Lithium-ion batteries (LIBs) are widely acknowledged as a very desirable power source owing to their numerous advantages, including a high operating voltage, elevated energy density, low self-discharge rate, exceptional stability, and environmentally friendly characteristics [

1,

2]. The overall performance of a lithium-ion battery is largely dependent on its main components. Its main components include the anode, cathode, electrolyte, diaphragm, and collector [

3]. Conventional lithium-ion batteries are mainly based on the lithium-ion intercalation mechanism, which cannot provide high charging capacity [

4]. To change this situation, new lithium-ion battery components are becoming increasingly popular [

5]. The enhancement and advancement of LIBs are being pursued through the creation of materials in order to enhance their efficiency and safety [

6,

7]. The utilization of aluminum foil as an electrode collector in batteries is prevalent due to its ability to enhance adhesion at the interface between the cathode material and the collector, as well as augment the ion transport capacity [

8,

9]. The lower thickness of the aluminum foil reduces the internal resistance of the battery, thus improving the cycling and storage performance of the battery [

10,

11]. The energy density of the battery is influenced by the thickness of the aluminum foil. The processing of aluminum foil leads to a significant range of thickness variations, hence impacting the overall performance of the battery [

12,

13]. Therefore, limiting significant fluctuations in the thickness of the aluminum foil is crucial to maximizing battery performance and life.

The thickness of the aluminum foil was influenced by various aspects throughout the rolling process, including the aluminum embryo, rolling oil, rolling parameters, sheet shape, and other relevant factors [

14]. The issue of variance in aluminum foil thickness can be mitigated through the adjustment of rolling settings. Xiao et al. [

15] constructed a theoretical framework to compute the attainable rolling thickness of ultra-thin strips by applying Fleck’s theory. The model was subsequently validated by experimental testing. By employing this model, the reduction process can be efficiently executed in a single iteration, considering factors such as the force applied per unit width, the unique technical requirements of the mill, the material’s yield strength, and the initial thickness of the strip. The equations for the greatest attainable thickness, considering the constraints of rolling force, were rectified. Sun et al. [

16] analyzed the work roll and the backup roll as an elastic continuum, taking into account the influence of shear force and moments of inertia. They then developed a dynamic model of the rolling mill. The two models were interconnected to establish the dynamic model. In the dynamic model, the thermal expansion of the rolls, the wear of the rolls, and other related parameters cannot be considered. A coupled static model of the rollers and the strip was employed to account for the dynamic model. A dynamic model of the rolling mill with thickness control was constructed by integrating the dynamic model with the compensation model.

The advancement of science and technology has led to the predominant utilization of automatic thickness control as the primary method for regulating the thickness of aluminum foil [

17]. Continuous measurement of the actual rolling thickness of rolled parts is achieved by employing several sensors, including but not limited to the thickness gauge, rolling seam instrument, and pressure head [

18]. By utilizing the computer function procedure, the measured value and the given value are compared to determine the deviation signal. This signal is then used to adjust the rolling seam, rolling force, tension, and roll speed in order to maintain thickness control within the acceptable deviation range [

19,

20]. The study conducted by Hu et al. [

21] investigates the rolling characteristics of the tandem cold-rolling process and introduces a novel technique for optimizing multiple variables. This technique utilizes inverse linear quadratic (ILQ) optimal control theory to effectively control the thickness and tension. At first, a new mathematical model of the tandem cold-rolling process was introduced and verified utilizing the fundamental equations of rolling technology and real-world data. Afterwards, a thorough examination of the rolling properties resulted in the discovery of important controlling principles for the complex rolling process. An innovative ILQ control strategy was applied to the thickness and tension control system for the intricate rolling process. Linearizing the mill stand model while preserving the nonlinearities of the rolling gap model leads to a computationally efficient optimization problem. This technique achieves a desirable equilibrium between precision and computational efficiency. The feedforward controllers are incorporated into the feedback loop of the AGC (Automatic Generation Control), utilizing a two-degree-of-freedom controller framework to rectify any disparities between the model and the plant. The simulation results, based on a validated mathematical model and first experimental data from an industrial pilot installation, clearly show a significant improvement compared to the existing AGC system without feedforward control [

22].

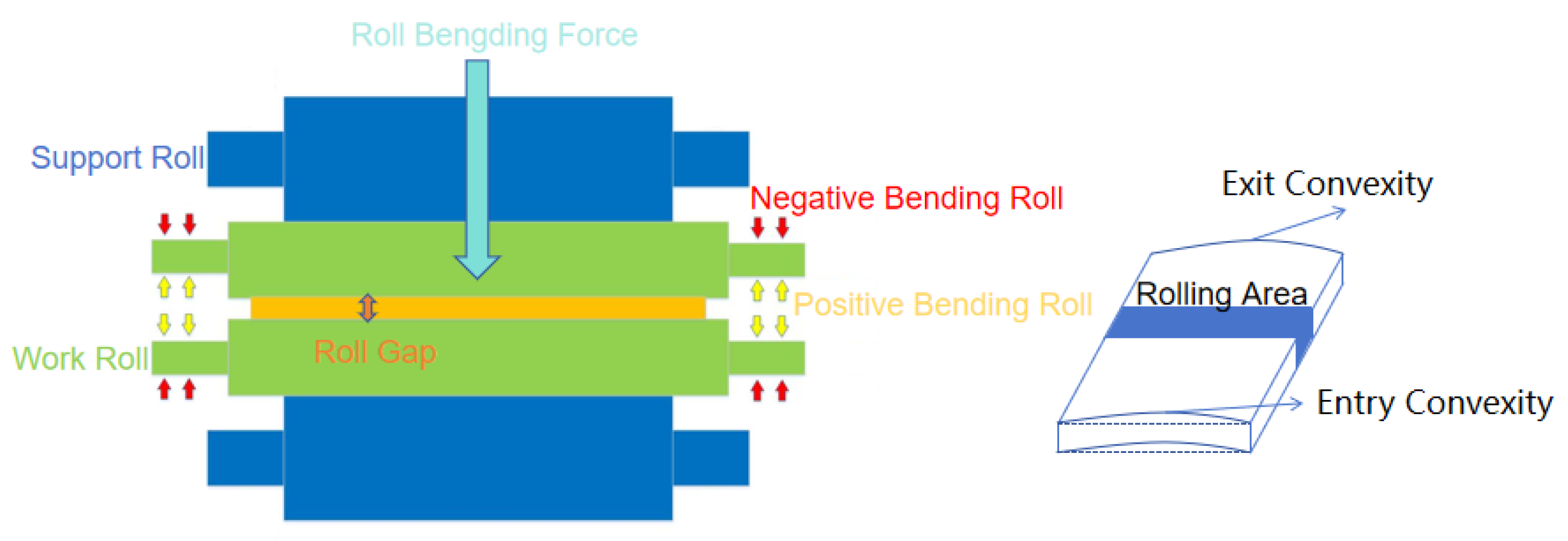

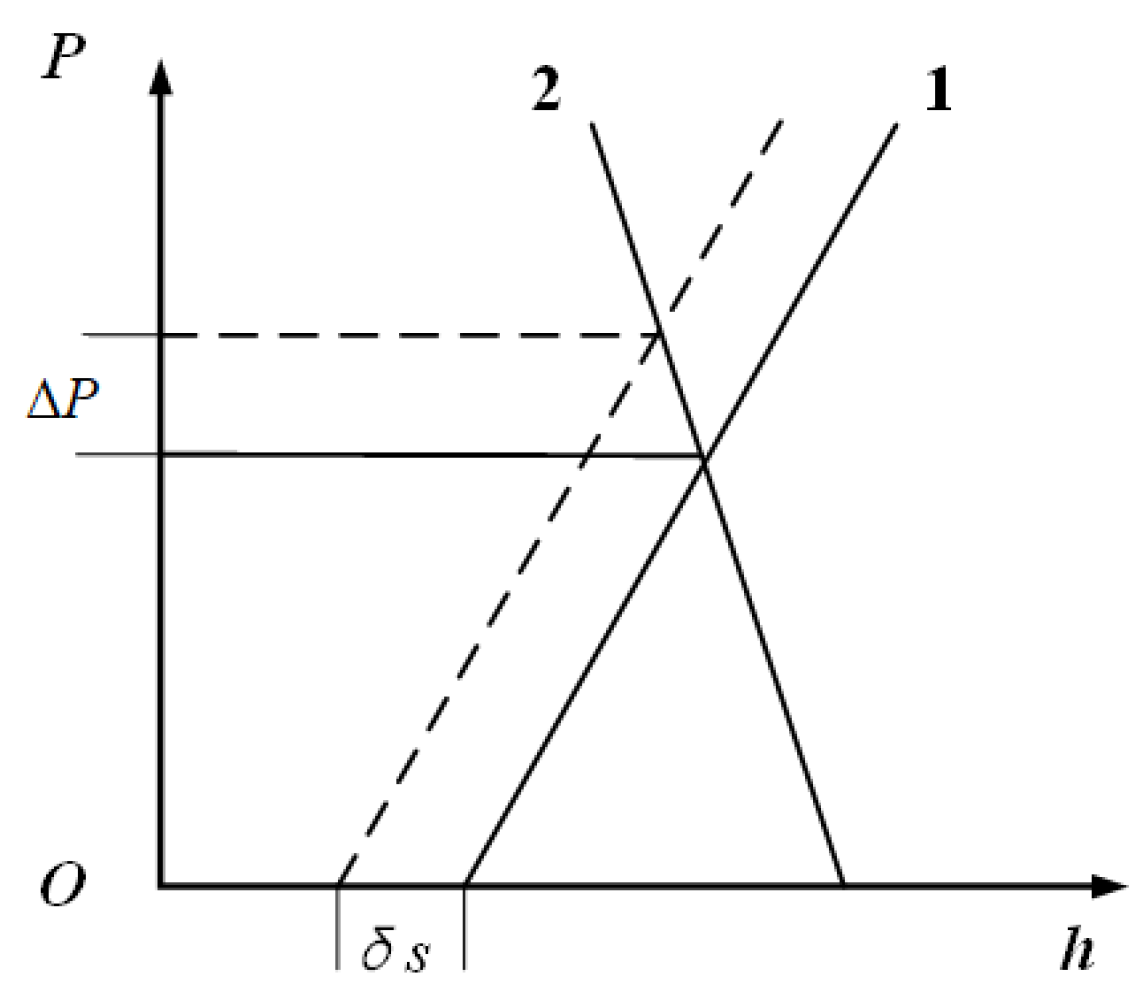

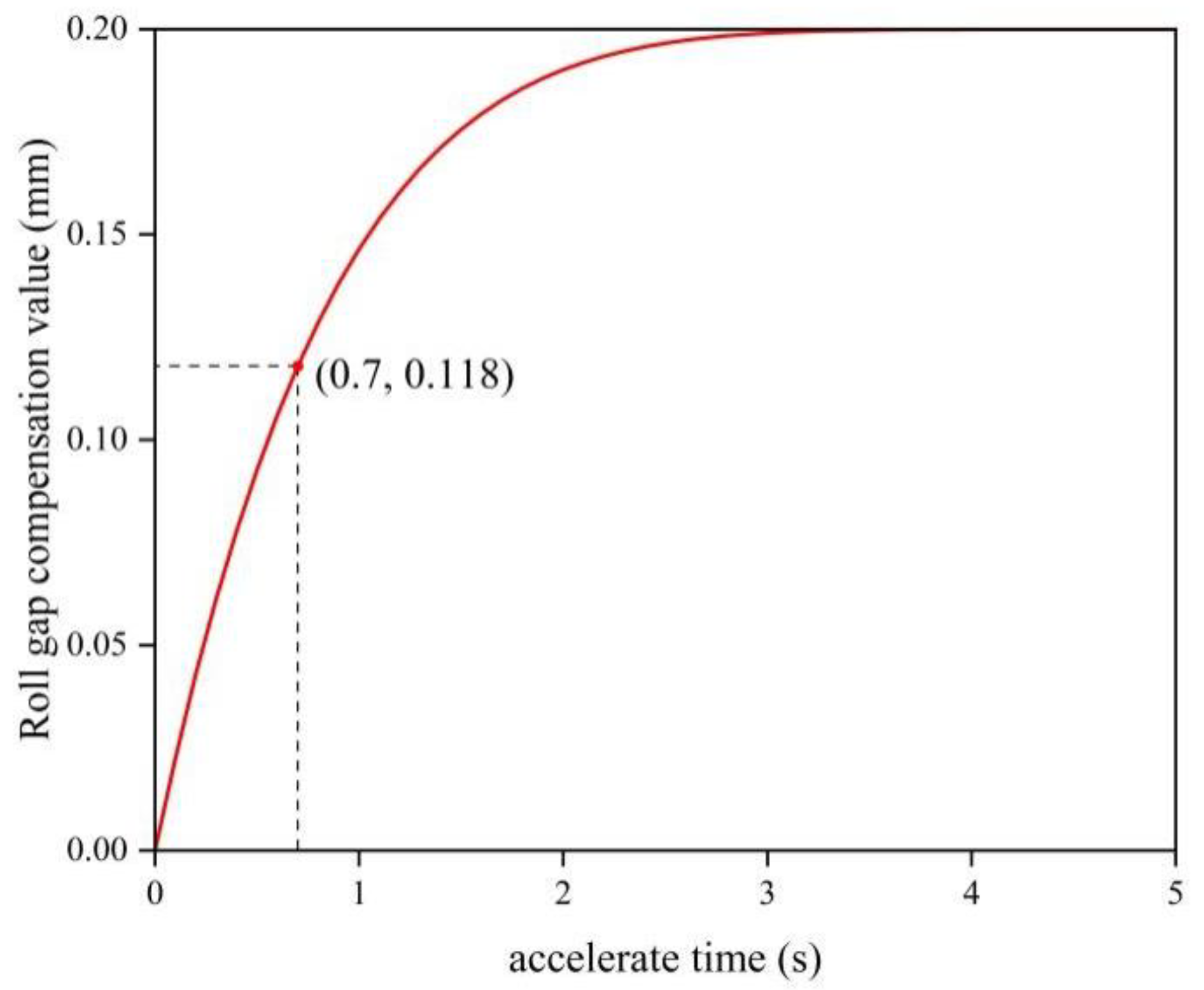

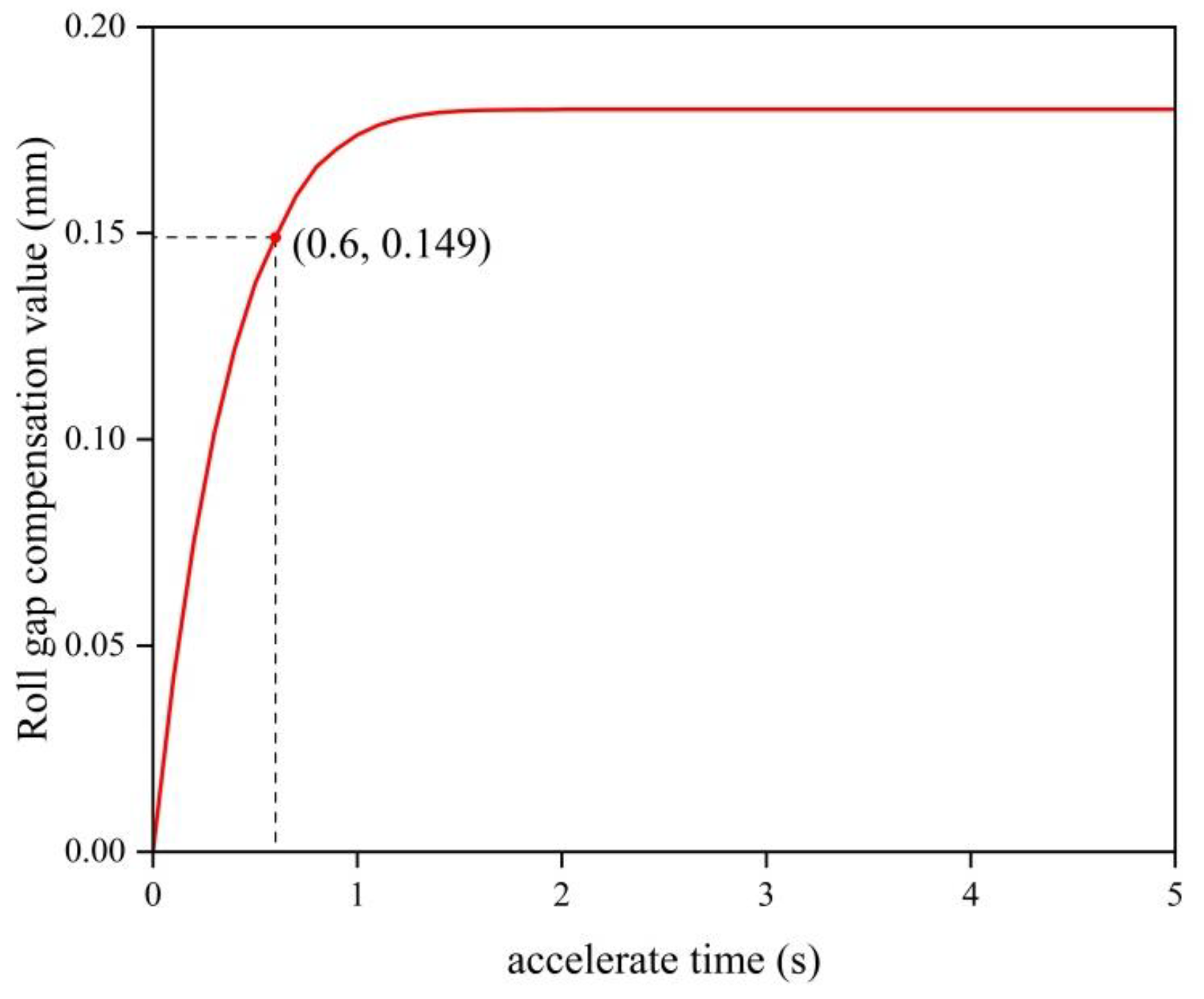

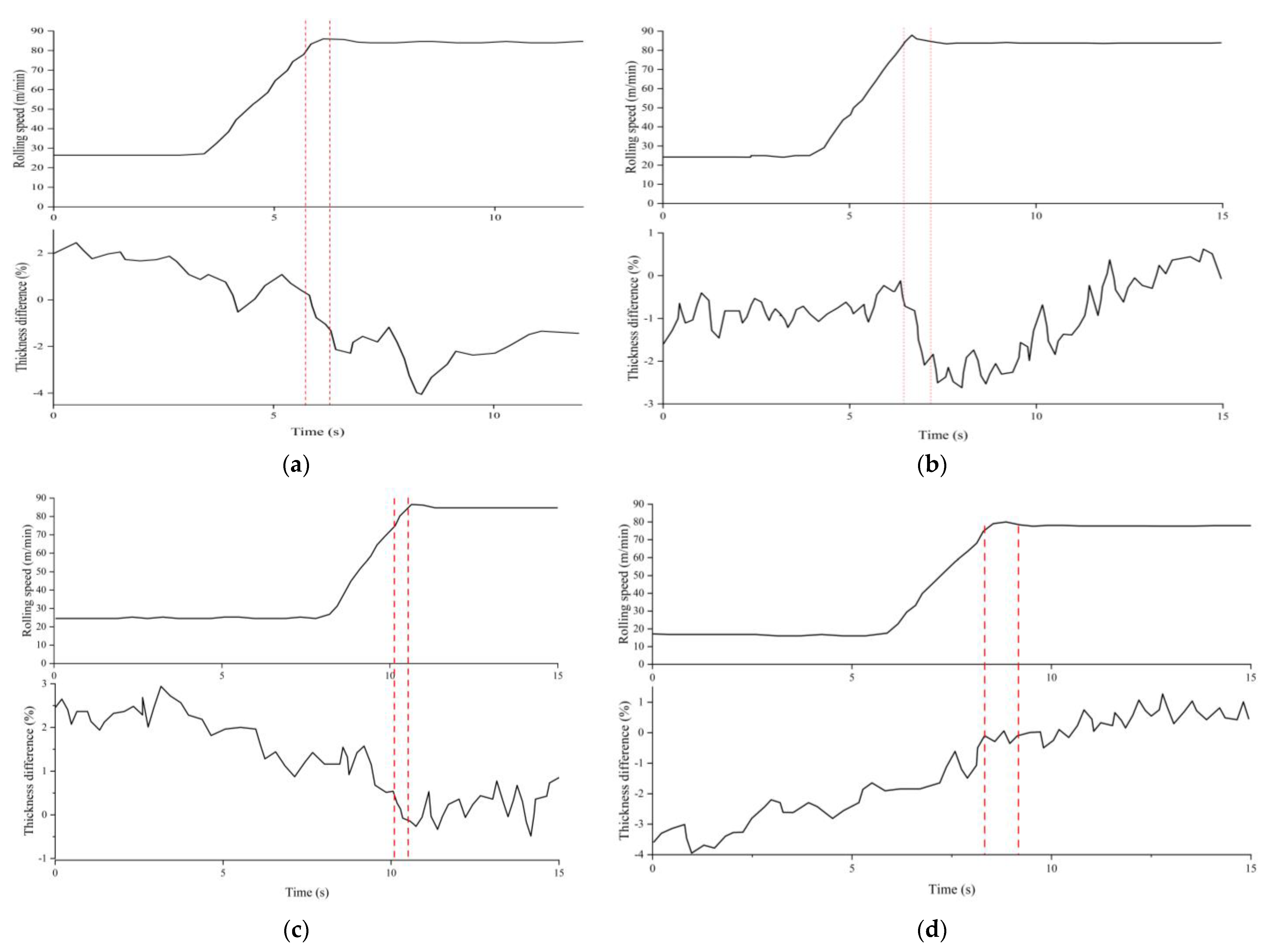

There are few studies that have investigated the effect of the roll-bending method on the head thickness inequality and the stability of the convexity of hot-rolled strips. Accordingly, the aim of this paper is to adjust the bending force through a set-up process and to implement a compensation factor for the bending force in the rolling gap. The statistical analysis consisted of studying the temperature-thermal expansion curves while controlling the coefficient of thermal expansion of the hot-rolled work rolls. At the same time, a non-linear compensation technique is proposed to solve the problem of thickness variation due to the sudden reduction of aluminum foil thickness during the acceleration phase. This has the potential to establish a reliable and precise technique for processing aluminum foil.