Abstract

The circular economy for sustainable economic deployment is strongly based on the re-use of secondary products and waste utilization. In the present study, a new effective cementation method for recovering valuable metallic copper from industrial wastewater using Fe0 powders is reported. A high-speed mixer-disperser (HSMD) capable of providing a cavitation effect was used for the rapid intake, dispersion, and mixing of Fe0 powder in an acidic wastewater solution (pH ≈ 2.9) containing copper ions mainly in the form of CuSO4. Three iron powders/particles were tested as the cementation agent: particles collected from industrial dust filters (CMS), water-atomized iron-based powder AHC100.29, and sponge-iron powder NC100.24. The effects of mixing regimes and related mixing conditions on the effectiveness of the Cu cementation process were evaluated by comparison between the HSMD and a laboratory paddle mixer. It was observed that the use of cavitation provided more efficient copper removal during the copper cementation process in comparison to the standard experiments with the propeller mixer. Under the cavitation regime, about 90% of copper was cemented in the first five minutes and the final copper removal of 95% was achieved using all three Fe0 powders after seven minutes of cementation. In comparison, only around 55% of copper was cemented in the first seven minutes of cementation using the traditional mixing method.

1. Introduction

Copper is one of the most important non-ferrous metals due to its high thermal and electrical conductivity. It can be applied as an electrical and heat conductor, a building material, an alloying component, and in metal finishing, electroplating, plastics, fungicides, etching, etc. [1,2,3,4]. Increases in the rate of copper production and widespread demand for applications in many fields have led to a considerable increase of copper ions leaking into the ecosystem, particularly in industrial wastewater [1,4,5,6]. As a heavy metal, the presence of copper may cause hazardous effects on human health, even at low concentrations [7,8,9].

The United States Environmental Protection Agency (USEPA) allows a maximum contaminant level (MCL) of only 1.3 mg/L for the concentration of copper ions in industrial effluents. The standardized MCL in drinking water for copper is 0.25 mg/L [10,11,12,13]. Effective copper removal from wastewater has always been of great interest to researchers around the world. Cementation [14,15,16,17], adsorption [5,9,10,18,19], membrane filtration [20,21,22], electrodialysis [20,23], and photocatalysis [19,24] are the most common methods and techniques for the extraction of copper from wastewater. Each method and/or technology has its own advantages and disadvantages [25,26,27,28,29]. Nevertheless, the cementation process is considered to be the most economical and effective method to remove valuable and/or toxic metals from industrial wastewater [1]. This method reduces copper ions in the copper’s salt-containing aqueous solution to its zero valent state at the interface of a more positive metal in the electromotive force series [14]. Low cost, low energy consumption, recovery of metals in pure metallic form, ease of control, simplicity of operation, and high efficiency make the cementation process most advantageous [1,30,31]. The most common cementation agents are iron and zinc [32]. The main disadvantage of the cementation technique is its excess sacrificial metal consumption [33].

Intensification of the cementation process has interested researchers in recent years. Nosier et al. has reported the use of ceramic for the enhancement of copper cementation under single-phase flow [17]. A bubble column reactor fitted with horizontal screens was used for copper removal from aqueous solutions [34]. A modified stirred tank reactor in combination with alcoholic additives increased the cementation rate of copper powder from wastewater containing CuSO4 [35]. In his paper, Konsowa used a special jet reactor to cement copper on a zinc disc from a dilute copper sulfate solution [14].

Ultrasonic cavitation is the well-known phenomenon in the ultrasonic cleaning method. In a liquid medium, the ultrasonic waves, generated by an electronic ultrasound generator and a special transducer suitably mounted under the bottom of a stainless-steel tank or directly to a metal cylinder (called a “horn”), produce compression and vacuum waves at a very high speed. Speed depends on the working frequency of the ultrasound generator. Normally, such apparatus operates at a frequency between 28 and 50 kHz. The pressure and vacuum waves in the liquid cause the phenomenon known as “ultrasonic cavitation”. However, this method is complicated for implementation on a commercial scale due to the low productivity and high cost of commercial ultrasonic devices. Another important factor is the risk to human health caused by long-term exposure to ultrasonic noise generated by ultrasound generators. In the present work, a rotational cavitation-generated device was employed to study the effect of cavitation on copper cementation from industrial wastewater.

2. Theory

Cementation is an electrochemical process that leverages the difference between the standard electrode potentials of ions of the extracted metal and the cementing metal. The cementing metal should have a more negative standard electrode potential than the extracted metal. This process in acid media can be described by following Equations (1)–(3).

CuSO4 + Fe → FeSO4 +Cu,

H2SO4 + Fe → H2 + FeSO4,

Fe2(SO4)3 + Fe → 3FeSO4.

However, the following reactions occur simultaneously ((4)–(6)):

Fe2(SO4)3 + Cu = CuSO4 + 2FeSO4,

Cu + 1/2O2 + H2SO4 = CuSO4 + H2O,

2FeSO4 + 1/2O2 + H2SO4 = Fe2(SO4)3 +H2O.

Standard electrode potentials of main species are given as follows [6]:

Cu → Cu2+ + 2e, E0 = +0.34 V,

Fe → Fe2+ + 2e, E0 = −0.44 V,

Fe3+ + e → Fe2+, E0 = +0.77 V,

O2 + 4e + 4H+←→ 2H2O, E0 = +1.23 V.

Reactions (4) and (5) reduce the amount of copper extraction in the cementation process. Also, in kinetic equilibrium, three following reactions occur simultaneously:

Cu ←→ Cu+ + e, E0 = +0.52 V,

Cu ←→ Cu2+ + 2e, E0 = +0.34 V,

Cu+ ←→ Cu2+ + e, E0 = +0.15 V.

The speed and limit of copper dissolution is determined by steady equilibrium potential. Cuprous ions are unstable in sulfate solutions and are spontaneously transformed into divalent copper to form a powder according to disproportionation (Equation (7)):

Cu2SO4 ←→ Cu + CuSO4.

In neutral solutions, copper sulfate is hydrolyzed to form dark red crystals of copper oxide (Equation (8)):

Cu2SO4 + H2O → Cu2O + H2SO4.

In acidic solutions, oxidation with oxygen present in the solution is the main reaction (Equation (9)):

Cu2SO4 + H2SO4 + 1/2O2 → 2CuSO4 + H2O.

An insufficient amount of free sulfuric acid in solutions creates favorable conditions for the hydrolysis of iron ions.

2Fe2(SO4)3 + 3H2O = Fe2(SO4)3·Fe2O3 + 3H2SO4,

Fe2(SO4)3Fe2O3 + 9H2O = 4Fe(OH)3 + 3H2SO4.

Theoretically, the copper cementation process terminates when the concentration of copper ions in the solution decreases to a certain value, at which the electrode potential for copper is equal the electrode potential for iron. The system achieves the equilibrium state. The concentration of copper ions in the solution at equilibrium can be calculated from the Nernst Equations (12) and (13) [6]:

If

then

where: E0 is the standard electrode potential, a is ion activity, R is the gas constant, F is the Faraday constant, and z is the number of electrons participating in reaction.

The solution of this equation at 25 °C gives the following expression:

At equilibrium, the concentration of copper ions in the solution is low (CCu2+ = 1.3 × 10−27), that is, cementation reaction can be considered as extending to the end. However, the thermodynamic equilibrium is not achieved due to kinetic difficulties. The mechanism of copper cementation can be represented by successive stages: delivery of ions to the cathode surface and removal of ions from the anode surface through a diffusion layer, discharge of copper ions to the cathode sections, and ionization of iron ions on the anodic sites (electrochemical conversion).

3. Materials and Methods

A high-speed cavitation-dispersion device (HSCD) (CORVUS Ltd., Riga, Latvia) and a paddle laboratory mixing device (LMD) EUROSTAR 40 digital (IKA, Staufen, Germany) were compared to determine the influence of mixing regimes and related parameters on the effectiveness of the copper extraction process. The duration of each test was 10 min. Samples were collected before and during the test after 1, 2, 3, 5, and 10 min. A total of 1500 mL of wastewater was used for every test.

Wastewater for treatment experiments was obtained from a European mining company. According to the non-disclosure agreement between the mining company and researchers, it is prohibited to reveal the source of wastewater. The chemical composition was provided by the supplier as listed in Table 1. The wastewater contained mainly copper ions in the form of CuSO4 with pH = 2.95. Three different iron powders from Höganäs AB, Sweden were provided for cementation experiments: (1) iron particles collected from industrial dust filter (CMS) (Höganäs AB, Höganäs, Sweden); (2) water-atomized iron-based powder AHC100.29 (AHC); and (3) sponge-iron powder NC100.24 (NC). The particle size distribution and surface area of the powders are shown in Table 2.

Table 1.

Physicochemical parameters of the wastewater sample.

Table 2.

Physical properties of iron powders—CMS: iron particles collected from industrial dust filter; AHC100.29: water-atomized iron-based powder; NC100.24: sponge-iron powder.

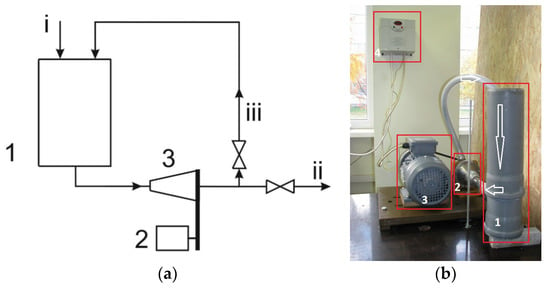

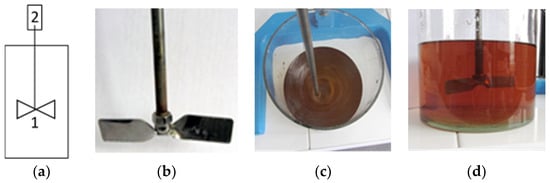

The HSCD was used for Cu extraction experiments with the setup and principles demonstrated in authors’ previous works as shown in Figure 1 [36,37,38]. As determined in the previous works [36,37,38], a linear speed over 24.13 m/s, which corresponds to 3847 rpm, is needed in order for the cavitation effect to appear in water media when HSCD is used. To ensure stable cavitation in all treated volumes, a rotor rotational frequency of 6000 rpm was applied. A reference laboratory mixer with an electric drive and a paddle-type sitter was used (Figure 2). Nylon syringe filters (pore size of 0.45 µm, diameter of 25 mm, supplied by Cole-Parmer, Hamburg, Germany) were used with the aim of avoiding the presence of Fe0, Cu0, and other solid particles, and to terminate cementation reactions in collected solutions. Each experiment was repeated four times with the deviation in measurement results less than 5%. Surface area was determined by the Brunauer–Emmett–Teller (BET) analysis, using the surface area analyzer Quadrasorb SI-KR/MP (Anton Paar GmbH, Berlin, Germany) with nitrogen adsorption/desorption at 77K.

Figure 1.

Scheme of the experimental setup for Cu2+-containing wastewater treatment. Principal scheme (a) 1—container for suspension; 2—engine; 3—mixer-disperser; i—supply components to be mixed; ii—suspension output; iii—recycle stream. General view (b) 1—container for suspension; 2—mixer-disperser; 3—engine; 4—engine rpm control unit Arrows indicate suspension circulation directions.

Figure 2.

Experimental setup for control experiment of a propeller-type sitter. (a) Scheme of process volume with a propeller-type sitter (1), and a laboratory mixer with electric drive (2). (b) Propeller-type sitter view. (c) Sitter axis located asymmetrically to the vessel. (d) Sitter location in processed wastewater volume.

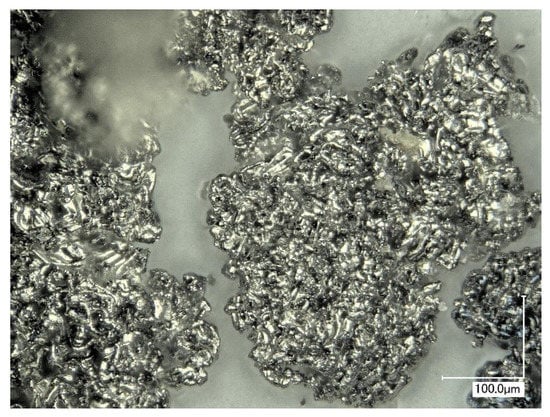

The stoichiometric amount of Fe0 powder needed for cementation tests was calculated according to reaction (1) and the initial concentration of Cu2+. It was found that 0.441 g/L of iron powder was necessary. On the other hand, taking into account simultaneous chemical reactions (2)–(4), four times the excess of the stoichiometric amount of iron powder was proposed and tested, corresponding to the ratio between the amount of iron powder and the solution volume of 1.764 g/L. Figure 3 shows a photograph of iron powder AHC 100.29 with sponge-like morphology. For microstructural characterization, optical imaging was carried out by the optical digital microscope VHX-2000 (Keyence Corporation, Osaka, Japan) equipped with lenses VH-Z20R/W and VH-Z500R/W. Metal concentrations in solutions were analyzed by the atomic absorption spectrometer GBC 932plus (GBC Scientific Equipment Ltd., Dandenong, Australia).

Figure 3.

Picture of sponge-like surface structure of AHC 100.29.

4. Results and Discussion

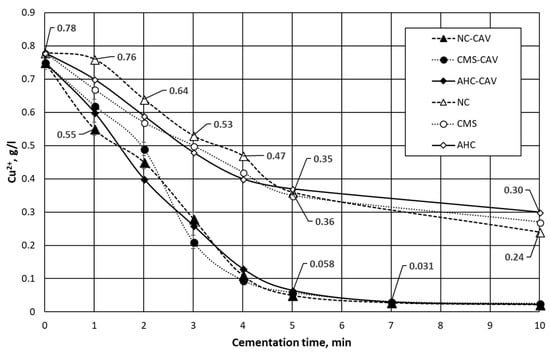

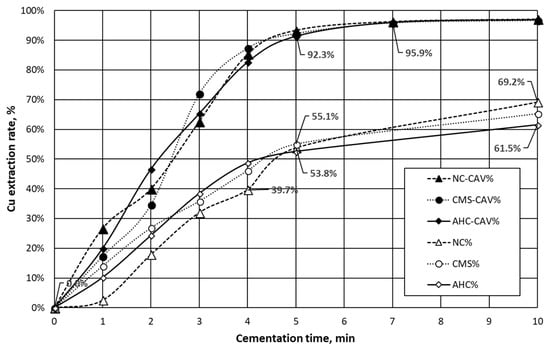

As shown in Figure 4 and Figure 5, cavitation dispersion provided more effective copper cementation from wastewater by Fe0 powders than the traditional mixing method using propellers. Using the high-speed mixer-disperser (HSMD), the copper concentration in wastewater decreased rapidly in first five minutes and achieved the steady state in only seven minutes, when about 95.9% of copper was cemented. Increasing the cementation duration to ten minutes did not result in a significant increase in cementation efficiency. Although the copper concentrations remaining in wastewater when three types of Fe0 powders were used varied slightly in the first 5 min of cementation, the final copper concentration after 10 min cementation with all three powders was almost identical, at about 31 mg/L. Therefore, it is more economical and ecological to use the powder from dust filters in practice. In contrast, the copper cementation using the conventional propeller sitter proceeded more slowly than the cementation using the HSMD and achieved only 53%–55% efficiency in the first five minutes of cementation for all three types of Fe0 powder. After that, the cementation process slowed down, with cementation efficiency varying from 61.5% for AHC powders to 69.2% for NC powders after ten minutes. It was also observed that the temperature of wastewater during cementation using the HSMD increased to about 35 °C after 7 min, while the temperature of wastewater during cementation using the propeller sitter remained unchanged, at 18 °C. It was probable that the increase in cementation temperature also contributed to some increase in the copper cementation efficiency by the cavitation-dispersion method.

Figure 4.

Dependence of Cu2+ concentration in the waste water, depending on the treatment time and used setup. NC-CAV: powder NC 100.24 with cavitation; CMS-CAV: powder CMS with cavitation; AHC-CAV: powder AHC 100.29 with cavitation; NC: powder NC 100.24 without cavitation; CMS: powder CMS without cavitation; AHC: powder AHC 100.29 without cavitation.

Figure 5.

Dependence of the copper extraction rate, depending on the treatment time and setup used.

As described in Section 2, the reduction of Cu2+ to Cu0 occurs on Fe0 surface, which will be gradually covered by a layer of cemented Cu0. During the first five minutes of cementation, the opened Fe0 surface was quite large, so cementation proceeded quickly. After that, cementation slowed down due to decreased accessible Fe0 surface on which Cu2+ ions can be cemented. This behavior was observed during cementation using all three types of Fe0 powders under both non-cavitated and cavitated cementation conditions. As shown in Table 2, all three Fe0 powders had similar specific surfaces, so in general, copper cementation courses using these Fe0 powders followed similar trends (Figure 4 and Figure 5).

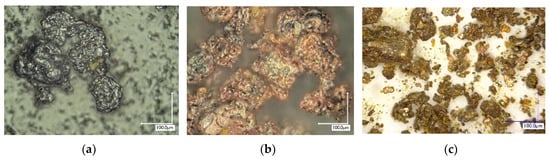

Figure 6 shows the original NC 100.24 Fe0 powders and their cemented particles obtained under the traditional mixing regime and the cavitation regime. Under the traditional mixing regime, Fe0 powders were covered by cemented Cu0. Some of them are agglomerated, probably by bridging of cemented Cu0, making the resulting Fe0 particles bigger than the original ones (Figure 6b). The cavitated samples consisted of some small particles with particle size ranging from 10 to 30 µm (Figure 6c). The majority of particles had particle size ranging from 50 to 100 µm, much smaller than the original particle size of 150 µm (Table 2). The formation of smaller particles and the reduction in particle size of the majority of original Fe0 particles were probably the results of the cavitation effects, which caused newly cemented Cu0 to rip off the Fe0 surface, creating small Cu0 particles and allowing additional cementation on the newly opened Fe0 surface. Together with increased diffusion of Cu2+ ions to Fe0 surfaces and/or through the pores of cemented Cu0 on Fe0 surfaces, the copper cementation process quickened during the cavitation regime. The other explanation for the formation of smaller particles in cavitated samples is that some of the Fe0 particles broke down during cavitation, leading to increased specific surface and increased copper cementation efficiency.

Figure 6.

(a) NC 100.24 Fe powder particles before cementation; (b) NC 100.24 Fe powder particles after cementation at 10th minute, without cavitation treatment; (c) NC 100.24 Fe powder particles after cementation at 10th minute, with cavitation treatment.

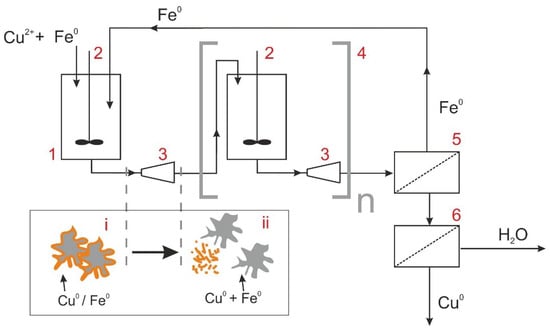

The commercial cementation process usually operates the flows at 100–300 m3/h. In order to implement the studied cavitation cementation method, repetition of the cavitation treatment using tanks can be envisaged. Figure 7 shows the following proposed commercial application scheme: Cu2+ contaminated waste water and Fe0 powder are continuously fed in to a tank (1) with a paddle mixer (2), the mixture flows through the HSMD (3), during cavitation treatment, Fe0 particles are cemented with Cu0 (i), and then separated and de-agglomerated (ii). The set-up has a multiple number (n) of set tanks, mixers, and HSMD (4). At the end of the process, the suspension with Fe0 and Cu0 flows through a magnetic separator (5) for unreacted Fe0 separation, which is returned to the extraction process via the reactor (1) for mechanical separation by filtration or sedimentation (6) of Cu0. According to a common electrochemical Equation (18), it is also possible to extract Cd, In, Tl, Co, Ni, Sn, Pb, Bi, Cu, Hg, Ag, and Au metals.

where Nn+ is the reduced metal ion (metal with a higher standard potential value), and M0 is metal that carries cementation (metal with a lower standard potential value).

Nn+ + M0 → N0+ Mm+,

Figure 7.

Principal scheme for commercial implementation for Cu extraction from mining waste water: 1—container for suspension; 2—paddle mixer; 3—mixer-disperser; 4—a set of tanks, mixers, and HSMD; 5—magnetic separator; 6—mechanical filter; i—Cu cemented on Fe particles before the cavitation; ii— cemented Cu and Fe particles after the cavitation; Arrows indicating flow directions.

5. Conclusions

Using a high-speed mixer-disperser (HSMD) as the mechanical cavitation source, it is possible to achieve copper extraction from mining wastewater with around 40% higher cementation efficiency, in a significantly faster time than by using the traditional mixing method. After seven minutes, over 95% of copper was cemented on Fe0 powders by applying the HSMD. Morphology and iron powder origins do not play a significant role in metal extraction by the cementation process. The investigated cementation process improvement could be foreseen as a route for obtaining fine powders of copper and other metals (e.g., Cd, In, Tl, Co, Ni, Sn, Pb, Bi, Cu, Hg, Ag, and Au). It could also be used at the industrial scale for mining and metallurgical wastewater purification.

Author Contributions

A.S., J.B., V.M., A.P. and J.B. conceptualized and designed the experiments; A.S., J.B., J.O. and A.P. performed the experiments; A.S., J.B., V.M. and J.O. analyzed the data; A.P. contributed reagents, materials, analysis, and necessary tools; H.V., A.S. and J.O. prepared the original draft; H.V. and P.N. reviewed and completed the final manuscript.

Funding

This research was partly supported by InterOcean Metals Joint Organization, Szczecin, Poland under international grant No. 106 19 0063.

Acknowledgments

This research was supported by COST Action CA15102.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Al-Saydeh, S.A.; El-Naasa, M.H.; Zaidi, S.J. Copper removal from industrial wastewater: A comprehensive review. J. Ind. Eng. Chem. 2017, 56, 35–44. [Google Scholar] [CrossRef]

- Trakal, L.; Šigut, R.; Šillerová, H.; Faturíková, D.; Komárek, M. Copper removal from aqueous solutions using biochar: Effect of chemical activation. Arab. J. Chem. 2014, 7, 43–52. [Google Scholar] [CrossRef]

- Ruyters, S.; Salaets, P.; Oorts, K.; Smolders, E. Copper toxicity in soils under established vineyards in Europe: A survey. Sci. Total Environ. 2013, 443, 470–477. [Google Scholar] [CrossRef] [PubMed]

- Zou, Y.; Wang, X.; Khan, A.; Wang, P.; Liu, Y.; Alsaedi, A.; Hayat, T.; Wang, X. Environmental Remediation and Application of Nanoscale Zero-Valent Iron and Its Composites for the Removal of Heavy Metal Ions: A Review. Environ. Sci. Technol. 2016, 50, 7290–7304. [Google Scholar] [CrossRef] [PubMed]

- Kong, Z.; Li, X.; Tian, J.; Yang, J.; Sun, S. Comparative study on the adsorption capacity of raw and modified litchi pericarp for removing Cu(II) from solutions. J. Environ. Manag. 2014, 134, 109–116. [Google Scholar] [CrossRef] [PubMed]

- Barakat, M.A. New trends in removing heavy metals from industrial wastewater. Arab. J. Chem. 2011, 4, 361–377. [Google Scholar] [CrossRef]

- Babel, S.; Kurniawan, T.A. Various treatment technologies to remove arsenic and mercury from contaminated groundwater: An overview. In Proceedings of the First International Symposium on Southeast Asian Water Environment, Bangkok, Thailand, 24–25 October 2003; pp. 433–440. [Google Scholar]

- Jaishankar, M.; Tsenten, T.; Anbalagan, N.; Mathew, B.B.; Beegegowda, K.N. Toxicity, mechanism and health effects of some heavy metals. Interdiscip. Toxicol. 2014, 7, 60–72. [Google Scholar] [CrossRef] [PubMed]

- Gong, J.L.; Wang, X.Y.; Zeng, G.M.; Chen, L.; Deng, J.H.; Zhang, X.R.; Niu, Q.Y. Copper (II) removal by pectin–iron oxide magnetic nanocomposite adsorbent. Chem. Eng. J. 2012, 185–186, 100–107. [Google Scholar] [CrossRef]

- Burakov, A.E.; Galunin, E.V.; Burakova, I.V.; Kucherova, A.; Agarwal, S.; Tkachev, A.G.; Gupta, V.K. Adsorption of heavy metals on conventional and nanostructured materials for wastewater treatment purposes: A review. Ecotoxicol. Environ. Saf. 2018, 148, 702–712. [Google Scholar] [CrossRef] [PubMed]

- Aydın, H.; Bulut, Y.; Yerlikaya, Ç. Removal of copper (II) from aqueous solution by adsorption onto low-cost adsorbents. J. Environ. Manag. 2008, 87, 37–45. [Google Scholar] [CrossRef] [PubMed]

- El-Ashtoukhy, E.S.; Amin, N.K.; Abdelwahab, O. Removal of lead (II) and copper (II) from aqueous solution using pomegranate peel as a new adsorbent. Desalination 2008, 223, 162–173. [Google Scholar] [CrossRef]

- Femina Carolin, C.; Senthil Kumar, P.; Saravanan, A.; Janet Joshiba, G.; Naushad, M. Efficient techniques for the removal of toxic heavy metals from aquatic environment: A review. J. Environ. Chem. Eng. 2017, 5, 2782–2799. [Google Scholar] [CrossRef]

- Konsowa, A.H. Intensification of the rate of heavy metal removal from wastewater by cementation. Desalination 2010, 254, 29–34. [Google Scholar] [CrossRef]

- Ahmed, I.M.; El-Nadi, Y.A.; Daoud, J.A. Cementation of copper from spent copper-pickle sulfate solution by zinc ash. Hydrometallurgy 2011, 110, 62–66. [Google Scholar] [CrossRef]

- Gross, F.; Baup, S.; Aurousseau, M. Copper cementation on zinc and iron mixtures: Part 1: Results on rotating disc electrode. Hydrometallurgy 2011, 106, 121–133. [Google Scholar] [CrossRef]

- Nosier, S.A.; Alhamed, Y.A.; Alturaif, H.A. Enhancement of copper cementation using ceramic suspended solids under single phase flow. Sep. Purif. Technol. 2007, 52, 454–460. [Google Scholar] [CrossRef]

- Dil, E.A.; Ghaedi, M.; Asfaram, A. The performance of nanorods materials as adsorbent for removal of azodyes and heavy ions: Application of ultrasound wave, optimization and modeling. Ultrason. Sonochem. 2017, 34, 792–802. [Google Scholar] [CrossRef] [PubMed]

- Kanakaraju, D.; Ravichandar, S.; Chin Lim, Y. Combined effects of adsorption and photocatalysis by hybrid TiO2/ZnO-calcium alginate beads for the removal of copper. J. Environ. Sci. 2017, 55, 214–223. [Google Scholar] [CrossRef] [PubMed]

- Su, Y.N.; Lin, W.S.; Hou, C.H.; Den, W. Performance of integrated membrane filtration and electrodialysis processes for copper recovery from wafer polishing wastewater. J. Water Proc. Eng. 2014, 4, 149–158. [Google Scholar] [CrossRef]

- Ferrer, O.; Gibert, O.; Cortina, J.L. Reverse osmosis membrane composition, structure and performance. Water Res. 2016, 103, 256–263. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Xu, Y.C.; Wang, Z.X.; Cheng, X.Q.; Xiao, Y.C.; Shao, L. Positively charged nanofiltration membranes via economically mussel-substance-simulated co-deposition for textile wastewater treatment. Chem. Eng. J. 2016, 303, 555–564. [Google Scholar] [CrossRef]

- Dong, Y.; Liu, J.; Sui, M.; Qu, Y.; Ambuchi, J.J.; Wang, H.; Feng, Y. A combined microbial desalination cell and electrodialysis system for copper-containing wastewater treatment and high-salinity-water desalination. J. Hazard. Mater. 2017, 321, 307–315. [Google Scholar] [CrossRef] [PubMed]

- Satyro, S.; Marotta, R.; Clarizia, L.; Di Somma, I.; Vitiello, G.; Dezotti, M.; Pinto, G.; Dantas, R.F.; Andreozzi, R. Removal of EDDS and copper from waters by TiO2 photocatalysis under simulated UV–solar conditions. Chem. Eng. J. 2014, 251, 257–268. [Google Scholar] [CrossRef]

- Ahmed, M.J.K.; Ahmaruzzaman, M. A review on potential usage of industrial waste materials for binding heavy metal ions from aqueous solutions. J. Water Process Eng. 2016, 10, 39–47. [Google Scholar] [CrossRef]

- Ruihua, L.; Lin, Z.; Tao, T.; Bo, L. Phosphorus removal performance of acid mine drainage from wastewater. J. Hazard. Mater. 2011, 190, 669–676. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, T.A.H.; Ngo, H.H.; Guo, W.S.; Zhang, J.; Liang, S.; Yue, Q.Y.; Li, Q.; Nguyen, T.V. Applicability of agricultural waste and by-products for adsorptive removal of heavy metals from wastewater. Bioresour. Technol. 2013, 148, 574–585. [Google Scholar] [CrossRef] [PubMed]

- Farooq, U.; Kozinski, J.A.; Khan, M.A.; Athar, M. Biosorption of heavy metal ions using wheat based biosorbents—A review of the recent literature. Bioresour. Technol. 2010, 101, 5043–5053. [Google Scholar] [CrossRef] [PubMed]

- Khan, I.; Abbas, A.; Al-Amer, A.M.; Laoui, T.; Al-Marri, M.J.; Nasser, M.S.; Khraisheh, M.; Atieh, M.A. Heavy metal removal from aqueous solution by advanced carbon nanotubes: Critical review of adsorption applications. Sep. Purif. Technol. 2016, 157, 141–161. [Google Scholar] [CrossRef]

- Aktas, S. Cementation of rhodium from waste chloride solutions using copper powder. Int. J. Miner. Process 2012, 114–117, 100–105. [Google Scholar] [CrossRef]

- Aktas, S. Rhodium recovery from rhodium-containing waste rinsing water via cementation using zinc powder. Hydrometallurgy 2001, 106, 71–75. [Google Scholar] [CrossRef]

- Wu, L.K.; Xia, J.; Zhang, Y.F.; Li, Y.Y.; Cao, Z.H.; Zheng, G.Q. Effective cementation and removal of arsenic with copper powder in a hydrochloric acid system. RSC Adv. 2016, 6, 70832–70841. [Google Scholar] [CrossRef]

- Demirkiran, N.; Kunkul, A. Recovering of copper with metallic aluminum. Trans. Nonferrous Met. Soc. China 2001, 21, 2778–2782. [Google Scholar] [CrossRef]

- El-Ashtoukhy, E.-S.Z.; Abdel-Aziz, M.H. Removal of copper from aqueous solutions by cementation in a bubble column reactor fitted with horizontal screens. Int. J. Min. Process. 2013, 121, 65–69. [Google Scholar] [CrossRef]

- Abdel-Aziz, M.H. Production of copper powder from wastewater containing CuSO4 and alcoholic additives in a modified stirred tank reactor by cementation. Hydrometallurgy 2011, 1091, 61–167. [Google Scholar] [CrossRef]

- Polyakov, A.; Polyakova, E.; Lazarenko, L. Mixer-Homogenizer. Latvia Patent LV13592 (B), 20 September 2007. [Google Scholar]

- Polyakov, A.; Polyakova, E. Hydrodynamic cavitation homogenizer. Latvia Patent LV15143 (A), 20 July 2016. [Google Scholar]

- Polyakov, A.; Mironovs, V.; Shishkin, A.; Baronins, J. Preparation of Coal-Water Slurries Using a High—Speed Mixer—Disperser. In Proceedings of the 4th International Scientific Conference Civil Engineering’ 13, Jeglava, Latvia, 16–17 May 2013; pp. 77–81. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).