Abstract

In this study, butt welds of QP980 steel were produced using small laser spot (0.1 mm) oscillating welding. The effect of beam oscillation with a circular trajectory on weld morphologies, microstructures, and mechanical properties was characterized. As the oscillating amplitude rose, the energy accumulation range enlarged, and the energy peak value was decreased, leading to the appearance of the cross-section changing from a nail-like shape to a cup-cone-like shape and then to a W-type shape. The weld zone is divided into the fusion zone, inner heat-affected zone, and outer soften zone. The fusion zone and inner heat-affected zone are full of typical lath martensite and have the highest hardness. The soften zone is composed of pre-existing martensite, temper martensite, ferrite, and retained austenite and has the lowest hardness. Compared to laser welding, beam oscillation could reduce the pre-existing block martensite to decompose, leading to a narrower width and higher hardness soften zone. Although the width of the fusion zone and soften zone increases with the oscillation amplitude, all welded samples failed at the base metal with 97% joint efficiency.

1. Introduction

Reducing fuel consumption and carbon emissions while increasing passenger safety has been a challenging task for the automotive industry in the past decades. Accordingly, numerous approaches have been attempted to solve issues, including the use of AHSS for automobile designs since this strategy allows a reduction in the sheet thickness, thereby leading to lightweight while improving safety. Compared to conventional high-strength low alloy, advanced high-strength steel (AHSS) induces superior comprehensive mechanical performance, including higher ultimate tensile strength, more uniform total elongation, and elevated initial work hardening rate. Hence, AHSS gained increasing interest in the automobile industry. Schmitt et al. [1] investigated AHSS issued from the first generation to the third generation of high-strength steel and found that some of these AHSS grades have already been widely applied in the automotive industry, while others are still in the development phase.

Recently, the third-generation AHSS based on the quenching and partitioning steels (QP) has been studied by Speer et al. [2]. Compared to the first generation, the plasticity of the third generation was significantly enhanced due to the complex microstructure of ferrite, martensite, and retained austenite in QP steel. Additionally, the QP steel possesses lower cost and better formability than the second generation, thereby becoming a promising candidate for the third-generation AHSSs in the automobile industry [3].

Currently, welding is a primary joining operation used in the manufacturing of automotive components. Achieving high-quality and efficient welding has attracted increasing attention in the manufacturing of automotive components. Laser welding has become a popular technology in the production of laser-welded blanks (LWBs) due to its high energy density, low heat input, large depth-to-width ratio, and excellent mechanical properties. These features are suitable for the fabrication of automotive body parts. As a result, laser welding has been successfully used in similar and dissimilar joining between different generation AHSSs, such as dual-phase steel welding [4,5,6,7,8], twinning-induced plasticity TWIP steel welding [9,10], QP steel welding [11,12,13], and QP-TWIP steel welding [14,15].

Similar to traditional welding methods, the heat-affected zone (HAZ) will be generated during laser welding. It is always the weakest between the fusion zone and the base metal. Generally, the width of the HAZ could be minimized by reducing the heat input to the weld zone, such as increasing the energy density of the laser beam and the welding speed. The energy density of the laser beam was decided by the laser power and the diameter of the laser spot. This indicates that the heat input could be reduced via small spot laser welding. On the one hand, a smaller spot could reduce the laser heating area, thereby narrowing the width of the heat-affected zone. On the other hand, a smaller spot would reduce the required power of the laser beam, resulting in lower manufacturing costs. However, the applicability of small laser spot welding is limited by the tiny focused beam spot, thereby requiring critical edge preparation and high joint fit-up accuracy [16,17].

To overcome the shortcomings of small spot laser welding, different approaches have been effectively used, including dual-beam technology [18,19] and oscillating beam welding. Among these methods, laser oscillating welding has recently attracted increasing interest in academia and industry. The deposition distribution of laser energy on the processing surface changes by the beam oscillation during laser oscillating welding, thereby promoting convection and stirring of the molten pool. Consequently, the stirring effects improve the assembly gap tolerance [20,21], enhance the weldability [22], refine grains [23,24,25], suppress the formation of pores, and stabilize the movement of the keyhole [26,27], resulting in better mechanical properties. However, studies focused on the correlation between the microstructures and mechanical properties of QP980 joints produced by oscillating beams are also conspicuously absent, and how the oscillation parameters affect the weld formation of QP980 in laser welding especially needs to be investigated. Moreover, the power used in references is high (>4 kW), and the diameter is more than 0.3 mm.

Therefore, in this paper, laser oscillating welding with lower power (1.4 kW) and a smaller laser beam (0.1 mm) was studied. The correlations between the mechanical properties, microstructural evolution, and laser energy distribution of QP980 butt joints produced by laser welding and laser oscillating welding were discussed. The evolved weld profiles, microstructures, tensile properties, and hardness curves were characterized. To this end, a series of experiments were conducted with different oscillating amplitudes. The results revealed that the oscillating amplitudes greatly influenced the microstructure and properties of the joints.

2. Materials and Methods

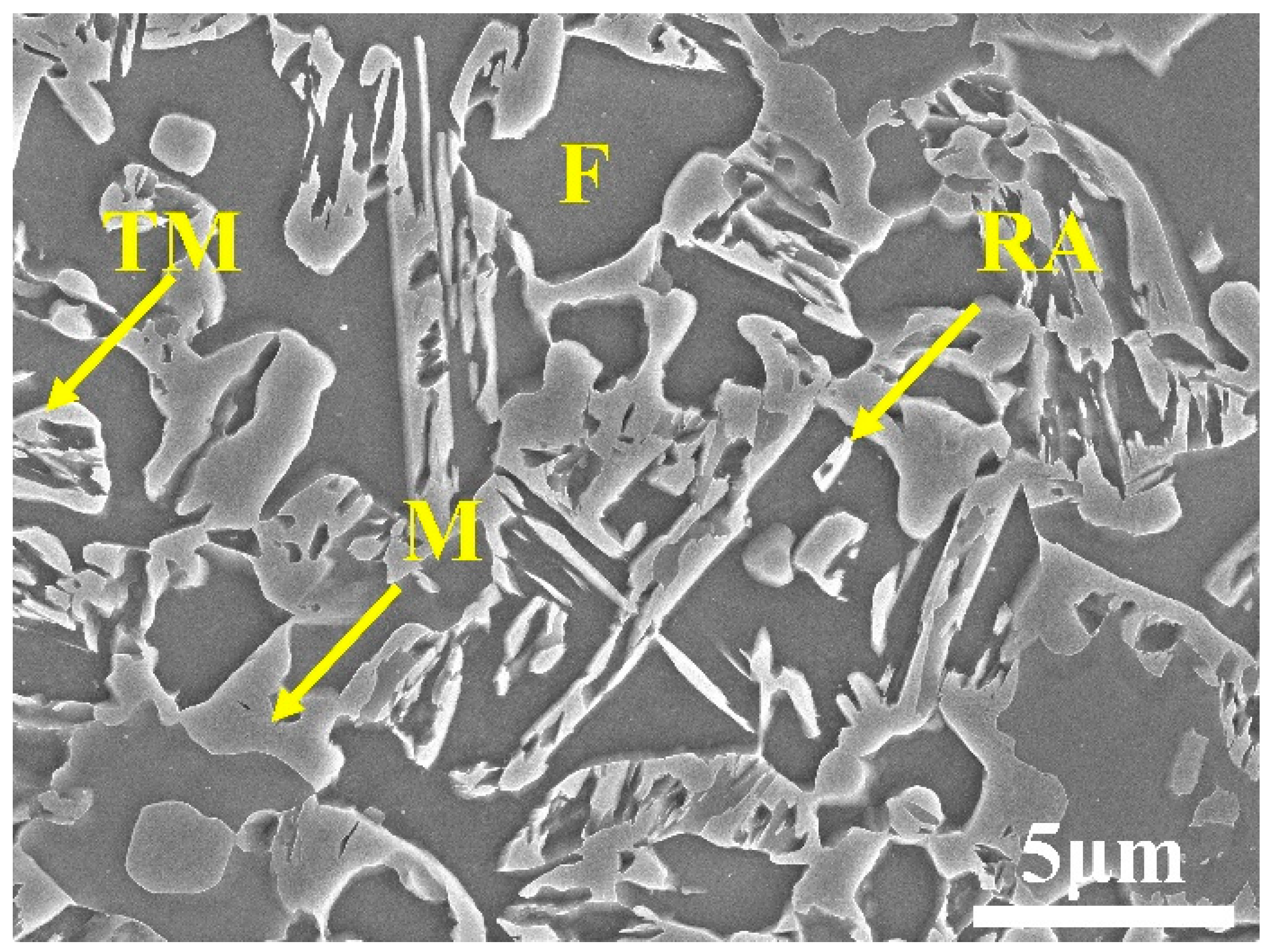

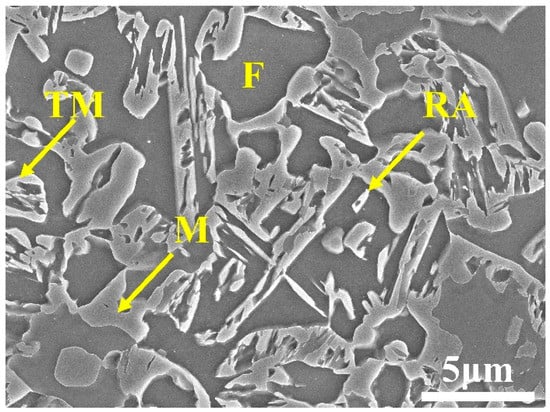

Cold-rolled QP980 steel sheet (2.0 mm in thickness, Baowu, Shanghai, China) was selected. The microstructure of the base metal is shown in Figure 1, and its chemical composition and mechanical properties are listed in Table 1. A typical microstructure of the QP980 was observed in Figure 1, mainly composed of ferrite (F), retained austenite (RA), blocky martensite, and tempered martensite (TM). The QP980 steel sheets were machined to pieces with a size of 30 cm × 12 cm. Before welding, the base metal within 1 cm of the weld was ground to remove any dirt and contamination present on the edges, followed by cleaning with acetone. The resulting specimens were then held with no gap in the fixture (Figure 2a).

Figure 1.

Microstructure of the base metal.

Table 1.

Chemical composition (wt%) and mechanical properties of QP980.

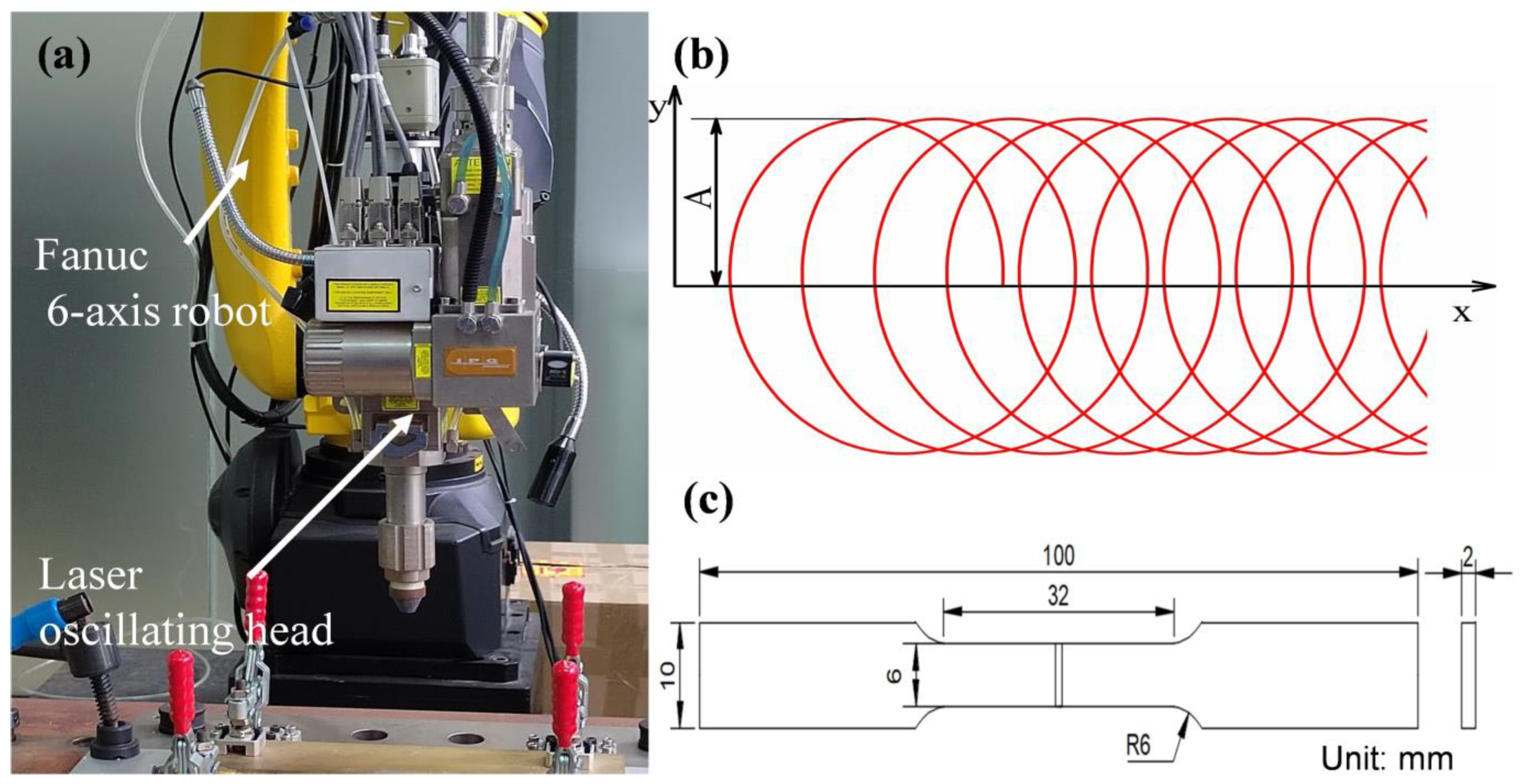

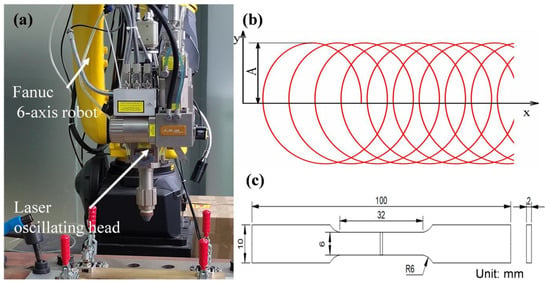

Figure 2.

(a) The welding platform, (b) the laser beam trajectory, and (c) welded sample geometry and dimensions of the tensile test.

Butt welding of QP980 sheets was performed using an IPG YLR-2000 fiber laser with a maximum output power of 2 kW. The laser wavelength was set to 1070 nm, and the laser spot diameter was approximately 0.1 mm. As shown in Figure 2, the IPG-D30 wobble beam oscillating head was mounted on a Fanuc 6-axis robot. During the welding process, the scan head was driven by the robot to move linearly, while the laser beam was set perpendicular to the surfaces of the plates being joined. A circular beam oscillation mode was employed in experiments (Figure 2b). The welding parameters are summarized in Table 2.

Table 2.

Experimental parameters used in laser oscillating welding.

The samples prepared for metallographic observations were cross-sectioned perpendicular to the welding direction. The microstructures were observed by light microscopy (OM, DMi-8C, Leica, Wetzlar, Germany) and scanning electron microscopy (SEM, JEOL-JSM7100F, JEOL Ltd., Tokyo, Japan).

The mechanical properties of the joints at room temperature were evaluated by tensile lap shear tests. To this end, the samples were machined following ASTM:E8/E8M standard. The geometry and dimensions of the test coupons are provided in Figure 2c. An AGX-100kNXD testing system (Shimadzu, Kagoshima, Japan ) with a constant crosshead speed of 2.0 mm/min was used. The tensile fracture surface morphologies were analyzed using SEM. The microhardness of each joint was determined using a Vickers hardness tester (HV-1000) at the load of 300 g and holding time of 15 s on the cross-section (1 mm below the top face of the weld).

3. Results and Discussion

3.1. Effect of Oscillation Amplitudes on the Weld Profiles and Laser Energy Distribution

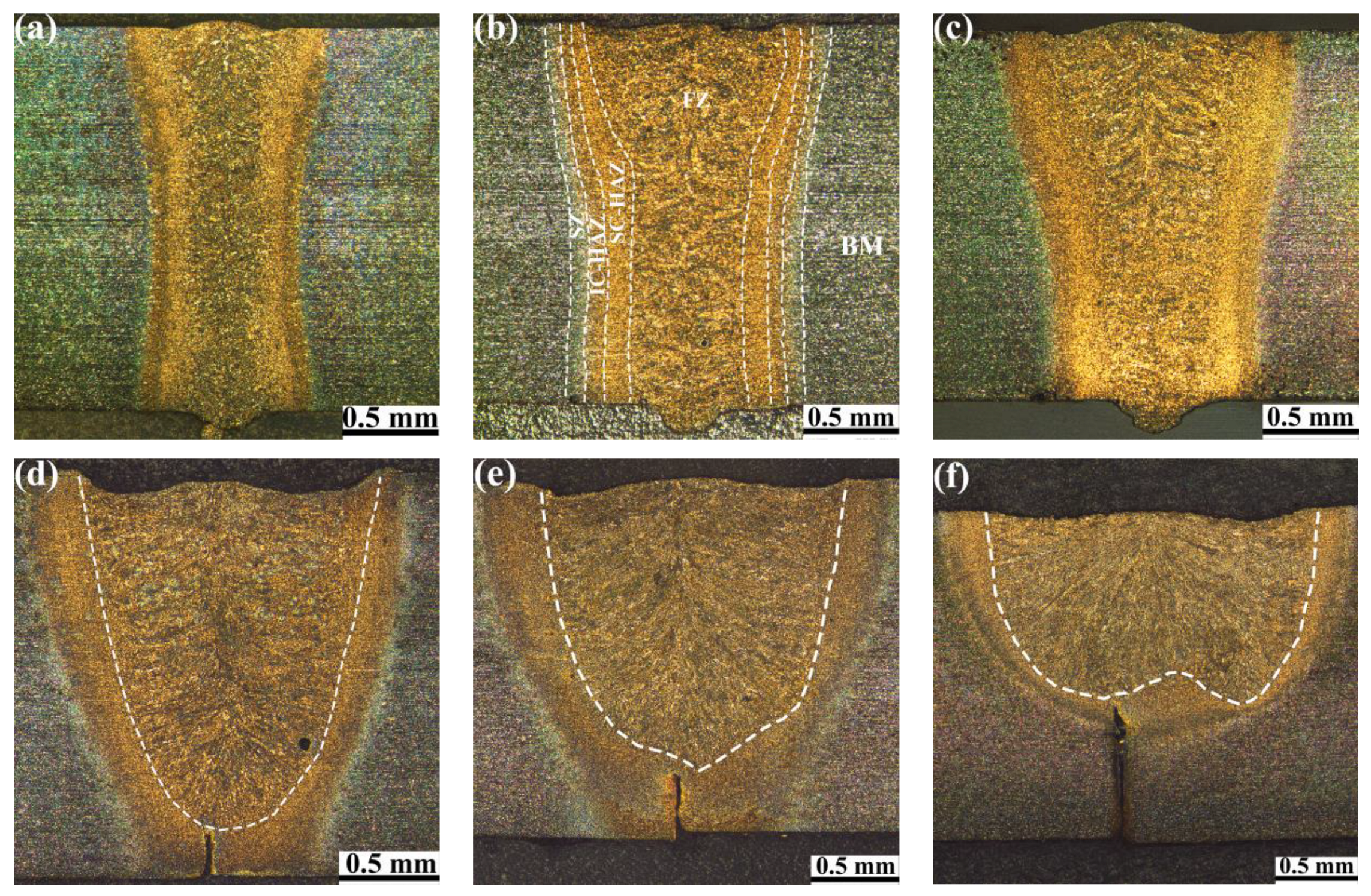

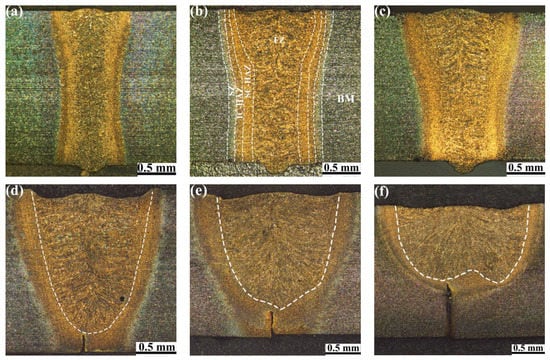

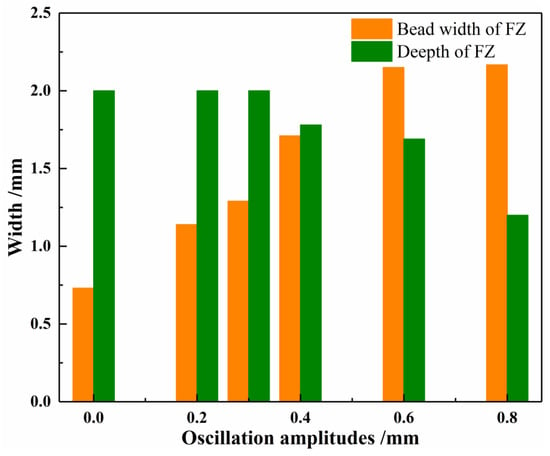

Figure 3 shows the cross-sections of the joints with different oscillating amplitudes. Obviously, complete full-penetration welds joints can be obtained at oscillation amplitudes below 0.4 mm and variable widths. The weld zones (FZs) showed nail-like shapes with a wide top and a narrow bottom. When the amplitude increases to 0.4 mm, the penetration is incomplete. The FZ revealed a cup-cone-like shape (the white dash line in Figure 3d). As the oscillation amplitude exceeds 0.4 mm, the appearance of FZ gradually changed from a cup-cone-like shape to a W-type shape (Figure 3e,f). The weld appearance in Figure 3a–f revealed an increase in the bead width of FZ as a function of the oscillation amplitude. By contrast, the maximum depth of FZ declined gradually at oscillation diameters beyond 0.4 mm (Figure 4). Furthermore, the welding mode shifted from keyhole to mixed, and the conduction rose with the oscillation diameter.

Figure 3.

Morphologies of weld cross-sections with different oscillating amplitudes: (a) weld of A = 0, (b) weld of A = 0.2 mm, (c) weld of A = 0.3 mm (d) weld of A = 0.4 mm (e) weld of A = 0.6 mm, (f) weld of A = 0.8 mm.

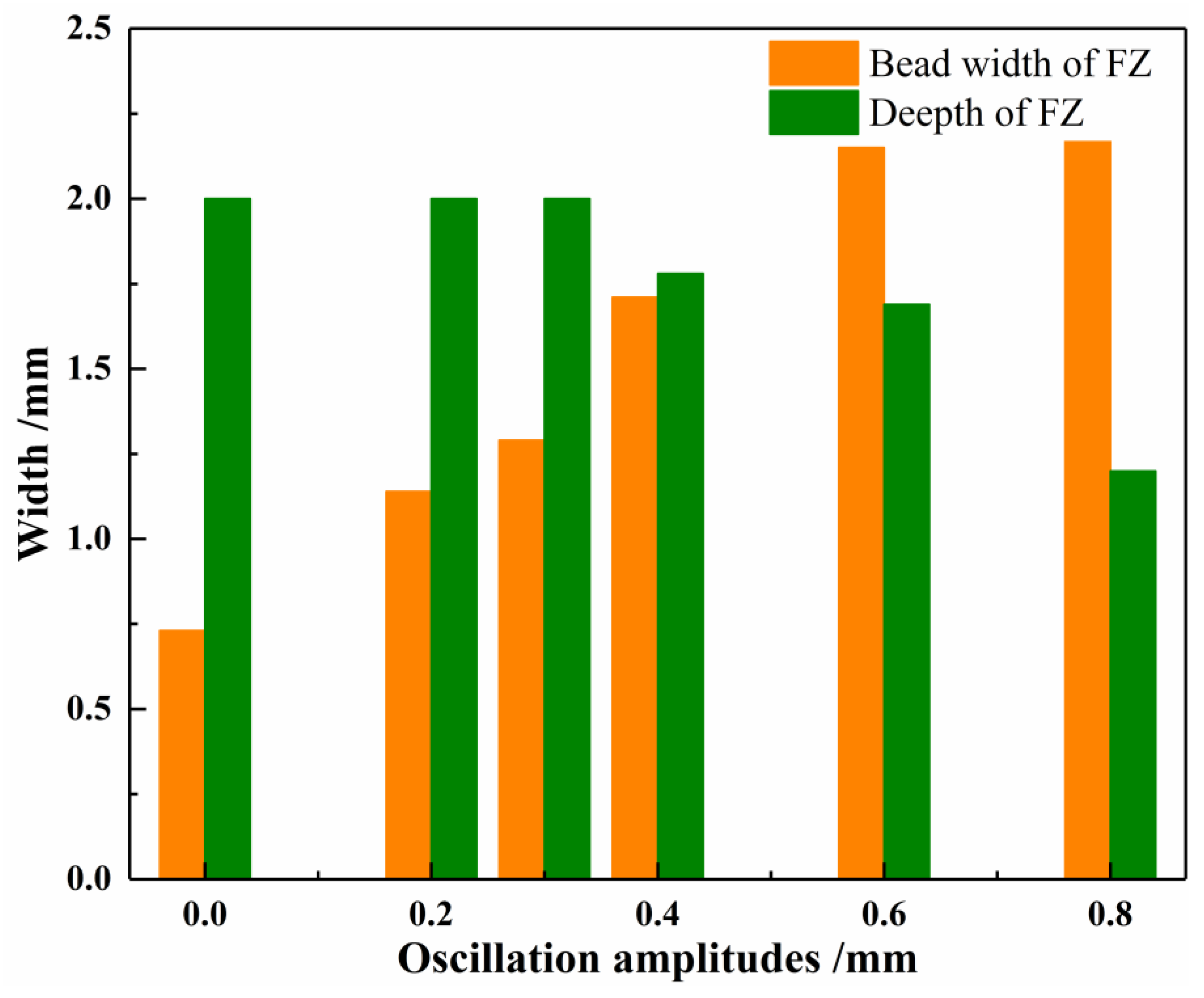

Figure 4.

Widths and depths of FZ obtained with different oscillating diameters.

The morphology of the melt pool is causally related to the energy distribution, as well as the interaction between the laser beam and matter during the welding process. During laser oscillating welding, laser beam oscillation along a circle trajectory would induce the dynamic distribution of energy around the molten pool, thereby changing the heat flow around the keyhole and resulting in different weld profiles.

In this study, the actual track of the laser beam combined linear and circular motions (Figure 2b), which can be expressed according to Equation (1):

where x(t) represents the beam spot position in the x-direction, and y(t) represents the y-direction at t moment. x0 and y0 are the initial position coordinates. v refers to welding speed, A is oscillating amplitude, and f denotes oscillating frequency. φx and φy are the initial phases, which can be simplified by zero.

The energy distribution of the laser beam can be described by Equation (2) [27]:

where η represents the laser absorptivity of materials, and r0 is the radius of the beam spot. x and y are the distances to the center of the beam spot in the x-direction and y-direction, respectively.

The energy deposition at the surface of the material being welded can be determined by integration (Equation (3)):

where E is the energy deposition distributions on the materials, and t is time.

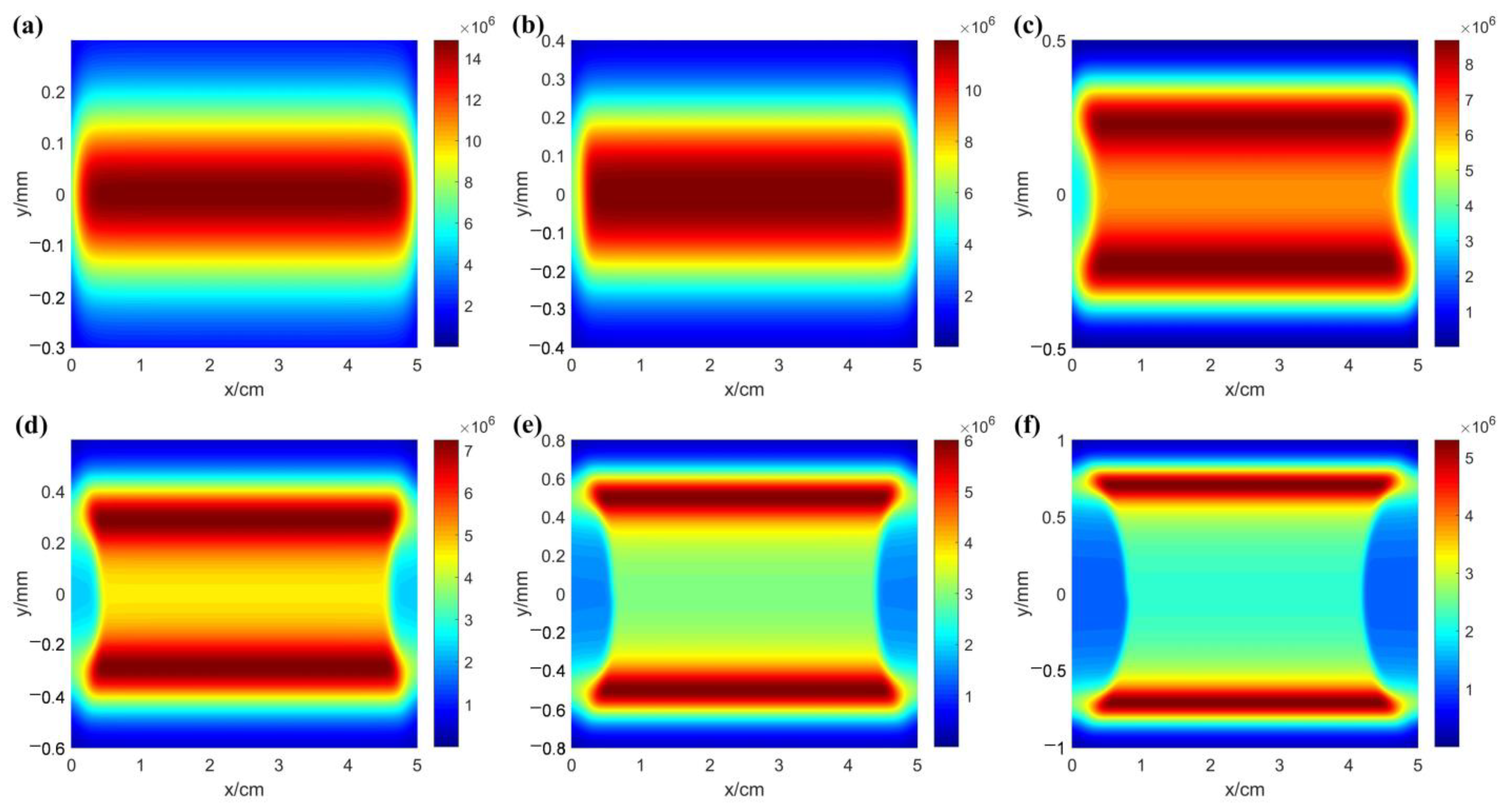

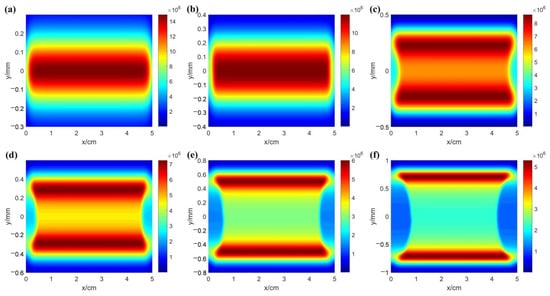

Equation (3) can be used to calculate the energy deposition distribution during the oscillating laser welding process when combining Equations (1) and (2). The results are displayed in Figure 5.

Figure 5.

Surface energy distributions with different oscillation amplitudes at the oscillation frequency of 150 Hz: (a) A = 0, (b) A = 0.2 mm, (c) A = 0.3 mm (d) A = 0.4 mm (e) A = 0.6 mm, (f) A = 0.8 mm.

The numerical results revealed predominately accumulated energy in the center of the weld, and the peak energy was distributed along the weld centerline during laser welding (Figure 5a). At the oscillating laser welding (Figure 5b–d), the energy accumulation range enlarged as the oscillating amplitude rose. Meanwhile, the churning effect on the molten pool was enhanced accordingly, and both the flow and heat transfer were promoted, leading to more evenly distributed energy in the molten pool. Therefore, the width of FZ reasonably increased with the oscillating amplitude. On the other hand, the increase in oscillation amplitude dispersed the constant energy of the laser beam, and the energy peak value was significantly reduced when compared to laser welding, yielding less penetration depth. In short, larger beam oscillating amplitudes generated smaller penetration depths. Meanwhile, the energy was mainly deposited on both sides of the weld. This would explain the W-type shape of the cross-section weld at oscillation diameters beyond 0.4 mm.

3.2. Effect of Oscillation Amplitudes on the Microstructure and Microhardness of the Welds

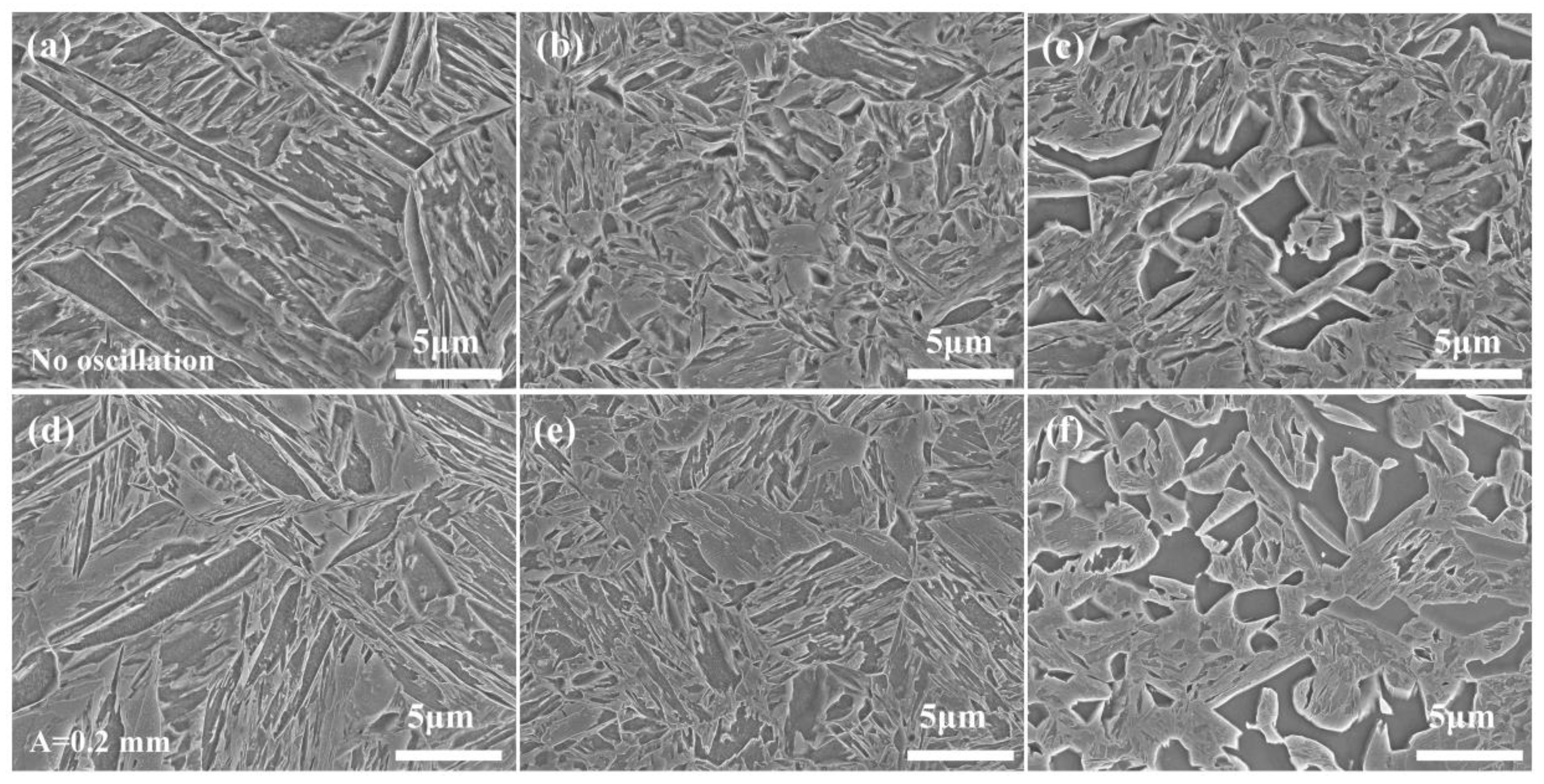

Figure 6 shows the typical joints produced by laser welding and laser beam oscillating welding (A = 0.2 mm). According to the microstructure (Figure 6) and hardness distribution (Figure 7), the welds could be divided into four different zones across the joint. These zones can be identified as FZ, inner heat-affected zone (HAZ), outer soften zone (SZ), and base material (BM). This agreed well with the weld cross-section exhibiting a heterogeneous structure (Figure 3). Similar results have been reported for laser welding of QP980 and DP980 [5,7,12].

Figure 6.

Microstructure of the joints at different zones: (a,d) FZ, (b,c) SC-HAZ, and (e,f) IC-HAZ.

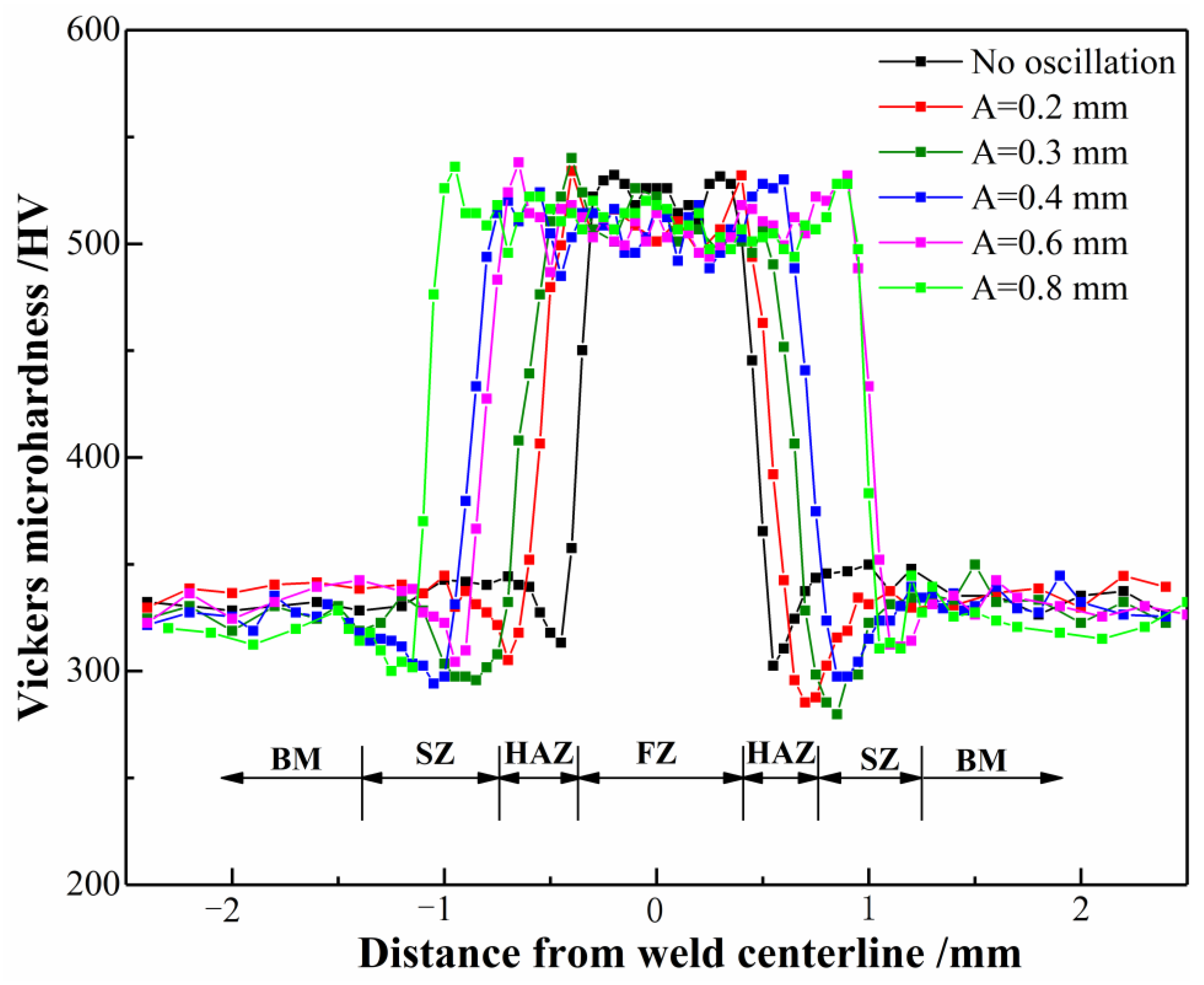

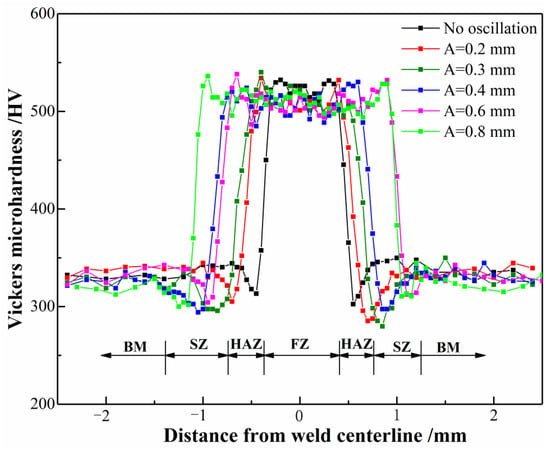

Figure 7.

Microhardness distributions of the joints with different oscillating amplitudes.

Figure 7 shows the microhardness of the joints under different oscillating amplitudes. The hardness distributions of six joints showed consistent trends, while the width of each joint increased with the oscillating amplitude. Although the hardness distributions have similar trends for different oscillation amplitudes, obvious differences can also be noticed. This is mainly attributed to the microstructure of the joints [28,29]. The average hardness of BM was measured as ~330 HV, while that of FZ reached above 500 HV. The latter value was approximately 1.50-fold higher than that of BM. As shown in Figure 6a,d, the FZs were composed of typical lath martensite. According to Gould et al. [30], the cooling rate of the welding pool during laser welding was much greater than the critical cooling rate of martensite forming. This finally formed lath-type martensite with an enhanced hardness of FZ.

Furthermore, the inner HAZ is outside the molten pool, as shown in Figure 2. According to the distance from the molten pool, the inner HAZ can be divided into the supercritical region (SC-HAZ) and intercritical region (IC-HAZ). Figure 6b,e show the microstructure of the SC-HAZ. Apparently, the microstructure of the SC-HAZ was also composed of martensite. In laser welding, the SC-HAZ was heated above the Ac3 temperature but below the melting point, making the original F, M, and RA of the BM turn into austenite. During the cooling process, the austenite was transformed to M under a high cooling rate. As a result, the hardness of SC-HAZ was much greater than that of BM. However, the hardness of SC-HAZ in the weld produced by laser welding was greater than that by laser oscillating welding (Figure 7). This is mainly attributed to the finer generated martensite in laser welding. As well known, the morphology of martensite is a key factor influencing the hardness during laser welding.

Figure 6c,f show the microstructure of the IC-HAZ. At this zone, the peak temperature was located between Ac1 and Ac3 lines, where the original F and M in BM were austenitized incompletely before being converted to irregularly shaped F and M. As depicted in Figure 6c,f, IC-HAZ was mainly composed of blocky M and fine F. On the one hand, the proportion of M was higher than in the BM but lower than in FZ and SC-HAZ. On the other hand, the proportion of F was lower in weld produced by laser welding was higher than that by laser oscillating welding.

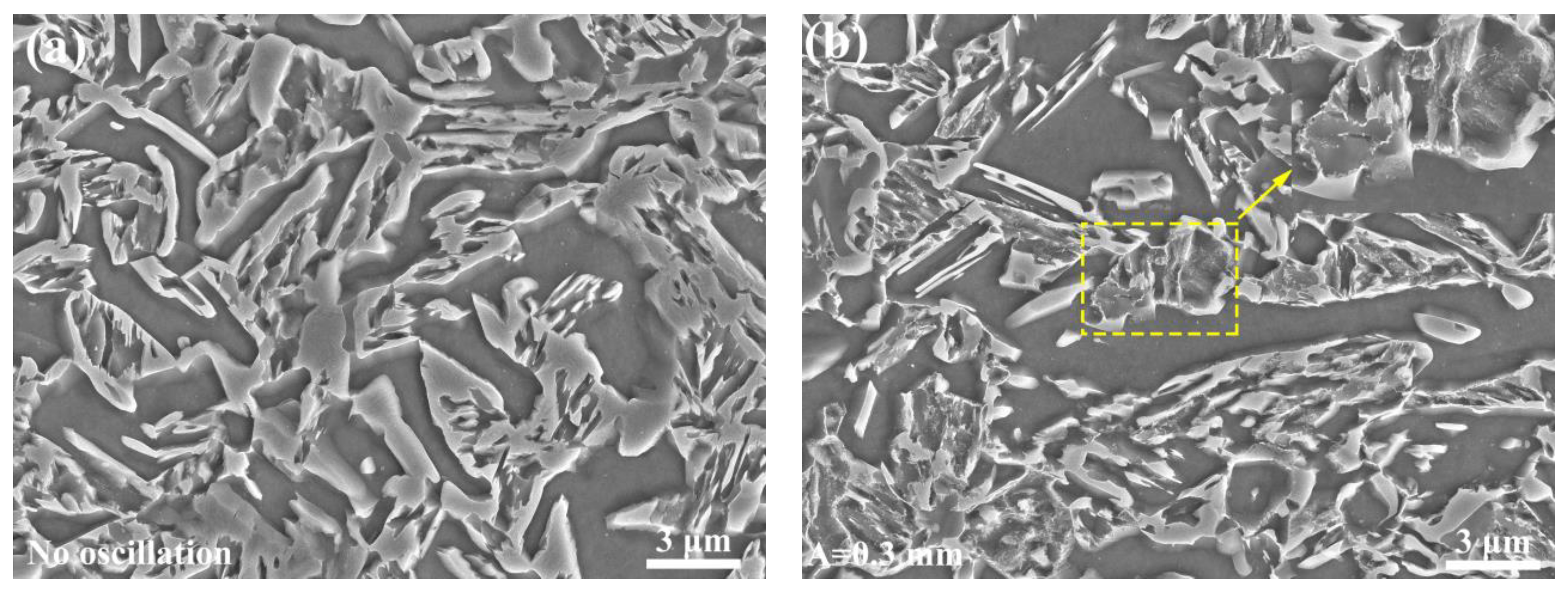

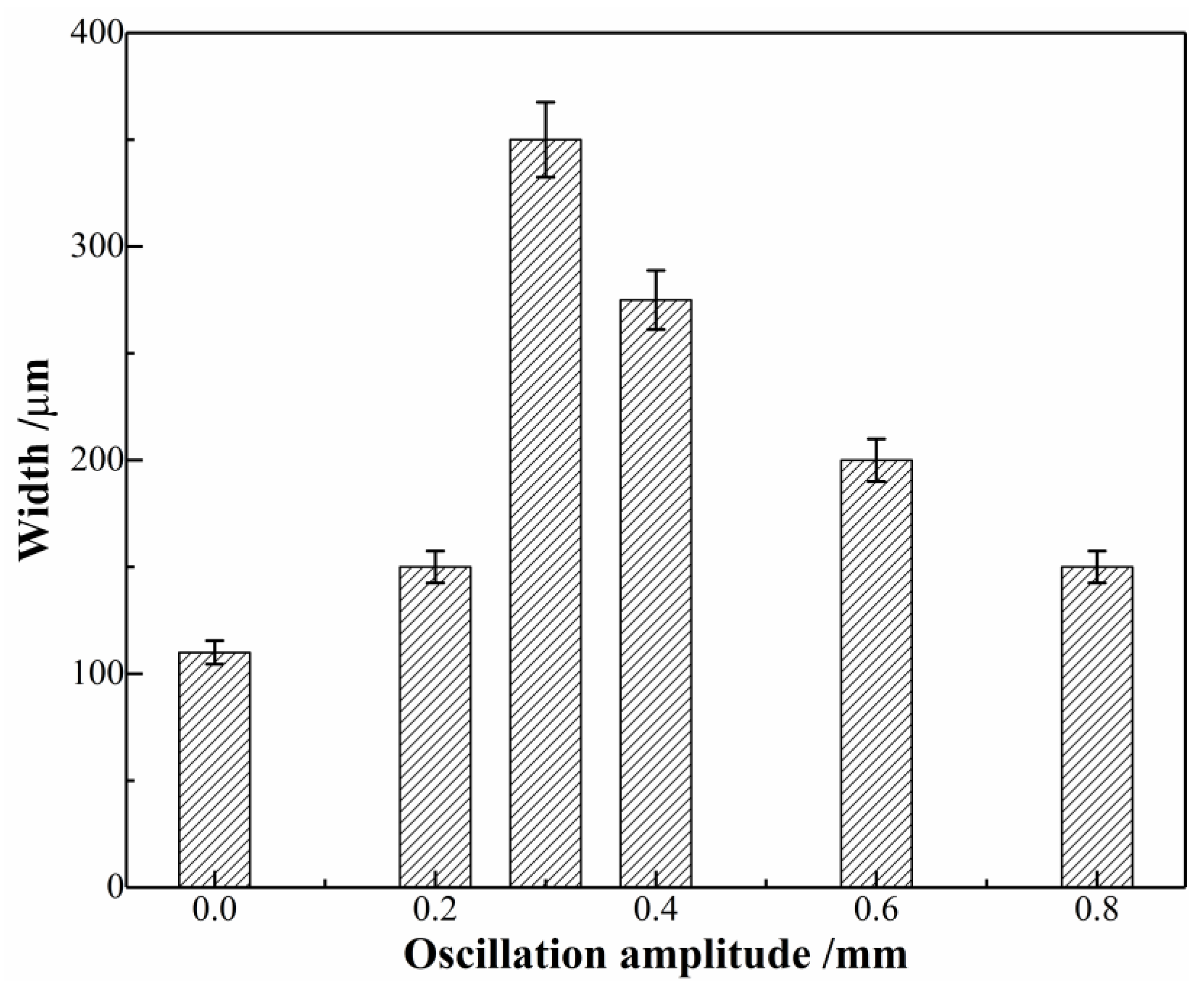

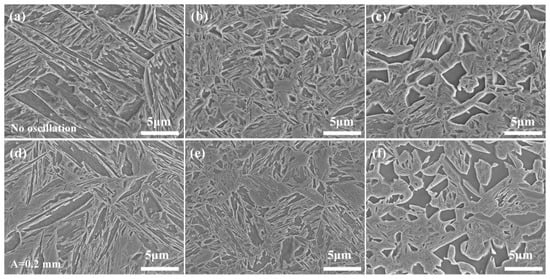

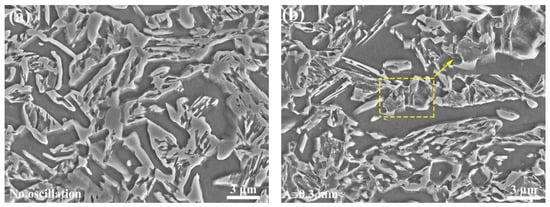

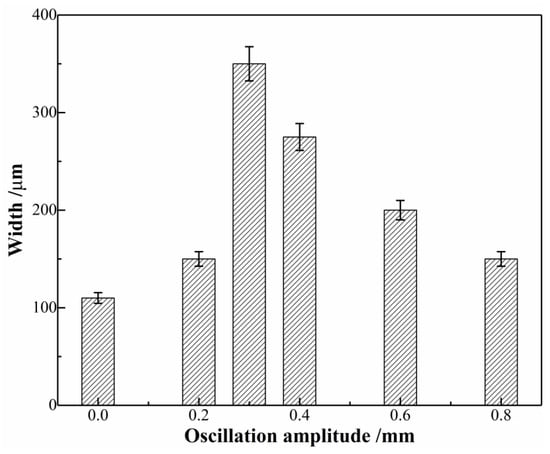

With a further rise in distance from the weld center, the peak temperature decreased below the Ac1 line. Partial pre-existing M in the BM decomposed into tempered martensite (TM). As a result, the microstructure of this zone (SZ) consisted of pre-existing M, TM, F, and RA, as shown in Figure 8. The hardness of the SZ became lower than that of BM. It seems in Figure 7 that the average hardness of SZ decreases with the oscillation amplitude. Moreover, the average width measured from SZ increased sharply and reached its maximum of 0.35 mm at the amplitude of 0.3 mm, as shown in Figure 9, which is attributed to the proportion of the decomposed M. As revealed in Figure 8, the ferrite phase of BM did not change in SZ, while the decomposition of M looked different at various oscillation parameters. In laser welding, the tempering characteristic was significant when compared to BM. More block M occurred to decompose, and a number of carbides dispersed at the grain boundary, as shown in Figure 8b. With the increase in oscillation amplitude, the internal region pre-existing block M was visible in Figure 8a. This is similar to the observations reported by Rossini et al. [9].

Figure 8.

Microstructure of the soft zones: (a) weld of A = 0, (b) weld of A = 0.2 mm.

Figure 9.

The average width of SZ with different oscillation amplitudes.

Based on the surface energy distributions in Section 3.2, it can be concluded that the microstructure evolution of SZ was closely related to the heating temperature and hold time at high temperatures. During the laser oscillating welding, the range of the laser exposure was enlarged, and the energy of the laser beam was dispersed. As a result, the molten pool expanded, which could prolong the time above the tempering temperature. On the other hand, the larger molten pool could accelerate heat dissipation when oscillating amplitudes exceeded the critical level, leading to more rapid cooling rates. Accompanied by lower energy density, less pre-existing martensite was decomposed, and the size of SZ decreased with the increase in oscillating amplitudes.

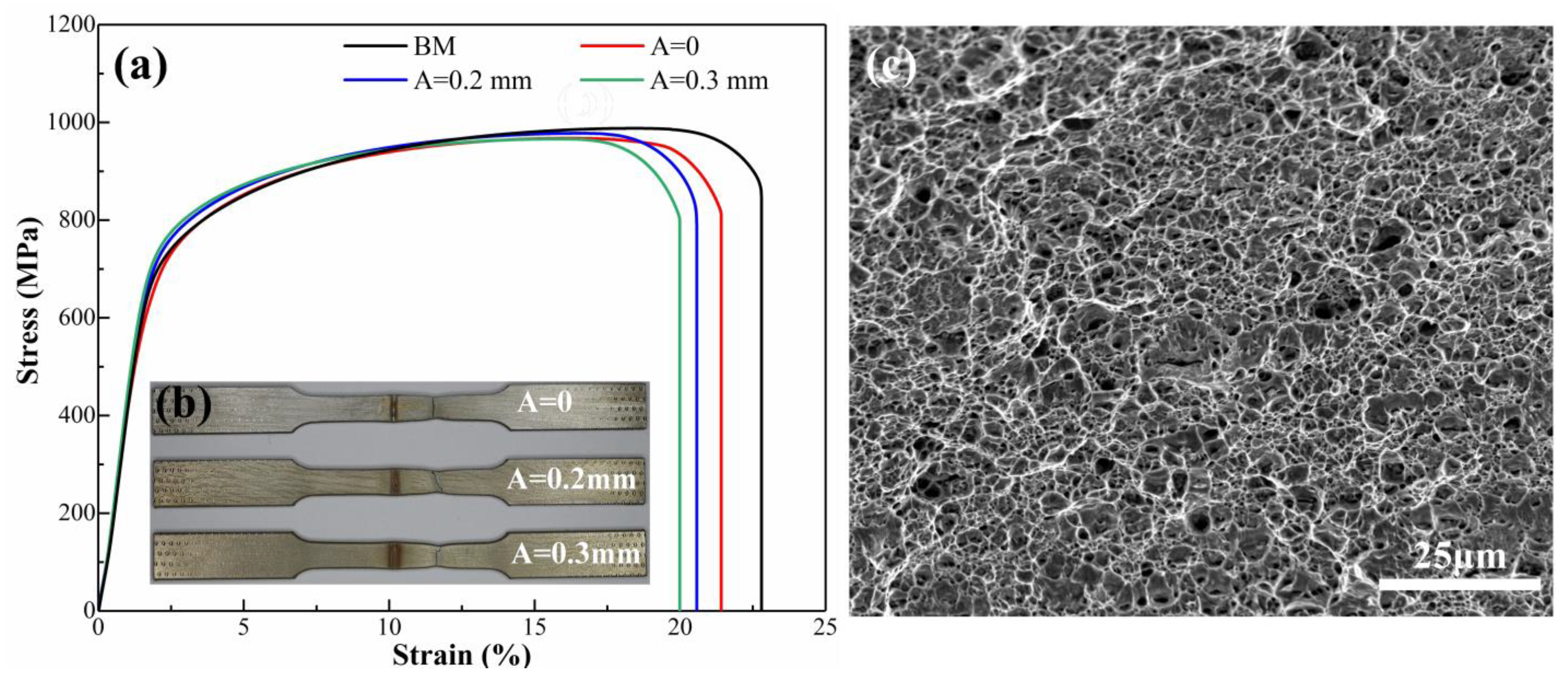

3.3. Effect of Oscillation Amplitudes on the Lap Shear Loads

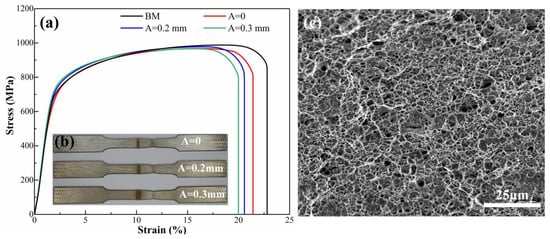

Tensile tests of the joints produced with and without beam oscillating were carried out to study the strength, elongation, and failure characteristics. The corresponding stress–strain curves of the joints and BM are presented in Figure 10a. The stress–strain curves of the joints showed the same trend as BM with impressive mechanical properties. These include the high ultimate tensile strength and absence of yield point elongation. The location of the tensile fracture of the joints in Figure 10b showed all welds broken at BM.

Figure 10.

(a) Stress–strain curves of prepared samples and BM, (b) tensile fracture samples with different oscillating amplitudes, and (c) microscopic fracture surface.

The detailed tensile results of the joints and BM are summarized in Table 3. The yield strength of all joints was stable and close to that of BM, whereas the ultimate tensile strength and total elongation were slightly lower than BM. Moreover, the ultimate tensile strength of the joints obtained with a stationary beam (about 97% of BM) was roughly the same as that produced with an oscillated beam. In other words, the beam oscillation did not significantly affect the weld yield strength and tensile strength. However, the joint produced with no oscillation showed a strain of 21.6% (about 88 % of BM), which is about 8% higher than that of the circle trajectory (20%). This can be attributed to the emergence of M in the weld, which is consisted of a hard phase able to reduce the effective length of the extension during the tensile test. The total elongation decreased as the width of FZ increased, meaning that the width of FZs played a key role in determining the total elongation of the joint. Thus, the smaller FZ and SZ (Figure 9) induced stationary beam welds with higher ductility than that of oscillated beam welds. Meanwhile, the tensile fracture was still broken at BM despite oscillated beam weld consisting of larger FZ and SZ. The microstructural morphology of the fracture surface of the joint in Figure 10c displayed several fine cup-like dimples, implying a ductile type of fracture.

Table 3.

Mechanical properties of welded joints.

4. Conclusions

The microstructures and properties of QP980 steel butt joints obtained by laser oscillating welding at different oscillation amplitudes were comprehensively studied. The major findings can be summarized as follows:

- (1)

- The laser energy deposition distribution on the processing surface changed significantly as a function of beam oscillation. As the oscillating amplitude rose, the energy accumulation range enlarged, while the energy peak value was decreased due to the dispersed constant energy of the laser beam. As a result, the appearance of the cross-section transformed gradually from a nail-like shape to a cup-cone-like shape and then to a W-type shape, and the weld depth decreased significantly with the oscillation amplitude.

- (2)

- The FZ and SC-HAZ were full of typical lath martensite, and IC-HAZ was composed of irregular-shaped ferrite and martensite. Beam oscillation could reduce the possibility of pre-existing block martensite decomposing, resulting in the decreasing width of the SZ and the increasing hardness.

- (3)

- Tensile fracture of all welds occurred at the BM, and the tensile strength was close to BM. Thus, the beam oscillation slightly affected weld tensile strength, while the elongation of the joints slightly decreased with the oscillation amplitude due to the wider FZ. The results indicated that beam oscillation could improve the weldability of QP980.

Author Contributions

Conceptualization, T.L. and J.C.; methodology, J.Y. and J.Q.; formal analysis, J.C.; investigation, T.L. and W.Y.; writing—original draft preparation, T.L.; writing—review and editing, J.Y.; project administration, J.Q.; funding acquisition, J.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China under Grant 51805084, 52265062; the Scientific Research Project of the Department of Education of Guangdong Province under Grant 2022KTSCX125, 2022ZDJS042; and the Scientific Research Project of Jihua Laboratory under Grant X220391TH220.

Data Availability Statement

Not applicable.

Acknowledgments

We would like to show our thanks to Hongjun Chen for his support.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Schmitt, J.H.; Iung, T. New developments of advanced high-strength steels for automotive applications. Comptes Rendus Phys. 2018, 19, 641–656. [Google Scholar] [CrossRef]

- Speer, J.; Matlock, D.K.; De Cooman, B.C.; Schroth, J.G. Carbon partitioning into austenite after martensite transformation. Acta Mater. 2003, 51, 2611–2622. [Google Scholar] [CrossRef]

- Zhao, J.W.; Jiang, Z.Y. Thermomechanical processing of advanced high strength steels. Prog. Mater. Sci. 2018, 94, 174–242. [Google Scholar] [CrossRef]

- Ferreira, C.C.A.; Braga, V.; Siqueira, R.H.M.; Carvalho, S.M.; Lima, M.S.F. Laser beam welding of DP980 dual phase steel at high temperatures. Opt. Laser Technol. 2020, 124, 105964. [Google Scholar] [CrossRef]

- Li, Y.; Zhu, Z.H.; Tang, X.H.; Han, S.Y.; Zhang, R.L.; Cui, H.C. Improvement of welding stability and mechanical properties of galvanized DP800 steel lap joint by high-speed tandem beam laser. Opt. Laser Technol. 2022, 150, 107958. [Google Scholar] [CrossRef]

- Di, H.S.; Sun, Q.; Wang, X.N.; Li, J.P. Microstructure and properties in dissimilar/similar weld joints between DP780 and DP980 steels processed by fiber laser welding. J. Mate. Sci. Technol. 2017, 33, 1561–1571. [Google Scholar] [CrossRef]

- Wang, X.N.; Sun, Q.; Zheng, Z.; Di, H.S. Microstructure and fracture behavior of laser welded joints of DP steels with different heat inputs. Mater. Sci. Eng. A 2017, 699, 18–25. [Google Scholar] [CrossRef]

- Alvesa, P.H.O.M.; Limab, M.S.F.; Raabec, D.; Sandima, H.R.Z. Laser beam welding of dual-phase DP1000 steel. J. Mater. Process. Technol. 2018, 252, 498–510. [Google Scholar] [CrossRef]

- Rossini, M.; Spena, P.R.; Cortese, L.; Matteis, P.; Firrao, D. Investigation on dissimilar laser welding of advanced high strength steel sheets for the automotive industry. Mater. Sci. Eng. A 2015, 628, 288–296. [Google Scholar] [CrossRef]

- Razmpoosh, M.H.; Macwan, A.; Biro, E.; Zhou, Y. Microstructure and dynamic tensile characteristics of dissimilar fiber laser welded advanced high strength steels. Mater. Sci. Eng. A 2020, 773, 138729. [Google Scholar] [CrossRef]

- Guo, W.; Wan, Z.D.; Peng, P.; Jia, Q.; Zou, G.S.; Peng, Y. Microstructure and mechanical properties of fiber laser welded QP980 steel. J. Mater. Process. Technol. 2018, 256, 229–238. [Google Scholar] [CrossRef]

- Li, W.D.; Ma, L.X.; Peng, P.; Jia, Q.; Wan, Z.D.; Guo, W. Microstructural evolution and deformation behavior of fiber laser welded QP980 steel joint. Mater. Sci. Eng. A 2018, 717, 124–133. [Google Scholar] [CrossRef]

- Xue, J.L.; Guo, W.; Zhang, Y.X.; Xia, M.S.; Jia, Q.; Chi, J.X.; Shi, J.X.; Wu, Y.; Zhang, H.Q. Local microstructure and mechanical characteristics of HAZ and tensile behavior of laser welded QP980 joints. Mater. Sci. Eng. A 2022, 854, 143862. [Google Scholar]

- Zhao, H.Y.; Huang, R.R.; Sun, Y.M.; Tan, C.W.; Wu, L.J.; Chen, B.; Song, X.G.; Li, G.X. Microstructure and mechanical properties of fiber laser welded QP980/press-hardened 22MnB5 steel joint. J. Mater. Res. Technol. 2020, 9, 10079–10090. [Google Scholar] [CrossRef]

- Guo, W.; Wan, Z.D.; Jia, Q.; Ma, L.X.; Zhang, H.Q.; Tan, C.W.; Peng, P. Laser weldability of TWIP980 with DP980/B1500HS/QP980 steels: Microstructure and mechanical properties. Opt. Laser Technol. 2020, 124, 105961. [Google Scholar] [CrossRef]

- Li, J.Z.; Sun, Q.J.; Liu, Y.B.; Zheng, Z.Y.; Sun, Q.; Feng, J.C. Melt flow and microstructural characteristics in beam oscillation superimposed laser welding of 304 stainless steel. J. Manuf. Process. 2020, 50, 629–637. [Google Scholar] [CrossRef]

- Aalderink, B.J.; Pathiraj, B.; Aarts, R.G.K.M. Seam gap bridging of laser based processes for the welding of aluminium sheets for industrial applications. Int. J. Adv. Manuf. Technol. 2010, 48, 143–154. [Google Scholar] [CrossRef]

- Chen, L.; Mi, G.Y.; Zhang, X.; Wang, C.M. Comparative investigation on single laser beam and dual laser beam for lap welding of aluminum alloy. J. Laser Appl. 2020, 32, 42012. [Google Scholar]

- Liu, B.W.; Jin, W.T.; Lu, A.J.; Liu, K.; Wang, C.M.; Mi, G.Y. Optimal design for dual laser beam butt welding process parameter using artificial neural networks and genetic algorithm for SUS316L austenitic stainless steel. Opt. Laser. Technol. 2020, 125, 106027. [Google Scholar]

- Müller, A.; Goecke, S.F.; Rethmeier, M. Laser beam oscillation welding for automotive applications. Weld. World. 2018, 62, 1039–1047. [Google Scholar] [CrossRef]

- Shah, L.H.; Khodabakhshi, F.; Gerlich, A. Effect of beam wobbling on laser welding of aluminum and magnesium alloy with nickel interlayer. J. Manuf. Process. 2019, 37, 212–219. [Google Scholar] [CrossRef]

- Hao, K.D.; Gao, M.; Wu, R.; Zeng, X.Y. Effect of oscillating laser beam offset on the microstructure and mechanical properties of dissimilar stainless steels joints. J. Mater. Process. Technol. 2020, 275, 116330. [Google Scholar] [CrossRef]

- Hu, K.; Muneer, Q.; Zhang, J.H.; Zhan, X.H. Effect of beam oscillating frequency on the microstructure and mechanical properties of dissimilar laser welding of AA2060 and AA6061 alloy. Mater. Sci. Eng. A 2022, 832, 142431. [Google Scholar] [CrossRef]

- Hao, K.D.; Wang, H.K.; Gao, M.; Wu, R.; Zeng, X.Y. Laser welding of AZ31B magnesium alloy with beam oscillation. J. Mate. Res. Technol. 2019, 8, 3044–3053. [Google Scholar] [CrossRef]

- Jiang, Z.G.; Chen, X.; Li, H.; Lei, Z.L.; Chen, Y.B.; Wu, S.B.; Wang, Y.H. Grain refinement and laser energy distribution during laser oscillating welding of Invar alloy. Mater. Des. 2020, 186, 108195. [Google Scholar] [CrossRef]

- Fetzer, F.; Sommer, M.; Weber, R.; Weberpals, J.P.; Graf, T. Reduction of pores by means of laser beam oscillation during remote welding of AlMgSi. Opt. Laser. Eng. 2018, 108, 68–77. [Google Scholar] [CrossRef]

- Zhang, C.; Yu, Y.; Chen, C.; Zeng, X.Y.; Gao, M. Suppressing porosity of a laser keyhole welded Al-6Mg alloy via beam oscillation. J. Mater. Process. Technol. 2020, 278, 116382. [Google Scholar]

- Rai, R.; Kelly, S.M.; Martukanitz, R.P.; Debroy, T. A convective heat-transfer model for partial and full penetration keyhole mode laser welding of a structural steel. Metall. Mater. Trans. A 2008, 39, 98–112. [Google Scholar]

- Wang, X.N.; Chen, C.J.; Wang, H.S.; Zhang, S.H.; Zhang, M.; Luo, X. Microstructure formation and precipitation in laser welding of microalloyed C-Mn steel. J. Mater. Process. Technol. 2015, 226, 106–114. [Google Scholar]

- Gould, J.E.; Khurana, S.P.; Li, T. Predictions of microstructures when welding automotive advanced high-strength steels. Weld. J. 2006, 85, 111. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).