Novel Characterization Techniques for Additive Manufacturing Powder Feedstock

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

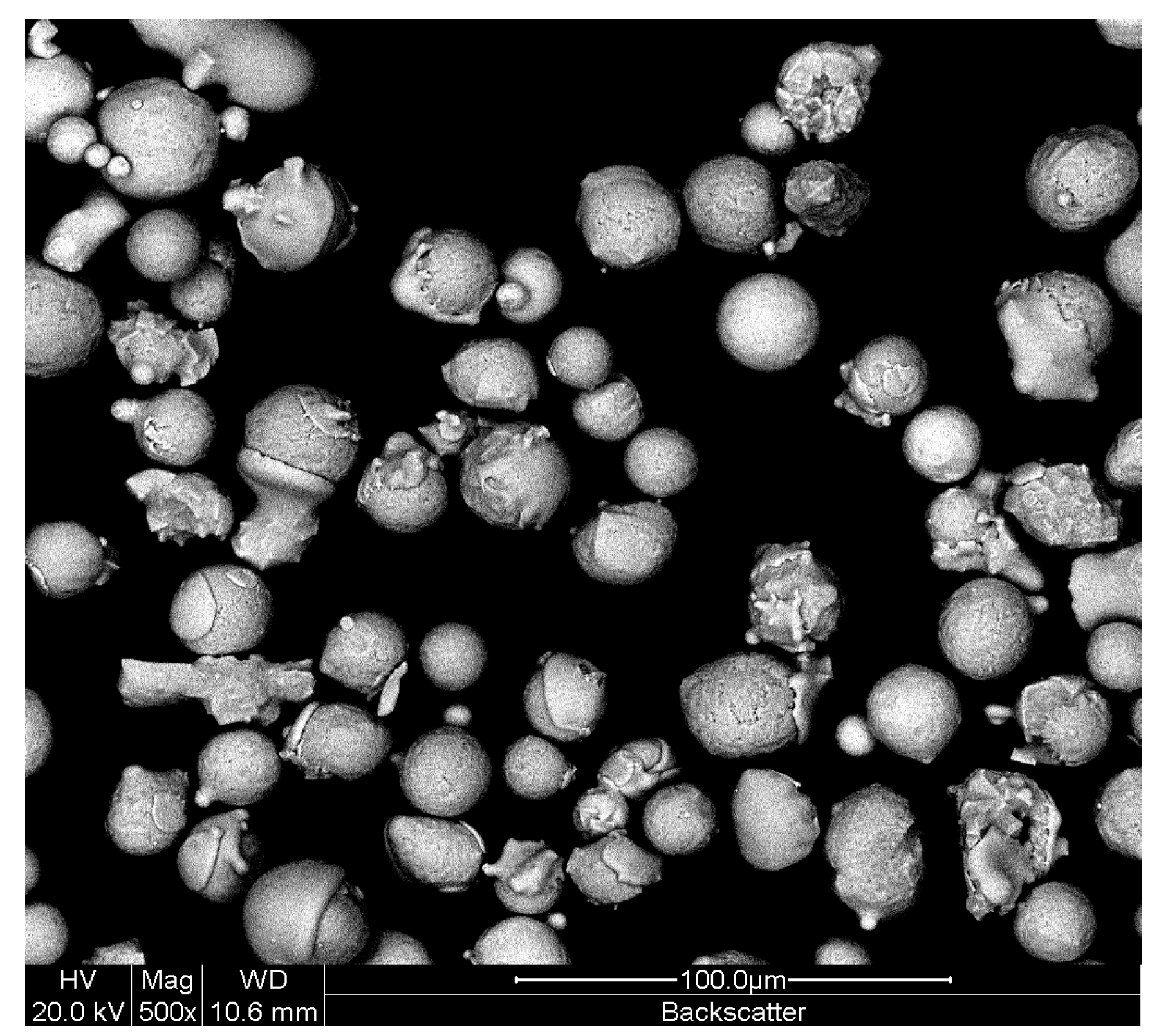

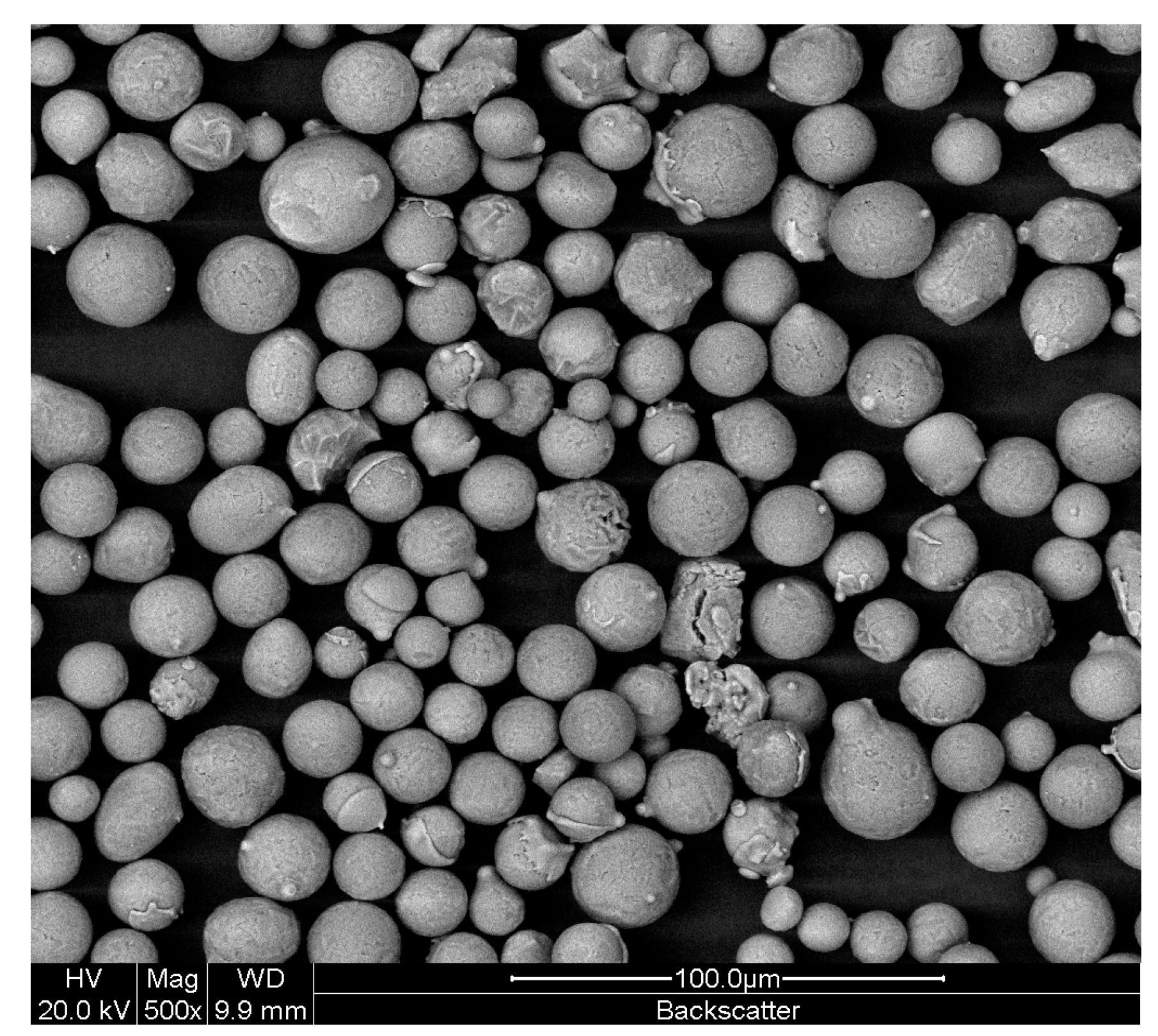

2.1.1. Quality Control of Cermet Powder Blends

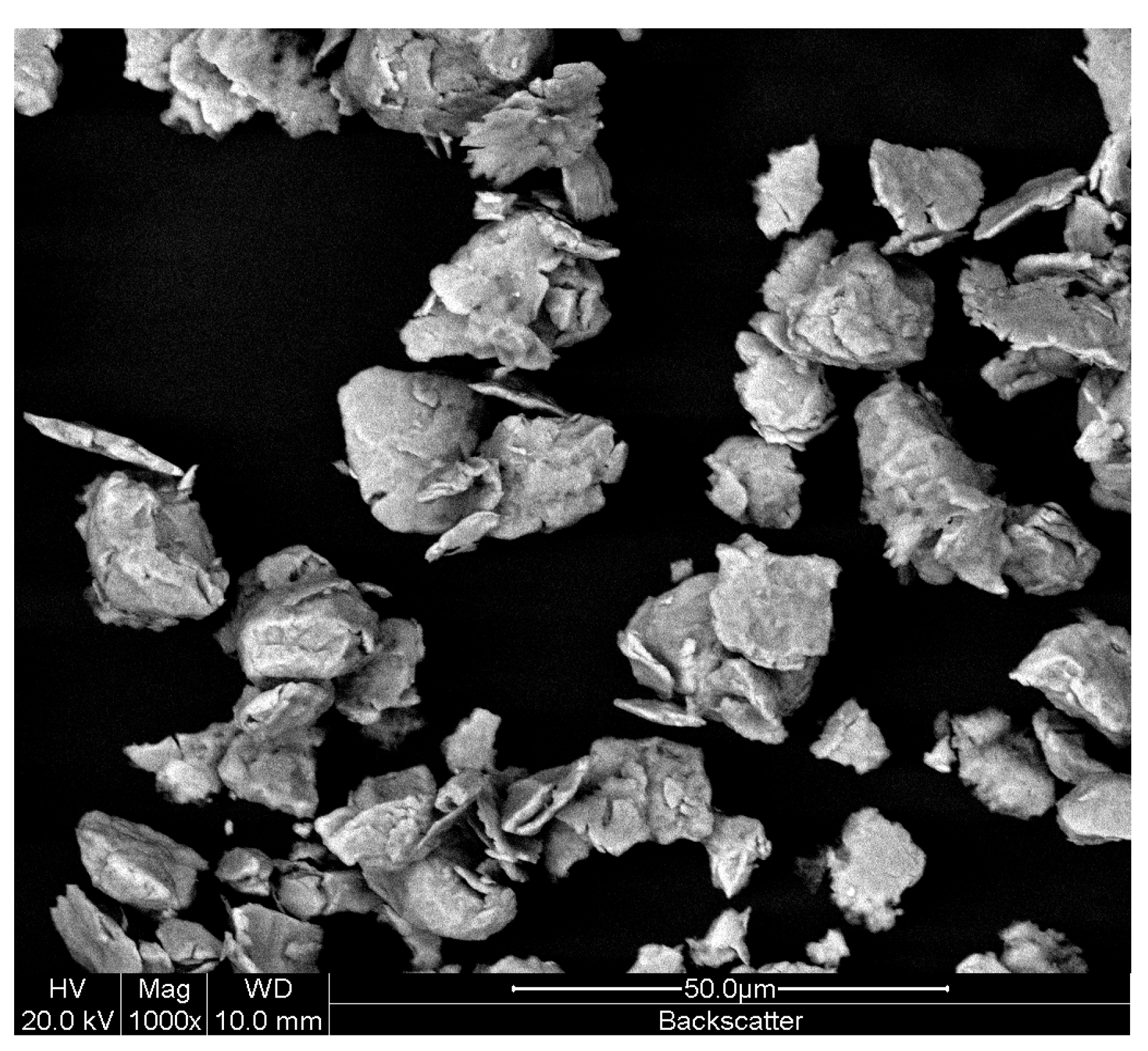

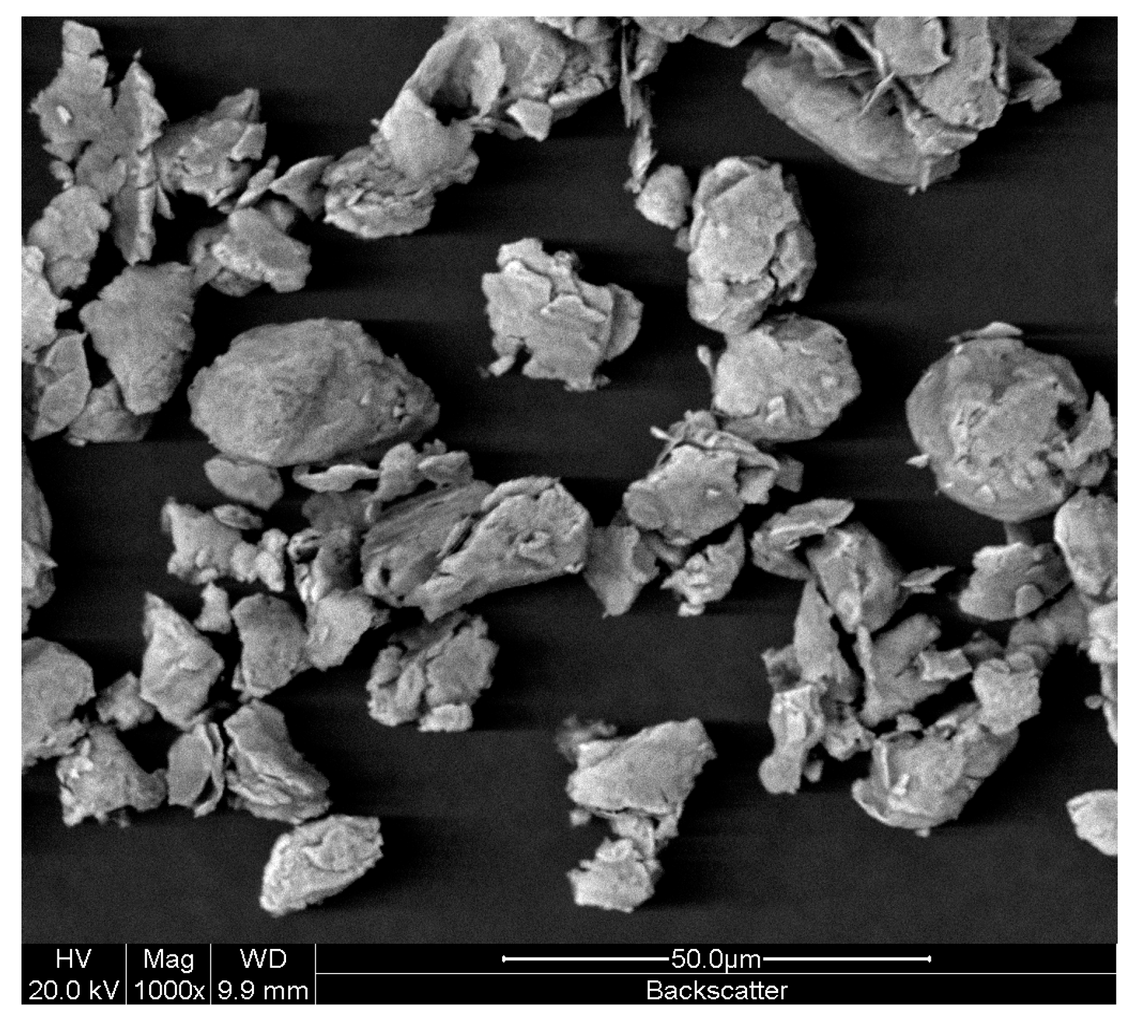

2.1.2. Pre-Processing of Chromium Powder

2.1.3. Pre-Processing of Aluminum 6061

2.2. Characterization

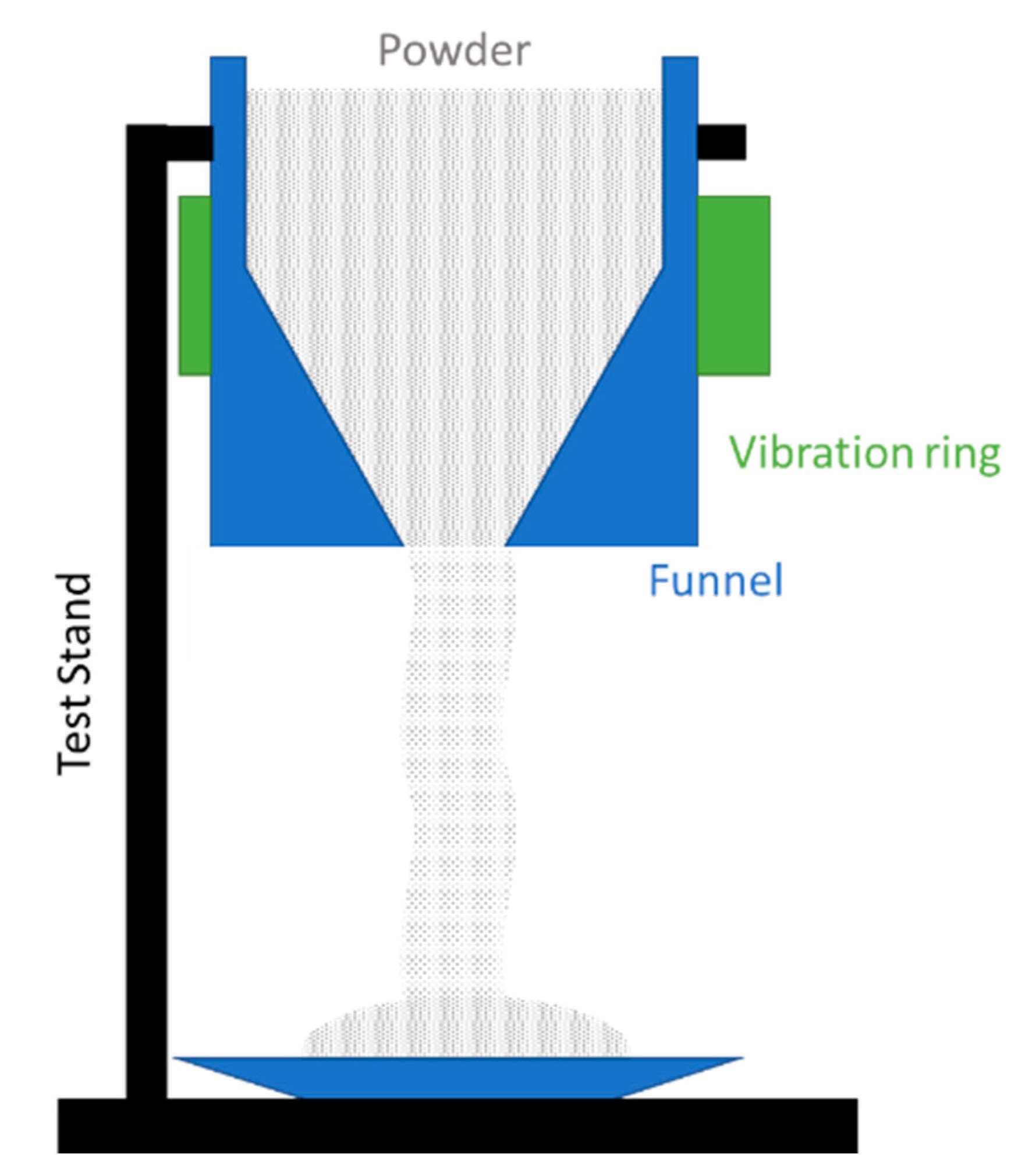

2.2.1. Flowability

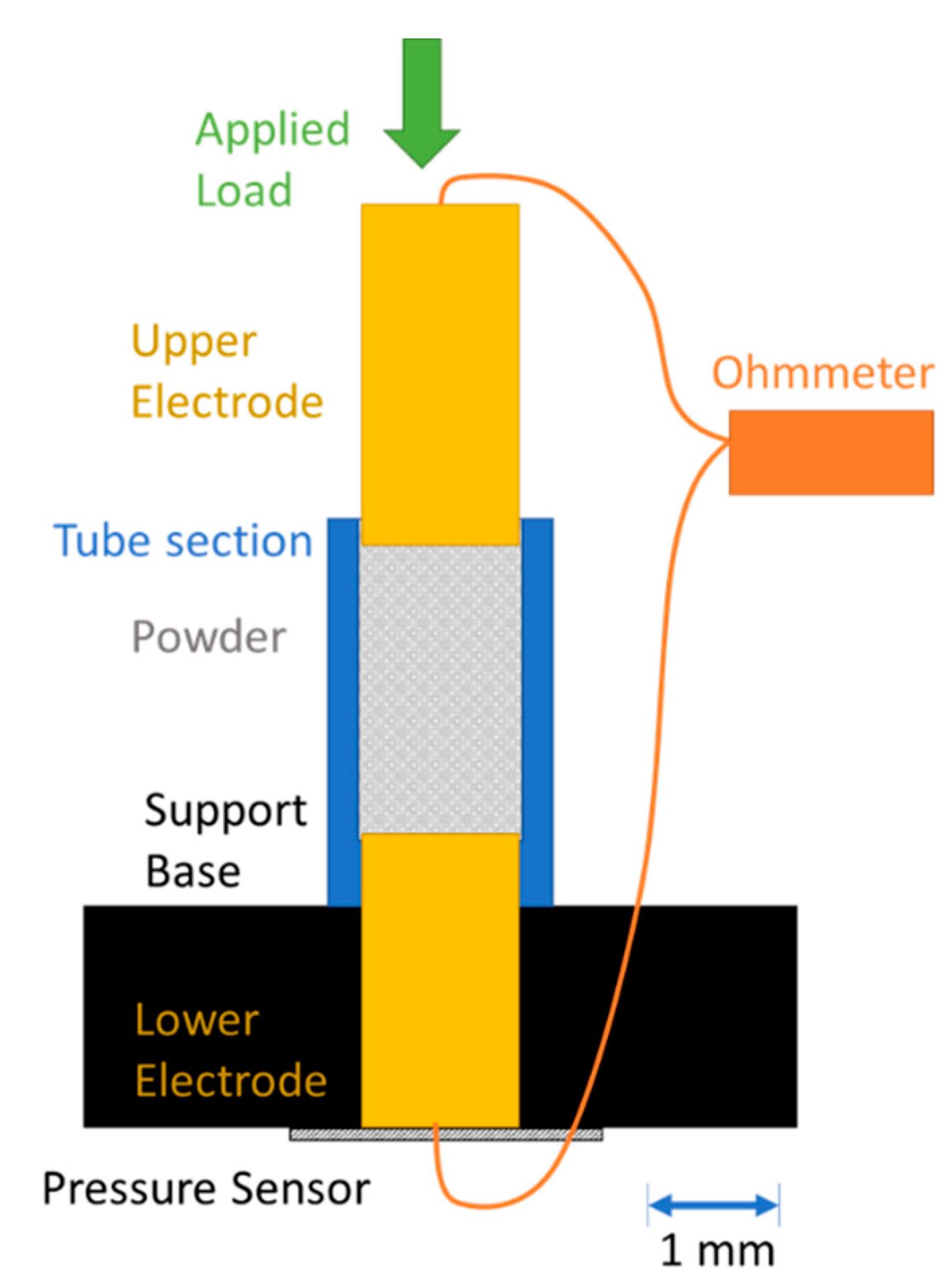

2.2.2. Compressibility

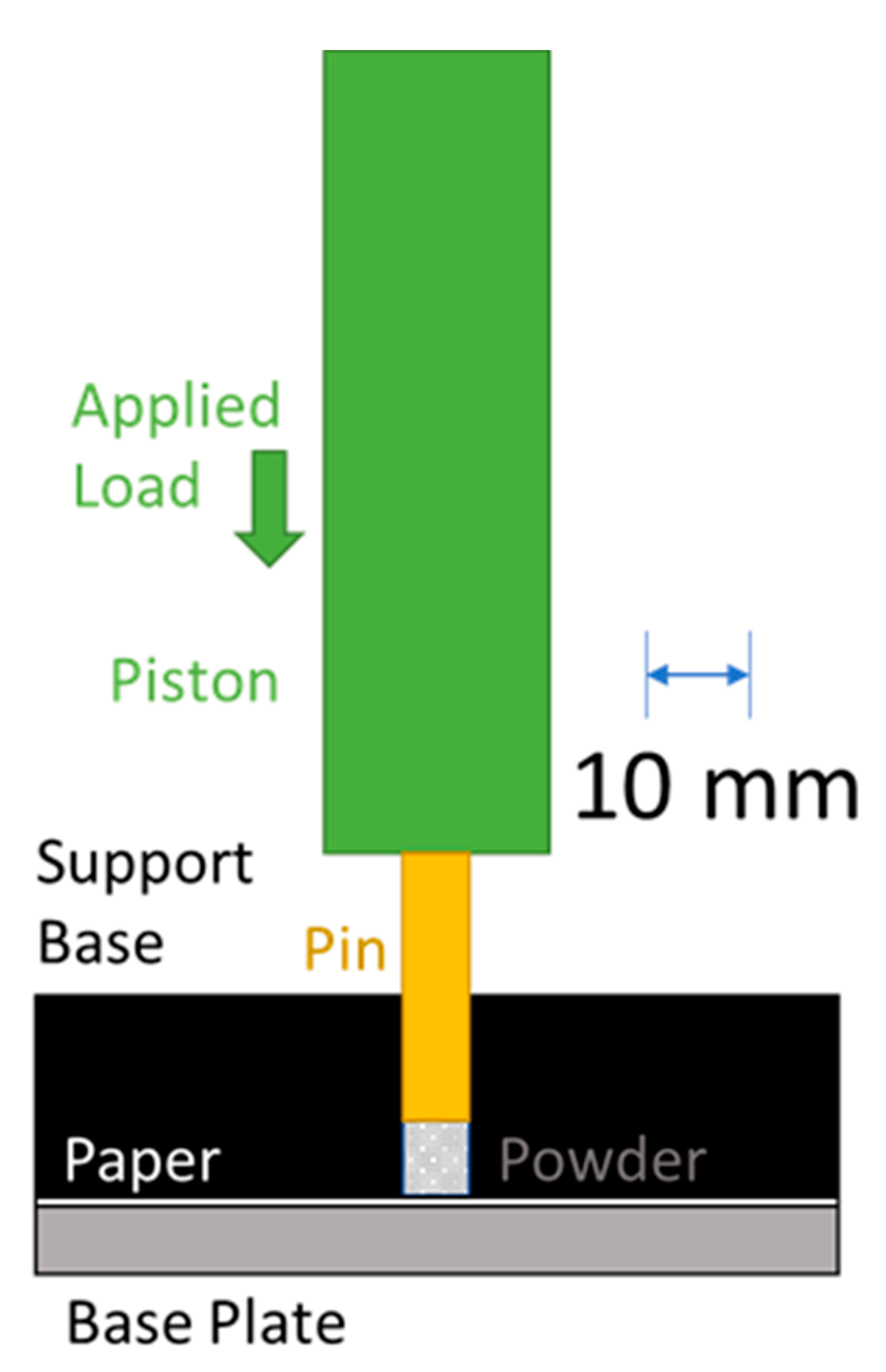

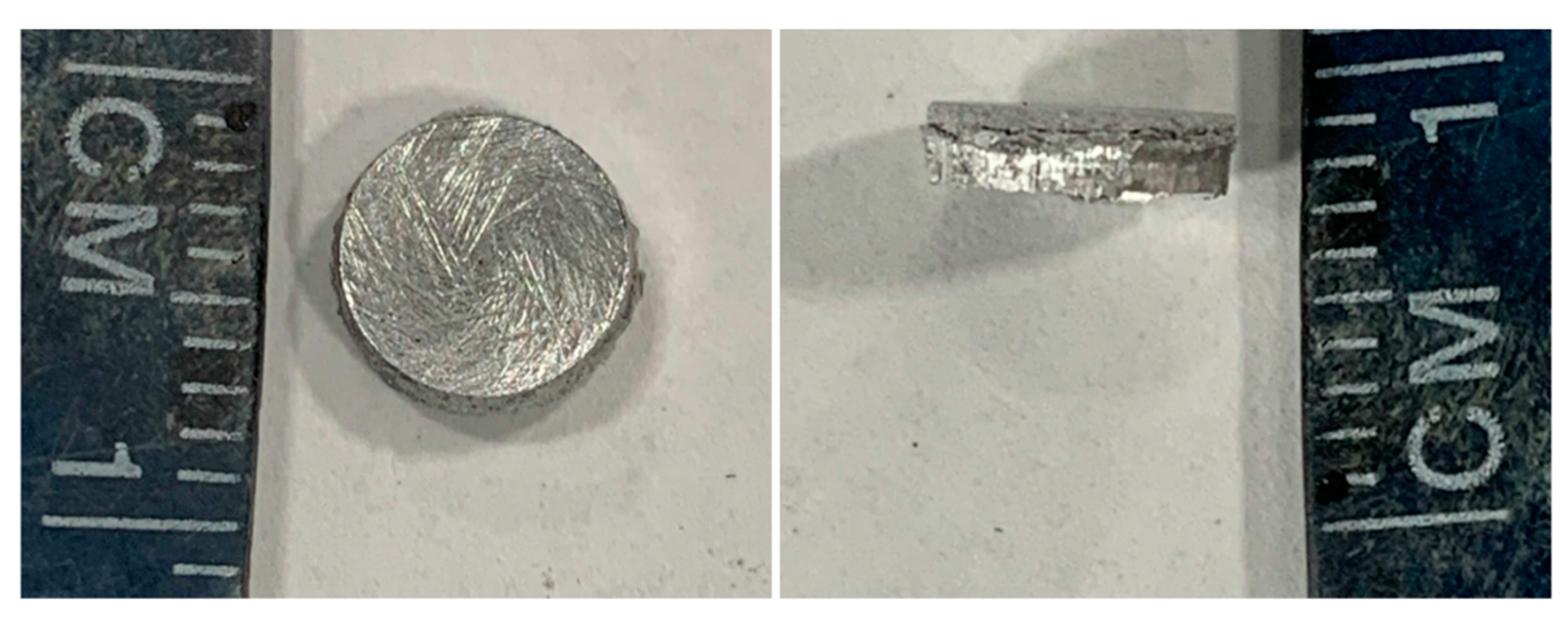

2.2.3. Compactibility

2.2.4. Cold Spray

3. Results and Discussion

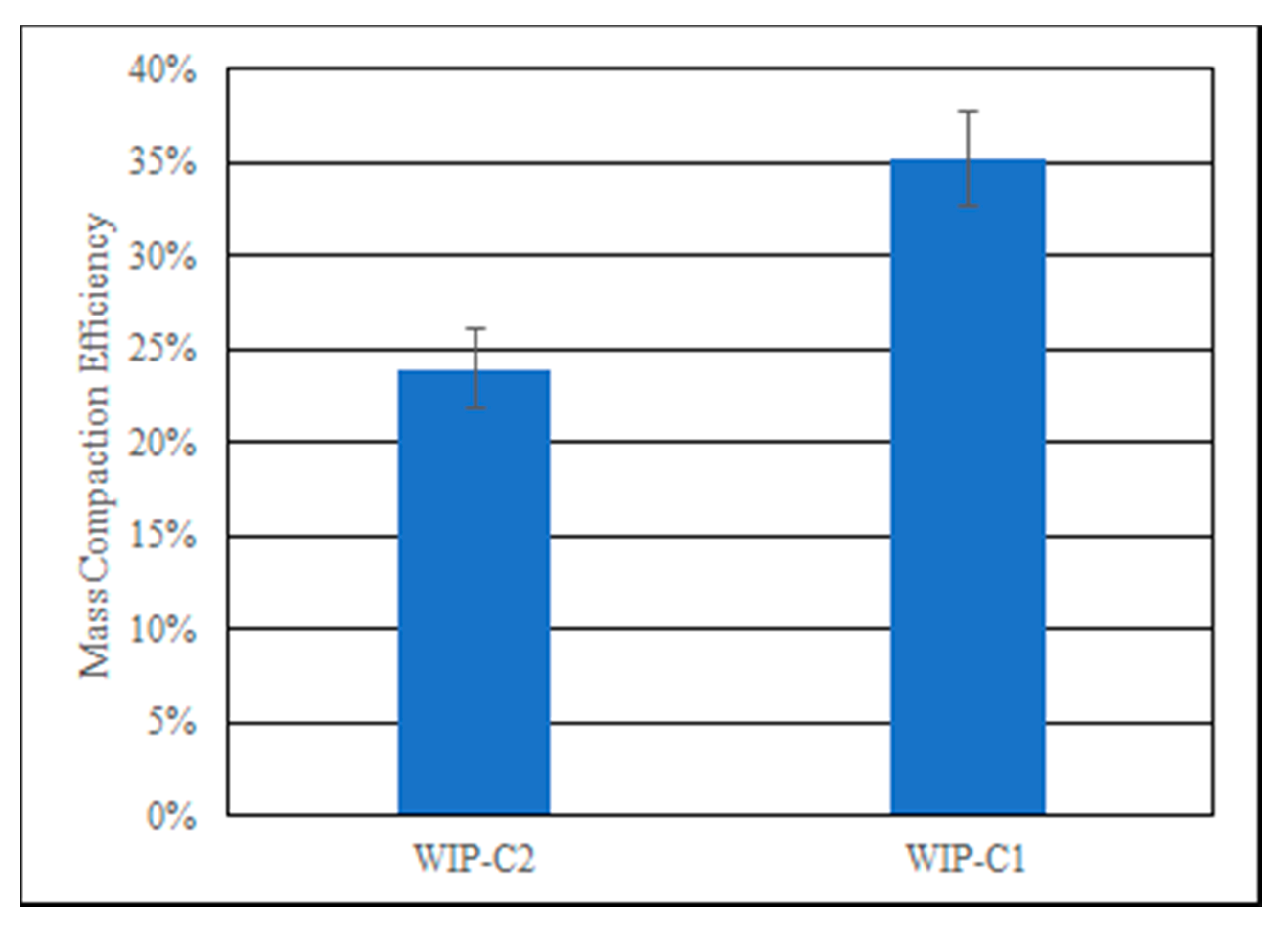

3.1. Quality Control of Cermet Powder Blends

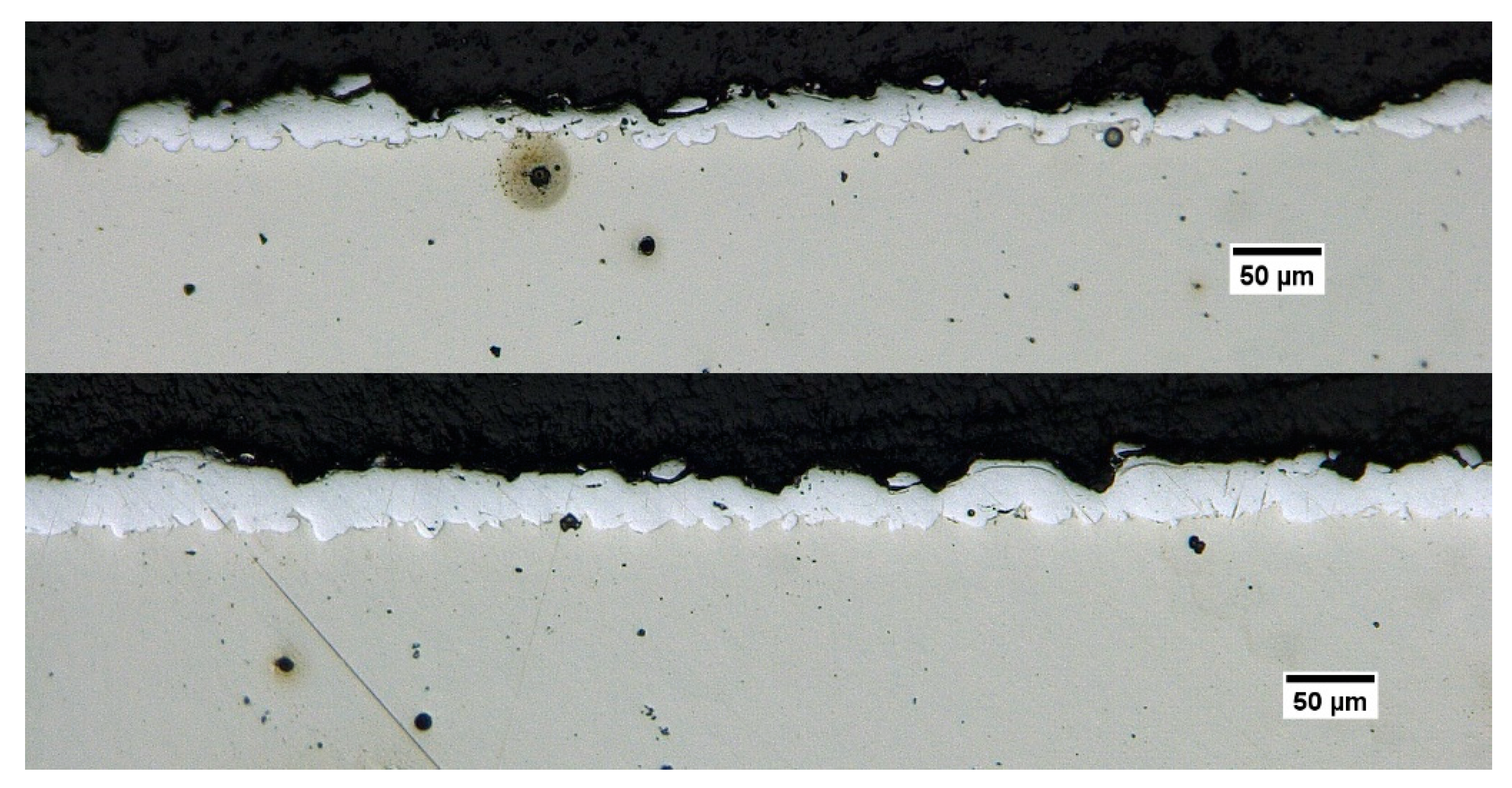

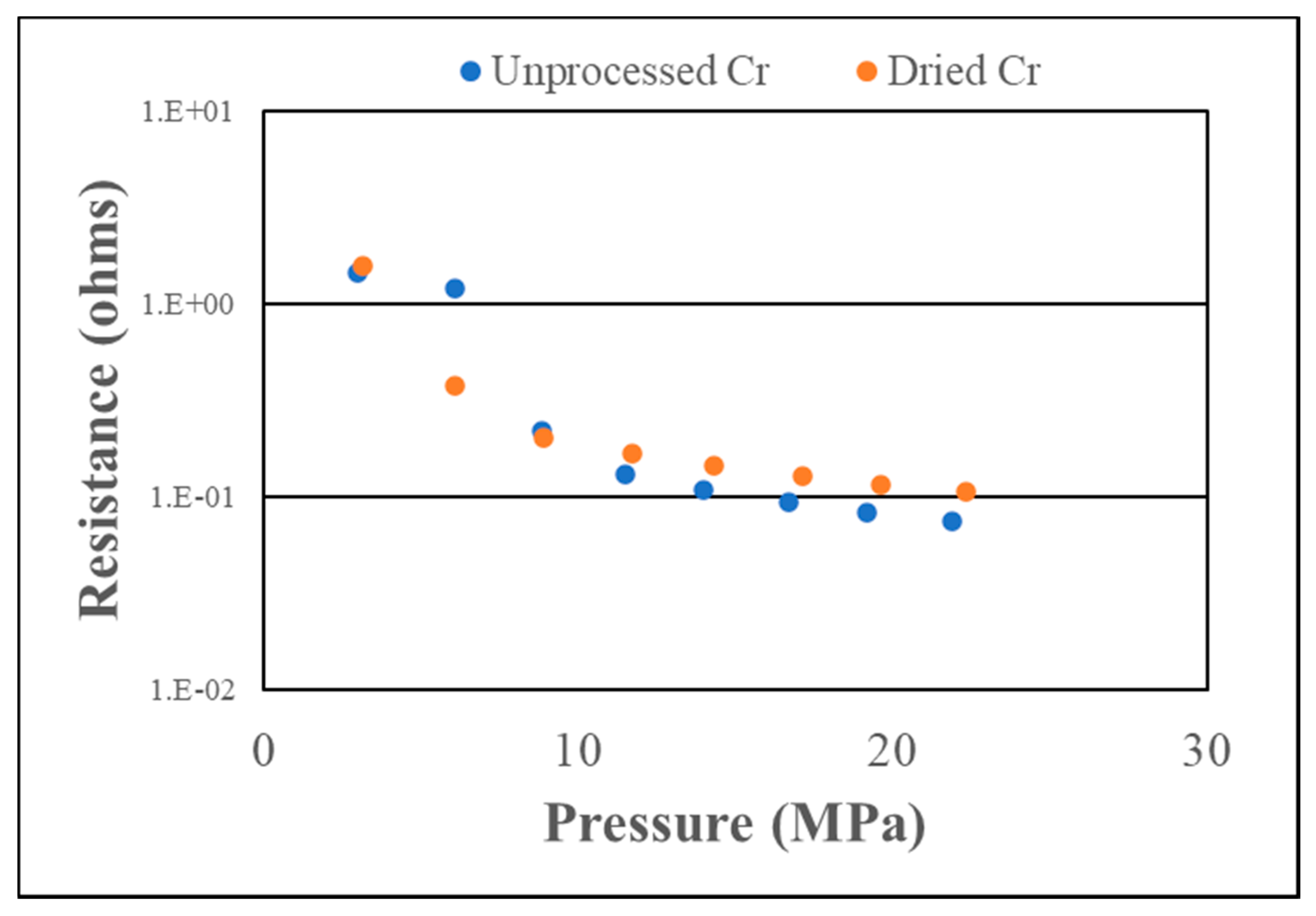

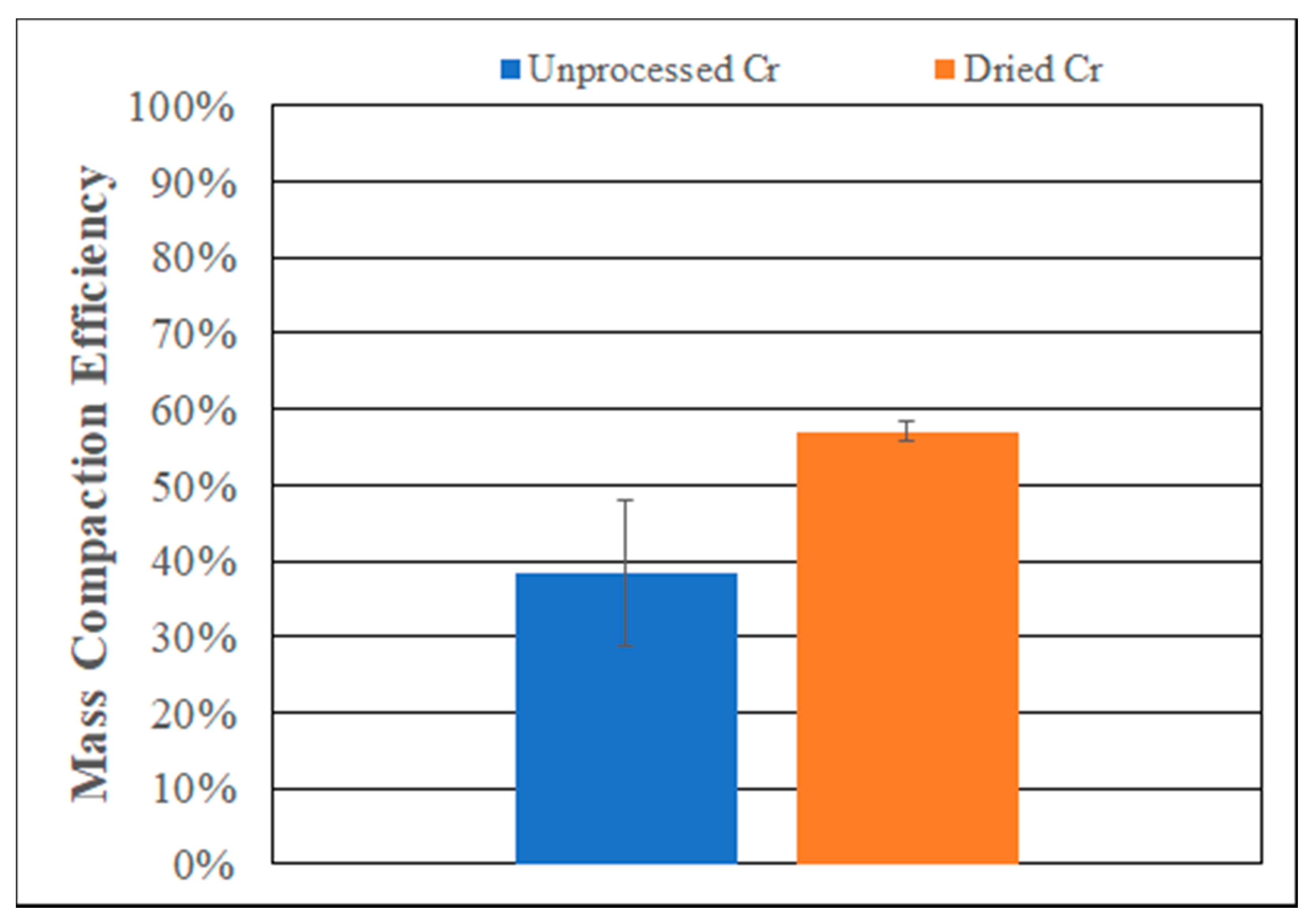

3.2. Pre-Processing of Chromium Powder

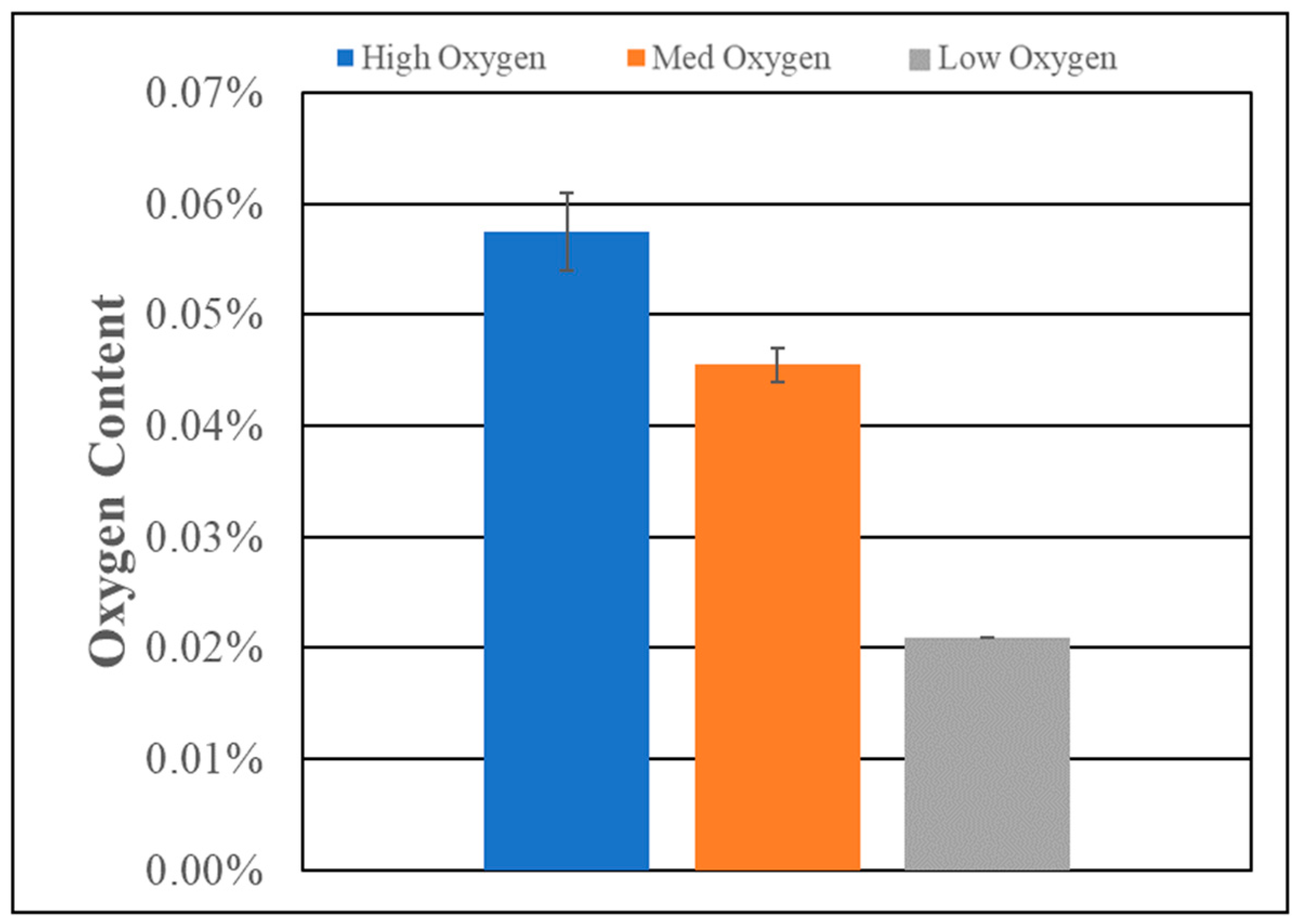

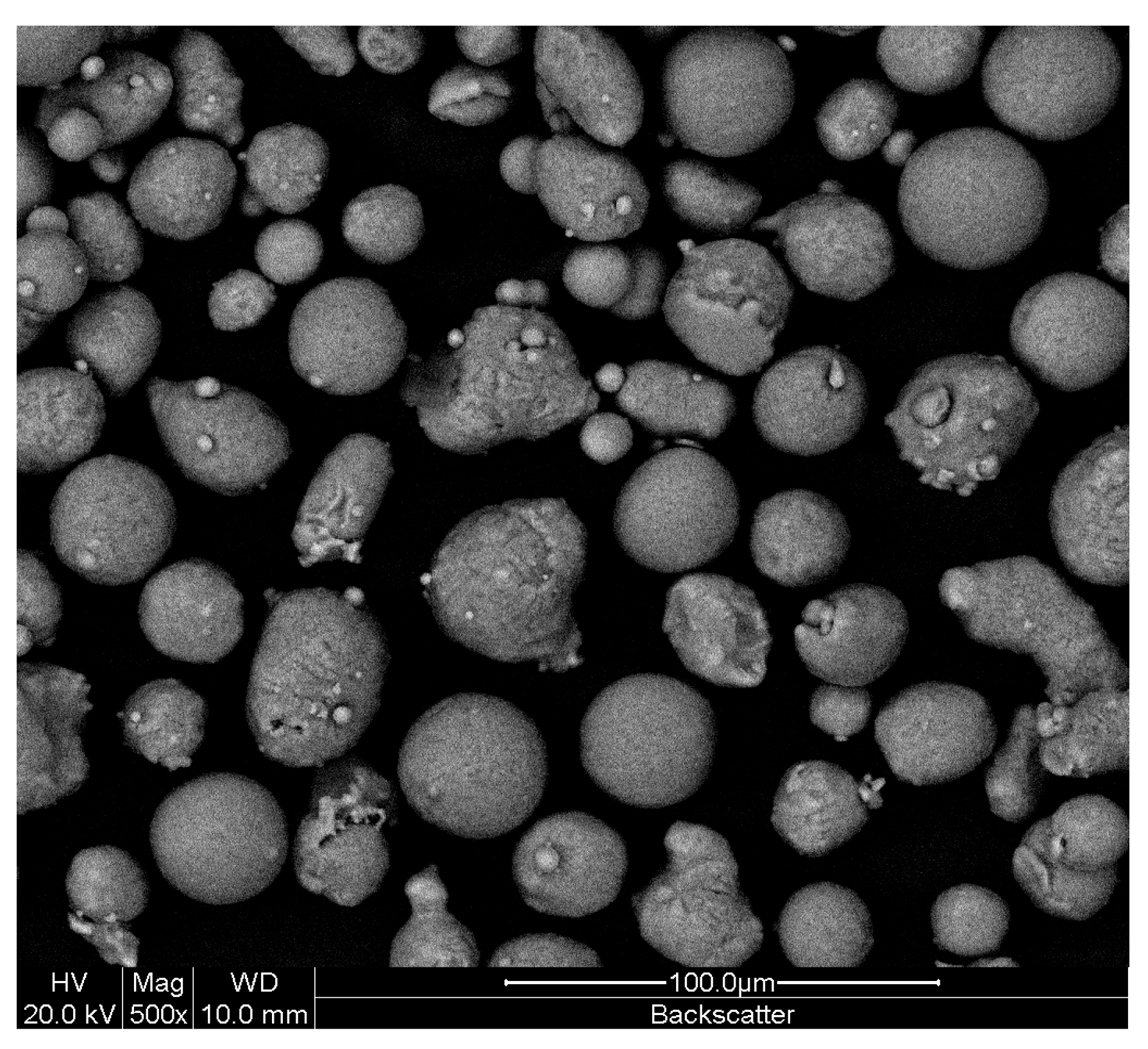

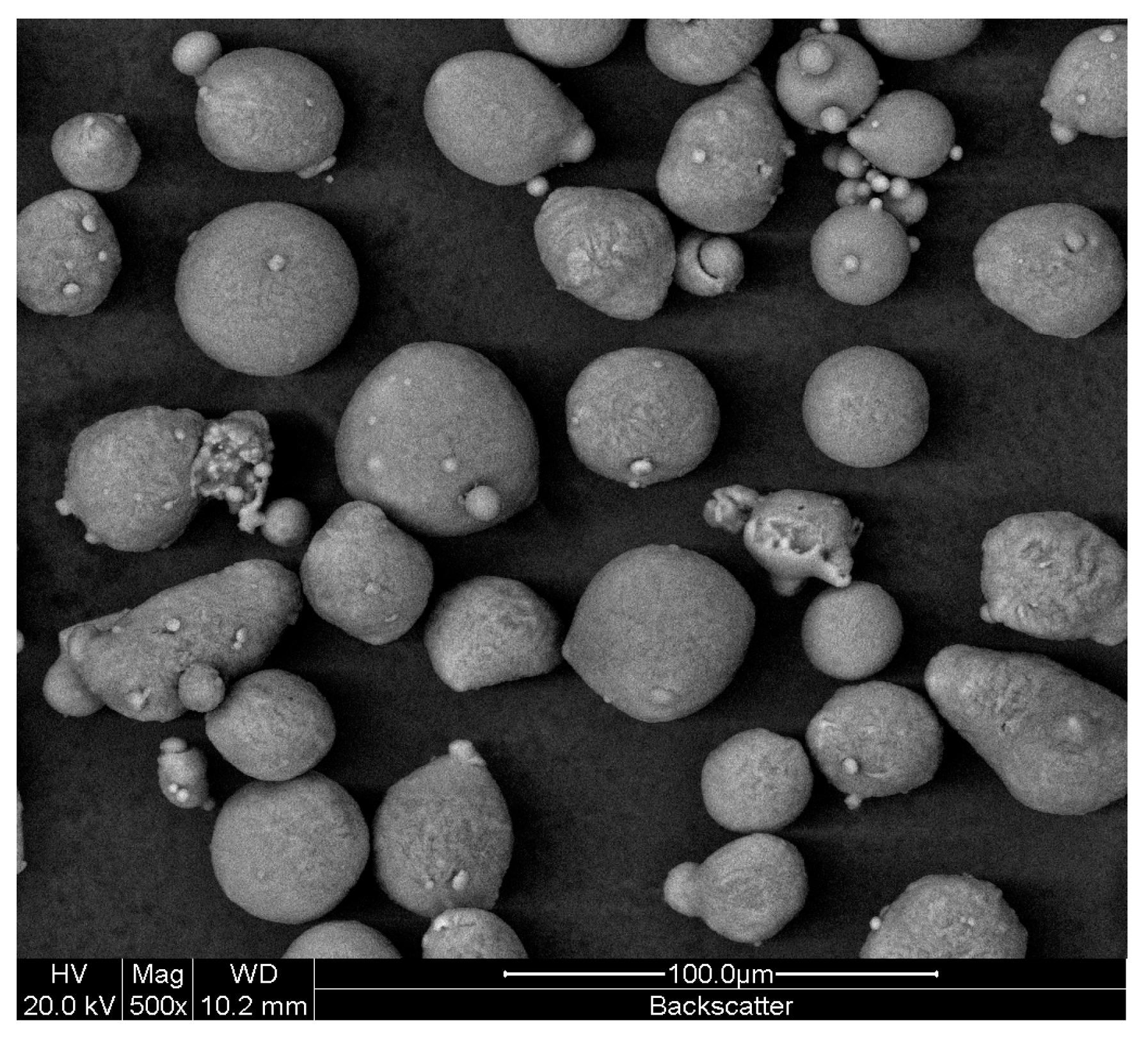

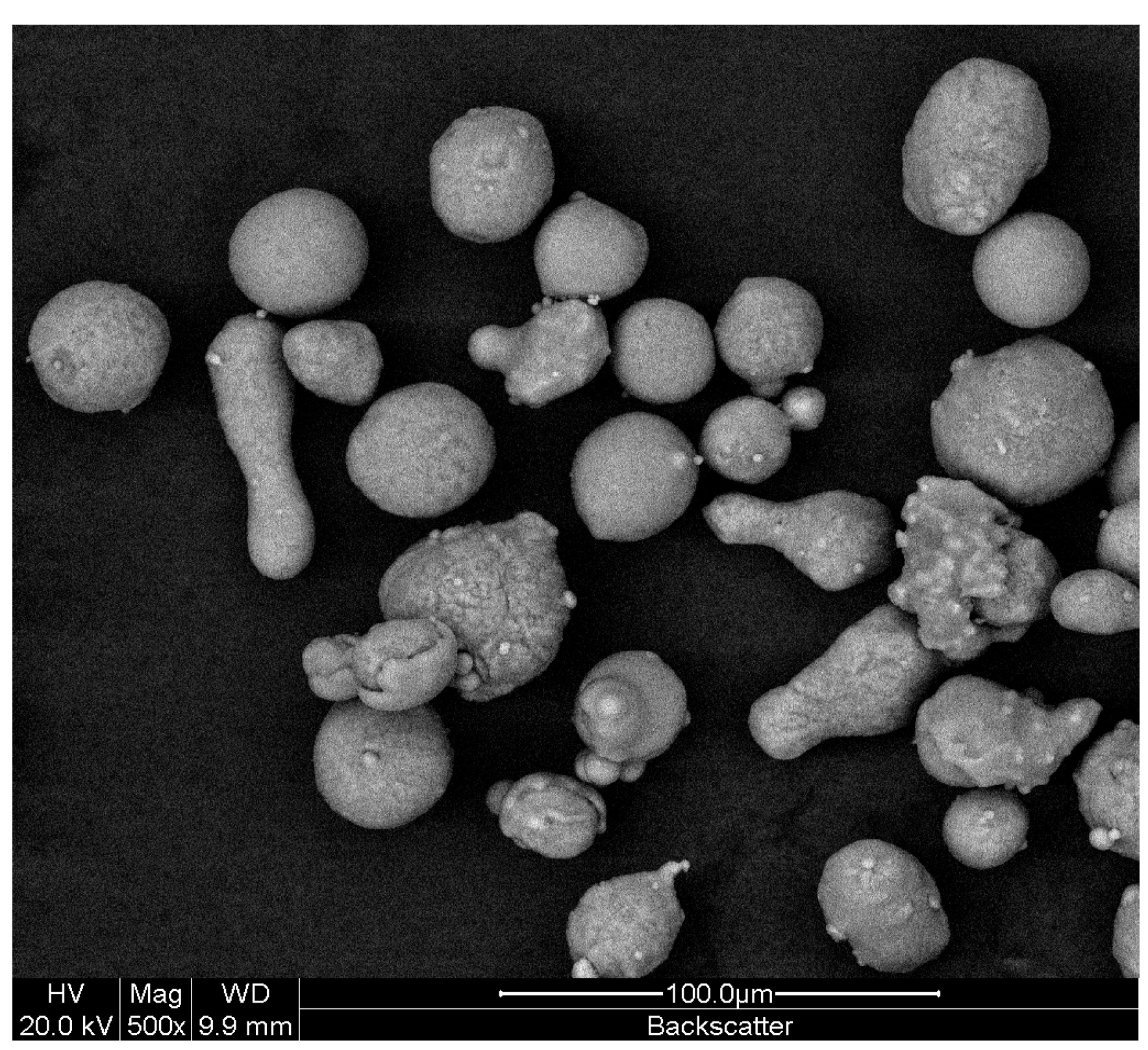

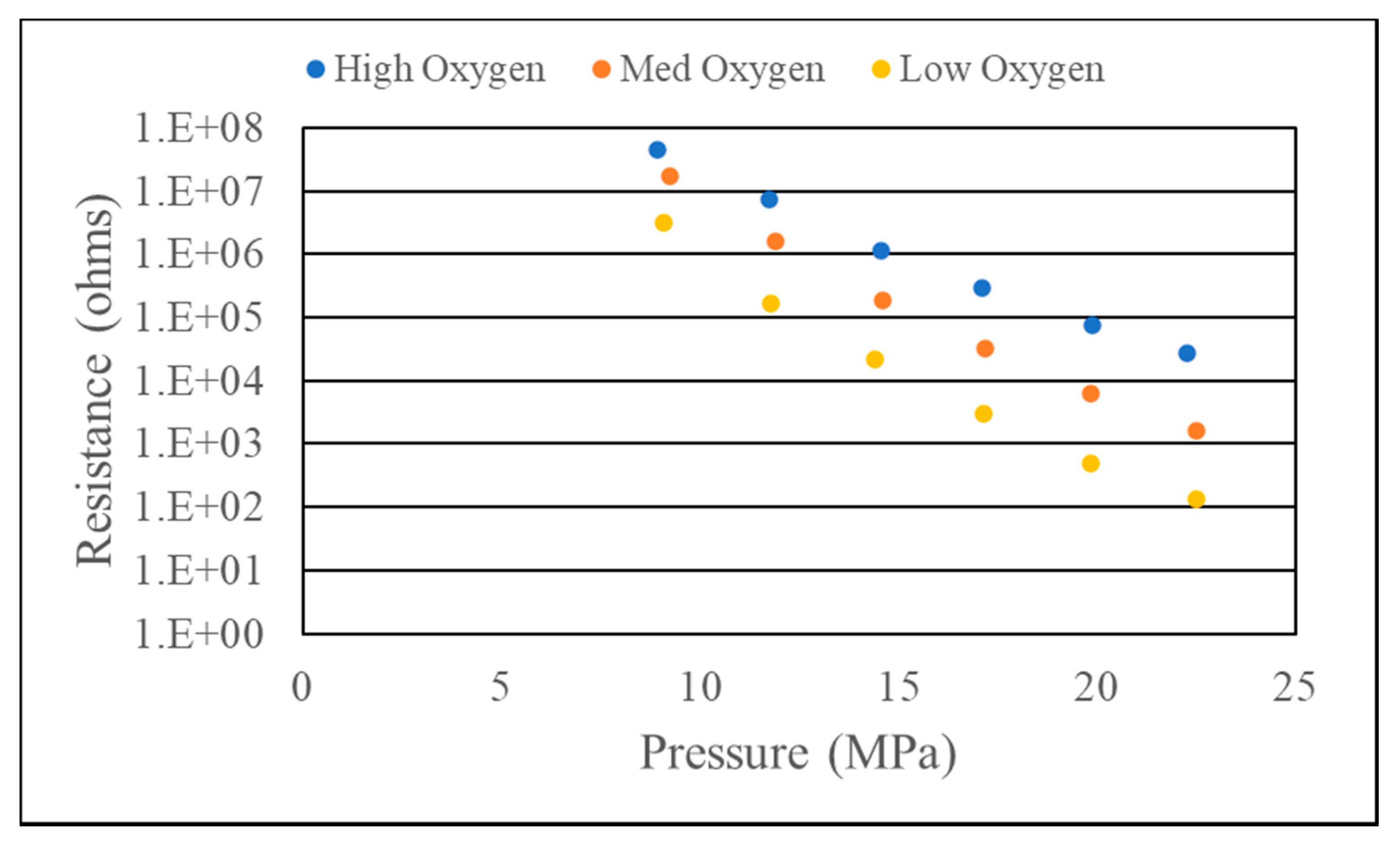

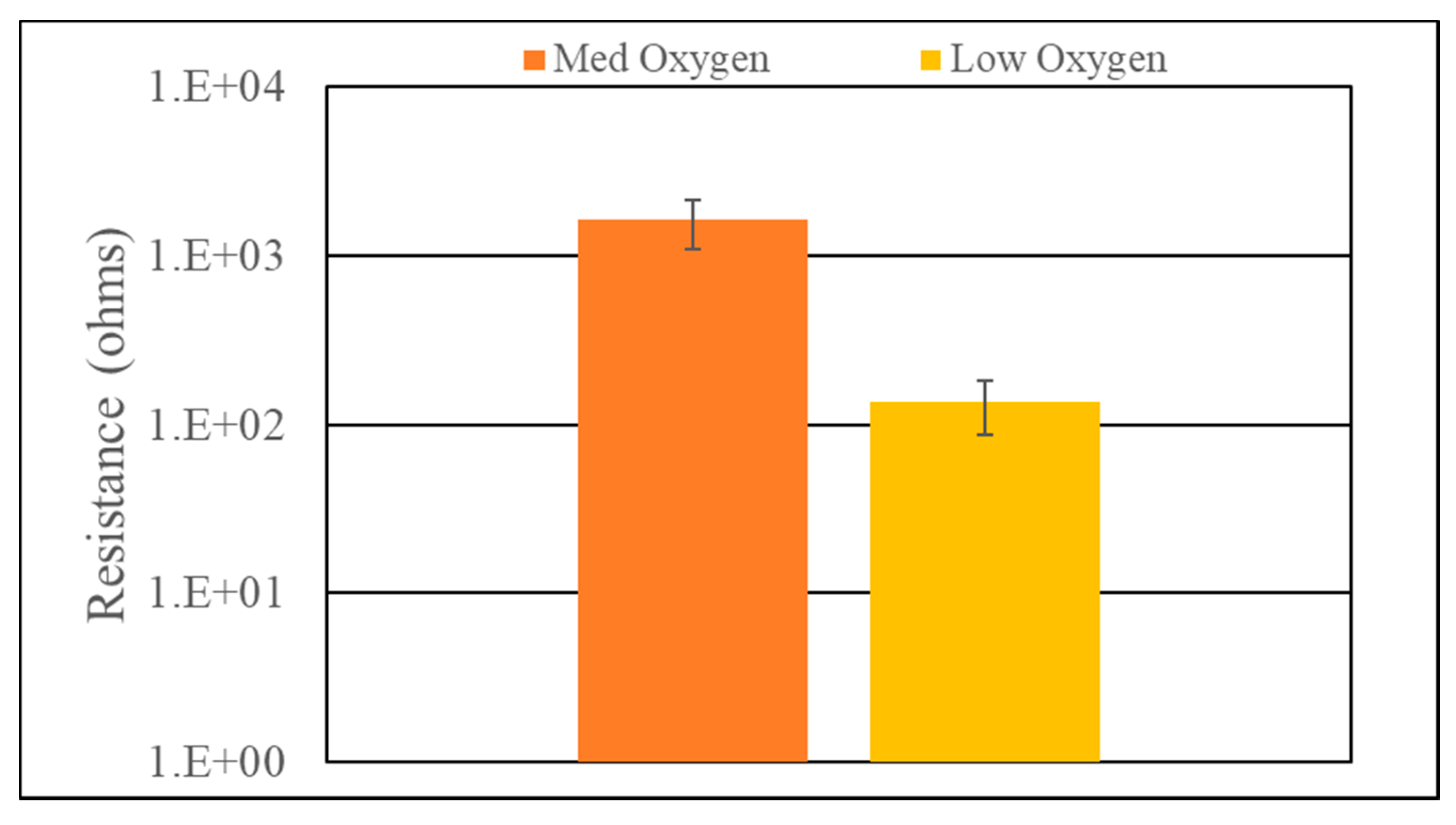

3.3. Pre-Processing of Aluminum 6061

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Abdulhameed, O.; Al-Ahmari, A.; Ameen, W.; Mian, S.H. Additive manufacturing: Challenges, trends, and applications. Adv. Mech. Eng. 2019, 11. [Google Scholar] [CrossRef]

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Wang, C.C.; Shin, Y.C.; Zhang, S.; Zavattieri, P.D. The status, challenges, and future of additive manufacturing in engineering. Comput.-Aided Des. 2015, 69, 65–89. [Google Scholar] [CrossRef]

- Gong, X.; Anderson, T.; Chou, K. Review on powder-based electron beam additive manufacturing technology. Manuf. Rev. 2014, 1, 2. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal additive manufacturing: A review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar]

- Guo, N.; Leu, M.C. Additive manufacturing: Technology, applications and research needs. Front. Mech. Eng. 2013, 8, 215–243. [Google Scholar] [CrossRef]

- Heiden, M.J.; Deibler, L.A.; Rodelas, J.M.; Koepke, J.R.; Tung, D.J.; Saiz, D.J.; Jared, B.H. Evolution of 316L stainless steel feedstock due to laser powder bed fusion process. Addit. Manuf. 2019, 25, 84–103. [Google Scholar] [CrossRef]

- Deputy Director for Strategic Technology Protection and Exploitation. Department of Defense Additive Manufacturing Strategy. [Online]. Available online: https://www.cto.mil/wp-content/uploads/2021/01/dod-additive-manufacturing-strategy.pdf (accessed on 24 February 2021).

- US Dept of Energy. Advanced Manufacturing Office Multi-Year Program Plan. Available online: https://www.energy.gov/sites/prod/files/2017/01/f34/DraftAdvancedManufacturingOfficeMYPP_1.pdf (accessed on 24 February 2021).

- US Food & Drug Administration. Technical Considerations for Additive Manufactured Medical Devices Guidance for Industry and Food and Drug Administration Staff Preface Public Comment. Available online: https://www.fda.gov/media/97633/download (accessed on 24 February 2021).

- Additive Manufacturing|NIST. National Institute of Standards and Technology. Available online: https://www.nist.gov/additive-manufacturing (accessed on 24 February 2021).

- Muñiz-Lerma, J.A.; Nommeots-Nomm, A.; Waters, K.E.; Brochu, M. A comprehensive approach to powder feedstock characterization for powder bed fusion additive manufacturing: A case study on AlSi7Mg. Materials 2018, 11, 2386. [Google Scholar] [CrossRef] [PubMed]

- Champagne, V.K. The Cold Spray Materials Deposition Process, 1st ed.; Woodhead Publishing: Cambridge, UK, 2007. [Google Scholar]

- ASTM B964-16. Standard Test Methods for Flow Rate of Metal Powders Using the Carney Funnel; ASTM International: West Conshohocken, PA, USA, 2016; Available online: www.astm.org (accessed on 31 March 2021).

- ASTM B213-20. Standard Test Methods for Flow Rate of Metal Powders Using the Hall Flowmeter Funnel; ASTM International: West Conshohocken, PA, USA, 2020; Available online: www.astm.org (accessed on 31 March 2021).

- ASTM F3049-14. Standard Guide for Characterizing Properties of Metal Powders Used for Additive Manufacturing Processes; ASTM International: West Conshohocken, PA, USA, 2014; Available online: www.astm.org (accessed on 31 March 2021).

- MIL-DTL-32495. Detail Specification: Aluminum-Based Powders for Cold Spray Deposition; Department of Defense: Washington, DC, USA, 2014.

- Khalkhali, Z.; Rothstein, J.P. Characterization of the cold spray deposition of a wide variety of polymeric powders. Surf. Coat. Technol. 2020, 383, 125251. [Google Scholar] [CrossRef]

- Heelan, J.; Langan, S.M.; Walde, C.; Nardi, A.; Siopis, M.; Barth, R.; Landry, T.; Birt, A. Effect of WC-Ni Powder Composition and Preparation on Cold Spray Performance. Coatings 2020, 10, 1196. [Google Scholar] [CrossRef]

- DeForce, B.; Eden, T.; Potter, J.; Champagne, V.; Leyman, P.; Helfritch, D. Application of aluminum coatings for the corrosion protection of magnesium by cold spray. In Proceedings of the Tri-Service Corrosion Conference, Denver, CO, USA, 3–6 December 2007; Available online: https://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.523.4800&rep=rep1&type=pdf (accessed on 31 March 2021).

- Montes, J.M.; Cuevas, F.G.; Cintas, J. Electrical Resistivity of Metal Powder Aggregates. Metall. Mater. Trans. B 2007, 38, 957–964. [Google Scholar] [CrossRef]

- Montes, J.M.; Cuevas, F.G.; Cintas, J. Electrical resistivity of a titanium powder mass. Granul. Matter 2011, 13, 439–446. [Google Scholar] [CrossRef]

- Barroso-Bogeat, A.; Alexandre-Franco, M.; Fernández-González, C.; Macías-García, A.; Gómez-Serrano, V. Electrical conductivity of activated carbon–metal oxide nanocomposites under compression: A comparison study. Phys. Chem. Chem. Phys. 2014, 16, 25161–25175. [Google Scholar] [CrossRef]

- Hemeda, A.A.; Zhang, C.; Hu, X.Y.; Fukuda, D.; Cote, D.; Nault, I.M.; Nardi, A.; Champagne, V.K.; Ma, Y.; Palko, J.W. Particle-based simulation of cold spray: Influence of oxide layer on impact process. Addit. Manuf. 2021, 37, 101517. [Google Scholar] [CrossRef]

- Ichikawa, Y.; Tokoro, R.; Tanno, M.; Ogawa, K. Elucidation of cold-spray deposition mechanism by auger electron spectroscopic evaluation of bonding interface oxide film. Acta Mater 2019, 164, 39–49. [Google Scholar] [CrossRef]

- Decost, B.L.; Jain, H.; Rollett, A.D. Computer Vision and Machine Learning for Autonomous Characterization of AM Powder Feedstock. JOM 2017, 69, 456–465. [Google Scholar] [CrossRef]

- Sousa, B.C.; Gleason, M.A.; Haddad, B.; Champagne, V.K.; Nardi, A.T.; Cote, D.L. Nanomechanical Characterization for Cold Spray: From Feedstock to Consolidated Material Properties. Metals 2020, 10, 1195. [Google Scholar] [CrossRef]

- Silvello, A.; Cavaliere, P.D.; Albaladejo, A.; Martos, A.; Dosta, S.; Cano, I.G. Powder Properties and Processign Conditions Affecting Cold Spray Deposition. Coatings 2020, 10, 91. [Google Scholar] [CrossRef]

- Tsaknopoulos, K.; Walde, C.; Tsaknopoulos, D.; Champagne, V.; Cote, D. Characterization of Thermally Treated Gas-Atomized Al 5056 Powder. Materials 2020, 13, 4051. [Google Scholar] [CrossRef]

- Valent, R.C.; Ostapenko, A.; Sousa, B.C.; Grubbs, J.; Massar, C.J.; Cote, D.B.; Neamtu, R. Classifying Powder Flowability for Cold Spray Additive Manufacturing Using Machine Learning. In Proceedings of the 2nd International Workshop on Big Data Tools, Methods, and Use Cases for Innovative Scientific Discvery, IEEE BigData Conference, Virtual, Atlanta, GA, USA, 10–13 December 2020. [Google Scholar]

- ISO 13322-1. Particle Size Analysis–Image Analysis Methods—Part 1: Static Image Anlaysis Methods; International Standards Organization: Geneva, Switzerland, 2014. [Google Scholar]

- ASTM B527-20. Standard Test Method for Tap Density of Metal Powders and Compounds; ASTM International: West Conshohocken, PA, USA, 2020; Available online: www.astm.org (accessed on 31 March 2021).

- Story, W.A.; Brewer, L.N. Heat Treatment of Gas-Atomized Powders for Cold Spray Deposition. Metall. Mater. Trans. A 2018, 49, 446–449. [Google Scholar] [CrossRef]

- Hall, A.C.; Cook, D.J.; Neiser, R.A.; Roemer, T.J.; Hirschfeld, D.A. The effect of a simple annealing heat treatment on the mechanical properties of cold-sprayed aluminum. J. Therm Spray Technol 2006, 15, 233–238. [Google Scholar] [CrossRef]

- Sabard, A.; McNutt, P.; Begg, H.; Hussain, T. Cold spray deposition of solution heat treated, artificially aged and naturally aged Al 7075 powder. Surf. Coat. Technol. 2020, 385, 125367. [Google Scholar] [CrossRef]

| Powder | Morphology | D10(µm) | D50(µm) | D90 (µm) | Apparent Density (g/mL) | Tapped Density (g/mL) | Hausner Ratio |

|---|---|---|---|---|---|---|---|

| WIP-C1 | Agglomerate | 18.0 | 28.0 | 41.2 | 3.9 | 4.4 | 1.1 |

| WIP-C2 | Agglomerate | 19.1 | 30.7 | 45.7 | 4.0 | 4.5 | 1.1 |

| Element Concentration (wt%) | Co | Cr | Fe | Ni | W | Al | B | Mo | Si | V | C |

|---|---|---|---|---|---|---|---|---|---|---|---|

| WIP-C1 | 0.02 | 68.45 | 0.08 | 27.84 | 0.01 | 0.06 | 0.04 | 0.01 | 0.43 | 0.01 | 3.00 |

| WIP-C2 | 0.01 | 72.01 | 0.08 | 24.35 | 0.01 | 0.07 | 0.04 | 0.01 | 0.39 | 0.01 | 2.94 |

| Powder | Morphology | D10 (µm) | D50 (µm) | D90 (µm) | Apparent Density (g/mL) | Tapped Density (g/mL) | Hausner Ratio |

|---|---|---|---|---|---|---|---|

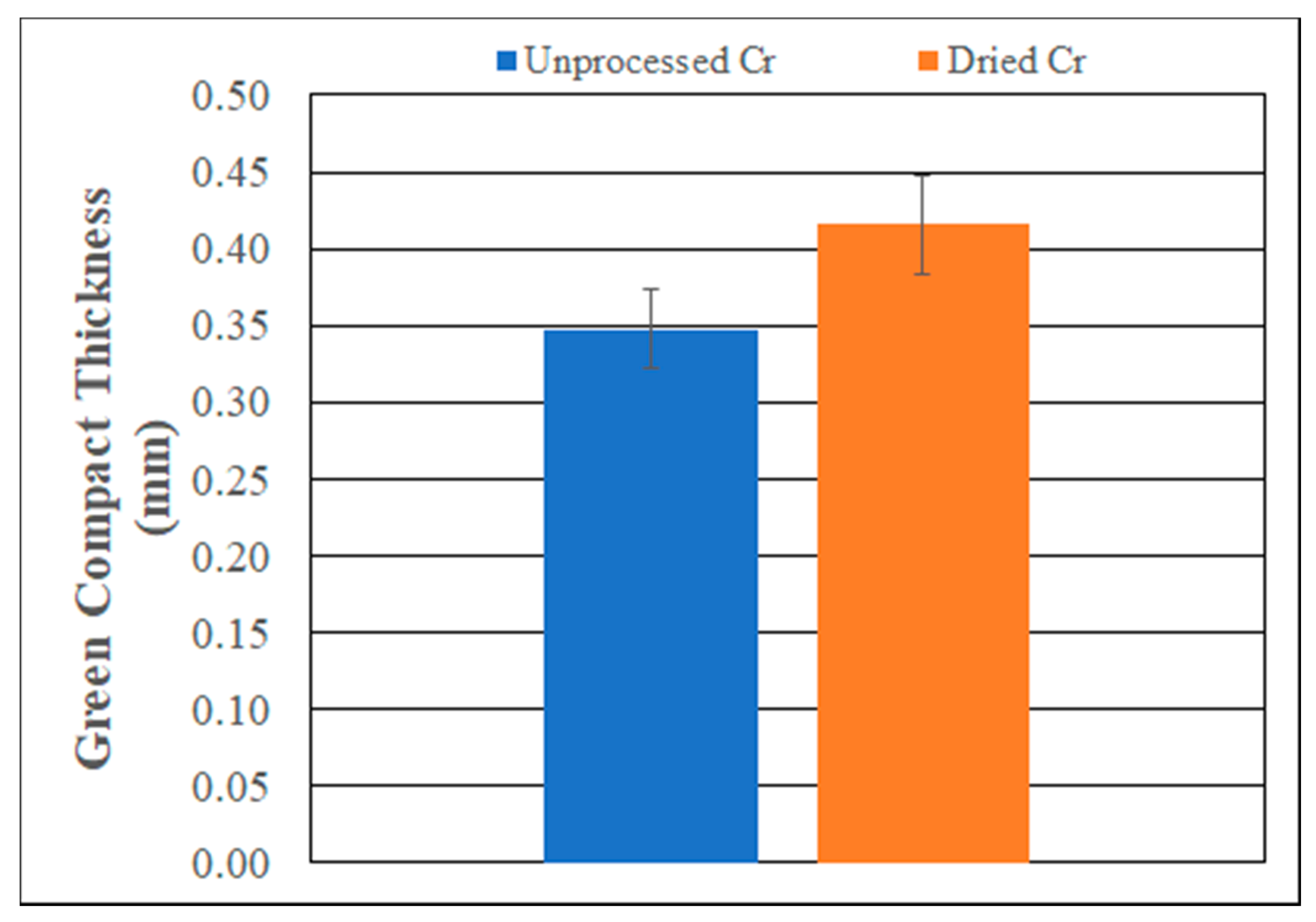

| Un-processed Chromium | Irregular | 9.8 | 16.9 | 24.0 | 2.2 | 3.2 | 1.5 |

| Dried Chromium | Irregular | 9.6 | 16.3 | 23.4 | 2.5 | 3.4 | 1.3 |

| Element | Cr | O | N | Si | C | Ni | Other |

|---|---|---|---|---|---|---|---|

| Concentration (ppm) | Bal | 1900 | 310 | 180 | 62 | 19 | <2115 |

| Powder | Morphology | D10 (µm) | D50 (µm) | D90 (µm) | Apparent Density (g/mL) | Tapped Density (g/mL) | Hausner Ratio |

|---|---|---|---|---|---|---|---|

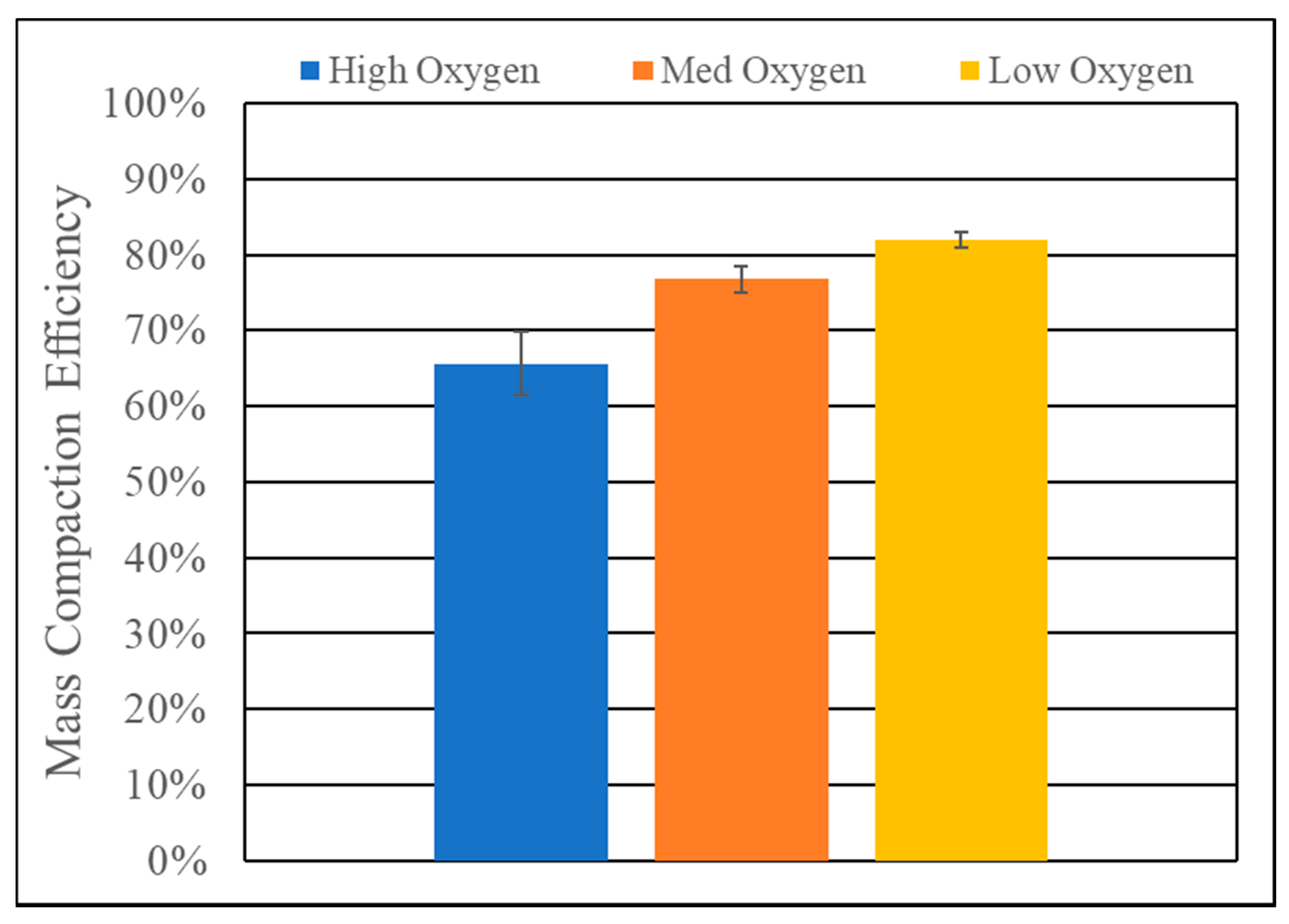

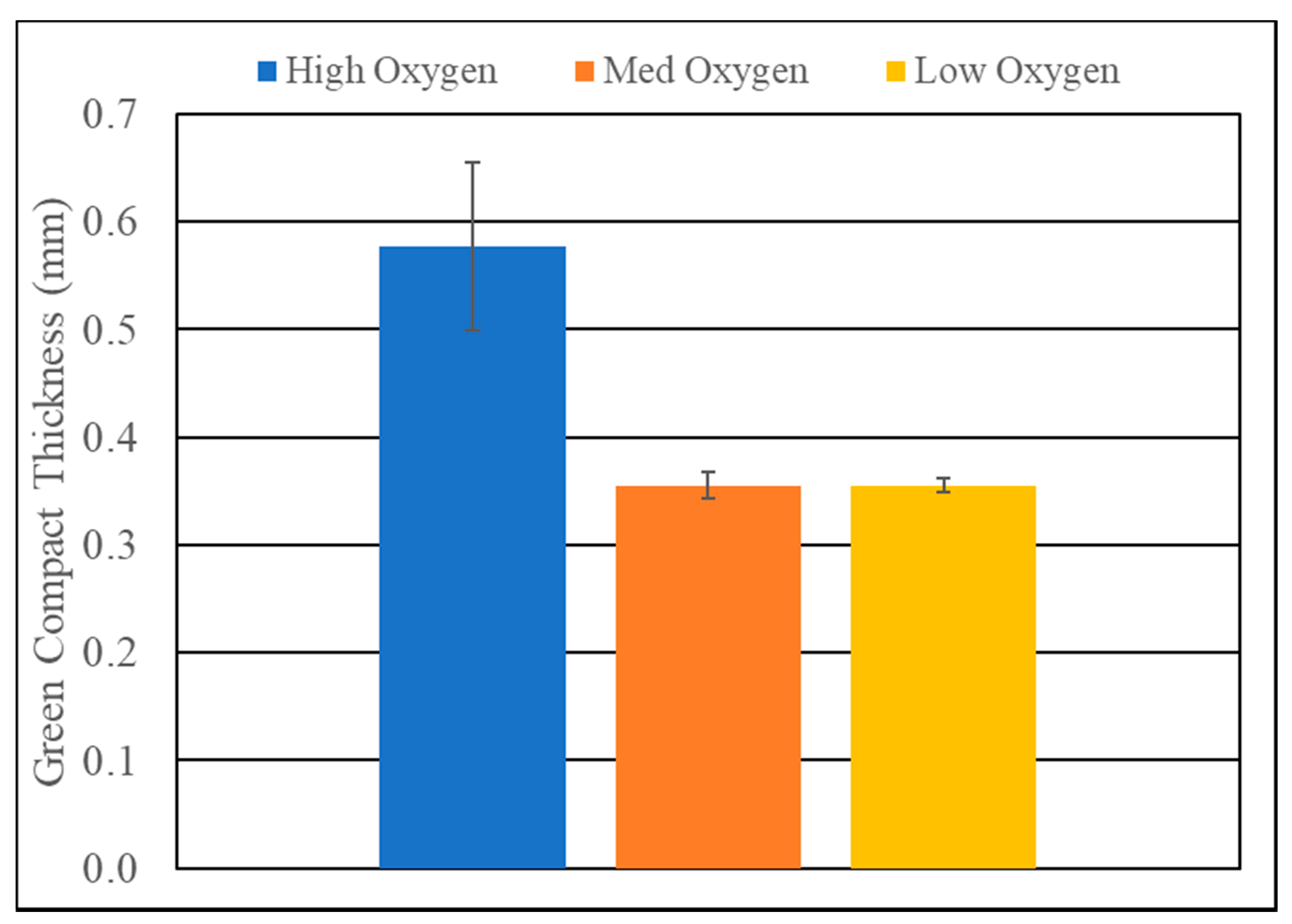

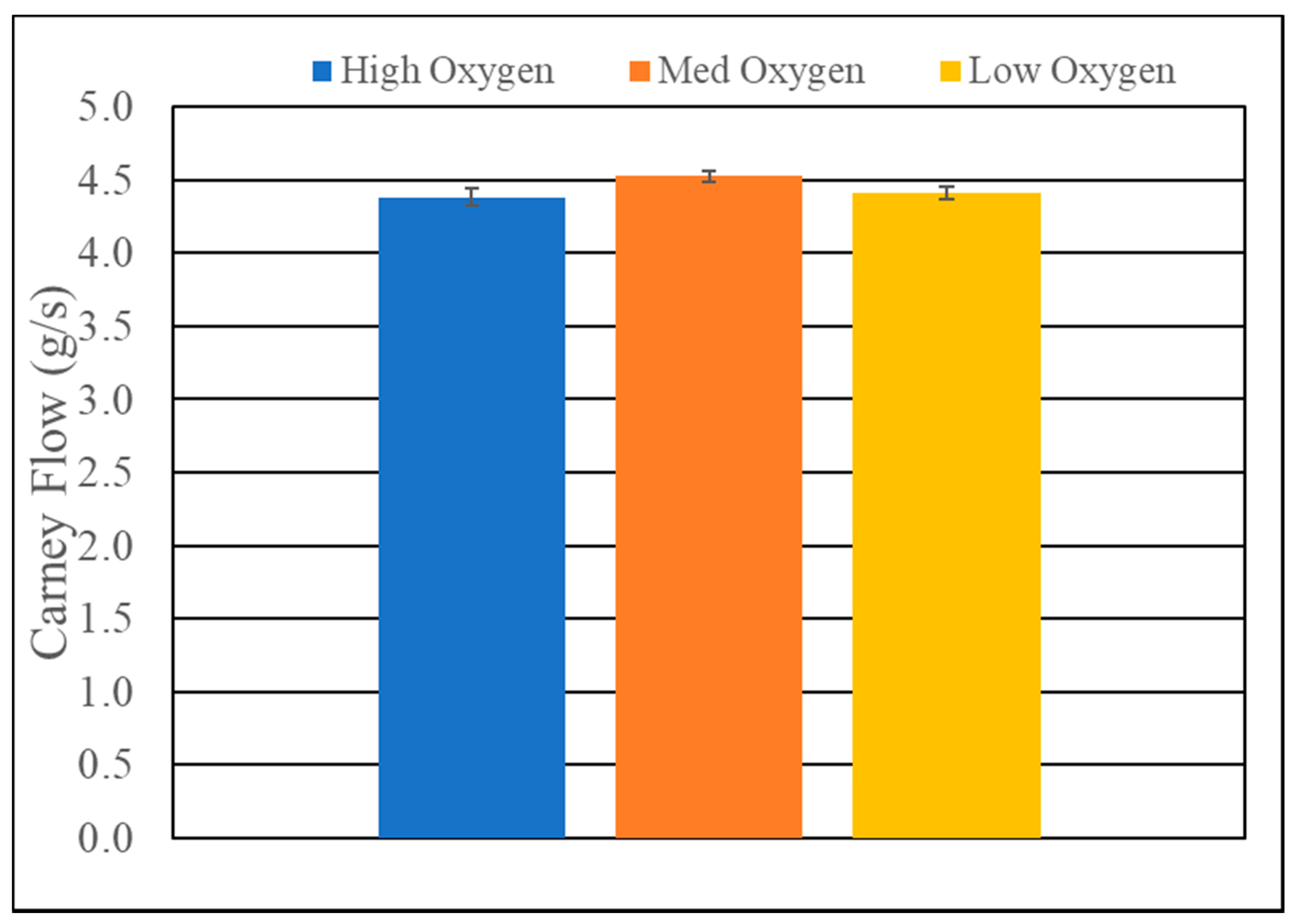

| High O 6061 | Spherical | 23.0 | 34.6 | 53.8 | 1.3 | 1.6 | 1.2 |

| Med O 6061 | Spherical | 23.0 | 34.3 | 54.2 | 1.3 | 1.6 | 1.2 |

| Low O 6061 | Spherical | 22.8 | 33.9 | 55.5 | 1.3 | 1.6 | 1.2 |

| Element | Cr | Cu | Fe | Mg | Mn | Si | Ti | Zn | Other | Al |

|---|---|---|---|---|---|---|---|---|---|---|

| Concentration (wt%) | 0.11 | 0.28 | 0.11 | 0.98 | 0.0043 | 0.61 | 0.01 | 0.014 | <0.20 | Bal |

| Powder | D50 µm) | D50 % dif. | Apparent Density (g/mL) | Apparent Density % dif. | Tapped Density (g/mL) | Tapped Density % dif. | Carney Flow (g/s) | Carney Flow % dif. |

|---|---|---|---|---|---|---|---|---|

| WIP-C1 | 28.0 | 3.93 | 4.40 | 17.3 | ||||

| 2.3% | 0.2% | 0.4% | 1.1% | |||||

| WIP-C2 | 30.7 | 3.96 | 4.47 | 18.1 |

| Powder | Standard Carney Flow Rate (g/s) | Standard Hall Flow Rate (g/s) | Vibrated Hall Flow Rate (g/s) |

|---|---|---|---|

| As-Received Cr | NF | NF | NF |

| Dried Cr | NF | NF | 0.07 g/s |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Young, B.; Heelan, J.; Langan, S.; Siopis, M.; Walde, C.; Birt, A. Novel Characterization Techniques for Additive Manufacturing Powder Feedstock. Metals 2021, 11, 720. https://doi.org/10.3390/met11050720

Young B, Heelan J, Langan S, Siopis M, Walde C, Birt A. Novel Characterization Techniques for Additive Manufacturing Powder Feedstock. Metals. 2021; 11(5):720. https://doi.org/10.3390/met11050720

Chicago/Turabian StyleYoung, Benjamin, Joseph Heelan, Sean Langan, Matthew Siopis, Caitlin Walde, and Aaron Birt. 2021. "Novel Characterization Techniques for Additive Manufacturing Powder Feedstock" Metals 11, no. 5: 720. https://doi.org/10.3390/met11050720

APA StyleYoung, B., Heelan, J., Langan, S., Siopis, M., Walde, C., & Birt, A. (2021). Novel Characterization Techniques for Additive Manufacturing Powder Feedstock. Metals, 11(5), 720. https://doi.org/10.3390/met11050720