Multiphysics Modelling of Ultrasonic Melt Treatment in the Hot-Top and Launder during Direct-Chill Casting: Path to Indirect Microstructure Simulation

Abstract

1. Introduction

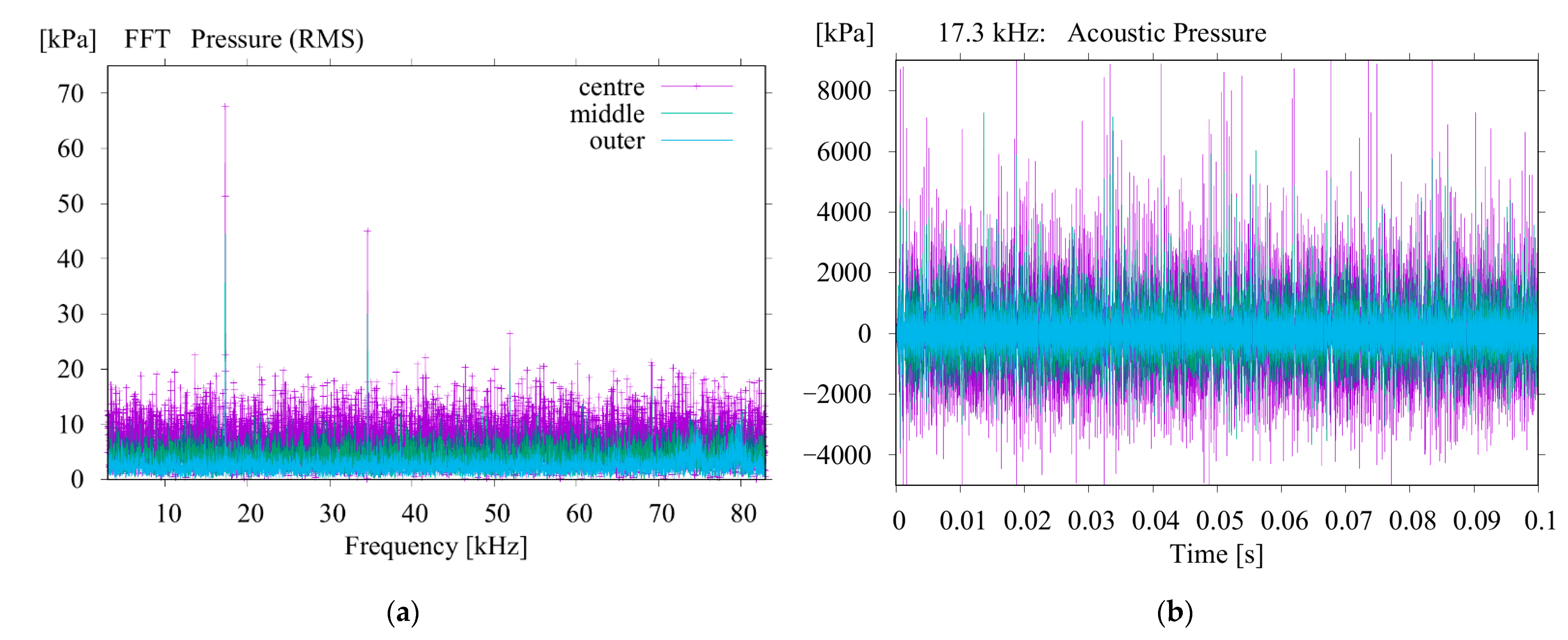

2. Experimental Setup

3. Numerical Methods

4. Results

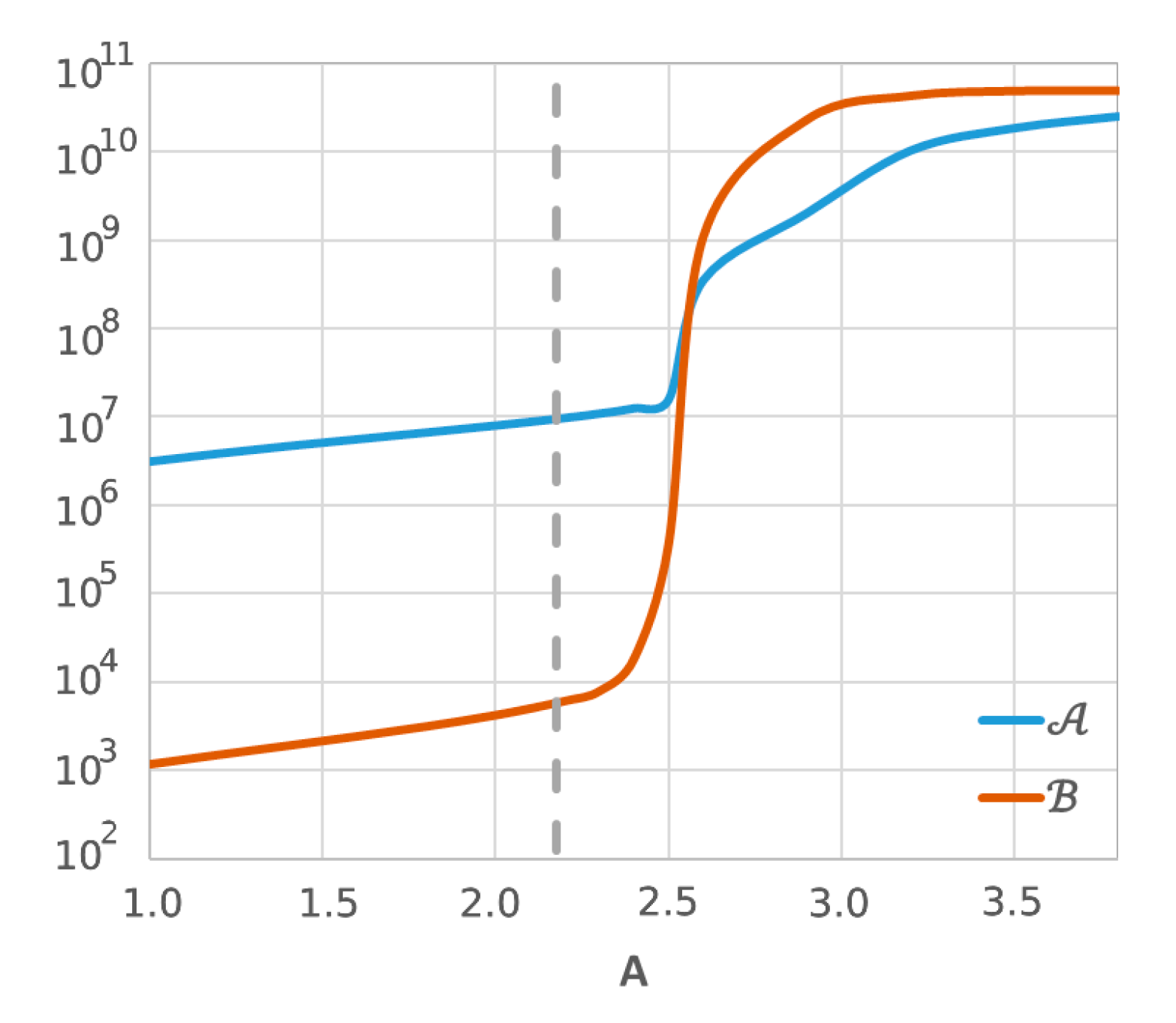

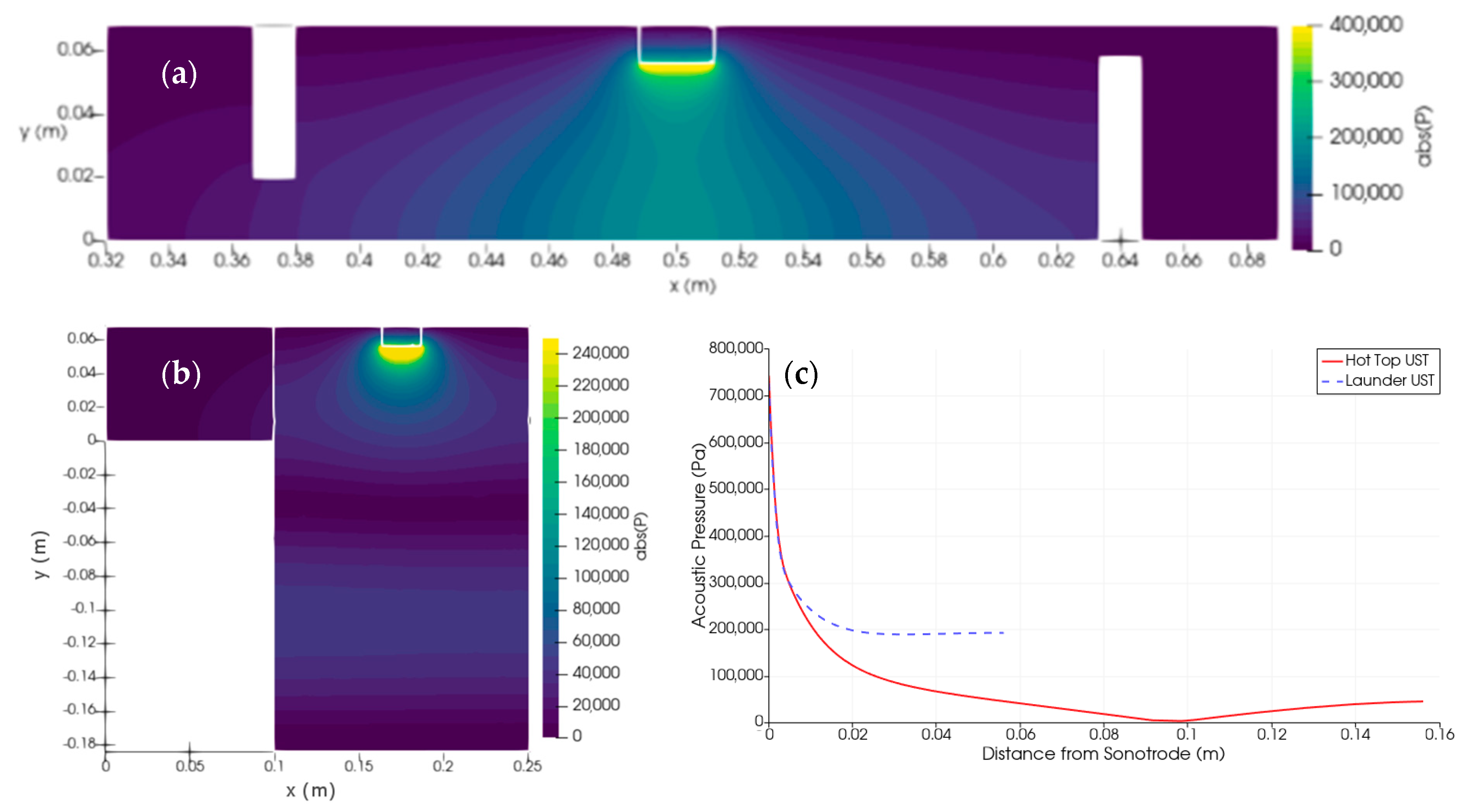

4.1. Bubble Simulation

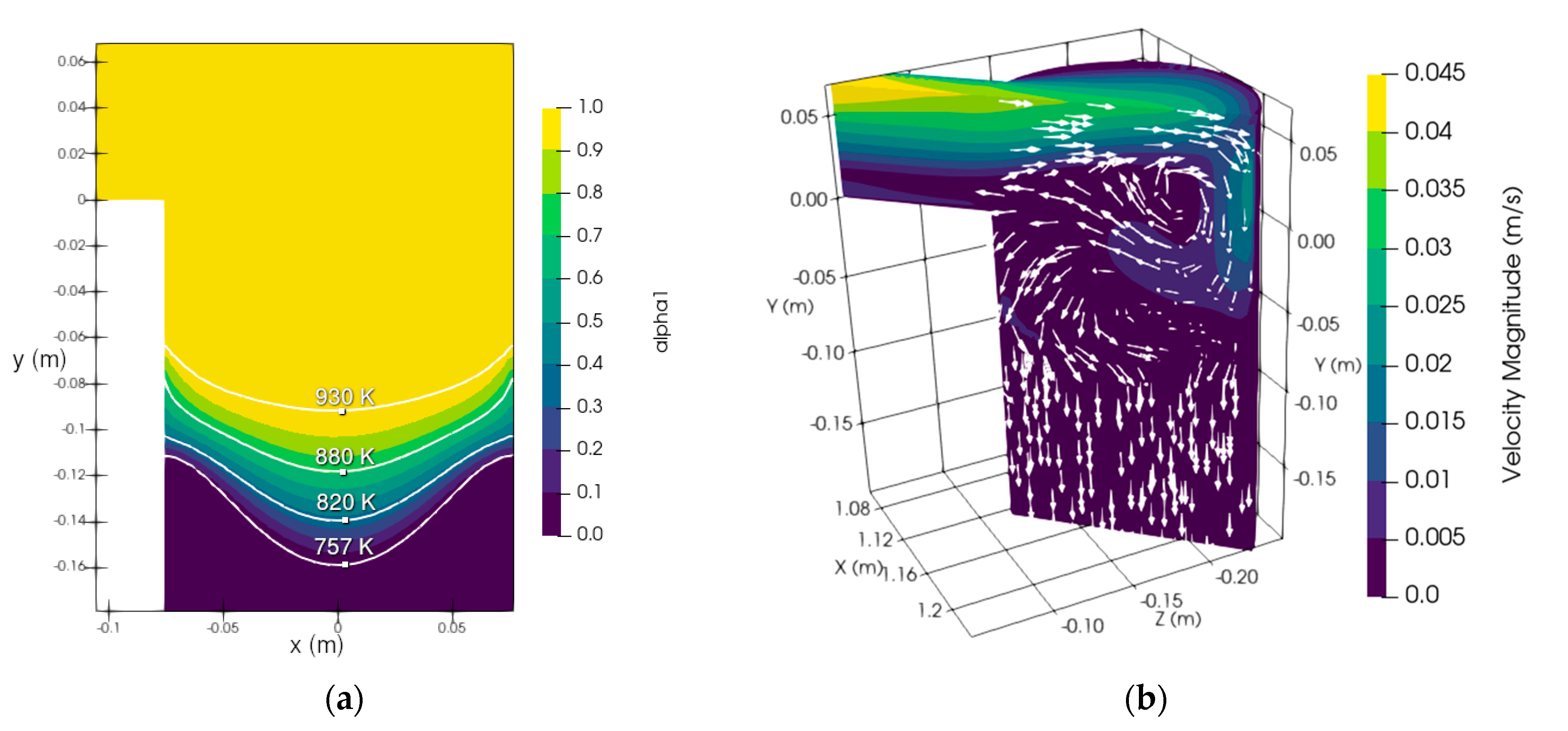

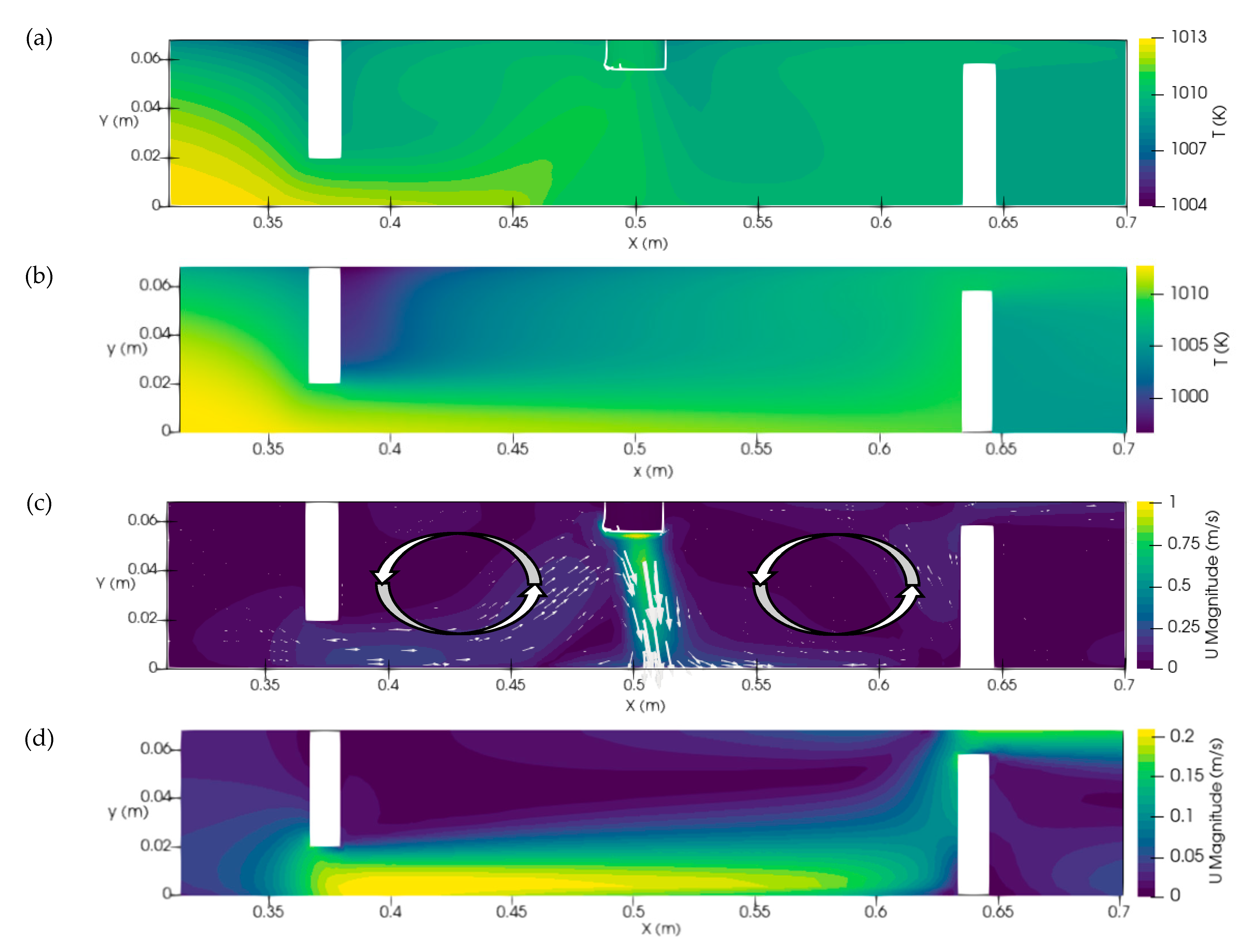

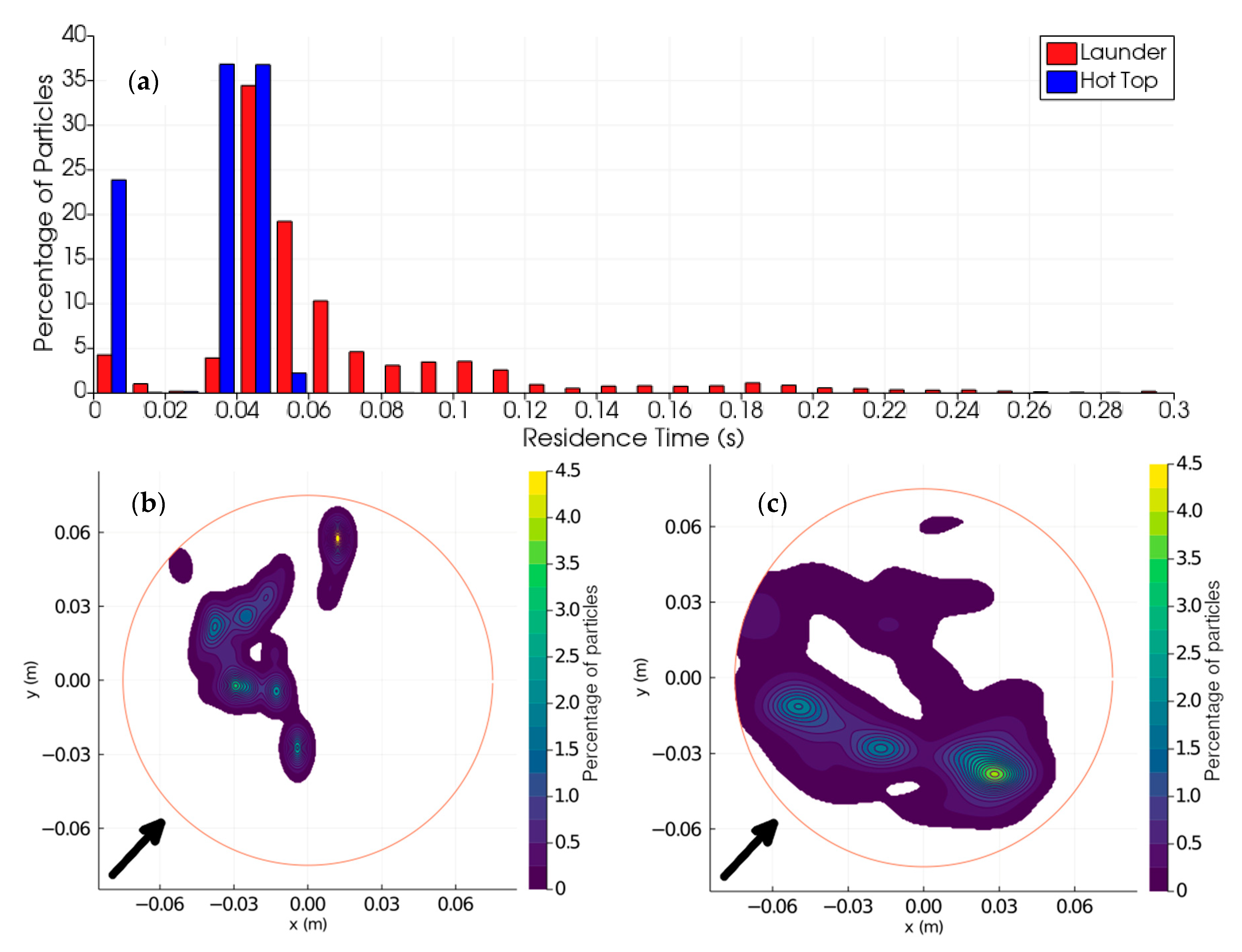

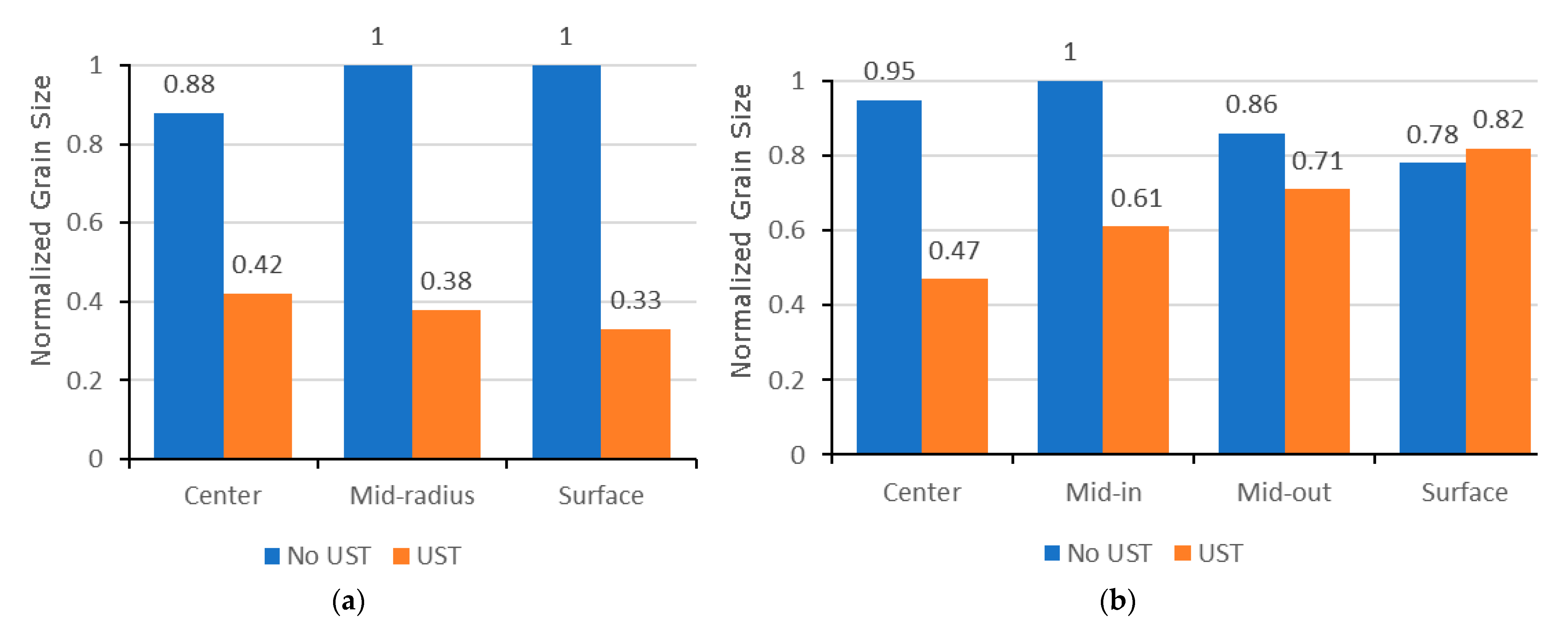

4.2. Casting Simulation

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, S.; Sadayappan, K.; Apelian, D. Role of Grain Refinement in the Hot Tearing of Cast Al-Cu Alloy. Met. Mater. Trans. A 2013, 44, 614–623. [Google Scholar] [CrossRef]

- Murty, B.S.; Kori, S.A.; Chakraborty, M. Grain refinement of aluminium and its alloys by heterogeneous nucleation and alloying. Int. Mater. Rev. 2002, 47, 3–29. [Google Scholar] [CrossRef]

- Eskin, G.I.; Eskin, D.G. Ultrasonic Treatment of Light Alloy Melts, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Pericleous, K.; Bojarevics, V.; Djambazov, G.; Dybalska, A.; Griffiths, W.D.; Tonry, C. Contactless Ultrasonic Cavitation in Alloy Melts. Materials 2019, 12, 3610. [Google Scholar] [CrossRef] [PubMed]

- Kaldre, I.; Bojarevičs, A.; Grants, I.; Beinerts, T.; Kalvāns, M.; Milgrāvis, M.; Gerbeth, G. Nanoparticle dispersion in liquid metals by electromagnetically induced acoustic cavitation. Acta Mater. 2016, 118, 253–259. [Google Scholar] [CrossRef]

- Leighton, T. The Acoustic Bubble, 1st ed.; Academic Press: London, UK, 1997; Volume 10, pp. 149–156. [Google Scholar]

- Flannigan, D.J.; Suslick, K.S. Plasma formation and temperature measurement during single-bubble cavitation. Nat. Cell Biol. 2005, 434, 52–55. [Google Scholar] [CrossRef]

- Tzanakis, I.; Eskin, D.; Georgoulas, A.; Fytanidis, D. Incubation pit analysis and calculation of the hydrodynamic impact pressure from the implosion of an acoustic cavitation bubble. Ultrason. Sonochem. 2014, 21, 866–878. [Google Scholar] [CrossRef]

- Zhang, L.; Li, X.; Li, R.; Jiang, R.; Zhang, L. Effects of high-intensity ultrasound on the microstructures and mechanical properties of ultra-large 2219 Al alloy ingot. Mater. Sci. Eng. A 2019, 763, 138154. [Google Scholar] [CrossRef]

- Subroto, T.; Eskin, D.G.; Beckwith, C.; Skalicky, I.; Roberts, D.; Tzanakis, I.; Pericleous, K. Structure Refinement Upon Ultrasonic Melt Treatment in a DC Casting Launder. JOM 2020, 72, 4071–4081. [Google Scholar] [CrossRef]

- Trujillo, F.J. A strict formulation of a nonlinear Helmholtz equation for the propagation of sound in bubbly liquids. Part I: Theory and validation at low acoustic pressure amplitudes. Ultrason. Sonochem. 2018, 47, 75–98. [Google Scholar] [CrossRef] [PubMed]

- Swaminathan, C.R.; Voller, V.R. A general enthalpy method for modeling solidification processes. Met. Mater. Trans. A 1992, 23, 651–664. [Google Scholar] [CrossRef]

- Lebon, G.B.; Tzanakis, I.; Djambazov, G.; Pericleous, K.; Eskin, D. Numerical modelling of ultrasonic waves in a bubbly Newtonian liquid using a high-order acoustic cavitation model. Ultrason. Sonochem. 2017, 37, 660–668. [Google Scholar] [CrossRef]

- Keller, J.B.; Miksis, M. Bubble oscillations of large amplitude. J. Acoust. Soc. Am. 1980, 68, 628–633. [Google Scholar] [CrossRef]

- Lebon, G.B.; Salloum-Abou-Jaoude, G.; Eskin, D.; Tzanakis, I.; Pericleous, K.; Jarry, P. Numerical modelling of acoustic streaming during the ultrasonic melt treatment of direct-chill (DC) casting. Ultrason. Sonochem. 2019, 54, 171–182. [Google Scholar] [CrossRef]

- Lebon, G.B.; Tzanakis, I.; Pericleous, K.; Eskin, D. Experimental and numerical investigation of acoustic pressures in different liquids. Ultrason. Sonochem. 2018, 42, 411–421. [Google Scholar] [CrossRef] [PubMed]

- Trujillo, F.J. A strict formulation of a nonlinear Helmholtz equation for the propagation of sound in bubbly liquids. Part II: Application to ultrasonic cavitation. Ultrason. Sonochem. 2020, 65, 105056. [Google Scholar] [CrossRef]

- Chang, S.; Stefanescu, D.M. A model for macrosegregation and its application to Al-Cu castings. Met. Mater. Trans. A 1996, 27, 2708–2721. [Google Scholar] [CrossRef]

- Bounds, S.; Morán, G.; Pericleous, K.; Cross, M.; Croft, T.N. A computational model for defect prediction in shape castings based on the interaction of free surface flow, heat transfer, and solidification phenomena. Met. Mater. Trans. A 2000, 31, 515–527. [Google Scholar] [CrossRef]

- Baserinia, A.R.; Ng, H.; Weckman, D.C.; Wells, M.A.; Barker, S.; Gallerneault, M. A Simple Model of the Mold Boundary Condition in Direct-Chill (DC) Casting of Aluminum Alloys. Met. Mater. Trans. A 2012, 43, 887–901. [Google Scholar] [CrossRef]

- Weckman, D.C.; Niessen, P. A numerical simulation of the D.C. continuous casting process including nucleate boiling heat transfer. Met. Mater. Trans. A 1982, 13, 593–602. [Google Scholar] [CrossRef]

- Haider, A.; Levenspiel, O. Drag coefficient and terminal velocity of spherical and nonspherical particles. Powder Technol. 1989, 58, 63–70. [Google Scholar] [CrossRef]

- Wang, F.; Eskin, D.; Mi, J.; Connolley, T.; Lindsay, J.; Mounib, M. A refining mechanism of primary Al3Ti intermetallic particles by ultrasonic treatment in the liquid state. Acta Mater. 2016, 116, 354–363. [Google Scholar] [CrossRef]

- Villars, P.; Cenzual, K. Al3Zr (ZrAl3 Rt) Crystal Structure: Datasheet from “PAULING FILE Multinaries Edition–2012”. Springer & Materials Phases Data System (MPDS), Switzerland & National Institute for Materials Science (NIMS), Japan. Available online: https://materials.springer.com/isp/crystallographic/docs/sd_1201137 (accessed on 27 January 2021).

- Subroto, T.; Eskin, D.G.; Beckwith, C.; Tzanakis, I.; Djambazov, G.; Pericleous, K. Improving Ultrasonic Melt Treatment Efficiency Through Flow Management: Acoustic Pressure Measurements and Numerical Simulations. In Light Metals; Springer: Cham, Switzerland, 2020; pp. 981–987. [Google Scholar]

- Tsitouras, C. Runge–Kutta pairs of order 5(4) satisfying only the first column simplifying assumption. Comput. Math. Appl. 2011, 62, 770–775. [Google Scholar] [CrossRef]

- Tonry, C.E.H.; Bojarevics, V.; Djambazov, G.; Pericleous, K. Contactless Ultrasonic Treatment in Direct Chill Casting. JOM 2020, 72, 4082–4091. [Google Scholar] [CrossRef]

- Mettin, R. Bubble Structures in Acoustic Cavitation; Bubble and Particle Dynamics in Acoustic Fields: Modern Trends and Applications; Research Singpost: Thiruvananthapuram, India, 2005; pp. 1–36. [Google Scholar]

- Li, Y.; Li, H.; Katgerman, L.; Du, Q.; Zhang, J.; Zhuang, L. Recent advances in hot tearing during casting of aluminium alloys. Prog. Mater. Sci. 2021, 117, 100741. [Google Scholar] [CrossRef]

- Atamanenko, T.V.; Eskin, D.G.; Zhang, L.; Katgerman, L. Criteria of Grain Refinement Induced by Ultrasonic Melt Treatment of Aluminum Alloys Containing Zr and Ti. Met. Mater. Trans. A 2010, 41, 2056–2066. [Google Scholar] [CrossRef]

- Zhang, L. Ultrasonic Processing of Aluminum Alloys. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2013. [Google Scholar] [CrossRef]

| Al | Si | Cu | Mg | Mn | Zr | Fe | Ti |

|---|---|---|---|---|---|---|---|

| Balance | 0.8 | 0.73 | 0.68 | 0.48 | 0.21 | 0.2 | 0.04 |

| Casting velocity (m s−1) | 0.0023 |

| Inlet temperature (K) | 1013.15 |

| Liquidus temperature (K) | 929.2 |

| Solidus temperature (K) | 757.4 |

| Latent Heat (J kg−1) | 375,696.0 |

| Density (kg m−3) | 2375 |

| Speed of sound (m s−1) | 4600 |

| Thermal expansion coefficient (K−1) | 2.3 × 10−5 |

| Kinematic viscosity (m2s−1) | 5.5 × 10−7 |

| Surface Tension (N m−1) | 0.860 |

| Vapour pressure (Pa) | 0 |

| Specific Heat Capacity (J kg−1 K−1) | 717 |

| Bulk Temperature (K) | 1013.15 |

| Ambient bubble radius (m) | 5 × 10−6 |

| P_rgh | |

| Inlet | TotalPressure uniform 0 |

| Outlet | ZeroGradient |

| Free Surface, Hot-Top, Graphite, Mold | fixedFluxPressure uniform 0 |

| Launder, Water, Sonotrode | fixedFluxPressure uniform 0 |

| P | |

| All | Calculated; |

| U | |

| Inlet | pressureInletOutletVelocity |

| Outlet | fixedValue uniform (0–uCast 0) |

| Launder, Water, Graphite, Mold, Sonotrode | noSlip |

| Free Surface, Hot Top | Slip |

| T | |

| Inlet | fixedValue uniform 1034 |

| Outlet, Free Surface, Hot Top, Launder | zeroGradient |

| Water, Mold, Graphite | Fixed Gradient = |

| Free Surface, Hot Top | |

| Alpha1 | |

| Inlet | 1 |

| Outlet, Free Surface, Hot Top, Sonotrode, Launder, Mold, Graphite | zeroGradient |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Beckwith, C.; Djambazov, G.; Pericleous, K.; Subroto, T.; Eskin, D.G.; Roberts, D.; Skalicky, I.; Tzanakis, I. Multiphysics Modelling of Ultrasonic Melt Treatment in the Hot-Top and Launder during Direct-Chill Casting: Path to Indirect Microstructure Simulation. Metals 2021, 11, 674. https://doi.org/10.3390/met11050674

Beckwith C, Djambazov G, Pericleous K, Subroto T, Eskin DG, Roberts D, Skalicky I, Tzanakis I. Multiphysics Modelling of Ultrasonic Melt Treatment in the Hot-Top and Launder during Direct-Chill Casting: Path to Indirect Microstructure Simulation. Metals. 2021; 11(5):674. https://doi.org/10.3390/met11050674

Chicago/Turabian StyleBeckwith, Christopher, Georgi Djambazov, Koulis Pericleous, Tungky Subroto, Dmitry G. Eskin, Dan Roberts, Ivan Skalicky, and Iakovos Tzanakis. 2021. "Multiphysics Modelling of Ultrasonic Melt Treatment in the Hot-Top and Launder during Direct-Chill Casting: Path to Indirect Microstructure Simulation" Metals 11, no. 5: 674. https://doi.org/10.3390/met11050674

APA StyleBeckwith, C., Djambazov, G., Pericleous, K., Subroto, T., Eskin, D. G., Roberts, D., Skalicky, I., & Tzanakis, I. (2021). Multiphysics Modelling of Ultrasonic Melt Treatment in the Hot-Top and Launder during Direct-Chill Casting: Path to Indirect Microstructure Simulation. Metals, 11(5), 674. https://doi.org/10.3390/met11050674