Abstract

Besides alloying, nanostructuring was implemented to improve the thermoelectric properties in Fe2VAl. This Heusler alloy indeed displays a thermoelectric figure of merit too small for applications (ZT ~ 0.1 at 300 K) which is caused by a large lattice thermal conductivity (λL = 27 W·m−1·K−1 at 300 K). The effect of nanostructuring on the microstructure and on the thermoelectric properties of alloyed Fe2VAl are therefore reviewed. By mechanical alloying followed by spark plasma sintering, the average grain size (D) was decreased to D ~ 300–400 nm in Fe2VAl0.9Si0.1, Fe2VAl0.9Si0.07Sb0.03, Fe2V1.05Al0.95, and Fe2V0.9W0.1Al. As expected, phonon scattering at the numerous grain boundaries lead to a strong decrease in the lattice thermal conductivity, which reached values as small as λL = 3.3 W·m−1·K−1. However, in all the reviewed examples, the thermoelectric figure of merit (ZT) is only marginally or not even improved when comparing to non-nanostructured samples because the electrical resistivity also increases upon nanostructuring. A significantly improved ZT = 0.3 at 500 K was only recently observed in severely deformed Fe2VAl0.95Ta0.05 by high pressure torsion because the very fine microstructure (D ~ 100 nm) strongly enhanced the thermal conductivity reduction.

1. Introduction

Thermoelectric devices can be used either as refrigerators (Peltier effect) or electric power generators (Seebeck effect). Despite their relatively small conversion efficiency, they are commercialized for localized or silent refrigeration and they are considered for powering the wireless sensors required by future applications such as the “Internet of Things” [1] or the “Industry 4.0” [2].

The conversion efficiency of a thermoelectric device (power generator or cooler) is related to the dimensionless figure of merit ZT of its constituting materials. ZT is defined by the expression ZT = (α2/ρ)(T/λ) with α the Seebeck coefficient, ρ the electrical resistivity, λ the thermal conductivity, and T the absolute temperature. Bismuth telluride (Bi2Te3), which is the material currently used in commercialized thermoelectric refrigerators, displays a high dimensionless figure of merit ZT = 1 at 300 K for both n- & p-type doping. Bismuth and tellurium are indeed chemical elements favorable in several ways to high thermoelectric performances. They often form small-gap semi-conducting compounds with a high electronic mobility, which arises from the non-ionic and strongly covalent character of their chemical bonds. The large atomic mass of these two elements also confer to their compounds a small thermal conductivity. However, the cost of tellurium (~150 $/kg) which arises from its scarcity in the Earth’s crust prevents a broader use of Bi2Te3 in applications: a mass-market based on bulk materials incorporating this element is most likely non-sustainable. Cheaper and more abundant thermoelectric materials are thus needed to replace Bi2Te3.

Fe2VAl is the Heusler alloy [3] that could challenge Bi2Te3 as a thermoelectric material. Its constituting chemical elements are inexpensive [4] and it displays a power factor equal to PF = α2/ρ ~ 5 mW·m−1·K−2 at 300 K [5], larger than in Bi2Te3. However, Fe2VAl is not yet a substitute of Bi2Te3 because its thermal conductivity is more than one order of magnitude larger (27 W·m−1·K−1 at 300 K in pristine Fe2VAl) than in Bi2Te3, leading to ZT ~ 0.1. It is thus mandatory to decrease its thermal conductivity to make it competitive with Bi2Te3. The thermal conductivity is the sum of the electronic thermal conductivity (λe) and the lattice thermal conductivity (λL). Once the power factor has been maximized by controlling the charge carrier concentration, the electronic thermal conductivity which varies like the electrical conductivity (Wiedemann-Franz law) cannot be reduced and only the lattice thermal conductivity can be decreased.

Several research paths have been undertaken in the literature to decrease the lattice thermal conductivity in Fe2VAl. The first one relies on scattering of heat carrying phonons by the atomic mass fluctuations which arise when one of the constituting element is substituted by a heavier one [6]. A decrease in the lattice thermal conductivity in alloyed Fe2VAl was first published by Nishino et al. [7] who substituted Al by Si or Ge: it decreased from λL = 27 W·m−1·K−1 at 300 K in Fe2VAl to λL = 15 W·m−1·K−1 in Fe2VAl0.9Si0.1 and λL = 11 W·m−1·K−1 in Fe2VAl0.9Ge0.1 at 300 K. Since then, many other chemical elements have been substituted and even multi-substituted Fe2VAl alloys have been investigated [8]. Most of the data reported in the literature on this subject are compiled in Table 1.

Table 1.

Compilation of published lattice thermal conductivity values, measured at 300 K in substituted Fe2VAl alloys.

One can easily notice in Table 1 that substitution by one or several heavy elements is an efficient way to decrease λL in Fe2VAl since it leads to a −80% reduction. Nonetheless, the lowest value of lattice thermal conductivity achieved in substituted Fe2VAl (5 W·m−1·K−1) is still three times larger than in Bi2Te3 (~1.5 W·m−1·K−1). Nanostructuring has been the other research path which was thus implemented to further decrease λL and it is the goal of this article to review its effect on the thermoelectric properties of Fe2Val.

2. Nanostructured Fe2VAl

Improved performances were observed in thermoelectric materials with strongly reduced grain sizes [16,17]. In these nanostructured materials, the improvement is related to a decrease in the lattice thermal conductivity promoted by enhanced rates of phonons scattering on the numerous grain boundaries induced by their fine microstructure [18,19]. Reductions of λL by 25%, 37%, and 90% at 300 K were for instance observed in n-type Half-Heusler (~200 nm crystals) [20], in n-type filled skutterudites (~150 nm crystals) [21] and in silicon (~20 nm crystals) [22] respectively. Methods such as ball milling (BM) combined with Spark Plasma Sintering (SPS), melt spinning (MS), and high pressure torsion (HPT) were thus implemented in alloyed Fe2VAl, leading to fine-grained samples and to a decrease in the lattice thermal conductivity. Nonetheless, the thermoelectric figure of merit was improved in only very few cases because upon nanostructuration, the electrical resistivity increases as well. In the next sections, a detailed examinations of these results will be presented.

2.1. Synthesis, Microstructure and Thermal Conductivity

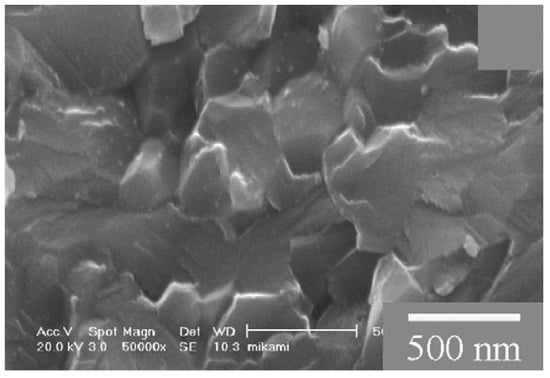

Mikami et al. [23] published the first research work on nanostructured Fe2VAl0.9Si0.1. They mechanically alloyed in a planetary ball mill powders of elemental Fe, V, and Si with a Fe-Al alloy [24] and obtained a powder constituted by a face-centered cubic solid solution of these elements. This powder is a collection of micrometric particles (~7 μm) which agglomerate much smaller nanocrystallites (~20 nm). After spark plasma sintering at temperature ranging between 900 and 1000 °C, this solid solution orders in the L21 structure. The densified samples are polycrystals with an average grain size (D) and a relative density (d) which increase with the sintering temperature and range from D ~ 100 nm to D ~ 400 nm and d = 80% to d = 98% respectively. A scanning electron microscope (SEM) image of the densest sample in Ref. [23] is displayed in Figure 1.

Figure 1.

Scanning electron microscope image of mechanically alloyed and sintered (1000 °C) Fe2VAl0.9Si0.1. Reproduced from [23], with copyright permission from Elsevier, 2008.

As expected, upon reduction of the grain size, the thermal conductivity decreases in Fe2VAl0.9Si0.1. It is nonetheless also decreased by the pores which are present in the samples since their relative density is smaller than 100%. In the present review, in order to account of the porosity and to compare values of thermal conductivity only affected by the grain size reduction, the original Mikami’s data were corrected by the effective medium theory expression of Odelevski [25]: where λmeas is the measured thermal conductivity, d is the relative density and λreal is the value of a 100% dense sample. For average grain sizes ranging from micron-size (arc-melted sample) to D ~ 400 nm and to D ~ 100 nm, the lattice thermal conductivity decreases from λL = 16.5 W·m−1·K−1 to λL = 13.4 W·m−1·K−1 and to λL = 7.9 W·m−1·K−1. Given the large uncertainty on the average grain size, it is difficult to use a model like Nan and Birringer’s [26] to assess more quantitatively the efficiency of phonon scattering by the grain boundaries. Anyway in Mikami’s work, this effect is strong enough to decrease λL by 12% when comparing the densest nanostructured Fe2VAl0.9Si0.1 (d = 98%, D = 400 nm) to the arc-melted (AM) one. Subsequently, by using more energetic conditions at the ball milling stage, a smaller average grain size of D ~ 300 nm was achieved in Fe2VAl0.9Si0.1 by Ref. [27]. This lead to λL = 9.2 W·m−1·K−1, a value even smaller which shows directly the effect of grain boundary scattering on thermal transport.

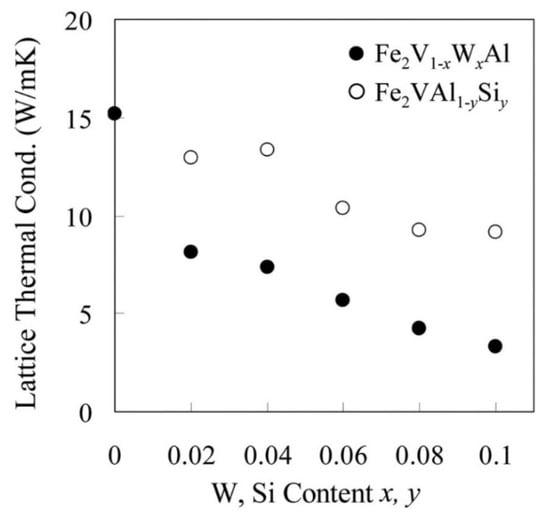

Other compositions than Si-substituted Fe2VAl were also nanostructured by the same techniques: for instance Fe2VAl0.9Si0.07Sb0.03 [28] and Fe2V1−yWyAl (0 ≤ y ≤ 0.1) [27] which displayed average grain sizes similar to the previously cited research works, D ~ 400 nm and D ~ 300 nm, respectively. Figure 2 shows the effect on the lattice thermal conductivity of varying the concentration of W in Fe2V1−yWyAl and compares it to Fe2VAl1−xSix (0 ≤ x ≤ 0.1). It can easily be noticed that substituting W, a heavy 5d element, rather than Si leads to an extra −6 W·m−1·K−1 decrease in the lattice thermal conductivity which is equal to λL = 3.3 W·m−1·K−1 in nanostructured (D ~ 300 nm and d ≥ 98%) Fe2V0.9W0.1Al.

Figure 2.

Lattice thermal conductivity at 300 K in nanostructured Fe2V1−yWyAl and Fe2VAl1−xSix as a function of W or Si concentration. Reproduced from [27], with copyright permission from American Institute of Physics, 2012.

Besides ball milling, high pressure torsion (HPT) followed by annealing was the other technique [29] recently implemented by Masuda et al. to refine the microstructure in alloyed Fe2VAl [30]. Fe2V1.05Al0.95 and Fe2VAl0.95Ta0.05 were the two investigated compositions, which indeed displayed differing properties under these severe deformations. The average grain size in the latter alloy is approximately D ~ 100 nm, a very small value for well densified Fe2VAl, whereas it is D ~ 400 nm in the former alloy. The authors ascribed this effect to a slowdown of the grain boundary migration by the excess Ta segregated at these grain boundaries. Microstrains have also been previously invoked in HPT-treated skutterudites [31] to act as phonon scatterers and to decrease the thermal conductivity. Nonetheless, the strain due to HPT deformation “almost vanished in Fe2VAl0.95Ta0.05 by annealing at 900 K” [30] and its effect on λL can be neglected. Hence, by the combined effect of the grain boundaries and the mass fluctuations arising from the substitution of heavy Ta, the lattice thermal conductivity is decreased to λL = 3.2 W·m−1·K−1, a value nearly 10 times smaller than in pristine Fe2VAl.

Finally, grain boundaries are not the only interface which can scatter phonons: antiphase boundaries separating antiphase domain have newly been shown to decrease the lattice thermal conductivity in Fe2Val [32]. Rapidly quenching Fe2VAl from temperatures where its disordered B2 or A2 variants are stable, allowed stabilizing a nanostructured variant of Fe2VAl. It is constituted by L21 antiphase domains (APDs) separated by antiphase boundaries (APBs), which indeed scatter the phonons. When domains as small as ~100 nm are synthesized, the lattice thermal conductivity is decreased from 28 to 17 W·m−1·K−1 [32].

2.2. Electronic Transport Properties and ZT

In all the previously cited references [23,27,28,30], despite differing compositions, the Seebeck coefficient peaks as a function of temperature (200–500 K) at the same value, e.g., ~ −130 μV·K−1. This is due to the well-established fact that the Seebeck coefficient in most cases does not depend on the exact nature of the dopant but depends on the charge carrier concentrations. Since this last parameter is weakly affected by the modifications of the microstructure, the Seebeck coefficient is also hardly modified and it does not influence the figure of merit.

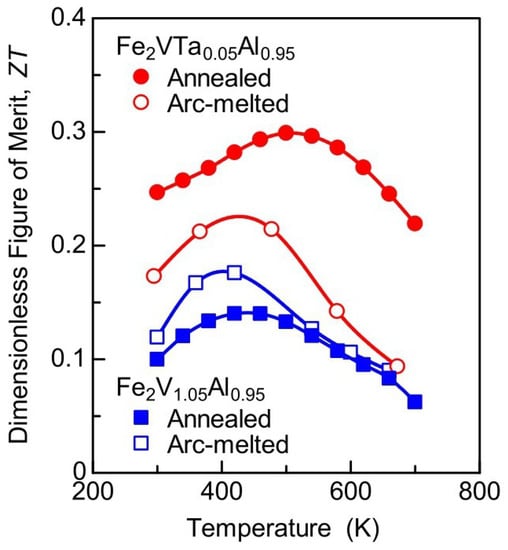

But the electrical resistivity is not immune to the changes of microstructure because grain boundaries also scatter electrons. In all the previously cited references, as can be noticed in Table 2 when comparing to arc melted samples displaying micrometric grain sizes, resistivity systematically increases when the grain sizes decreases. This compensates the reduction of lattice thermal conductivity previously discussed and hence ZT only marginally increases when the grain size is decreased to D ~ 400 nm. In an attempt to circumvent this effect, Mikami et al. synthesized Fe2VAl0.9Si0.1 + Bi nanocomposites but they did not improve ZT [33]. As can be seen in Figure 3, it is only very recently that, in severely deformed (HPT) and annealed Fe2VAl0.95Ta0.05, the strong decrease in λL arising from the very small D ~ 100 nm grain size overcomes the increase in electrical resistivity and leads to the improved value of figure of merit ZT = 0.3 (+50%) at 500 K. This last example shows that nanostructring is a promising research path, which leads to improvements of ZT in alloyed Fe2VAl and that it deserves to be pursued in the next future.

Table 2.

Average grain size (D), thermal, and electronic transport properties in various nanostructured and substituted Fe2VAl alloys at 300 K except ZTmax which is the maximum value of the dimensionless thermoelectric figure of merit as a function of temperature. “AM” stands for arc melted.

Figure 3.

Dimensionless thermoelectric figure of merit as a function of temperature in Fe2V1.05Al0.95 and in Fe2VAl0.95Ta0.05. “Annealed” means severely deformed by HPT, followed by annealing. Reproduced from [30], with copyright permission from American Institute of Physics, 2012.

3. Conclusions

Ball milling or high pressure torsion lead to nanometric grain size in alloyed Fe2VAl. The heat carrying phonons are not only scattered by the mass fluctuations provided by alloying but also by the numerous grain boundaries introduced in the microstructure. The lattice thermal conductivity is thus strongly decreased but in most of the reviewed cases, the electrical resistivity is also increased by the refined microstructure and this precludes any gain of ZT. Nonetheless, in severely deformed Fe2VAl0.95Ta0.05 with D ~ 100 nm [30], the strong decrease in the lattice thermal conductivity overcompensate the electrical resistivity increase and an improved ZT = 0.3 is reached at 500 K. These promising results will certainly be followed by similar research effort to improve ZT by nanostructuring Fe2VAl.

Conflicts of Interest

The author declares no conflict of interest.

References

- Wikipedia. Internet of Things. Available online: https://en.wikipedia.org/wiki/Internet of things (accessed on 18 October 2018).

- Wikipedia. Industry 4.0. Available online: https://en.wikipedia.org/wiki/Industry_4.0 (accessed on 18 October 2018).

- Felser, C.; Hirohata, A. Heusler Alloys; Springer: Cham, Switzerland, 2016; Volume 222. [Google Scholar]

- Ferrovanadium Price. Available online: https://minerals.usgs.gov/minerals/pubs/commodity/vanadium/mcs-2018-vanad.pdf (accessed on 18 October 2018).

- Kato, H.; Kato, M.; Nishino, Y.; Mizutani, U.; Asano, S. Effect of Silicon Substitution on Thermoelectric Properties of Heusler-type Fe2VAl Alloy. J. Jpn. Inst. Met. 2001, 65, 652–656. [Google Scholar] [CrossRef]

- Bhandari, C.M. Minimizing the Thermal Conductivity. In CRC Handbook of Thermoelectrics; Rowe, D.M., Ed.; CRC Press: Boca Raton, FL, USA, 1995. [Google Scholar]

- Nishino, Y.; Deguchi, S.; Mizutani, U. Thermal and transport properties of the Heusler-type Fe2VAl1−xGex (0 < x < 0.20) alloys: Effect of doping on lattice thermal conductivity, electrical resistivity, and Seebeck coefficient. Phys. Rev. B 2006, 74, 115115. [Google Scholar]

- Takeuchi, T.; Terazawa, Y.; Furuta, Y.; Yamamoto, A.; Mikami, M. Effect of Heavy Element Substitution and Off-Stoichiometric Composition on Thermoelectric Properties of Fe2VAl-Based Heusler Phase. J. Electron. Mater. 2013, 42, 2084–2090. [Google Scholar] [CrossRef]

- Kobayashi, F.; Ide, N.; Nishino, Y. Effects of Re Substitution on Thermoelectric Properties of Pseudogap System Fe2VAl. J. Jpn. Inst. Met. 2007, 71, 208–212. [Google Scholar] [CrossRef]

- Kurosaki, K.; Muta, H.; Endo, Y.; Charoenphakdee, A.; Uno, M.; Yamanaka, S. Effect of Nb substitution for V on the thermoelectric properties of Fe2VAl. J. Alloys Compd. 2009, 486, 507–510. [Google Scholar] [CrossRef]

- Mori, T.; Ide, N.; Nishino, Y. Thermoelectric Properties of p-Type Fe2V1−x−yTixTayAl Alloys. J. Jpn. Inst. Met. 2008, 72, 593–598. [Google Scholar] [CrossRef]

- Renard, K.; Mori, A.; Yamada, Y.; Tanaka, S.; Miyazaki, H.; Nishino, Y. Thermoelectric properties of the Heusler-type Fe2VTaxAl1−x alloys. J. Appl. Phys. 2014, 115, 033707. [Google Scholar] [CrossRef]

- Lu, W.; Zhang, W.; Chen, L. Thermoelectric properties of (Fe1−xCox)2VAl Heusler-type compounds. J. Alloys Compd. 2009, 484, 812–815. [Google Scholar] [CrossRef]

- Knapp, I.; Budinska, B.; Milosavljevic, D.; Heinrich, P.; Khmelevskyi, S.; Moser, R.; Podloucky, R.; Prenninger, P.; Bauer, E. Impurity band effects on transport and thermoelectric properties of Fe2−xNixVAl. Phys. Rev. B 2017, 96, 045204. [Google Scholar] [CrossRef]

- Sugiura, T.; Nishino, Y. Doping Effects of Transition Metals on Thermoelectric Properties of Off-Stoichiometric Fe2VAl Alloys. J. Jpn. Inst. Met. 2009, 73, 846–851. [Google Scholar] [CrossRef]

- Poudel, B.; Hao, Q.; Ma, Y.; Lan, Y.; Minnich, A.; Yu, B.; Yan, X.; Wang, D.; Muto, A.; Vashace, D.; et al. High thermoelectric performance of nanostructured bismuth antimony telluride bulk alloys. Science 2008, 320, 634–638. [Google Scholar] [CrossRef] [PubMed]

- Joshi, G.; Lee, H.; Lan, Y.; Wang, X.; Zhu, G.; Wang, D.; Gould, R.W.; Cuff, D.C.; Tang, M.Y.; Dresselhaus, M.S.; et al. Enhanced Thermoelectric Figure-of-Merit in Nanostructured p-type Silicon Germanium Bulk Alloys. Nano Lett. 2008, 8, 4670–4674. [Google Scholar] [CrossRef] [PubMed]

- Minnich, A.J.; Dresselhaus, M.S.; Ren, Z.F.; Chen, G. Bulk nanostructured thermoelectric materials: Current research and future prospects. Energy Environ. Sci. 2009, 2, 466–479. [Google Scholar] [CrossRef]

- Vineis, C.J.; Shakouri, A.; Majumdar, A.; Kanatzidis, M.G. Nanostructured Thermoelectrics: Big Efficiency Gains from Small Features. Adv. Mater. 2010, 22, 3970–3980. [Google Scholar] [CrossRef] [PubMed]

- Joshi, G.; Yan, X.; Wang, H.; Liu, W.; Chen, G.; Ren, Z. Enhancement in Thermoelectric Figure-of-Merit of an N-Type Half-Heusler Compound by the Nanocomposite Approach. Adv. Energy Mater. 2011, 1, 643–647. [Google Scholar] [CrossRef]

- Benyahia, M.; Ohorodniichuk, V.; Leroy, E.; Dauscher, A.; Lenoir, B.; Alleno, E. High thermoelectric figure of merit in mesostructured In0.25Co4Sb12 n-type skutterudite. J. Alloys Compd. 2018, 735, 1096–1104. [Google Scholar] [CrossRef]

- Bux, S.K.; Blair, R.G.; Gogna, P.K.; Lee, H.; Chen, G.; Dresselhaus, M.S.; Kaner, R.B.; Fleurial, J.P. Nanostructured Bulk Silicon as an Effective Thermoelectric Material. Adv. Funct. Mater. 2009, 19, 2445–2452. [Google Scholar] [CrossRef]

- Mikami, M.; Matsumoto, A.; Kobayashi, K. Synthesis and thermoelectric properties of microstructural Heusler Fe2VAl alloy. J. Alloys Compd. 2008, 461, 423–426. [Google Scholar] [CrossRef]

- Kamiya, N.; Ozaki, K.; Kobayashi, K.; Ozaki, K.; Mikami, H. Heusler iron-Based Thermoelectric Powder and Manufacture of Heusler Iron-Based Thermoelectric Material. Patent No. JP2011233797A, 17 November 2011. [Google Scholar]

- Odelevskii, V.I. Calculation of general conductivity of heterogeneous systems II. Random mixtures of non-elongated particles. J. Tech. Phys. 1951, 21, 678–685. [Google Scholar]

- Nan, C.-W.; Birringer, R. Determining the Kapitza resistance and the thermal conductivity of polycrystals: A simple model. Phys. Rev. B 1998, 57, 8264–8268. [Google Scholar] [CrossRef]

- Mikami, M.; Kinemuchi, Y.; Ozaki, K.; Terazawa, Y.; Takeuchi, T. Thermoelectric properties of tungsten-substituted Heusler Fe2VAl alloy. J. Appl. Phys. 2012, 111, 093710. [Google Scholar] [CrossRef]

- Mikami, M.; Tanaka, S.; Kobayashi, K. Thermoelectric properties of Sb-doped Heusler Fe2VAl alloy. J. Alloys Compd. 2009, 484, 444–448. [Google Scholar] [CrossRef]

- Zhilyaev, A.P.; Langdon, T.G. Using high-pressure torsion for metal processing: Fundamentals and applications. Prog. Mater. Sci. 2008, 53, 893–979. [Google Scholar] [CrossRef]

- Masuda, S.; Tsuchiya, K.; Qiang, J.; Miyazaki, H.; Nishino, Y. Effect of high-pressure torsion on the microstructure and thermoelectric properties of Fe2VAl-based compounds. J. Appl. Phys. 2018, 124. [Google Scholar] [CrossRef]

- Zhang, L.; Grytsiv, A.; Bonarski, B.; Kerber, M.; Setman, D.; Schafler, E.; Rogl, P.; Bauer, E.; Hilscher, G.; Zehetbauer, M. Impact of high pressure torsion on the microstructure and physical properties of Pr0.67Fe3CoSb12, Pr0.71Fe3.5Ni0.5Sb12, and Ba0.06Co4Sb12. J. Alloys Compd. 2010, 494, 78–83. [Google Scholar] [CrossRef]

- Maier, S.; Perrière, L.; Bourgon, J.; Leroy, E.; Beaudhuin, M.; Alleno, E. Phonon scattering by antiphase boundaries in the Fe2VAl Heusler alloy. 2018; under review. [Google Scholar]

- Mikami, M.; Kobayashi, K. Effect of Bi addition on microstructure and thermoelectric properties of Heusler Fe2VAl sintered alloy. J. Alloys Compd. 2008, 466, 530–534. [Google Scholar] [CrossRef]

© 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).