Abstract

ŠTORE STEEL Ltd. is one of the three steel plants in Slovenia. Continuous cast 180 mm × 180 mm billets can undergo cooling to room temperature using a turnover cooling bed. They can also be cooled down under hoods or heat treated to reduce residual stresses. Additional operations of heat treatment from 36 h up to 72 h and cooling of the billets for 24 h, with limited capacities (with only two heat treatment furnaces and only six hoods), drastically influence productivity. Accordingly, the casting must be carefully planned (i.e., the main thing is casting in sequences), while the internal quality of the billets (i.e., the occurrence of inner defects) may be compromised. Also, the stock of billets can increase dramatically. As a result, it was necessary to consider the abandoning of cooling under hoods and heat treatment of billets. Based on the collected scrap data after ultrasonic examination of rolled bars, linear regression and genetic programming were used for prediction of the occurrence of inner defects. Based on modeling results, cooling under hoods and heat treatment of billets were abandoned at the casting of several steel grades. Accordingly, the casting sequences increased, and the stock of billets decreased drastically while the internal quality of the rolled bars remained the same.

1. Introduction

During continuous casting and melt solidification, many different defects and phenomena can occur due to thermomechanical behavior, which all influence final product properties. Among them is shrinkage porosity [1,2,3], and segregations [4,5,6] can be mentioned. Shrinkage porosity is attributed to the shrinkage of the material during cooling, accompanied by unequal solidification of individual sections and resulting in insufficient flow of metal and the occurrence of voids or holes in the solidified structure [1,2,3]. Segregations can be defined as an uneven distribution of chemical elements over the solidified cross-section, originating from gradual solidification with simultaneous changing of the heat removal [4,5,6]. Both drastically influence macro- and microstructure and as such the mechanical properties of the final product, especially in case of the formation of inner cracks [5,7,8,9,10,11,12,13,14].

During and after solidification, to reduce stresses due to heat removal, macrostructure, and segregations (i.e., chemical nonhomogeneity), which also affect its geometry (e.g., rhomboidity and straightness) and further processing, cast products can be heat treated or control cooled [3,15,16]. Control cooling covers cooling in a mold (i.e., primary cooling), water spray cooling (i.e., secondary cooling), and cooling after complete solidification (i.e., tertiary cooling).

Several studies have been carried out to reduce stresses arising from thermal behavior and their influence on defect occurrence [15,17,18,19,20,21,22]. In most cases, finite elements models [17,18,19,22,23] and meshless methods [15,16] have been used to predict the thermal field and, consequently, stresses during cooling. The modeling results have also been confirmed experimentally in the laboratory [19,21,24] and also in practice [3,17]. Some of the more important studies are presented below.

The stress distribution of continuous cast round billets was optimized in [17] by rearranging the secondary cooling nozzles. For analyzing the influences of several parameters (e.g., nozzle arrangement, distance from the billet, segments, and cooling zone length), a finite element model was developed. By changing the segment design and distance from the billet, the variations in the temperature and, consequently, stresses during secondary cooling were increased. In this way, mid-way cracks were completely eliminated.

Article [18] presents a similar approach. In addition, phase transformations affecting ductility during solidification were considered. The finite element model was used for determining the problematic zones during changes in several cooling rates. Experimental results support the calculations.

Similarly, the phase transformations causing stress concentration zones in solidified continuously cast steel were analyzed in [23]. The finite element method was used to predict the residual stresses while changing several cooling rates and, as a result, the probability of crack occurrence.

The study in [22] also focuses on phase transformations in slabs with different chemical compositions influencing crack occurrence after complete solidification. A finite element model was developed for thermal and stress analysis. Additionally, fracture toughness and impact toughness tests with six steel grades were performed. Based on simulations and laboratory results, it can be concluded that unalloyed steel with a carbon content of 0.3% is most prone to cracking. Several methods were proposed to reduce the cracking during cooling after solidification.

Heavy reduction rolling during the continuous casting of crack-sensitive steel micro-alloyed with niobium was studied in [19]. Due to temperature differences between the core and the surface and its association with crack occurrence, a finite element method model was developed. Also, specially prepared specimens were used in the laboratory for hot compression tests to support the model calculations. Findings were implemented in several trials in the steel plant. The cracking, which occurs usually in the center of the casting, was also reduced by increasing the rolling diameter.

Small deformations were used in research [24] to compensate stresses induced by temperature differences on the surface and in the core of continuous cast 34CrMo billets. The temperature field after solidification was calculated using MSC Marc software. Also, hot ductility tests were performed. The porosity and segregations were completely eliminated, and at the same time, the center crack occurrence criteria were determined.

The authors in [21] analyzed the creeping of continuous cast slabs, which is conditioned by the macrostructure and defects of the solidified structure. Experimentally, the creeping was analyzed under several continuous casting parameters. Based on measured temperatures, the stresses were evaluated and a constitutive model for creeping was obtained. Based on the results, microcrack initiation and propagation can be avoided. As a result, strand straightening can be optimized.

In [25], meshless methods were used primarily for modeling thermo-mechanically induced stresses in a mold. The developed model can predict the occurrence of off-corner cracks in the billet during solidification. The simulation results can be compared with the results obtained with the finite element model. With the developed models, the casting parameters can be optimized and also used for simulating the cooling after billet complete solidification.

The authors of [15] optimized 150KhNM steel grade billet parameters before rolling. Several different heat treatment regimes were investigated to obtain suitable mechanical properties of the rolled material. Additionally, with the selected heat treatment regime, crack occurrence was completely eliminated.

In the research in [16], square billets after cutting and after continuous casting were used as a thermostat for storing heat before the rolling process. A mathematical model was developed for calculating the temperature field. Several different heat treatment regimes were used during simulations. The calculated temperature field can also be used for the calculation of stresses during the heat treatment of billets.

In paper [26], the influences of previously deformed chromium steel billets on the properties of radial-shear-rolled seamless pipes are elaborated. Several laboratory tests were performed to predict the seamless pipes’ mechanical properties. It was found that the deformation ratio most influences the mechanical properties of seamless pipes and, consequently, the structure of billets. Based on the findings, the additional heat treatment of cast billets is proposed to improve the mechanical properties of rolled seamless pipes.

Due to the lack of literature and experience, this article presents an analysis of the influences of control cooling under hoods and heat treatment of continuous cast square billets on scrap rate after ultrasonic examination of rolled bars. Additional operations of control cooling under hoods and heat treatment of the billets burden steelmaking productivity, refractory material consumption, the additional processing of the billets (i.e., rolling), and their stock capacities. Accordingly, at the beginning of the article, a typical production process in a steel plant is presented. Next, the influential parameters and data collection are described, followed by the prediction of the occurrence of defects in rolled bars detected with ultrasonic examination using logistic regression and genetic programming. The results and industrial implementation are then presented. Finally, conclusions are drawn.

2. Materials and Methods

In the company ŠTORE STEEL Ltd., Štore, Slovenia the following processes are carried out in the steel plant before a rolling operation:

- -

- scrap melting in an electric arc furnace;

- -

- ladle (50 tons) treatment (alloying, slag forming, and homogenization);

- -

- continuous casting of square billets 180 mm × 180 mm using a 9 m radius continuous caster;

- -

- cooling of billets using:

- turnover cooling bed;

- hoods (for 24 h);

- heat treatment (from 36 h up to 72 h at 650 °C).

- -

- storing of the cooled-down (to room temperature) billets (stock with a capacity of 12,000 tons).

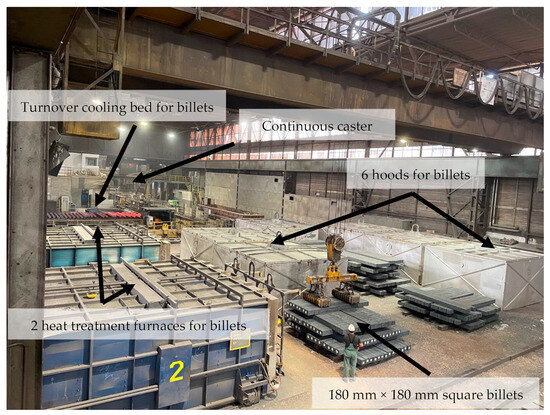

Figure 1 shows a continuous caster, turnover cooling bed, 2 heat treatment furnaces, and 6 hoods for billets.

Figure 1.

Continuous caster, turnover cooling bed, 2 heat treatment furnaces, and 6 hoods for billets.

On average, they produce up to 15 heats per day. Due to the presence of shrinkage porosity, the reduction in residual stresses, and the possibility of promoting the formation of internal cracks, billet heat treatment is prescribed for 139 grades of steel for rolled bars from 40 mm to 110 mm thick. Hoods are used for the same types of steel and rolled bars with lower thicknesses than prescribed for the heat treatment of billets.

In addition, it should be emphasized that due to the small cooling capacity using hoods (6 hoods × 2 heats) and heat treatment (2 heat treatment furnaces × 2 heats), it is necessary to reduce the number of casting sequences, which impairs the productivity and consumption of refractory materials. The storage capacities of billets are also reduced.

Based on the technical conditions of delivery, the rolled material (round or flat bars) is examined (internal and surface control) by automatic control lines (visual inspection, magnetic particle inspection, and ultrasonic control), and flat bars only manually. A KARL DEUTSCH Ultrasonic Testing System ECHOGRAPH, Wuppertal, Germany and a Krautkramer USM 36 Ultrasonic Flaw Detector, Waygate Technologies, Huerth, Germany are used for automatic and manual ultrasonic control.

To analyze the effect of cooling under hoods and heat treatment of the billets on scrap after ultrasonic examination of rolled bars, the following parameters were gathered from 1 January 2021 to 31 December 2022:

- Chemical composition: content of carbon (C), silicon (SI), manganese (MN), sulfur (S), chromium (CR), molybdenum (MO), nickel (NI), aluminum (AL), and vanadium (V) [%];

- Casting parameters:

- The average temperature of the melt in the tundish (TEMP) [°C].

- Mold water flow (MOLDQ) [l/min].

- The average difference between input and output mold cooling water temperature (DELTAT) [°C].

- The average cooling water flow [l/min] and pressure [bar] in the first (Z1Q and Z1P), second (Z2Q and Z2P), and third zone (Z3Q and Z3P) of secondary cooling.

- Time of cooling of cast billets under hoods (HOODS) [h].

- Time of heating of cast billets in the furnace at 650 °C (HT) [h].

- Reduction rate—the ratio between billet and ultrasonically examined rolled material cross-section area (REDUCTION).

- The occurrence/detection of defects using ultrasonic testing (automatic control line and manual). If the scrap rate was over 2%, the occurrence was defined as 1, otherwise 0.

There were 119,475 tons of material (out of 286,896 tons produced) examined ultrasonically during the period from 1 January 2021 to 31 December 2022. In 505 out of 3921 cases (i.e., rolling working orders, different roll bar dimensions, and different steel grades), inner defects were found using ultrasonic examination. Out of 505 cases with inner defects, the billets were cooled under hoods after continuous casting in 111 cases and heat treated after continuous casting in 190 cases. Accordingly, only in 204 cases were the billets cooled to room temperature right after continuous casting.

Based on the gathered data, logistic regression and genetic programming were used to establish a correlation between parameters and the occurrence of defects after the rolling of differently heat-treated continuous cast billets.

3. Results

The occurrence of defects was predicted using logistic regression and genetic programming. In the case of a scrap rate over 2%, the occurrence was defined as 1, otherwise 0. The sum of absolute differences between actual and predicted occurrences was chosen as a fitness function.

3.1. Modeling of Occurrence of Defects Using Logistic Regression

The following linear function f was obtained using logistic regression:

Based on the obtained logistic regression models, the sum of absolute differences between actual and predicted occurrences is 499. Only 38 out of 505 cases where defects were found during the ultrasonic examination were predicted correctly. On the other hand, the same model predicts 19 occurrences of defects where the material was actually not defected.

C, Si, Mn, S, Cr, Mo, Ni, Al, V, TEMP, MOLDQ, DELTAT, Z1Q, Z1P, Z2Q, Z2P, Z3Q, Z3P, HOODS, HT, and REDUCTION are statistically significant parameters. Accordingly, based on logistic regression results, the cooling under hoods and heat treatment of the billets decrease (negative sign) the occurrence of inner defects after the rolling of continuous cast billets. There were only 70 cases out of 505 where the occurrence of inner defects after the rolling of continuous cast billets was predicted using logistic regression.

In the case of removing the hoods, heat treatment of the billets, or both, the logistic regression model predicts 91, 147, and 168 cases where inner defects would be found during the ultrasonic examination, respectively. Based on logistic regression modeling (i.e., the predicted increase in cases with detected inner defects), the keeping of the cooling under hoods and heat treatment of continuous cast billets is essential.

3.2. Modeling of Occurrence of Defects Using Genetic Programming

Similarly, the genetic programming method was used for predicting the occurrence of inner defects. In genetic programming [27,28,29], the mathematical expressions (predictive models) consist of genes that can be selected functions (e.g., essential arithmetical functions), selected input parameters, or random constants. Based on selected genes, random mathematical expressions are built at the beginning of the simulated evolution. They are constantly being modified with genetic operations (e.g., crossover and mutation) during several iterations (i.e., generations). After the completion of mathematical expression modification, a new generation is obtained. All mathematical expressions are evaluated using the fitness function. The process is repeated until the termination criterion is fulfilled.

An in-house-developed genetic programming system, made with AutoLISP (integrated into Autodesk AutoCAD software) [4,30,31,32] was used. Its settings were as follows:

- size of the population of organisms: 200;

- maximum number of generations: 30;

- reproduction probability: 0.3;

- crossover probability: 0.7;

- maximum permissible depth in the creation of the population: 30;

- maximum permissible depth after the operation of crossover of two organisms: 30;

- smallest permissible depth of organisms in generating new organisms: 2.

The tournament method with tournament size 7 was used for the selection of organisms. Occurrence/detection was set to 1 for positive model results and 0 for other cases.

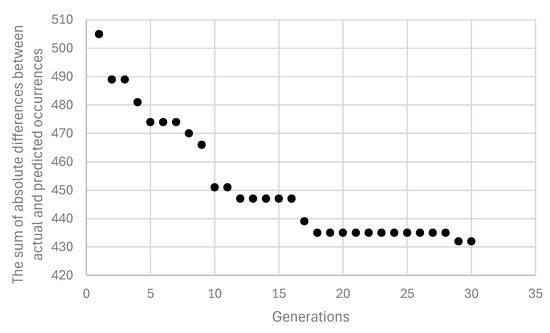

To demonstrate the operation of the aforementioned system for genetic programming, the evolution of the best mathematical model for the prediction of the occurrence of defects in rolled bars from the best civilization (i.e., the individual run of the genetic programming system) was carried out.

At the start of the genetic programming system, random mathematical models are generated. From the first generation (i.e., the first iteration of a single run of the genetic programming system), the best mathematical model is very simple:

where the sum of absolute differences between actual and predicted occurrences is 505. The model was randomly built only from the following genes/parameters: nickel (NI) and vanadium (V) content and also the cooling water flow in the third zone of the secondary cooling (Z3Q). All other parameters were not used to build the presented mathematical model.

On the other hand, among 200 randomly generated mathematical models for the prediction of the occurrence of defects in rolled bars, there is also the worst one:

where the sum of absolute differences between actual and predicted occurrences is as much as 3416.

After 28 iterations of changing mathematical models (i.e., in the 29th generation), the best mathematical model for the prediction of the occurrence of defects in rolled bars, obtained from a genetic programming system, evolved:

where the sum of absolute differences between actual and predicted occurrences is 432. The model successfully predicted 109 out of 505 cases where defects were found during the ultrasonic examination, which is, compared with logistic regression, 2.87 times better. On the other hand, the same model predicted 86 occurrences of defects where the material was actually not defected. The evolution of the models in the best civilization (i.e., the civilization where the best model occurred) is presented in Figure 2 using the sum of absolute differences between actual and predicted occurrences of defects.

Figure 2.

The evolution of the models in the best civilization using the sum of absolute differences between actual and predicted occurrences of defects.

It is also important to mention that in the case of removing the cooling under hoods, heat treatment of the billets, or both, the genetic programming model predicts that in 132, 154, and 167 cases, inner defects would be found during the ultrasonic examination, respectively. Based on genetic programming modeling (i.e., the predicted decrease in cases with detected inner defects), keeping the cooling under hoods and heat treatment of continuous cast billets will not increase the number of cases with detected inner defects.

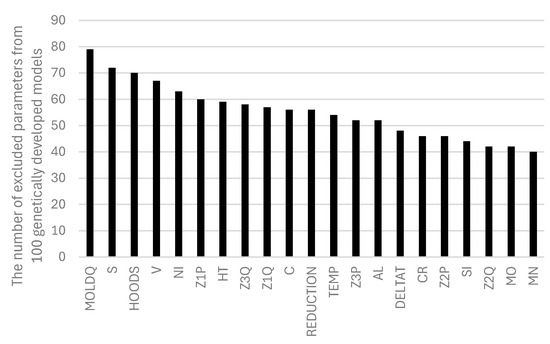

Additionally, it is necessary to emphasize that the genetically developed model does not contain the following parameters: V, C, Z3Q, Z2P, Z1Q, and MOLDQ. Similarly, while checking the other 100 models obtained using genetic programming, it can be concluded that the HOODS (time of cooling of cast billets under hoods) and HT (time of heating of cast billets in the furnace at 650 °C) parameters were each one of top six parameters which were excluded from the developed models. The number of excluded parameters is presented in Figure 3.

Figure 3.

The number of excluded parameters from 100 genetically developed models.

The number of parameters excluded from 100 genetically developed models supports the idea of abandoning the cooling under hoods and heat treatment of continuous cast billets.

3.3. Validation of Modeling Results

Despite the different conclusions from logistic regression and genetic programming modeling, cooling under hoods and heat treatment of billets were abandoned at the casting of the following steel grades in January 2023: 16MnCr5, 16MnCrB5, 16MnCrS5, 16NiCrS4, 20CrMoS5, 20MnCr5, 20MnV6, 20NiCrMo2-2, 25CrMo4, 30CrNiMo8, 30MnVS6, 33MnCrB5, 38MnVS6, 41Cr4, 42CrMo4, 42CrMoS4, 51CrV4, 61SiCr7, 90MnCrV8, C10, C15, C22, C45, C45S, C50, C60, C70S6, P460NH, S235JR, and S355J2. In Table 1, the ratio between the number of cases with detected inner defects and examined cases and the examined quantity from 2022, 2023, and 2024 are presented. Only the steel grades that were produced for at least two years (out of three) are presented. The trend of improvement can be observed.

Table 1.

The ratio between the number of cases with detected inner defects and examined cases and the examined quantity from 2022, 2023, and 2024. Only the steel grades that were produced for at least two years (out of three) are presented.

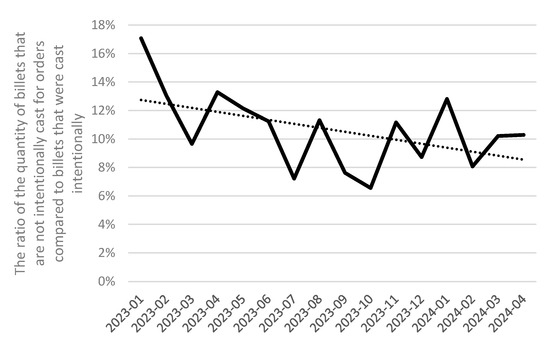

Also, the stock of billets was analyzed. Due to the purposeful use of steel, billets of the same quality of steel must be stored separately for cooling down under hoods or heat treatment, which increases the stock in the steel plant warehouse. Additionally, the quantity of billets that are not intentionally cast for typically small orders increases. Figure 4 shows the decreasing the ratio of the quantity of billets that were not intentionally cast for orders compared to billets that were cast intentionally from January 2023 to April 2024. The ratio of the quantity of billets that were not intentionally cast for orders compared to billets that were cast intentionally decreased from 17.07% to 10.29%. Please note that the average stored quantity of billets from this period to April 2024 is 7161 tons.

Figure 4.

The ratio of the quantity of billets that were not intentionally cast for orders compared to billets that were cast intentionally from January 2023 to April 2024.

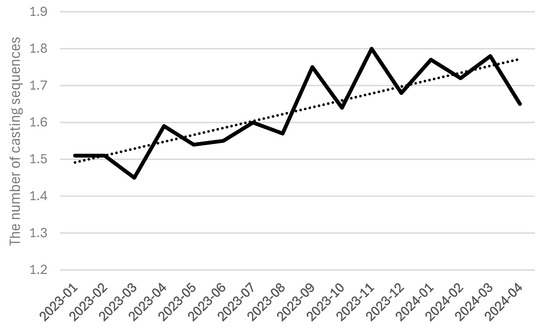

Due to small cooling capacities using hoods (6 hoods × 2 heats) and heat treatment (2 heat treatment furnaces × 2 heats), it was necessary to reduce the number of casting sequences. Figure 5 shows the increased number of casting sequences after abandoning the cooling under hoods and heat treatment of continuous cast billets from January 2023 to April 2024 from 1.51 to 1.63 (by 7.95%).

Figure 5.

The number of casting sequences after abandoning the cooling under hoods and heat treatment of continuous cast billets from January 2023 to April 2024.

4. Conclusions

In the article, an analysis of the influences of control cooling under hoods and heat treatment of continuous cast square billets on scrap rate using ultrasonic examination of rolled bars is presented. The additional operations of control cooling under hoods and heat treatment of the billets burden the additional processing of the billets (i.e., rolling) and their stock capacities.

There were 119,475 tons of material examined ultrasonically during the period from 1 January 2021 to 31 December 2022. In 505 out of 3921 cases (i.e., rolling working orders, different roll bar dimensions, and different steel grades), inner defects were found using ultrasonic examination.

Chemical composition, casting parameters, time of cooling of cast billets under hoods, time of heating of cast billets in the furnace at 650 °C, reduction rate, and occurrence/detection of defects using ultrasonic testing were gathered.

The occurrence of defects was predicted using logistic regression and genetic programming. In the case of a scrap rate over 2%, the occurrence was defined as 1, otherwise 0. The sum of absolute differences between actual and predicted occurrences was chosen as a fitness function.

Based on the obtained logistic regression models, the sum of absolute differences between actual and predicted occurrences is 499. Only 38 out of 505 cases where defects were found during the ultrasonic examination were predicted correctly. Also statistically significant were both the parameters control cooling under hoods and heat treatment of the billets. Based on logistic regression modeling (i.e., the predicted increase in cases with detected inner defects), keeping the cooling under hoods and heat treatment of continuous cast billets is essential.

The best genetic programming model (out of the developed 1000 models) successfully predicted 109 out of 505 cases where defects were found during the ultrasonic examination. On the other hand, the same model predicted 86 occurrences of defects where the material was actually not defected. In the case of removing the cooling under hoods, heat treatment of the billets, or both, the genetic programming model predicts that in 132, 154, and 167 cases, inner defects would be found during the ultrasonic examination, respectively. Based on genetic programming modeling (i.e., the predicted decrease in cases with detected inner defects), keeping the cooling under hoods and heat treatment of continuous cast billets will not increase the number of cases with detected inner defects.

Despite the different conclusions from logistic regression and genetic programming modeling, cooling under hoods and heat treatment of billets were abandoned at the casting of several steel grades in January 2023. The number of cases with detected inner defects and examined cases significantly decreased. Also, the ratio of the quantity of billets that were not intentionally cast for orders compared to billets that were cast intentionally decreased from 17.07% to 10.29% from January 2023 to April 2024. On the other hand, the number of casting sequences in the same period increased from 1.51 to 1.63 (for 7.95%).

In the future, the rolling process, cooling after rolling, and heat treatment of the rolled bars will be taken into account. Also, it makes sense to consider removing the heat treatment furnaces and hoods, so that the storage of billets can be increased (up to 20%).

Author Contributions

Conceptualization, U.Ž. and M.K.; methodology, M.K.; software, M.K.; validation, M.K., A.Z. and R.V.; formal analysis, A.Z.; investigation, R.V.; resources, A.Z.; data curation, R.V.; writing—original draft preparation, M.K.; writing—review and editing, U.Ž.; visualization, M.K.; supervision, M.K.; project administration, M.K.; funding acquisition, M.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the SLOVENIAN RESEARCH AND INNOVATION AGENCY; grant number L2-3173.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Conflicts of Interest

Author Miha Kovačič, Aljaž Zupanc, Robert Vertnik were employed by the company ŠTORE STEEL, d.o.o. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Balan, K.P. Casting defects in iron and steel. In Metallurgical Failure Analysis; Elsevier: Amsterdam, The Netherlands, 2018; pp. 93–110. [Google Scholar] [CrossRef]

- Vynnycky, M. On the formation of centreline shrinkage porosity in the continuous casting of steel. J. Math. Ind. 2020, 10, 14. [Google Scholar] [CrossRef]

- Kovačič, M.; Župerl, U. Continuous caster final electromagnetic stirrers position optimization using genetic programming. Mater. Manuf. Process 2023, 38, 2009–2017. [Google Scholar] [CrossRef]

- Kovačič, M.; Župerl, U. Genetic programming in the steelmaking industry. Genet. Program. Evolvable Mach. 2020, 21, 99–128. [Google Scholar] [CrossRef]

- Hutny, A.M.; Warzecha, M.; Derda, W.; Wieczorek, P. Segregation of Elements in Continuous Cast Carbon Steel Billets Designated for Long Products. Arch. Metall. Mater. 2016, 61, 2037–2042. [Google Scholar] [CrossRef]

- Scholes, A. Segregation in continuous casting. Ironmak. Steelmak. 2005, 32, 101–108. [Google Scholar] [CrossRef]

- Yao, Y.; Liu, Z.; Li, B.; Xiao, L.; Gan, Y. Effect of steel strip feeding on the columnar-equiaxed solidification in a large continuous casting round bloom. J. Mater. Res. Technol. 2022, 20, 1770–1785. [Google Scholar] [CrossRef]

- Kotas, P.; Tutum, C.C.; Thorborg, J.; Hattel, J.H. Elimination of Hot Tears in Steel Castings by Means of Solidification Pattern Optimization. Metall. Mater. Trans. B 2012, 43, 609–626. [Google Scholar] [CrossRef]

- Li, X.; Wang, X.; Bao, Y.; Gong, J.; Pang, W.; Wang, M. Effect of Electromagnetic Stirring on the Solidification Behavior of High-Magnetic-Induction Grain-Oriented Silicon Steel Continuous Casting Slab. JOM 2020, 72, 3628–3633. [Google Scholar] [CrossRef]

- Zeng, J.; Chen, W.; Wang, Q.; Wang, G. Improving Inner Quality in Continuous Casting Rectangular Billets: Comparison Between Mechanical Soft Reduction and Final Electromagnetic Stirring. Trans. Indian Inst. Met. 2016, 69, 1623–1632. [Google Scholar] [CrossRef]

- Xu, Y.; Xu, R.; Fan, Z.; Li, C.; Deng, A.; Wang, E. Analysis of cracking phenomena in continuous casting of 1Cr13 stainless steel billets with final electromagnetic stirring. Int. J. Miner. Metall. Mater. 2016, 23, 534–541. [Google Scholar] [CrossRef]

- Wu, H.J.; Xu, C.J.; Jin, H.Y.; Gao, Y.L.; Zhang, X.B.; Jin, Y.K. Effect of different positions of final electromagnetic stirring for ϕ800mm vertical round billet on fluid flow and heat transfer. Appl. Phys. A 2022, 128, 108. [Google Scholar] [CrossRef]

- Zong, N.; Huang, J.; Liu, Y.; Jing, T.; Lu, Z. Controlling centre segregation and shrinkage cavities without internal crack in as-cast bloom of steel GCr15 induced by soft reduction technologies. Ironmak. Steelmak. 2021, 48, 944–952. [Google Scholar] [CrossRef]

- Tao, H.; Zhang, H.; Wang, M. Research on solidification structure and internal quality defects of 0.1%C–5%Mn Steel. Ironmak. Steelmak. 2020, 47, 351–360. [Google Scholar] [CrossRef]

- Kirpichnikov, M.S.; Sinitsyn, E.O.; Borovinskikh, M.P. Heat treatment technology for roll billets of steel 150KhNM for improving their quality and operating life. Metallurgist 2011, 54, 791–792. [Google Scholar] [CrossRef]

- Lukin, S.V.; Levashev, K.Y. Improvement of Heat-Treatment Conditions for Square-Cross-Section Steel Billets Downstream of a Continuous-Section Billet Casting Machine. Metallurgist 2019, 63, 249–256. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, D.-F.; Zhang, C.-Q.; Wang, S.-G.; Hwang, W.-S.; Han, M.-R. Effects of an even secondary cooling mode on the temperature and stress fields of round billet continuous casting steel. J. Mater. Process Technol. 2015, 222, 315–326. [Google Scholar] [CrossRef]

- Ai, S.; Long, M.; Yang, X.; Chen, D.; Duan, H. Prediction model for crack sensitive temperature region and phase fractions of slab under continuous casting cooling rates based on finite number of experiments. J. Mater. Res. Technol. 2023, 22, 1103–1117. [Google Scholar] [CrossRef]

- Li, T.; Li, H.; Li, R.; Wang, Z.; Wang, G. Analysis of ductile fractures at the surface of continuous casting steel during hot-core heavy reduction rolling. J. Mater. Process Technol. 2020, 283, 116713. [Google Scholar] [CrossRef]

- Jayakrishna, P.; Chakraborty, S.; Ganguly, S.; Talukdar, P. Computational investigation of the transient cyclic thermal distortion of funnel shaped mould in thin slab continuous casting process. Therm. Sci. Eng. Prog. 2022, 36, 101508. [Google Scholar] [CrossRef]

- Sui, Y.; Zhang, H.; Zhang, X. Study on the creep behavior and microstructure evolution of a low alloy steel in continuous casting processing. Mater. Sci. Eng. A 2022, 838, 142828. [Google Scholar] [CrossRef]

- Lee, Y.-S.; Kim, S.; Jang, D.-W.; Lee, S.-B. Mechanism of crack initiation and propagation in high-alloy steel slabs during the cooling and scarfing processes after the continuous casting process. Mech. Mater. 2022, 166, 104240. [Google Scholar] [CrossRef]

- Allazadeh, M.R.; Garcia, C.I. FEM technique to study residual stresses developed in continuously cast steel during solid–solid phase transformation. Ironmak. Steelmak. 2011, 38, 566–576. [Google Scholar] [CrossRef]

- Li, G.; Yu, W.; Cai, Q. Investigation of reduction pretreatment process for continuous casting. J. Mater. Process Technol. 2016, 227, 41–48. [Google Scholar] [CrossRef]

- Zhang, L.; Shen, H.F.; Rong, Y.; Huang, T.Y. Numerical simulation on solidification and thermal stress of continuous casting billet in mold based on meshless methods. Mater. Sci. Eng. A 2007, 466, 71–78. [Google Scholar] [CrossRef]

- Galkin, S.P.; Aleschenko, A.S.; Romantsev, B.A.; Gamin, Y.V.; Iskhakov, R.V. Effect of Preliminary Deformation of Continuously Cast Billets by Radial-Shear Rolling on the Structure and Properties of Hot-Rolled Chromium-Containing Steel Pipes. Metallurgist 2021, 65, 185–195. [Google Scholar] [CrossRef]

- Koza, J.R. The genetic programming paradigm: Genetically breeding populations of computer programs to solve problems. In Dynamic, Genetic, and Chaotic Programming; John Wiley: Hoboken, NJ, USA, 1992; pp. 203–321. [Google Scholar]

- Koza, J.R. Genetic Programming II: Automatic Discovery of Reusable Programs; MIT Press: Cambridge, MA, USA, 1994. [Google Scholar]

- John, R.K.; Forrest, H.B.I.; David, A.; Martin, A.K. Genetic Programming III: Darwinian Invention and Problem Solving; Morgan Kaufmann: Cambridge, MA, USA, 1999. [Google Scholar]

- Kovačič, M.; Salihu, S.; Gantar, G.; Župerl, U. Modeling and Optimization of Steel Machinability with Genetic Programming: Industrial Study. Metals 2021, 11, 426. [Google Scholar] [CrossRef]

- Kovačič, M.; Župerl, U. Modeling of Tensile Test Results for Low Alloy Steels by Linear Regression and Genetic Programming Taking into Account the Non-Metallic Inclusions. Metals 2022, 12, 1343. [Google Scholar] [CrossRef]

- Kovačič, M.; Lešer, B.; Brezocnik, M. Modelling and optimization of sulfur addition during 70MnVS4 steelmaking: An industrial case study. Adv. Prod. Eng. Manag. 2021, 16, 253–261. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).