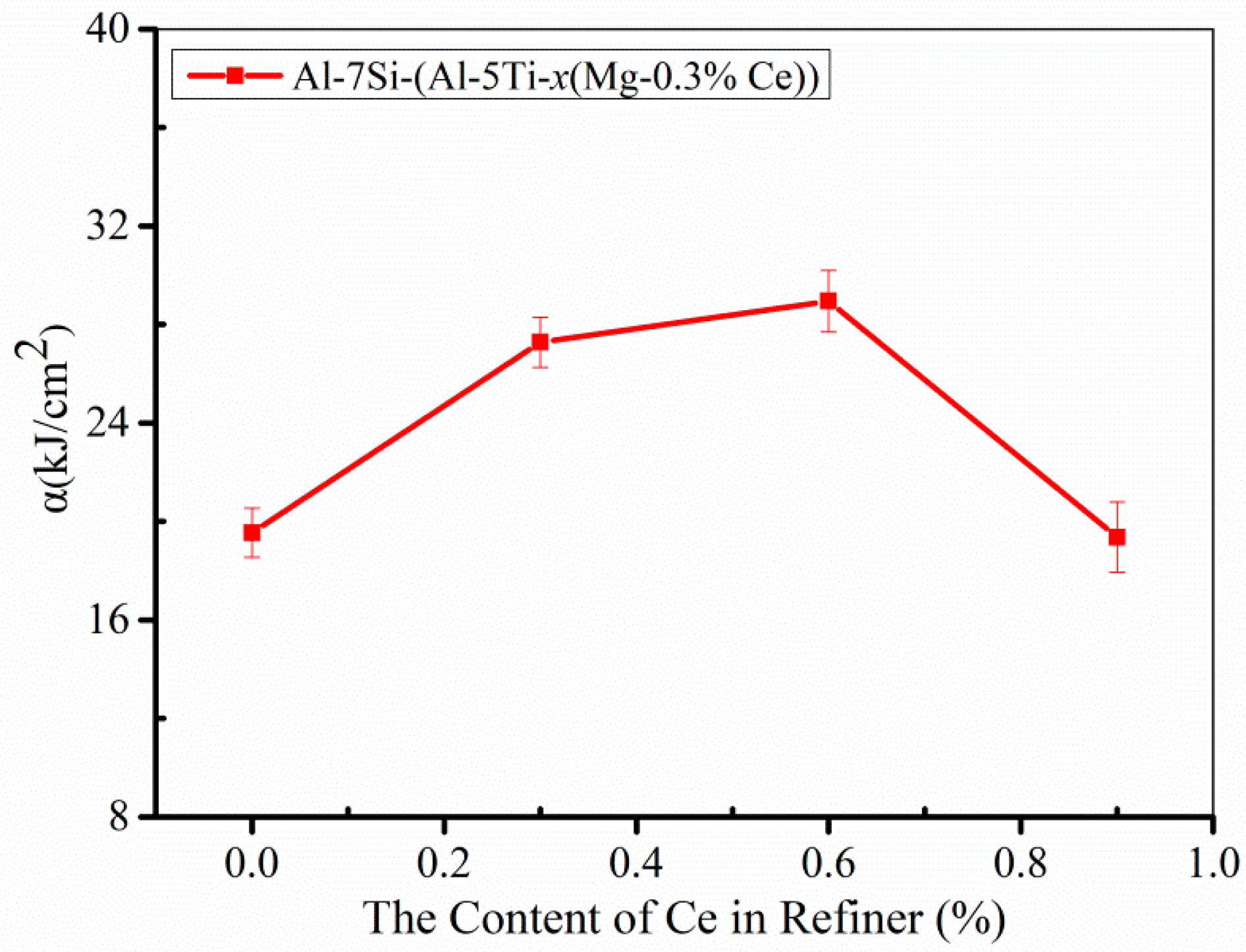

3.5. Impact Performance of Al–Si Alloy

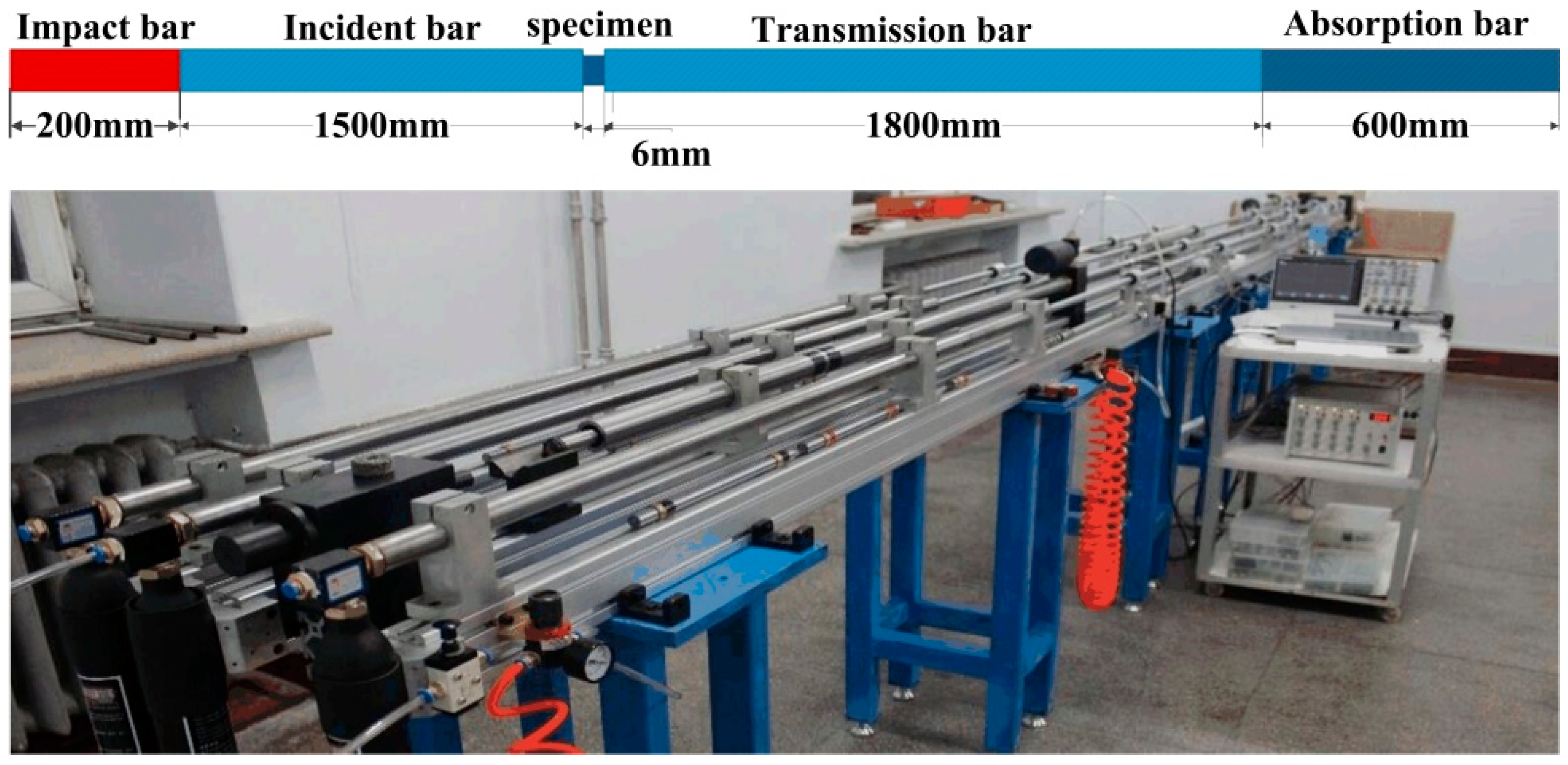

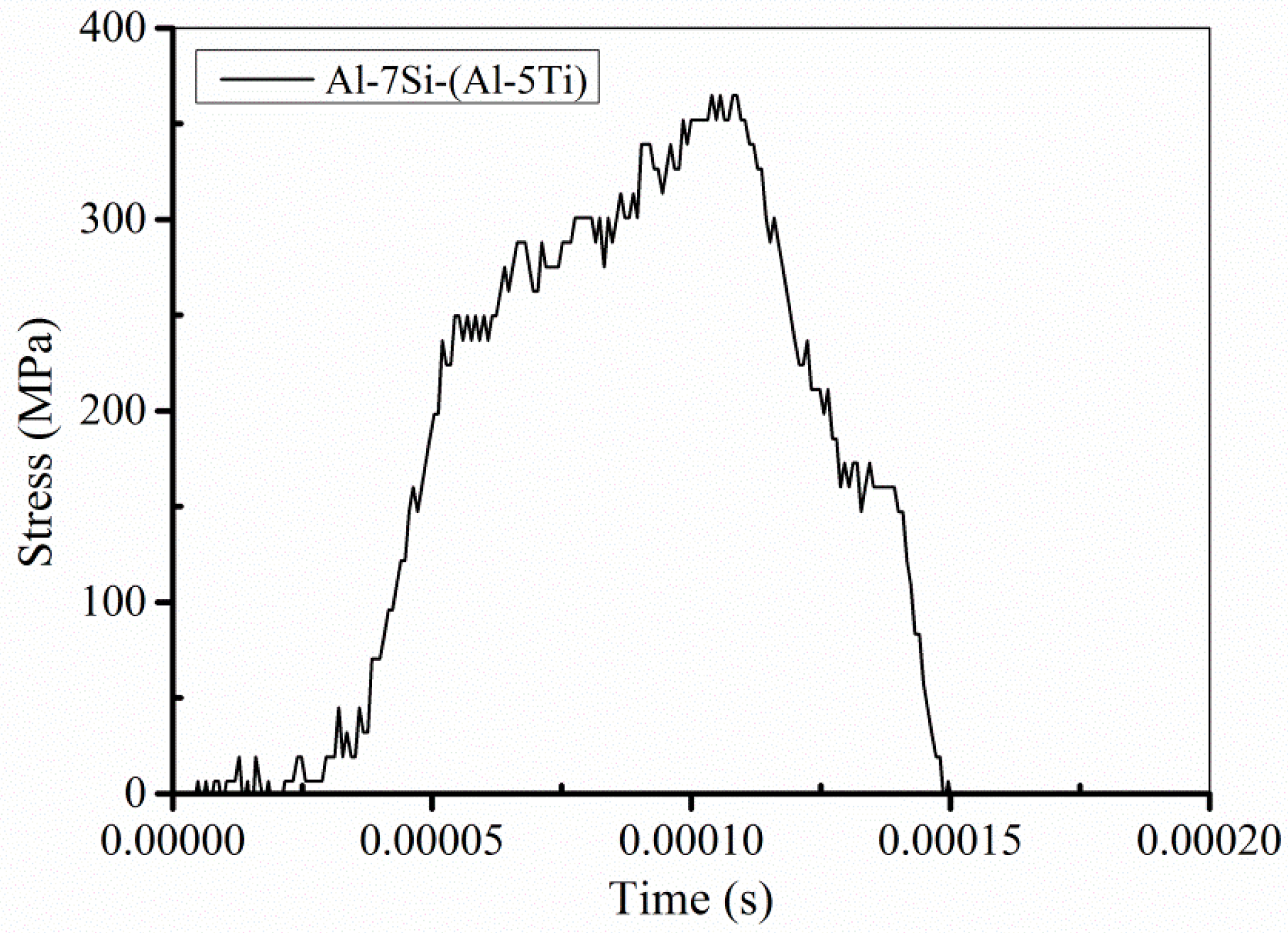

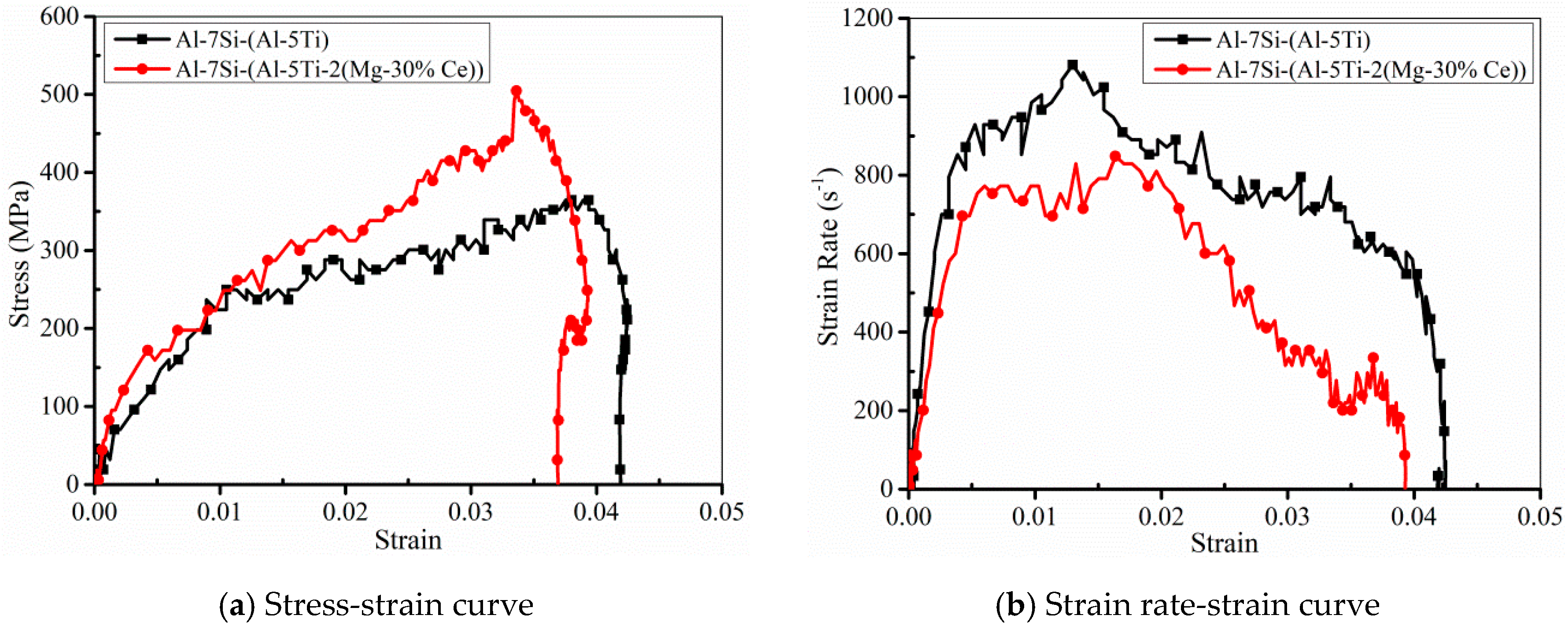

3.6. Dynamic Compression Properties of Al–Si Alloy

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Nakai, M.; Eto, T. New aspects of development of high strength aluminum alloys for aerospace applications. Mater. Sci. Eng. A 2000, 285, 62–68. [Google Scholar] [CrossRef]

- Heinz, A.; Haszler, A.; Keidel, C.; Miller, W.S. Recent development in aluminum alloys for aerospace applications. Mater. Sci. Eng. A 2000, 280, 102–107. [Google Scholar] [CrossRef]

- Zhu, M.; Jian, Z.Y.; Yang, G.C.; Zhou, Y.H. Effects of T6 heat treatment on the microstructure, tensile properties, and fracture behavior of the modified A356 alloys. Mater. Des. 2012, 36, 243–249. [Google Scholar] [CrossRef]

- Wang, X.J.; Luo, X.X.; Cong, F.G.; Cui, J.Z. Research progress of microstructure control for aluminium solidification process. Chin. Sci. Bull. 2013, 58, 468–473. [Google Scholar] [CrossRef]

- Birol, Y. AlB3 master alloy to grain refine AlSi10Mg and AlSi12Cu aluminium foundry alloys. J. Alloys Compd. 2012, 513, 150–153. [Google Scholar] [CrossRef]

- Wang, T.M.; Chen, Z.N.; Fu, H.W.; Gao, L.; Li, T.J. Grain refinement mechanism of pure aluminum by inoculation with Al-B master alloys. Mater. Sci. Eng. A 2012, 549, 136–143. [Google Scholar] [CrossRef]

- Birol, Y. Grain refinement of pure aluminium and Al-7Si with Al-3B master alloy. Mater. Sci. Eng. A 2013, 28, 363–367. [Google Scholar] [CrossRef]

- Ravi, M.; Pillai, U.T.S.; Pai, B.C.; Damodaran, A.D.; Dwarakadasa, E.S. The Effect of Mischmetal Addition on the Structure and Mechanical Properties of a Cast Al-7Si-0.3Mg Alloy Containing Excess Iron (up to 0.6 Pct). Metall. Mater. Trans. A 2002, 33, 391–400. [Google Scholar] [CrossRef]

- Kori, S.A.; Murty, B.S.; Chakraborty, M. Development of an efficient grain refiner for Al-7Si alloy. Mater. Sci. Eng. A 2000, 280, 58–61. [Google Scholar] [CrossRef]

- Rao, A.P.; Das, K.; Murty, B.S.; Chakraborty, M. Effect of grain refinement on wear properties of Al and Al-7Si alloy. Wear 2004, 257, 148–153. [Google Scholar] [CrossRef]

- Chen, Z.N.; Kang, H.J.; Fan, G.H.; Li, J.J.; Lu, Y.P.; Jie, J.C.; Zhang, Y.B.; Li, T.J.; Jian, X.G.; Wang, T.M. Grain refinement of hypoeutectic Al-Si alloys with B. Acta Mater. 2016, 120, 168–178. [Google Scholar] [CrossRef]

- Samuel, E.; Golbahar, B.; Samuel, A.M.; Doty, H.W.; Valtierra, S.; Samuel, F.H. Effect of grain refiner on the tensile and impact properties of Al-Si-Mg cast alloys. Mater. Des. 2014, 56, 468–479. [Google Scholar] [CrossRef]

- Song, M.; Chen, K.H.; Huang, L.P. Effects of Ce and Ti on the microstructures and mechanical properties of an Al-Cu-Mg-Ag alloy. Rare Met. 2007, 26, 28–32. [Google Scholar] [CrossRef]

- Pio, L.Y.; Sulaiman, S.; Hamouda, A.M.; Ahmad, M.M.H.M. Grain refinement of LM6 Al-Si alloy sand castings to enhance mechanical properties. J. Mater. Process. Technol. 2005, 162–163, 435–441. [Google Scholar] [CrossRef]

- Jigajinni, S.M.; Venkateswarlu, K.; Kori, S.A. Effect of a grain refiner cum modifier on mechanical Properties of Al-7Si and Al-11Si alloys. Met. Mater. Int. 2013, 19, 171–181. [Google Scholar] [CrossRef]

- Wang, X.J.; Xu, C.; Muhammad, A.; Hanada, S.; Yamagata, H.; Wang, W.H.; Ma, C.L. Effects of Al-Ti-B-RE grain refiner on microstructure and mechanical properties of Al-7.0Si-0.55Mg alloy. Trans. Nonferrous Met. Soc. China 2014, 24, 2244–2250. [Google Scholar] [CrossRef]

- Timelli, G.; Camicia, G.; Ferraro, S. Effect of grain refinement and cooling rate on the microstructure and mechanical properties of secondary Al-Si-Cu alloys. J. Mater. Eng. Perform. 2014, 23, 611–621. [Google Scholar] [CrossRef]

- Easton, M.; John, D. Grain refinement of aluminum alloys: Part, I. The nucleant and solute paradigms—A review of the literature. Metall. Mater. Trans. A 1999, 30, 1613–1623. [Google Scholar] [CrossRef]

- Nogita, K.; Mcdonald, S.D.; Dahle, A.K. Eutectic modification of Al-Si alloys with rare earth metals. Mater. Trans. 2004, 45, 323–326. [Google Scholar] [CrossRef]

- Yao, X.; Mcdonald, S.D.; Dahle, A.K. Modeling of grain refinement: Part III. Al-7Si-0.3Mg aluminum alloy. J Mater. Res. 2008, 23, 1301–1306. [Google Scholar] [CrossRef]

- Brinkman, H.J.; Zupazi, F.; Duszezyk, J.; Katgerman, L. Production of Al-Ti-C grain refiner alloys by reactive synthesis of elemental powders: Part I. Reactive synthesis and characterization of alloys. J. Mater. Res. 2000, 15, 2620–2627. [Google Scholar] [CrossRef]

- Wang, J.; He, S.X.; Sun, B.D.; Guo, Q.X.; Nishio, M. Grain refinement of Al-Si alloy (A356) by melt thermal treatment. J. Mater. Process. Technol. 2003, 141, 29–34. [Google Scholar] [CrossRef]

- Mousavi, G.S.; Emamy, M.; Rassizadehghani, J. The effect of mischmetal and heat treatment on the microstructure and tensile properties of A357 Al-Si casting alloy. Mater. Sci. Eng. A 2012, 556, 573–581. [Google Scholar] [CrossRef]

- Ebrahimi, S.S.; Emamy, M. Effects of Al-5Ti-1B and Al-5Zr master alloys on the structure, hardness and tensile properties of a highly alloyed aluminum alloy. Mater. Des. 2010, 31, 200–209. [Google Scholar] [CrossRef]

- Du, Y.Z.; Zheng, M.Y.; Qiao, X.G.; Wu, K.; Liu, X.D.; Wang, G.J.; Lv, X.Y. Microstructure and mechanical properties of Mg-Zn-Ca-Ce alloy processed by semi-continuous casting. Mater. Sci. Eng. A 2013, 582, 134–139. [Google Scholar] [CrossRef]

- Riestra, M.; Ghassemali, E.; Bogdanoff, T.; Seifeddine, S. Interactive effects of grain refinement, eutectic modification and solidification rate on tensile properties of Al-10Si alloy. Mater. Sci. Eng. A 2017, 703, 270–279. [Google Scholar] [CrossRef]

- Basavakumar, K.G.; Mukunda, P.G.; Chakraborty, M. Impact toughness in Al-12Si and Al-12Si-3Cu cast alloys-Part 1: Effect of process variables and microstructure. Int. J. Impact Eng. 2008, 35, 199–205. [Google Scholar] [CrossRef]

- Samuel, A.M.; Doty, H.W.; Valtierra, S.; Samuel, F.H. Effect of grain refining and Sr-modification interactions on the impact toughness of Al-Si-Mg cast alloys. Mater. Des. 2014, 56, 264–273. [Google Scholar] [CrossRef]

- Abuhasel, K.A.; Ibrahim, M.F.; Elgallad, E.M.; Samuel, F.H. On the impact toughness of Al-Si cast alloys. Mater. Des. 2016, 91, 388–397. [Google Scholar] [CrossRef]

- Rathia, S.K.; Sharma, A.; Sabatino, M.D. Effect of mould temperature, grain refinement and modification on hot tearing test in Al-7Si-3Cu alloy. Eng. Fail. Anal. 2017, 79, 592–605. [Google Scholar] [CrossRef]

- Tan, Z.H.; Chen, C.; Han, X.; Wang, F.R. Investigation on the dynamic compressive behavior and energy absorption properties of aluminium-silicon foam. Eng. Mech. 2013, 30, 360–364. [Google Scholar] [CrossRef]

- Yin, D.S.; Zhao, J.T.; Nan, J.F.; Wang, Z.T.; Zhang, Z.K.; Xu, J.W. Influence of Ce and Mg-Ce master alloy on the microstructure of Al-STi alloy. Spec. Cast. Nonferrous Alloys 2015, 35, 987–990. [Google Scholar] [CrossRef]

- Chen, C.; Liu, Z.X.; Ren, B. Influences of complex modification of P and RE on microstructure and mechanical properties of hypereutectic Al-20Si alloy. Trans. Nonferrous Met. Soc. China 2007, 17, 301–306. [Google Scholar] [CrossRef]

- Wang, S.C.; Li, J.L.; Gan, C.L. Grain refinement mechanism and effective nucleation phase of Al-5Ti-1B master alloy. Mater. Sci. Forum 2017, 898, 1231–1235. [Google Scholar] [CrossRef]

- Robson, J.D. Effect of Rare-Earth Additions on the Texture of Wrought Magnesium Alloys: The Role of Grain Boundary Segregation. Metall. Mater. Trans. A 2014, 45, 3205–3212. [Google Scholar] [CrossRef]

- Monhanty, P.S.; Gruzleski, J.E. Mechanism of grain refinement in aluminium. Acta Metall. Mater. 1995, 43, 2001–2012. [Google Scholar] [CrossRef]

- Abbott, T.B.; Parker, B.A. Coarsening of silicon fibres in modified eutectic aluminium-silicon alloys. J. Mater. Sci. Lett. 1988, 7, 88–90. [Google Scholar] [CrossRef]

- Zhang, X.X.; Wang, D.Z.; Geng, L. Coarsening of eutectic silicon in squeeze-cast alumina fiber reinforced eutectic Al-Si aluminum composites. J. Mater. Sci. Lett. 2003, 22, 861–863. [Google Scholar] [CrossRef]

- Samuel, A.M.; Elgallad, E.M.; Doty, H.W.; Valtierra, S.; Samuel, F.H. On the Microstructure, Hardness and Impact Toughness of 356 and 413 Alloys. Int. J. Metalcast. 2017, 11, 240–254. [Google Scholar] [CrossRef]

- Zhang, G.; Zhang, J.; Li, B. Double-stage hardening behavior and fracture characteristics of a heavily alloyed Al-Si piston alloy during low-cycle fatigue loading. Mater. Sci. Eng. A 2013, 561, 26–33. [Google Scholar] [CrossRef]

- Ammar, H.R.; Samuel, A.M.; Samuel, F.H. Porosity and the fatigue behavior of hypoeutectic and hypereutectic aluminum-silicon casting alloys. Int. J. Fatigue 2008, 30, 1024–1035. [Google Scholar] [CrossRef]

| Specimen | Al–7Si-(Al–5Ti-x(Mg–30%Ce)) | |||

|---|---|---|---|---|

| Distance (μm)/x(wt%) | 0 | 1.0 | 2.0 | 3.0 |

| 1 | 126 | 109 | 90 | 103 |

| 2 | 130 | 112 | 88 | 105 |

| 3 | 132 | 108 | 92 | 100 |

| 4 | 125 | 117 | 86 | 102 |

| 5 | 129 | 107 | 93 | 106 |

| Average | 129 | 111 | 90 | 103 |

| Alloy | Al–7Si-(Al–5Ti-x(Mg–30%Ce)) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number | 1# | 2# | 3# | 4# | ||||||||

| x(wt%) | 0 | 1.0 | 2.0 | 3.0 | ||||||||

| Specimen | σ0.2/MPa | σb/MPa | A/% | σ0.2/MPa | σb/MPa | A/% | σ0.2/MPa | σb/MPa | A/% | σ0.2/MPa | σb/MPa | A/% |

| 1 | 144 | 195 | 2.42 | 154. | 209 | 2.84 | 161 | 254 | 4.84 | 155 | 233 | 4.05 |

| 2 | 144 | 196 | 2.45 | 152 | 208 | 2.88 | 162 | 255 | 4.9 | 154 | 234 | 4.22 |

| 3 | 141 | 197 | 2.31 | 150 | 214 | 2.78 | 158 | 258 | 4.88 | 157 | 231 | 4.14 |

| 4 | 142 | 194 | 2.44 | 150 | 214 | 2.89 | 159 | 258 | 4.75 | 159 | 233 | 4.09 |

| 5 | 142 | 195 | 2.49 | 149 | 206 | 2.79 | 163 | 256 | 4.91 | 152 | 232 | 3.99 |

| Average | 143 | 196 | 2.42 | 151 | 210 | 2.84 | 161 | 256 | 4.86 | 155 | 232 | 4.1 |

| SD | 1 | 1 | 0.06 | 2 | 3 | 0.04 | 2 | 1 | 0.06 | 2 | 1 | 0.08 |

| Specimen | H0: Al–7Si-(Al–5Ti) | Hm1: Al–7Si-(Al–5Ti-2(Mg–30%Ce)) | ||||||

|---|---|---|---|---|---|---|---|---|

| Average Strain Rate (s−1) | Yield Stress (MPa) | Average Strain Rate (s−1) | Yield Stress (MPa) | |||||

| Velocity (m/s) | 5 | 12 | 5 | 12 | 5 | 12 | 5 | 12 |

| 1 | 796 | 2616 | 160 | 349 | 711 | 2309 | 172 | 393 |

| 2 | 794 | 2590 | 153 | 331 | 689 | 2278 | 174 | 400 |

| 3 | 803 | 2589 | 159 | 350 | 695 | 2287 | 169 | 390 |

| 4 | 802 | 2604 | 166 | 348 | 704 | 2310 | 173 | 389 |

| 5 | 806 | 2599 | 164 | 339 | 699 | 2317 | 178 | 388 |

| Average | 800 | 2600 | 160 | 343 | 700 | 2300 | 173 | 392 |

| SD | 4.49 | 9.93 | 4.5 | 7.34 | 7.53 | 14.99 | 2.93 | 4.34 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, J.; Shi, M.; Wang, Z.; Xu, L. Effect of a New Grain Refiner (Al–Ti–Mg–Ce) on Hardness, Tensile, and Impact Properties of Al–7Si Alloy. Metals 2019, 9, 228. https://doi.org/10.3390/met9020228

Zhao J, Shi M, Wang Z, Xu L. Effect of a New Grain Refiner (Al–Ti–Mg–Ce) on Hardness, Tensile, and Impact Properties of Al–7Si Alloy. Metals. 2019; 9(2):228. https://doi.org/10.3390/met9020228

Chicago/Turabian StyleZhao, Jitao, Mingfang Shi, Zhenqing Wang, and Lidan Xu. 2019. "Effect of a New Grain Refiner (Al–Ti–Mg–Ce) on Hardness, Tensile, and Impact Properties of Al–7Si Alloy" Metals 9, no. 2: 228. https://doi.org/10.3390/met9020228

APA StyleZhao, J., Shi, M., Wang, Z., & Xu, L. (2019). Effect of a New Grain Refiner (Al–Ti–Mg–Ce) on Hardness, Tensile, and Impact Properties of Al–7Si Alloy. Metals, 9(2), 228. https://doi.org/10.3390/met9020228