Anisotropic Tensile and Compressive Strengths of Al–4 wt.%Cu Alloy Powder: Part 1—Effects of Compaction Loads and Heat Treatments

Abstract

:1. Introduction

2. Materials and Methods

2.1. Initial Materials, Powder Production, and Compaction

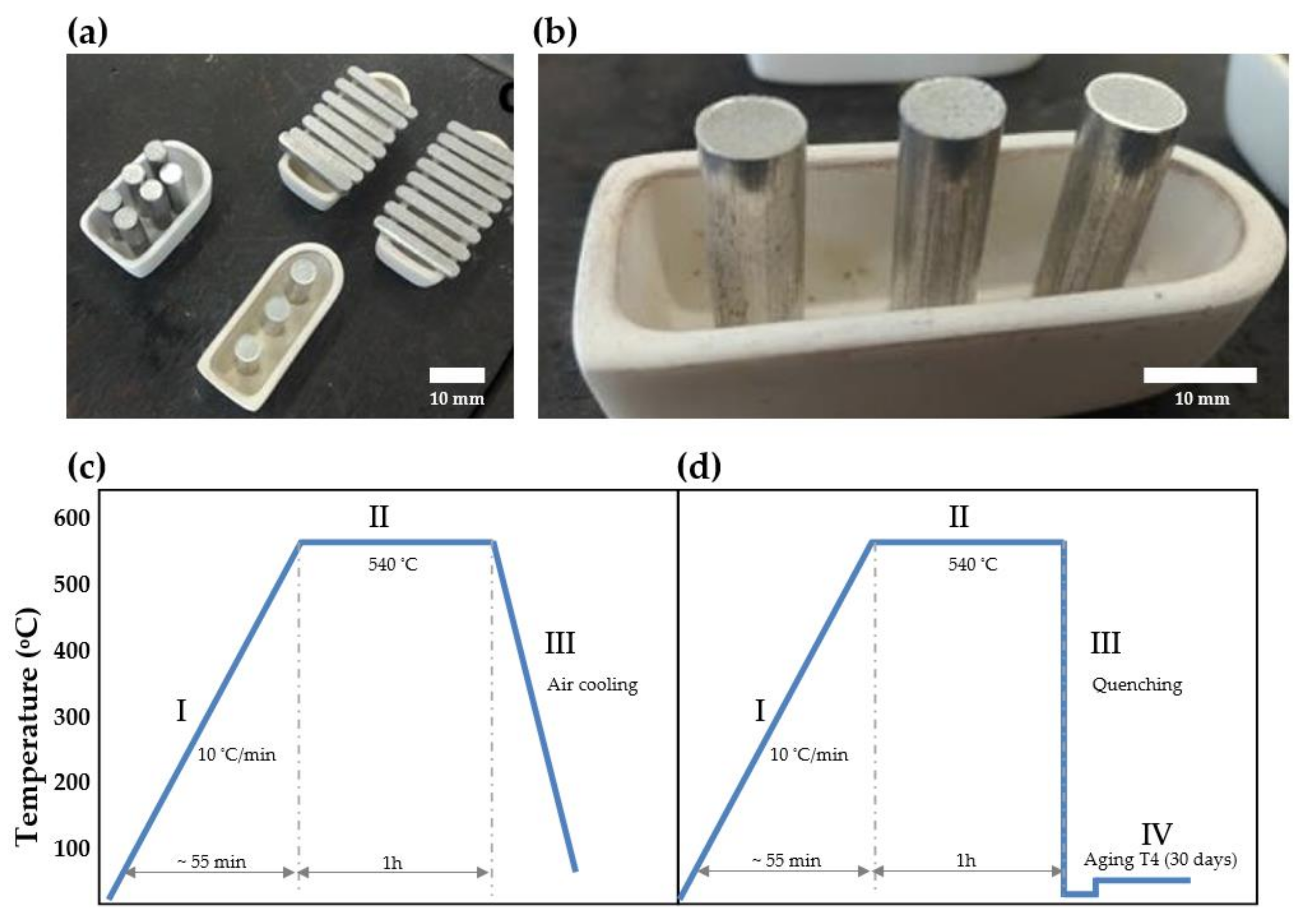

2.2. Densification Measurements and Heat Treatments

2.3. Mechanical Properties and Microstructural Characterization

3. Results and Discussion

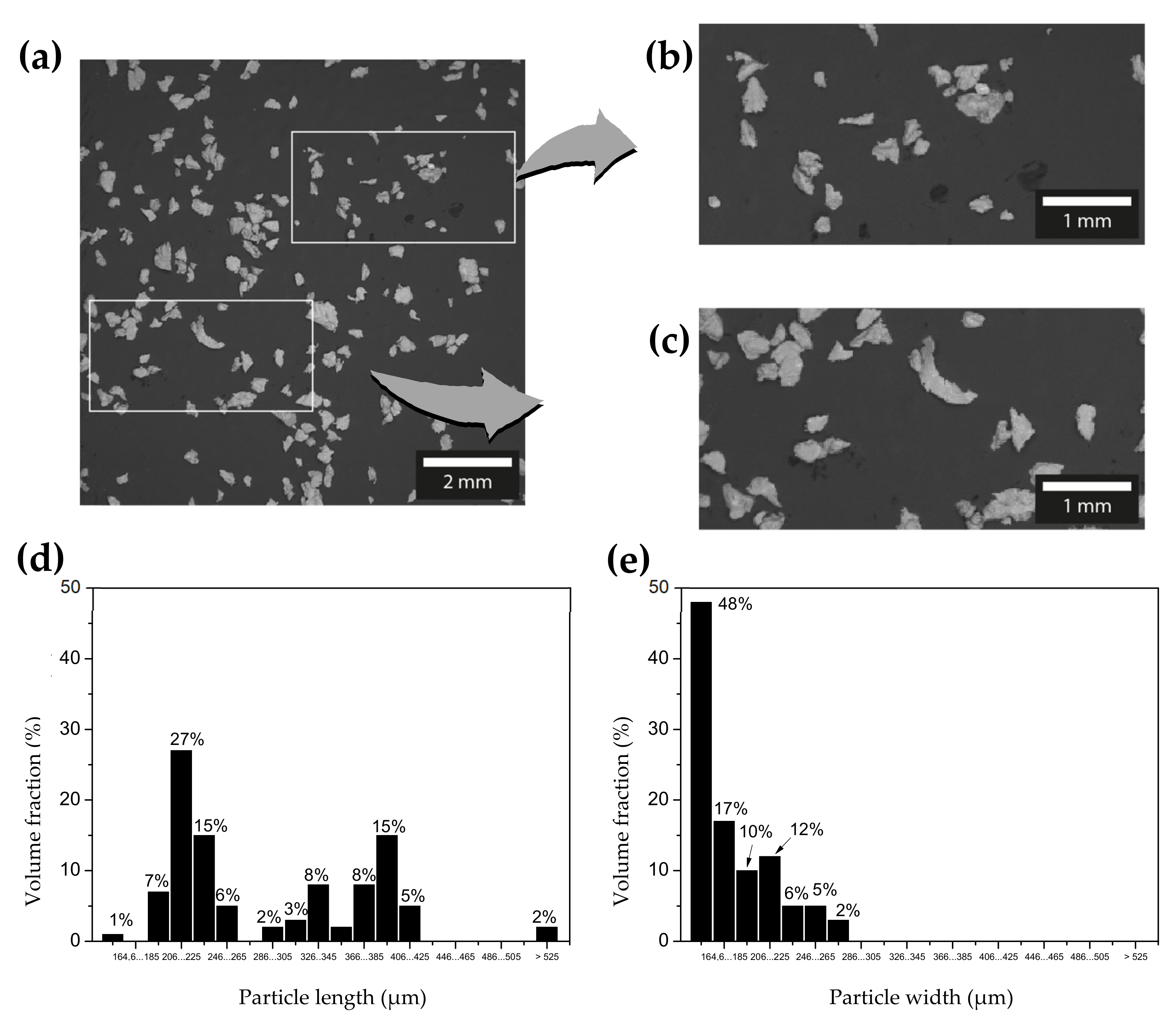

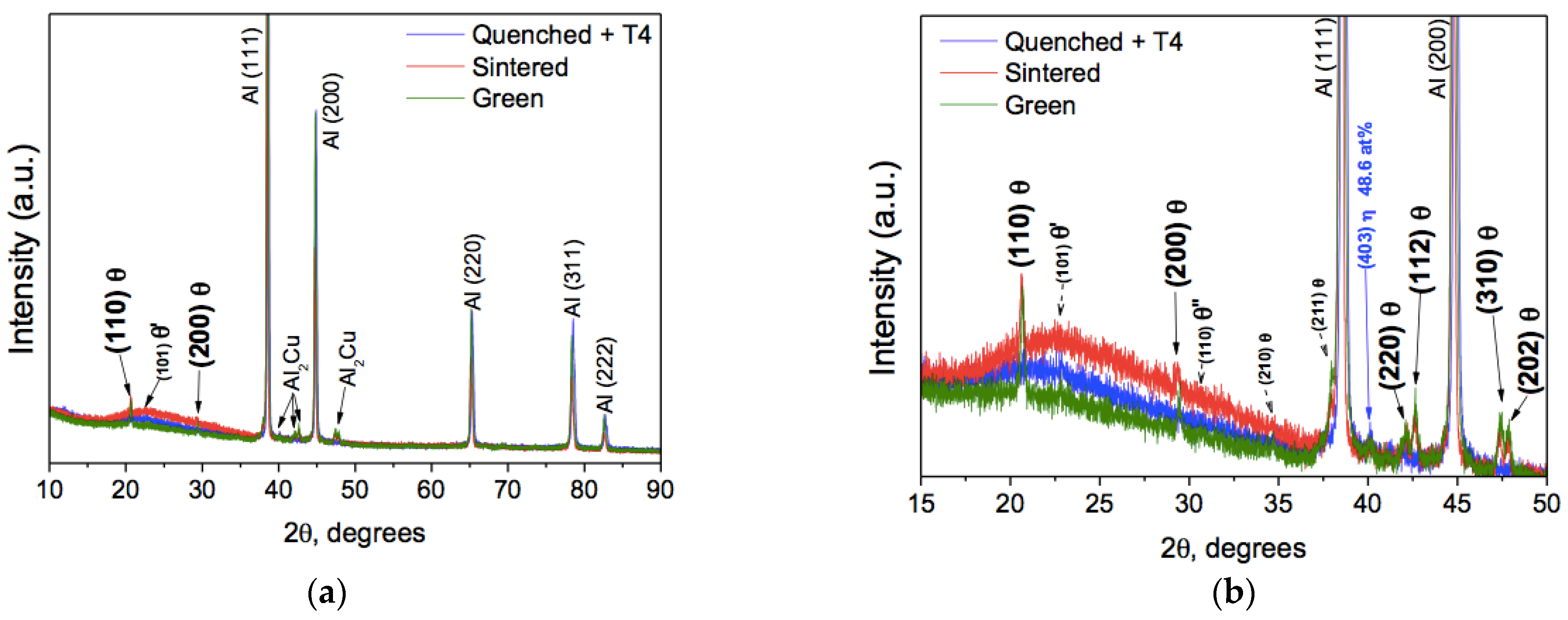

3.1. Alloy Powders and Anisotropic Effect on Densification

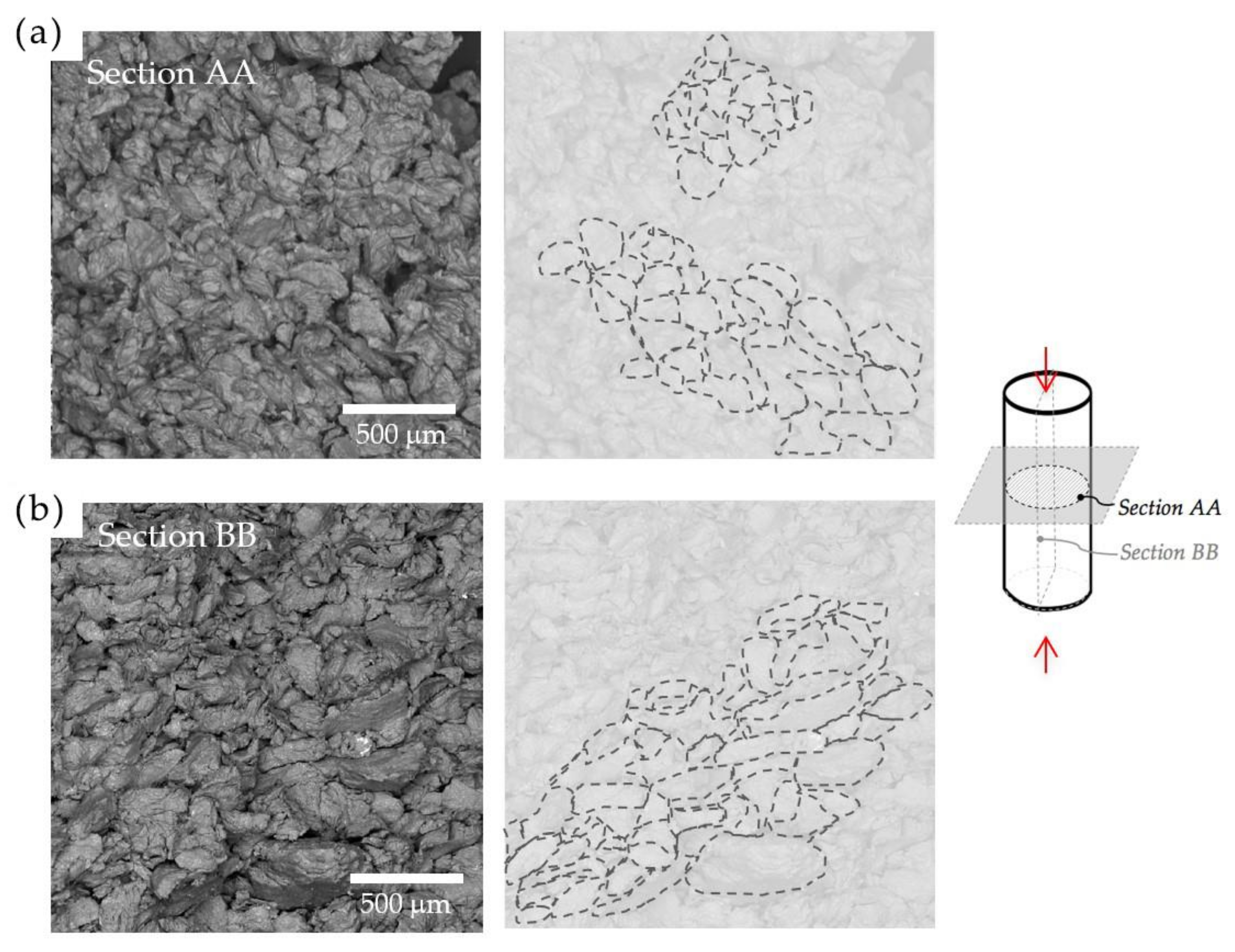

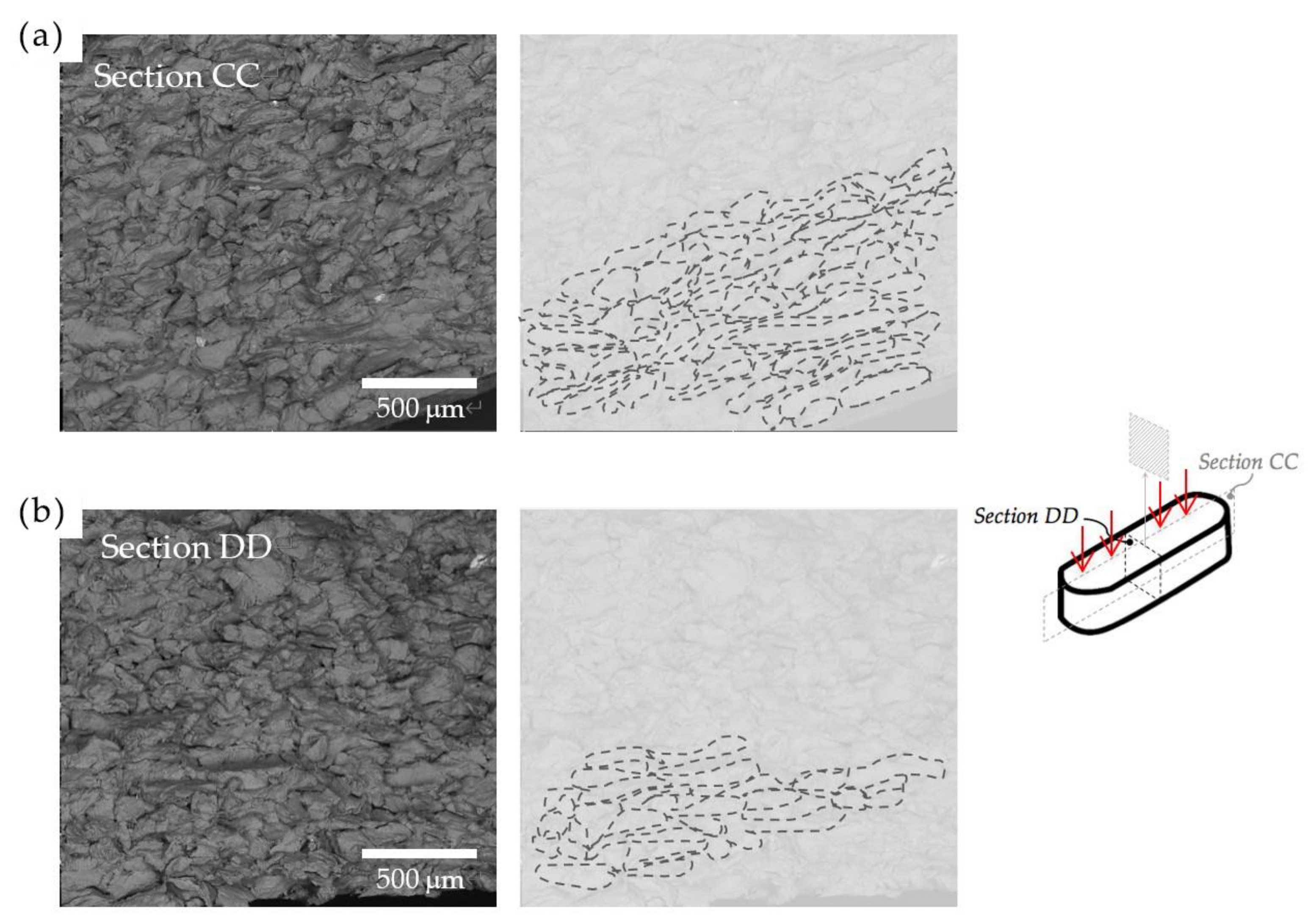

3.2. Anisotropic Effect on Morphology of Compacted Particles

3.3. Anisotropic and Mechanical Properties

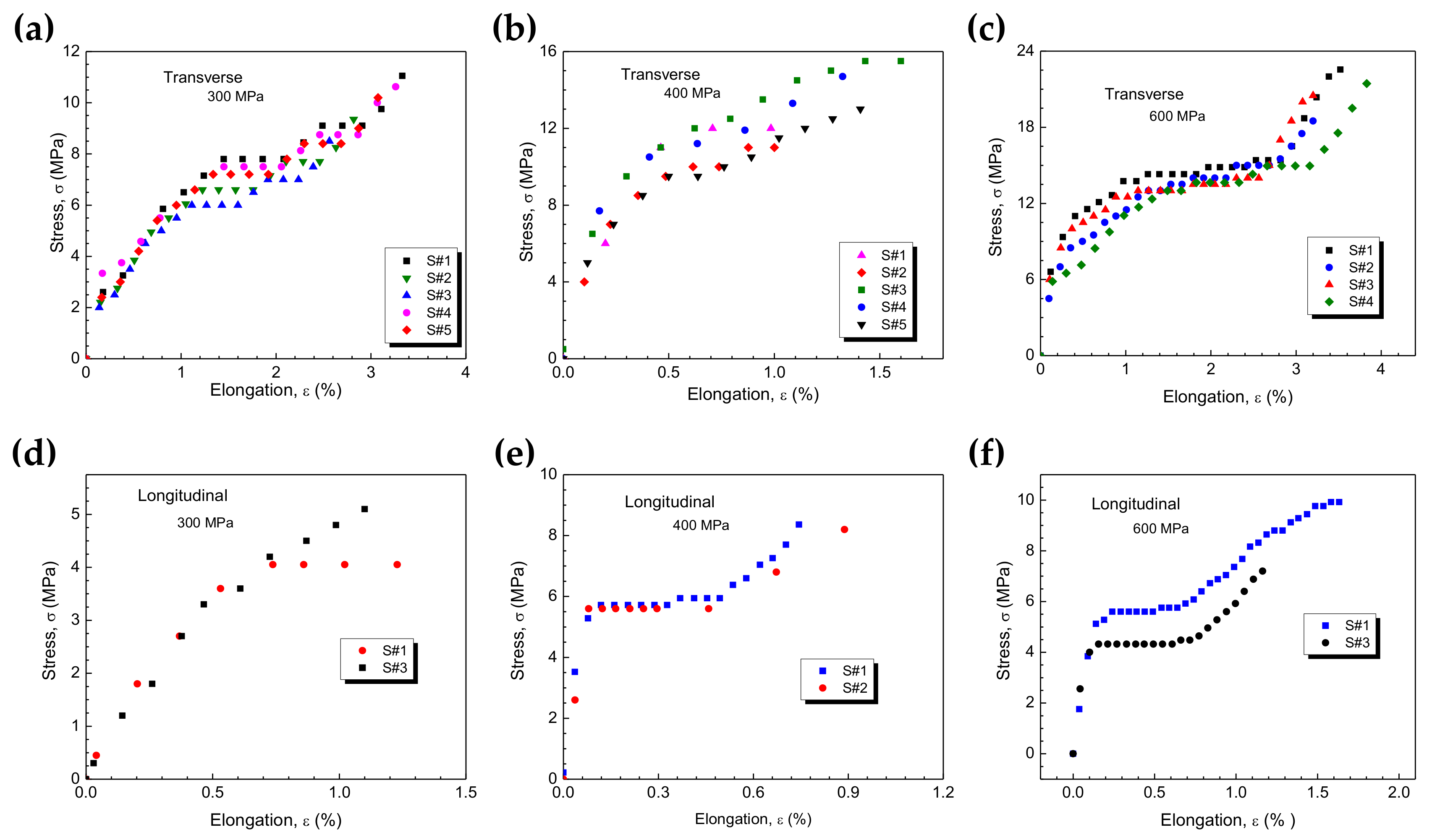

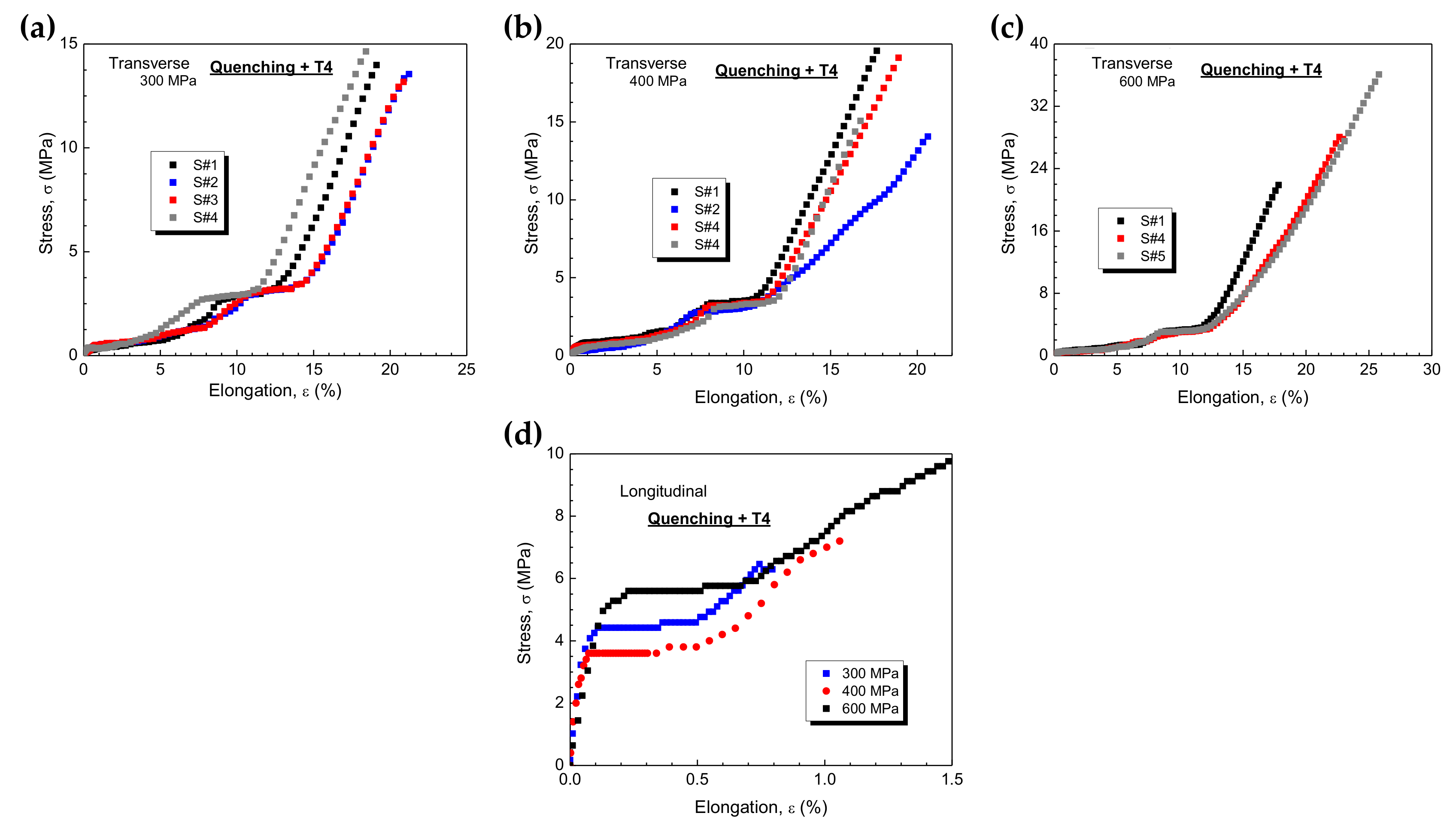

3.3.1. Tensile Strengths and Heat Treatments

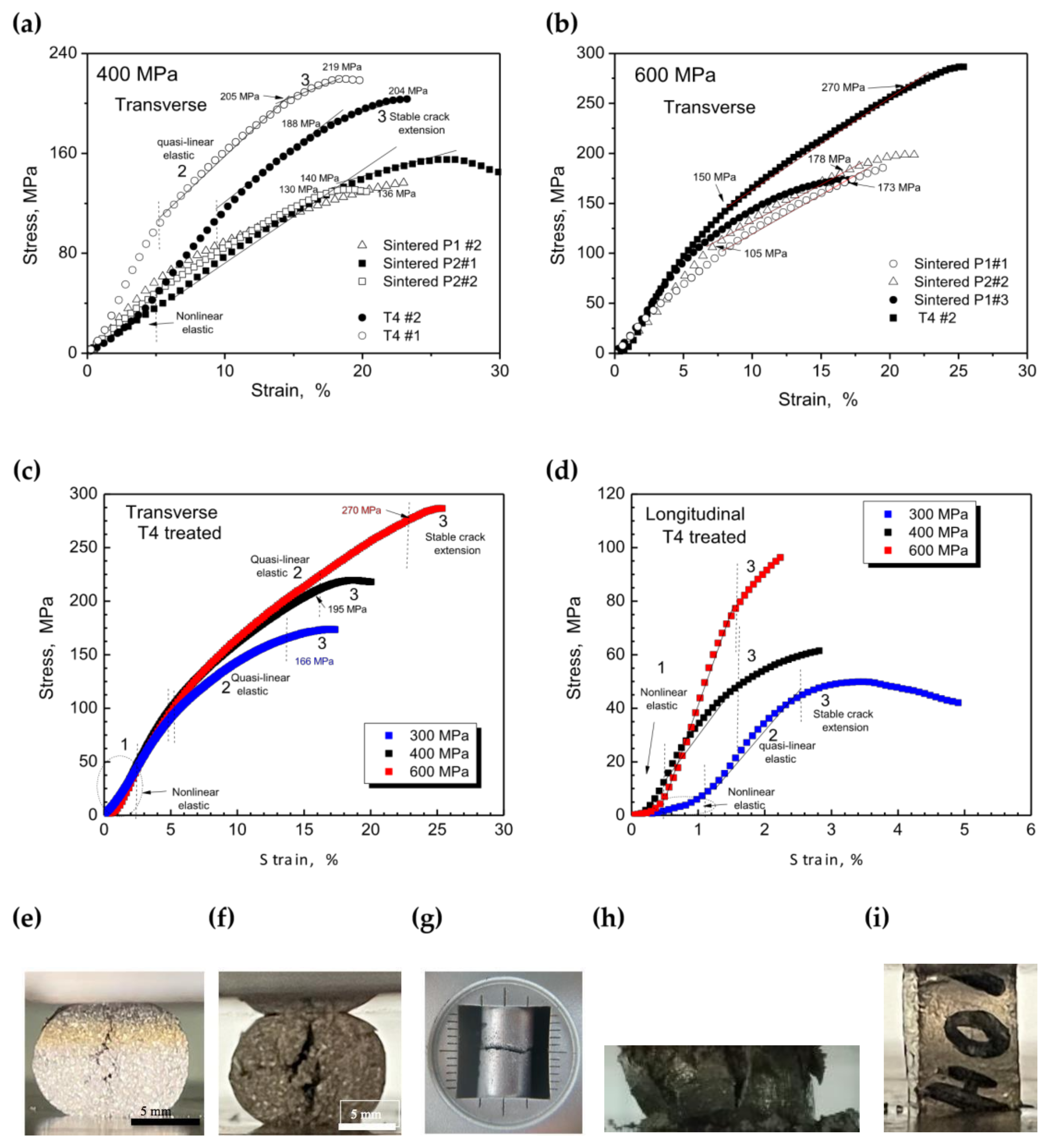

3.3.2. Compressive Strengths and Heat Treatments

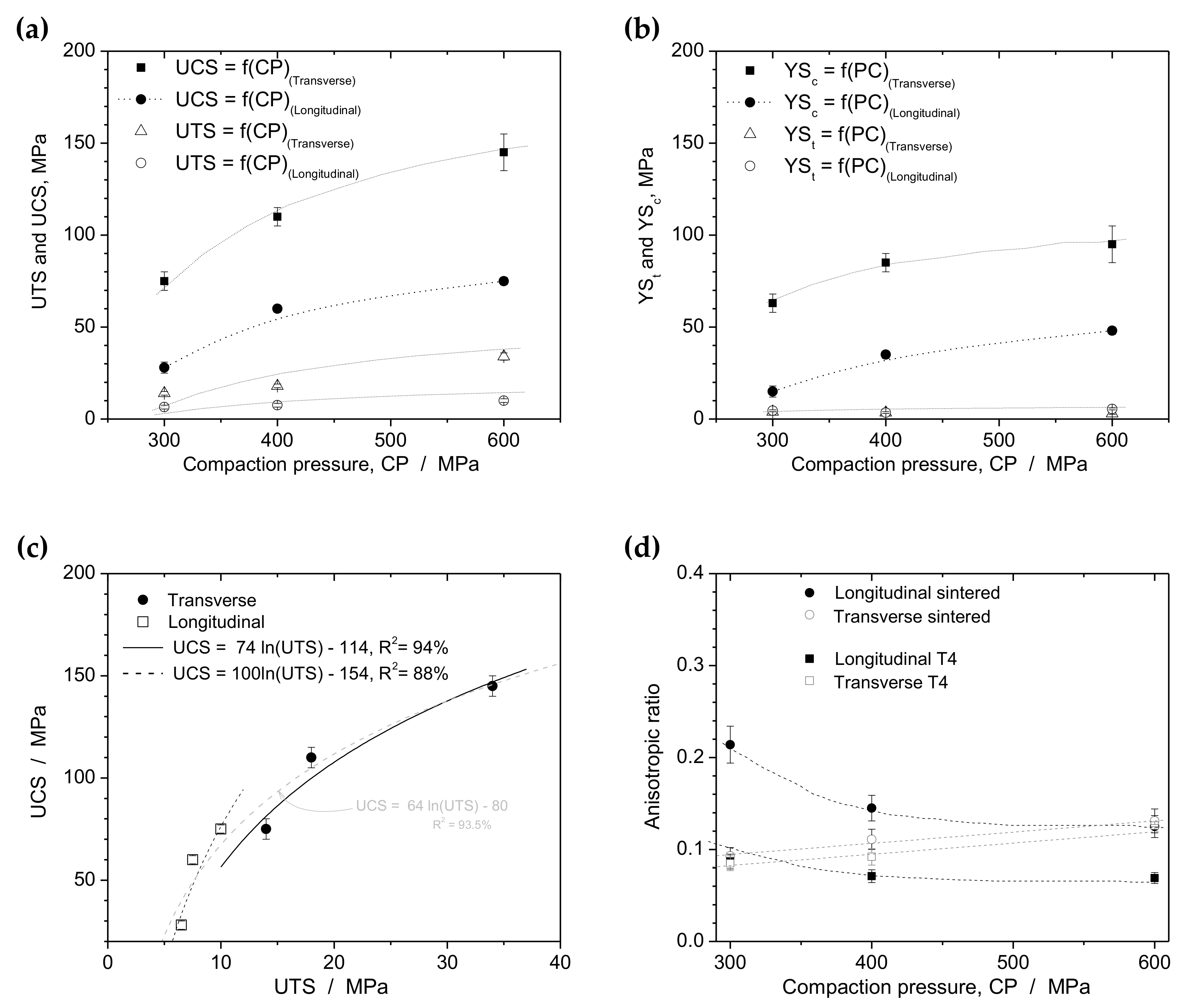

3.3.3. Mechanical Behavior Correlations

4. Conclusions

- Distinctive Morphologies: Compacting the powders in different directions (longitudinal and transverse) results in unique morphologies. Longitudinal compaction leads to spheroidal-like shapes, while transverse compaction results in elongated-like shapes. These morphological differences contribute to a bridging effect among the powder particles, ultimately impacting mechanical behavior. Notably, sintered transverse and longitudinal samples exhibit similar deformation capacity, but the transverse samples achieve higher densification (~90%) compared to longitudinal samples (~87%). Therefore, the compaction direction significantly influences both densification and resulting mechanical properties.

- T4 Treatment Impact: T4-treated samples consistently exhibit the highest values of ultimate tensile strength (UTS) and ultimate compressive strength (UCS) compared to other experimental conditions. As expected, UCS values are higher than UTS values. In general, transverse samples outperform longitudinally compacted samples in terms of mechanical performance.

- Anisotropic Ratios: Anisotropic ratios, which quantify the degree of anisotropy, are determined by comparing the maximum values of UCS and UTS for each compaction direction and heat treatment used in this study. Transverse samples display relatively consistent anisotropic ratios, with a slight increasing trend as compaction pressure rises. Conversely, longitudinal samples show non-linear decreasing trends in anisotropic ratios with increasing compaction pressure. The ratios for longitudinal samples exhibit more dispersion compared to transverse samples. Consequently, sintered longitudinal samples tend to be more isotropic than T4-treated longitudinal samples.

- Morphological Influence: The resulting morphology of the longitudinal samples, characterized by a more spheroidal shape compared to transverse samples, is closely linked to the compaction direction. This observation underscores the significance of the initial morphology, compaction load, and heat treatment in impacting strength anisotropy. These findings imply that recycled powder particles from conventional machining processes can be used to manufacture components with specific mechanical requirements. This approach not only offers environmental benefits by reducing metallic fumes but also reduces the energy consumption associated with melting processes.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Guo, M.X.; Wang, M.P. Effects of particle size, volume fraction, orientation and distribution on the high temperature compression and dynamic recrystallization behaviors of particle-containing alloys. Mat. Sci. Eng. A 2012, 546, 15–25. [Google Scholar] [CrossRef]

- Loidolt, P.; Ulz, M.H.; Khinast, J. Prediction of the anisotropic mechanical properties of compacted powders. Powder Technol. 2019, 345, 589–600. [Google Scholar]

- Akisanya, A.R.; Cocks, A.C.F.; Fleck, N.A. The yield behavior of metal powders. Int. J. Mech. Sci. 1997, 39, 1315–1324. [Google Scholar] [CrossRef]

- Vityaz, P.A.; Sheleg, V.K.; Kaptsevich, V.M.; Kusin, R.A.; Gurevich, A.A. Plasticity condition of anisotropic high-porosity powder materials. Poroshkovaya Metall. 1984, 9, 1–5. [Google Scholar]

- Weston, J.E. Origin of strength anisotropy in hot-pressed silicon nitride. J. Mater. Sci. 1980, 15, 1568–1576. [Google Scholar] [CrossRef]

- Zavaliangos, A.; Bouvard, D. Numerical simulation of anisotropy in sintering due to prior compaction. Met. Powder Rep. 2002, 57, 39. [Google Scholar] [CrossRef]

- Galen, S.; Zavaliangos, A. Strength anisotropy in cold compacted ductile and brittle powders. Acta Mater. 2005, 53, 4801–4815. [Google Scholar] [CrossRef]

- Cao, L.; Zeng, W.; Xie, Y.; Liang, J.; Zhang, D. Effect of powder oxidation on the anisotropy in tensile mechanical properties of bulk Al samples fabricated by spark plasma sintering. Mater. Sci. Eng. A 2019, 764, 138246. [Google Scholar]

- Brünig, M.; Gerke, S.; Koirala, S. Biaxial Experiments and Numerical Analysis on Stress-State-Dependent Damage and Failure Behavior of the Anisotropic Aluminum Alloy EN AW-2017A. Metals 2021, 11, 1214. [Google Scholar] [CrossRef]

- Reis, D.A.P.; Couto, A.A.; Domingues, N.I., Jr.; Hirschmann, A.C.O.; Zepka, S.; Neto, C.M. Effect of artificial aging on the mechanical properties of an aerospace aluminum alloy 2024. Defect Diffus. Forum 2012, 326–328, 193–198. [Google Scholar] [CrossRef]

- Hu, X.; Bahl, S.; Shyam, A.; Plotkiwski, A.; Milligan, B.; Allard, L.; Haynes, J.A.; Ren, Y.; Chuang, A. Repurposing the q (Al2Cu) phase to simultaneously increase the strength and ductility of an additively manufactured Al-Cu alloy. Mater. Sci. Eng. A 2022, 850, 143511. [Google Scholar] [CrossRef]

- Iswanto, P.T.; Pambekti, A. Heat treatment T4 and T6 effects on mechanical properties in Al-Cu alloy after remelt with different pouring temperatures. Metalurgija 2020, 59, 171–174. [Google Scholar]

- Ying, P.; Lin, C.; Liu, Z.; Bai, S.; Levchenko, V.; Zhang, P.; Wu, J.; Yang, T.; Huang, M.; Yang, G.; et al. Pre-Aging Effect on the Formation of Ω Phase and Mechanical Properties of the Al-Cu-Mg-Ag Alloy. Metals 2022, 12, 1208. [Google Scholar] [CrossRef]

- Feng, Y.; Chen, X.; Hao, Y.; Chen, B. Ageing evolution process of the q’-phase in Al-Si-Cu-Mg alloys: Atomic-scale observations and first-principles calculations. J. Alloys Compd. 2023, 968, 171787. [Google Scholar] [CrossRef]

- Rivera-Cerezo, H.; Gaona-Tiburcio, C.; Cabral-Miramontes, J.; Bautista-Margulis, R.G.; Nieves-Mendoza, D.; Maldonado-Bandala, E.; Estupiñán-López, F.; Almeraya-Calderón, F. Effect of Heat Treatment on the Electrochemical Behavior of AA2055 and AA2024 Alloys for Aeronautical Applications. Metals 2023, 13, 429. [Google Scholar] [CrossRef]

- Cai, Y.; Su, Y.; Liu, K.; Hua, A.; Wang, X.; Cao, H.; Zhang, D.; Ouyang, Q. Effect of Sc microalloying on fabrication, microstructure and mechanical properties of SiCp/Al-Cu-Mg-Sc composites via powder metallurgy. Mater. Sci. Eng. A 2023, 877, 145152. [Google Scholar] [CrossRef]

- Meyer, Y.A.; Bonatti, R.S.; Costa, D.; Bortolozo, A.D.; Osório, W.R. Compaction pressure and Si content effects on compressive strengths of Al/Si/Cu alloy composites. Mater. Sci. Eng. A 2019, 770, 138547. [Google Scholar] [CrossRef]

- Bonatti, R.S.; Siqueira, R.R.; Padilha, G.S.; Bortolozo, A.D.; Osório, W.R. Distinct Alp/Sip composites affecting its densification and mechanical behavior. J. Alloys Compd. 2018, 757, 434–447. [Google Scholar] [CrossRef]

- Gao, Z.H.; Gao, H.J.; Wu, Q. Experiment and mechanism investigation o the efect of heat treatment on residual stress and mechanical properties of SiCp/Al-Cu-Mg composites. Mater. Sci. Eng. A 2023, 884, 145555. [Google Scholar] [CrossRef]

- Fogagnolo, J.; Robert, M.; Torralba, J. Mechanically alloyed AlN particle-reinforced Al-6061 matrix composites: Powder processing, consolidation and mechanical strength and hardness of the as-extruded materials. Mater. Sci. Eng. A 2006, 426, 85–94. [Google Scholar] [CrossRef]

- Espinosa-Méndez, C.; Maquieira, C.P.; Arias, J.T. The impact of ESG performance on the value of family firms: The moderating role of financial constrainsts and agency problems. Sustainability 2023, 15, 6176. [Google Scholar] [CrossRef]

- Kurz, W.; Fisher, D.J. Fundamentals of Solidification; Trans Tech Publications: Zurich, Switzerland, 1992. [Google Scholar]

- Hamza, H.M.; Deen, K.M.; Haider, W. Microstructural examination and corrosion behavior of selective laser melted and conventionally manufactured Ti6Al4V for dental applications. Mater. Sci. Eng. C 2020, 113, 110980. [Google Scholar] [CrossRef]

- The Materials Project. Al2Cu/mp-998. Available online: https://next-gen.materialsproject.org (accessed on 15 August 2023).

- Alam, S.N.; Shrivastava, P.; Panda, D.; Gunale, B.; Susmitha, K.; Pola, P. Synthesis of Al2Cu intermetallic compound by mechanical alloying. Mater. Today Commun. 2022, 31, 103267. [Google Scholar] [CrossRef]

- Zhou, J.; Duszczyk, J. Preparation of Al-20Si-4.5Cu alloy and its composite from elemental powders. J. Mater. Sci. 1999, 34, 5067–5073. [Google Scholar] [CrossRef]

- Ramberger, R.; Burger, A. On the application of the Heckel and Kawakita equations to powder compaction. Powder Technol. 1985, 43, 1–9. [Google Scholar] [CrossRef]

- Han, P.; An, X.; Wang, D.; Fu, H.; Yang, X.; Zhang, H.; Zou, Z. MPFEM simulation of compaction densification behavior of Fe-Al composite powders with different size ratios. J. Alloys Compd. 2018, 741, 473–481. [Google Scholar] [CrossRef]

- Shi, J.; Hu, Q.; Zhao, X.; Liu, J.; Zhou, J.; Xu, W.; Chen, Y. Densification, microstructure and anisotropic corrosion behavior of Al-Mg-Mn-Sc-Er-Zr alloy processed by selective laser melting. Coatings 2023, 13, 337. [Google Scholar] [CrossRef]

- Bouvard, D. Densification behaviour of mixtures of hard and soft powders under pressure. Powder Technol. 2000, 111, 231–239. [Google Scholar] [CrossRef]

- Hafizpour, H.R.; Simchi, A. Investigation on compressibility of Al–SiC composite powders. Powder Met. 2008, 51, 217–223. [Google Scholar] [CrossRef]

- Gokçe, A.; Findik, F. Mechancial and physical properties of sintered aluminum powders. J. Achiev. Mater. Manufact. Eng. 2008, 30, 157–164. [Google Scholar]

- Sweet, G.A.; Brochu, M.; Hexemer, R.L., Jr.; Donaldson, I.W.; Bishop, D.P. Microstructure and mechanical properties of air atomized aluminum powder consolidated via spark plasma sintering. Mater. Sci. Eng. A 2014, 608, 273–282. [Google Scholar] [CrossRef]

- Jonsén, P.; Häggblad, H.; Sommer, K. Tensile strength and fracture energy of pressed metal powder by diametral compression test. Powder Technol. 2007, 176, 148–155. [Google Scholar] [CrossRef]

- Baiocco, D.; Zhang, Z.; He, Y.; Zhang, Z. Relationship between the Young’s Moduli of Whole Microcapsules and Their Shell Material Established by Micromanipulation Measurements Based on Diametric Compression between Two Parallel Surfaces and Numerical Modelling. Micromachines 2023, 14, 123. [Google Scholar] [CrossRef]

- Aguechari, N.; Boudiaf, A.; Ouali, M.O. Effect of artificial aging treatment on microstructure, mechanical properties and fracture behavior of 2017A alloy. Met. Mater. Eng. 2022, 28, 305–318. [Google Scholar] [CrossRef] [PubMed]

- Vargas-Martínez, J.; Estela-García, J.E.; Suárez, O.M.; Vega, C.A. Fabrication of a Porous Metal via Selective Phase Dissolution in Al-Cu Alloys. Metals 2018, 8, 378. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, R.; Chen, P.; Li, X.; Liu, Z. Microstructural evolution of Al2Cu phase and mechanical properties of the large-scale Al alloy components under different consecutive manufacturing processes. J. Alloys Compd. 2019, 808, 151634. [Google Scholar] [CrossRef]

| Samples | Sintered | Quenched + T4 | ||||

|---|---|---|---|---|---|---|

| Transversal | YS, MPa | UTS, MPa | ε, % | YS, MPa | UTS, MPa | ε, % |

| 300 MPa | 7 (±1) | 11 (±1) | 3.5 (±0.2) | 4 (±0.5) | 14 (±1) | 18 (±0.2) |

| 400 MPa | 10 (±0.5) | 15 (±1) | 1.5 (±0.2) | 3.5 (±0.5) | 18 (±1) | 19 (±0.2) |

| 600 MPa | 14 (±0.5) | 23 (±1) | 3.6 (±0.2) | 3.0 (±0.5) | 34 (±2) | 23 (±0.2) |

| Longitudinal | YS, MPa | UTS, MPa | ε, % | YS, MPa | UTS, MPa | ε, % |

| 300 MPa | 4.0 (±0.5) | 6 (±1.0) | 0.9 (±0.2) | 4.5 (±0.5) | 6.5 (±0.5) | 0.8 (±0.1) |

| 400 MPa | 4.5 (±0.5) | 8 (±0.5) | 0.8 (±0.2) | 3.5 (±0.5) | 7.5 (±0.5) | 1.2 (±0.1) |

| 600 MPa | 4.5 (±0.5) | 10 (±0.5) | 1.3 (±0.3) | 4.5 (±0.5) | 10 (±0.5) | 1.5 (±0.2) |

| Samples | Sintered | Quenched + T4 | ||||

|---|---|---|---|---|---|---|

| TRANSVERSE | YS, MPa | UCS, MPa | YS, MPa | UCS, MPa | F, N | DC, MPa |

| 300 MPa | 65 (±5) | 118 (±6) | 92 (±5) | 165(±10) | --- | --- |

| 400 MPa | 80 (±10) | 135 (±10) | 118 (±5) | 195 (±10) | --- | --- |

| 600 MPa | 105 (±8) | 175 (±8) | 150(±10) | 270 (±10) | --- | --- |

| LONGITUDINAL | YS, MPa | UCS, MPa | YS, MPa | UCS, MPa | F, N | DC, MPa |

| 300 MPa | 15 (±2) | 28 (±5) | 63 (±5) | 75 (±6) | 0.9 (±0.2) | 8.6 (±3) |

| 400 MPa | 35 (±2) | 55 (±5) | 85 (±5) | 110 (±8) | 1.2 (±0.2) | 11.6 (±3) |

| 600 MPa | 48 (±4) | 80 (±8) | 95 (±10) | 145 (±10) | 2.3 (±0.1) | 23.2 (±0.8) |

| Sintered | Longitudinal | Transverse |

|---|---|---|

| 300 MPa | 0.214 | 0.093 |

| 400 MPa | 0.145 | 0.111 |

| 600 MPa | 0.125 | 0.131 |

| Quenched + T4 | Longitudinal | Transverse |

| 300 MPa | 0.087 | 0.085 |

| 400 MPa | 0.071 | 0.092 |

| 600 MPa | 0.069 | 0.126 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bonatti, R.S.; Bortolozo, A.D.; Baldo, R.F.G.; Poloni, E.; Osório, W.R. Anisotropic Tensile and Compressive Strengths of Al–4 wt.%Cu Alloy Powder: Part 1—Effects of Compaction Loads and Heat Treatments. Metals 2023, 13, 1710. https://doi.org/10.3390/met13101710

Bonatti RS, Bortolozo AD, Baldo RFG, Poloni E, Osório WR. Anisotropic Tensile and Compressive Strengths of Al–4 wt.%Cu Alloy Powder: Part 1—Effects of Compaction Loads and Heat Treatments. Metals. 2023; 13(10):1710. https://doi.org/10.3390/met13101710

Chicago/Turabian StyleBonatti, Rodrigo S., Ausdinir D. Bortolozo, Rodrigo F. G. Baldo, Erik Poloni, and Wislei R. Osório. 2023. "Anisotropic Tensile and Compressive Strengths of Al–4 wt.%Cu Alloy Powder: Part 1—Effects of Compaction Loads and Heat Treatments" Metals 13, no. 10: 1710. https://doi.org/10.3390/met13101710

APA StyleBonatti, R. S., Bortolozo, A. D., Baldo, R. F. G., Poloni, E., & Osório, W. R. (2023). Anisotropic Tensile and Compressive Strengths of Al–4 wt.%Cu Alloy Powder: Part 1—Effects of Compaction Loads and Heat Treatments. Metals, 13(10), 1710. https://doi.org/10.3390/met13101710