On the Macrosegregation of Continuous Casting of High Carbon Steel Billet with Strand Reduction Process

Abstract

1. Introduction

2. Development and Application of Numerical Analysis Model

2.1. Numerical Criteria for Macrosegregation of High Carbon Steel Billet

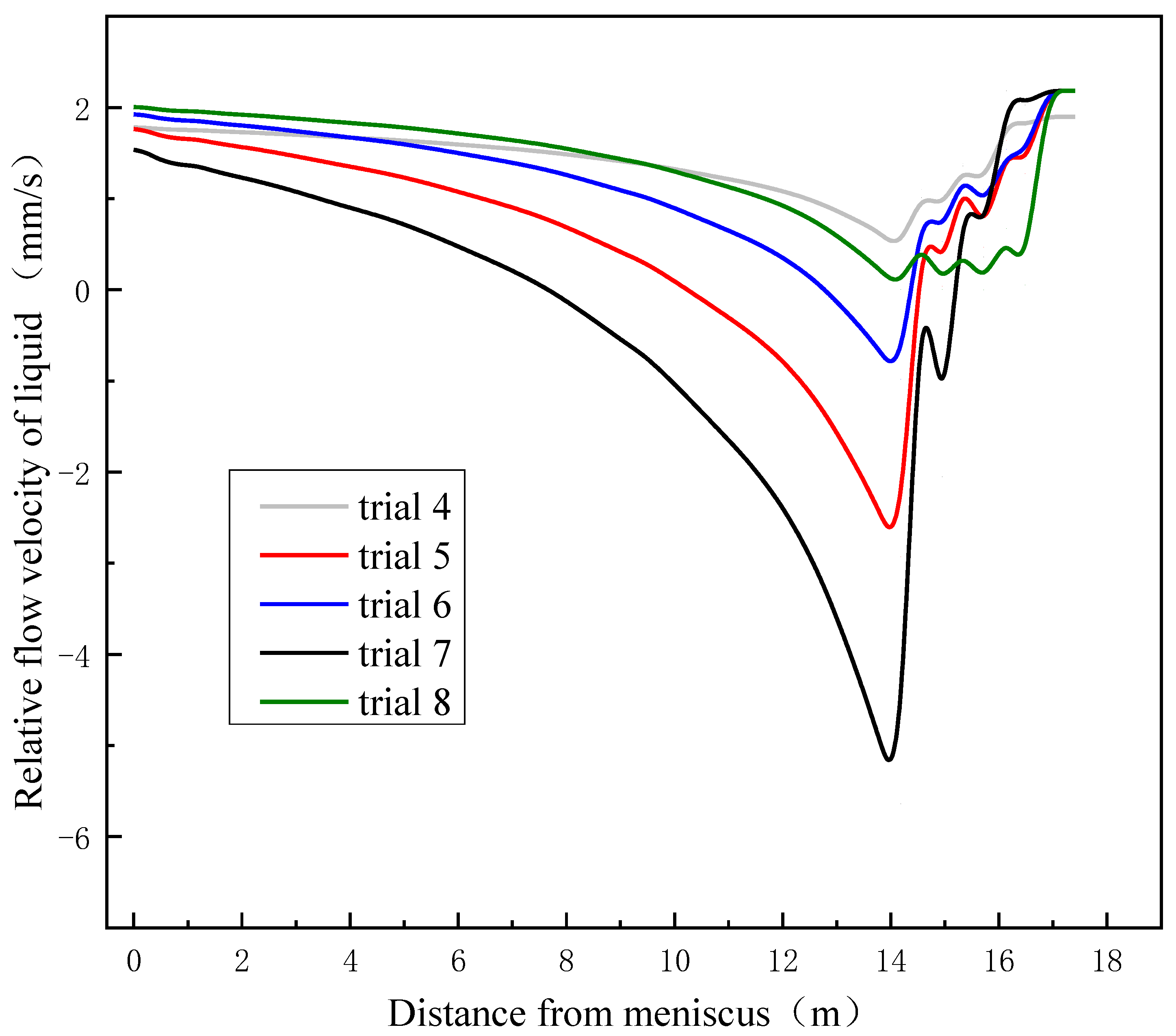

2.2. Mathematical Expression for Relative Flow Velocity of Liquid

3. Materials and Methods

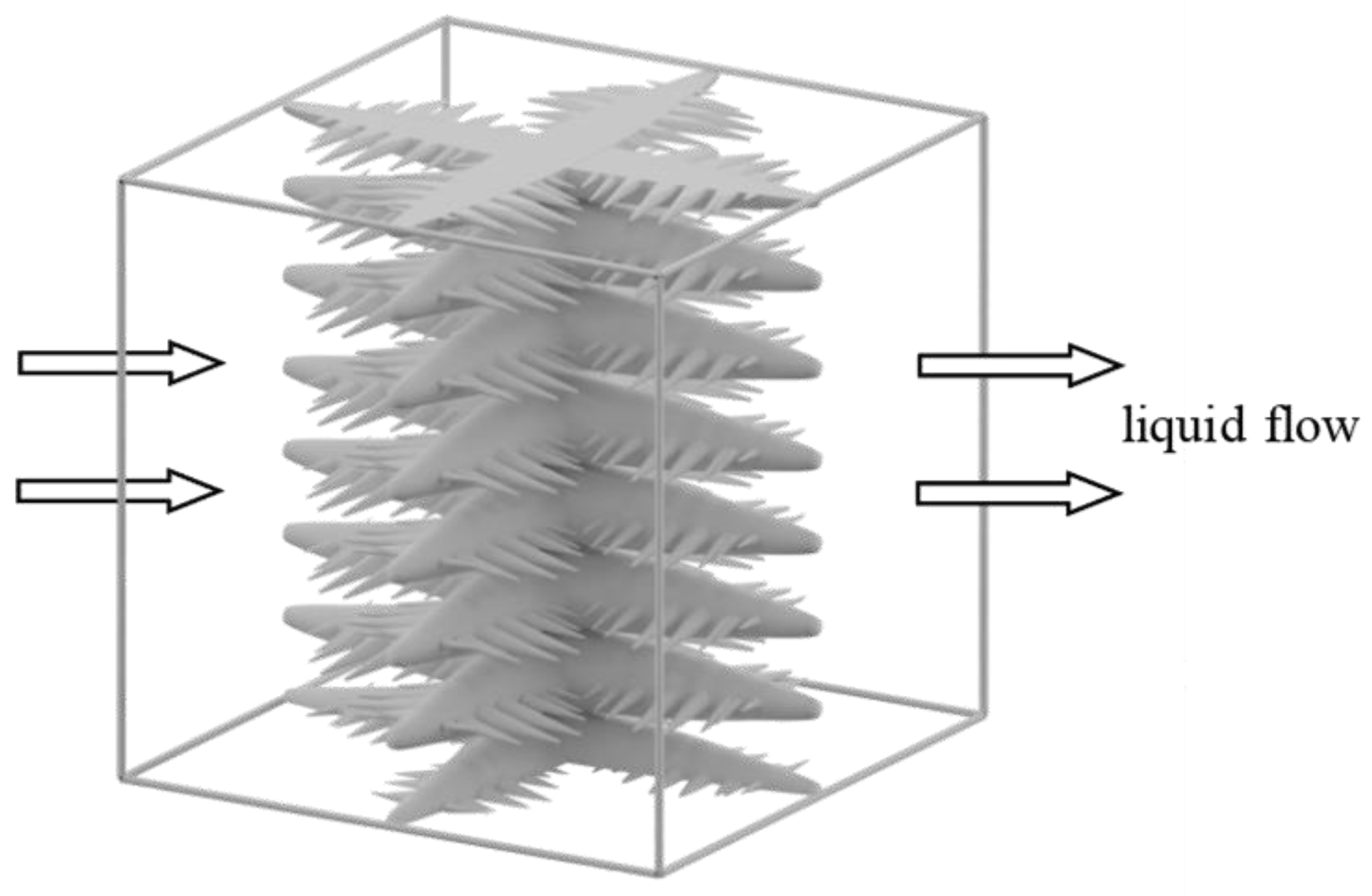

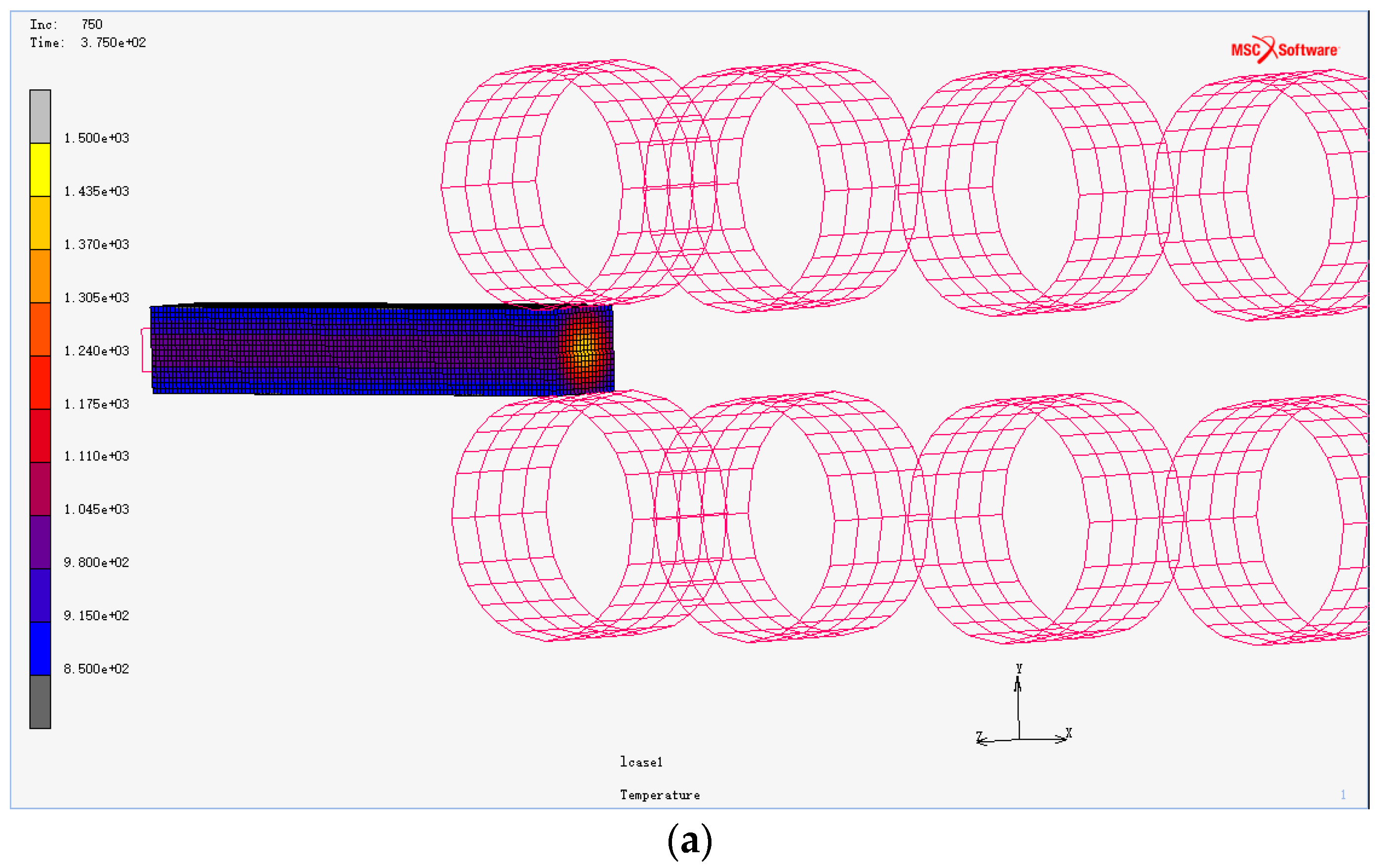

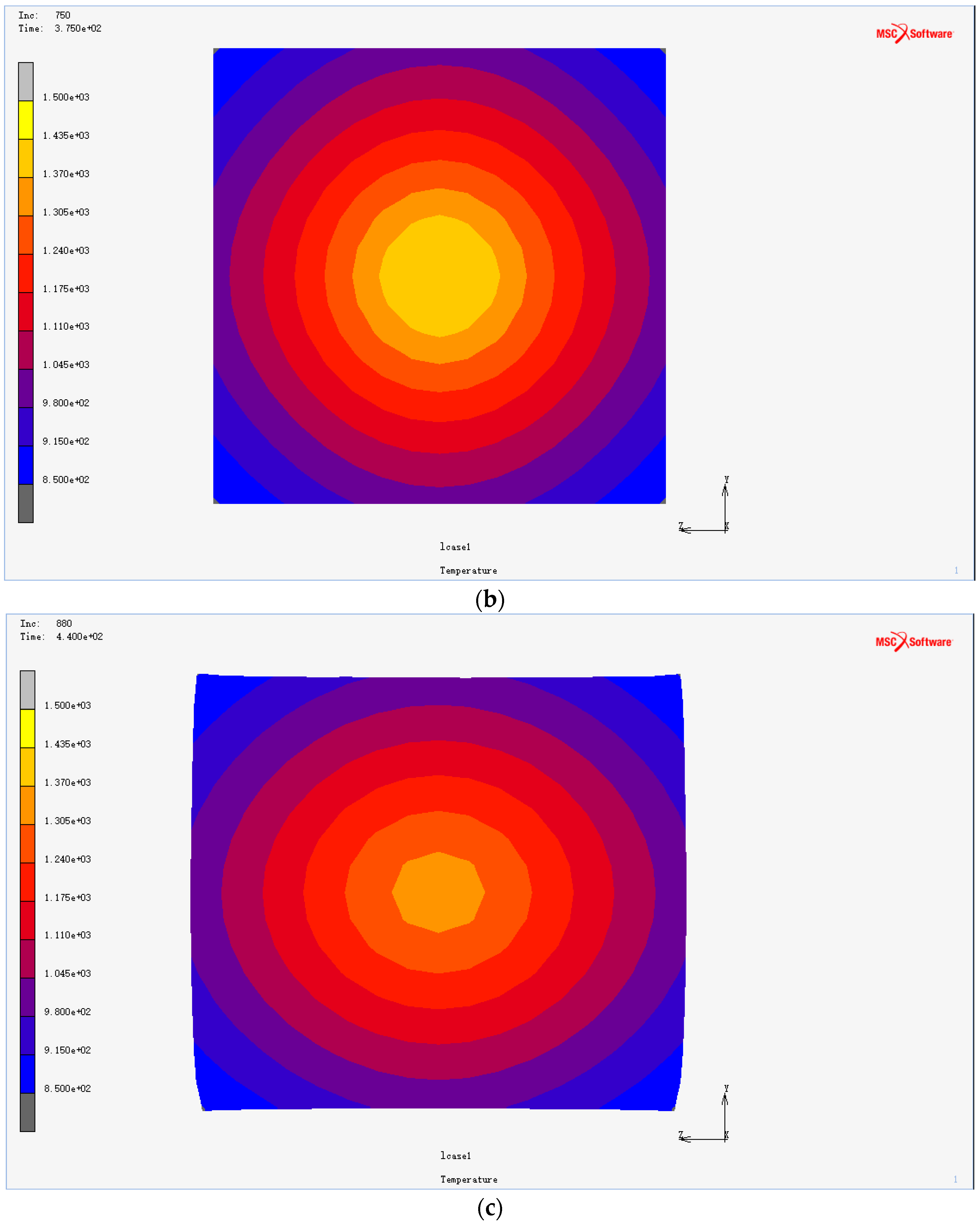

3.1. Description of Thermal–Mechancial Coupling Simulation

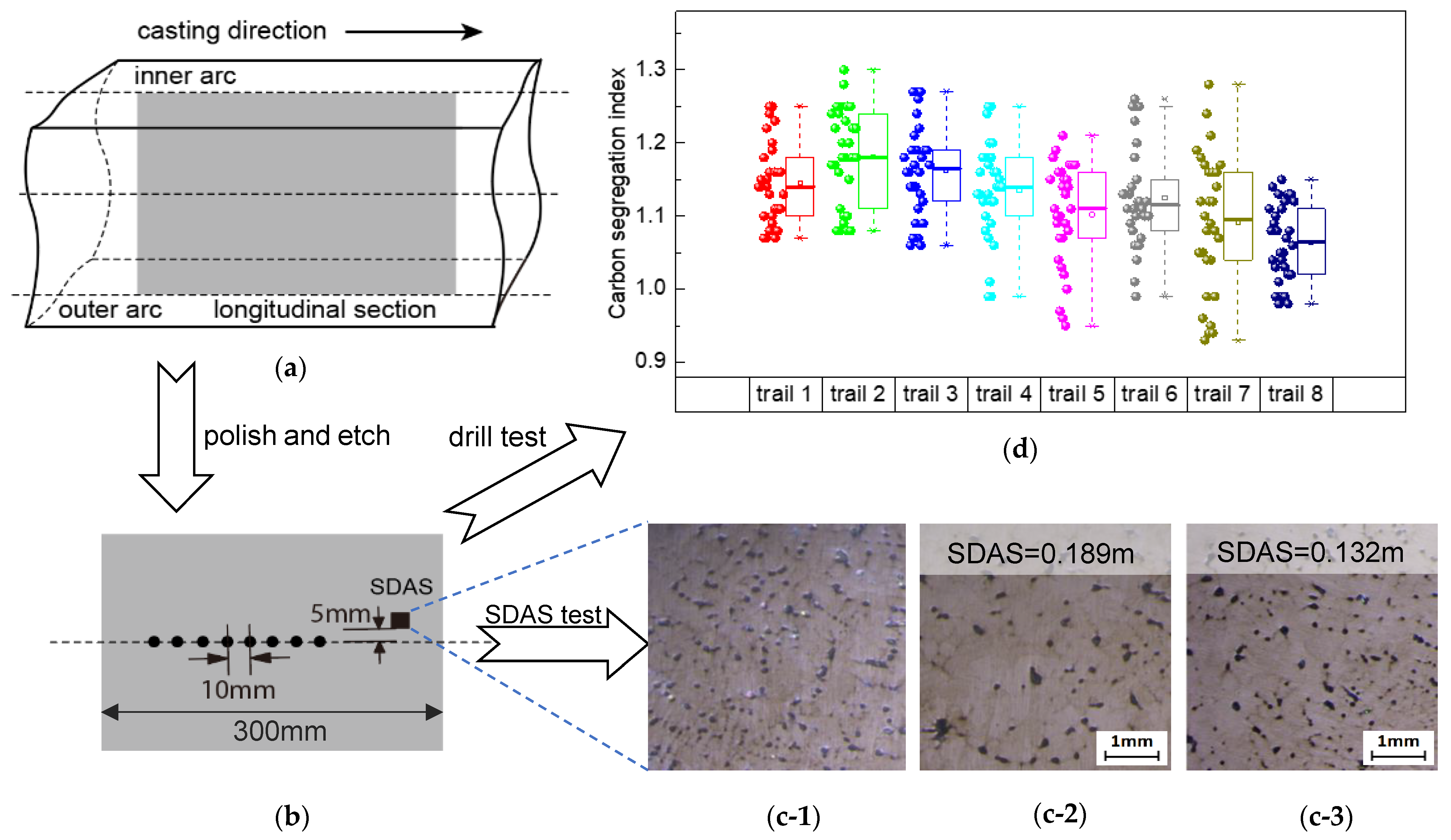

3.2. Description of Plant Trials

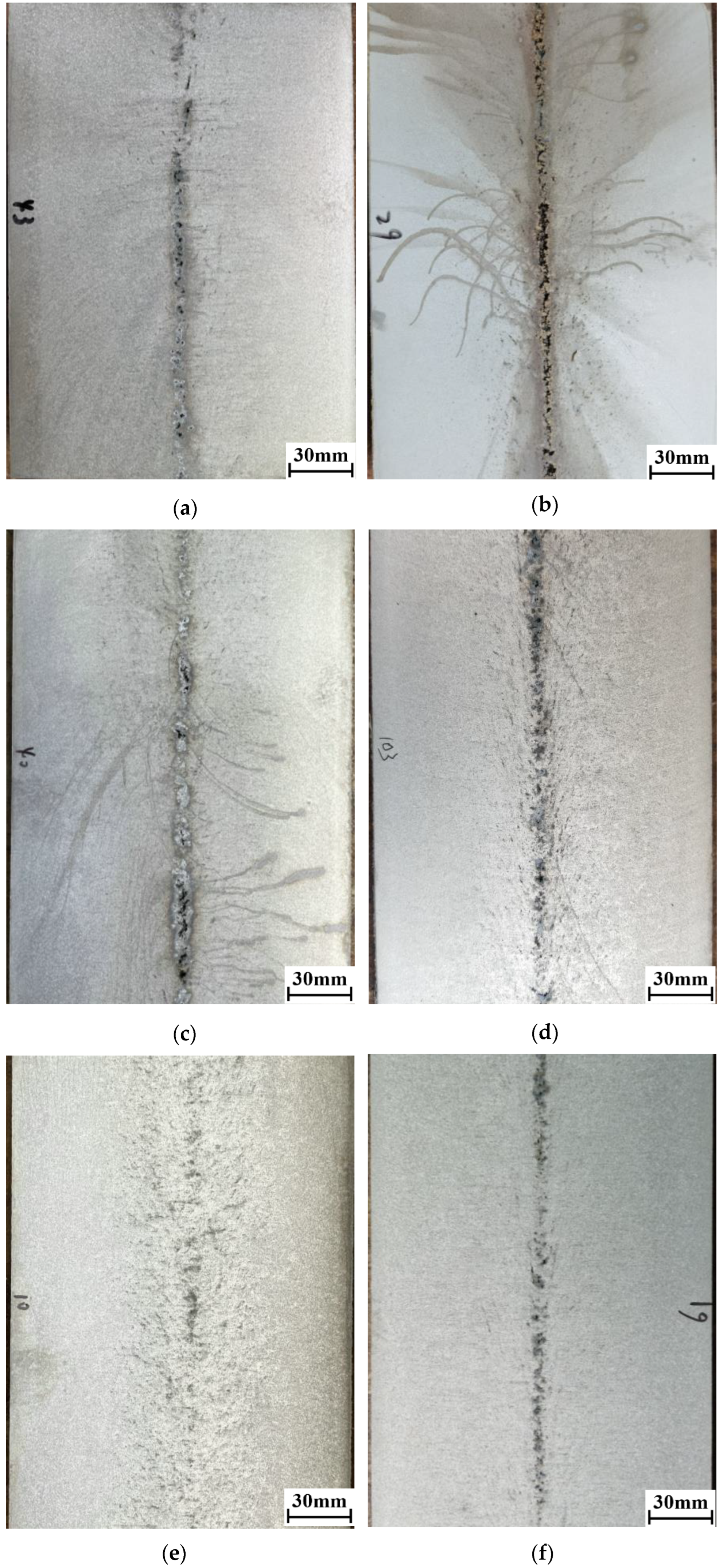

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| time | |

| average density | |

| density of liquid | |

| density of solid | |

| volume fraction of liquid | |

| volume fraction of solid | |

| shrinkage factor, | |

| the concentration of liquid | |

| the concentration of solid | |

| the average concentration of solid | |

| the initial average concentration of solute in the RVE | |

| distribution factor of solute, | |

| temperature | |

| solidification rate, | |

| shifting direction and distance of isotherm line | |

| vector component shifting in x direction | |

| vector component shifting in y direction | |

| vector component shifting in z direction | |

| cross section of billet at a distance of x from meniscus | |

| cross section area of liquid | |

| cross section area of solid | |

| flow velocity of liquid along the strand | |

| flow velocity of solid along the strand | |

| the relative flow velocity of liquid | |

| casting velocity | |

| the distance from meniscus | |

| the distance from meniscus where the cross section is just completely solidified | |

| average carbon content for billet samples | |

| minimum carbon content for billet samples | |

| maximum carbon content for billet samples | |

| carbon content at the specific sampling location, Co | |

| the bulk carbon content of billet sample | |

| RVE | representative volume element |

| SDAS | secondary dendrite arm spacing |

References

- Birat, J.P.; Bobadilla, M.; Jacquot, J.L. Continuous casting and electromagnetic stirring of steels with large solidification interval. Contin. Cast. 1985, 18, 18–23. [Google Scholar]

- Ludwig, A.; Wu, M.H.; Kharicha, A. On macrosegregation. Metall. Mater. Trans. A. 2015, 46, 4854–4867. [Google Scholar] [CrossRef]

- Kajitani, T.; Drezet, J.M.; Rappaz, M. Numerical simulation of deformation-induced segregation in continuous casting of steel. Metall. Mater. Trans. A 2001, 32, 1479–1491. [Google Scholar] [CrossRef]

- Quinelato, F.P.; Garcao, W.J.L.; Paradela, K.G. Continuous casting process: Effect of pouring temperatures on the macrosegregation and macrostructure in steel slab. Mater. Res. Ibero. Am. J. 2020, 23, e20200023. [Google Scholar]

- Zeng, J.; Chen, W. Effect of casting speed on solidification structure and central macrosegregation during continuous casting of high-carbon rectangular billet. Metall. Ital. 2015, 7–8, 43–50. [Google Scholar]

- OH, K.S.; Young, W.C. Macrosegregation behavior in continuously cast high carbon steel blooms and billets at the final stage of solidification in combination stirring. ISIJ Int. 1995, 35, 866–875. [Google Scholar] [CrossRef]

- Grundy, A.N.; Münch, S.; Feldhaus, S.; Bratberg, J. Continuous casting of high carbon steel: How does hard cooling influence solidification, micro-and macro segregation. IOP Conf. Ser. Mater. Sci. Eng. 2019, 529, 012069. [Google Scholar] [CrossRef]

- Choudh, S.K.; Ghosh, A. Morphology and macrosegregation in continuously cast steel billets. ISIJ Int. 1994, 34, 338–345. [Google Scholar] [CrossRef]

- Zhang, Z.; Wu, M.H.; Zhang, H.J.; Hahn, S.; Wimmer, F.; Ludwig, A.; Kharicha, A. Modeling of the as-cast structure and macrosegregation in the continuous casting of a steel billet: Effect of M-EMS. J. Mater. Proc. Tech. 2022, 30, 117434. [Google Scholar] [CrossRef]

- Dong, Q.P.; Zhang, J.M.; Qian, L.; Yin, Y.B. Numerical modeling of macrosegregation in round billet with different microsegregation models. ISIJ Int. 2017, 57, 814–823. [Google Scholar] [CrossRef]

- Jiang, D.B.; Zhu, M.Y. Solidification structure and macrosegregation of billet continuous casting process with dual electromagnetic stirrings in mold and final stage of solidification: A numerical study. Metall. Mater. Trans. B 2016, 47, 3446–3458. [Google Scholar] [CrossRef]

- Han, Y.S.; Yan, W.; Zhang, J.S.; Chen, J.; Chen, W.Q.; Liu, Q. Comparison and integration of final electromagnetic stirring and thermal soft reduction on continuous casting billet. J. Iron Steel Res. Int. 2021, 28, 160–167. [Google Scholar] [CrossRef]

- Zeng, J.; Chen, W.Q.; Wang, Q.X.; Wang, G.S. Improving Inner quality in continuous casting rectangular billets: Comparison between mechanical soft reduction and final electromagnetic stirring. Trans. Indian. Inst. Met. 2016, 69, 1623–1632. [Google Scholar] [CrossRef]

- Jiang, D.B.; Zhang, L.F.; Zhu, M.Y. Center segregation evolution in slab continuous casting with mechanical reduction: A 3D simulation. Steel Res. Int. 2022, 93, 2100569. [Google Scholar] [CrossRef]

- Yang, B.; Wang, M.L.; Zhang, H. Optimization of heavy reduction process on continuous-casting bloom. Metals 2022, 12, 1873. [Google Scholar] [CrossRef]

- Hu, W.G.; Ji, C.; Zhu, M.Y. Numerical simulation of continuous casting round blooms with different solidification end reduction strategies. Metall. Mater. Trans. B 2021, 52B, 4130–4140. [Google Scholar] [CrossRef]

- Zhang, J.Y.; Wu, C.H.; Ji, C. Evolution of microporosities in wide-thick continuous casting slab during heavy reduction process. Steel Res. Int. 2022, 93, 2000601. [Google Scholar] [CrossRef]

- Jiang, M.; Yang, E.J.; Hou, Z.W.; Wang, X.H. Decreasing porosities in continuous casting thick slab by soft reduction technology. Metall. Mater. Trans. B 2021, 52, 2753–2759. [Google Scholar] [CrossRef]

- Chen, X.H.; Deng, W.; Niu, S. Industrial application of mechanical reduction on continuous casting of bearing steel bloom. Processes 2021, 9, 2280. [Google Scholar] [CrossRef]

- Byrne, C.; Tercelli, C. Mechanical soft reduction in billet casting. Steel Times Int. 2002, 26, 33–35. [Google Scholar]

- Gao, Y.B.; Bao, Y.P.; Wang, Y.; Wang, M.; Zhang, M.Y. Development of a novel strand reduction technology for the continuous casting of homogeneous high-carbon steel billet. Steel Res. Int. 2023, 94, 2200740. [Google Scholar] [CrossRef]

- Nian, Y.; Zhang, L.Q.; Zhang, C.J. Application status and development trend of continuous casting reduction technology: A review. Processes 2022, 10, 2669. [Google Scholar] [CrossRef]

- Wu, M.H.; Domitner, J.; Ludwig, A. Using a two-phase columnar solidification model to study the principle of mechanical soft reduction in slab casting. Metall. Mater. Trans. B 2012, 43, 945–964. [Google Scholar] [CrossRef]

- Beckermann, C. Modelling of macrosegregation: Applications and future needs. Int. Mater. Rev. 2002, 47, 244–261. [Google Scholar] [CrossRef]

- Zhang, M.Y.; Bao, Y.P.; Zhao, L.H.; Chen, J.; Zheng, H.W. Formation and control of central cracks in alloy steel ZKG223. Steel Res. Int. 2022, 93, 2200289. [Google Scholar] [CrossRef]

- Li, G.L.; Ji, C.; Zhu, M.Y. Prediction of internal crack initiation in continuously cast blooms. Metall. Mater. Trans. B 2021, 52B, 1164–1178. [Google Scholar] [CrossRef]

- Guan, R.; Ji, C.; Wu, C.H.; Zhu, M.Y. Numerical modelling of fluid flow and macrosegregation in a continuous casting slab with asymmetrical bulging and mechanical reduction. Int. J. Heat Mass Transf. 2019, 141, 503–516. [Google Scholar] [CrossRef]

- Wu, C.H.; Ji, C.; Zhu, M.Y. Numerical simulation of bulging deformation for wide-thick slab under uneven cooling conditions. Metall. Mater. Trans. B 2018, 49B, 1346–1359. [Google Scholar] [CrossRef]

- Chakraborty, S.; Dutta, P. Effects of dendritic arm coarsening on macroscopic modelling of solidification of binary alloys. Mater. Sci. Technol. 2001, 17, 1531–1538. [Google Scholar] [CrossRef]

- Netto, P.G.Q.; Guthrie, R.I.L. Modelling of a novel configuration for single-belt caster: The influence of empirical parameters on the solidification profile. ISIJ Int. 2000, 40, 460–468. [Google Scholar] [CrossRef]

- Zong, N.F.; Huang, J.; Liu, Y. Controlling centre segregation and shrinkage cavities without internal crack in as-cast bloom of steel GCr15 induced by soft reduction technologies. Ironmak. Steelmak. 2021, 48, 944–952. [Google Scholar] [CrossRef]

| Section of Billet (mm × mm) | Radius of Caster (m) | Effective Mold Length (mm) | Length of Secondary Cooling Zones (m) | Location of Reduction Pinch Rollers (m) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Z1 | Z2 | Z3 | Z4 | R1 | R2 | R3 | R4 | |||

| 160 × 160 | 10 | 800 | 0.5 | 2.1 | 2.4 | 2.7 | 14.2 | 14.9 | 15.6 | 16.3 |

| Composition | C | Si | Mn | P | S | Cr | Ni | Cu |

|---|---|---|---|---|---|---|---|---|

| mass fraction (wt%) | 0.86 | 0.26 | 0.58 | 0.009 | 0.006 | 0.01 | 0.02 | 0.001 |

| Trial | Casting Speed (m/min) | Secondary Cooling Intensity (L/kg) | Reduction Zone (Central fs) | Reduction Amount (mm) | Reduction Distribution (mm) | |||

|---|---|---|---|---|---|---|---|---|

| R1 | R2 | R3 | R4 | |||||

| 1 | 2.0 | 0.35 | - | - | - | - | - | - |

| 2 | 2.3 | 0.35 | - | - | - | - | - | - |

| 3 | 2.3 | 0.62 | - | - | - | - | - | - |

| 4 | 2.0 | 0.62 | 0.52–1.00 | 16 | 4 | 4 | 4 | 4 |

| 5 | 2.3 | 0.62 | 0.26–0.78 | 16 | 4 | 4 | 4 | 4 |

| 6 | 2.3 | 0.62 | 0.26–0.78 | 12 | 3 | 3 | 3 | 3 |

| 7 | 2.3 | 0.62 | 0.26–0.78 | 16 | 6 | 5 | 3 | 2 |

| 8 | 2.3 | 0.62 | 0.26–0.78 | 16 | 2 | 3 | 5 | 6 |

| Trial | Cavg/Co | Cmax/Co | Cmin/Co | Proportion of Ci/Co ≥ 1.15 | Proportion of Ci/Co ≥ 1.20 | Proportion of Ci/Co ≤ 0.96 |

|---|---|---|---|---|---|---|

| 1 | 1.15 | 1.25 | 1.07 | 0.47 | 0.20 | 0.00 |

| 2 | 1.18 | 1.30 | 1.08 | 0.73 | 0.47 | 0.00 |

| 3 | 1.16 | 1.27 | 1.06 | 0.57 | 0.23 | 0.00 |

| 4 | 1.13 | 1.25 | 0.99 | 0.43 | 0.17 | 0.00 |

| 5 | 1.10 | 1.21 | 0.95 | 0.37 | 0.03 | 0.10 |

| 6 | 1.13 | 1.26 | 0.99 | 0.23 | 0.13 | 0.00 |

| 7 | 1.09 | 1.28 | 0.93 | 0.33 | 0.07 | 0.17 |

| 8 | 1.06 | 1.15 | 0.98 | 0.03 | 0.00 | 0.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Y.; Bao, Y.; Wang, M.; Zhang, M. On the Macrosegregation of Continuous Casting of High Carbon Steel Billet with Strand Reduction Process. Metals 2024, 14, 157. https://doi.org/10.3390/met14020157

Gao Y, Bao Y, Wang M, Zhang M. On the Macrosegregation of Continuous Casting of High Carbon Steel Billet with Strand Reduction Process. Metals. 2024; 14(2):157. https://doi.org/10.3390/met14020157

Chicago/Turabian StyleGao, Yubo, Yanping Bao, Min Wang, and Mengyun Zhang. 2024. "On the Macrosegregation of Continuous Casting of High Carbon Steel Billet with Strand Reduction Process" Metals 14, no. 2: 157. https://doi.org/10.3390/met14020157

APA StyleGao, Y., Bao, Y., Wang, M., & Zhang, M. (2024). On the Macrosegregation of Continuous Casting of High Carbon Steel Billet with Strand Reduction Process. Metals, 14(2), 157. https://doi.org/10.3390/met14020157