Abstract

This study investigates the impact of varying extrusion ratios on the microstructure and mechanical properties of AlSiCuFeMnYb alloy. Following hot extrusion, significant enhancements are observed in the microstructure of the cast rare earth aluminium alloy. Within the cross-sectional microstructure, the α-Al phase is reduced in size, and its dendritic morphology is eliminated. The morphology of the eutectic Si phase transitions from long strips to short rods, fine fibres, or granular forms. Similarly, the Fe-rich phase changes from a coarse skeletal and flat noodle shape to small strips and short skeletal forms resembling Chinese characters. The CuAl2 phase evolves from large blocks to smaller blocks and granular forms, while the Yb (Ytterbium)-rich rare earth phase shifts from large blocks to smaller, more uniformly distributed blocks. In the longitudinal section, the structure aligns into strips along the extrusion direction, with the spacing between these strips decreasing as the extrusion ratio increases. At an extrusion ratio of 22.56, the alloy demonstrates superior mechanical properties with a tensile strength of 325.50 MPa, a yield strength of 254.44 MPa, a hardness of 143.90 HV, and an elongation of 15.47%. These represent improvements of 27.8%, 36.5%, 38.9%, and 236.4%, respectively, compared with the as-cast rare earth alloy. In addition, the fracture surface of the extruded rare earth alloy exhibits obvious ductile fracture characteristics. Additionally, the alloy undergoes dynamic recrystallisation and dislocation entanglement during hot extrusion. The emergence of a twinned Si phase and a dynamically precipitated nanoscale CuAl2 phase are critical for enhancing deformation strengthening, modification strengthening, and dynamic precipitation strengthening of the extruded alloys.

1. Introduction

Aluminium–silicon alloys are extensively utilised in aviation engines, automotive components, and various aircraft parts owing to their high specific strength, low density, and excellent casting performance [1,2,3,4]. However, technological advancements have led to increased demands for the comprehensive performance of aluminium alloys. The microstructure of aluminium–silicon alloys typically contains many coarse secondary phases that are prone to segregation. This segregation can induce stress concentration by cleaving the matrix when the alloy is subjected to stress, severely impairing its mechanical properties [5,6,7]. Numerous studies have demonstrated that the effects of rare earths on aluminium alloys primarily involve modification, purification, and alloying [8,9,10]. Incorporating an appropriate quantity of rare earth elements into aluminium–silicon alloys can significantly enhance the microstructure, improving the size and morphology of secondary phases, refining the secondary dendrite arm spacing, and reducing porosity [11,12,13]. He et al. [14] investigated the impact of the Er element on the microhardness and precipitation behaviour of heat-treated Al-Si-Mg alloys. Their findings suggested that the thermal stability of over-aged Al-Si-Mg-Er alloy was closely associated with the average size of precipitates. Without natural ageing in the Al-Si-Mg-Er alloy, the β″ phase exhibited a smaller average size than that in the A-Si-Mg alloy, with a more concentrated size distribution. However, when natural ageing preceded artificial ageing, the size and distribution of precipitates in the Al-Si-Mg-Er alloy were similar to those in the Al-Si-Mg alloy. Furthermore, Wang et al. [15] explored the effect of the rare earth element Y on the microstructure and properties of A-7Si-0.3Mg-1.0Fe casting alloy. They identified that adding 0.3 wt.% Y significantly refined the Al5FeSi phase within the structure, minimising the spacing among secondary dendrite arms. The eutectic silicon phase was also substantially refined, and the Y-modified alloy exhibited optimal tensile performance under T6 heat treatment conditions. Therefore, the addition of rare earths to aluminium silicon alloys can markedly improve their microstructure and mechanical properties.

In addition, studies have shown that hot extrusion can significantly enhance the microstructure and overall mechanical properties of metal alloys [16,17,18]. MirJavadi et al. [19] investigated the impact of hot extrusion and T6 heat treatment on the microstructure and properties of graphene-reinforced Al-10Zn-3.5Mg-2.5Cu alloy. Their research revealed a uniform dispersion of graphene within the matrix, predominantly at grain boundaries. As the graphene content increased, the grain size of both as-cast and hot-extruded nanocomposites considerably decreased. Concurrently, the ultimate tensile strength of these nanocomposites improved, reaching up to 0.7% under both as-cast and hot extrusion conditions. Wei et al. [20] examined the influence of hot extrusion on the microstructure and mechanical properties of A356 alloy modified with rare earth Y. Following extrusion, significant enhancements were observed in the microstructure and properties; with a 0.2 wt.% Y addition, the ultimate tensile strength, hardness, and elongation of the extruded rare earth alloy were substantially increased to 328.2 MPa, 110.4 HV, and 21.3%, respectively, representing corresponding increases of 42.01%, 37.71%, and 481.91% over the cast matrix alloy. Furthermore, Gutiérrez et al. [21] explored the effects of alloying and hot extrusion on the texture, microstructure, and mechanical properties of graphene-reinforced 7075 alloy. Their findings indicated that the particle size of mechanically ground powder influences the grain size in the extruded samples. Most extruded samples exhibited deformation texture components, with less than 2° variation in orientation within the grains, suggesting recrystallisation driven by directional nucleation.

Overall, hot extrusion significantly improves the microstructure and properties of aluminium alloys. However, research on the hot extrusion of Al-Si alloys modified with rare earth elements is limited. Most research has focused on rare earth modification of cast Al-Si alloys, while there is relatively little research on the modification mechanism of rare earth Al-Si alloys after hot extrusion. In addition, many studies have found that hot extrusion can eliminate porosity inclusions and promote the flow and recrystallization of secondary phases in the alloy. Thus, investigating the hot extrusion of Al-Si alloys modified with rare earth elements is highly pertinent. This study utilised rare earth Yb to modify an AlSiCuFeMn alloy and examined the microstructure and mechanical properties of the resulting AlSiCuFeMnYb alloy under various extrusion ratios. Additionally, the toughening mechanisms of rare earth aluminium alloy under extrusion conditions were explored, aiming to establish a foundation for expanding the research and application of rare earth aluminium alloys.

2. Experimental

2.1. Experimental Materials

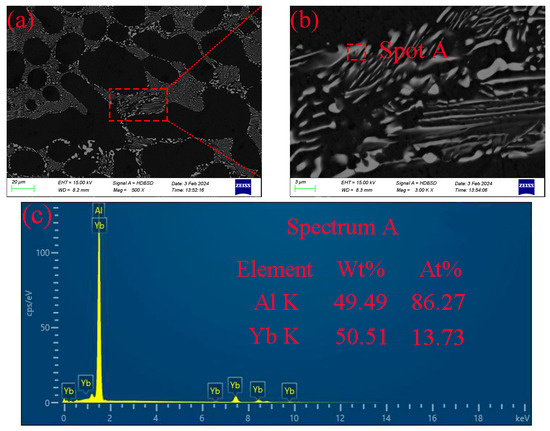

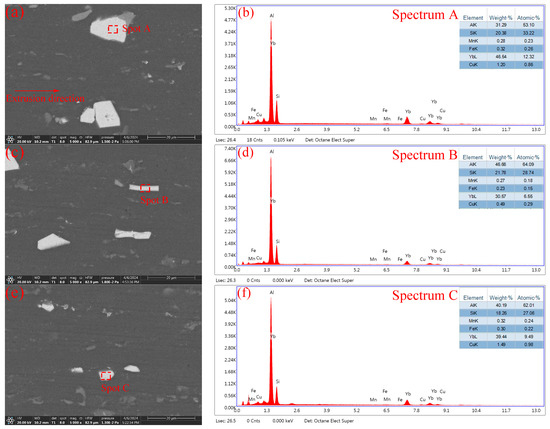

The matrix material for preparing the AlSiCuFeMnYb alloy was proportioned according to the mass fraction of each element, and its main composition is similar to that of the Al383 (ADC12) alloy, as detailed in Table 1. In the experiment, the direct addition of rare earth Yb to the matrix material could lead to significant burning loss during melting because of Yb’s high reactivity, thereby complicating the accurate determination of the specific rare earth content. By contrast, using an Al-10Yb (with a mass fraction of 10% Yb) intermediate alloy in the matrix can minimise the burning loss of Yb [22,23,24]. Additionally, compared with pure rare earth Yb, the Al-10Yb intermediate alloy facilitates a quicker diffusion of rare earth elements into the matrix, enhancing the modification effect. Therefore, the Al-10Yb intermediate alloy was selected as the rare earth material for this experiment. Figure 1 illustrates the scanning electron microscopy and energy spectrum analysis of the Al-10Yb intermediate alloy. Figure 1a shows the low-magnification scanning electron micrograph of the alloy, revealing a network-like structure of the intermetallic compound composed of rare earth Yb and Al. The area within the red box in Figure 1a is enlarged in Figure 1b, where the rare earth intermetallic compounds appear as strips, short rods, or particles. Energy spectrum analysis performed on point A in Figure 1b revealed its composition, as presented in Figure 1c.

Table 1.

Chemical composition of the AlSiCuFeMn alloy (mass fraction).

Figure 1.

SEM image of the Al-10Yb master alloy: (a) low-magnification SEM image, (b) an enlarged view of the red area in (a), and (c) eds of spot A in (b).

2.2. Preparation of AlSiCuFeMnYb Alloy

This experiment involved preparing rare earth Yb-modified AlSiCuFeMn alloy using an ultrasound-assisted method. The procedure is as follows: First, dry all necessary experimental instruments, such as graphite crucibles, moulds, and other operating tools. Then, place a specific weight of the chopped matrix alloy into a graphite crucible. Position the crucible in a resistance furnace and set the temperature to approximately 760 °C. Once the matrix alloy is completely melted, introduce a specified weight of the prepared Al-10Yb rare earth intermediate alloy. In order to reduce the burning loss of the intermediate alloy, the Al-10Yb intermediate alloy should be coated with aluminium foil. The added mass fraction of Yb constitutes 1.0 wt.% of the total alloy melt (whenever preparing rare earth aluminium alloys, the base aluminium alloy weighs 250 g, and the Al-10Yb intermediate alloy weighs 27.8 g). After incorporating all the Al-10Yb alloy, maintain the melt warm for 30 min before subjecting it to ultrasonic vibration at a power of 1.4 kW and a frequency of 20 kHz for 10 min. Following vibration, promptly skim off the slag and pour the molten aluminium into the preheated mould (The preheating temperature of the mould is 200 °C). The inner diameter of the mould is 38 mm, the outer diameter is 50 mm, and the height is 70 mm. Once the metal in the mould cools and solidifies, remove the sample to produce the cast AlSiCuFeMnYb alloy material. For comparison, also prepare an as-cast matrix alloy under the same process conditions.

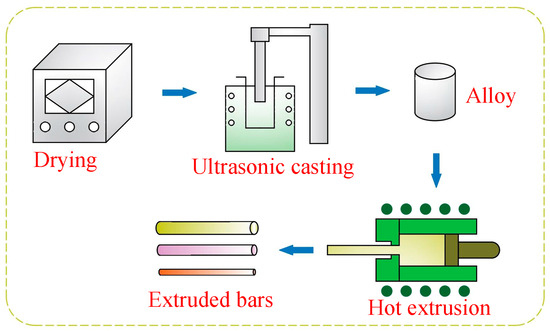

The subsequent steps include conducting hot extrusion experiments on the cast materials. Prior to hot extrusion, hold the alloy materials at the required extrusion temperature for 3 h. Following this, load cylindrical AlSiCuFeMnYb alloy ingots, measuring 38 mm in diameter and 60 mm in height, into a hot extrusion machine. Carry out the hot extrusion deformation of the material on a four-column hydraulic press with model HM035-200. The extrusion parameters include a temperature of 400 °C and a speed of 5 mm/min (under these extrusion parameters, the microstructure in the alloy is less prone to coarsening and segregation phenomena), with extrusion diameters of 16, 12, and 8 mm, corresponding to extrusion ratios of 5.64, 10.03, and 22.56, respectively (the value of extrusion ratio is equal to πR2/πr2, where R and r are the radius before and after extrusion, respectively). Immediately after extrusion, quench the cylindrical samples in water to obtain the final extruded form. Figure 2 presents the schematic of the AlSiCuFeMnYb alloy preparation process.

Figure 2.

Schematic diagram of the preparation process of the AlSiCuFeMnYb alloy.

2.3. Performance Testing and Material Characterization

The microstructural morphology of the alloy sample was examined using a Nican-M300 optical microscope (OM, Nikon Metrology, Inc., Brighton, UK), and the metallographic sample was etched with a 0.5% HF solution. Microhardness was assessed using an HVS-1000A microhardness tester (Laizhou Huayin Testing Instrument Co., Ltd., Laizhou, China). Room temperature mechanical properties were evaluated with a WDW-10PC universal testing machine (Electrical Equipment Co., Ltd., Zhuhai, China). The microstructure and fracture morphology were characterised and analysed using a Hitachi Regulus 8100 scanning electron microscope (Thermo Fisher Scientific, Ltd., South Bend, OR, USA), while microscopic characterisation of rare earth intermetallic compounds was conducted using a JEM-2100 transmission electron microscope (Japan Electron Optics Laboratory Co., Ltd., Akishima, Tokyo).

3. Results and Discussion

3.1. Cross-Sectional Optical Microstructure

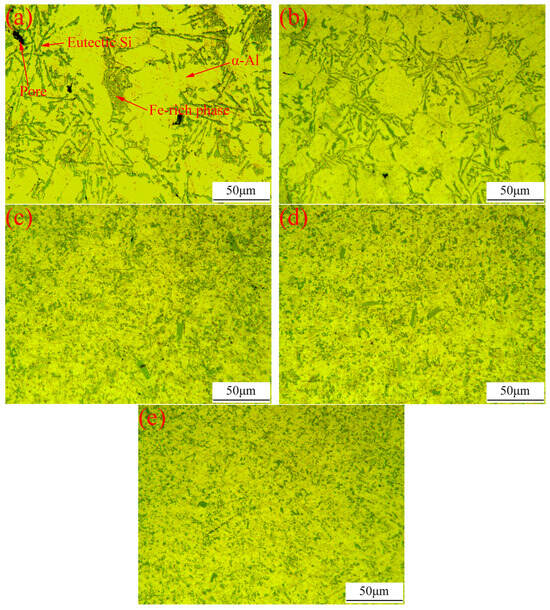

Figure 3 illustrates the cross-sectional optical microstructure of the as-cast AlSiCuFeMn alloy and the AlSiCuFeMnYb alloy under as-cast conditions and at various extrusion ratios. Figure 3a,b show the microstructure of the matrix and rare earth aluminium alloy under as-cast conditions, respectively. Figure 3c–e depict the microstructure of rare earth aluminium at extrusion ratios of 5.64, 10.03, and 22.56, respectively. Figure 3a reveals that the α-Al phase in the cast matrix aluminium alloy is relatively coarse, exhibiting some dendritic morphology. The secondary phases primarily consist of eutectic Si, CuAl2, iron-rich, and rare earth phases. The eutectic Si phase predominantly appears as long rods or long needle-shaped structures, while the iron-rich phase presents as long rods and skeletal structures. The CuAl2 and rare earth phases are indistinguishable in the optical microscope structure [25,26,27]. In addition, some big pores can be observed in Figure 3a, indicating that the microstructure density of the as-cast matrix alloy is poor. After adding rare earth Yb to the matrix alloy, the microstructure was refined, the dendritic α-Al phase decreased, the secondary dendritic arm spacing decreased, the eutectic Si phase transformed into a short rod shape, and the iron-rich phase was also refined to a certain extent, as shown in Figure 3b. After hot extrusion, the secondary phases in the microstructure of the cast rare earth aluminium alloy appeared refined. Figure 3c shows that with an extrusion ratio of 5.64, the dendritic morphology of the α-Al phase vanished, the size of the α-Al phase reduced, the eutectic Si phase transformed into smaller, fibrous forms, and the iron-rich phase assumed the shape of small, short skeletal Chinese characters. At an extrusion ratio of 10.03, the secondary phases were further refined, the eutectic Si phase became granular, and the iron-rich phase was refined into finer strips and short rods, as depicted in Figure 3d. Increasing the extrusion ratio to 22.56 results in significant refinement of the secondary phases, as shown in Figure 3e. The eutectic Si phase evolves into fine particles, while the iron-rich phase is reduced to small, short rods. These phases are more evenly distributed within the matrix following hot extrusion, reducing stress concentrations and significantly enhancing both the microstructure and properties of the alloy [28,29].

Figure 3.

The cross-sectional optical microstructure of the as-cast AlSiCuFeMn alloy and AlSiCuFeMnYb alloy in both as-cast and extruded states: (a) as-cast microstructure of the AlSiCuFeMn alloy, (b) as-cast microstructure of the AlSiCuFeMnYb alloy, (c) microstructure of the AlSiCuFeMnYb alloy with an extrusion ratio of 5.64, (d) microstructure of the AlSiCuFeMnYb alloy with an extrusion ratio of 10.03, and (e) microstructure of the AlSiCuFeMnYb alloy with an extrusion ratio of 22.56.

3.2. Longitudinal Optical Microstructure of Extruded AlSiCuFeMnYb Alloy

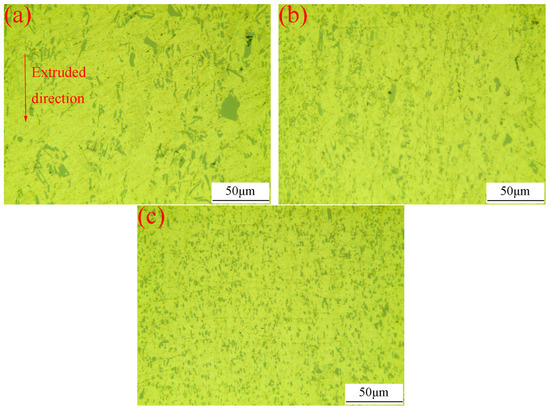

Figure 4 illustrates the longitudinal optical microstructure of the AlSiCuFeMnYb alloy under different extrusion ratios. Figure 4a presents the microstructure of the longitudinal section at an extrusion ratio of 5.64. This figure reveals that only a minor portion of the secondary phases have an extension direction misaligned with the extrusion direction. Predominantly, the secondary phases within the matrix extend towards the extrusion direction, forming a series of banded structures. Because of the relatively low extrusion ratio and the corresponding inadequate shear force, these banded structures are spaced relatively widely [30,31]. Additionally, Figure 4a shows a minor quantity of large secondary phase particles alongside evidence of segregation. As the extrusion ratio increases to 10.03, the orientation of these banded structures predominantly aligns with the extrusion direction, and the size of the secondary phases decreases. The spacing between these banded structures also reduces, although a small portion still exhibits larger gaps, as depicted in Figure 4b. Upon further increasing the extrusion ratio to 22.56, the secondary phases within the microstructure become more refined, the spacing between the banded structures decreases further, and the dimensions become more uniform, with no apparent segregation, as demonstrated in Figure 4c.

Figure 4.

Longitudinal optical microstructure of the extruded AlSiCuFeMnYb alloy: (a) microstructure with an extrusion ratio of 5.64, (b) microstructure with an extrusion ratio of 10.03, and (c) microstructure with an extrusion ratio of 22.56.

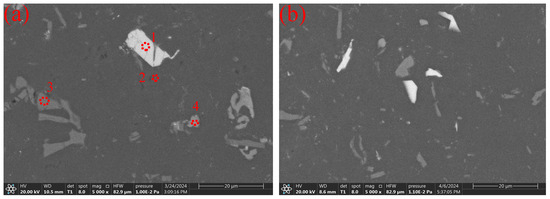

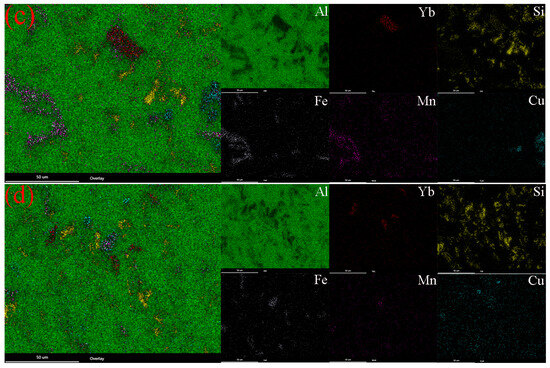

3.3. Comparative Analysis of Scanning Electron Microscopy

Figure 5 shows the backscattered high-magnification scanning electron micrograph and surface scanning distribution of the AlSiCuFeMnYb alloy in as-cast form and with an extrusion ratio of 22.56. Figure 5a,b reveal that the microstructure exhibits phases of differing colours and morphologies. Figure 5c and Figure 5d correspond to the surface scan distributions of the elements in Figure 5a and Figure 5b, respectively. Figure 5a reveals large blocks of bright-coloured phases, deep grey skeletal phases, deep grey strip-like phases, and light grey small block-like phases within the cast microstructure. After applying a higher compression ratio, as shown in Figure 5b, these secondary phases in the microstructure are significantly reduced in size. Analysis of Figure 5a,c indicates that the distribution of Yb is primarily concentrated in the bright white block phases, while Si is distributed relatively uniformly with an average eutectic Si phase length of approximately 16.4 µm. The Fe element predominantly resides in the deep grey skeletal and strip-like phases, with Mn distribution largely overlapping that of Fe. The Cu element is primarily found in the light grey small block-like phases. Observations in Figure 5b,d demonstrate that Yb remains concentrated in small bright white block-like phases, whereas the Si distribution becomes even more uniform, with the average eutectic Si phase length reducing to approximately 6.5 µm. Fe and Mn are mainly located in the small strip or block phases of dark grey, with Mn presenting a lower density than Fe, and Cu is predominantly located in the granular light grey phases.

Figure 5.

SEM microstructure of the AlSiCuFeMnYb alloy as-cast and extruded: (a) scanning microstructure as-cast, (b) scanning microstructure with an extrusion ratio of 22.56, (c):(a) corresponding surface scan; and (d):(b) corresponding surface scan.

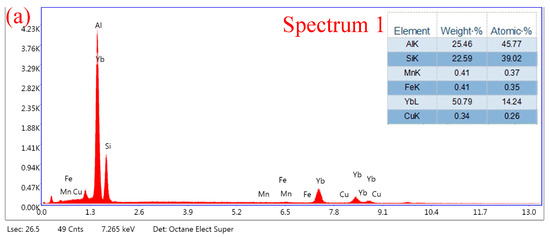

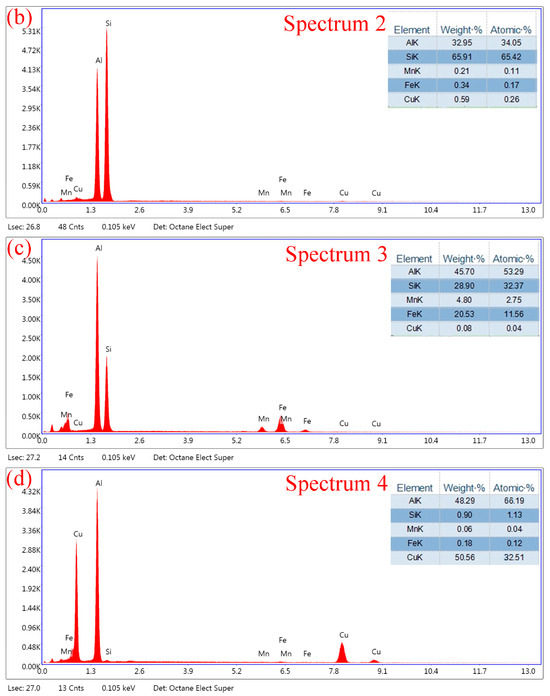

To investigate the specific composition of various phases in rare earth aluminium alloys, energy spectrum analysis was conducted on the four designated points in Figure 5a, as depicted in Figure 6. Figure 6a presents the energy spectrum analysis corresponding to point 1 in Figure 5a. This analysis reveals that the bright white block-like phase is a rare earth intermetallic compound, primarily composed of Al, Si, and Yb, with an atomic ratio of approximately 3:3:1. Figure 6b corresponds to the energy spectrum analysis of point 2 in Figure 5a. In conjunction with Figure 5c, it is evident that this light-coloured, short rod-shaped or small block-shaped phase is an eutectic Si phase, predominantly consisting of Al and Si, with an atomic ratio of approximately 1:2. Figure 6c relates to the energy spectrum analysis of point 3 in Figure 5a. Together with Figure 5c, the observations indicate that the dark grey skeletal or strip-shaped phase is an iron-rich phase, composed mainly of Al, Si, Fe, and Mn, with the atomic proportions of these elements being approximately 19:12:4:1. Figure 6d corresponds to the energy spectrum analysis of point 4 in Figure 5a, which shows a predominance of Cu and Al with an atomic ratio of approximately 1:2. This light grey small block phase is identified as the CuAl2 phase.

Figure 6.

Energy spectrum analysis corresponding to different points in Figure 5a: (a) EDS corresponding to point 1; (b) EDS corresponding to point 2; (c) EDS corresponding to point 3; and (d) EDS corresponding to point 4.

Figure 7 presents the scanning electron microscopy and energy spectrum analysis of the AlSiCuFeMnYb alloy under varying extrusion ratios. Figure 7a shows the high-magnification scanning electron micrograph of the longitudinal section of the rare earth aluminium alloy at an extrusion ratio of 5.64. This figure reveals that the secondary phase is aligned along the extrusion direction, with two bright white phases visible within the microstructure. One rare earth phase appears sheared into two smaller fragments by the extrusion pressure and is on the verge of separation. The scanning electron microscopy analysis in Figure 5 suggests that this phase is a rare earth intermetallic compound. Figure 7b provides the energy spectrum analysis at point A from Figure 7a, confirming that this bright white phase is a rare earth phase. Figure 7c depicts the high-magnification scanning electron micrograph of the longitudinal section of the rare earth aluminium alloy at an extrusion ratio of 10.03. It shows the rare earth phase sheared into short rod-like and small block-like shapes along the extrusion direction. Figure 7d follows with the energy spectrum analysis of point B from Figure 7c. As the extrusion ratio increases to 22.56, the rare earth phases are further compressed into small or even granular forms, uniformly distributed, as illustrated in Figure 7e. Figure 7f shows the energy spectrum analysis for point C in Figure 7e. The analyses from Figure 7b,d,f reveal that the bright white rare earth phase predominantly comprises the following three elements: Al, Si, and Yb. Additionally, some rare earth phases also contain a trace amount of Cu, while the content of the Fe and Mn elements is negligible.

Figure 7.

Longitudinal section scanning microstructure and corresponding energy spectrum of AlSiCuFeMnYb alloys under different extrusion ratios: (a) longitudinal section microstructure of rare earth alloys with an extrusion ratio of 5.64; (b) energy spectrum analysis at point A; (c) longitudinal section microstructure of rare earth alloys with an extrusion ratio of 10.03; (d) energy spectrum analysis at point B; (e) longitudinal section microstructure of rare earth alloys with an extrusion ratio of 22.56; and (f) energy spectrum analysis at point C.

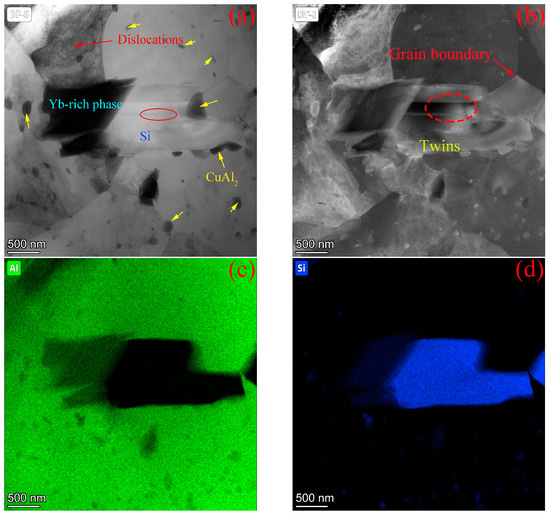

3.4. Analysis of Transmission Electron Microscopy

Figure 8 shows the transmission electron microscopy structure of the AlSiCuFeMnYb alloy at an extrusion ratio of 22.56. Figure 8a presents the bright-field image of the microstructure, while Figure 8b illustrates the corresponding dark-field image. Figure 8c–f depict the surface scans for the elements Al, Si, Yb, and Cu as identified in Figure 8a. Figure 8a reveals dark black block-like phases and lighter black small or granular phases. Additionally, dislocation entanglement is evident above the dark black bulk phase, and a light white bulk phase is also visible to its right [32,33]. Figure 8b distinctly reveals the twinning structure on the light white block phase, and fine grain boundaries are also observable. Figure 8c shows the surface distribution of the Al element, indicating that, apart from the black phase visibly outlined in Figure 8a, the Al element predominates in most other areas. Figure 8d identifies the distribution of the Si element, which is primarily concentrated in the light white block phase area shown in Figure 8a, with some Si elements also present in the dark black block phase area. Figure 8e demonstrates that the Yb element is mainly located within the dark black block phase area. Figure 8f illustrates that the Cu element is predominantly distributed within the range of light black small or granular phases in Figure 8a, with a minor enrichment of Cu also evident in the deep black block phase area. Figure 8a–f indicate that this dark block phase is a rare earth phase, mainly comprising the Al, Yb, and Si elements. Some rare earth phases also contain a small amount of Cu, consistent with the scanning energy spectrum results from Figure 4 and Figure 5. This light black small or granular form is identified as the CuAl2 phase, distributed within the crystal and at grain boundaries, with sizes reaching the nanometre level because of the dynamic precipitation phenomenon observed in rare earth aluminium alloy during hot extrusion. Additionally, the light white phase adjacent to the block-like rare earth phase is determined to be the eutectic Si phase, where a twinned Si structure has formed. This occurs during the solidification of the alloy, as α-Al nucleates and grows prior to the Si phase. Concurrently, Si and Yb atoms are expelled to the front of the solid–liquid interface, enriching the silicon content in the liquid phase. During the eutectic reaction, as the silicon crystal grows along the {111} crystal plane and <211> crystal direction, Yb atoms induce a single-layer lattice distortion on the Si crystal surface. Instead of occupying the expected lattice positions, they preferentially adsorb at the twin boundaries, resulting in a twinned structure [34]. This phenomenon slows the growth of silicon atom tetrahedral stacking along the twin boundaries, forcing the Si crystal to branch along the <100> or <110> crystal directions, thereby transforming the Si phase from long strips or plate strips into short rods, small blocks, fibrous forms, or even fine particles. Figure 8g presents the diffraction patterns corresponding to the rare earth elements shown in Figure 8a. Figure 8h shows the high-density dislocations generated in the microstructure of the extruded alloy. Fine submicron-sized grains, resulting from dynamic recrystallisation of the rare earth aluminium alloy during hot extrusion, can also be observed [35,36].

Figure 8.

Transmission electron microscopy structure of the AlSiCuFeMnYb alloy with an extrusion ratio of 22.56: (a) bright-field image, (b) dark-field image, (c) surface scan of the Al element, (d) surface scan of the Si element, (e) surface scan of the Yb element, (f) surface scan of the Cu element, (g) diffraction spot of rare earth phase, and (h) dislocation.

3.5. Mechanical Performance Testing and Fracture Scanning

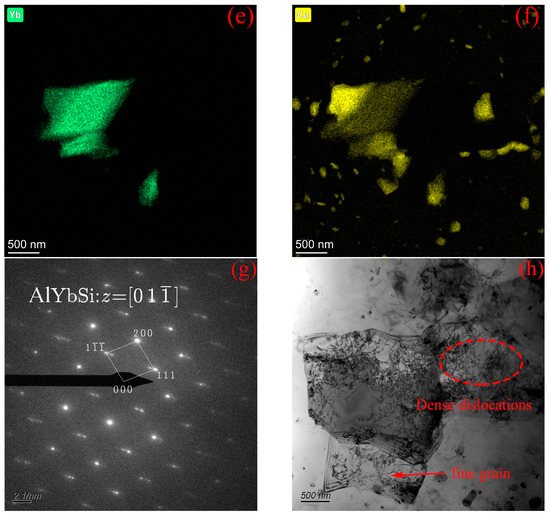

Figure 9 illustrates the mechanical properties of the as-cast AlSiCuFeMn alloy and the AlSiCuFeMnYb alloy in both as-cast and extruded states. Figure 9a shows that the tensile strength and yield strength of the as-cast matrix alloy are 183.6 and 140.9 MPa, respectively. After adding rare earth Yb to the matrix alloy, its tensile strength and yield strength are 254.7 MPa and 186.4 MPa, respectively, which increased by 38.7% and 32.3% compared to the as-cast matrix alloy, respectively. Following hot extrusion, these strengths improve to varying extents. Particularly, at an extrusion ratio of 22.56, the alloy exhibits enhanced mechanical properties with a tensile strength of 325.50 MPa and a yield strength of 254.44 MPa; these represent increases of 27.8% and 36.5%, respectively, compared with the as-cast rare earth aluminium alloy. Figure 9b provides a comparative analysis of the alloy’s elongation. The elongation of the as-cast matrix aluminium alloy and rare earth aluminium alloy are 2.5% and 4.6%, respectively. As the extrusion ratio increases within a certain range, there is a continuous increase in elongation. At an extrusion ratio of 22.56, the elongation reaches 15.47%, which is 236.4% higher than that of the as-cast rare earth aluminium alloy. Figure 9c provides a comparative analysis of the alloy’s hardness. The hardness of the as-cast rare earth aluminium alloy is measured at 103.6 HV. With an extrusion ratio of 5.64, the hardness increases to 122.56 HV, marking an 18.3% improvement. At an extrusion ratio of 10.03, the hardness further rises to 129.71 HV, showing a modest increase. As the extrusion ratio reaches 22.56, the hardness increases to 143.90 HV, which is 38.9% higher than that of the as-cast rare earth aluminium alloy. Therefore, from the comparison of these performances, it can be seen that a good microstructure determines excellent performance [37].

Figure 9.

Tensile properties of the as-cast AlSiCuFeMn alloy and the as-cast and extruded AlSiCuFeMnYb alloy: (a) tensile strength, (b) elongation, and (c) hardness.

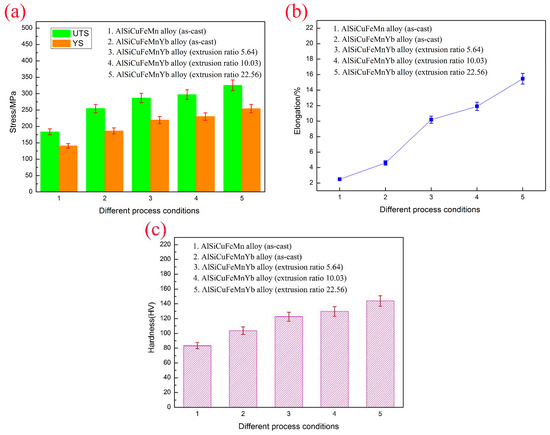

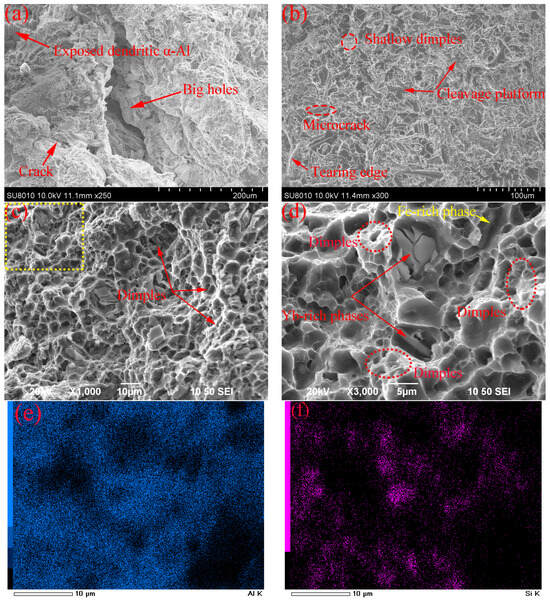

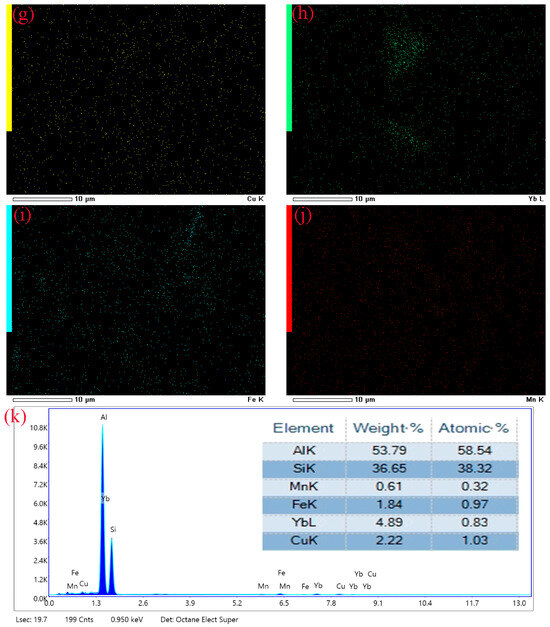

Figure 10 illustrates the tensile fracture scanning of the as-cast AlSiCuFeMn alloy and the AlSiCuFeMnYb alloy in both as-cast and extruded states (extrusion ratio of 22.56). Figure 10a presents the fracture surface of the as-cast matrix alloy. In Figure 10a, big pores and some obvious cracks can be observed. The formation is attributed to the stress concentration caused by the intrusion of coarse secondary phases, such as elongated and large-sized iron-rich and rare earth phases, under load, which significantly reduces the mechanical properties of the material. In addition, the exposed α-Al phase can also be observed in Figure 10a, and there are almost no obvious ductile dimples on the fracture surface, which is a clear characteristic of brittle fracture [38]. Figure 10b shows the fracture surface of the as-cast rare earth alloy. The figure reveals large cleavage platforms, coarse tearing ridges, and the presence of microcracks on the fracture surface, indicative of brittle fracture. Additionally, Figure 10b shows a small number of shallow ductile dimples, suggesting ductile fracture characteristics on the fracture surface of the alloy. After extrusion, as shown in Figure 10c, numerous small, uniform, and deep ductile dimples emerge on the fracture surface of the cast alloy material. The square area is magnified for closer observation in Figure 10d, where many small submicron-sized dimples on the fracture surface are visible, with some crushed secondary phases embedded deeply within the larger dimples. Elemental surface scanning analysis was conducted on the fracture morphology, as depicted in Figure 10e–j. Figure 10e demonstrates that the distribution of the Al element is relatively uniform, except in areas with deep dimples where there is no aggregation. Figure 10f shows that the eutectic Si phase, which became smaller in size and more evenly distributed after hot extrusion and rare earth Yb modification, is primarily concentrated in these small dimples. The morphology of this phase transformed from long bars to short rods, fibres, small blocks, and even granular forms, predominantly enriched at the grain boundaries and forming small grains. Consequently, under tensile stress, many small submicron-sized dimples readily form around the enriched Si phase. Figure 10g confirms that the distribution of the Cu element is relatively uniform. Figure 10h shows the distribution of the Yb element, while Figure 10i,j illustrate the distributions of Fe and Mn elements, respectively. Together with Figure 10d, the observations indicate that the block-like and short rod-like phases embedded deep in the ductile dimples are rare earth Yb phases. The block-like rare earth phases are fragmented, and small strip-like Fe-rich phases are distributed in the upper right corner of the ductile dimples. These phases, which are relatively small in size, contribute to strengthening the alloy under stress. Figure 10k shows the corresponding element fractions of Al, Si, Cu, Yb, Fe, and Mn. In summary, the fracture morphology of the cast rare earth aluminium alloy gradually transitions from mixed-mode fracture to predominantly ductile fracture following a certain degree of hot extrusion.

Figure 10.

Scanning observation of the fracture surface of the as-cast AlSiCuFeMn alloy and AlSiCuFeMnYb alloy in the as-cast and extrusion ratio of 22.56: (a) fracture surface of the as-cast matrix alloy; (b) fracture surface of the as-cast rare earth alloy; (c) extruded alloy fracture surface; (d) an enlarged view of the yellow area in (c); (e–j) surface scanning of the Al, Si, Cu, Yb, Fe, Mn elements; and (k) the element fractions of Al, Si, Cu, Yb, Fe, and Mn.

3.6. Analysis of the Strengthening Mechanism

There may be two reasons for the mechanism of rare earth Yb modification of aluminium–silicon alloys. The first reason concerns grain refinement induced by undercooling: adding rare earth Yb to an aluminium–silicon alloy can lower the eutectic reaction temperature, altering the distribution of Al and Si atoms at the solid–liquid interface. This generates greater undercooling, changes the growth mode of the eutectic microstructure, and consequently refines the microstructure [39]. The second reason is the strong ability of rare earth Yb to modify the eutectic Si phase: given the atomic radius of rare earth Yb is 0.222 nm and that of Si is 0.134 nm, the radius ratio of Yb to Si is 1.657. The IIT theoretical model [40] proposes that when the ratio of rare earth atoms to silicon atoms approximates 1.65, rare earth atoms are most likely to adsorb on the surface of silicon crystals, inhibiting their growth. In this experiment, the value of 1.657 closely aligns with 1.65, suggesting that rare earth Yb effectively modifies and strengthens the alloy.

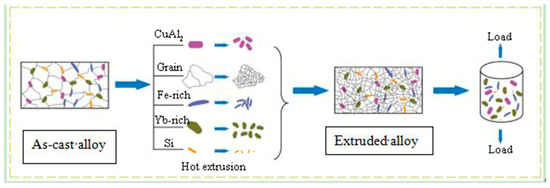

Figure 11 is a schematic of the microstructural changes in rare earth aluminium alloy during the hot extrusion process. The figure illustrates the presence of α-Al, CuAl2, Fe-rich, rare earth Yb, and eutectic Si phases, which initially have relatively coarse grains and secondary phases. With sufficient hot extrusion, these secondary phases are fragmented under the action of extensive shear forces. Concurrently, the number of pore inclusions within the structure significantly diminishes, and the density of the structure markedly improves. High-density dislocations also appear within the alloy. The stored distortion energy from dislocation promotes dynamic recrystallisation during hot extrusion, enhancing grain refinement. Furthermore, hot extrusion refines and uniformly disperses the rare earth Yb phase, enhancing the metamorphic strengthening effect of the Yb. Therefore, the hot extrusion process induces secondary phase dispersion strengthening, fine-grained strengthening, and dislocation strengthening, collectively contributing to a significant deformation–strengthening effect [41]. Additionally, dynamic precipitation of the CuAl2 phase occurs during the alloy’s hot extrusion. Most of these precipitated phases are small nanospheres, uniformly distributed within the grains and at the grain boundaries, and they significantly enhance the precipitation strengthening of the alloy [42,43].

Figure 11.

Schematic diagram of microstructure changes in rare earth aluminium alloy during the hot extrusion process.

4. Conclusions

A rare earth Yb-modified AlSiCuFeMn alloy was prepared by ultrasonic casting, and the results showed that rare earth Yb can refine the α-Al phase and eutectic Si phase to a certain extent in the microstructure. Following hot extrusion, significant enhancements are observed in the microstructure of the cast rare earth aluminium alloy.

As the extrusion ratio increases, the mechanical properties of AlSiCuFeMnYb alloy gradually improve. At an extrusion ratio of 22.56, the alloy demonstrates superior mechanical properties with a tensile strength of 325.50 MPa, a yield strength of 254.44 MPa, a hardness of 143.90 HV, and an elongation of 15.47%. These represent improvements of 27.8%, 36.5%, 38.9%, and 236.4%, respectively, compared to the as-cast rare earth alloy. In addition, the fracture surface of the extruded rare earth alloy exhibits obvious ductile fracture characteristics.

The alloy undergoes dynamic recrystallisation and dislocation entanglement during hot extrusion. The emergence of a twinned Si phase and dynamically precipitated nanoscale CuAl2 phase are critical for enhancing deformation strengthening, modification strengthening, and dynamic precipitation strengthening of the extruded alloys.

Author Contributions

Conceptualization, X.J., J.X. and L.Z.; methodology, X.J. and J.X.; investigation, X.J. and J.X.; resources, X.J. and J.X.; data curation, X.J., J.X. and L.Z.; writing—original draft, X.J. and J.X.; writing—review and editing, X.J., J.X. and L.Z.; supervision, X.J.; project administration, X.J. and J.X.; funding acquisition, X.J. and L.Z. All authors have read and agreed to the published version of this manuscript.

Funding

This study was supported by the High-level Talents Research Project of West Anhui University (Grant Nos. WGKQ2022058) and the Fundamental Research Funds for the Central Universities of China (Grant No.PA2023GDSK0057).

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Xu, C.; Xiao, W.L.; Hanada, S.; Yamagata, H.; Ma, C.L. The effect of scandium addition on microstructure and mechanical properties of Al-Si-Mg alloy a multi-refinement modifier. Mater Charact. 2015, 110, 160–169. [Google Scholar] [CrossRef]

- Liu, W.Y.; Xiao, W.L.; Xu, C.; Liu, M.W.; Ma, C.L. Synergistic effects of Gd and Zr on grain refinement and eutectic Si modification of Al-Si cast alloy. Mater. Sci. Eng. A 2017, 693, 93–100. [Google Scholar] [CrossRef]

- Zheng, Q.J.; Zhang, B.; Chen, T.; Wu, J. Achieving superior grain refinement efficiency for Al–Si casting alloys through a novel Al-La-B grain refiner. J. Mater. Res. Technol. 2024, 30, 52–60. [Google Scholar] [CrossRef]

- Li, Q.L.; Xia, T.D.; Lan, Y.F.; Zhao, W.J.; Fan, L.; Li, P.F. Effect of rare earth cerium addition on the microstructure and tensile properties of hypereutectic Al-20%Si alloy. J. Alloys Compd. 2013, 562, 25–32. [Google Scholar] [CrossRef]

- Dimitrova, R.; Simeonova, T.; Krastev, B.; Velikov, A.; Petkov, V.; Manolov, V. Al and A356 Alloy Foam Castings Modified with Low Concentrations of Nano-Sized Particles: Structural Study and Compressive Strength Tests. Metals 2024, 14, 542. [Google Scholar] [CrossRef]

- Hu, Z.H.; Peng, X.; Wu, G.H. Microstructure evolution and mechanical properties of rheo-processed ADC12 alloy. Trans. Nonferrous Met. Soc. China 2016, 26, 3070–3080. [Google Scholar] [CrossRef]

- Lei, X.X.; Li, Y.K.; Du, X.D. Microstructural features of AlFeSi spherical particles in hypoeutectic Al-Si alloy. Mater. Today Commun. 2023, 37, 107105. [Google Scholar] [CrossRef]

- Cardinale, A.M.; Maccio, D.; Luciano, G.; Canepa, E.; Traverso, P. Thermal and corrosion behavior of as cast Al-Si alloys with rare earth elements. J. Alloys Compd. 2017, 695, 2180–2189. [Google Scholar] [CrossRef]

- Mao, G.L.; Yan, H.; Zhu, C.C.; Wu, Z.; Gao, W.L. The varied mechanisms of yttrium (Y) modifying a hypoeutectic Al-Si alloy under conditions of different cooling rates. J. Alloys Compd. 2019, 806, 909–916. [Google Scholar] [CrossRef]

- Kazuhiro, N.; Stuart, D.M.; Arne, K.D. Eutectic modification of Al-Si alloys with rare earth metals. Mater Trans. 2004, 2, 323. [Google Scholar]

- Pandee, P.; Gourlay, C.; Belyakov, S.; Patakham, U. AlSi2Sc2 intermetallic formation in Al-7Si-0.3Mg-xSc alloys and their effects on as-cast properties. J. Alloys Compd. 2018, 731, 1159–1170. [Google Scholar] [CrossRef]

- Ye, K.F.; Cai, X.L.; Sun, B. Effect of rare earth Ce on the microstructure and mechanical properties of cast Al7Si alloys. J. Sci.-Adv. Mater. Dev. 2023, 8, 100634. [Google Scholar]

- Hu, Z.; Ruan, X.M.; Yan, H. Effects of neodymium addition on microstructure and mechanical properties of near-eutectic Al-12Si alloys. Trans. Nonferrous Met. Soc. China 2015, 25, 3877–3885. [Google Scholar] [CrossRef]

- He, Y.; Xi, H.H.; Ming, W.Q. Thermal stability and precipitate microstructures of Al-Si-Mg-Er alloy. Trans. Nonferrous Met. Soc. China 2021, 31, 1–10. [Google Scholar] [CrossRef]

- Wan, B.B.; Chen, W.P.; Liu, L.S. Effect of trace yttrium addition on the microstructure and tensile properties of recycled Al-7Si-0.3Mg-1.0Fe casting alloys. Mater. Sci. Eng. A 2016, 666, 165–175. [Google Scholar] [CrossRef]

- Li, L.; Zhang, C.C.; Lv, H.; Liu, C.R.; Wen, Z.Z.; Jiang, J.W. Texture development and tensile properties of Mg–Yb binary alloys during hot extrusion and subsequent annealing. J. Magnes. Alloys 2022, 10, 249–265. [Google Scholar] [CrossRef]

- Yang, Z.; Xu, C.; Nakata, T.; Kamado, S. Effect of extrusion ratio and temperature on microstructures and tensile properties of extruded Mg-Gd-Y-Mn-Sc alloy. Mater. Sci. Eng. A 2021, 800, 140330. [Google Scholar] [CrossRef]

- Deaquino-Lara, R.; Soltani, N.; Bahrami, A.; Gutiérrez-Castañeda, E.; García-Sánchez, E.; Hernandez-Rodríguez, M.A.L. Tribological characterization of Al7075-graphite composites fabricated by mechanical alloying and hot extrusion. Mater. Des. 2015, 67, 224–231. [Google Scholar] [CrossRef]

- Mirjavadi, S.S.; Alipour, M.; Hamouda, A.M.S.; Kord, S.; Praveennath, G.K.; Abuzin, Y.A.; Keshavamurthy, R. Effect of hot extrusion and T6 heat treatment on microstructure and mechanical properties of Al-10Zn-3.5Mg-2.5Cu nanocomposite reinforced with graphene nanoplatelets. J. Manuf. Process. 2018, 36, 264–271. [Google Scholar] [CrossRef]

- Wei, Z.F.; Lei, Y.S.; Yan, H.; Xu, X.H.; He, J.J. Microstructure and mechanical properties of A356 alloy with yttrium addition processed by hot extrusion. J. Rare Earths 2019, 37, 659–667. [Google Scholar] [CrossRef]

- Gutiérrez, E.; Salazar, E.; Salinas, A.; Deaquino, R.; Ponce, A.; Yacaman, M.; Alducin, D.; Ortega, E.; Bedolla, A.; Fernández, B.; et al. Texture, microstructure and mechanical properties of AA7075-graphite composites produced through mechanical alloying and hot-extrusion. Mater. Chem. Phys. 2023, 296, 127323. [Google Scholar]

- Amer, S.M.; Glavatskikh, M.V.; Barkov, R.Y.; Khomutov, M.G.; Pozdniakov, A.V. Phase composition and mechanical properties of Al-Si based alloys with Yb or Gd addition. Mater. Lett. 2022, 320, 132320. [Google Scholar] [CrossRef]

- Wang, W.Y.; Pan, Q.L.; Lin, G.; Wang, X.P.; Sun, Y.Q.; Wang, X.D.; Ye, J.; Sun, Y.W.; Yu, Y.; Jiang, F.Q.; et al. Microstructure and properties of novel Al-Ce-Sc, Al-Ce-Y, Al-Ce-Zr and Al-Ce-Sc-Y alloy conductors processed by die casting, hot extrusion and cold drawing. Mater. Sci. Technol. 2020, 58, 155–170. [Google Scholar] [CrossRef]

- Alkahtani, S.A.; Elgallad, E.M.; Tash, M.M.; Samuel, A.M.; Samuel, F.H. Effect of rare earth metals on the microstructure of Al-Si based alloys. Materials 2016, 9, 45. [Google Scholar] [CrossRef] [PubMed]

- Shi, Z.P.; He, R.H.; Chen, Y.; Yan, H.; Song, H.G.; Luo, C.; Nie, Q.; Hu, Z. Microstructural evolution and strengthening mechanisms of a novel Al-11Si-3Cu alloy microalloyed with minor contents of Sr and Sc. Mater. Sci. Eng. A 2022, 853, 143738. [Google Scholar] [CrossRef]

- Saijo, S.; Koyama, S.; Shohji, I. Liquid Phase Diffusion Bonding of AC2C/ADC12 Aluminum Casting Alloy by Using Metal Salt Coated Zn Sheet. Procedia Eng. 2017, 184, 284–289. [Google Scholar] [CrossRef]

- Khalifa, W.; Tsunekawa, Y.; Okumiya, M. Effect of ultrasonic treatment on the Fe-intermetallic phases in ADC12 die cast alloy. J. Mater. Process. Technol. 2010, 210, 2178–2187. [Google Scholar] [CrossRef]

- Ding, C.; Hao, H.L.; Lu, Z.G.; Yu, C.Y.; Wu, X.Z.; Yu, P.; Ye, S.L. Fabrication of hypereutectic Al-Si alloy with improved mechanical and thermal properties by hot extrusion. Mater. Charact. 2023, 202, 113026. [Google Scholar] [CrossRef]

- Wan, S.X.; Su, H.; Shao, B.; Zong, Y.Y.; Shan, D.B.; Guo, B. Changes in microstructure and mechanical properties of 2219 Al alloy during hot extrusion and post-extrusion aging. J. Mater. Res. Technol. 2023, 24, 3453–3463. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, X.Y.; Lu, Y.L.; Li, X.P. Microstructure and mechanical properties of as-extruded Mg-Sn-Zn-Ca alloy with different extrusion ratios. Trans. Nonferrous Met. Soc. China 2018, 28, 2190–2198. [Google Scholar] [CrossRef]

- Demirci, H.I.; Evlen, H. Effect of extrusion ratio on the wear behaviour of Al-Si and Al-Mg alloys. J. Alloys Compd. 2012, 510, 26–32. [Google Scholar] [CrossRef]

- Fu, R.; Feng, Z.Q.; Huang, X.X. Orientation distribution and deviation behaviors of dislocation loops in a quenched Al-Cu alloy. Acta Mater. 2024, 270, 119837. [Google Scholar] [CrossRef]

- Thirathipviwat, P.; Nozawa, S.; Furusawa, M.; Onuki, Y.; Hasegawa, M.; Matsumoto, K.; Sato, S. In-situ neutron diffraction study on a dislocation density in a correlation with strain hardening in Al-Mg alloys. Mater. Sci. Eng. A 2022, 855, 143956. [Google Scholar] [CrossRef]

- Lu, S.Z.; Hellawell, A. The Mechanism of Silicon modification in Aluminium-Silicon Alloys: Impurity Induced Twinning. Metall. Trans. A 1987, 18, 1721–1725. [Google Scholar] [CrossRef]

- Wang, H.; Qin, G.L.; Li, C.A.; Liang, G.D. Effect of deformation parameters and Al2Cu evolution on dynamic recrystallization of 2219-O Al alloy during hot compression. J. Mater. Res. Technol. 2023, 26, 4093–4106. [Google Scholar] [CrossRef]

- Canelo-Yubero, D.; Kovács, Z.; Thierry Simonet Fotso, J.F.; Tolnai DScheel NGroma, I.; Poletti, C. In-situ characterization of continuous dynamic recrystallization during hot torsion of an Al-Si-Mg alloy. J. Alloys Compd. 2020, 822, 153282. [Google Scholar] [CrossRef]

- Starink, M.J.; Gao, N.; Kampa, N.; Wang, S.C.; Pitcherb, P.D.; Sinclair, I. Relations between microstructure, precipitation, age-formability and damage tolerance of Al-Cu-Mg-Li (Mn, Zr, Sc) alloys for age forming. Mater. Sci. Eng. A 2006, 418, 241–249. [Google Scholar] [CrossRef]

- Xiong, J.J.; Liu, Z.B.; Yan, H. Effects of hot extrusion on the microstructure and mechanical properties of 2024Al-GNPs composites. Diam. Relat. Mater. 2023, 131, 109551. [Google Scholar] [CrossRef]

- Knuutinen, A.; Nogita, K.; McDonald, S.D.; Dahle, A.K. Porosity formation in aluminium alloy A356 modified with Ba, Ca, Y and Yb. J. Light Met. 2001, 1, 241–245. [Google Scholar] [CrossRef]

- Nogita, K.; Yasuda, H.; Yoshiya, M.; McDonald, S.D.; Uesugi, K.; Takeuchi ASuzuki, Y. The role of trace element segregation in the eutectic modification of hypoeutectic Al-Si alloys. J. Alloys Compd. 2010, 489, 415–420. [Google Scholar] [CrossRef]

- Sivasankaran, S.; MIrfan ORamkumar, K.R.; Ammar, H.R.; Al-Mufadi, F.A.; Alaboodi, A.S.; Kim, H.S. Manufacturing of (Al-10Zn)/TiB2 in-situ nanocomposites by reactive liquid metallurgy and hot-extrusion for enhanced interfacial bonding and mechanical properties. Mater. Sci. Eng. A 2022, 859, 144200. [Google Scholar] [CrossRef]

- Li, M.X.; Yang, W.K.; Tian, X.L.; Chen, L.W.; Hou, H.; Zhao, Y.H. Precipitation and refining of Al2Cu in graphene nanoplatelets reinforced 2024 Al composites. Mater. Charact. 2023, 200, 112854. [Google Scholar] [CrossRef]

- KIMNJ Design of high performance structural alloys using second phase. Mater. Sci. Eng. A 2007, 449–451, 51–56.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).