Abstract

Despite the widespread use of TiAl alloys in many fields, their poor impact resistance has recently emerged again as a major issue. Therefore, in this study, the practical effects of additive elements were examined by considering impact resistance as the most important property of practical TiAl cast alloys. The impact resistance was evaluated via the Charpy impact test, which has been rarely applied to TiAl alloys, revealing that only V, Cr, Mn, and B slightly improved the impact resistance, compared to that of the Ti–Al binary alloy, both in the as-cast and heat-treated states. In contrast, Nb, Mo, W, Fe, Ni, Si, C, and N decreased the impact resistance. If a slight decrease in impact resistance is permitted, then only Si and C can improve the creep strength, and Nb and W can improve the anti-oxidation resistance. These results confirm the excellence of practical TiAl cast alloys developed a considerable time ago, containing these elements in addition to Cr, Mn, and B.

1. Introduction

For the practical applications of TiAl alloys, cast materials [1,2,3,4,5,6] are primarily employed. Although extruded and hot-forged materials are also utilized in race-car engine valves [7] and large structural defense components [8], respectively, these materials are produced in small amounts. Recently, TNM alloys [9,10] were used as isothermally forged materials [9,10,11] for manufacturing the low-pressure turbine blades of the PW1100G jet engine. However, their application was suddenly withdrawn because the low impact resistance of the TiAl alloys is inadequate for use in the high-bypass geared turbofan engine. Many blades were destroyed owing to the collision of debris scattered from inside the engine during flight [12]. Although a widespread use of additive manufacturing methods [13,14] is expected in the future, the use of cast materials will be continued in large-scale production because of their cost effectiveness.

There are two forms of TiAl castings that are expected to be used similarly to how they are used today. (1) A product used in the as-cast state at temperatures of 850 °C or higher, e.g., the turbine wheel of a passenger car turbocharger [1,2]. (2) A product used after hot isostatic pressing (HIP) at temperatures of 750 °C or lower, e.g., a jet engine low-pressure turbine blade, such as that in the LEAP [5] engine.

Although many properties, such as tensile strength/ductility, high/low cycle fatigue strength, and wear resistance are required for TiAl cast materials to be used in these two types of products, Table 1 only summarizes the essential properties that are required. The author believes that impact resistance is the most important property among those listed in Table 1. Further, creep strength and anti-oxidation resistance are important for high-temperature components. Finally, castability has recently been considered at production sites to reduce costs when there is an increase in the production volume of the cast TiAl alloy parts.

Table 1.

Essential properties required for TiAl cast materials.

As mentioned above, despite the widespread use of TiAl alloys in various products, their poor impact resistance has again emerged as a major drawback. Specifically, as can be seen from the unfortunate experience of using TNM alloys, evaluating the impact resistance is extremely important for practical applications of TiAl alloys. To date, only a limited number of studies have been performed to systematically investigate the impact resistance of TiAl alloys. In other words, it is insignificant to evaluate the impact resistance of TiAl alloys because they are brittle. However, the reported issues involving the unfortunate experience with TNM alloys indicate the importance of mitigating the problem of impact resistance in practical applications.

There has been no practical research on Ti–Al binary alloys, and it is common practice to add additive elements. Each additive element is selected to improve the creep strength or anti-oxidation resistance, etc., however, many elements yield uncertain effects. In addition, few researchers have attempted to examine the effects of each additive element on the impact resistance. Therefore, this study focused on impact resistance, and the effects of each additive element on the properties of practical TiAl cast materials were investigated. With respect to impact resistance, a foreign object damage (FOD) test is required to investigate in detail the cause of impact fractures of TNM alloy. However, the influence of each additive element could not be evaluated practically, as many tests are required for this evaluation. Therefore, the author adopted the Charpy impact test, which is generally accepted as a test method for estimating the impact resistance of industrial materials.

The following procedure was employed for the examination. For a Ti–Al binary alloy, an appropriate amount of Al was selected in the range of 43–49 at.%, considering the impact resistance of as-cast and post heat treatment assuming HIP, which is the state of use for the two types of practical products.

Next, the effect of each element on the impact resistance was examined in the ternary alloy, wherein each element was added to the Al amount determined by above examination. Twelve elements, viz. Nb [15,16], V [17,18], Mo [19,20], W [21,22], Fe [23,24], Cr [25,26], Mn [27,28], Ni [29,30], Si [31,32], C [33,34], N [35,36], and B [37,38], were added. The amount of addition varied based on the amount commonly used for each element. This evaluation was conducted for as-cast and post heat treatment states, and the appropriate addition amount for each element was selected from the viewpoint of impact resistance.

Finally, the practical usefulness of each additive element was determined by evaluating the creep rupture strength, anti-oxidation resistance, and castability of the ternary alloy containing the above-mentioned appropriate amount of the additive element.

2. Materials and Methods

Cast materials were produced by melting the raw materials in an yttria crucible in an induction melting furnace and then pouring the molten metal into a metal mold. This method involves melting in a ceramic crucible, and is not normally used with TiAl alloys. However, the yttria crucible was selected because it afforded a relatively small increase in the oxygen content, and limited deterioration in the mechanical properties [39,40]. Further, the author considered that there would be no problem in the relative comparison between the effect of each element on impact resistance. Thus, this approach was adopted considering the cost and speed of sample production.

Melting was conducted in an Ar atmosphere, wherein Ar was replaced after the evacuation. Ti sponge, Al shot, and various additives, such as Nb flakes; V, Fe, Cr, Mn, Ni, and Si granules; and Mo and W powders were used as the raw materials. Further, C, N, and B were added as TiC, TiN, and TiB2 powders, respectively. Approximately 500 g of the raw material was melted per charge. A cast material was manufactured by holding for approximately 3 min after the whole raw material was melted, and then by pouring into a metal mold with a flat plate-shaped cavity. Figure 1 shows a representative example of the cast material. Table 2 shows the amount of each additive element in the ternary alloy. Three cast materials with the same composition were produced.

Figure 1.

Example of the fabricated cast materials.

Table 2.

Examined addition amounts for ternary alloy.

The test pieces of approximately 10/10/55 mm were processed from the flat plate portion of this cast material in the as-cast state and post heat treatment (4 h at 1200 °C followed by cooling at 10 °C/min). The heat treatment condition assumes the HIP condition performed on the low-pressure turbine blades of a jet engine.

The impact resistances of all cast materials in the as-cast state and post heat treatment were compared based on the absorbed energy obtained in the Charpy impact test, performed using the above-mentioned test pieces. The absorbed energy would have been very small if a notch had been inserted in the test piece as usual, and it would have been difficult to find the difference between the compositions; therefore, the notch was not inserted during this evaluation. Further, a small Charpy impact tester with a capacity of 15 J was used because a small value of the absorbed energy cannot be measured accurately with the normal Charpy impact tester, such as that with a capacity of 300 J. Five tests were conducted under the same conditions, and the results were averaged, because the measured absorbed energy values showed significant fluctuations. The difference in each composition was compared with the average value.

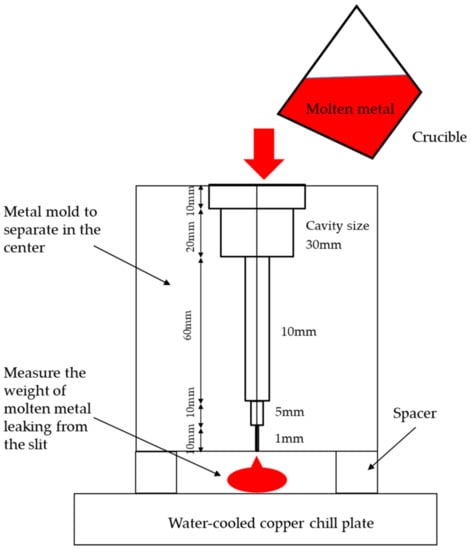

To evaluate the creep rupture strength, a test piece with a gauge diameter of 4 mm was processed from the cast material, a creep rupture test with a stress of 140 MPa was performed at 850 °C, and the difference in each composition was compared based on the rupture life. This condition was tested with the TiAl alloy used in a turbocharger [41]. The anti-oxidation resistance of each composition was compared using a test piece of approximately 15/15/2 mm held in the atmosphere at 1000 °C for 100 h, and then by measuring the weight gain. The fluidity of molten metal is the most important factor for castability; however, no simple method has been devised to evaluate it for TiAl alloys. Therefore, as shown in Figure 2, a 1-mm slit was made at the bottom of the metal mold, the weight of the molten metal leaking from this slit during casting was measured, and it was judged that the larger the weight, the better the fluidity. Because this result also exhibited a large fluctuation, the difference in each composition was compared by averaging the weights for three samples. In future, to improve the accuracy, measurement of the viscosity of the molten metal will also be considered.

Figure 2.

Schematic of the experimental procedure used for comparing the fluidity of the molten metals.

3. Results and Discussion

3.1. Impact Resistance of the Fabricated Ti–Al Binary Alloys

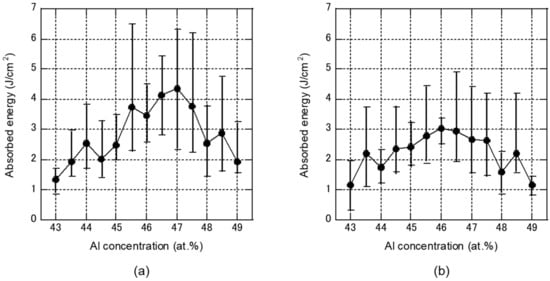

Figure 3 shows the Charpy absorbed energy of the as-cast and heat-treated Ti-43–49 at.% Al binary alloy samples. The absorbed energy exhibited by the heat-treated samples was lower than that exhibited by the as-cast samples, because of the reduced strength of the heat-treated samples. The absorbed energy was relatively large for both the as-cast and heat-treated samples, with 45.5–47.5 at.% Al. To the best of my knowledge, this is the first report on the effect of Al concentration on the impact resistance of Ti–Al binary alloys.

Figure 3.

Charpy absorbed energy of the Ti-43–49 at.% Al binary alloy in the (a) as-cast state, and (b) after heat treatment at 1200 °C for 4 h, followed by cooling at 10 °C/min.

The cast TiAl alloys that are already being used or were close to practical use are as follows: GE’s TiAl4822 [42] (Ti-48Al-2Nb-2Cr (at.%)), Howmet’s 45XD, 47XD [43,44] (Ti-45, 47Al-2Nb-2Mn-0.8 vol.% TiB2), ABB’s ABB alloy [45] (Ti-46Al-2W-0.5Si (at.%)), and Daido’s DAT-TA2 [46] (Ti-31.8Al-7.5Nb-1.0Cr-0.5Si-0.03C (mass%), which is Ti-46.2Al-3.2Nb-0.75Cr-0.7Si-0.1C (at.%), when converted to at.%). The Al concentration of these alloys is within the range of the Al amount with a good impact resistance obtained in this study, except for TiAl4822. Thus, although it is unclear whether they were intended at the time of development of these alloys, an appropriate amount of Al was selected from the viewpoint of impact resistance.

TiAl4822 is currently used in large quantities in low-pressure turbine blades for jet engines such as LEAP engines. The median Al content is set to a slightly lower value in the current material specifications of the product, which is approximately 47 at.%; therefore, in reality, it is in the appropriate range of the Al amount obtained in this study from the viewpoint of impact resistance.

3.2. Effect of Each Additive Element on the Impact Resistance

The amount of Al, which had a relatively good impact resistance both in the as-cast state and after heat treatment, was 45.5–47.5 at.% Al; therefore, 46.5 at.% Al, which is the central value, was used in the evaluation of the ternary alloy.

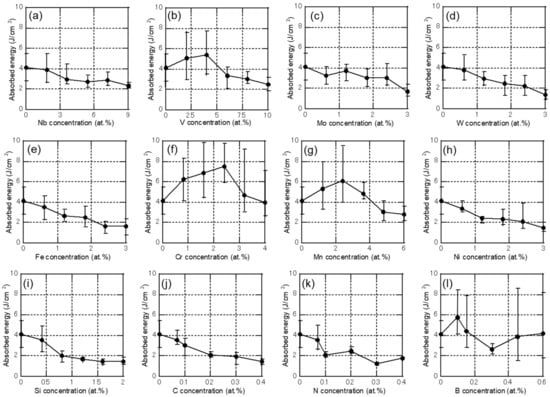

Figure 4 shows the additive-amount-dependent variation in the absorbed energy of each as-cast sample containing Nb, V, Mo, W, Fe, Cr, Mn, Ni, Si, C, N, and B. The added concentration of each additive element was set with reference to developed examples. The value at 0 at.% of all additives indicates the absorbed energy of the Ti–46.5Al binary alloy. Evidently, only the alloy samples containing V (added 2.0, 4.0 at.%), Cr (added 0.8, 1.6, 2.4 at.%), Mn (added 1.2, 2.4 at.%), and B (added 0.1 at.%) exhibit slightly higher absorbed energies than that exhibited by the binary alloy. The absorbed energy of the ternary alloys containing the other elements showed a decreasing trend at all additional amounts compared to that of the binary alloy. These results indicate that in the as-cast state, the only elements slightly useful for improving the impact resistance are V, Cr, Mn, and B added in the appropriate amounts, whereas all other elements adversely affect the impact resistance.

Figure 4.

Charpy absorbed energies of the Ti-Al-X ternary alloy in the as-cast state: (a) Nb; (b) V; (c) Mo; (d) W; (e) Fe; (f) Cr; (g) Mn; (h) Ni; (i) Si; (j) C; (k) N; and (l) B.

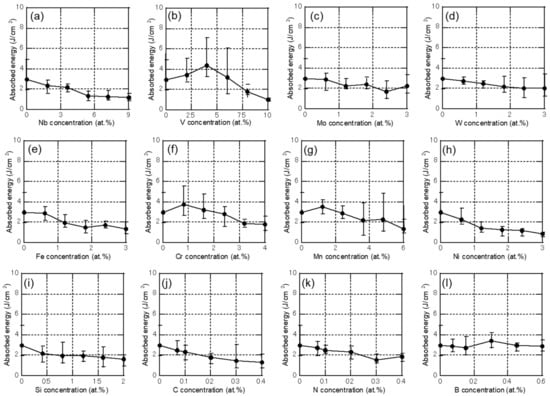

Figure 5 shows the same results for the heat-treated samples. Similar to the binary alloy, the absorbed energy of the heat-treated alloys is also lower than that of the as-cast samples. V (added 4.0 at.%) is the only element for which a certain increase in the absorbed energy is observed. Although the heat-treated samples containing Cr (added 0.8 at.%), Mn (added 1.2 at.%), and B (added 0.3 at.%) also show a slight increase in the absorbed energy, the degree of increase is small compared to that of the as-cast samples. For the heat-treated ternary alloys containing the other elements, the absorbed energy is lower than that of the binary alloy at all additive amounts, similar to that of the as-cast samples. To the best of my knowledge, this paper reports the first systematic demonstration of the effects of additive elements on the impact resistance of TiAl alloys.

Figure 5.

Charpy absorbed energies of the Ti-Al-X ternary alloys after heat treatment at 1200 °C for 4 h, followed by cooling at 10 °C/min: (a) Nb; (b) V; (c) Mo; (d) W; (e) Fe; (f) Cr; (g) Mn; (h) Ni; (i) Si; (j) C; (k) N; and (l) B.

These results reveal that only the addition of V, Cr, Mn, and B in appropriate amounts can improve the impact resistance of TiAl alloys both in the as-cast and heat-treated states; thus, the addition of all other elements should be avoided to prevent impact-resistance reduction. However, some of these elements can be added if a slight decrease in the impact resistance is allowed, and if the other properties, such as creep strength or anti-oxidation resistance, are improved compared to those of the binary alloys.

3.3. Evaluation of the Effect of Each Additive Element and Comparison with Practical Alloys

As summarized in Table 1, the products for high-temperature applications used in the as-cast state should exhibit a higher creep strength, anti-oxidation resistance, and castability along with a higher impact resistance. Therefore, the creep strength, anti-oxidation resistance, and castability of the as-cast ternary alloys were evaluated.

The amount of V, Cr, Mn, and B was selected to impart the highest impact resistance to the Ti–46.5Al binary alloys. In contrast, all other elements decreased the impact resistance of the alloys. However, because there is a possibility to improve the other properties, a slight decrease in the impact resistance is allowed. For the alloys containing Nb, Mo, W, Fe, Ni, Si, C, and N, various characteristics were examined for the minimum addition amounts tested in this study. The absorbed energy in this case was approximately 80–95% of that of the binary alloy.

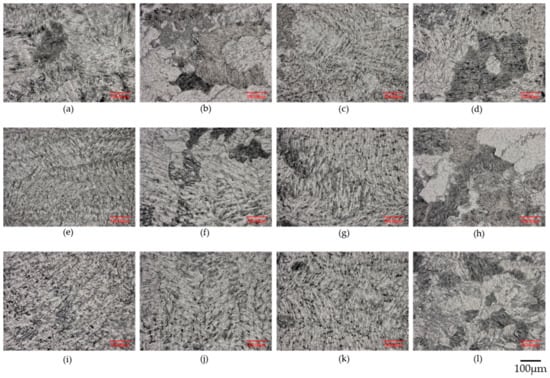

Figure 6 shows the optical micrographs of each ternary alloy with this additional amount in the as-cast state. Because of the as-cast state, all samples show a similar fully lamellar structure, which is common in as-cast TiAl alloys, and there is no significant difference. Therefore, when comparing the influence of each element on the material properties, it is considered that the influence of the microstructure is small.

Figure 6.

Optical micrographs of Ti–Al–X ternary alloy in as-cast state; (a) 1.8Nb; (b) 4.0V; (c) 0.6Mo; (d) 0.6W; (e) 0.6Fe; (f) 2.4Cr; (g) 2.4Mn; (h) 0.6Ni; (i) 0.4Si; (j) 0.07C; (k) 0.07N; (l) 0.10B.

Regarding the effect of each additive element on the impact resistance, since each ternary alloy shows similar microstructure, and the amount added is small, each element is thought to solid-dissolve into the γ phase or α2 phase to change the mechanical properties of these phases. When compared with other mechanical properties, solid-dissolved Cr [47,48,49] and Mn [49], which are reported to improve the tensile ductility at room temperature, improved the impact resistance in this study. On the other hand, the solid-dissolved Mo [49] and Nb [47,49], which are reported to reduce the tensile ductility at room temperature, were the opposite and worsened the impact resistance. That is, it is considered that the effect of each solid-dissolved additive element on the impact resistance is correlated with the effect on the tensile ductility at room temperature.

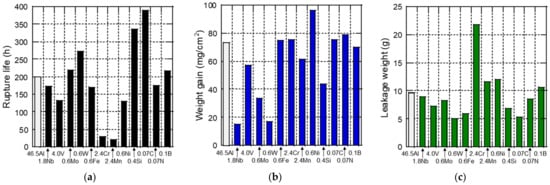

Figure 7a shows the rupture life obtained during the creep rupture test performed at 850 °C/140 MPa for the as-cast samples of each ternary alloy containing the aforementioned additives, in comparison to that of the as-cast Ti-46.5Al binary alloy. Figure 7b presents the weight gain observed during the atmospheric oxidation test at 1000 °C/100 h for the same materials. Figure 7c shows the average leakage weight of three castings (for molten metal leaking from the 1-mm slit during the casting, as shown in Figure 2) as a comparison of the castability for each composition.

Figure 7.

Effect of added elements in added amounts, considering the impact resistance, in the as-cast state: (a) rupture life in creep rupture test at 850 °C/140 MPa; (b) weight gain in the atmospheric oxidation test at 1000 °C/100 h; and (c) leakage weight of the molten metal during casting (average of three samples).

Table 3 summarizes the effects of each element in the added amount, considering the impact resistance, obtained from the above-mentioned test results. Cr, and Mn, which slightly improved the impact resistance, reduced the creep strength. In contrast, Si and C improved the creep strength, while Nb and W improved the anti-oxidation resistance, even at the minimum addition amount examined.

Table 3.

Effect of additive elements, with added amounts, compared to binary alloys considering the impact resistance in the as-cast state.

It has already been reported that the addition of Si [50,51] and C [50,51] improves the creep strength, and the reason for this is considered to be the precipitation strengthening during the test due to the addition of these elements. Furthermore, it has already been reported that the addition of Nb [16,52] and W [52] improves the oxidation resistance, and it is considered that the reason is that TiO2 and Al2O3, which are the oxide layers of the TiAl alloy, become more protective. In this study, it was confirmed that the effect of improving the creep strength and oxidation resistance of these elements can be maintained even with the additional amount without a significant decrease in impact resistance.

The castability remained almost unchanged when the addition amount was small. However, as the additive amount was increased, a significant improvement in the castability was observed for the Cr addition than for the other elements. No merit was found for Mo, Fe, Ni, and N for any of the properties.

The excellence of the practical alloys developed long ago can be clearly observed from this result. In the case of the cast alloys, only Cr and Nb were added to GE’s TiAl4822 (Ti-48Al-2Nb-2Cr (at.%)) [42]; only Mn, Nb, and B were added to Howmet’s 45XD, 47XD (Ti-45,47Al-2Nb-2Mn-0.8 vol.% TiB2) [43,44]; and only W and Si were added to the ABB alloy (Ti-46Al-2W-0.5Si (at.%)) [45], which is suitable for high-temperature applications despite its slightly lower impact resistance. Finally, only Cr, Nb, Si, and C were added to Daido’s DAT-TA2 (Ti-31.8Al-7.5Nb-1.0Cr-0.5Si-0.03C (mass%), converted to at.%, Ti-46.2Al-3.2Nb-0.75Cr-0.7Si-0.1C (at.%)) [46], which is also considered to be slightly less impact resistant but suitable for high-temperature applications.

Forged alloys, such as TNM alloy (Ti-43.5 Al-4Nb-1Mo-0.1B (at.%)), have a completely different microstructure, such as a small grain size and the presence of many B2 phases, from that of cast materials, indicating that a simple comparison between these two materials is difficult. However, such a comparison was performed as a reference in this study. There are many factors that can decrease impact resistance in forged alloys. For example, the Al content of the forged alloy is 44 at.% or less, which results in inherently low impact resistance, furthermore, a large number of elements that deteriorate the impact resistance, such as Mo and Nb, are added. In other words, the impact resistance of forged alloys is expected to be inferior to that of cast alloys with relatively high impact resistance. In the future, the impact resistance of the cast and forged alloys will be evaluated at various temperatures to clarify this point.

4. Summary

In this study, poor impact resistance, which is the major drawback of TiAl alloys in practical use, was investigated in detail using the Charpy impact test, which is a simple evaluation method. Furthermore, the effects of each additive element on the TiAl cast alloys were examined on the premise of maintaining impact resistance. The following results were obtained.

- (1)

- In Ti-Al binary alloys, 45.5–47.5 at.% Al was found to be adequate for maintaining a high impact resistance in both the as-cast and heat-treated states.

- (2)

- V, Cr, Mn, and B slightly improved the impact resistance compared to that of binary alloys when appropriate amounts were added, both in the as-cast and heat-treated states. In contrast, the addition of Nb, Mo, W, Fe, Ni, Si, C, and N decreased the impact resistance.

- (3)

- When a slight decrease in the impact resistance was allowed, Si and C improved the creep strength, while Nb and W improved the anti-oxidation resistance in the as-cast state.

- (4)

- The excellence of the past practical TiAl cast alloys, to which only Cr, Mn, B, and the above elements were added, could be confirmed.

In future, the impact resistance of the practically used cast and forged TiAl alloys will be evaluated at various temperatures.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The author declares no conflict of interest.

References

- Tetsui, T. Development of a TiAl turbocharger for passenger vehicles. Mater. Sci. Eng. A 2002, 329, 528–588. [Google Scholar] [CrossRef]

- Noda, T. Application of cast gamma TiAl for automobiles. Intermetallics 1998, 6, 709–713. [Google Scholar] [CrossRef]

- Bewlay, B.P.; Nag, S.; Suzuki, A.; Weimer, M. TiAl alloys in commercial aircraft engines. Mater. High Temp. 2016, 33, 549–559. [Google Scholar] [CrossRef]

- Bewlay, B.P.; Weimer, M.; Kelly, T.; Suzuki, A.; Subramanian, P.R. The science, technology, and implementation of TiAl alloys in commercial aircraft engines. In Symposium JJ—Intermetallic-Based Alloys—Science, Technology and Applications; Haislmaier, M., Baker, V., Kumar, S., Yoshimi, K., Eds.; MRS Online Proceedings Library: Online, 2013; Volume 1516, pp. 49–58. [Google Scholar]

- Perrut, M.; Caron, P.; Thomas, M.; Couret, A. High temperature materials for aerospace applications: Ni-based superalloys and γ-TiAl alloys. C. R. Phys. 2018, 19, 657–671. [Google Scholar] [CrossRef]

- Brotzu, A.; Felli, F.; Mondal, A.; Pilone, D. Production issues in the manufacturing of TiAl turbine blades by investment casting. Procedia Struct. Integr. 2020, 25, 79–87. [Google Scholar] [CrossRef]

- Burtscher, M.; Klein, T.; Lindemann, J.; Lehmann, O.; Fellmann, H.; Güther, V.; Clemens, H.; Mayer, S. An advanced TiAl alloy for high-performance racing applications. Metals 2020, 13, 4720. [Google Scholar] [CrossRef]

- Tetsui, T. Practical use of hot-forged-type Ti-42Al-5Mn and various recent improvements. Metals 2021, 11, 1361. [Google Scholar] [CrossRef]

- Habel, U.; Heutling, F.; Kunze, C.; Smarsly, W.; Das, G.; Clemens, H. Chapter 208, Forged intermetallic γ-TiAl-based alloy low-pressure turbine blade in the geared turbofan. In Proceedings of the 13th World Conference on Titanium; Vasisht Venkatesh, V., Pilchak, A.L., Allison, J.E., Ankem, S., Boyer, R., Christodoulou, J., Fraser, H.L., Imam, M.A., Kosaka, Y., Rack, H.J., et al., Eds.; Wiley: Hoboken, NJ, USA, 2016; pp. 1223–1227. [Google Scholar]

- Clemens, H.; Mayer, S. Intermetallic titanium aluminides in aerospace applications—Processing, microstructure and properties. Mater. High Temp. 2016, 33, 560–570. [Google Scholar] [CrossRef]

- Wang, X.; Xu, W.; Xu, P.; Zhou, H.; Kong, F.; Chen, Y. High Nb–TiAl intermetallic blades fabricated by isothermal die forging process at low temperature. Metals 2020, 10, 757. [Google Scholar] [CrossRef]

- Flightglobal.com. Available online: https://www.flightglobal.com/engines/faa-orders-pw1100g-low-pressure-turbine-blade-replacement/135575.article (accessed on 13 January 2022).

- Dzogbewu, T.C.; Preez, W.B. Additive manufacturing of Ti-based intermetallic alloys: A review and conceptualization of a next-generation machine. Materials 2021, 14, 4317. [Google Scholar] [CrossRef]

- Mizuta, K.; Hijikata, Y.; Fujii, T.; Gokan, K.; Kakehi, K. Characterization of Ti-48Al-2Cr-2Nb built by selective laser melting. Scr. Mater. 2021, 203, 114107. [Google Scholar] [CrossRef]

- Liu, Z.C.; Lin, J.P.; Chen, G.L. Effects of Nb and Al on the microstructures and mechanical properties of high Nb containing TiAl base alloys. Intermetallics 2002, 10, 653–659. [Google Scholar] [CrossRef]

- Lin, J.P.; Zhao, L.L.; Li, G.Y.; Zhang, L.Q.; Song, X.P.; Ye, F.; Chen, G.L. Effect of Nb on oxidation behavior of high Nb containing TiAl alloys. Intermetallics 2011, 19, 131–136. [Google Scholar] [CrossRef]

- Huang, S.C.; Hall, E.L. Characterization of the effect of vanadium additions to TiAl base alloy. Acta Metall. et Mater. 1991, 39, 1053–1060. [Google Scholar] [CrossRef]

- Nobuki, M.; Vanderschueren, D.; Nakamura, M. High temperature mechanical properties of vanadium alloyed γ base titanium-aluminides. Acta Metall. et Mater. 1994, 42, 2623–2632. [Google Scholar] [CrossRef]

- Anada, H.; Shida, Y. Effect of Mo addition on the oxidation behavior of TiAl intermetallic compound. Mater. Trans. JIM 1995, 36, 533–539. [Google Scholar] [CrossRef]

- Remez, M.V.; Prerov, Y.M.; Bondar, A.A.; Wasiewicz, V.; Hecht, U.; Tsyganenko, N.I.; Bilous, O.O.; Petyukh, V.M. Structure and properties of TiAl-based alloys doped with 2 at.% Mo. Powder Metall. Met. Ceram. 2020, 59, 454–466. [Google Scholar] [CrossRef]

- Dymek, S.; Wrobel, M.; Blicharski, M. Influence of tungsten on microstructure of mechanically alloyed γ-TiAl. J. Microsc. 2006, 223, 292–294. [Google Scholar] [CrossRef]

- Voisin, T.; Monchoux, J.P.; Thomas, M.; Deshayes, C.; Couret, A. Mechanical properties of the TiAl IRIS alloy. Metall. Mater. Trans. A 2016, 47, 6097–6108. [Google Scholar] [CrossRef]

- Lee, D.B. Effect of Fe on the high temperature oxidation of TiAl alloys. Met. Mater. Int. 2005, 11, 313. [Google Scholar] [CrossRef]

- Levin, L.; Tokar, A.; Talianker, M.; Evangelista, E. Non-equilibrium microstructures in TiAl–2Fe alloy. Intermetallics 1999, 7, 1317–1322. [Google Scholar] [CrossRef]

- Hamzah, E.; Kanniah, M.; Harun, M. Effect of chromium addition on microstructure, tensile properties and creep resistance of as-cast Ti-48Al alloy. J. Mater. Sci. 2007, 42, 9063–9069. [Google Scholar] [CrossRef]

- Wang, F.; Tang, Z.; Wu, W. Effect of chromium on the oxidation resistance of TiAl intermetallics. Oxid. Met. 1997, 48, 381–390. [Google Scholar] [CrossRef]

- Lee, D.B.; Jang, Y.D.; Nakamura, M. High temperature oxidation of Ti–47%Al–1%Mn alloy. Mater. Trans. 2002, 43, 2531–2535. [Google Scholar] [CrossRef][Green Version]

- Tetsui, T.; Shindo, K.; Kobayashi, S.; Takeyama, M. A newly developed hot-worked TiAl alloy was used for blades and structural components. Scr. Mater. 2002, 47, 399–403. [Google Scholar] [CrossRef]

- Bauer, J.; Rogl, P.; Perrin, A.; Bohn, M.; Wolf, W.; Podloucky, R.; Le Friec, Y.; Antoine, D. TiAl-based alloys with nickel. Intermetallics 1996, 4, 71–76. [Google Scholar] [CrossRef]

- Mantyi, H.C.; Cornish, L.A.; Chown, L.H.; Mwamba, I.A. Investigating the high temperature oxidation behavior of TiAl-based alloys with nickel and ruthenium additions. Adv. Mater. Res. 2014, 1019, 294–301. [Google Scholar] [CrossRef]

- Maki, K.; Shioda, M.; Sayashi, M.; Shimizu, T.; Isobe, S. Effect of silicon and niobium on oxidation resistance of TiA1 intermetallics. Mater. Sci. Eng. A 1992, 153, 591–596. [Google Scholar] [CrossRef]

- Li, X.Y.; Taniguchi, S. Oxidation behavior of a γ-TiAl-based alloy implanted by silicon and/or carbon. Mater. Sci. Eng. A 2005, 398, 268–274. [Google Scholar] [CrossRef]

- Park, Y.S.; Ahn, W.S.; Nam, S.W.; Hwang, S.K. The enhancement of low cycle fatigue life by carbon addition in lamellar TiAl alloy. Mater. Sci. Eng. A 2002, 336, 196–201. [Google Scholar] [CrossRef]

- Klein, T.; Schachermayer, M.; Martin, F.M.; Schoberl, T.; Rashkova, B.; Clemens, H.; Mayer, S. Carbon distribution in multi-phase γ-TiAl based alloys and its influence on mechanical properties and phase formation. Acta Mater. 2015, 94, 205–213. [Google Scholar] [CrossRef]

- Cho, H.S.; Nam, S.W.; Yun, J.H.; Wee, D.M. Effect of 1 at.% nitrogen addition on the creep resistance of two phase TiAl alloy. Mater. Sci. Eng. A 1999, 262, 129–136. [Google Scholar] [CrossRef]

- Schuon, S.R.; Druschitz, A.P. Microalloying TiAl with Nitrogen and Tungsten. JOM 1987, 39, 36–37. [Google Scholar] [CrossRef]

- Hu, D. Role of boron in TiAl alloy development: A review. Rare Met. 2016, 35, 1–14. [Google Scholar] [CrossRef]

- Feng, C.R.; Michel, D.J.; Crowe, C.R. The Effects of Boron in TiA1/Ti3A1. Scr. Metall. 1989, 23, 1707–1712. [Google Scholar] [CrossRef]

- Tetsui, T.; Kobayashi, T.; Mori, T.; Kishimoto, T.; Harada, H. Evaluation of yttria applicability as a crucible for induction melting of TiAl alloy. Mater. Trans. 2010, 51, 1656–1662. [Google Scholar] [CrossRef]

- Tetsui, T.; Kobayashi, T.; Harada, H. Consideration of the influence of contamination from oxide crucibles on TiAl cast material, and the possibility of achieving low-purity TiAl precision cast turbine wheels. Intermetallics 2012, 31, 274–281. [Google Scholar] [CrossRef]

- Tetsui, T. Development of a Second Generation TiAl Turbocharger. Mater. Sci. Forum 2007, 561–565, 379–382. [Google Scholar] [CrossRef]

- Bartolotta, P.; Barrett, J.; Kelly, T.; Smashey, R. The use of cast Ti-48Al-2Cr-2Nb in jet engines. J. Miner. 1997, 49, 48–50. [Google Scholar] [CrossRef]

- Larsen, D.E.; Christodoulou, L.; Kampe, S.L.; Sadler, R. Investment-Cast processing of XDTM near-γ titanium aluminides. Mater. Sci. Eng. A 1991, 144, 45–49. [Google Scholar] [CrossRef]

- McQuay, P.A.; Simpkins, R.; Seo, D.Y.; Bieler, T.R. Alloy and process improvements for cast gamma TiAl alloy applications. In Gamma Titanium Aluminides 1999; Kim, Y.W., Dimiduk, D.M., Loretto, M.H., Eds.; The Minerals, Metals & Materials Society: Warrendale, PA, USA, 1999; pp. 197–207. [Google Scholar]

- Lapin, J.; Nazmy, M. Microstructure and creep properties of a cast intermetallic Ti–46Al–2W–0.5Si alloy for gas turbine applications. Mater. Sci. Eng. A 2004, 380, 298–307. [Google Scholar] [CrossRef]

- Koyanagi, Y.; Sumi, Y.; Takabayashi, H. Development of titanium aluminide alloy with good high temperature properties for turbine wheel (in Japanese). Denki Seiko 2014, 85, 121–125. [Google Scholar]

- Kawabata, T.; Tamura, T.; Izumi, O. Effect of Ti/Al ration and Cr, Nb, and Hf additions on material factors and mechanical properties in TiAl. Mater. Trans. A 1993, 24, 141–150. [Google Scholar] [CrossRef]

- Huang, S.C.; Hall, E.L.; Shih, D.S. Microstructure and ductility of TiAl alloys modified by Cr additions. ISIJ. Int. 1991, 31, 1100–1105. [Google Scholar] [CrossRef][Green Version]

- Takagi, S.; Ouchi, C. Effects of alloying elements and heat treatment on the strength and ductility of Cast-Hipped TiAl (in Japanese). J. Jpn. Inst. Met. 1994, 58, 1001–1007. [Google Scholar] [CrossRef][Green Version]

- Karthikeyan, S.; Mills, M.J. The role of microstructural stability on compression creep of fully lamellar g-TiAl alloys. Intermetallics 2002, 13, 985–992. [Google Scholar] [CrossRef]

- Kim, Y.-W.; Kim, S.-L. Effects of microstructure and C and Si additions on elevated temperature creep and fatigue of gamma TiAl alloys. Intermetallics 2014, 53, 92–101. [Google Scholar] [CrossRef]

- Shida, Y.; Anada, H. Role of W, Mo, Nb and Si on oxidation of TiAl in air at high temperatures. Mater. Trans. JIM 1994, 35, 623–631. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).