1. Introduction

The advent of miniaturization in addition to perpetual consumer demands and competitive markets are driving companies to extensively consider new methods of manufacturing. Moreover, the universal adoption of artificial intelligence, information and communication technologies as well as the requirements for product compactness, portability, flexibility have necessitated the development of innovative and new paradigms in the production industries. As a result of miniaturization, micro-machining applications have increased substantially in recent times. In fact, a large number of sectors which thrive on miniaturization involve predominantly automation-enabled electromechanical system products. The majority of products involving micro-machining can be associated with the automotive industries (diesel engine injection nozzles, typically with micro-jet holes of diameter < 300 µm, depth > 1 mm with a number of holes > 4), semiconductor devices, biotechnology products, medical tools etc. [

1]. Its applications have flourished with the realization of the benefits of micro-machined features. For example, micro-nozzles in injectors directly affect the performance of diesel engines in terms of combustion, noise, emissions and reliability. Additionally, miniaturization has resulted in better atomization, penetration, and spatial distribution of injected fuel in high pressure diesel engines [

2]. There are numerous applications such as valves, industrial torch tips and a large number of products in the medical, aerospace industries, etc., where micro-features are crucial.

Aspects such as the dimensional accuracy of micro-features, their surface finish, profile, etc., are critical to the overall functioning of the respective product. Indeed, different micro-machining approaches each with inherent benefits and limitations can be pointed out. As a consequence of the size effect and slender tools in the case of mechanical micro-machining, the machining forces are very high, which leads to frequent tool breakage, burr formation, surface cracks, etc. [

3]. Similarly, laser-based micro-machining results in a poor surface profile and inferior surface integrity. Among several alternatives, electric discharge machining (EDM) has emerged as a reliable process for miniature and micro-machining applications owing to its numerous benefits [

4,

5]. Furthermore, the EDM process can be utilized independently of the hardness of the workpiece material, since no mechanical action of the cutting tool or the abrasive tool is involved in the process [

6]. As a result of the latest enhancements and accomplishments in the EDM process, micro-machining—which was earlier regarded as unfeasible or impractical—has now become achievable [

7]. On account of its abundant benefits, different special purpose variants based on EDM principles can be listed, such as micro-EDM, aerospace EDM, medical EDM, semi-conductor EDM, etc. Micro-EDM, on account of its low discharge energy and high frequency, can successfully achieve the desired accuracy and surface finish, as compared to conventional EDM. The effective and efficient operation of micro-EDM depends on the appropriate selection of process parameters and their range [

8]. The spark gap in the case of conventional EDM is primarily chosen depending on the material removal rate (MRR) and the desired surface finish. In the case of micro-EDM, the spark gap is kept very small to achieve the desired accuracy and limit the electrode wear rate (EWR). The performance of micro-EDM depends on many factors, including the dielectric used, pulse current, pulse profile (e.g., shape, length, etc.), frequency, etc. [

9]. The EWR can be minimized with the use of lesser spark energy. Still, it is a matter of serious concern when a combination of micro and macro-features need to be produced (often required in generating complex 3D micro-profiles) in micro-EDM. This can be attributed to differential EWR in micro and macro features, which deteriorate the electrode profile. The drilling of a blind hole using an electrode with a constant wear rate often results in a smaller diameter than required [

10]. Actually, as a result of the constant wear rate, the electrode diameter reduces continuously with increasing depth, thus producing an inaccurate hole. Even though a narrow spark gap in micro-EDM results in higher accuracy and lower EWR, it hinders the process of debris removal. Subsequently, the higher concentration of debris between the electrode and the workpiece along with continued feed provides inaccurate geometry as well as poor surface integrity [

11].

Machining at the micro level itself is a complicated process that requires precision and accuracy to obtain good quality. If the micro-machining is done on difficult-to-machine material, the task becomes more exacting. Ni-Ti based shape memory alloys (SMA) are one such difficult-to-machine material with applications in numerous fields (automobile actuators, biomedical, aerospace, micro-electromechancial systems, etc.) [

12,

13]. These alloys possess the unique properties of pseudo-elasticity, bio-compatibility, corrosion resistance and shape memory effect. These properties make them an excellent material for various applications, yet these properties also hinder their machining characteristics. While Ni-Ti-based materials are hard to machine, the shape memory effect complicates the machining issue. Furthermore, during the conventional machining of micro-sized shapes, the slender tool is required and the machining forces are high due to the size effect. Thus, non-traditional methods such as micro-EDM are the best alternative for machining micro-shapes on SMAs. Even for micro-EDM, the selection of the range of parameters and the optimal solution is a challenge, as during machining the electrode itself undergoes erosion, undermining the accuracy in cases where the erosion is beyond acceptable limits. Therefore, it is important to find an appropriate combination of input machining parameters for machining SMAs. Hsieh et al. [

14] studied the machining characteristics of Ti-Ni-X SMA during wire electro-discharge machining. Laser-based micromachining of Ni-Ti-based SMA was explored to study the single and multishot ablation threshold fluence and the incubation coefficient effect on the quality of microfeatures [

15]. The optimization of the process parameters of the high speed milling of Ni-Ti-based SMA was conducted [

16]. It was revealed that to obtain low machining forces, a burr size of 15 m/min cutting speed is optimal. Rasheed et al. [

8] investigated the effect of the process parameters of micro-EDM on hole quality while drilling micro-holes in Ni-Ti SMA. Jahan et al. [

17] compared the surface characteristics of Ni-Ti-based SMA with Ti-6Al-4V, when machined by the micro-EDM process. It was discovered that Ni-Ti-based SMA possessed a comparatively smoother surface finish.

The accomplishment of the desired dimensional accuracy, profile, surface finish, MRR, EWR, etc., in micro-machining such as micro-drilling and micro-milling is a daunting task. It depends on the appropriate selection of process parameters, their range, etc. The task becomes more complex with the presence of more than one response and the requirement of their simultaneous control within a closed range of acceptability limits. Notably, each process parameter has a variable and contradictory effect on each response. It means an optimization tool which can identify the most suitable combination of process parameters is crucial for the superlative performance of the micro-EDM process. Multi-performance-characteristic (MPC) optimization is one such tool that can achieve acceptable micro-machined quality. Generally, there exist a large number of MPC optimization techniques, with each technique possessing its own merits and demerits. A particular MPC technique may be ideal for some applications, but the same technique may produce inaccurate results for another application. Therefore, the selection of the appropriate MPC tool for a given application is very important to achieve the desired results in micro-EDM. This issue has been convincingly addressed by [

18]. They demonstrated that the application of Taguchi-based grey relational analysis (GRA) compounded with principal component analysis (PCA) in precise machining. This approach was all about synchronization between the robustness of Taguchi’s experiment design, the conversion of characteristic response data into comparable normalized sequences without affecting its inherent essence through GRA and the coupling of normalized-multiple-responses by applying an inherent weighting of each response that is statistically derived through the inherent process characteristics by employing PCA. As compared to a general MPC optimization technique, which is subjective in nature and depend upon expert opinion, Taguchi-based Grey-PCA is quantitative in nature. The analysis of responses and subsequent statistical processing brings out the weighting estimates through the inherent nature of the process. Similarly, Chiang [

19] optimized the process parameters of the injection-molded thermoplastic part using a fuzzy GRA technique. GRA was also used by Chiang and Chang [

20] in the multi-response optimization (removal rate and surface roughness) of wire-EDM process parameters for Al

2O

3 particle-reinforced composite. Moreover, Palanikumar et al. [

21] employed GRA and Lin [

22] applied the Taguchi-based GRA for the multi-response optimization of turning process parameters. There have been numerous investigations in the literature, where single and multi-response optimizations were carried out. However, the multi-response optimization of process parameters for the micro-machining of Ni-Ti-based SMA using micro-EDM process is close to negligible in the literature. Therefore, this study is conducted to make some progress in the field.

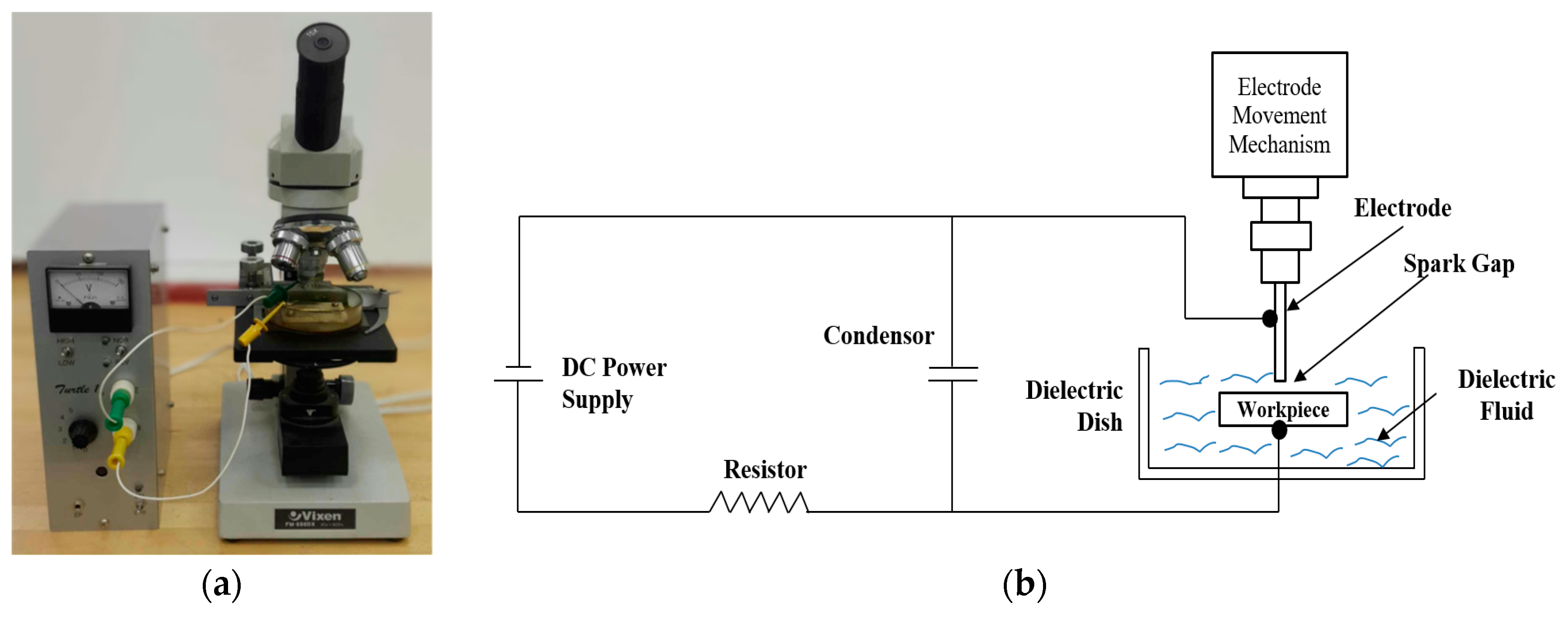

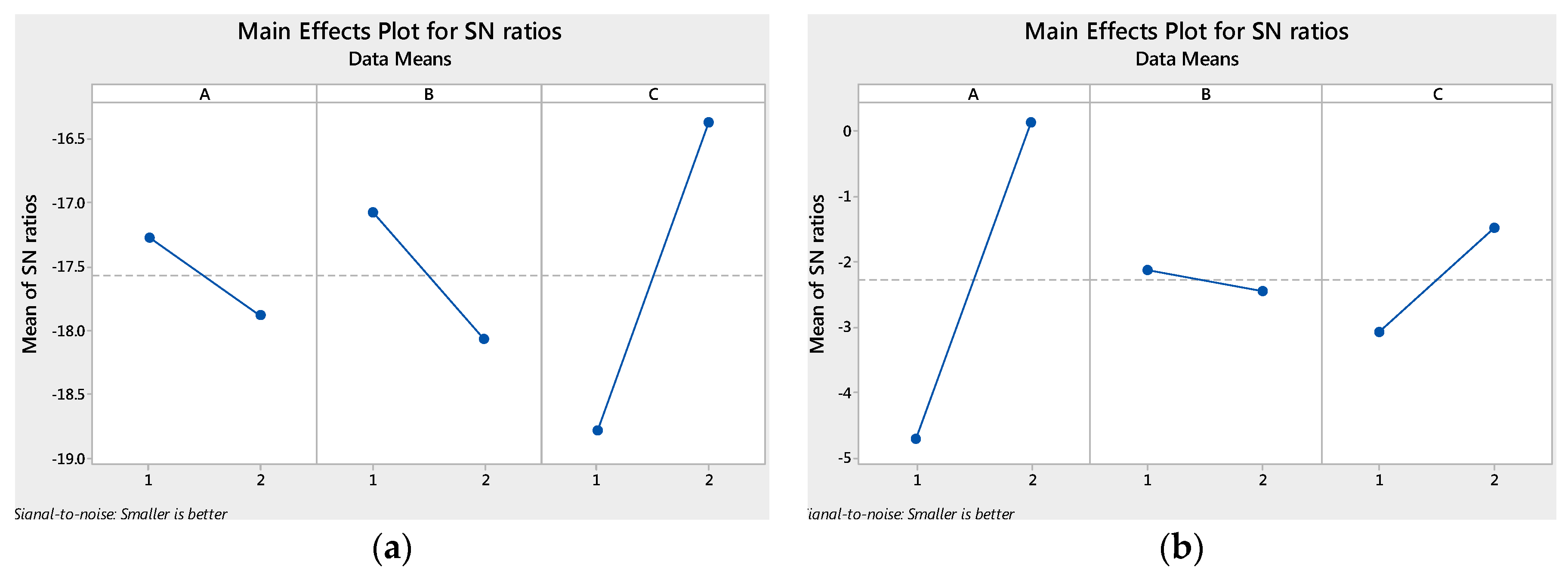

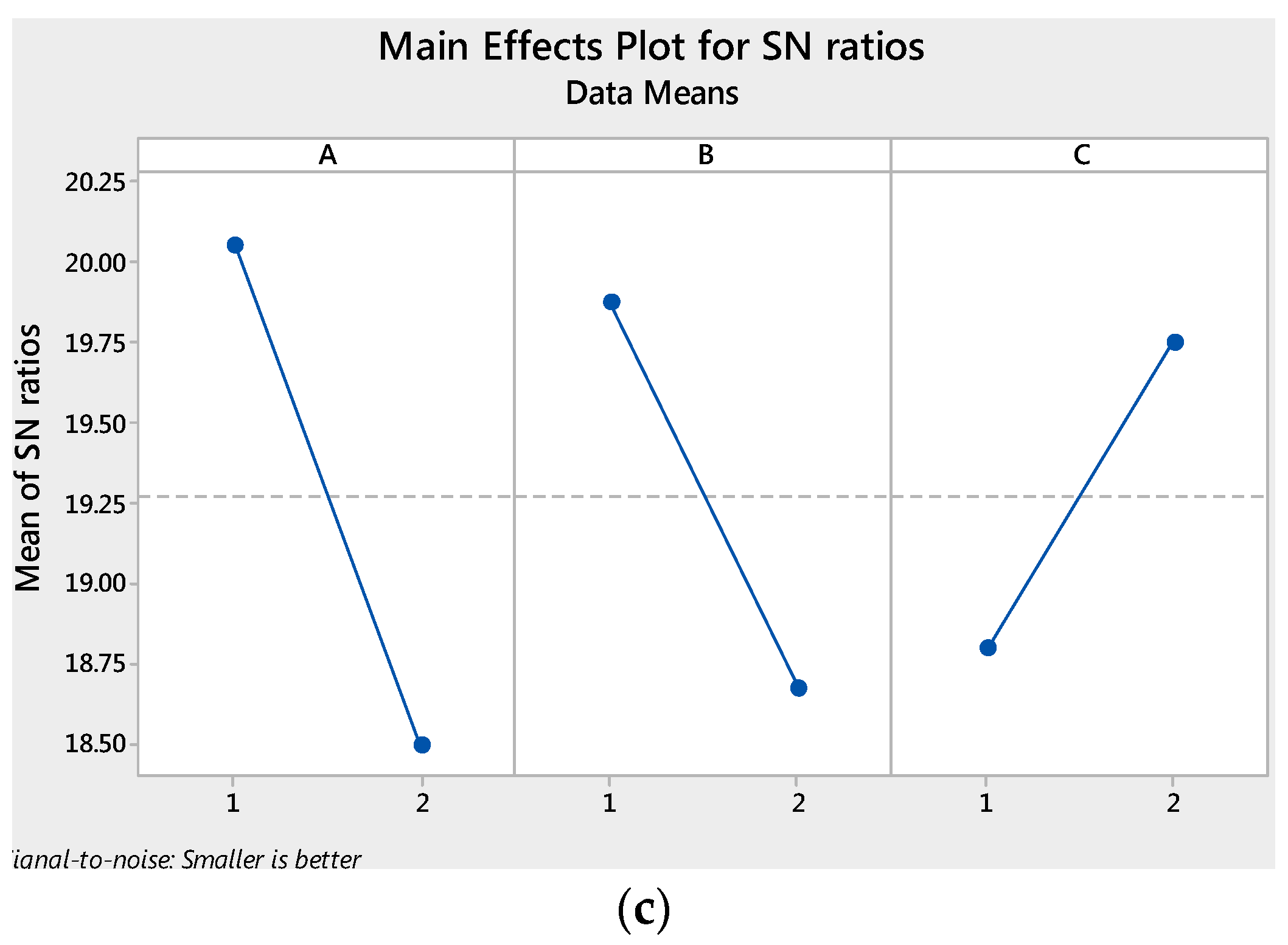

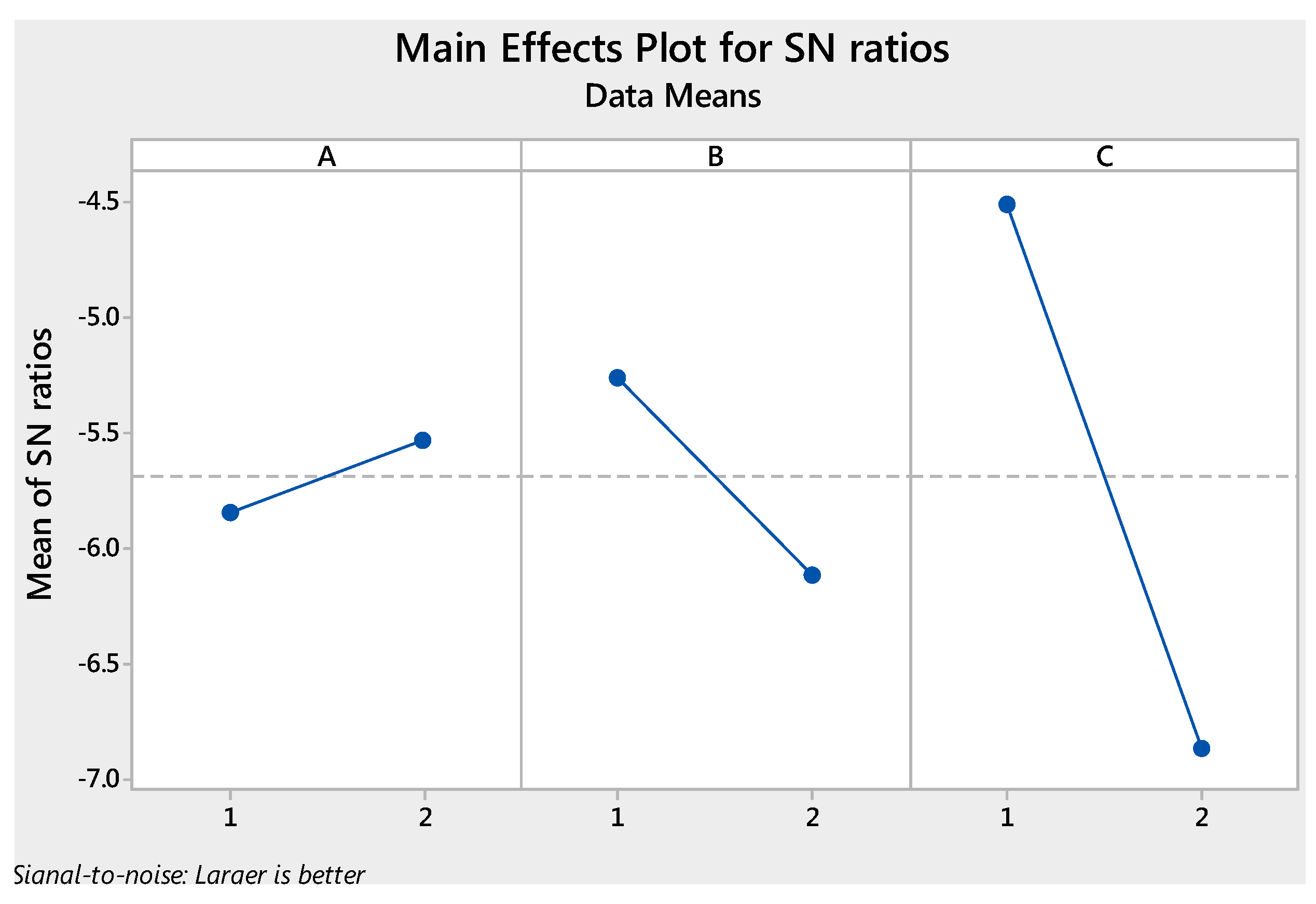

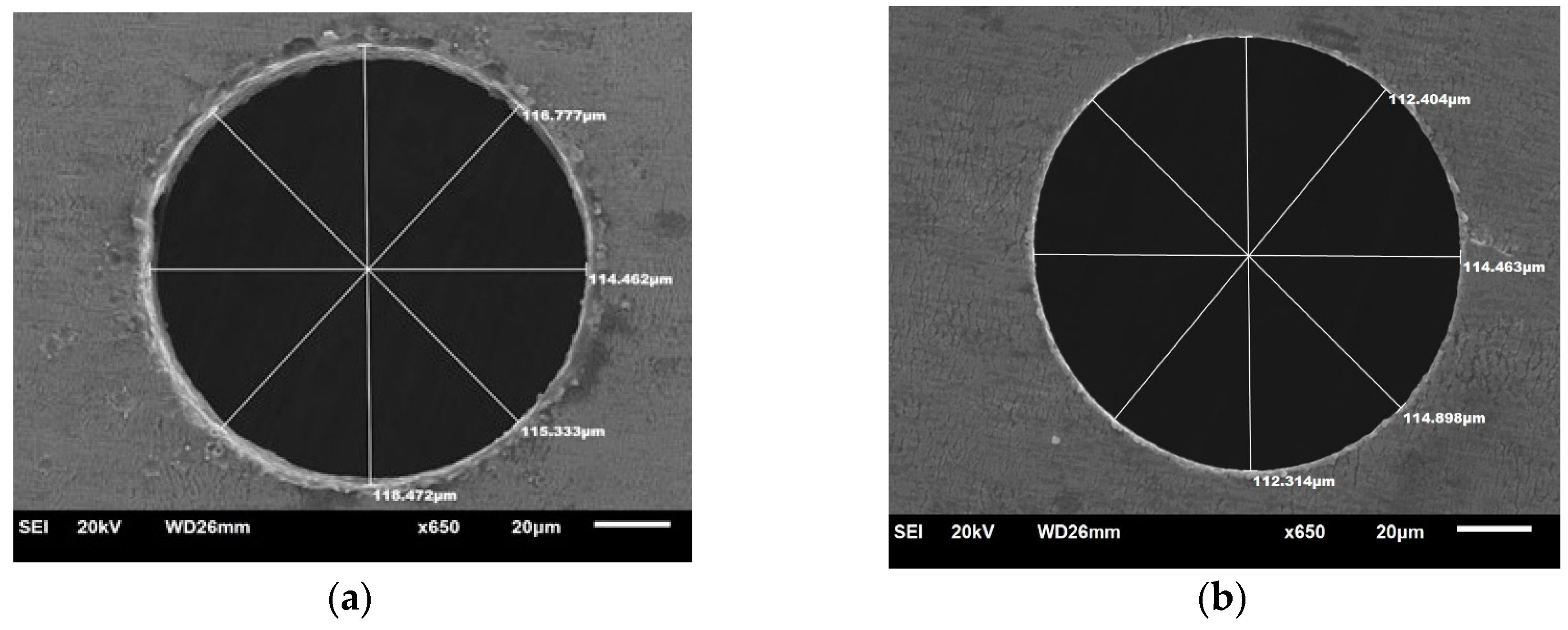

The objective of this study is the improvement of the quality of micro-machining in Ni-Ti based alloy using micro-EDM. A methodology for optimizing the multiple quality characteristics, namely overcut, taper angle and surface roughness has been developed. In this work, a Taguchi-based grey relational analysis coupled with principal component analysis (Grey PCA) was implemented to investigate the effect of three important micro-EDM process parameters, namely capacitance, voltage and electrode material.