Effects of Sample and Indenter Configurations of Nanoindentation Experiment on the Mechanical Behavior and Properties of Ductile Materials

Abstract

1. Introduction

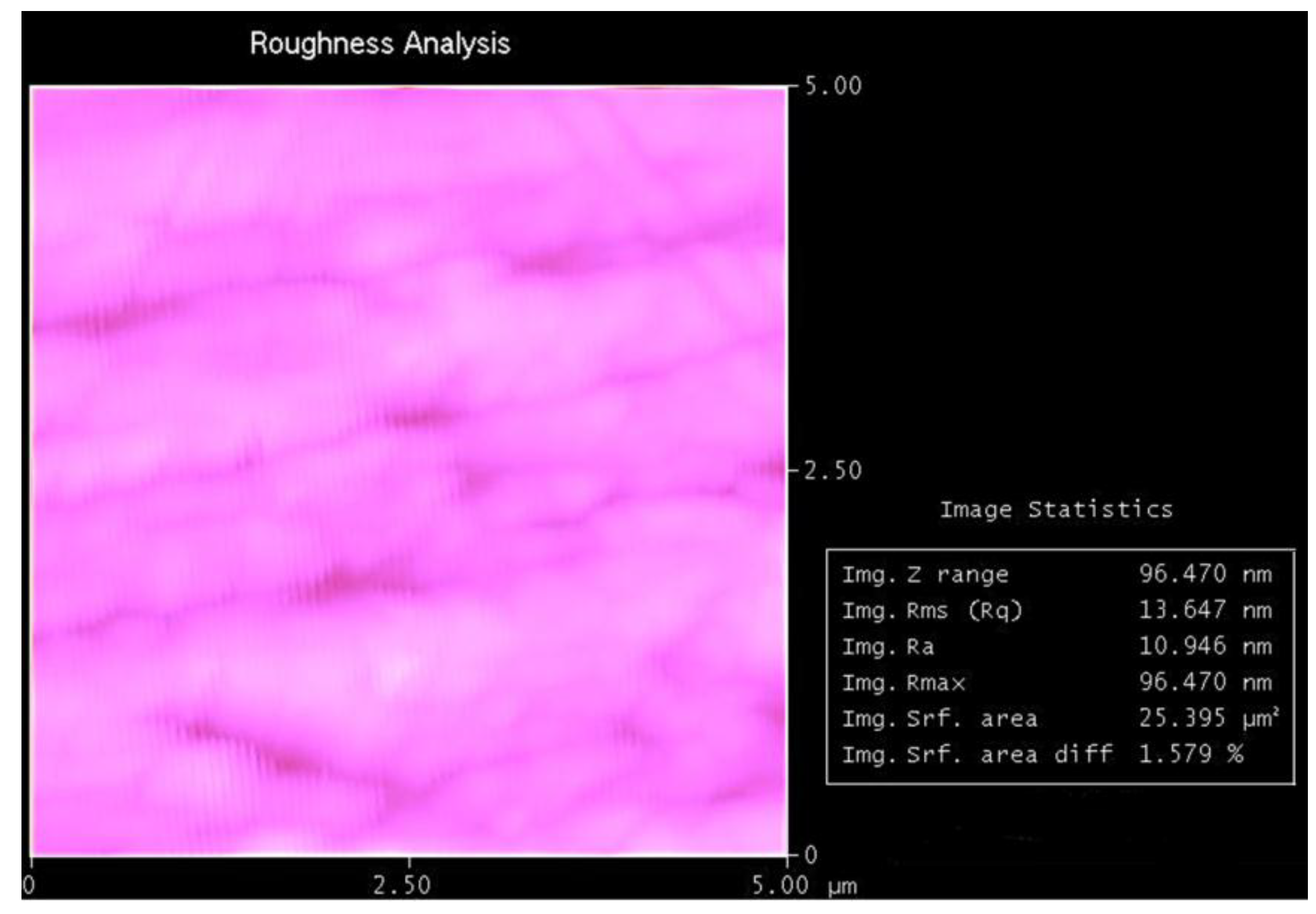

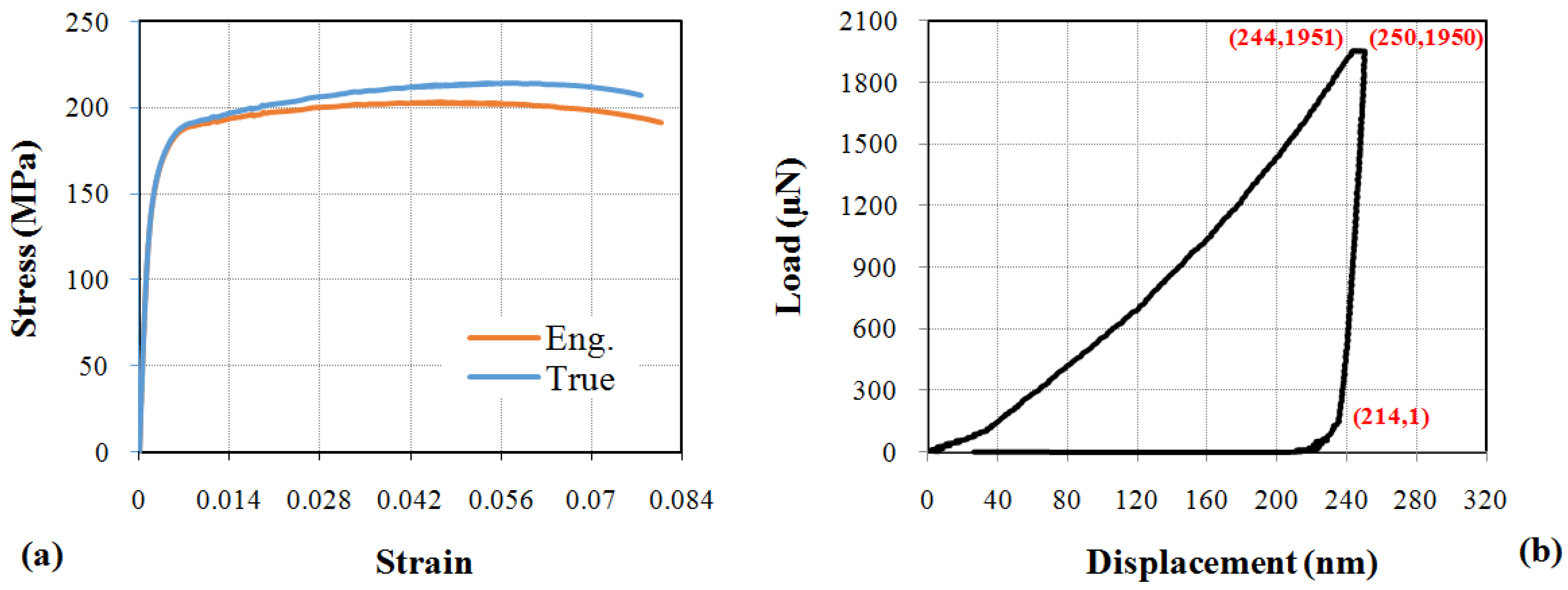

2. Nanoindentation Experiment

The Young’s Modulus and Hardness

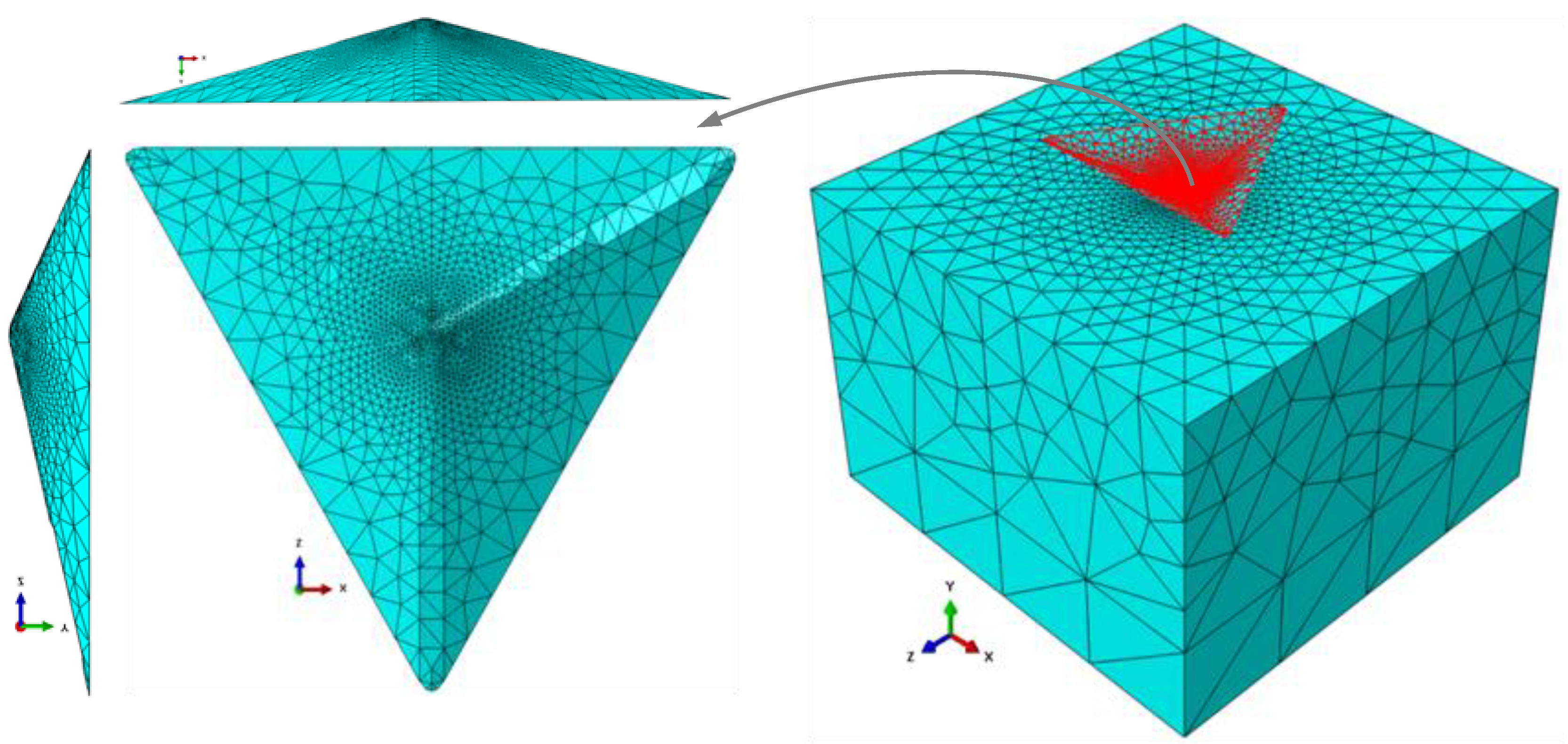

3. Finite Element Modeling

4. Results and Discussion

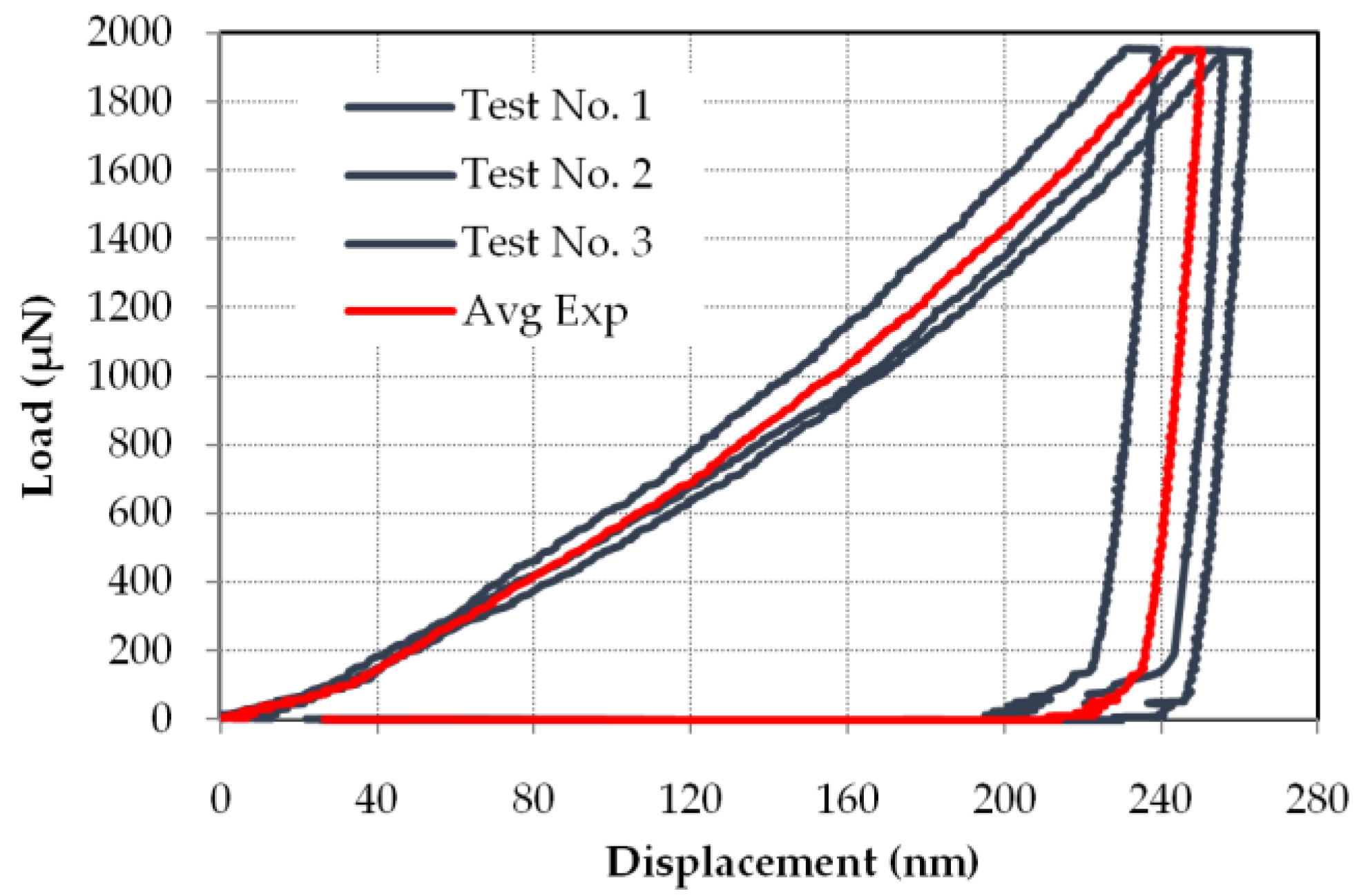

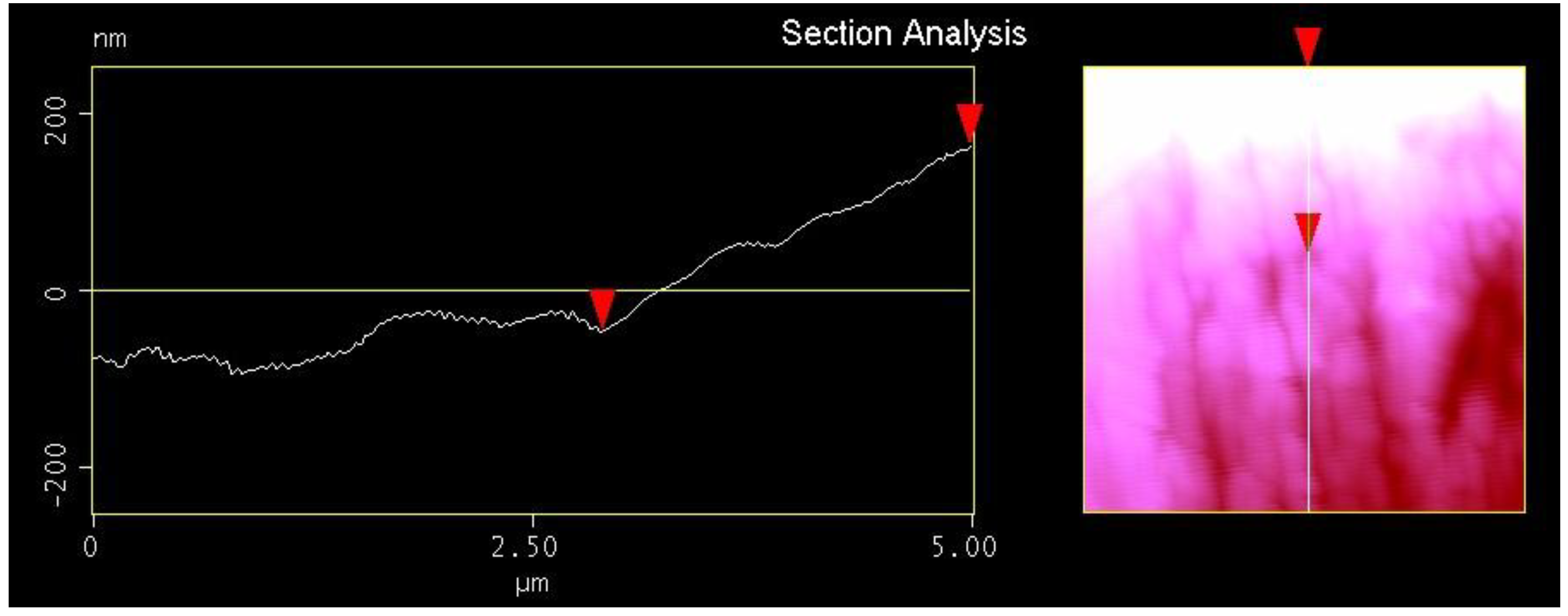

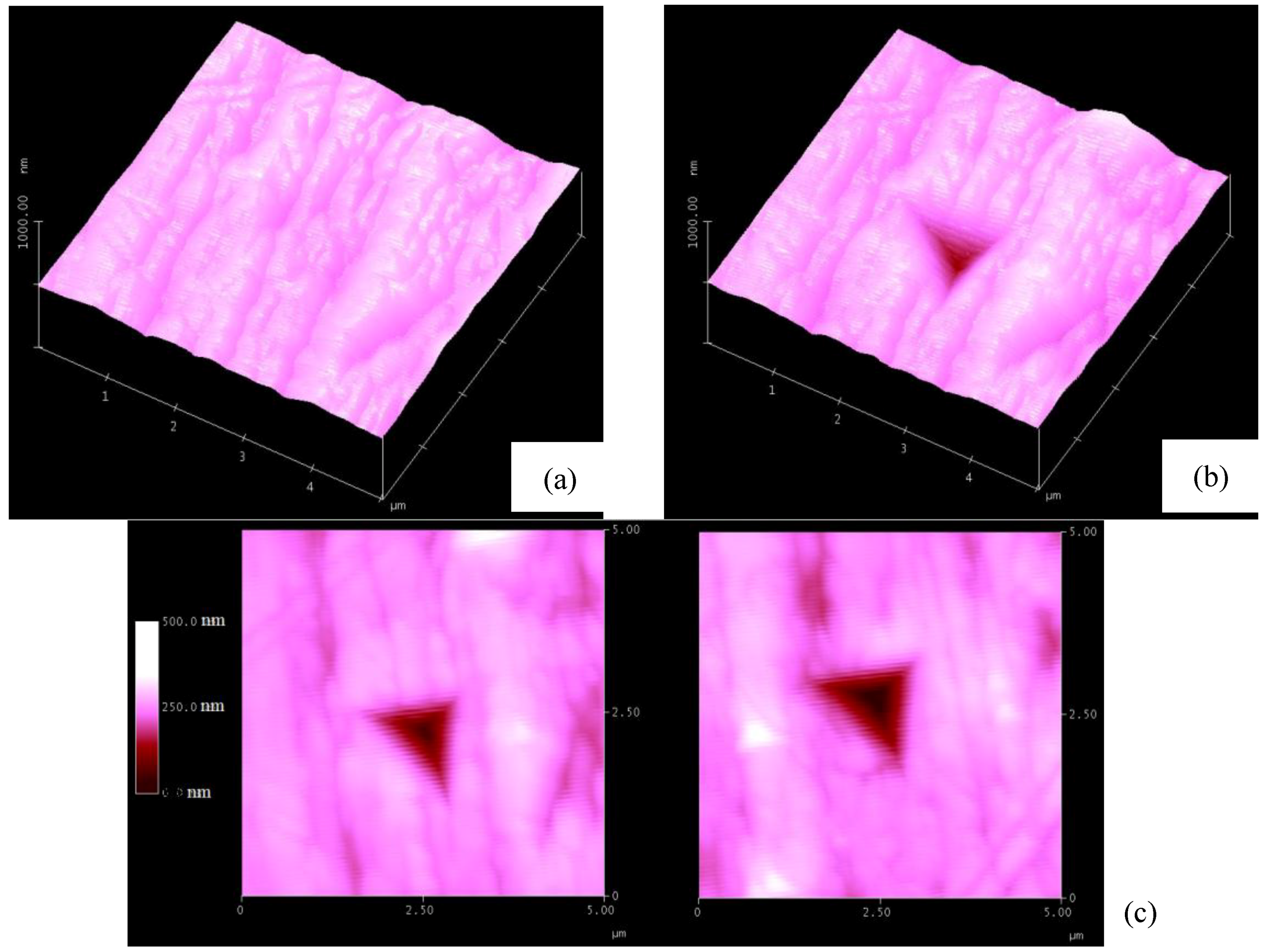

4.1. Experiment Results

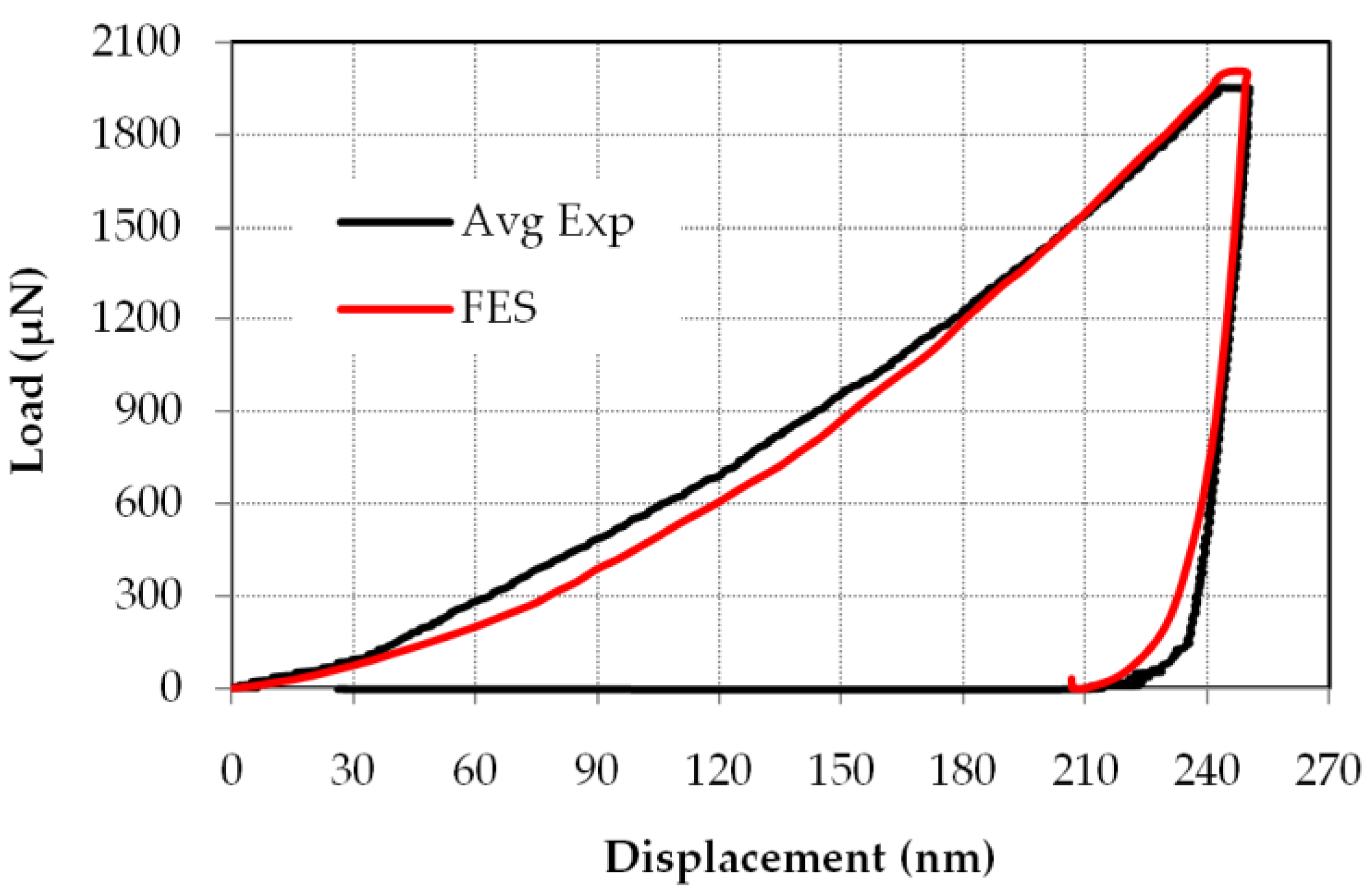

4.2. FE Simulation Results

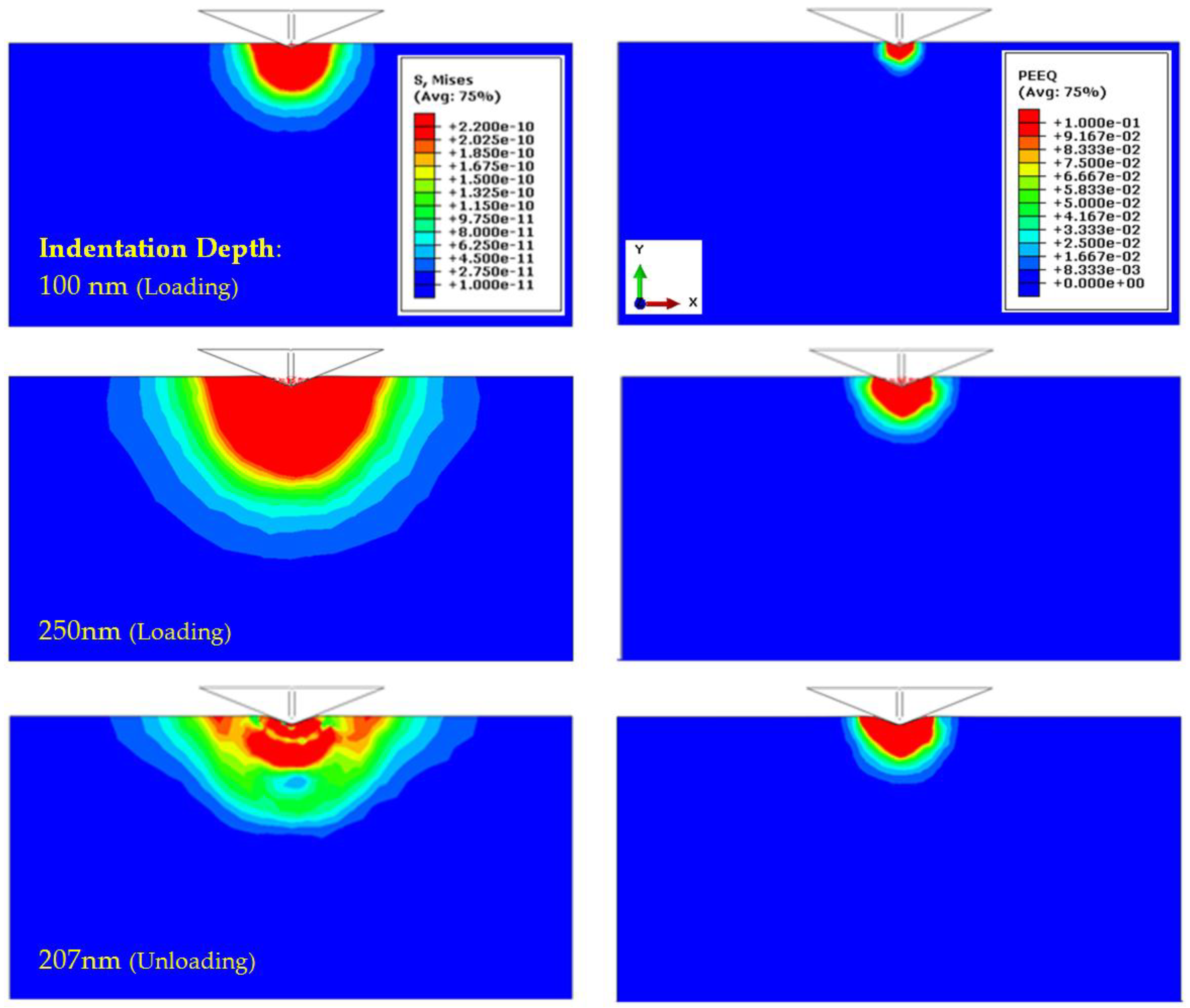

4.2.1. Validation of the FE Model and Simulation Process

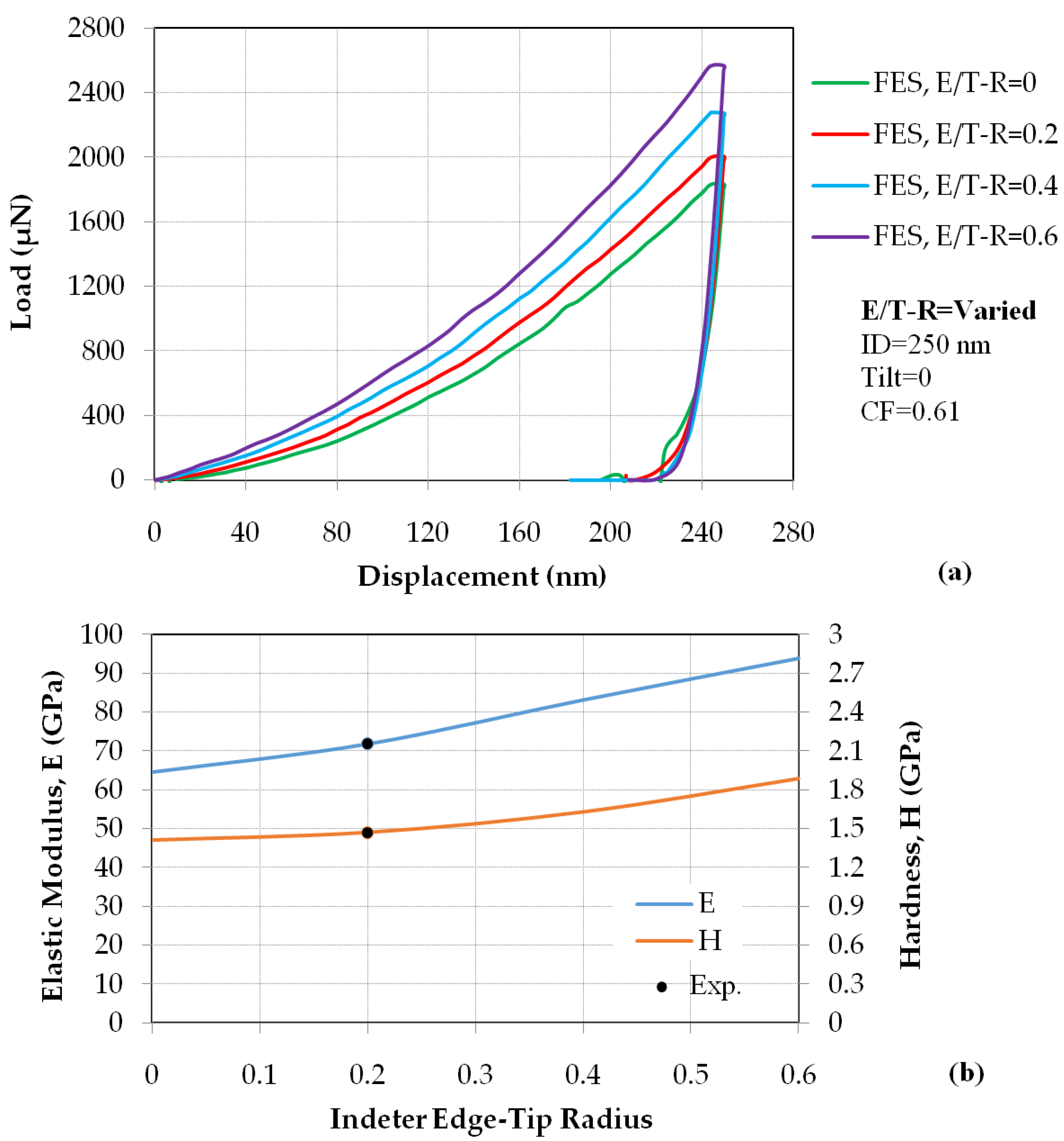

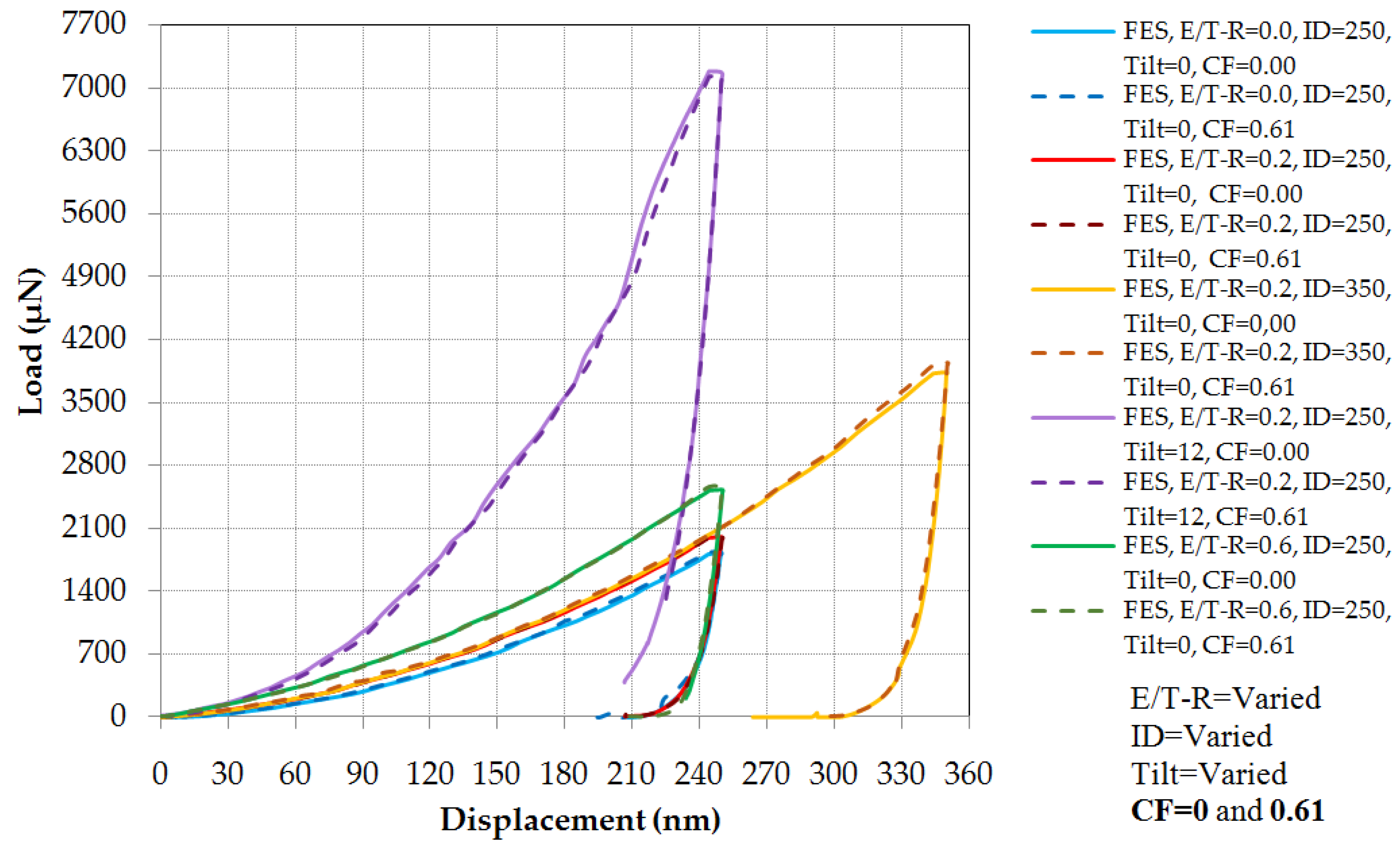

4.2.2. Results of the FE Model with Different Indenter Edge-Tip Radii

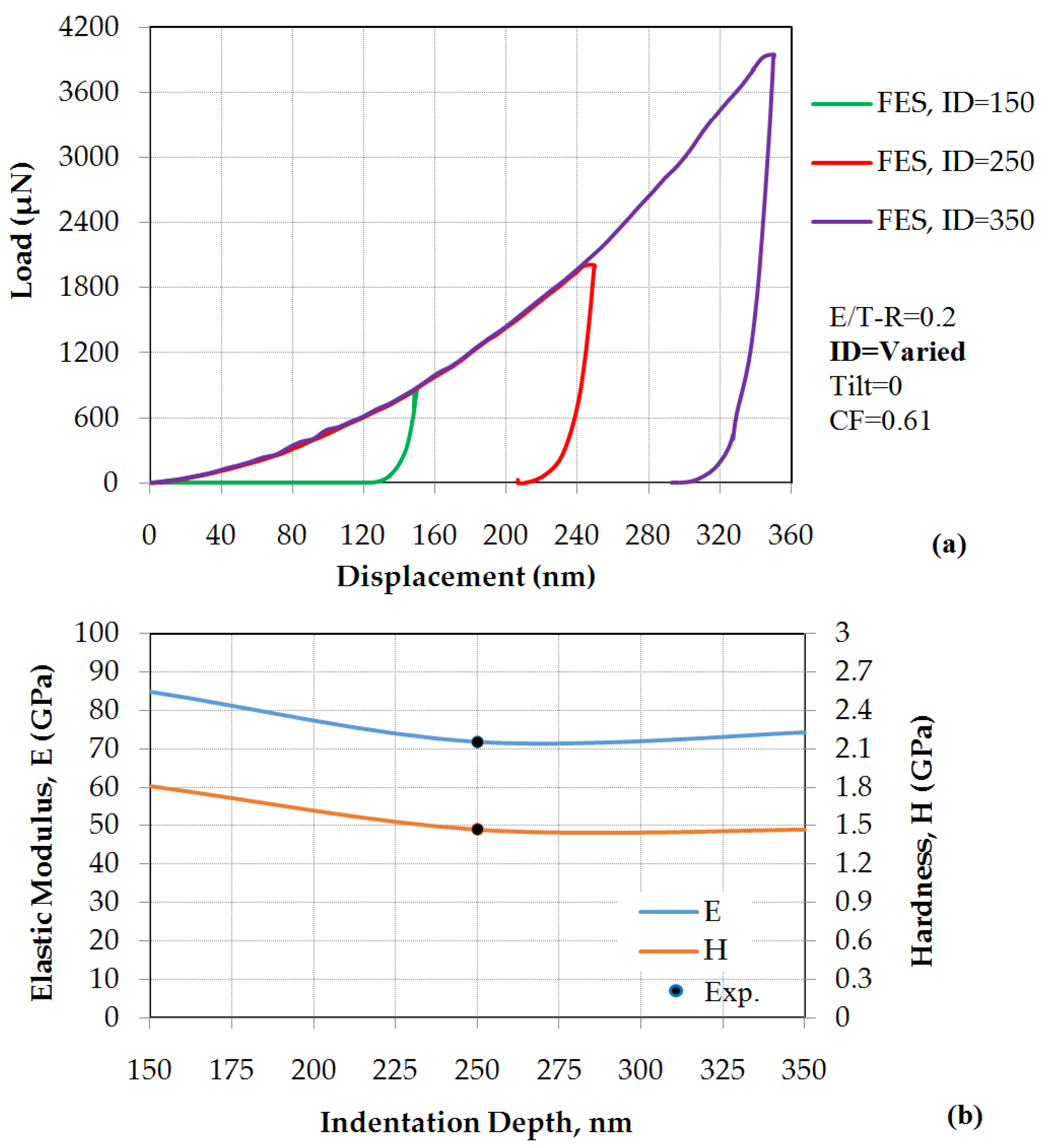

4.2.3. Results of the FE Model with Different Indentation Depths

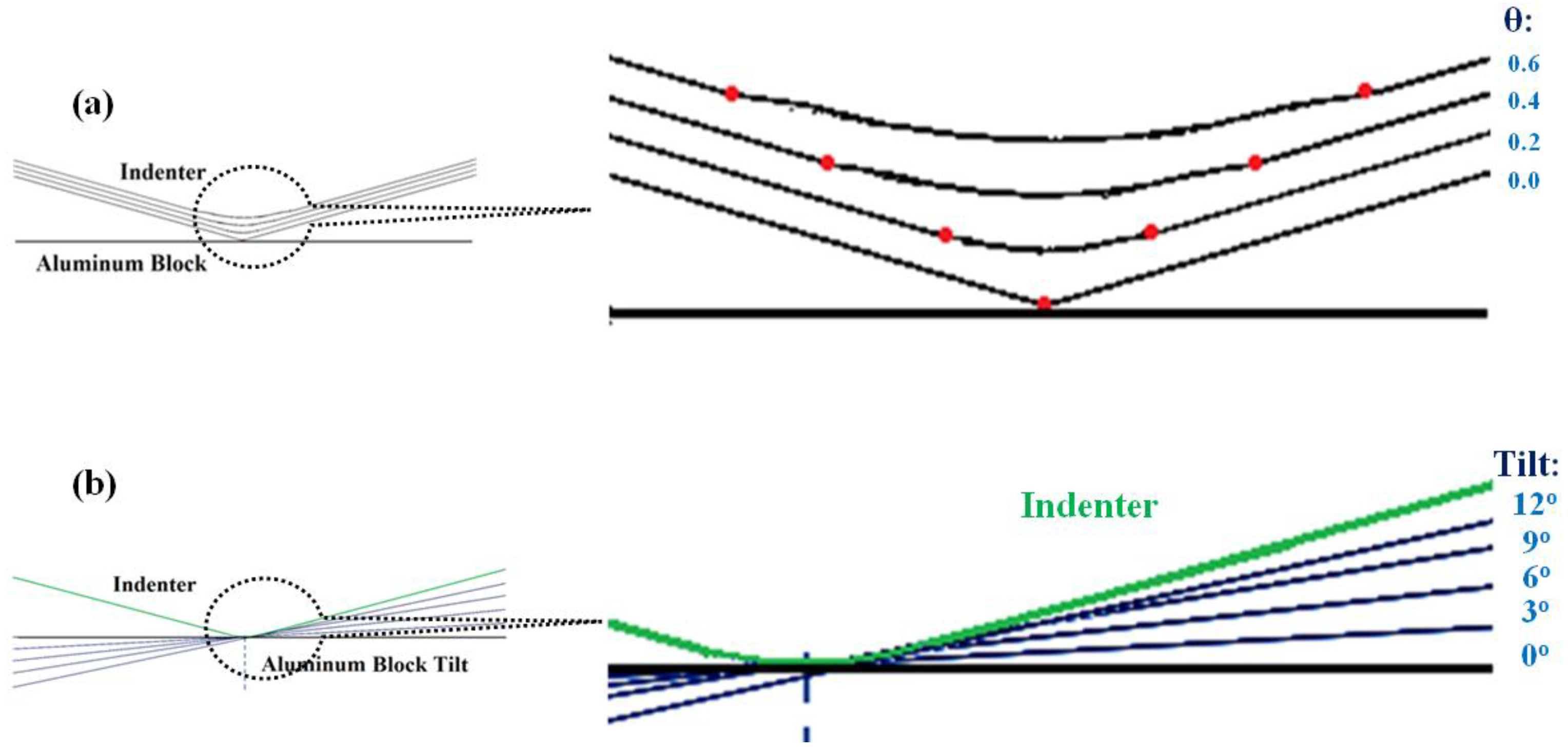

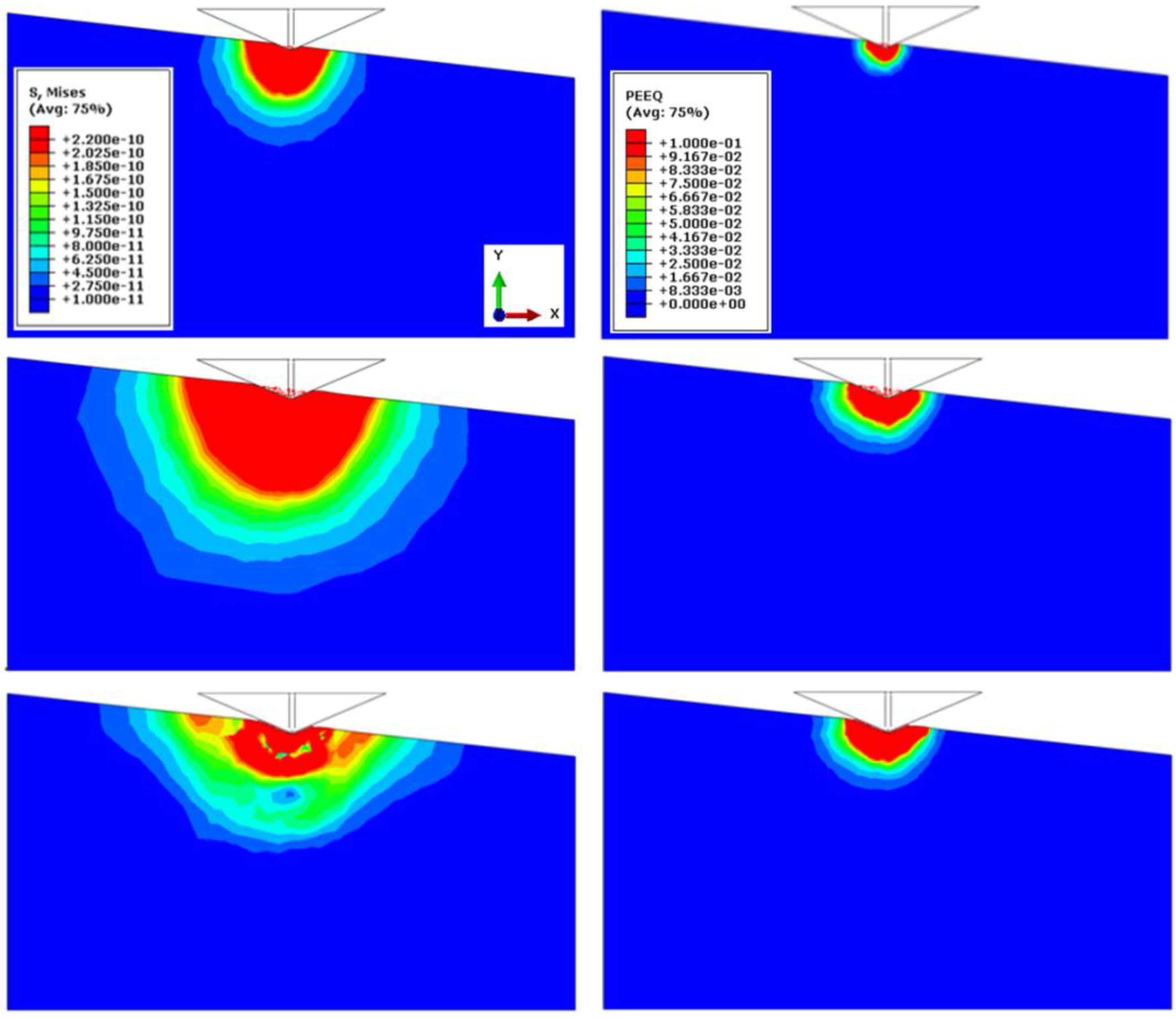

4.2.4. Results of the FE Model with Different Sample Tilts

4.2.5. Results of the FE Model with Different Frictions between Sample and Indenter

5. Conclusions

- The average elastic modulus and hardness values of aluminum for different ranges of indenter edge-tip radii were 78.34 ± 14.58 and 1.6 ± 0.24 GPa, respectively. The results indicated the size dependency of indenter edge-tip radius in structural response through nanoindentation process, and subsequently, in the calculation of the mechanical properties.

- Average values of 77.03 ± 6.54 and 1.58 ± 0.17 GPa were calculated for the elastic modulus and hardness of aluminum under different indentation depths, respectively. The values of these parameters were slightly higher for low depth indentation, due to the small size of the indentation hole and permanent deformation.

- The uneven surface morphology in the form of an oriented local indentation plane, indicated an exponential increase in the extracted values of the elastic modulus and hardness, ranging from 71.83 and 1.47 GPa (for the reference case, θ = 0) to 243.39 and 5.05 GPa at θ = 12°. The results of nanoindentation on the samples with , could not be used to obtain the mechanical properties of ductile materials.

- The effect of friction and frictionless condition in the simulation of the nanoindentation experiment of ductile materials was negligible. Therefore, similar structural responses as well as mechanical properties were obtained for both conditions.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Campos, R.P.; Cuevas, A.C.; Muñoz, R.A.E. Characterization of Metals and Alloys; Springer International Publishing: Basel, Switzerland, 2016. [Google Scholar]

- Tiwari, A.; Natarajan, S. Applied Nanoindentation in Advanced Materials; Wiley: Hoboken, NJ, USA, 2017. [Google Scholar]

- Balokhonov, R.; Romanova, V.; Panin, A.; Martynov, S.; Kazachenok, M. Numerical study of stress-strain localization in the titanium surface modified by an electron beam treatment. Facta Univ. Ser. Mech. Eng. 2016, 14, 329–334. [Google Scholar] [CrossRef]

- Smith, B.H.; Szyniszewski, S.; Hajjar, J.F.; Schafer, B.W.; Arwade, S.R. Characterization of steel foams for structural components. Metals 2012, 2, 399–410. [Google Scholar] [CrossRef]

- Ramazani, A.; Mukherjee, K.; Abdurakhmanov, A.; Abbasi, M.; Prahl, U. Characterization of microstructure and mechanical properties of resistance spot welded dp600 steel. Metals 2015, 5, 1704–1716. [Google Scholar] [CrossRef]

- Wan, L.; Huang, Y. Microstructure and mechanical properties of al/steel friction stir lap weld. Metals 2017, 7, 542. [Google Scholar] [CrossRef]

- Papangelo, A. Adhesion between a power-law indenter and a thin layer coated on a rigid substrate. Facta Univ. Ser. Mech. Eng. 2018, 16, 19–28. [Google Scholar] [CrossRef]

- Alao, A.-R.; Yin, L. Nanoindentation characterization of the elasticity, plasticity and machinability of zirconia. Mater. Sci. Eng. A 2015, 628, 181–187. [Google Scholar] [CrossRef]

- Mesbah, M.; Fadaeifard, F.; Karimzadeh, A.; Nasiri-Tabrizi, B.; Rafieerad, A.; Faraji, G.; Bushroa, A.R. Nano-mechanical properties and microstructure of ufg brass tubes processed by parallel tubular channel angular pressing. Met. Mater. Int. 2016, 22, 1098–1107. [Google Scholar] [CrossRef]

- Sapezanskaia, I.; Roa, J.J.; Fargas, G.; Turon-Viñas, M.; Trifonov, T.; Kouitat Njiwa, R.; Redjaïmia, A.; Mateo, A. Deformation mechanisms induced by nanoindentation tests on a metastable austenitic stainless steel: A fib/sim investigation. Mater. Charact. 2017, 131, 253–260. [Google Scholar] [CrossRef]

- Ayatollahi, M.R.; Karimzadeh, A. Nano-indentation measurement of fracture toughness of dental enamel. Int. J. Fract. 2013, 183, 113–118. [Google Scholar] [CrossRef]

- Jin, T.; Niu, X.; Xiao, G.; Wang, Z.; Zhou, Z.; Yuan, G.; Shu, X. Effects of experimental variables on pmma nano-indentation measurements. Polym. Test. 2015, 41, 1–6. [Google Scholar] [CrossRef]

- Karimzadeh, A.; Ayatollahi, M.R. Investigation of mechanical and tribological properties of bone cement by nano-indentation and nano-scratch experiments. Polym. Test. 2012, 31, 828–833. [Google Scholar] [CrossRef]

- Wang, H.; Huang, Z.; Lu, Z.; Wang, Q.; Jiang, J. Determination of the elastic and plastic deformation behaviors of Yb:Y3Al5O12 transparent ceramic by nanoindentation. J. Alloy. Compd. 2016, 682, 35–41. [Google Scholar] [CrossRef]

- Randall, N.X.; Vandamme, M.; Ulm, F.-J. Nanoindentation analysis as a two-dimensional tool for mapping the mechanical properties of complex surfaces. J. Mater. Res. 2011, 24, 679–690. [Google Scholar] [CrossRef]

- Zhang, H.; Schuster, B.E.; Wei, Q.; Ramesh, K.T. The design of accurate micro-compression experiments. Scr. Mater. 2006, 54, 181–186. [Google Scholar] [CrossRef]

- Nix, W.D. Mechanical properties of thin films. Metall. Trans. A 1989. [Google Scholar] [CrossRef]

- Oliver, W.C. Alternative technique for analyzing instrumented indentation data. J. Mater. Res. 2001, 16, 3202–3206. [Google Scholar] [CrossRef]

- Pharr, G.M. Measurement of mechanical properties by ultra-low load indentation. Mater. Sci. Eng. 1998, A253, 151–159. [Google Scholar] [CrossRef]

- Pharr, G.M.; Bolshakov, A. Understanding nanoindentation unloading curves. J. Mater. Res. 2002, 17, 2660–2671. [Google Scholar] [CrossRef]

- Gadelrab, K.R.; Chiesa, M. Influence of nanoindenter tip radius on the estimation of the elastic modulus. MRS Proc. 2011, 1297, 3–47. [Google Scholar] [CrossRef]

- Sagadevan, S.; Murugasen, P. Novel analysis on the influence of tip radius and shape of the nanoindenter on the hardness of materials. Procedia Mater. Sci. 2014, 6, 1871–1878. [Google Scholar] [CrossRef]

- Yu, N.; Polycarpou, A.A.; Conry, T.F. Tip-radius effect in finite element modeling of sub-50 nm shallow nanoindentation. Thin Solid Films 2004, 450, 295–303. [Google Scholar] [CrossRef]

- Alisafaei, F.; Han, C.-S. Indentation depth dependent mechanical behavior in polymers. Adv. Condens. Matter Phys. 2015. [Google Scholar] [CrossRef]

- Voyiadjis, G.Z.; Yaghoobi, M. Review of nanoindentation size effect: Experiments and atomistic simulation. Crystals 2017, 7, 321. [Google Scholar] [CrossRef]

- Kashani, M.S.; Madhavan, V. Analysis and correction of the effect of sample tilt on results of nanoindentation. Acta Mater. 2011, 59, 883–895. [Google Scholar] [CrossRef]

- Laurent-Brocq, M.; Béjanin, E.; Champion, Y. Influence of roughness and tilt on nanoindentation measurements: A quantitative model. Scanning 2015, 37, 350–360. [Google Scholar] [CrossRef] [PubMed]

- Xu, Z.H.; Li, X. Effect of sample tilt on nanoindentation behaviour of materials. Philosophil. Mag. 2007, 87, 2299–2312. [Google Scholar] [CrossRef]

- Karimzadeh, A.; Ayatollahi, M.R.; Alizadeh, M. Finite element simulation of nano-indentation experiment on aluminum 1100. Comput. Mater. Sci. 2014, 81, 595–600. [Google Scholar] [CrossRef]

- Chen, X.; Ashcroft, I.A.; Wildman, R.D.; Tuck, C.J. A combined inverse finite element—Elastoplastic modelling method to simulate the size-effect in nanoindentation and characterise materials from the nano to micro-scale. Int. J. Solids Struct. 2017, 104–105, 25–34. [Google Scholar] [CrossRef]

- Xia, Y.; Bigerelle, M.; Bouvier, S.; Iost, A.; Mazeran, P.E. Quantitative approach to determine the mechanical properties by nanoindentation test: Application on sandblasted materials. Tribol. Int. 2015, 82, 297–304. [Google Scholar] [CrossRef]

- Haghshenas, M.; Khalili, A.; Ranganathan, N. On room-temperature nanoindentation response of an Al–Li–Cu alloy. Mater. Sci. Eng. A 2016, 676, 20–27. [Google Scholar] [CrossRef]

- Stegall, D.E. An Examination of the Indentation Size Effect in Fcc Metals and Alloys from a Kinetics Based Perspective Using Nanoindentation. Ph.D. Thesis, Old Dominion University, Norfolk, VA, USA, 2016. [Google Scholar]

- Pharr, G.M.; Herbert, E.G.; Gao, Y. The indentation size effect: A critical examination of experimental observations and mechanistic interpretations. Annu. Rev. Mater. Res. 2010, 40, 271–292. [Google Scholar] [CrossRef]

- Sangwal, K. On the reverse indentation size effect and microhardness measurement of solids. Mater. Chem. Phys. 2000, 63, 145–152. [Google Scholar] [CrossRef]

- Zhang, C.; Voyiadjis, G.Z. Rate-dependent size effects and material length scales in nanoindentation near the grain boundary for a bicrystal fcc metal. Mater. Sci. Eng. A 2016, 659, 55–62. [Google Scholar] [CrossRef]

- Voyiadjis, G.Z.; Zhang, C. The mechanical behavior during nanoindentation near the grain boundary in a bicrystal fcc metal. Mater. Sci. Eng. A 2015, 621, 218–228. [Google Scholar] [CrossRef]

- Aifantis, K.E.; Ngan, A.H.W. Modeling dislocation—grain boundary interactions through gradient plasticity and nanoindentation. Mater. Sci. Eng. A 2007, 459, 251–261. [Google Scholar] [CrossRef]

- Lian, J.; Garay, J.E.; Wang, J. Grain size and grain boundary effects on the mechanical behavior of fully stabilized zirconia investigated by nanoindentation. Scr. Mater. 2007, 56, 1095–1098. [Google Scholar] [CrossRef]

- Voyiadjis, G.Z.; Faghihi, D.; Zhang, C. Analytical and experimental determination of rate-and temperature-dependent length scales using nanoindentation experiments. J. Nanomech. Micromech. 2011, 1, 24–40. [Google Scholar] [CrossRef]

- Casals, O.; Forest, S. Finite element crystal plasticity analysis of spherical indentation in bulk single crystals and coatings. Comput. Mater. Sci. 2009, 45, 774–782. [Google Scholar] [CrossRef]

- Almasri, A.H.; Voyiadjis, G.Z. Nano-indentation in fcc metals: Experimental study. Acta Mech. 2010. [Google Scholar] [CrossRef]

- Voyiadjis, G.Z.; Peters, R. Size effects in nanoindentation: An experimental and analytical study. Acta Mech. 2010, 211, 131–153. [Google Scholar] [CrossRef]

- Liu, M.; Lu, C.; Tieu, K.A.; Peng, C.-T.; Kong, C. A combined experimental-numerical approach for determining mechanical properties of aluminum subjects to nanoindentation. Sci. Rep. 2015, 5, 15072. [Google Scholar] [CrossRef] [PubMed]

- Ehtemam-Haghighi, S.; Cao, G.; Zhang, L.-C. Nanoindentation study of mechanical properties of Ti based alloys with fe and ta additions. J. Alloy. Compd. 2017, 692, 892–897. [Google Scholar] [CrossRef]

- Attar, H.; Ehtemam-Haghighi, S.; Kent, D.; Okulov, I.V.; Wendrock, H.; Bӧnisch, M.; Volegov, A.S.; Calin, M.; Eckert, J.; Dargusch, M.S. Nanoindentation and wear properties of Ti and Ti-TiB composite materials produced by selective laser melting. Mater. Sci. Eng. A 2017, 688, 20–26. [Google Scholar] [CrossRef]

- Guo, H.; Jiang, C.; Yang, B.; Wang, J. On the fracture toughness of bulk metallic glasses under berkovich nanoindentation. J. Non-Cryst. Solids 2018, 481, 321–328. [Google Scholar] [CrossRef]

- Yang, L.W.; Mayer, C.; Li, N.; Baldwin, J.; Mara, N.A.; Chawla, N.; Molina-Aldareguia, J.M.; Llorca, J. Mechanical properties of metal-ceramic nanolaminates: Effect of constraint and temperature. Acta Mater. 2018, 142, 37–48. [Google Scholar] [CrossRef]

- Han, J.-K.; Li, X.; Dippenaar, R.; Liss, K.-D.; Kawasaki, M. Microscopic plastic response in a bulk nano-structured tial intermetallic compound processed by high-pressure torsion. Mater. Sci. Eng. A 2018, 714, 84–92. [Google Scholar] [CrossRef]

- Huang, C.; Peng, X.; Yang, B.; Xiang, H.; Sun, S.; Chen, X.; Li, Q.; Yin, D.; Fu, T. Anisotropy effects in diamond under nanoindentation. Carbon 2018, 132, 606–615. [Google Scholar] [CrossRef]

- Durst, K.; Backes, B.; Göken, M. Indentation size effect in metallic materials: Correcting for the size of the plastic zone. Scr. Mater. 2005, 52, 1093–1097. [Google Scholar] [CrossRef]

- Liu, T.; Phang, I.Y.; Shen, L.; Chow, S.Y.; Zhang, W.-D. Morphology and mechanical properties of multiwalled carbon nanotubes reinforced nylon-6 composites. Macromolecules 2004, 37, 7214–7222. [Google Scholar] [CrossRef]

- Hu, Y.; Shen, L.; Yang, H.; Wang, M.; Liu, T.; Liang, T.; Zhang, J. Nanoindentation studies on nylon 11/clay nanocomposites. Polym. Test. 2006, 25, 492–497. [Google Scholar] [CrossRef]

- Saber-Samandari, S.; Gross, K.A. Effect of angled indentation on mechanical properties. J. Eur. Ceram. Soc. 2009, 29, 2461–2467. [Google Scholar] [CrossRef]

- Roa, J.; Rayon, E.; Morales, M.; Segarra, M. Contact mechanics at nanometric scale using nanoindentation technique for brittle and ductile materials. Recent Pat. Nanotechnol. 2012, 6, 142–152. [Google Scholar] [CrossRef] [PubMed]

- ISO-14577. Metallic Materials—Instrumented Indentation Test for Hardness and Materials Parameters—Part 1: Test Method; International Organization for Standardization (ISO): Geneva, Switzerland, 2002. [Google Scholar]

- Fischer-Cripps, A.C. Nanoindentation, 3rd ed.; Springer: New York, NY, USA, 2011. [Google Scholar]

- Sneddon, I.N. The relation between load and penetration in the axisymmetric boussinesq problem for a punch of arbitrary profile. Int. J. Eng. Sci. 1965, 3, 47–57. [Google Scholar] [CrossRef]

- Stauss, S.; Schwaller, P.; Bucaille, J.L.; Rabe, R.; Rohr, L.; Michler, J.; Blank, E. Determining the stress–strain behaviour of small devices by nanoindentation in combination with inverse methods. Microelectron. Eng. 2003, 67–68, 818–825. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- Li, Y.; Kanouté, P.; François, M. Disturbance induced by surface preparation on instrumented indentation test. Mater. Sci. Eng. A 2015, 642, 381–390. [Google Scholar] [CrossRef]

- Zhang, Y.; Dhaigude, M.; Wang, J. The anvil effect in the spherical indentation testing of sheet metals. J. Manuf. Process. 2017, 27, 169–178. [Google Scholar] [CrossRef]

- Pelletier, H.; Krier, J.; Cornet, A.; Mille, P. Limits of using bilinear stress–strain curve for finite element modeling of nanoindentation response on bulk materials. Thin Solid Films 2000, 379, 147–155. [Google Scholar] [CrossRef]

- Lu, Y.; Kurapati, S.; Yang, F. Finite element analysis of cylindrical indentation for determining plastic properties of materials in small volumes. J. Phys. D Appl. Phys. 2008, 41, 115415. [Google Scholar] [CrossRef]

- Vaughan, T.; McCarthy, C. A combined experimental-numerical approach for generating statistically equivalent fibre distributions for high strength laminated composite materials. Compos. Sci. Technol. 2010, 70, 291–297. [Google Scholar] [CrossRef]

- Bucaille, J.L.; Stauss, S.; Felder, E.; Michler, J. Determination of plastic properties of metals by instrumented indentation using different sharp indenters. Acta Mater. 2003, 51, 1663–1678. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rahimian Koloor, S.S.; Karimzadeh, A.; Tamin, M.N.; Abd Shukor, M.H. Effects of Sample and Indenter Configurations of Nanoindentation Experiment on the Mechanical Behavior and Properties of Ductile Materials. Metals 2018, 8, 421. https://doi.org/10.3390/met8060421

Rahimian Koloor SS, Karimzadeh A, Tamin MN, Abd Shukor MH. Effects of Sample and Indenter Configurations of Nanoindentation Experiment on the Mechanical Behavior and Properties of Ductile Materials. Metals. 2018; 8(6):421. https://doi.org/10.3390/met8060421

Chicago/Turabian StyleRahimian Koloor, Seyed Saeid, Atefeh Karimzadeh, Mohd Nasir Tamin, and Mohd Hamdi Abd Shukor. 2018. "Effects of Sample and Indenter Configurations of Nanoindentation Experiment on the Mechanical Behavior and Properties of Ductile Materials" Metals 8, no. 6: 421. https://doi.org/10.3390/met8060421

APA StyleRahimian Koloor, S. S., Karimzadeh, A., Tamin, M. N., & Abd Shukor, M. H. (2018). Effects of Sample and Indenter Configurations of Nanoindentation Experiment on the Mechanical Behavior and Properties of Ductile Materials. Metals, 8(6), 421. https://doi.org/10.3390/met8060421