Quantitative Research on the Effect of Natural Aging on the Mechanical Properties and Bake Hardening Properties of AA6014 Alloy within Six Months

Abstract

1. Introduction

2. Materials and Methods

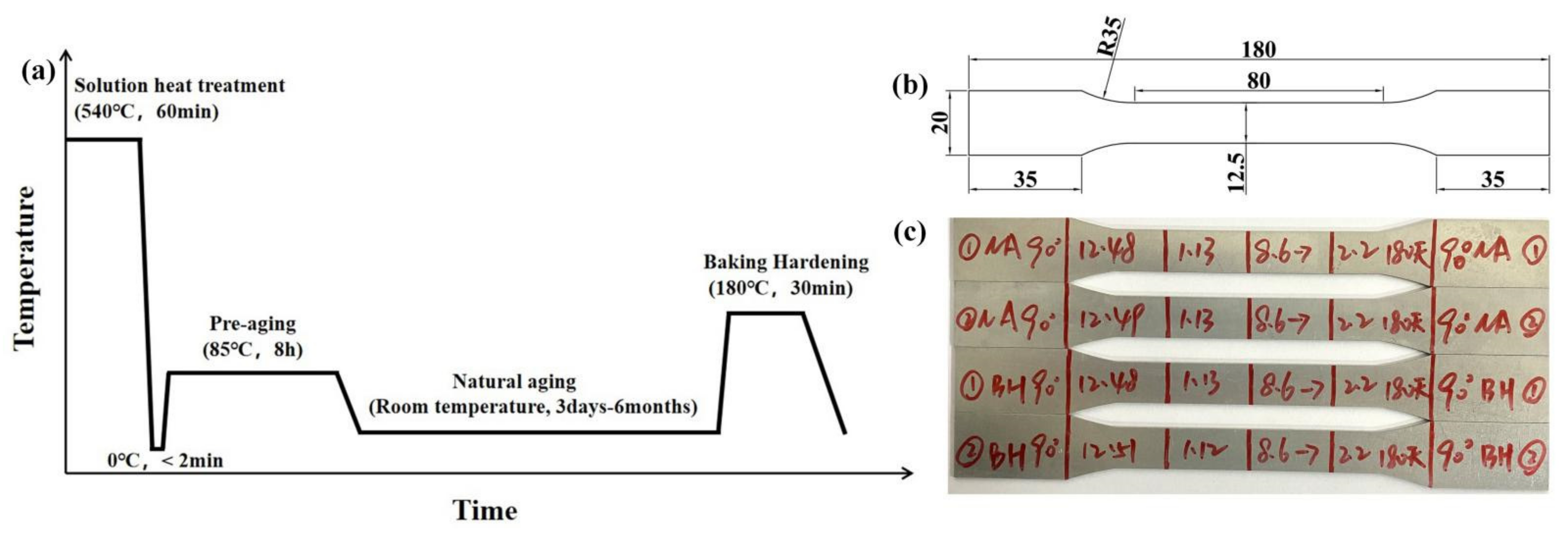

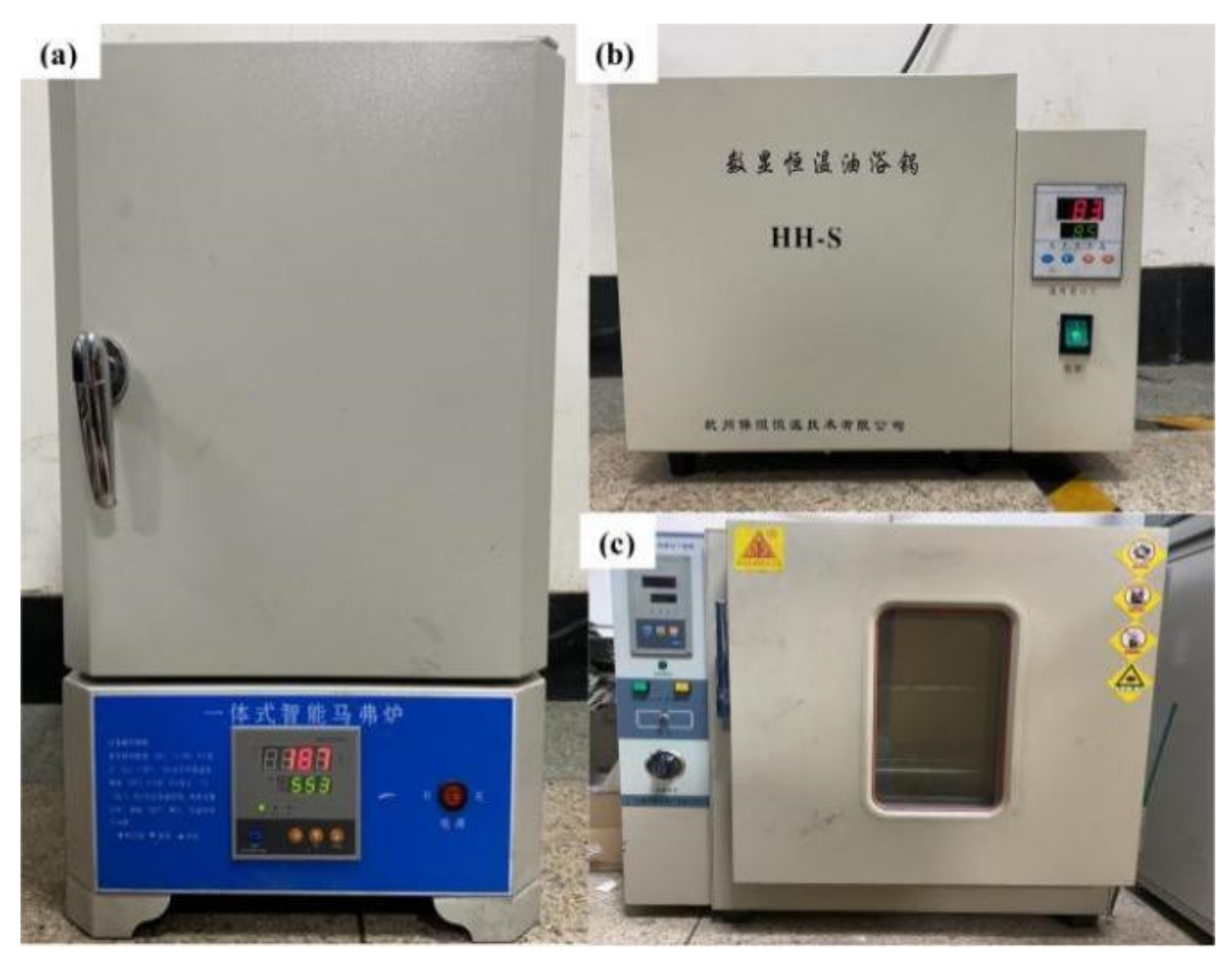

2.1. Heat Treatment Process

2.2. Experiments

3. Results

3.1. The Changes of Mechanical Properties during Six Months of NA

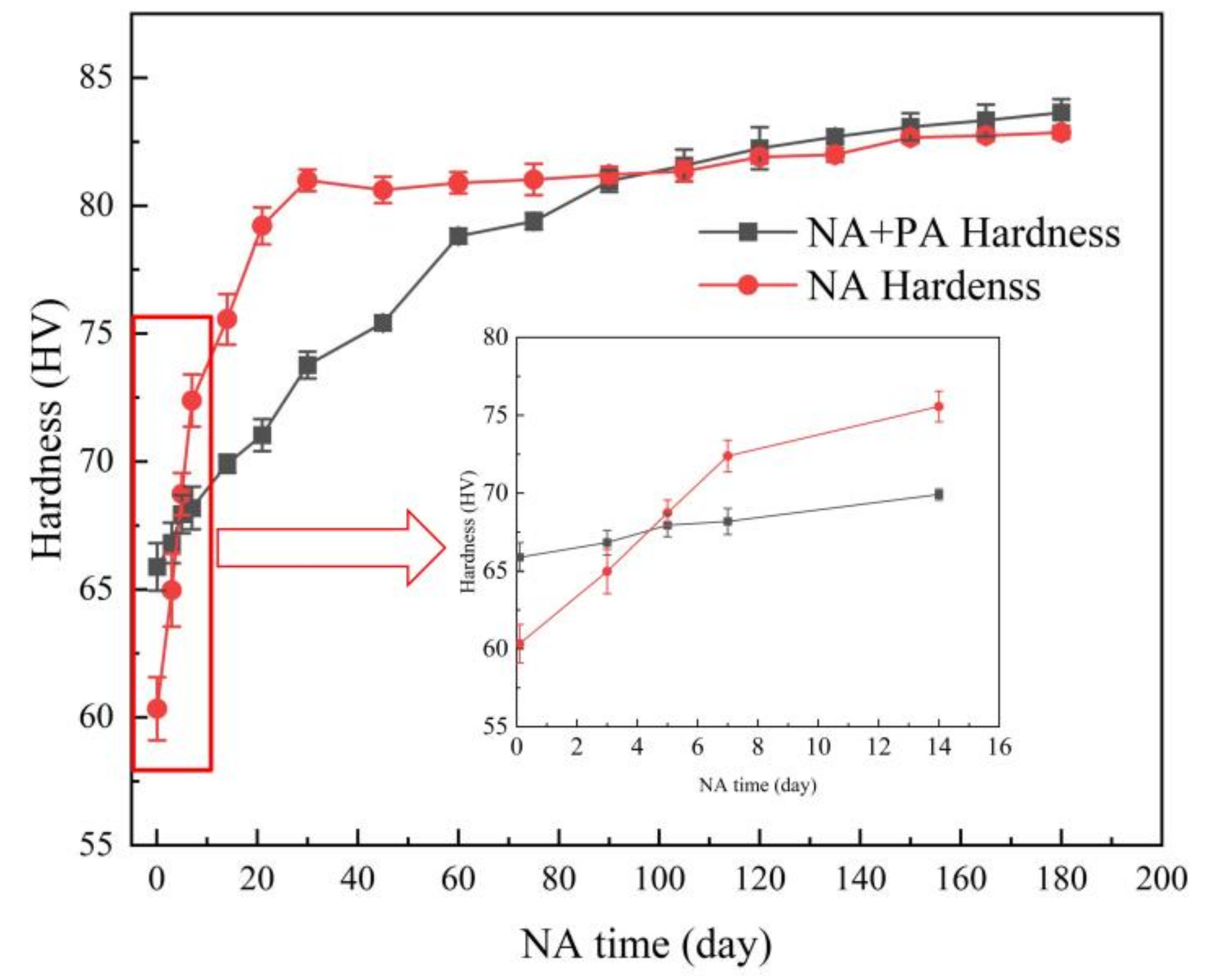

3.1.1. Hardness

3.1.2. Tensile Tests at Room Temperature

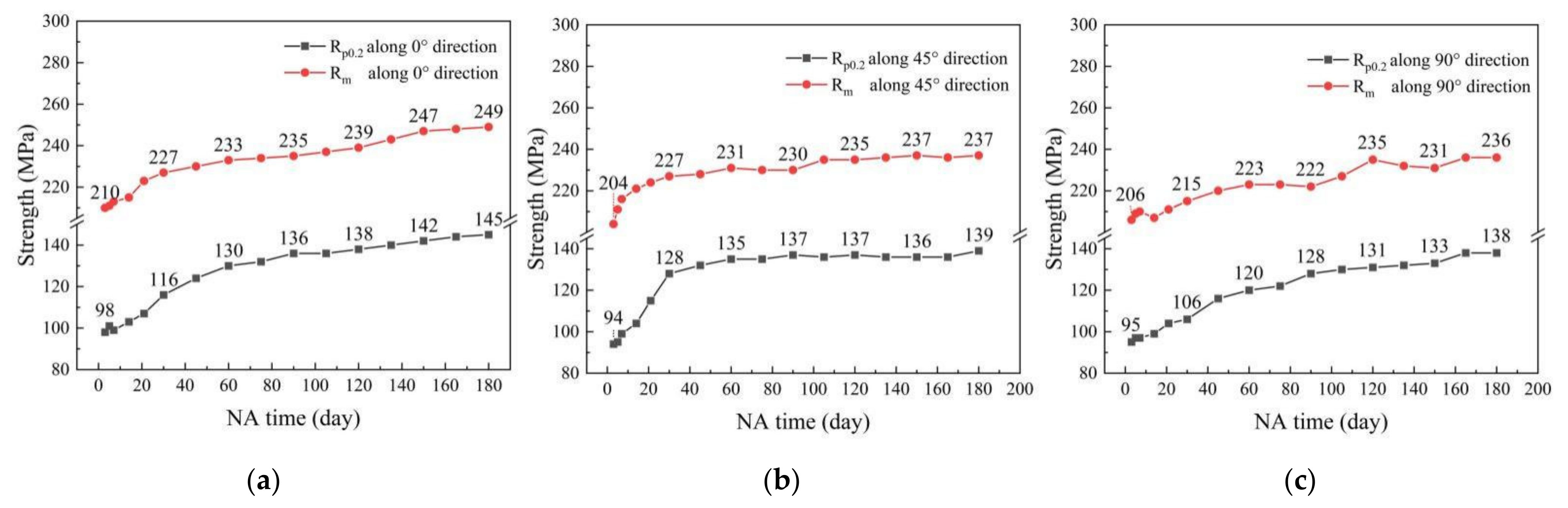

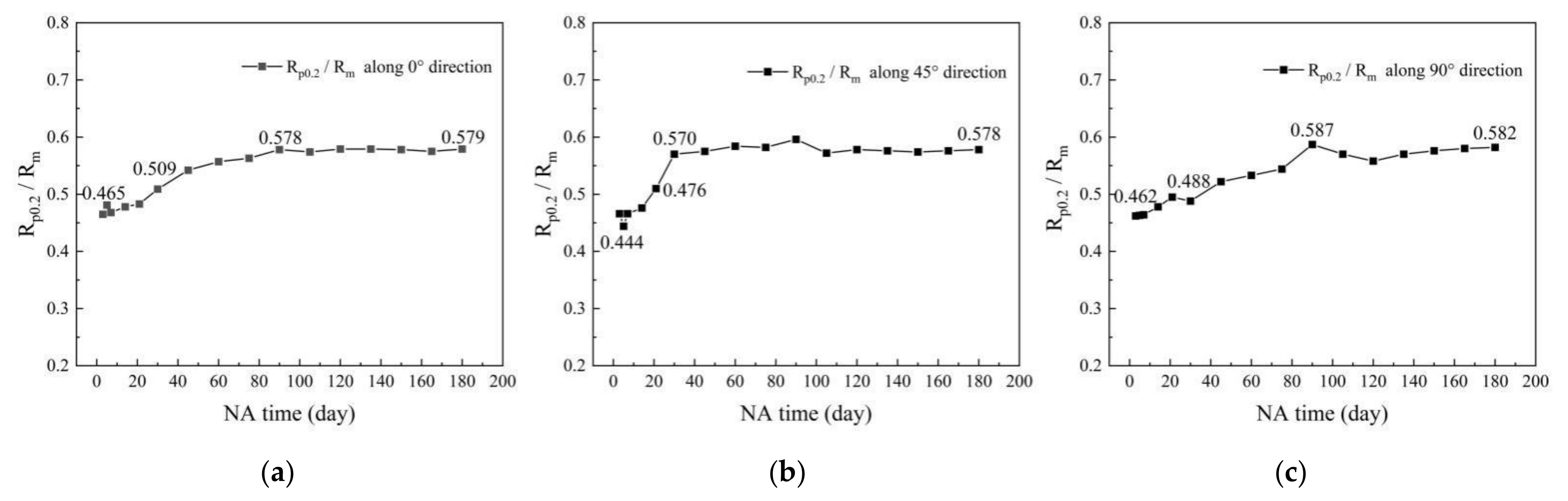

3.1.3. The Changes of Rp0.2, Rm, and Rp0.2/Rm during Six Months of NA along 0°, 45°, and 90° Directions

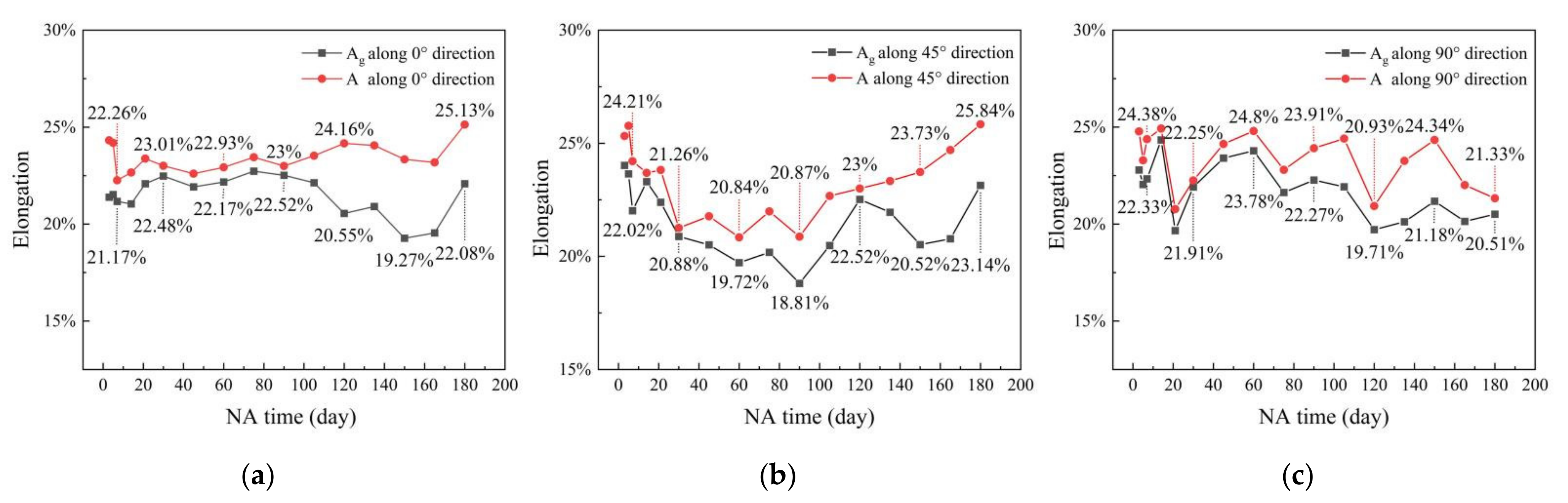

3.1.4. The Changes of Ag and A during Six Months of NA along 0, 45, and 90° Directions

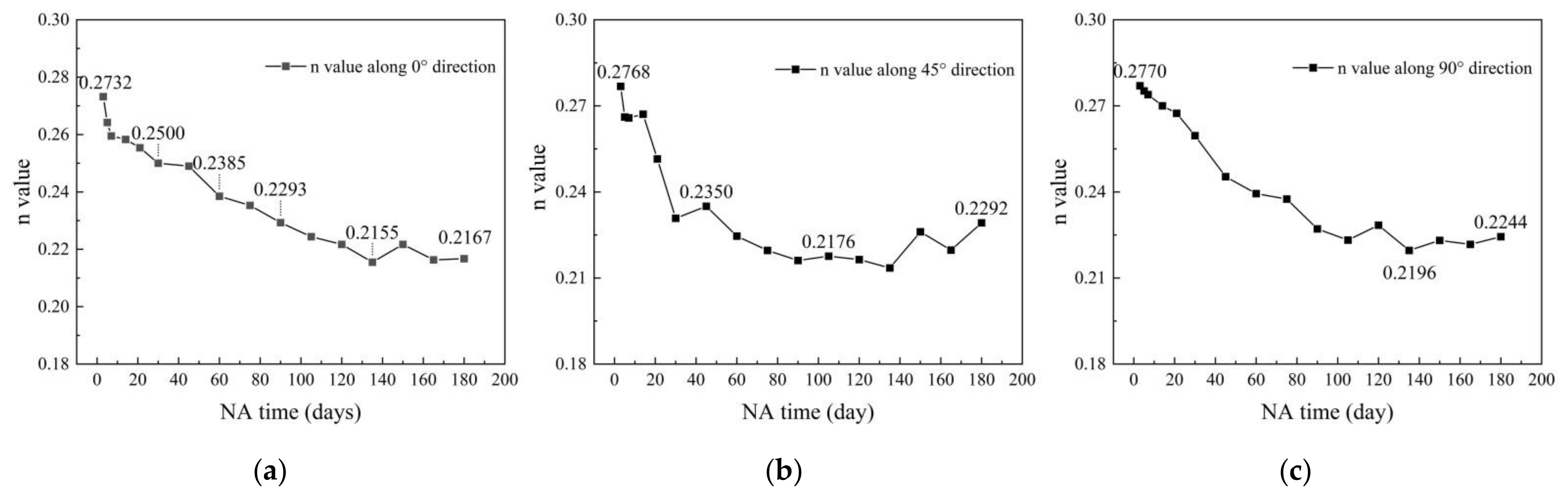

3.1.5. The Changes of n Value during Six Months of NA along 0°, 45°, and 90° Directions

3.2. The Changes of Bake Hardening Properties during Six Months of NA

3.2.1. Tensile Tests at Room Temperature after Bake Hardening

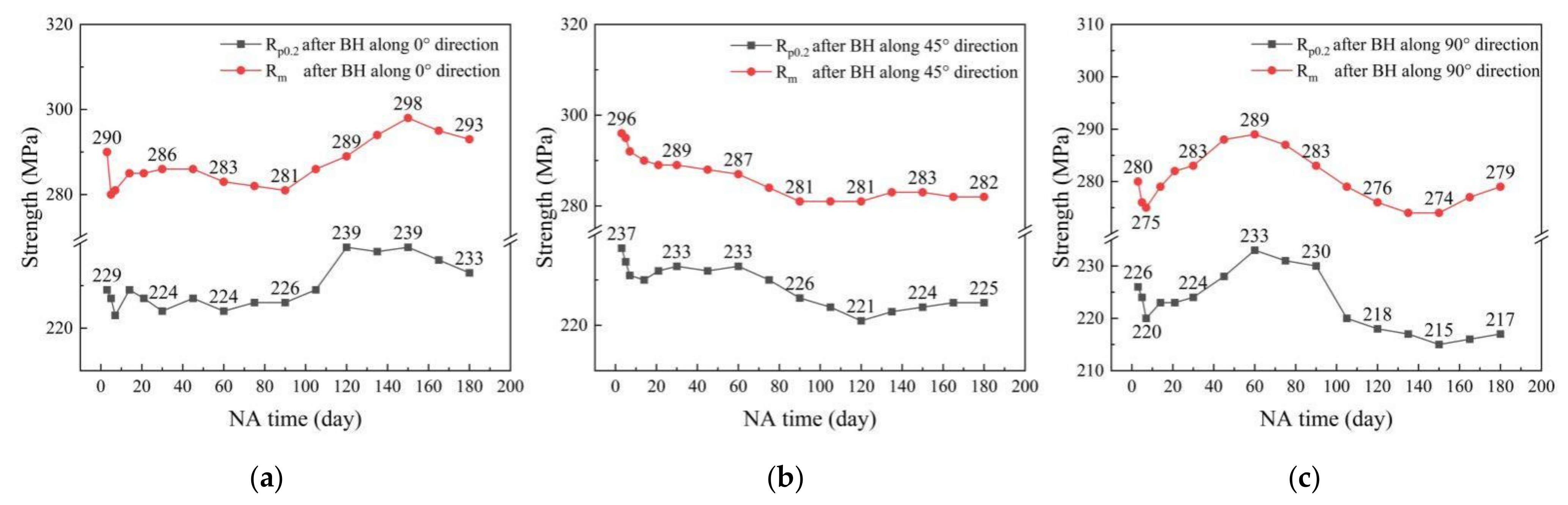

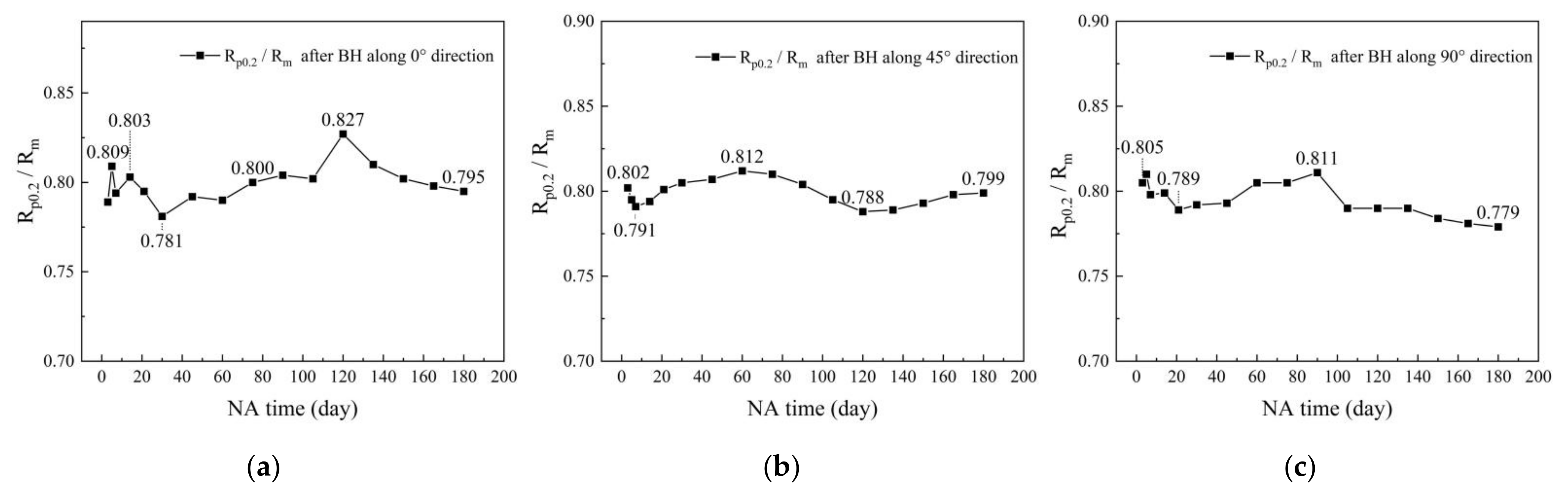

3.2.2. The Changes of Rp0.2, Rm and Rp0.2/Rm after Bake Hardening along 0, 45, and 90° Directions

3.2.3. The Changes of Rp0.2 Increment and Rm Increment after Bake Hardening along 0, 45, and 90° Directions

3.2.4. The Changes of Ag and A after Bake Hardening along 0, 45, and 90° Directions

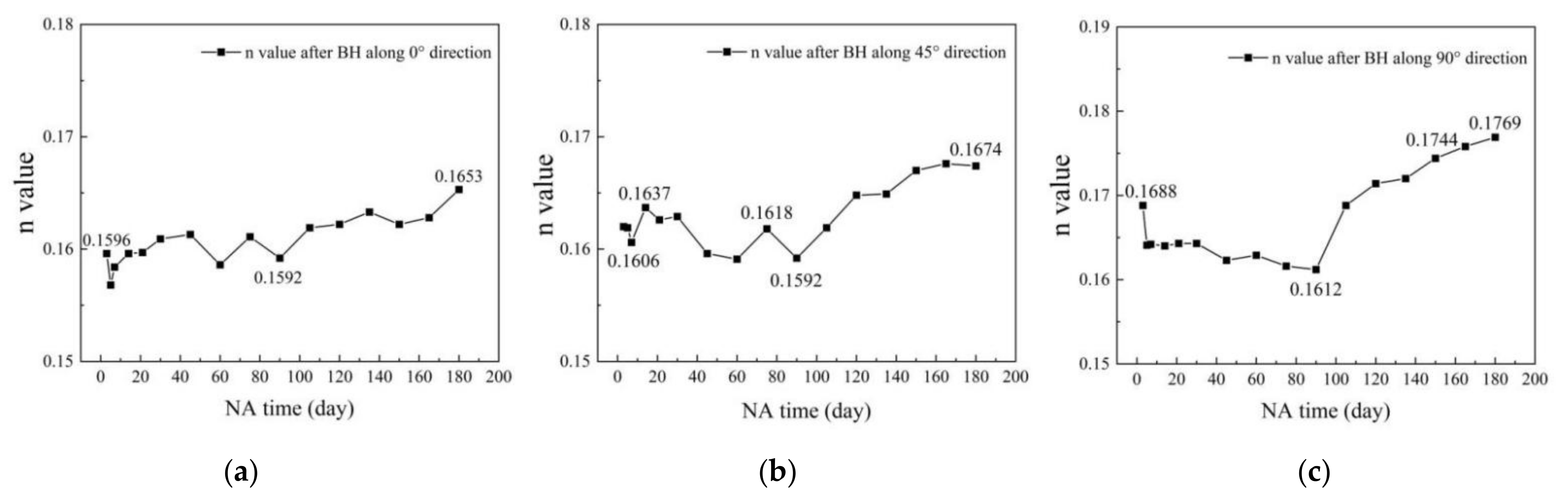

3.2.5. The Changes of n Value after Bake Hardening along 0, 45, and 90° Directions

4. Discussion

4.1. Formula Fitting for the Change of Rp0.2 during the NA Process

| Trinomial polynomial | |

| HILL1 Formula | |

| WeibullCDF Formula |

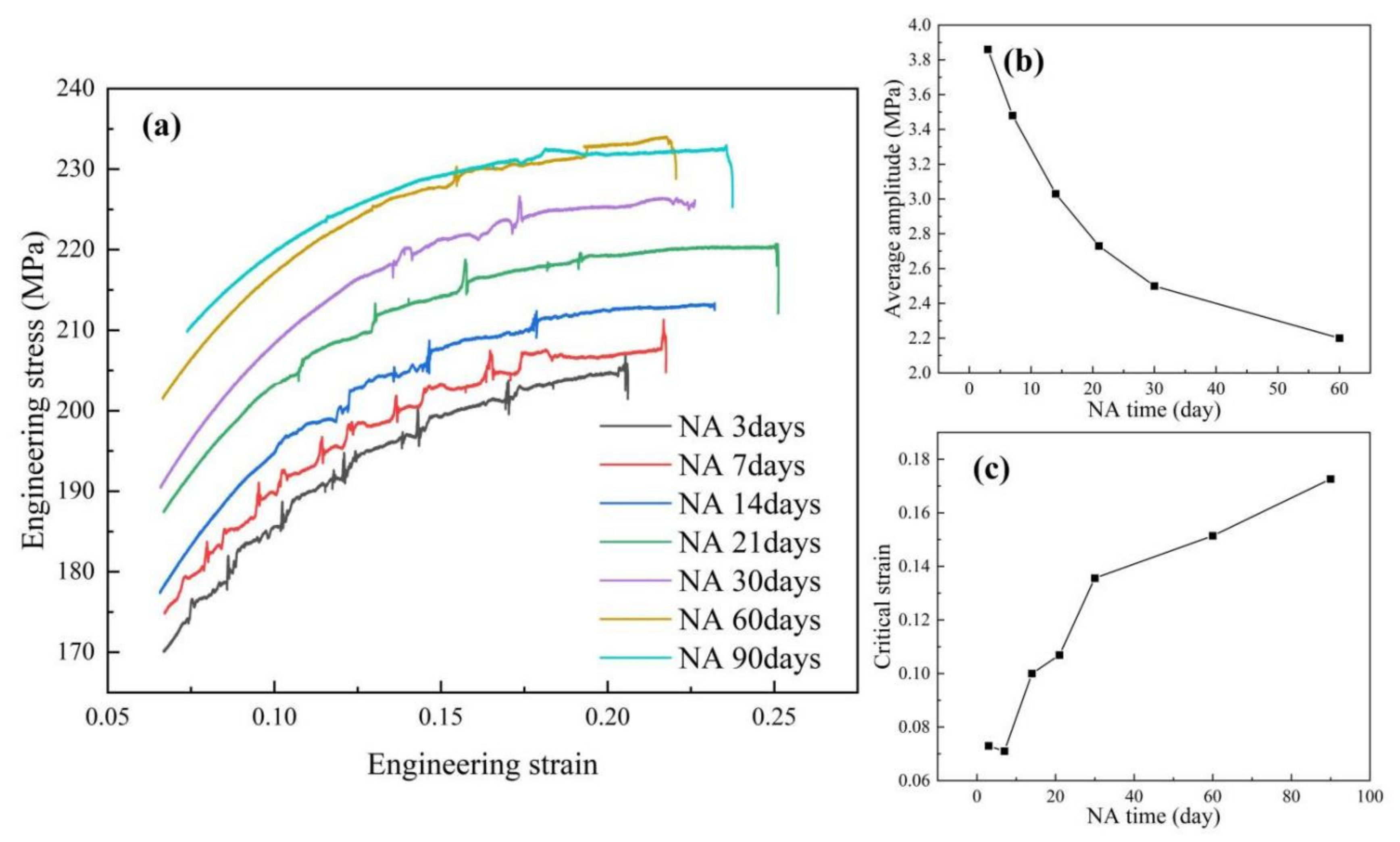

4.2. The PLC Phenomenon during the NA Process

5. Conclusions

- (1)

- With the extension of NA, Rp0.2 and Rm along the three directions all change significantly and the percentage of increase is about ~46% and ~16%, respectively. Different lengths of NA time before bake hardening have a great impact on the Rp0.2 increment and Rm increment. Along 0, 45, and 90° directions, from 3 to 180 days, the Rp0.2 increment, respectively, decreased from 130 to 87 MPa, from 144 to 85 MPa, and from 131 to 78 MPa, while the Rm increment, respectively, decreased from from 80 to 44 MPa, from 92 to 45 MPa, and from 75 to 43 MPa.

- (2)

- The trends of Rp0.2 and Rm obtained by bake hardening are fluctuating and not consistent along the three directions. This is not only related to the transformation and dissolution of precipitates but also related to the texture change caused by bake hardening, which is worth further study.

- (3)

- Ag and A will not decrease significantly with the extension of NA but fluctuate within a specific range regardless of the directions or whether undergoing bake hardening. Ag remains above 18% during the six-month NA, and the average value is ~21%. A remains above 20%, and the average value is ~23%. Bake hardening will reduce elongation by ~ 7%, which is not only due to the increase in strength but also due to the decrease in the n value. The engineering strain of AA6014 alloy from necking to fracture after bake hardening is ~2.3%.

- (4)

- During the process of NA, the n value shows a downward trend, decreasing from 0.28 to 0.21. However, after bake hardening treatment, with the extension of the NA time experienced before bake hardening, the n value keeps almost unchanged during the first three months of NA and then gradually shows an upward trend. Among the three directions, the n value along 90° direction is the largest regardless of bake hardening.

- (5)

- The microstructure of AA6014 alloy at room temperature tends to be stable after 90 days of NA, which is proved by the almost disappearing PLC effect and almost constant Rp0.2.

Author Contributions

Funding

Conflicts of Interest

References

- Tisza, M.; Czinege, I. Comparative study of the application of steels and aluminium in lightweight production of automotive parts. Int. J. Lightweight Mater. Manuf. 2018, 1, 229–238. [Google Scholar] [CrossRef]

- Li, H.; Yan, Z.; Cao, L. Bake Hardening Behavior and Precipitation Kinetic of a Novel Al-Mg-Si-Cu Alu-minum Alloy for Lightweight Automotive Body. Mater. Sci. Eng. A 2018, 728, 88–94. [Google Scholar] [CrossRef]

- Gao, G.; Li, Y.; Wang, Z.; Di, H.; Li, J.; Xu, G. Effects of the Quenching Rate on the Microstructure, Mechanical Properties and Paint Bake-Hardening Response of Al–Mg–Si Automotive Sheets. Materials 2019, 12, 3587. [Google Scholar] [CrossRef] [PubMed]

- Gao, G.J.; Li, Y.; Wang, Z.D.; Misra, R.D.K.; Di, H.S.; Li, J.D.; Xu, G.M. Interaction between Natural Aging and Pre-Aging Processes and its Impact on the Age-Hardening Behavior of Al-Mg-Si Automotive Sheets. JOM 2019, 71, 4405–4413. [Google Scholar] [CrossRef]

- Fallah, V.; Langelier, B.; Ofori-Opoku, N.; Raeisinia, B.; Provatas, N.; Esmaeili, S. Cluster Evo-lution Mechanisms During Aging in Al–Mg–Si Alloys. Acta Mater. 2016, 103, 290–300. [Google Scholar] [CrossRef]

- Cao, L.; Rometsch, P.A.; Couper, M.J. Clustering Behaviour in an Al–Mg–Si–Cu Alloy During Natural Ageing and Subsequent under-Ageing. Mater. Sci. Eng. A 2013, 559, 257–261. [Google Scholar] [CrossRef]

- Ines, H.; Boumerzoug, Z.; Chabane, F. Study of Precipitation Kinetics of an Al-Mg-Si Alloy Using Differ-ential Scanning Calorimetry. Acta Metall. Slovaca 2017, 23, 155–160. [Google Scholar]

- Banhart, J.; Chang, C.S.T.; Liang, Z.; Wanderka, N.; Lay, M.D.H.; Hill, A.J. Natural Aging in Al-Mg-Si Alloys—A Process of Unexpected Complexity. Adv. Eng. Mater. 2010, 12, 559–571. [Google Scholar] [CrossRef]

- Edwards, G.A.; Stiller, K.; Dunlop, G.L.; Couper, M.J. The Precipitation Sequence in Al–Mg–Si Alloys. Acta Mater. 1998, 46, 3893–3904. [Google Scholar] [CrossRef]

- Murayama, M.; Hono, K. Pre-Precipitate Clusters and Precipitation Processes in Al–Mg–Si Alloys. Acta Mater. 1999, 47, 1537–1548. [Google Scholar] [CrossRef]

- Buha, J.; Lumley, R.N.; Crosky, A.G.; Hono, K. Secondary Precipitation in an Al–Mg–Si–Cu Alloy. Acta Mater. 2007, 55, 3015–3024. [Google Scholar] [CrossRef]

- Jin, S.; Ngai, T.; Zhang, G.; Zhai, T.; Jia, S.; Li, L. Precipitation strengthening mechanisms during natural ageing and subsequent artificial aging in an Al-Mg-Si-Cu alloy. Mater. Sci. Eng. A 2018, 724, 53–59. [Google Scholar] [CrossRef]

- Liu, C.H.; Lai, Y.X.; Chen, J.H.; Tao, G.H.; Liu, L.M.; Ma, P.P.; Wu, C.L. Natural-Aging-Induced Reversal of the Pre-cipitation Pathways in an Al–Mg–Si Alloy. Scr. Mater. 2016, 115, 150–154. [Google Scholar] [CrossRef]

- Aruga, Y.; Kozuka, M.; Takaki, Y.; Sato, T. Effects of natural aging after pre-aging on clustering and bake-hardening behavior in an Al–Mg–Si alloy. Scr. Mater. 2016, 116, 82–86. [Google Scholar] [CrossRef]

- Zi, Y.; Zeqin, L.; Leyvraz, D.; Banhart, J. Effect of pre-ageing on natural secondary ageing and paint bake hardening in Al–Mg–Si alloys. Materialia 2019, 7, 100413. [Google Scholar] [CrossRef]

- Yang, Z.; Liang, Z.; Leyvraz, D.; Banhart, J. Hardness data related to pre-ageing, natural secondary ageing, and paint bake hardening in Al-Mg-Si alloys. Data Brief 2019, 27, 104494. [Google Scholar] [CrossRef]

- Takaki, Y.; Masuda, T.; Kobayashi, E.; Sato, T. Effects of Natural Aging on Bake Hardening Behavior of Al–Mg–Si Alloys with Multi-Step Aging Process. Mater. Trans. 2014, 55, 1257–1265. [Google Scholar] [CrossRef]

- Yang, S.L.; Fu, S.H.; Cai, Y.L.; Zhang, D.; Zhang, Q.C. Experimental Investigation on the Influence of Mg Content on Portevin-Le Chatelier Effect in Al-Based Alloys by Using Digital Image Correlation. Acta Phys. Sin. 2017, 66, 100233. [Google Scholar]

- Cai, Y.; Yang, S.; Fu, S.; Zhang, D.; Zhang, Q. Investigation of Portevin–Le Chatelier Band Strain and Elastic Shrinkage in Al-Based Alloys Associated with Mg Contents. J. Mater. Sci. Technol. 2017, 33, 580–586. [Google Scholar] [CrossRef]

- Pogatscher, S.; Antrekowitsch, H.; Leitner, H.; Ebner, T.; Uggowitzer, P.J. Mechanisms Controlling the Artificial Aging of Al–Mg–Si Alloys. Acta Mater. 2011, 59, 3352–3363. [Google Scholar] [CrossRef]

- Starink, M.; Cao, L.; Rometsch, P. A model for the thermodynamics of and strengthening due to co-clusters in Al–Mg–Si-based alloys. Acta Mater. 2012, 60, 4194–4207. [Google Scholar] [CrossRef]

- Serizawa, A.; Hirosawa, S.; Sato, T. Three-Dimensional Atom Probe Characterization of Nanoclusters Responsible for Multistep Aging Behavior of an Al-Mg-Si Alloy. Met. Mater. Trans. A 2008, 39, 243–251. [Google Scholar] [CrossRef]

- Werinos, M.; Antrekowitsch, H.; Ebner, T.; Prillhofer, R.; Uggowitzer, P.J.; Pogatscher, S. Hardening of Al–Mg–Si Alloys: Effect of Trace Elements and Prolonged Natural Aging. Mater. Des. 2016, 107, 257–268. [Google Scholar] [CrossRef]

- Marioara, C.D.; Andersen, S.J.; Jansen, J.; Zandbergen, H.W. The Influence of Temperature and Storage Time at Rt on Nucleation of the Β″ Phase in a 6082 Al–Mg–Si Alloy. Acta Mater. 2003, 51, 789–796. [Google Scholar] [CrossRef]

- Yin, D.; Xiao, Q.; Chen, Y.; Liu, H.; Yi, D.; Wang, B.; Pan, S. Effect of natural ageing and pre-straining on the hardening behaviour and microstructural response during artificial ageing of an Al–Mg–Si–Cu alloy. Mater. Des. 2016, 95, 329–339. [Google Scholar] [CrossRef]

| Element | Mg | Si | Fe | Cu | Mn | Ti | Zn | Cr | Al |

|---|---|---|---|---|---|---|---|---|---|

| wt% | 0.65 | 0.59 | 0.22 | 0.12 | 0.08 | 0.03 | 0.01 | 0.01 | Bal. |

| Data Description | Effect of NA on Mechanical Properties | Effect of NA on Bake Hardening Properties | ||

|---|---|---|---|---|

| Sample 1 | Sample 2 | Sample 1 | Sample 2 | |

| Rp0.2/MPa | Rp0.2-NA-1 | Rp0.2-NA-2 | Rp0.2-NA-3Rp0.2-BH-1 | Rp0.2-NA-4Rp0.2-BH-2 |

| Rm/MPa | Rm-NA-1 | Rm-NA-2 | Rm-BH-1 | Rm-BH-2 |

| Ag/% | Ag-NA-1 | Ag-NA-2 | Ag-BH-1 | Ag-BH-2 |

| A/% | A-NA-1 | A-NA-2 | A-BH-1 | A-BH-2 |

| n value | n10%~Ag--NA-1 | n10%~Ag--NA-2 | n5%~Ag--BH-1 | n5%~Ag--BH-2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gu, Z.; Han, Y.; Tang, Z.; Yi, L.; Yu, G. Quantitative Research on the Effect of Natural Aging on the Mechanical Properties and Bake Hardening Properties of AA6014 Alloy within Six Months. Metals 2021, 11, 673. https://doi.org/10.3390/met11040673

Gu Z, Han Y, Tang Z, Yi L, Yu G. Quantitative Research on the Effect of Natural Aging on the Mechanical Properties and Bake Hardening Properties of AA6014 Alloy within Six Months. Metals. 2021; 11(4):673. https://doi.org/10.3390/met11040673

Chicago/Turabian StyleGu, Zhengwei, Yuting Han, Ziming Tang, Lingling Yi, and Ge Yu. 2021. "Quantitative Research on the Effect of Natural Aging on the Mechanical Properties and Bake Hardening Properties of AA6014 Alloy within Six Months" Metals 11, no. 4: 673. https://doi.org/10.3390/met11040673

APA StyleGu, Z., Han, Y., Tang, Z., Yi, L., & Yu, G. (2021). Quantitative Research on the Effect of Natural Aging on the Mechanical Properties and Bake Hardening Properties of AA6014 Alloy within Six Months. Metals, 11(4), 673. https://doi.org/10.3390/met11040673