Comparing the Structure and Mechanical Properties of Welds on Ductile Cast Iron (700 MPa) under Different Heat Treatment Conditions

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sibodur® 700-10

2.2. Sample Preparation

2.3. Sample Reference Coding

- CP—Sample number;

- x—Pre-heating cycle temperature (°C);

- y—Post-welding heat treatment cycle temperature (°C);

- 1st P—First pre-weld heat cycle, at temperature x (x is equal to zero if no heat cycle is used);

- N—Pre-addition of nickel to chamfered edge (N only appears when nickel is used);

- 2nd P—Second pre-weld heat cycle, at temperature x (x is equal to zero if no heat cycle is used);

- W—Welding, with Inconel as FM;

- z—Number of weld passes;

- 3rd P—Post-weld heat cycle, at temperature y (y is equal to zero if no heat cycle is used).

2.4. Heating Cycle Parameters

2.5. Welding Parameters

2.6. Sample Parameters

2.7. Weld Joint Analysis

3. Results

3.1. Tensile Test Results

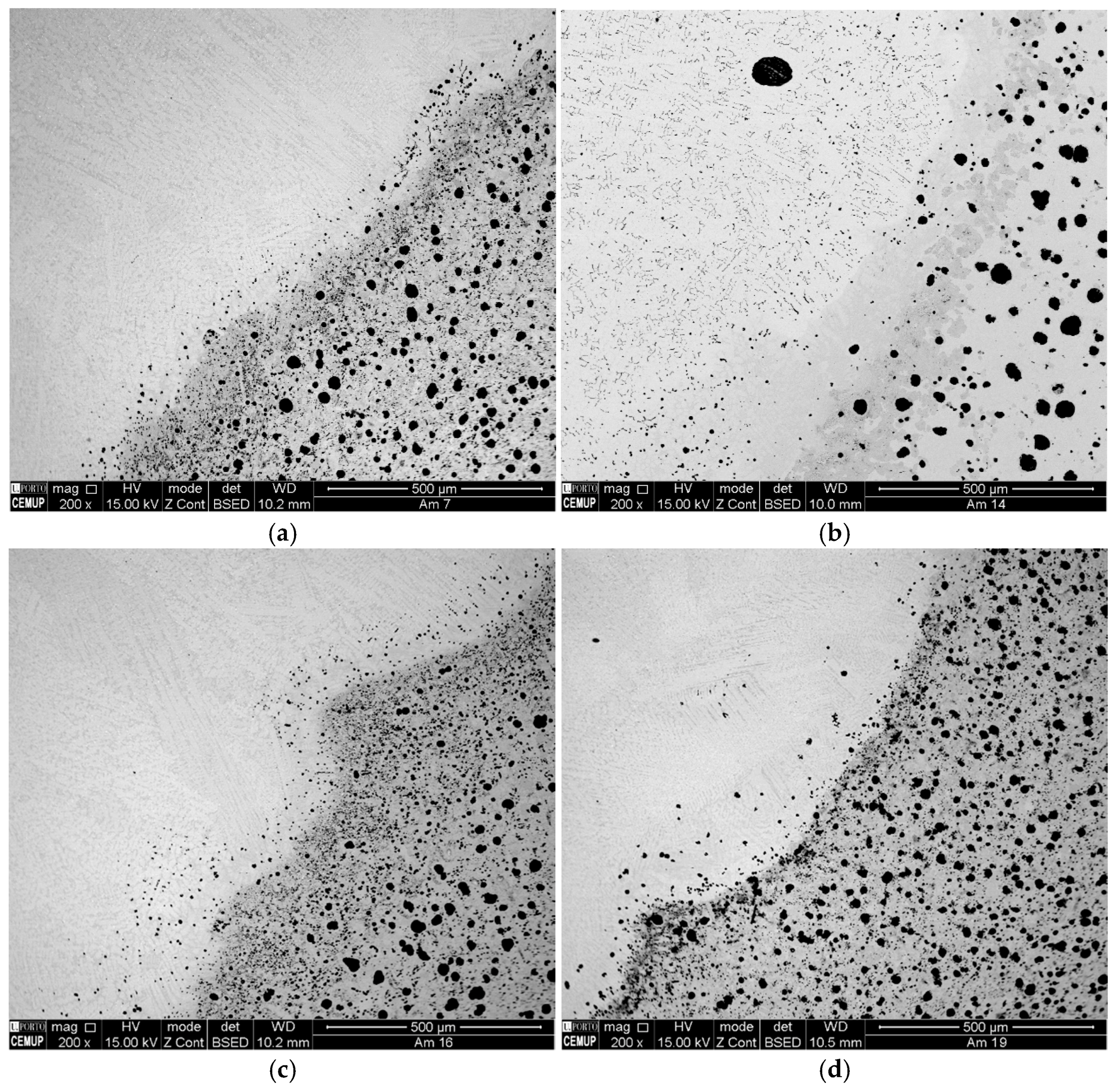

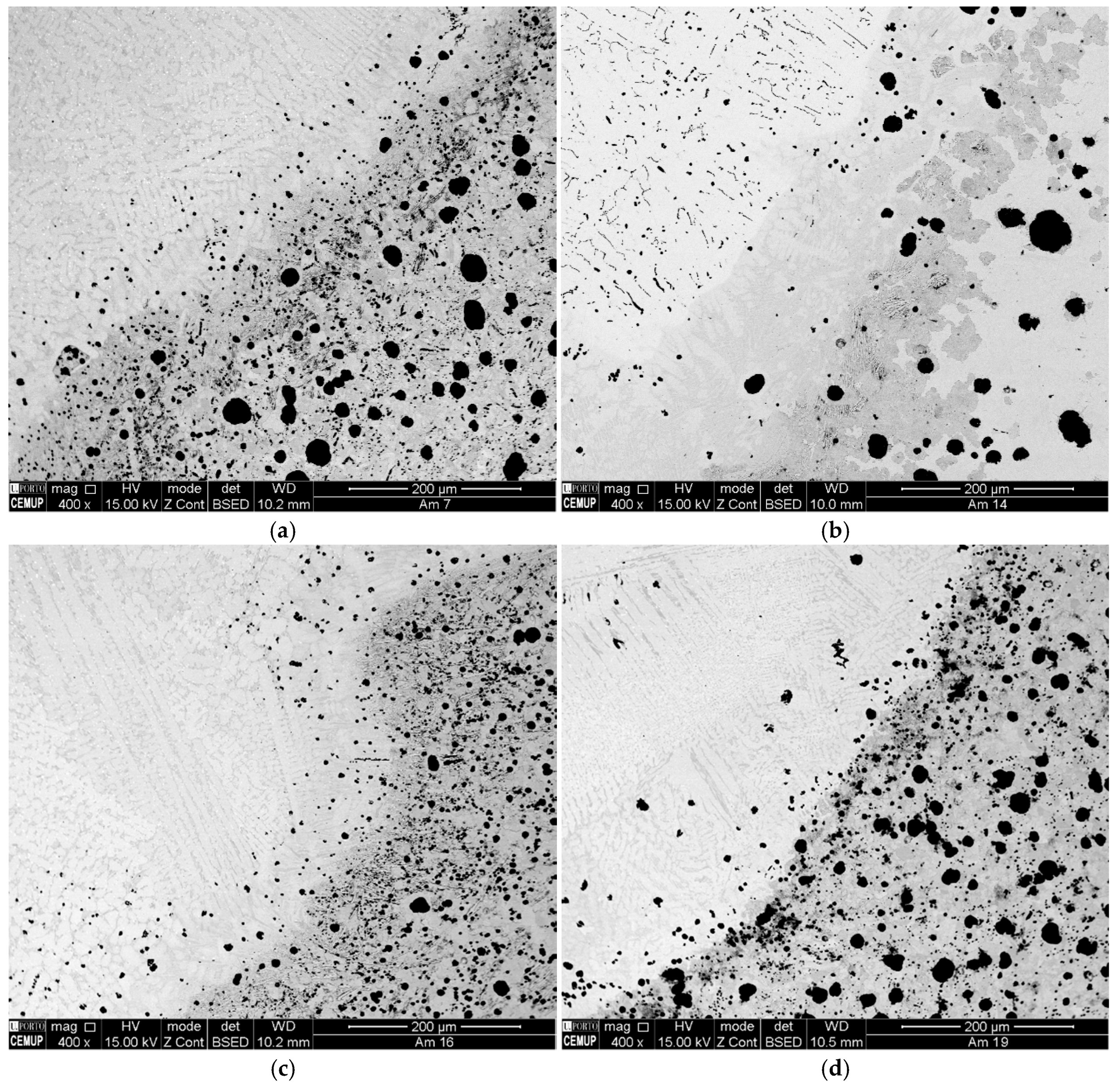

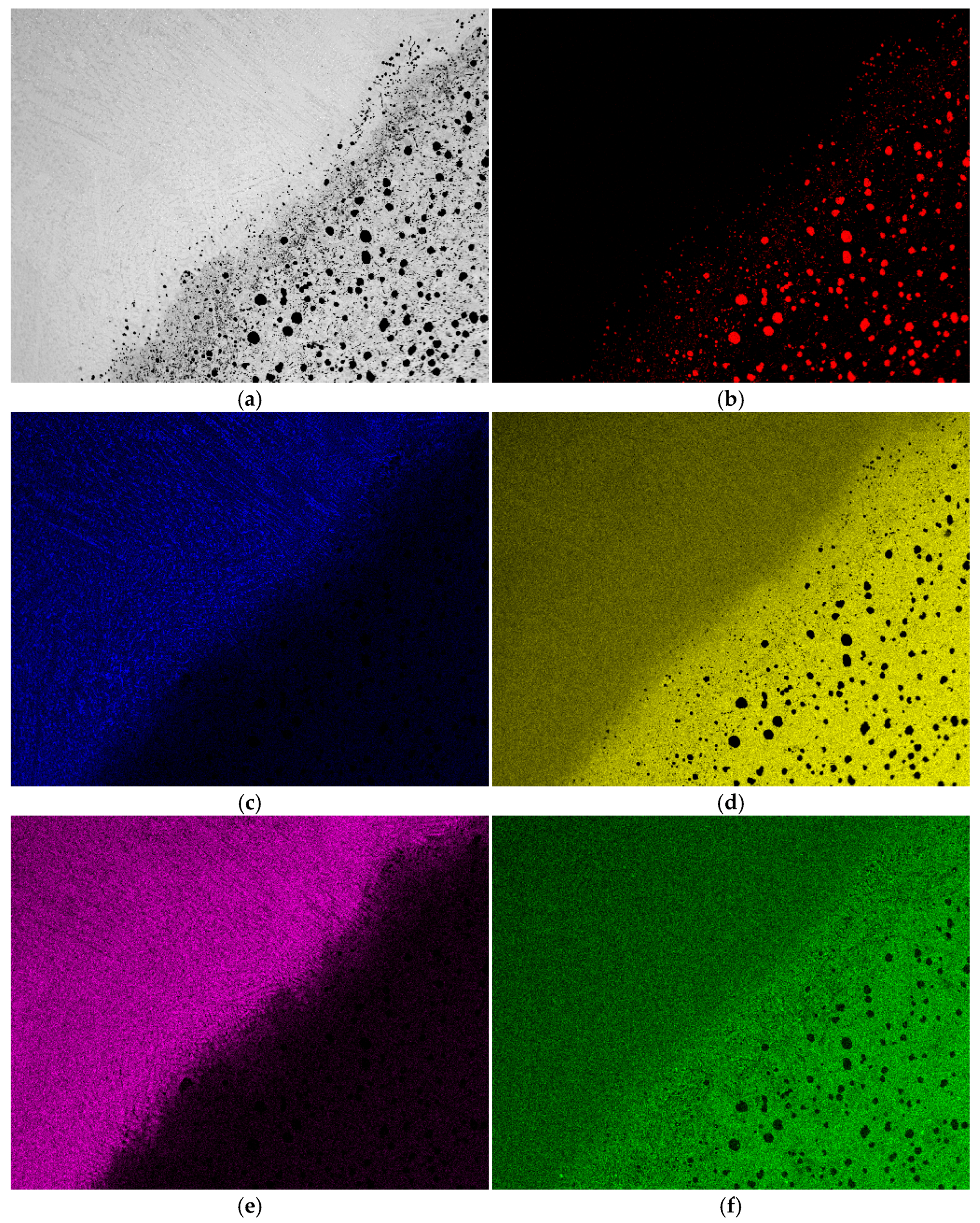

3.2. Metallography Inspection

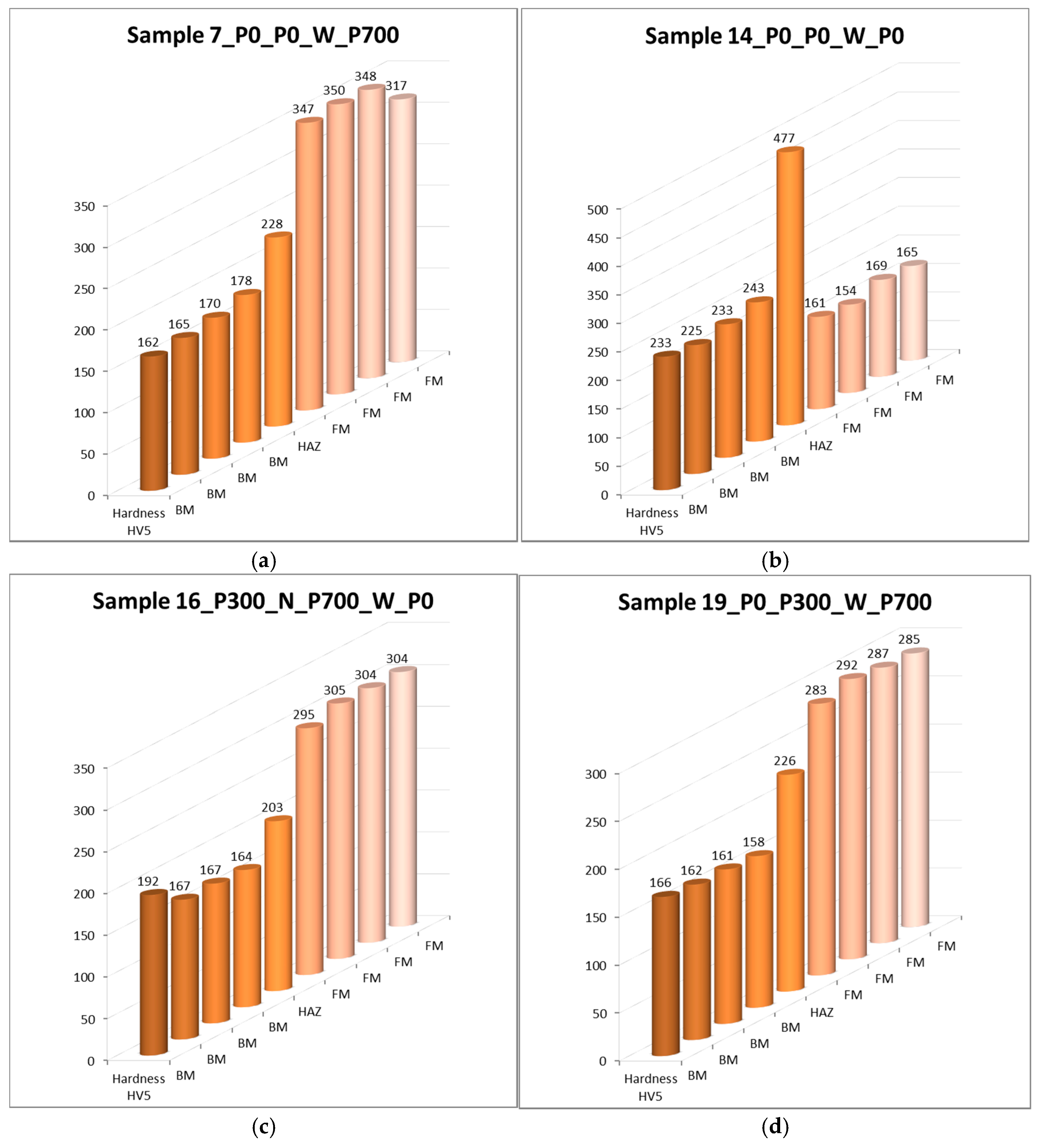

3.3. Hardness Test Results

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Arabi-Jeshvaghani, R.; Shamanian, M.; Jaberzadeh, M. Enhancement of wear resistance of ductile iron surface alloyed by stellite 6. Mater. Des. 2011, 32, 2028–2033. [Google Scholar] [CrossRef]

- Iacoviello, F.; Di Cocco, V. Influence of the graphite elements morphology on the fatigue crack propagation mechanisms in a ferritic ductile cast iron. Eng. Fract. Mech. 2016, 167, 248–258. [Google Scholar] [CrossRef]

- Hütter, G.; Zybell, L.; Kuna, M. Micromechanisms of fracture in nodular cast iron: From experimental findings towards modeling strategies—A review. Eng. Frac. Mech. 2015, 144, 118–141. [Google Scholar] [CrossRef]

- Kolukisa, S. The effect of the welding temperature on the weldability in diffusion welding of martensitic (AISI 420) stainless steel with ductile (spheroidal graphite-nodular) cast iron. J. Mater. Process. Technol. 2007, 186, 33–36. [Google Scholar] [CrossRef]

- Blackmore, P.; Morton, K. Structure-property relationships in graphitic cast irons. Int. J. Fatigue 1982, 4, 149–155. [Google Scholar] [CrossRef]

- Davis, J. ASM Specialty Handbook: Cast Iron; ASM International: Geauga County, OH, USA, 1996; ISBN 978-0-87170-564-8. [Google Scholar]

- Cavallini, M.; Di Bartolomeo, O.; Iacoviello, F. Fatigue crack propagation damaging micromechanisms in ductile cast irons. Eng. Fract. Mech. 2008, 75, 694–704. [Google Scholar] [CrossRef]

- Konecna, R.; Nicoletto, G.; Bubenko, L.; Fintová, S. A comparative study of the fatigue behavior of two heat-treated nodular cast irons. Eng. Fract. Mech. 2013, 108, 251–262. [Google Scholar] [CrossRef]

- Mirhedayatian, S.; Vahdat, S.; Jelodar, M.; Saen, R. Welding process selection for repairing nodular cast iron engine block by integrated fuzzy data envelopment analysis and TOPSIS approaches. Mater. Des. 2013, 43, 272–282. [Google Scholar] [CrossRef]

- Chaengkham, P.; Srichandr, P. Continuously cast ductile iron: Processing, structures, and properties. J. Mater. Process. Technol. 2011, 211, 1372–1378. [Google Scholar] [CrossRef]

- Collini, L.; Pirondi, A.; Bianchi, R.; Cova, M.; Milella, P. Influence of casting defects on fatigue crack initiation and fatigue limit of ductile cast iron. Procedia Eng. 2011, 10, 2898–2903. [Google Scholar] [CrossRef]

- Ferro, P.; Lazzarin, P.; Berto, F. Fatigue properties of ductile cast iron containing chunky graphite. Mater. Sci. Eng. A 2012, 554, 122–128. [Google Scholar] [CrossRef]

- Collini, L.; Pirondi, A. Fatigue crack growth analysis in porous ductile cast iron microstructure. Int. J. Fatigue 2014, 62, 258–265. [Google Scholar] [CrossRef]

- Iacoviello, F.; Di Cocco, V. Degenerated graphite nodules influence on fatigue crack paths in a ferritic ductile cast iron. Frat. Integritá Strutt. 2015, 9, 406–414. [Google Scholar]

- Sun, D.; Gu, X.; Liu, W.; Xuan, Z. Welding consumable research for austempered ductile iron (ADI). Mater. Sci. Eng. A 2005, 402, 9–15. [Google Scholar] [CrossRef]

- Automotive, G.F. Ductile Iron: SiboDur® and GJS Family. Material Data Sheets, Research and Development; Georg Fischer Automotive: Schaffhausen, Switzerland, 2015. [Google Scholar]

- Santos, J.; Gouveia, R.; Silva, F. Designing a new sustainable approach to the change for lightweight materials in structural components used in truck industry. J. Clean. Prod. 2017, 164, 115–123. [Google Scholar] [CrossRef]

- Pascual, M.; Cembrero, J.; Salas, F.; Pascual-Martínez, M. Analysis of the weldability of ductile iron. Mater. Lett. 2008, 62, 1359–1362. [Google Scholar] [CrossRef]

- Askary-Paykani, M.; Shayan, M.; Shamanian, M. Weldability of Ferritic Ductile Cast Iron Using Full Factorial Design of Experiment. J. Iron Steel Res. Int. 2014, 21, 252–263. [Google Scholar] [CrossRef]

- El-Banna, E.; Nageda, M.; El-Saadat, M. Study of restoration by welding of pearlitic ductile cast iron. Mater. Lett. 2000, 42, 311–320. [Google Scholar] [CrossRef]

- Winiczenko, R.; Salat, R.; Awtoniuk, M. Estimation of tensile strength of ductile iron friction welded joints using hybrid intelligent methods. Trans. Nonferr. Met. Soc. China 2013, 23, 385–391. [Google Scholar] [CrossRef]

- Ebrahimnia, M.; Ghaini, F.; Gholizade, S.; Salari, M. Effect of cooling rate and powder characteristic on the soundness of heat affected zone in powder welding of ductile cast iron. Mater. Des. 2012, 33, 551–556. [Google Scholar] [CrossRef]

- El-Banna, E. Effect of preheat on welding of ductile cast iron. Mater. Lett. 1999, 41, 20–26. [Google Scholar] [CrossRef]

- Gouveia, R.; Silva, F.; Paiva, O.; Andrade, M.; Silva, L.; Moselli, P.; Papis, K. Study of the Heat-Treatments Effect on High Strength Ductile Cast Iron Welded Joints. Metals 2017, 7, 382. [Google Scholar] [CrossRef]

- Pouranvari, M. On the weldability of grey cast iron using nickel based filler metal. Mater. Des. 2010, 31, 3253–3258. [Google Scholar] [CrossRef]

- Pascual, M.; Ferrer, C.; Rayón, E. Weldability of spheroidal graphite ductile cast iron using Ni/Ni-Fe electrodes. In Revista de Metalurgia; Departmento de Publicaciones del CSIC: Madrid, Spain, 2009; Volume 45, pp. 334–338. [Google Scholar]

- Xu, G.; Kutsuna, M.; Liu, Z.; Zhang, H. Characteristics of Ni-based coating layer formed by laser and plasma cladding processes. Mater. Sci. Eng. A. 2006, 417, 63–72. [Google Scholar] [CrossRef]

- Kesavan, D.; Kamaraj, M. The microstructure and high temperature wear performance of a nickel base hardfaced coating. Surf. Coat. Technol. 2010, 204, 4034–4043. [Google Scholar] [CrossRef]

- Kelly, J.; Bishel, R.; Wilson, R. Welding of Ductile Iron with Ni-Fe-Mn Filler Metal. Weld. Res. Suppl. 1985, 1, 79s–85s. [Google Scholar]

- Connor, L.P. Welding technology. In Welding Hand Book, 8th ed.; American Welding Society: Miami, FL, USA, 1987; Volume 1, pp. 169–178. ISBN 978-0871712813. [Google Scholar]

| Base Material Mechanical Properties | |||

|---|---|---|---|

| Ultimate Yield Strength (rm) | ≥700 n/mm2 | Hardness (hb) | 240–290 HBW |

| Offset Yield Strength (rp0.2) | ≥440 n/mm2 | Density (ρ) | 6.9 (600 °C) g/cm3 |

| Strain (a) | ≥6–12% | Iso-v Notch Impact (ak) | 2 (−40 °C) 5 (RT 1) J/cm2 |

| Offset Compressive Strength (σd0.2) | ≥370 n/mm2 | Thermal Expansion Coefficient | 11.8 (20–10 °C) 13.7 (20–60°C) 10−6/K |

| Shear Stress (tab) | ≥545 n/mm2 | Specific Thermal Capacity | 0.52 (100 °C) 0.73 (600 °C) J/(g·K) |

| Young’s Modulus (e) | 176 (RT1) 154 (400 °C) kn/mm2 | Specific Electrical Resistivity | 0.62 (RT 1) 0.77 (600 °C) µΩ·m |

| Shear Modulus (g) | 68 kn/mm2 | Thermal Conductivity | 28.8 (100 °C) 26.5 (600 °C) W/(K·m) |

| Sample Reference | Parameters/Sequence | ||||

|---|---|---|---|---|---|

| 1st Pre-Weld Heat Cycle | Ni Edge Weld Deposition | 2nd Pre-Weld Heat Cycle | Inconel Joint Welding | Post-Weld Heat Cycle | |

| 1_P300_N_P300_W_P0 | 300 °C/2 h | 60 A/2 passes | 300 °C/2 h | 80 A/2 passes | - |

| 2_P300_N_P300_W_P0 | |||||

| 3_P300_N_P300_W_P0 | |||||

| 4_P700_N_P700_W_P0 | 700 °C/2 h | 60 A/2 passes | 700 °C/2 h | 80 A/2 passes | - |

| 5_P700_N_P700_W_P0 | |||||

| 6_P700_N_P700_W_P0 | |||||

| 7_P0_P0_W_P700 | - | - | - | 80 A/2 passes | 700 °C/2 h * |

| 8_P0_P0_W_P700 | |||||

| 9_P0_P0_W_P700 | |||||

| 10_P0_P0_W_P800 | - | - | - | 80 A/2 passes | 800 °C/2 h * |

| 11_P0_P0_W_P800 | |||||

| 12_P0_P0_W_P800 | |||||

| 13_P0_P0_W_P0 | - | - | - | 80 A/2 passes | - |

| 14_P0_P0_W_P0 | |||||

| 15_P0_P0_W_P0 | |||||

| 16_P300_N_P700_W_P0 | 300 °C/2 h | 60 A/2 passes | 700 °C/2 h | 80 A/2 passes | - |

| 17_P300_N_P700_W_P0 | |||||

| 18_P300_N_P700_W_P0 | |||||

| 19_P0_P300_W_P700 | - | - | 300 °C/2 h | 80 A/2 passes | 700 °C/2 h * |

| 20_P0_P300_W_P700 | |||||

| 21_P0_P300_W_P700 | |||||

| Test Procedure | Standard |

|---|---|

| Visual inspection | ISO 17633 (2003) |

| Penetrating dye | ISO 23277 (2015) |

| Magnetic particle | ISO 23278 (2009) |

| Tensile testing | ISO 4136 (2012) |

| Hardness testing | ISO 9015-1 (2001) |

| Metallographic analysis | ISO 17639 (2003) |

| Sample Reference | Tensile Test Results | |||

|---|---|---|---|---|

| UTS (MPa) | Average UTS (MPa) | Strain (%) | Average Strain (%) | |

| BM_1 | 687.0 | 667.3 ± 17.62 | 19.5 | 17.7 ± 2.62 |

| BM_2 | 644.2 | 14.0 | ||

| BM_3 | 670.7 | 19.7 | ||

| 1_P300_N_P300_W_P0 | 270.6 | 256.4 ± 10.55 | 5.01 | 5.3 ± 1.00 |

| 2_P300_N_P300_W_P0 | 245.4 | 4.43 | ||

| 3_P300_N_P300_W_P0 | 253.1 | 6.44 | ||

| 4_P700_N_P700_W_P0 | 377.1 | 350.9 ± 26.21 | 9.31 | 8.2 ± 1.16 |

| 5_P700_N_P700_W_P0 | 321.6 | 7.03 | ||

| 6_P700_N_P700_W_P0 | 353.8 | 8.31 | ||

| 7_P0_P0_W_P700 | 434.7 | 399.1 ± 35.57 | 11.1 | 9.0 ± 2.14 |

| 8_P0_P0_W_P700 | 360.5 | 6.82 | ||

| 9_P0_P0_W_P700 | 402.1 | 8.91 | ||

| 10_P0_P0_W_P800 | 174.0 | 210.5 ± 34.51 | 3.24 | 3.8 ±0.62 |

| 11_P0_P0_W_P800 | 245.5 | 4.43 | ||

| 12_P0_P0_W_P800 | 212.0 | 3.71 | ||

| 13_P0_P0_W_P0 | 335.6 | 334.2 ± 11.21 | 4.32 | 4.3 ± 0.40 |

| 14_P0_P0_W_P0 | 344.7 | 4.72 | ||

| 15_P0_P0_W_P0 | 322.4 | 3.94 | ||

| 16_P300_N_P700_W_P0 | 401.8 | 361.4 ± 28.67 | 10.2 | 8.6 ± 1.09 |

| 17_P300_N_P700_W_P0 | 338.5 | 7.70 | ||

| 18_P300_N_P700_W_P0 | 343.9 | 7.92 | ||

| 19_P0_P300_W_P700 | 405.7 | 387.6 ± 18.12 | 9.61 | 8.4 ± 1.22 |

| 20_P0_P300_W_P700 | 371.5 | 7.23 | ||

| 21_P0_P300_W_P700 | 385.5 | 8.30 | ||

| Sample Groups | UTS | % UTS * (%) | Strain (%) | % Strain (%) * |

|---|---|---|---|---|

| BM | 667.3 | - | 17.7 | - |

| P0_P0_W_P700 | 399.1 | 59.8 | 9.02 | 50.8 |

| P0_P300_W_P700 | 387.6 | 58.1 | 8.41 | 47.5 |

| P300_N_P700_W_P0 | 361.4 | 54.2 | 8.60 | 48.6 |

| P700_N_P700_W_P0 | 350.9 | 52.6 | 8.23 | 46.3 |

| P0_P0_W_P0 | 334.2 | 50.1 | 4.72 | 26.6 |

| P300_N_P300_W_P0 | 256.4 | 38.4 | 5.30 | 29.9 |

| P0_P0_W_P800 | 210.5 | 31.5 | 3.81 | 21.5 |

| Group of Parameters | Average UTS (MPa) | Average Strain (%) | 1st Pre-Weld Heat Cycle | Ni Edge Weld Deposition | 2nd Pre-Weld Heat Cycle | Inconel Joint Welding | Post-Welding Heat Treatment (PWHT) |

|---|---|---|---|---|---|---|---|

| BM | 667.3 | 17.7 | - | - | - | - | - |

| P0_P0_W_P700 | 399.1 | 9.03 | - | - | - | 80 A/2 passes | 700 °C/2 h |

| P0_P300_W_P700 | 387.6 | 8.41 | - | - | 300 °C/2 h | 80 A/2 passes | 700 °C/2 h |

| P300_N_P700_W_P0 | 361.4 | 8.60 | 300 °C/2 h | 60 A | 700 °C/2 h | 80 A/2 passes | - |

| P700_N_P700_W_P0 | 350.9 | 8.22 | 700 °C/2 h | 60 A | 700 °C/2 h | 80 A/2 passes | - |

| P0_P0_W_P0 | 334.2 | 4.71 | - | - | - | 80 A/2 passes | - |

| P300_N_P300_W_P0 | 256.4 | 5.32 | 300 °C/2 h | 60 A | 300 °C/2 h | 80 A/2 passes | - |

| P0_P0_W_P800 | 210.5 | 3.84 | - | - | - | 80 A/2 passes | 800 °C/2 h |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gouveia, R.M.; Silva, F.J.G.; Paiva, O.C.; De Fátima Andrade, M.; Pereira, L.A.; Moselli, P.C.; Papis, K.J.M. Comparing the Structure and Mechanical Properties of Welds on Ductile Cast Iron (700 MPa) under Different Heat Treatment Conditions. Metals 2018, 8, 72. https://doi.org/10.3390/met8010072

Gouveia RM, Silva FJG, Paiva OC, De Fátima Andrade M, Pereira LA, Moselli PC, Papis KJM. Comparing the Structure and Mechanical Properties of Welds on Ductile Cast Iron (700 MPa) under Different Heat Treatment Conditions. Metals. 2018; 8(1):72. https://doi.org/10.3390/met8010072

Chicago/Turabian StyleGouveia, Ronny M., Francisco J. G. Silva, Olga C. Paiva, Maria De Fátima Andrade, Lucas Augusto Pereira, Paulo Cezar Moselli, and Konrad J. M. Papis. 2018. "Comparing the Structure and Mechanical Properties of Welds on Ductile Cast Iron (700 MPa) under Different Heat Treatment Conditions" Metals 8, no. 1: 72. https://doi.org/10.3390/met8010072

APA StyleGouveia, R. M., Silva, F. J. G., Paiva, O. C., De Fátima Andrade, M., Pereira, L. A., Moselli, P. C., & Papis, K. J. M. (2018). Comparing the Structure and Mechanical Properties of Welds on Ductile Cast Iron (700 MPa) under Different Heat Treatment Conditions. Metals, 8(1), 72. https://doi.org/10.3390/met8010072