Abstract

In this paper, phase transitions and microstructure evolution in titanium Ti-6Al-4V alloy parts produced by electron beam melting (EBM) under hydrogenation was investigated. Hydrogenation was carried out at the temperature of 650 °C to the absolute hydrogen concentrations in the samples of 0.29, 0.58, and 0.90 wt. %. Comparative analysis of microstructure changes in Ti-6Al-4V alloy parts was performed using scanning electron microscopy (SEM), transmission electron microscopy (TEM), and X-ray diffraction (XRD). Furthermore, in-situ XRD was used to investigate the phase transitions in the samples during hydrogenation. The structure of Ti-6Al-4V parts produced by EBM is represented by the α phase plates with the transverse length of 0.2 μm, the β phase both in the form of plates and globular grains, and metastable α″ and ω phases. Hydrogenation to the concentration of 0.29 wt. % leads to the formation of intermetallic Ti3Al phase. The dimensions of intermetallic Ti3Al plates and their volume fraction increase significantly with hydrogen concentration up to 0.58 wt. % along with precipitation of nano-sized crystals of titanium δ hydrides. Individual Ti3Al plates decay into nanocrystals with increasing hydrogen concentration up to 0.9 wt. % accompanied by the increase of proportion and size of hydride plates. Hardness of EBM Ti-6Al-4V alloy decreases with hydrogen content.

1. Introduction

Additive manufacturing (AM) including the method of electron beam melting (EBM) is one of the promising directions in the production of structural metal materials with a unique set of properties. The advantages of AM over traditional methods are quick manufacturing process, economy of material, and producing light-weight structures with complex shape and geometry. Titanium alloys especially Ti-6Al-4V are widely used in aerospace industry due to excellent mechanical properties, low density, high corrosion resistance. The properties of titanium alloys produced by electron-beam melting are widely discussed in the literature [1,2,3,4,5,6]. Researchers pay particular attention to the microstructure of the manufactured materials as the mechanical properties of titanium alloys directly depend on the structural-phase state of the material. At the same time, the microstructure of titanium alloys plays an important role in the interaction of alloys with an aggressive medium, in particular, with hydrogen [7,8]. The microstructure of titanium products depends on the process parameters of EBM [2,3] and cooling rate. The formation of the structural-phase state of Ti-6Al-4V alloy occurs as the result of powder melting at the temperature of 1900 °C and subsequent rapid cooling to a temperature of ~700 °C followed by cooling to the room temperature. If the titanium product is maintained above the temperature of 700 °C in the EBM manufacturing process, a rather fine annealed α + β-structure has been observed [4]. The authors of [4] also mention that in the EBM-process nucleation of the β-grains occurred heterogeneously from boundary layers either at the build plate or the part surfaces. At the part surfaces, this has been found to be formed from partially melted powder in the surrounding bed. Safdar et al. [5] notes that the structure of electron beam melted Ti-6Al-4V consists of prior β phase in form of columnar grains which grow along the build direction and Widmanstätten α platelets. Similar structure was also observed in [8]. The authors of [9] established that the lamellae of the thin walled 0.5 and 1.0 mm samples were significantly smaller compared to those of the thicker samples. Thus, thicker lamellas were observed in all samples with the wall thickness of at least 2 mm. Further to the work of Safdar, Tan et al. [6] showed basket-weave morphology as well as numerous singular bulges within the prior β grains. Along with α and β phases, the martensitic α′ and α″ phases could be presented in the microstructure of the Ti-6Al-4V samples produced by EBM. Usually, martensitic phases are observed in small samples [10,11]. Al-Bermani [10] found the formation of martensitic phase in 1–5 mm samples produced by EBM. The martensitic microstructure was observed on the top of samples with such dimensions. According to Mur et al. [11], the full transformation of α′ → α + β at 700 °C in Ti-6Al-4V alloy takes 30 min that much shorter than holding time during the alloy processing.

The main applications of AM-produced Ti-6Al-4V are medicine, auto, and aerospace industries [12]. The application of additively manufactured Ti-6Al-4V in harsh environment, especially in hydrogen contained medium, open new challenges for investigation of its corrosion and hydrogen resistance. During operating in corrosive environments, hydrogen penetrates and accumulates in titanium alloys. Accumulating in titanium alloys, hydrogen causes significant changes in their physical, chemical and mechanical properties. Under hydrogen effect in titanium alloys, there are hydrogen-induced ductility loss (hydrogen embrittlement) and hydrogen-induced cracking occurs [7,13,14,15]. Hydrogen embrittlement and hydrogen-induced cracking can lead to destruction of parts and structures [7,13]. Hydrogen can change the microstructure that affects the mechanical properties of titanium alloys. This is the main difficulty in studying the direct or intrinsic effect of hydrogen in multi-phase systems [14,15].

The effect of hydrogen on the phase composition and microstructure of the Ti-6Al-4V alloy produced by traditional technologies has been studied for a long time [16,17,18,19,20,21,22,23,24]. Hydrogen expands the β phase region and narrows the α phase region, which hydrogen solubility less than 7.9 at. % [16]. It is noted that the concentration of β phase increased with the hydrogen content in hydrogenated alloys [17,18]. Hydrogenation of the Ti-6Al-4V alloy initiates several phase transformations that depends on hydrogenation parameters. Martensitic α′ and α″ phases, hydrides [18,19,20,21,22], and intermetallics could be formed during hydrogenation. Cubic δ hydride and martensite phases are observed in the structure of Ti-6Al-4V alloy after hydrogenation at the temperature below 900 °C and hydrogen concentrations above 0.29 wt. %. The authors [17] showed that the needle hexagonal close-packed (hcp) martensite began to form during hydrogenation at 800 °С and hydrogen content of 0.4 wt. %. In [19], the α″ and δ hydride phases were observed after hydrogenation at 750 °C in the samples with hydrogen content above 0.278 wt. % and 0.514 wt. %. It was shown that δ hydrides could precipitate only in β phase during hydrogenation at high temperatures when the hydrogen content is relatively high, and hydrides cannot precipitate in α phase at high temperatures [22]. There are few articles about hydrogen interaction with AM material. The authors of [25] showed that the 3D specimens demonstrated higher resistance to hydrogen embrittlement in gaseous hydrogen atmosphere than the cast material. The effect of hydrogen treatment on the structure and mechanical properties of samples made from Ti-6Al-4V powder by selective laser melting was investigated in ref. [26]. However, the effect of hydrogen on the structure and phase state of the samples produced by EBM is still unclear. Moreover, as shown above, the EBM-produced materials microstructure differs from the microstructure of materials obtained by traditional methods. The microstructure of EBM-produced Ti-6Al-4V can significantly influence the hydrogen absorption, structural and phase states under hydrogen effect, and as a consequence a degradation in the mechanical properties. The aim of present research was to investigate the effect of hydrogen on the phase transitions and microstructure evolution in titanium Ti-6Al-4V parts produced by electron beam melting.

2. Materials and Experimental Procedure

2.1. Samples Preparation

The samples were produced from powder of titanium Ti-6Al-4V alloy (Ti6Al4V ELI) using ARCAM A2 EBM (Arcam AB, Mölndal, Sweden) machine [27]. The powder was purchased from ARCAM AB. The powder particle size was varied from 50 to 150 μm. The samples were coin-shaped with the diameter 8 mm and height 2 mm. All the samples were manufactured in the same batch with the built direction parallel to the round surface. Powder layer thickness was 70 μm and standard ARCAM parameter settings for solid Ti64 were used. The samples were carefully blasted in the ARCAM powder recovery system using the same precursor powder. Finally, all samples were mechanically grinded to obtain homogeneous surface.

2.2. Experimental Procedure

The gas-phase hydrogenation of the samples was performed using Gas Reaction Controller (Advanced Materials Corporation, Pittsburgh, PA, USA) equipment at temperature 650 °С. The special software of Gas Reaction Controller equipment was used to control and analyze the process of hydrogen sorption, and reveal the specifics of hydrogen interaction with materials [28,29]. The heating and cooling rates were 6 °С/s and 1 °С/s, respectively. The absolute hydrogen concentration in the samples after hydrogenation was measured by the method of melting in inert gas media (argon) using hydrogen analyzer RHEN602 (LECO, Saint Joseph, MI, USA). Hydrogen concentration in the samples before hydrogenation was 0.007 wt. %. The measured hydrogen concentrations in the samples after hydrogenation were 0.29, 0.58 and 0.90 wt. %.

The microstructure of samples was observed by scanning electron microscopy using SEM 515 (Philips, Eindhoven, The Netherlands). The samples were etched out by Kroll’s reagent to reveal the structure of the samples after mechanical polishing. The phase identification and structural investigations were performed by X-ray diffraction (XRD) and transmission electron microscopy (TEM). X-ray diffraction studies were performed with CuKα radiation (1.5410 Å wavelength) using XRD-7000S diffractometer (Shimadzu, Kyoto, Japan) in Bragg-Brentano geometry from 30° to 80° with the scan speed of 10.0°/min, the sampling pitch of 0.0143°, the preset time of 42.972 s at 40 kV and 30 mA. The diffraction patterns were collected using OneSight (Shimadzu, Kyoto, Japan) wide-range array high speed detector with 1280 channels. A JEM-2100F (JEOL, Akishima, Tokyo, Japan) transmission electron microscope was employed for the microstructural characterization of the samples. The survey was conducted at accelerating 200 kV. The samples were prepared by ion milling using Ion Slicer EM-09100IS (JEOL, Akishima, Tokyo, Japan). During preparation, argon was used as working gas, accelerating voltage was 8 kV, and etching angle was 1.5–4°. The ion milling process was controlled by charged coupled device (CCD) camera.

Phase transitions in the samples during hydrogenation were investigated by in-situ synchrotron XRD at the station “Precision diffractometry” at Siberian Synchrotron and Terahertz Radiation Center of the Budker Institute of Nuclear Physics of the Siberian Branch of Russian Academy of Science. The station is located on the sixth channel of the synchrotron radiation source VEPP-3 (electron storage). The main advantage of the laboratory is the use of the one-dimensional high speed detector OD-3M (Budker Institute of Nuclear Physics, Novosibirsk, Russia) [30,31,32]. OD-3M detect scattered radiation in wide-range angles (~30°) using 3328 channels. In-situ investigation was performed using a high temperature reactor chamber XRK-900 (Anton Paar, Graz, Austria) in hydrogen stream. The wave length of synchrotron radiation was 1.0102 Å. The samples were uniformly heated to the temperature of 650 °C at the rate of 6 °C/min. The hydrogenation time was 80 min. The diffraction patterns were recorded every minute during hydrogenation. Interpretation of the results and identification of reflexes was carried out using programs PDF-4+ (ICDD, Newtown Township, PA, USA), Crystallographica Search-Match (Oxford Cryosystems, Oxford, UK).

Micro hardness testing was done on KB30S (Pruftechnik, Ismaning, Germany) Vickers hardness testing machine with 0.5 kg load.

3. Results and Discussion

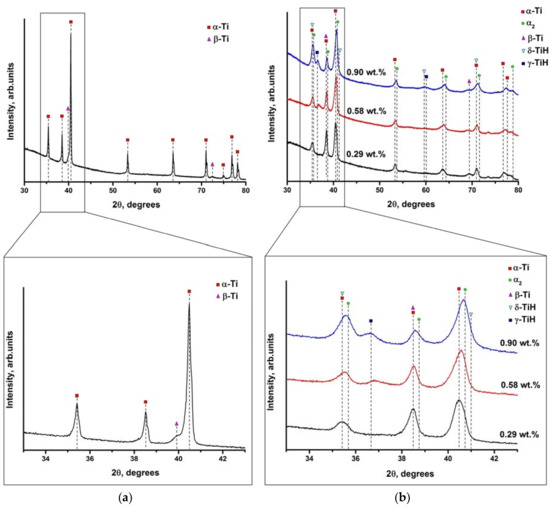

3.1. X-ray Diffraction

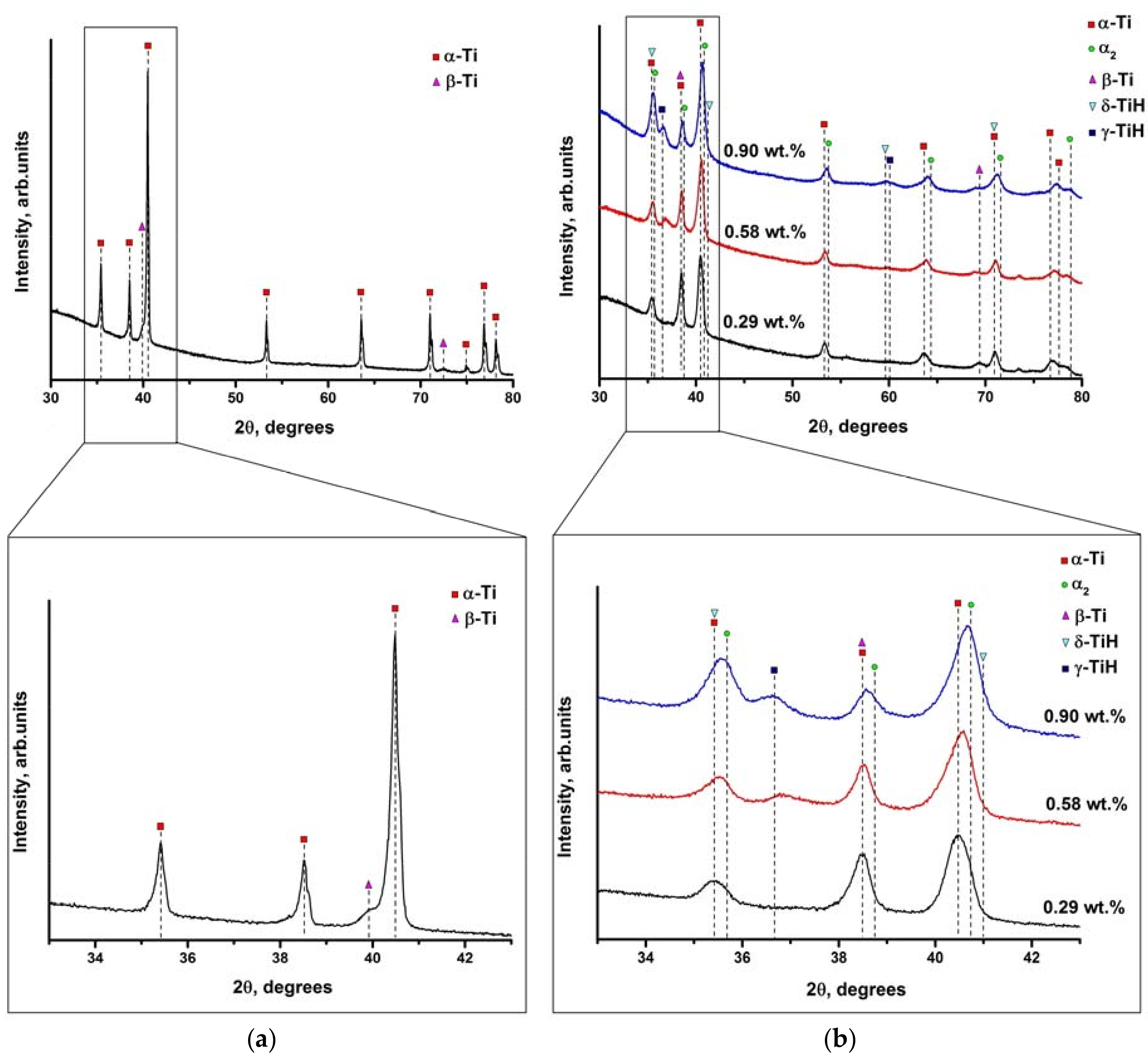

X-ray diffraction patterns of titanium Ti-6Al-4V parts produced by EBM are showed in Figure 1a.

Figure 1.

X-ray diffraction (XRD) patterns of Ti-6Al-4V parts produced by electron beam melting (EBM) before (a) and after (b) gas-phase hydrogenation.

According to XRD the structure of the samples before hydrogenation is represented by the α phase of titanium with a hexagonal close-packed (hcp) lattice and the β phase of titanium with body-centered cubic (bcc) crystal modification. The volume content of the β phase is approximately 4%. Martensitic phases were not detected by the XRD method.

Significant changes in diffraction patterns occur after hydrogenation, the results are shown in Figure 1b. The β phase reflexes shift toward smaller angles due to the solubility of hydrogen atoms in this phase [33]. It is also observed that the volume content of the β phase increases with hydrogen concentration to 0.29 wt. %, since hydrogen is a stabilizer of the β phase [34].

It should be noted that the hydrogenation causes the broadening of all α Ti diffraction reflexes. The latter is probably due to the elastic lattice strain of α phase and the overlap of the reflexes belonging to the α-Ti phase and intermetallic Ti3Al phase with hcp lattice in the hydrogenated samples.

When hydrogen concentration reaches 0.58 wt. %, along α Ti phase the cubic δ and tetragonal γ phases of titanium hydride and intermetallic Ti3Al phase with hcp lattice were observed. Further hydrogenation to 0.90 wt. % leads to redistribution of the intensities in the diffraction pattern, which indicates increase in the volume content of δ-TiH and γ-TiH phases and decrease of the β phase content. It should be noted that the overlap of the δ-TiH, Ti3Al, and α-Ti phases in hydrogenated samples causes broadening of some reflexes compared to the additively manufactured alloy.

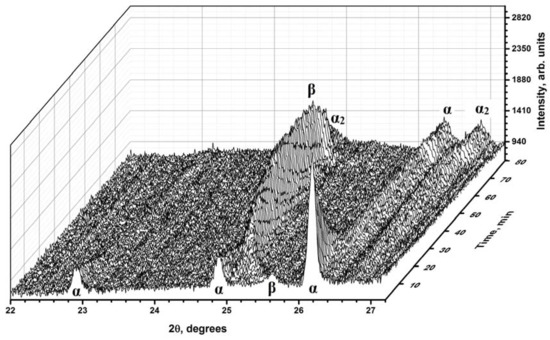

3.2. In-Situ XRD

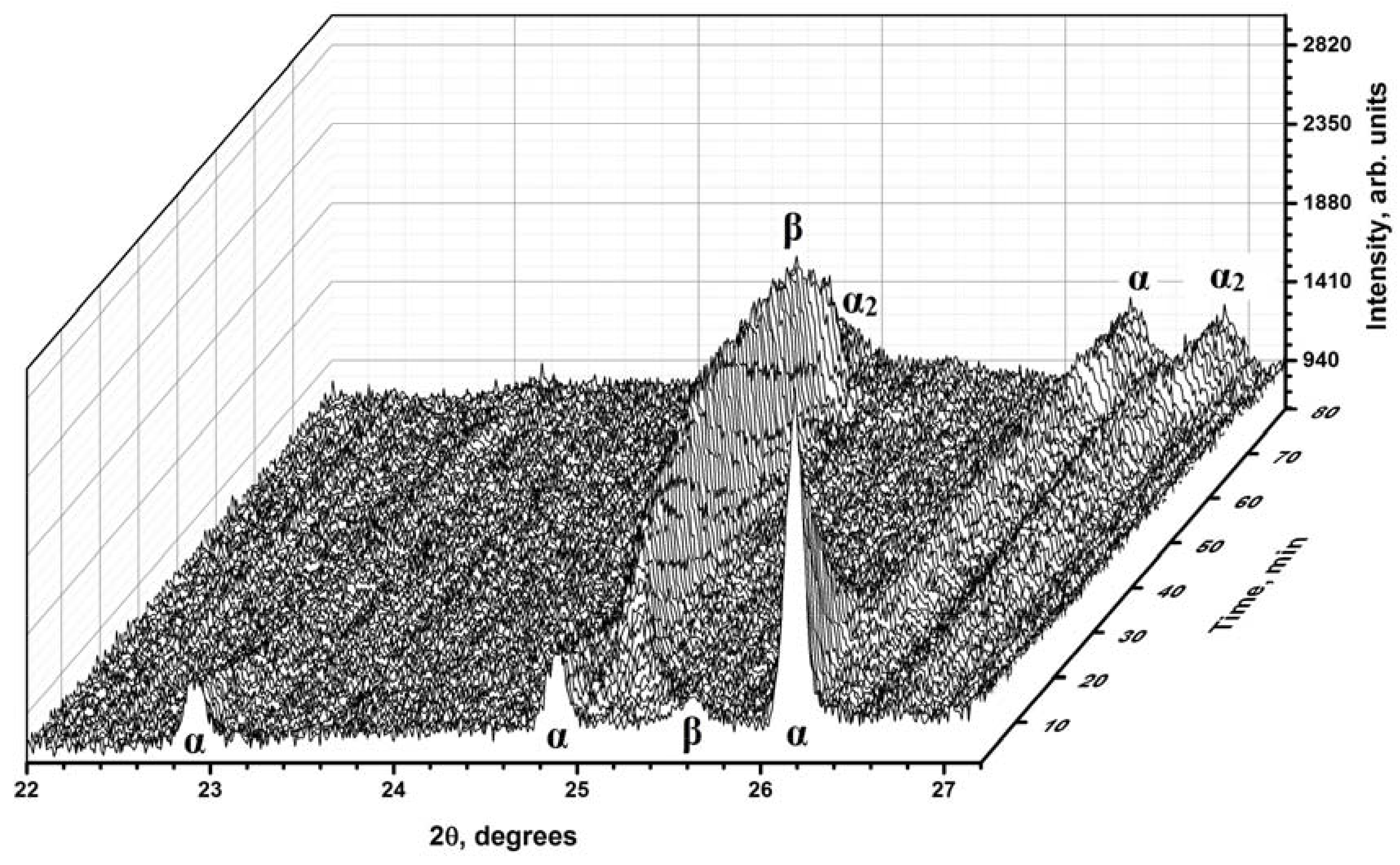

The results of in-situ XRD studies of the samples of titanium Ti-6Al-4V parts produced by EBM during hydrogenation at 650 °C are shown in Figure 2.

Figure 2.

The phase transitions in Ti-6Al-4V parts produced by EBM during hydrogenation at 650 °C.

At the initial stage of hydrogenation (about 10 min), the β phase reflection shifts toward small angles, while the position of the α phase reflections does not change significantly. This is due to the fact that the solubility of hydrogen, in the α phase, is negligible compared to the β phase [33]. The rate of hydrogen sorption is relatively low, since the diffusion of hydrogen proceeds mainly through the α phase which volume content is higher than 95%. Since hydrogen is a stabilizer of the β phase in titanium, the α phase is transformed to β phase, which hydrogen solubility is 1.52 wt. % [33]. Thus, the increase in the volume fraction of the β phase in the next stage of hydrogenation (10–20 min) occurs. After 20 min of hydrogenation, along with increase in the volume fraction of β phase, the α phase is transformed into the α2 phase based on the intermetallic Ti3Al. The hydrogenation could lead to redistribution of Al in titanium and local accumulation of Al above 7 wt. % resulting in the formation of the α2 phase [34]. The mechanism of the α2 phase formation is described in Section 3.3. The α → α2 phase transition under gas-phase hydrogenation at the temperature of 650 °C was also observed in ref. [35]. It should be noted that the formation of δ titanium hydride in the process of hydrogenation in a stream of hydrogen was not observed. The measured hydrogen concentration in the sample after hydrogenation was 0.60 wt. %.

3.3. SEM and TEM Analysis

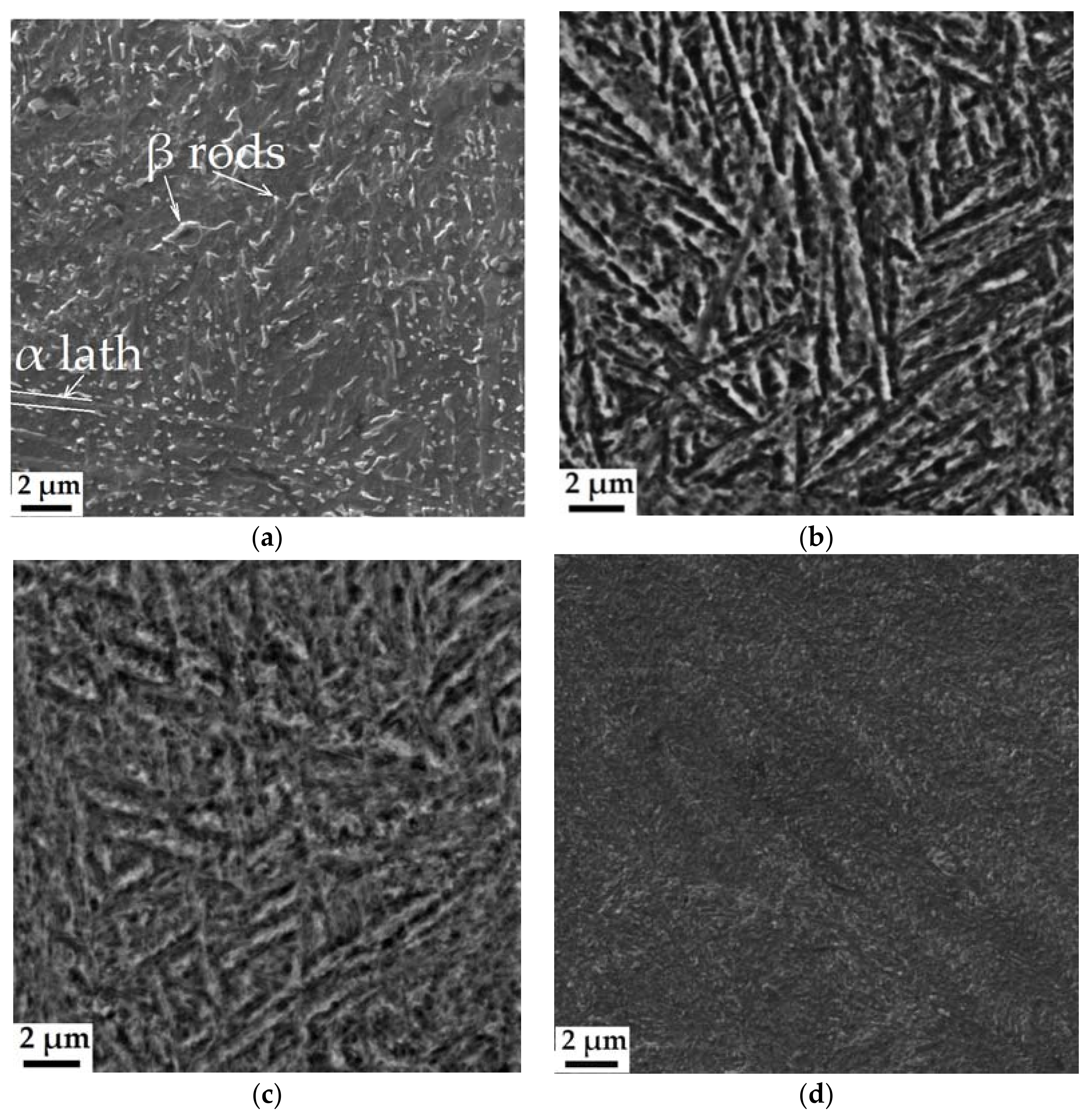

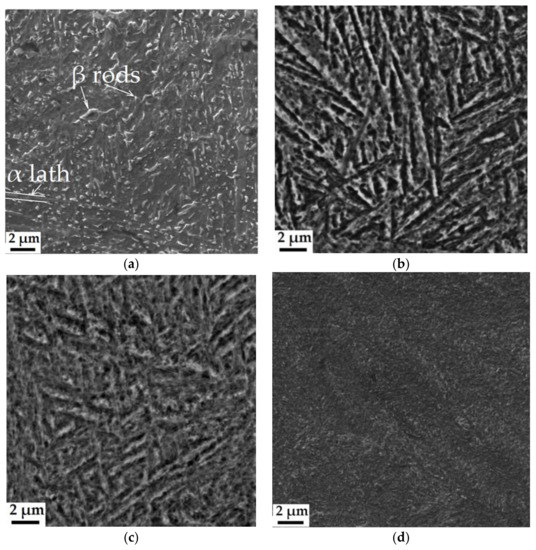

Figure 3 shows surface scanning electron microscopy (SEM) images of the Ti-6Al-4V parts produced by EBM before and after gas-phase hydrogenation. The microstructure of EBM Ti-6Al-4V before hydrogenation consists of α laths with different sizes and orientations inside the prior β grains. In addition, fine β rods embedded into continuous α phase is observed. Hydrogenation of EBM Ti-6Al-4V leads to fragmentation of α laths and refining the microstructure. The grain boundaries of α plates does not observed in the Ti-6Al-4V hydrogenated to 0.9 wt. %, the lamellar structure disappeared (Figure 3d). The detailed microstructural analysis was performed by transmission electron microscopy (TEM).

Figure 3.

Scanning electron microscopy (SEM) images of EBM Ti-6Al-4V parts: (a)—initial state (b)—hydrogen content 0.29 wt. %; (c)—hydrogen content 0.58 wt. %; (d)—hydrogen content 0.9 wt. %.

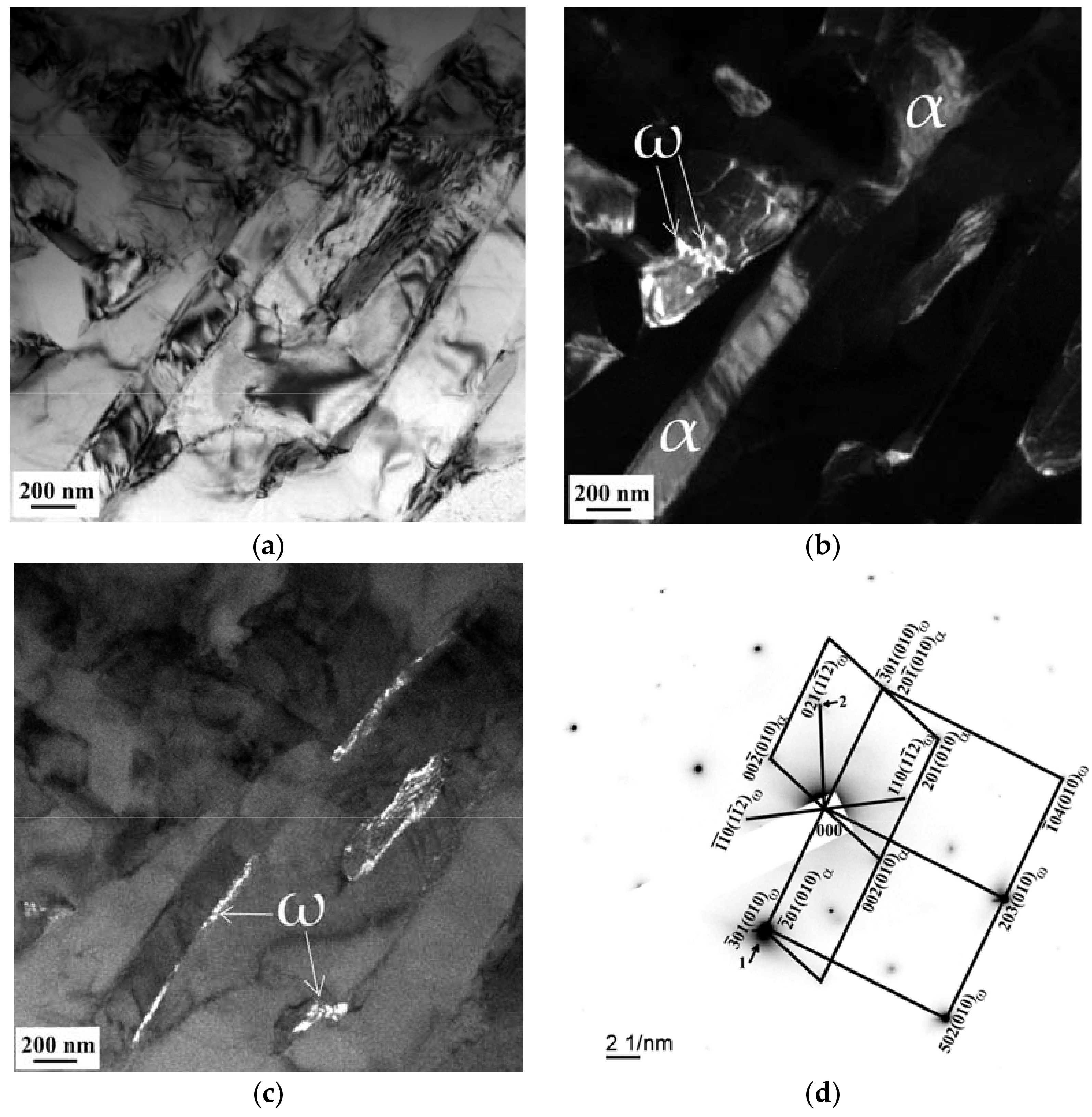

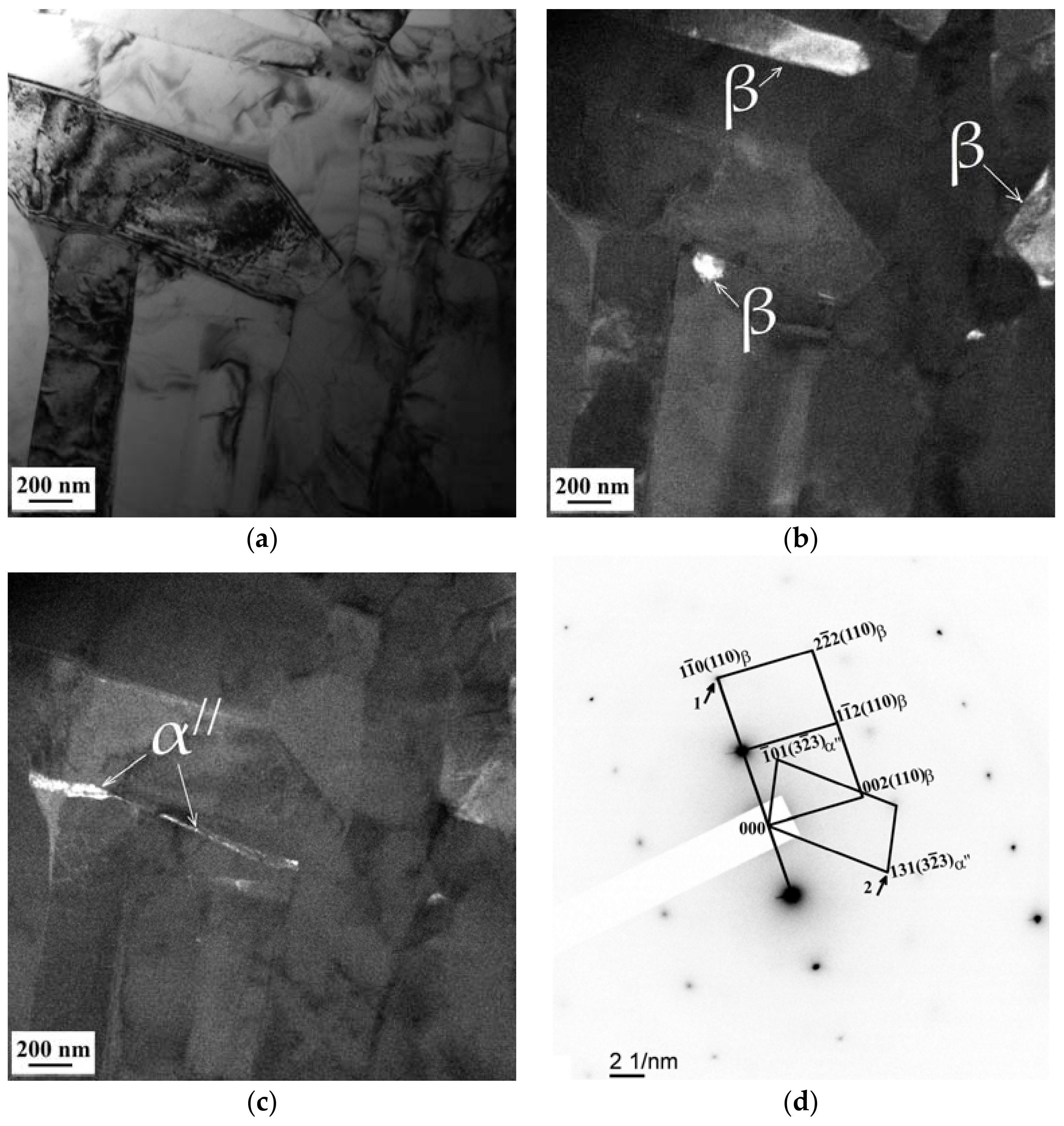

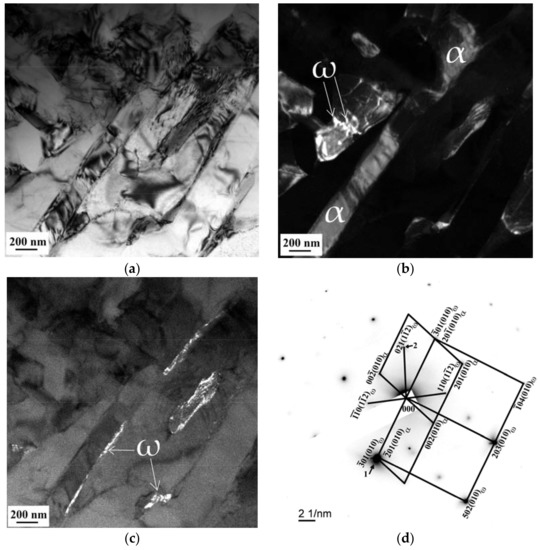

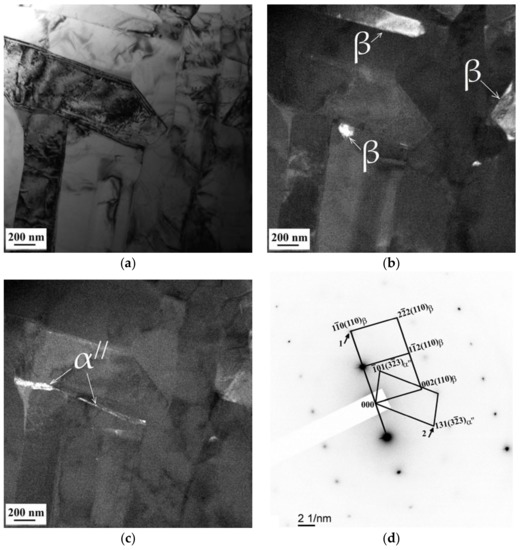

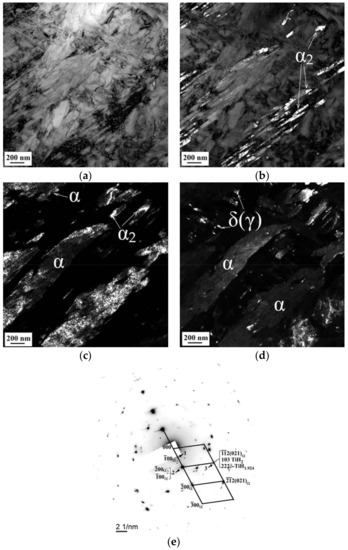

Figure 4 and Figure 5 show the TEM images of the microstructure of the Ti-6Al-4V parts produced by EBM. The structure of the Ti-6Al-4V parts before hydrogenation is represented by lamellar α phase (also called martensitic α′ phases) with the transverse plate size of 0.2–0.6 μm (Figure 4a,b) and β phase both in the form of plates and globular grains of 0.15–0.2 μm size embedded in the grain boundaries of α phase (Figure 4a,b). Moreover, the formation of metastable martensitic α″ phase (Figure 5c) and ω (Figure 4b,c) phase were observed. The nanoscale grains of α″ and ω phase are isolated inside α plates and at their grain boundaries mainly in the region of ternary joints. It has been noted that the large number of extinction contours presented in the TEM image indicate a high level of residual microstrain [36].

Figure 4.

Transmission electron microscopy (TEM) bright- (a) and dark-field images (b,c) and associated selected area electron diffraction (SAED) pattern (d) of the microstructure of EBM titanium Ti-6Al-4V parts; b—the dark-field image obtained with α-Ti and ω-Ti reflections (marked by an arrow 1); c—the dark-field image obtained with 021 ω-Ti reflection (marked by an arrow 2).

Figure 5.

TEM bright- (a) and dark-field images (b,c) and associated SAED pattern (d) of the microstructure of EBM titanium Ti-6Al-4V parts; b—the dark-field image obtained with β-Ti reflection (marked by an arrow 1); c—the dark-field image obtained with 131 α″-Ti reflection (marked by an arrow 2).

It is known that the structure of the titanium alloy depends on the cooling rate under heat treatment [37]. The change in the cooling rate regulates not only dispersion of the secondary α phase particles, but also the phase composition of the alloys. Sharp cooling (104–106 K/s [38]) is responsible to the appearance of metastable α′, α″, and ω phases in the titanium Ti-6Al-4V alloy produced by EBM. The α′ and α″ phases are a supersaturated solid solution based on α titanium phase also called martensitic phases [37]. The metastable ω phase is also called the special type of martensitic phase since it is supersaturated solid solution formed by the shear mechanism typical for martensitic transformations. Due to slowed diffusion processes β → α′ transformation via the diffusionless martensitic mechanism occur. However segregation of alloying elements to dislocations results in appearance of intermediate α″ and ω phase inside α plates. Moreover, concentration inhomogeneous is also responsible for formation of the above-mentioned metastable phases on the grain boundaries of α plates and prior β grains. However, these mechanisms require further investigation.

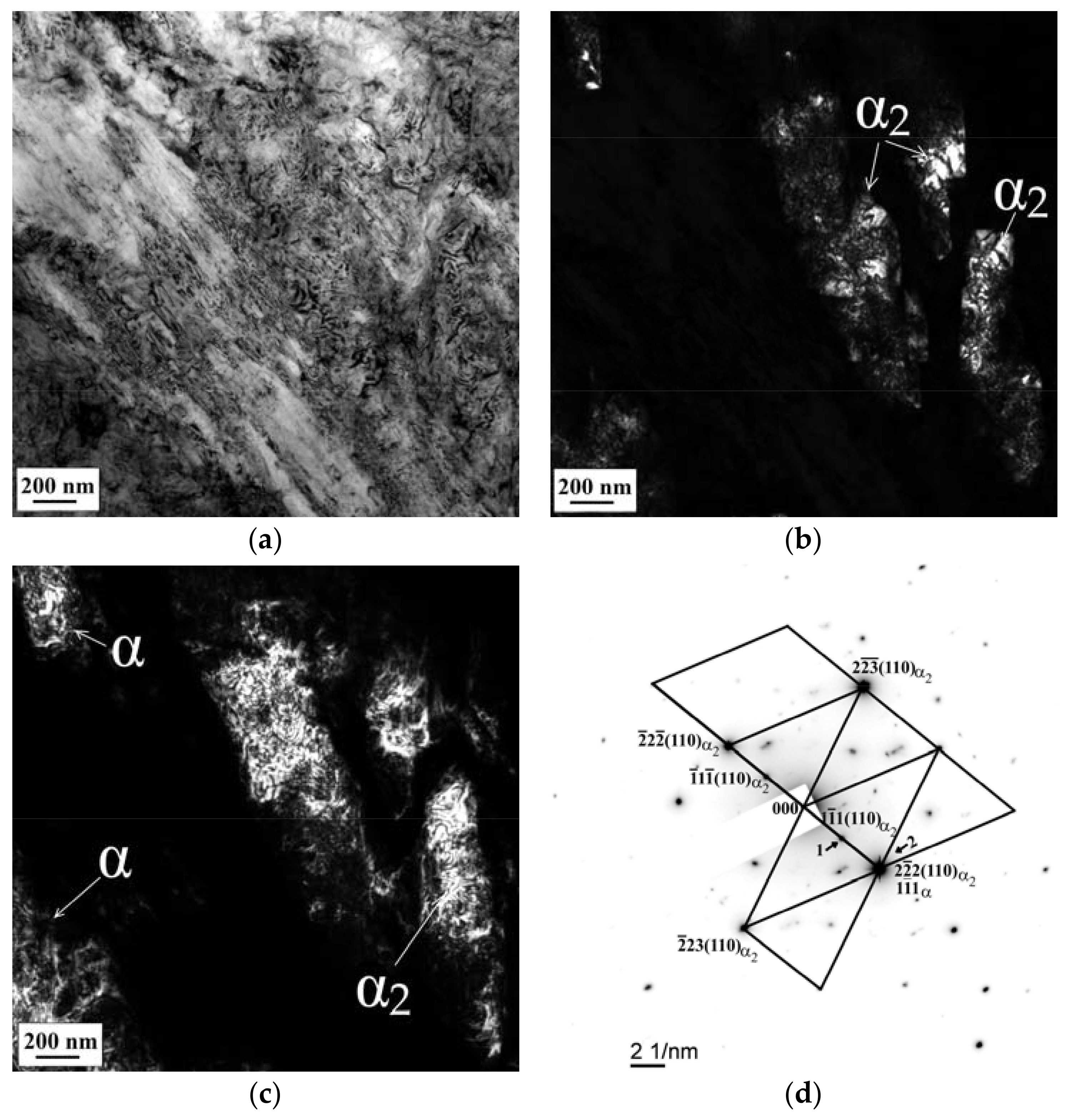

The results of the TEM investigation of the titanium Ti-6Al-4V parts produced by EBM after hydrogenation to 0.29 wt. % are shown in Figure 6. Intensive migration of grain boundaries of α plates during hydrogen treatment occur that is clearly demonstrated by the curvature of their boundaries (Figure 6). According to in situ XRD studies, the α → β and α → α2 phase transitions were detected, thus the above mentioned migration of grain boundaries is probably attributed to β grain growth. Obviously, the curvature of the α grain boundaries originate from β grains under inverse β → α transformation during cooling.

Figure 6.

TEM bright- (a) and dark-field images (b,c) and associated SAED pattern (d) of the microstructure of EBM titanium Ti-6Al-4V parts after hydrogenation to 0.29 wt. %; b—the dark-field image obtained with Ti3Al superstructure reflection (marked by an arrow 1); c—the dark-field image obtained with Ti3Al and α-Ti reflection (marked by an arrow 2).

The dark-field TEM images of the samples after hydrogenation to 0.29 wt. % showed that Ti3Al intermetallic particles with plate-like morphology precipitate inside the α plates (Figure 6b,c). The length and width of Ti3Al plates are less than 100 and 15 nm, respectively. This effect is attributed to redistribution of the alloying elements (Al and V) between the α and β phases under hydrogenation, and the enrichment of the β phase with aluminum. As a result, in the primary α (α″) phase, the ordering processes take place with the formation of the α2 phase based on the intermetallic Ti3Al phase. According to the theory of decohesion [39,40], hydrogen diffuses into the places of high concentration of elastic tensile stresses and reduces the forces of mutual attraction of metal ions in the crystal lattice. The probable electronic mechanism for the attenuation of metal bonds is the transfer of the electron from hydrogen to the 3d level of the metal. The diffusion coefficient of Al and V elements in the Ti-6Al-4V alloy was estimated in [41]. The authors found that hydrogenation of the titanium alloy significantly increase the self-diffusion ability of metal atoms and the diffusivity of dissolved atoms. The distortion of the crystal lattice of the α and β grains caused by the formation of solid solution with hydrogen, results in development of tensile stresses. The latter affects the dislocation distribution inside the hydrogenated titanium Ti-6Al-4V parts produced by EBM forming a large number of subgrain boundaries within the plates. Since the hydrogenation temperature is sufficiently high, the grain-boundary segregation of impurity atoms (primarily Al) could be expected. In this case, when the lamellar β grains acquire an hcp structure under cooling of hydrogenated samples, the transition α2 phase could be formed at the subgrain boundaries instead of the formation of α phase. Since the α″ and ω phases were not detected on the TEM images after hydrogenation, it could be assumed that these metastable phases are transformed into Ti3Al particles. The volume of unit cells of α″ (0.0698 nm3) and ω (0.052 nm3) phases substantially exceeds the unit cell of α (0.035 nm3) phase, thus their transformation into the Ti3Al phase is an effective way for relaxation of hydrogen-induced internal stresses in the α titanium grains . At the same time, both X-ray and selected area electron diffractions do not reveal the hydride phase formation after hydrogenation to 0.29 wt. %. It is obvious that the hydrogen in Ti-6Al-4V samples is dissolved mostly in the β phase and partly in the intermetallic particles due to lower hydrogen solubility of Ti3Al [42].

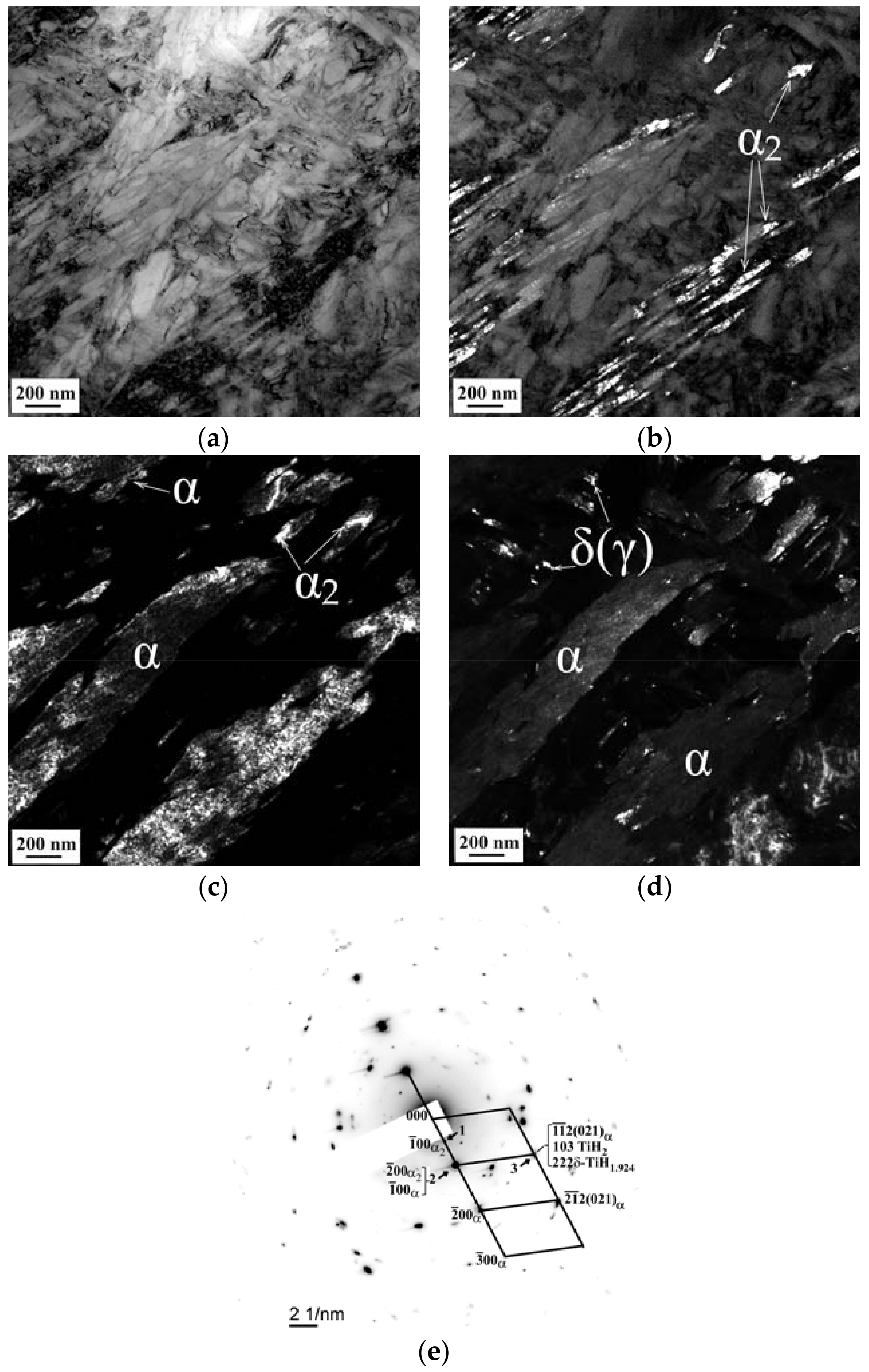

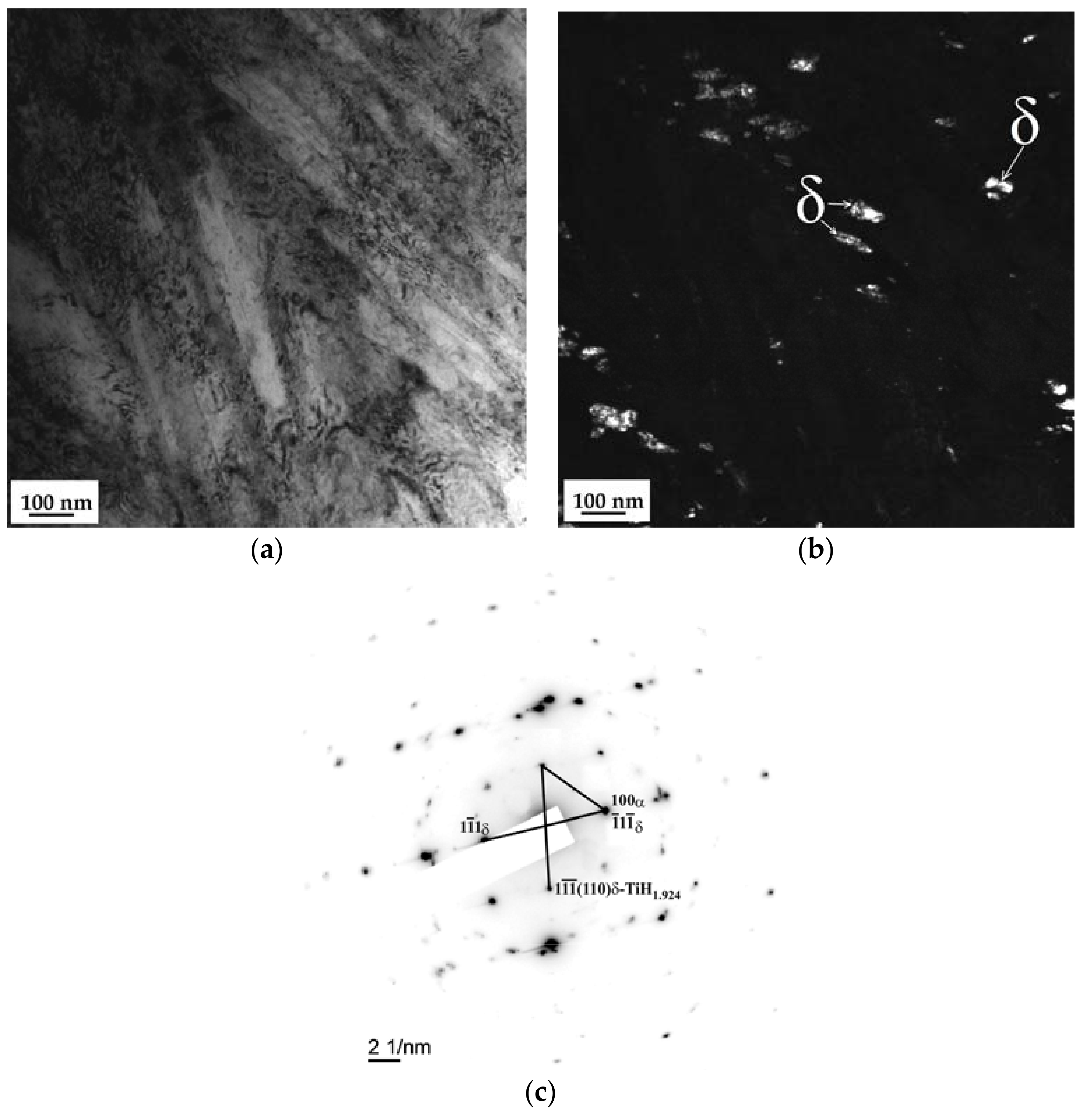

The results of the TEM investigation of the titanium Ti-6Al-4V parts produced by EBM after hydrogenation to 0.58 wt. % are shown in Figure 7.

Figure 7.

TEM bright- (a) and dark-field images (b–d) and associated SAED pattern (e) of the microstructure of EBM titanium Ti-6Al-4V parts after hydrogenation to 0.58 wt. %; b—the dark-field image obtained with Ti3Al superstructure reflection (marked by an arrow 1); c—the dark-field image obtained with Ti3Al and α-Ti reflection (marked by an arrow 2); d—the dark-field image obtained with α-Ti, 103 γ-TiH and 222 δ- TiH phase reflections (marked by an arrow 3).

Lath dual phase α + α2 structure consisting of Ti3Al plates embedded in a matrix of the α phase still observed after hydrogenation to 0.58 wt. %. However the dimensions of the intermetallic Ti3Al plates and their volume fraction significantly increased. It is obvious that with increase of hydrogenation time and hydrogen concentration in the samples, not only grain-boundary segregation of Al atoms, but also the so-called wetting phase transition takes place [43,44,45]. In other words, at the initial stage of hydrogenation, grain-boundary segregation of impurity atoms leads to the formation of solid solution of Al in α phase at small-angle boundaries. Subsequently, the presence of the solid solution causes a significant increase in the rate of grain-boundary diffusion. Accordingly, the subgrain boundaries are enriched with Al atoms leading to an increase in the size of the intermetallic phase. At the same time, the formation of nano-sized crystals of titanium δ-hydrides takes place in the samples hydrogenated to 0.58 wt. % (Figure 6c,d).

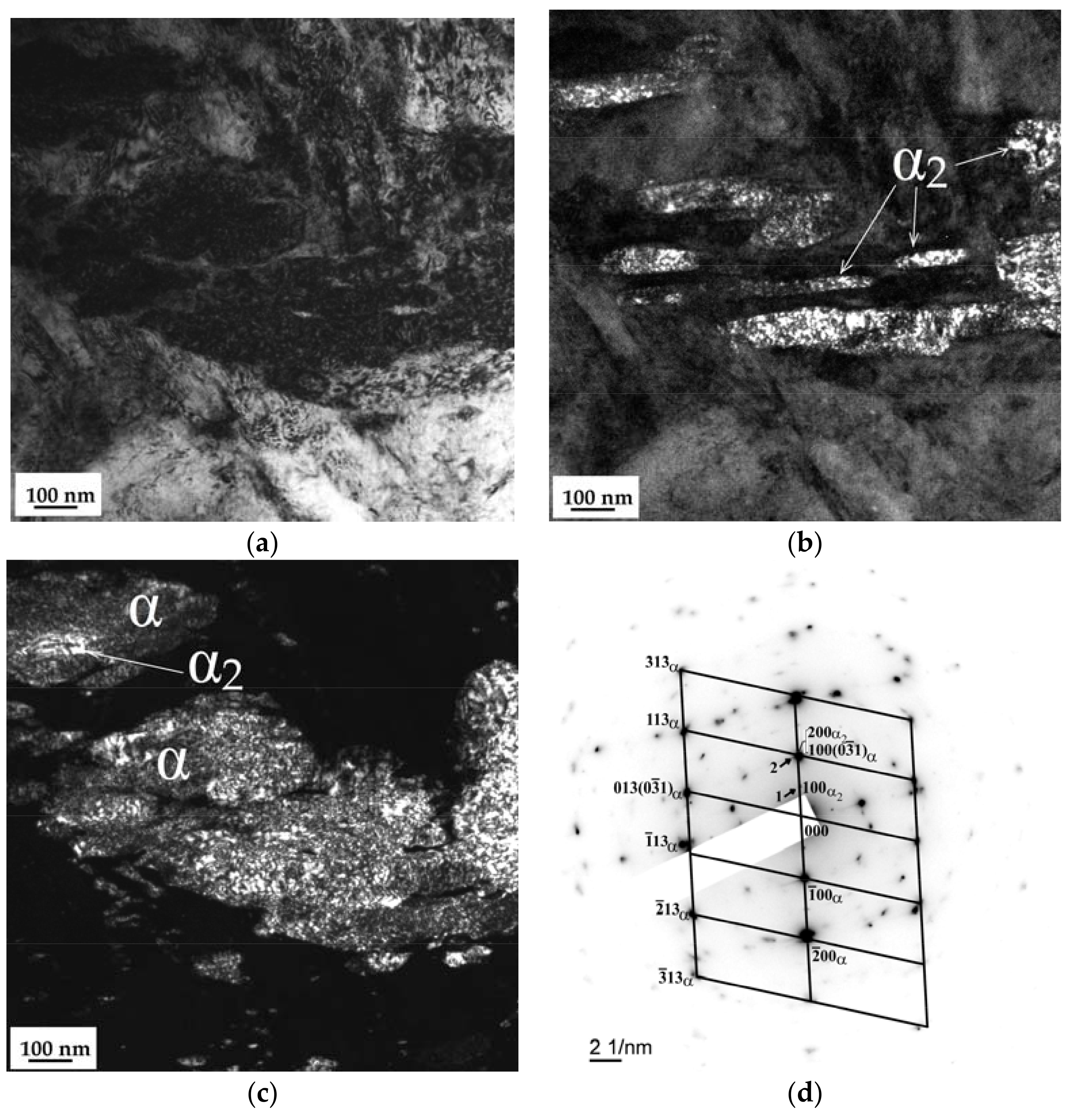

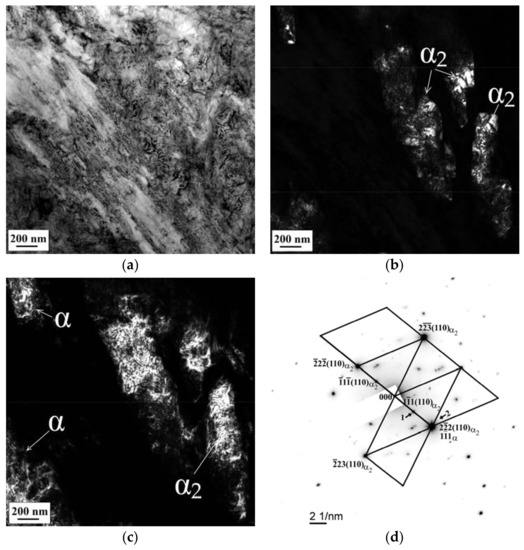

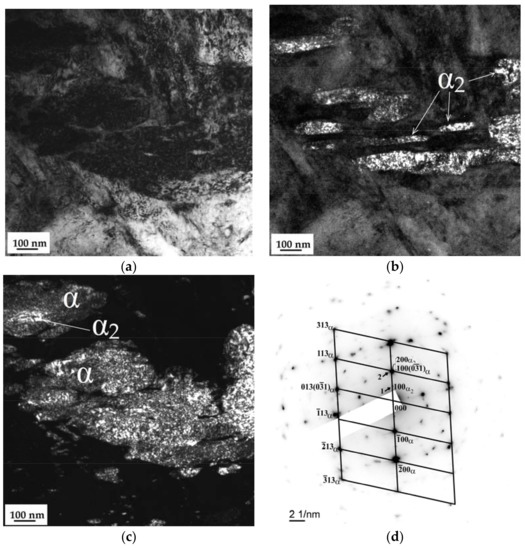

The results of the TEM investigation of the titanium Ti-6Al-4V parts produced by EBM after hydrogenation to 0.9 wt. % are shown in Figure 8.

Figure 8.

TEM bright- (a) and dark-field images (b,c) and associated SAED pattern (d) of the microstructure of EBM titanium Ti-6Al-4V parts after hydrogenation to 0.9 wt. %; b—the dark-field image obtained with Ti3Al superstructure reflection (marked by an arrow 1); c—the dark-field image obtained with Ti3Al and α-Ti reflection (marked by an arrow 2).

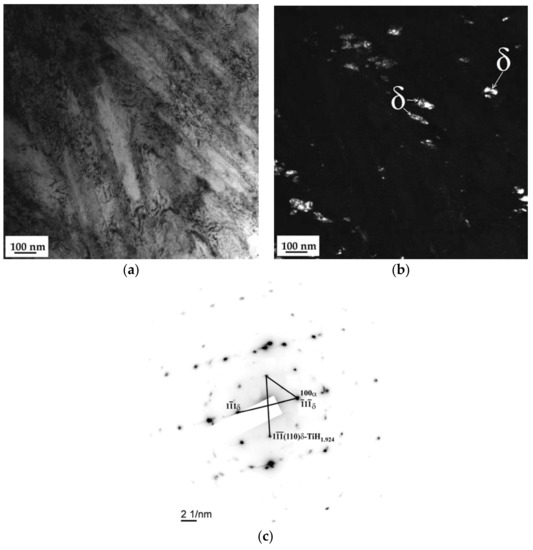

When the concentration of hydrogen in the samples is increased to 0.9 wt. %, the grain boundaries of the primary α plates continue to migrate, and their longitudinal and lateral dimensions increase (Figure 8). Furthermore, the dimensions of Ti3Al plates increase and decay into individual nanocrystals (Figure 8b). It should be noted that the α″ and ω phases are still not observed in hydrogenated Ti-6Al-4V samples. At the same time, the dimensions of the hydride plates grow (Figure 9b).

Figure 9.

TEM bright- (a) and dark-field images (b) and associated SAED pattern (c) of the microstructure of EBM titanium Ti-6Al-4V parts after hydrogenation to 0.9 wt. %. The dark-field image obtained with δ-TiH reflection.

Hydrogen diffusion in titanium Ti-6Al-4V alloy is determined by many factors, such as hydrogenation temperature, hydrogen pressure, microstructure, phase composition, defect structure, and other [46]. At the indicated hydrogenation conditions, the diffusion coefficients in the α and β phases, evaluated from equations [47]: , , where Dα = 1 × 10−9 m2/s and Dβ = 5.3 × 10−9 m2/s, respectively. Hydrogenation is accompanied by the β phase stabilization and the α2 phase formation. The diffusion coefficient in the latter is Dα2 = 1.3 × 10−10 m2/s [48]. Thus, it is assumed that hydrogen diffuses mainly through the β phase and interacts with α phase at the α/β interface. Due to the low solubility of hydrogen in the α phase, local excess of the dissolved hydrogen in the α phase leads to hydrides precipitation in the form of nanoscale crystals, which dimensions increase with hydrogen content.

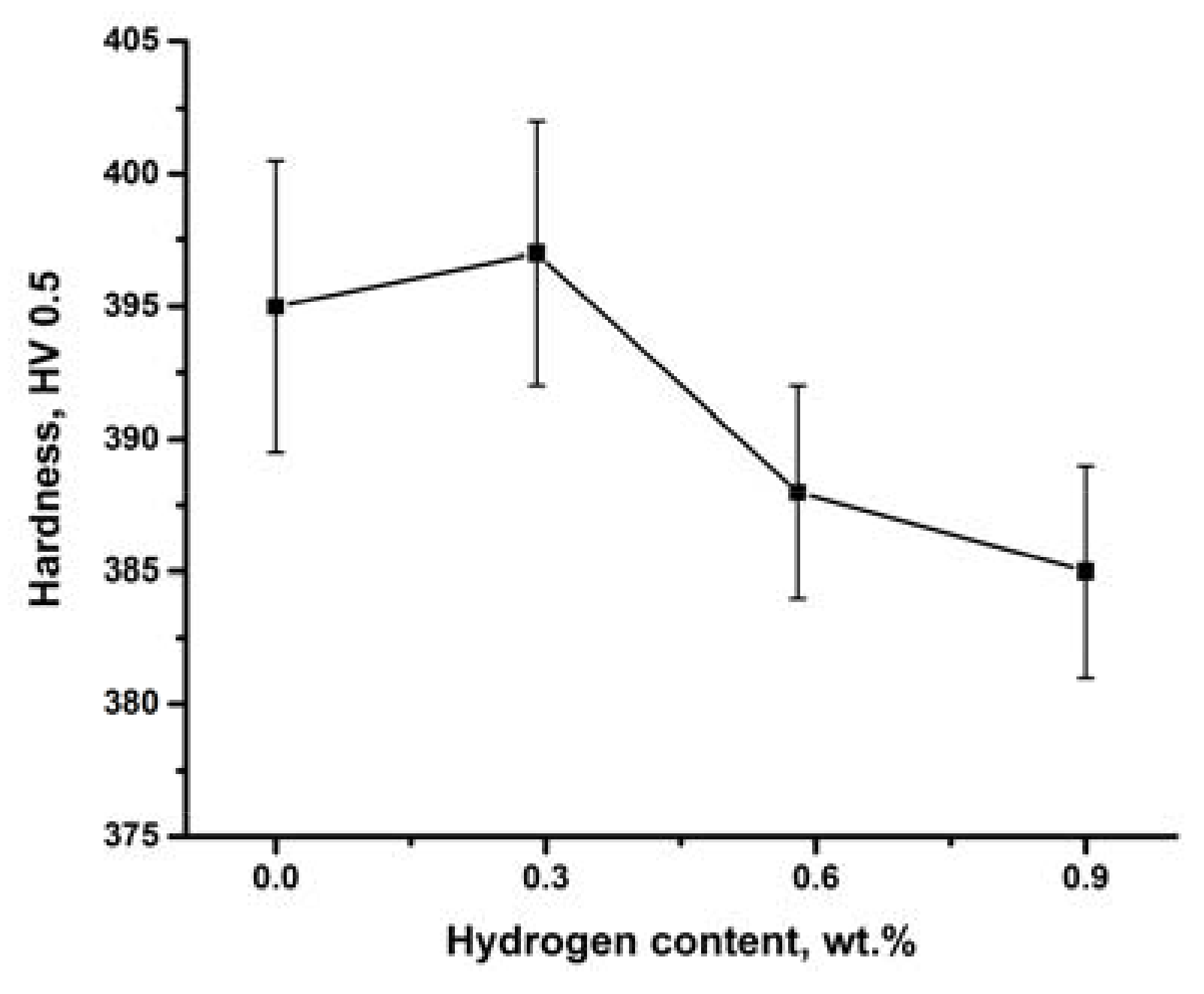

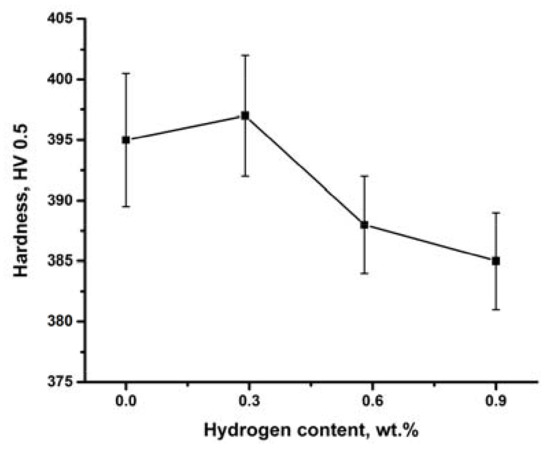

3.4. Microhardness

Figure 10 shows the measured hardness values of EBM Ti-6Al-4V parts before and after hydrogenation. It could be seen that hydrogenation to 0.29 wt. % insignificantly increase microhardness of the Ti-6Al-4V sample, while the softening trend is observed with increasing hydrogen content from 0.29 to 0.9 wt. %. The high value of microhardness of the as-received Ti-6Al-4V part (395 HV) is due to the fine lamellar structure as well as the presence of martensitic α″ phase in the alloy structure. The microstructure of the sample hydrogenated to 0.29 wt. % is refined, however, the lamellar structure is still present. Moreover, hard intermetallic Ti3Al phase plates are formed in the structure. Therefore, both refined microstructure and α2 precipitates could increase hardness of hydrogenated EBM Ti-6Al-4V samples, which was also observed for cast alloys in [49,50]. The microstructure becomes finer with increasing hydrogen content to 0.58 and 0.9 wt. %, but the lamellar structure of the alloy is destroyed and δ hydrides are formed, which apparently leads to the decrease in the hardness of hydrogenated EBM Ti-6Al-4V samples. It should be noted that the fraction of the softer β phase increases with hydrogen content that could also reduce the hardness of the hydrogenated samples. For cast Ti-6Al-4V alloys, the inverse relationship—hardness increase with hydrogen content is usually observed due to refined microstructure, hydrides, and α2 precipitations. However, this difference is attributed to coarser microstructure and initially lower hardness of cast Ti-6Al-4V alloys (300–360 HV) compared to Ti-6Al-4V alloys manufactured by EBM and selective laser melting (SLM) methods. Bilgin et al. [26] also observed the reduction of microhardness of Ti-6Al-4V alloy (manufactured by SLM) after hydrogenation at 650 °C (hydrogen content 1.18 wt. %). The authors supposed that reduction of microhardness is caused by stress release and additional δ and softer β-phases formation. Therefore, it is assumed that the softening of the hydrogenated EBM Ti-6Al-4V parts with increasing hydrogen content occurs due to increase in the fraction of the softer β phase, disruption of the lamellar structure, and hydride precipitation in the alloy structure.

Figure 10.

Hardness of EBM titanium Ti-6Al-4V parts as the function of hydrogen content.

4. Conclusions

The microstructural evolution and phase transitions in the samples of titanium Ti-6Al-4V parts produced by EBM under hydrogenation at 650 °C were investigated. The following conclusions were made:

(1) The structure of the Ti-6Al-4V samples produced by EBM is represented by a lamellar α phase with the transverse size of 0.2–0.6 μm and a β phase both in the form of plates and globular grains of 0.15–0.2 μm size embedded in the grain boundaries of the α plates. The volume content of the β phase is approximately 4%. Moreover, the nanoscale grains of metastable α″ and ω phases isolated inside α plates and at their grain boundaries are also observed.

(2) Hydrogenation to the concentration of 0.29 wt. % leads to aluminum enrichment of the primary α phase forming α2 phase based on the intermetallic Ti3Al. At the same time, the formation of hydride phase was not found by XRD, TEM, nor in-situ XRD methods indicating that the dissolved hydrogen is predominantly found in the β phases and partly in the intermetallic Ti3Al. In-situ hydrogenation at 650 °C also reveals the increase in the volume fraction of β phase accompanied by decrease of α phase and following α → α2 transformation.

(3) The growth of Ti3Al plates and their volume fraction occur with increasing hydrogen concentration to 0.58 wt. %. According to TEM and XRD results the following phase transformations [α(α″,ω) + β] → [α(α2) + β + δ + γ]. The formation of hydrides is a special feature of this structure after hydrogenation and subsequent cooling.

(4) The migration and growth of the grain boundaries of the primary α plates occur in the samples with increasing hydrogen concentration to 0.9 wt. %. Moreover, Ti3Al plates decay into individual nanocrystals and the volume fraction of δ titanium hydrides increases.

(5) The reduction of microhardness of hydrogenated EBM Ti-6Al-4V alloy is caused by the fraction of softer β phase, disruption of lamellar structure, and hydrides precipitation.

Author Contributions

N.P. carried out hydrogen concentration measurements, SEM, analyzed the results, and prepared the paper. A.P. and O.P. performed TEM investigations and analyzed the results. M.S. and E.K. carried out in-situ diffraction studies and analyzed results. V.N.K. performed hydrogenation of samples. R.L. carried out microhardness testing and samples preparation for hydrogenation. A.L. performed X-ray diffraction studies and analyzed results. A.K. carried out samples fabrication by the EBM method.

Funding

Russian Science Foundation: 17-79-20100.

Acknowledgments

This research was funded by Russian Science Foundation, research project No. 17-79-20100. The authors thank Yu. Shanenkova for SEM analysis. The authors also thank Tomsk Polytechnic University Competitiveness Enhancement Program.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Murr, L.E.; Gaytan, S.M.; Ramirez, D.A.; Martinez, E.; Hernandez, J.; Amato, K.N.; Shindo, P.W.; Medina, F.R.; Wicker, R.B. Metal Fabrication by Additive Manufacturing Using Laser and Electron Beam Melting Technologies. J. Mater. Sci. Technol. 2012, 28, 1–14. [Google Scholar] [CrossRef]

- Hrabe, N.; Quinn, T. Effects of processing on microstructure and mechanical properties of a titanium alloy (Ti-6Al-4V) fabricated using electron beam melting (EBM), Part 2: Energy input, orientation, and location. Mater. Sci. Eng. A 2013, 573, 271–277. [Google Scholar] [CrossRef]

- Hrabe, N.; Quinn, T. Effects of processing on microstructure and mechanical properties of a titanium alloy (Ti-6Al-4V) fabricated using electron beam melting (EBM), Part 1: Distance from build plate and part size. Mater. Sci. Eng. A 2013, 573, 264–270. [Google Scholar] [CrossRef]

- Antonysamy, A.A.; Meyer, J.; Prangnell, P.B. Effect of build geometry on the β-grain structure and texture in additive manufacture of Ti6Al4V by selective electron beam melting. Mater. Charact. 2013, 84, 153–168. [Google Scholar] [CrossRef]

- Safdar, A.; Wei, L.-Y.; Snis, A.; Lai, Z. Evaluation of microstructural development in electron beam melted Ti-6Al-4V. Mater. Charact. 2012, 65, 8–15. [Google Scholar] [CrossRef]

- Tan, X.; Kok, Y.; Tan, Y.J.; Descoins, M.; Mangelinck, D.; Tor, S.B.; Leong, K.F.; Chua, C.K. Graded microstructure and mechanical properties of additive manufactured Ti-6Al-4V via electron beam melting. Acta Mater. 2015, 97, 1–16. [Google Scholar] [CrossRef]

- Tal-Gutelmacher, E.; Eliezer, D. Hydrogen cracking in titanium-based alloys. J. Alloys Compd. 2005, 404–406, 621–625. [Google Scholar] [CrossRef]

- Murr, L.E. Metallurgy of additive manufacturing: Examples from electron beam melting. Addit. Manuf. 2015, 5, 40–53. [Google Scholar] [CrossRef]

- Algardh, J.K.; Horn, T.; West, H.; Aman, R.; Snis, A.; Engqvist, H.; Lausmaa, J.; Harrysson, O. Thickness dependency of mechanical properties for thin-walled titanium parts manufactured by Electron Beam Melting (EBM)®. Addit. Manuf. 2016, 12, 45–50. [Google Scholar] [CrossRef]

- Al-Bermani, S.S.; Blackmore, M.L.; Zhang, W.; Todd, I. The Origin of Microstructural Diversity, Texture, and Mechanical Properties in Electron Beam Melted Ti-6Al-4V. Metall. Mater. Trans. A 2010, 41, 3422–3434. [Google Scholar] [CrossRef]

- Gil Mur, F.X.; Rodríguez, D.; Planell, J.A. Influence of tempering temperature and time on the α′-Ti-6Al-4V martensite. J. Alloys Compd. 1996, 234, 287–289. [Google Scholar] [CrossRef]

- Dutta, B.; Froes, F.H. The Additive Manufacturing (AM) of titanium alloys. Met. Powder Res. 2017, 72, 96–106. [Google Scholar] [CrossRef]

- Tal-Gutelmacher, E.; Eliezer, D. High fugacity hydrogen effects at room temperature in titanium based alloys. J. Alloys Compd. 2005, 404–406, 613–616. [Google Scholar] [CrossRef]

- Tal-Gutelmacher, E.; Pundt, A.; Kirchheim, R. The effect of residual hydrogen on hydrogenation behavior of titanium thin films. Scr. Mater. 2010, 62, 709–712. [Google Scholar] [CrossRef]

- Tao, J.; Hu, S.; Ji, L. Effect of trace solute hydrogen on the fatigue life of electron beam welded Ti-6Al-4V alloy joints. Mater. Sci. Eng. A 2017, 684, 542–551. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, S.Q.; Tao, C. Hydrogenation behavior of Ti-25Al-10Nb-3V-1Mo alloy and effect of hydrogen on its microstructure and hot deformability. Int. J. Hydrog. Energy 1997, 22, 125–129. [Google Scholar] [CrossRef]

- Liu, H.; Cao, J.; He, P.; Feng, J.C. Effect of hydrogen on diffusion bonding of commercially pure titanium and hydrogenated Ti6Al4V alloys. Int. J. Hydrog. Energy 2009, 34, 1108–1113. [Google Scholar] [CrossRef]

- Luo, L.; Su, Y.; Guo, J.; Fu, H. Formation of titanium hydride in Ti-6Al-4V alloy. J. Alloys Compd. 2006, 425, 140–144. [Google Scholar] [CrossRef]

- Zhao, J.; Ding, H.; Zhao, W.; Tian, X.; Hou, H.; Wang, Y. Influence of hydrogenation on microstructures and microhardness of Ti6Al4V alloy. Trans. Nonferr. Met. Soc. China 2008, 18, 506–511. [Google Scholar] [CrossRef]

- Zhao, J.; Ding, H.; Zhong, Y.; Lee, C.S. Effect of thermo hydrogen treatment on lattice defects and microstructure refinement of Ti6Al4V alloy. Int. J. Hydrog. Energy 2010, 35, 6448–6454. [Google Scholar] [CrossRef]

- Shaoqing, Z.; Linruo, Z. Effect of hydrogen on the superplasticity and microstructure of Ti-6Al-4V alloy. J. Alloys Compd. 1995, 218, 233–236. [Google Scholar] [CrossRef]

- Liu, H.J.; Zhou, L.; Liu, P.; Liu, Q.W. Microstructural evolution and hydride precipitation mechanism in hydrogenated Ti-6Al-4V alloy. Int. J. Hydrog. Energy 2009, 34, 9596–9602. [Google Scholar] [CrossRef]

- Mishin, I.P.; Grabovetskaya, G.P.; Zabudchenko, O.V.; Stepanova, E.N. Influence of Hydrogenation on Evolution of Submicrocrystalline Structure of Ti-6Al-4V Alloy upon Exposure to Temperature and Stress. Russ. Phys. J. 2014, 57, 423–428. [Google Scholar] [CrossRef]

- Skvortsova, S.V.; Panin, P.V.; Nochovnaya, N.A.; Grushin, I.A.; Mitropolskaya, N.G. The influence of hydrogen on phase and structural transformations in a titanium alloy VT6. Technol. Light Alloy 2011, 4, 35–40. (In Russian) [Google Scholar]

- Baek, S.-W.; Song, E.J.; Kim, J.H.; Jung, M.; Baek, U.B.; Nahm, S.H. Hydrogen embrittlement of 3-D printing manufactured austenitic stainless steel part for hydrogen service. Scr. Mater. 2017, 130, 87–90. [Google Scholar] [CrossRef]

- Bilgin, G.M.; Esen, Z.; Akın, Ş.K.; Dericioglu, A.F. Optimization of the mechanical properties of Ti-6Al-4V alloy fabricated by selective laser melting using thermohydrogen processes. Mater. Sci. Eng. A 2017, 700, 574–582. [Google Scholar] [CrossRef]

- ASTM F3001-14, Standard Specification for Additive Manufacturing Titanium-6 Aluminum-4 Vanadium ELI (Extra Low Interstitial) with Powder Bed Fusion; ASTM International: West Conshohocken, PA, USA, 2014. [CrossRef]

- Kudiiarov, V.N.; Syrtanov, M.S.; Bordulev, Y.S.; Babikhina, M.N.; Lider, A.M.; Gubin, V.E.; Murashkina, T.L. The hydrogen sorption and desorption behavior in spherical powder of pure titanium used for additive manufacturing. Int. J. Hydrog. Energy 2017, 42, 15283–15289. [Google Scholar] [CrossRef]

- Cheng, H.H.; Deng, X.X.; Li, S.L.; Chen, W.; Chen, D.M.; Yang, K. Design of PC based high pressure hydrogen absorption/desorption apparatus. Int. J. Hydrog. Energy 2007, 32, 3046–3053. [Google Scholar] [CrossRef]

- Sadykov, V.; Okhlupin, Y.; Yeremeev, N.; Vinokurov, Z.; Shmakov, A.; Belyaev, V.; Uvarov, N.; Mertens, J. In situ X-ray diffraction studies of Pr2−xNiO4+δ crystal structure relaxation caused by oxygen loss. Solid State Ion. 2014, 262, 918–922. [Google Scholar] [CrossRef]

- Sadykov, V.A.; Pavlova, S.N.; Vinokurov, Z.S.; Shmakov, A.N.; Eremeev, N.F.; Fedorova, Y.E.; Yakimchuk, E.P.; Kriventsov, V.V.; Bolotov, V.A.; Tanashev, Y.Y.; et al. Application of SR Methods for the Study of Nanocomposite Materials for Hydrogen Energy. Phys. Procedia 2016, 84, 397–406. [Google Scholar] [CrossRef]

- Syrtanov, M.S.; Kudiiarov, V.N.; Kashkarov, E.B.; Shmakov, A.N.; Vinokurov, Z.S.; Babikhina, M.N.; Zolotarev, K.V. Application of Synchrotron Radiation for In Situ XRD Investigation of Zirconium Hydrides Formation at Gas-phase Hydrogenation. Phys. Procedia 2016, 84, 342–348. [Google Scholar] [CrossRef]

- Zhu, T.; Li, M. Effect of 0.770 wt% H addition on the microstructure of Ti-6Al-4V alloy and mechanism of δ hydride formation. J. Alloys Compd. 2009, 481, 480–485. [Google Scholar] [CrossRef]

- Kim, Y.-K.; Kim, H.-K.; Jung, W.-S.; Lee, B.-J. Atomistic modeling of the Ti-Al binary system. Comput. Mater. Sci. 2016, 119, 1–8. [Google Scholar] [CrossRef]

- Sun, P.; Fang, Z.Z.; Koopman, M.; Paramore, J.; Chandran, K.S.R.; Ren, Y.; Lu, J. An experimental study of the (Ti-6Al-4V)-xH phase diagram using in situ synchrotron XRD and TGA/DSC techniques. Acta Mater. 2015, 84, 29–41. [Google Scholar] [CrossRef]

- Perevalova, O.B.; Panin, A.V.; Kalashnikov, M.P.; Akulinkin, A.A.; Bozhko, I.A.; Sergeev, V.P. Elastic stresses and microstructure of TiAlN coatings. Inorg. Mater. Appl. Res. 2017, 8, 434–443. [Google Scholar] [CrossRef]

- Yingying, Z.; Shuhui, H.; Yingjuan, F.; Debin, S. Hydrogen induced softening mechanism in near alpha titanium alloy. J. Alloys Compd. 2012, 541, 60–64. [Google Scholar] [CrossRef]

- Kolachev, B.A.; Mamonova, F.S.; Lyasotskaya, V.S. Characteristics of the structure and properties of quenched titanium alloys. Met. Sci. Heat Treat. 1975, 17, 695–697. [Google Scholar] [CrossRef]

- Yan, M.; Yu, P. An Overview of Densification, Microstructure and Mechanical Property of Additively Manufactured Ti-6Al-4V—Comparison among Selective Laser Melting, Electron Beam Melting, Laser Metal Deposition and Selective Laser Sintering, and with Conventional Powder. In Sintering Techniques of Materials; InTech: London, UK, 2015. [Google Scholar] [CrossRef]

- Johnson, H.H.; Morlet, J.G.; Troiano, A.R. Hydrogen crack initiation and delayed failure in steel. Trans. Metall. Soc. Am. Inst. Min. Metall. Pet. Eng. 1958, 212, 528–536. [Google Scholar]

- Van Leeuwen, H.P. A failure criterion for internal hydrogen embrittlement. Eng. Fract. Mech. 1977, 9, 291–296. [Google Scholar] [CrossRef]

- Baoguo, Y.; Yujie, W.; Yubin, Z.; Longqing, G. Hydrogenation Behavior of Ti6Al4V Alloy. Rare Met. Mater. Eng. 2017, 46, 1486–1490. [Google Scholar] [CrossRef]

- Bratanich, T.I.; Skorokhod, V.V.; Kopylova, L.I.; Kotko, A.V. Ti3Al destructive hydrogenation. Int. J. Hydrog. Energy 2011, 36, 1276–1286. [Google Scholar] [CrossRef]

- Straumal, B.; Baretzky, B. Grain Boundary Phase Transitions and their Influence on Properties of Polycrystals. Interface Sci. 2004, 12, 147–155. [Google Scholar] [CrossRef]

- Bokstein, B.S. Grain Boundary Diffusion, Stresses and Segregation. Defect Diffus. Forum 2012, 323–325, 31–40. [Google Scholar] [CrossRef]

- Fisher, D.J. Hydrogen Diffusion in Metals: A 30-Year Retrospective; Scitec Publications: Zurich-Uetikon, Switzerland, 1999; pp. 167–168. ISBN 9783908450429. [Google Scholar]

- Hirohata, Y.; Aihara, Y.; Hino, T.; Miki, N.; Nakagawa, S. Evaluation of hydrogen sorption and desorption for Ti-6A1-4V alloy as a vacuum vessel material. In Fusion Technology 1996; Elsevier: Amsterdam, The Netherlands, 1997; pp. 363–366. [Google Scholar]

- Miyoshi, T.; Naito, S.; Yamamoto, M.; Doi, M.; Kimura, M. Diffusion of hydrogen in titanium, Ti88Al12 and Ti3Al. J. Chem. Soc. Faraday Trans. 1996, 92, 483. [Google Scholar] [CrossRef]

- Shen, C.-C.; Wang, C.-M. Effects of hydrogen loading and type of titanium hydride on grain refinement and mechanical properties of Ti-6Al-4V. J. Alloys Compd. 2014, 601, 274–279. [Google Scholar] [CrossRef]

- Shen, C.C.; Yu, C.Y.; Perng, T.P. Variation of structure and mechanical properties of Ti-6Al-4V with isothermal hydrogenation treatment. Acta Mater. 2009, 57, 868–874. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).