1. Introduction

Oxide dispersion-strengthened (ODS) alloys containing homogeneously dispersed yttrium nanoparticles allows for the operation limit of structural materials to be increased to very high temperatures of up to 1300 °C. The thermally very stable nano-oxides act as obstacles to the movement of dislocations in the matrix and thus contribute to the strengthening within a very wide range of temperatures. In the case of classical ODS alloys, usually, a small amount (about 0.3 wt.%) of homogeneously dispersed yttrium nano-sized particles is used [

1,

2]. Furthermore, strategies based on the addition of complex oxides (Y, Hf, Zr, Ce, La) for the enhancement of strengthening ODS EUROFER steel can be found in the literature (see [

3] and references therein). The mechanism of strengthening by yttrium nano-oxides has also been investigated for other complex materials. Hadraba et al. [

4] investigated the effect of oxide dispersion on the strength properties of CoCrFeNiMn high entropy alloy in detail and confirmed the positive effect of the dislocation pinning mechanism of nano-oxides at room and elevated temperatures.

Yttrium particles are introduced to ODS materials by the powder metallurgy route. As reported in detail by Svoboda et al. (see e.g., [

5]), during mechanical alloying (MA), the heavily deformed matrix of the prepared powder contains a very high density of defects acting as traps for oxygen, and, therefore, up to 5 at. % of oxygen (several orders of magnitude more than in the defect-free system) can be dissolved in the powder matrix. The theoretical explanation for this rather surprising phenomenon is presented in [

6]. This inspired us to develop a class of new-generation ODS alloys strengthened by yttrium nano-precipitates of the volume fraction up to 5%.

The new-generation ODS alloys are prepared in three processing steps:

mechanical alloying of the input powders in an evacuated attritor for a sufficient time to achieve sufficient homogenization and saturation of the properties;

full consolidation of canned powders by hot rolling, provoking an intensive repeated dynamic recrystallization leading to an ultra-fine grained (100–150 nm) microstructure; and

annealing of the consolidated alloy to provoke secondary recrystallization leading to drastic coarsening of grains (200–500 μm) by keeping a rather fine dispersion of the nano-oxides (15–30 nm) in the grains.

It should be pointed out that the dynamic recrystallization provoked by hot rolling significantly decreases the density of defects in the matrix and causes a significant supersaturation of the lattice by oxygen. This causes spontaneous precipitation of nano-oxides with a size of about 5 nm during hot rolling, where the phenomenon can be termed as recrystallization induced precipitation.

Most experiments in the literature concerning ODS alloys have focused mainly on the description of the microstructure evolution at elevated temperature [

5,

7,

8], tensile tests [

9], and creep properties [

10], but results concerning the fatigue behavior are rather rare. The effect of cyclic loading was monitored in [

11] using the three-point bending fatigue test at cycle asymmetry ratio R = 0.1 at ambient temperature. The microstructural stability of ODS steels exposed to cyclic loading at temperatures up to 750 °C was published in [

8].

The basic cyclic stress–strain curve (CSSC) is most often evaluated from the constant strain amplitude test or constant plastic strain amplitude test on a set of specimens loaded at different levels. In fatigue tests with constant amplitude loading, the material response to the cyclic loading often tends to stabilize (i.e., an initial period of rapid hardening or softening is followed by saturation). In the case that saturation is not completed until specimen fracture, some reasonable values are taken, for example, values at half-life [

12].

In addition to the basic CSSC, a short-cut procedure known as the incremental fatigue step test can be adopted for an experimental determination of CSSC. The main advantage of this procedure is the possibility of using only a single specimen. According to [

13,

14], the incremental CSSC did not differ from the CSSC obtained on several specimens for copper, low-carbon steels, or nickel-based superalloys. Petrenec [

15] and Smid [

14] investigated two types of Inconel (738LC and 792-5A) cyclically strained at 23 °C and 800 °C within the blocks of cycles with step-wise increasing strain amplitudes and, subsequently, the stress–strain response of the Inconel was analyzed. Parameters of CSSC determined by using the short-cut procedure are in good agreement with the parameters of the standard CSSC at both used temperatures.

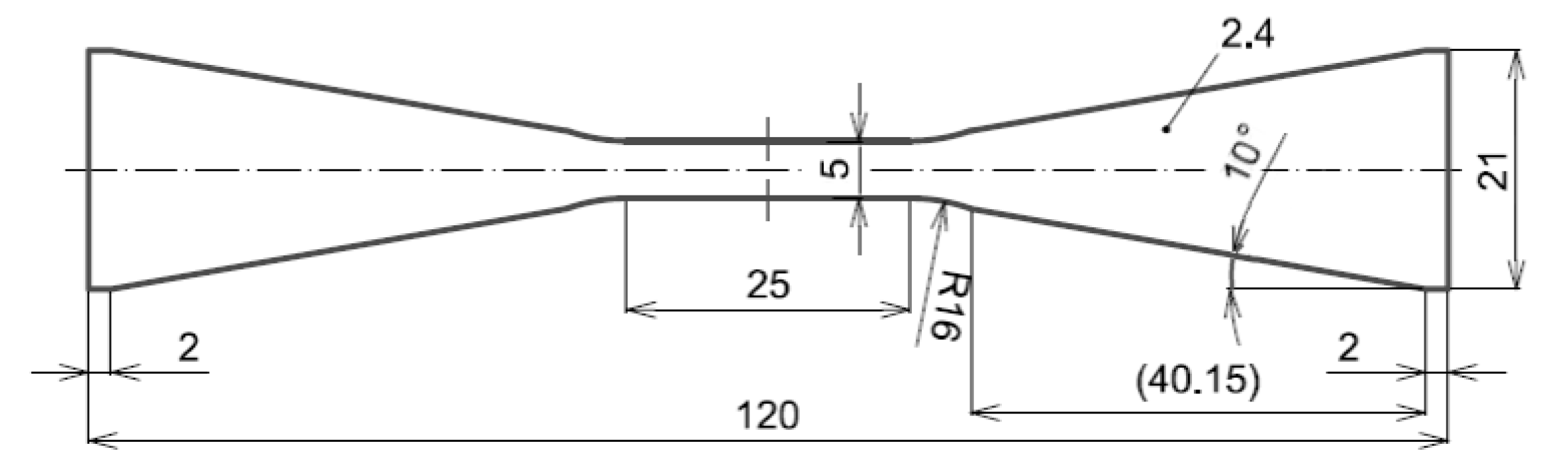

The main aim of this paper was to introduce a new-generation of ODS alloys containing a high volume fraction of yttrium nano-precipitates prepared by mechanical alloying and to demonstrate its high temperature cyclic plastic response. The fatigue characteristics served as a preliminary check of the material performances at high temperature in comparison with conventionally produced materials. Results of the incremental fatigue step test were accompanied by microstructural characterization and fractographic analysis. The results obtained at 800 °C were found to be quite promising.

3. Results and Discussion

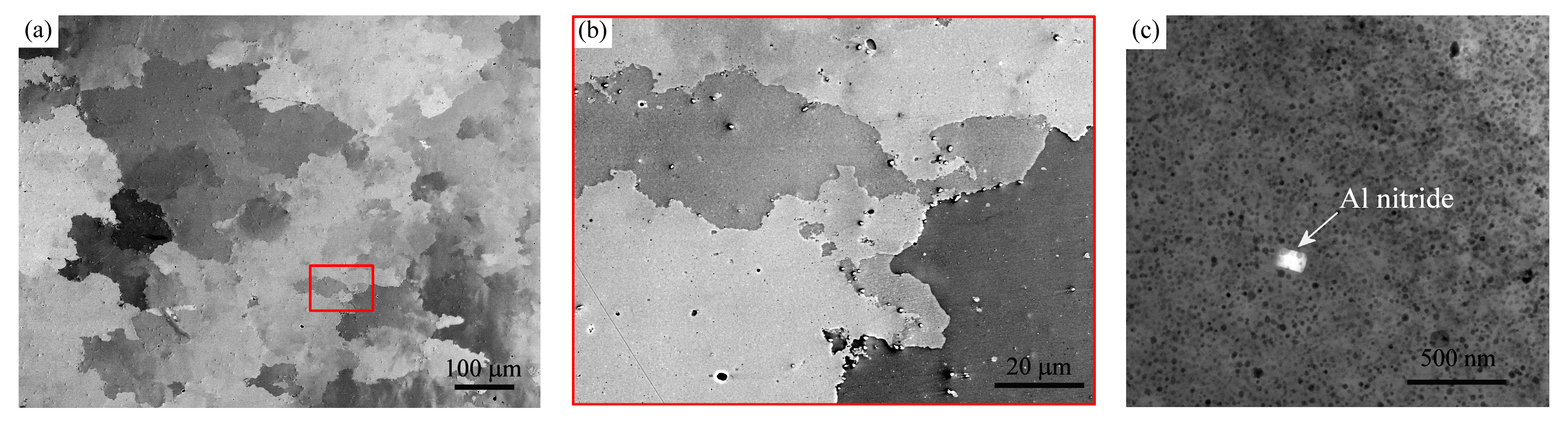

The microstructure of the material under investigation is shown in

Figure 2. There were no changes observed in the microstructure before and after the termination of the fatigue test at 800 °C. The material had a non-uniform fine to coarse-grained structure (see overview in

Figure 2a). The grain size varied from approximately 20 μm to nearly 300 μm. The average grain size evaluated on approximately 500 grains using the linear interception method was 129 μm. The grain boundaries were strongly wrinkled (see

Figure 2b). The particles with a size up to 1 μm observed on the metallographic cross section (see spots in

Figure 2b) and TEM foil (

Figure 2c) were analyzed by EDX and evaluated as Al nitrides. In the presented study, neither the SEM nor TEM investigations provided any evidence of the detrimental effect of Al nitrides on the fatigue behavior of the investigated ODS alloy. The nitrides stemmed from the nitrogen involved in the Fe powder used for the production of the ODS powder by mechanical alloying. The Al nitrides coarsened significantly during secondary recrystallization, where one could appreciate the drastic difference between the coarsening kinetics of AlN and Y

2O

3 precipitates.

The occurrence of pores was only very occasional (not presented here), in other words, the compaction of the powder achieved by hot rolling was satisfactory. For a similar material system studied in [

7] (i.e., for the alloy with ferritic Fe-10Al matrix strengthened with fine alumina dispersion), the evolution of grain coarsening during annealing was related to Vickers hardness HV5. Significant increase in grain size was accompanied by a considerable decrease in hardness. The material with the final grain size of 45 μm exhibited a Vickers hardness HV5 of 320. Material studied in this work contained grains approximately three times larger (i.e., mean grain size (evaluated by linear interception method) was approximately 129 μm), nevertheless, the Vickers hardness HV5 reached the value of almost 380. The bigger grain size, together with very fine oxide dispersion, seems to be positive also from the point of view of creep properties because fine-grained ODS steels exhibit generally much worse creep properties than coarse-grained ones (see [

16]).

The internal microstructure of the new-generation ODS alloy after fatigue loading was studied using TEM (see

Figure 3) in scanning mode.

Figure 3a shows an overview of the microstructure with a high quantity of nano-particles of spherical shape homogeneously distributed in the material (detail of nano-sized yttrium particles with the size of approximately 25 nm in the inlet in the left corner). The amount of Y

2O

3 nanoparticles was significantly higher than that reported in the literature because of the presence of 4 wt.% of Y

2O

3 compared to the typical 0.25 wt.% for previously reported ODS steels [

1,

2].

Figure 3b shows a microstructure after fatigue loading (incremental step test) in higher magnification where reinforcing yttrium nanoparticles were present together with dislocations (marked by white arrows). Dislocations were observed with the electron beam vector parallel to the [010] zone axis. This indicates that the dislocation structure of the density to the order of magnitude 10

14 m

−2 developed in the grains during the fatigue experiment.

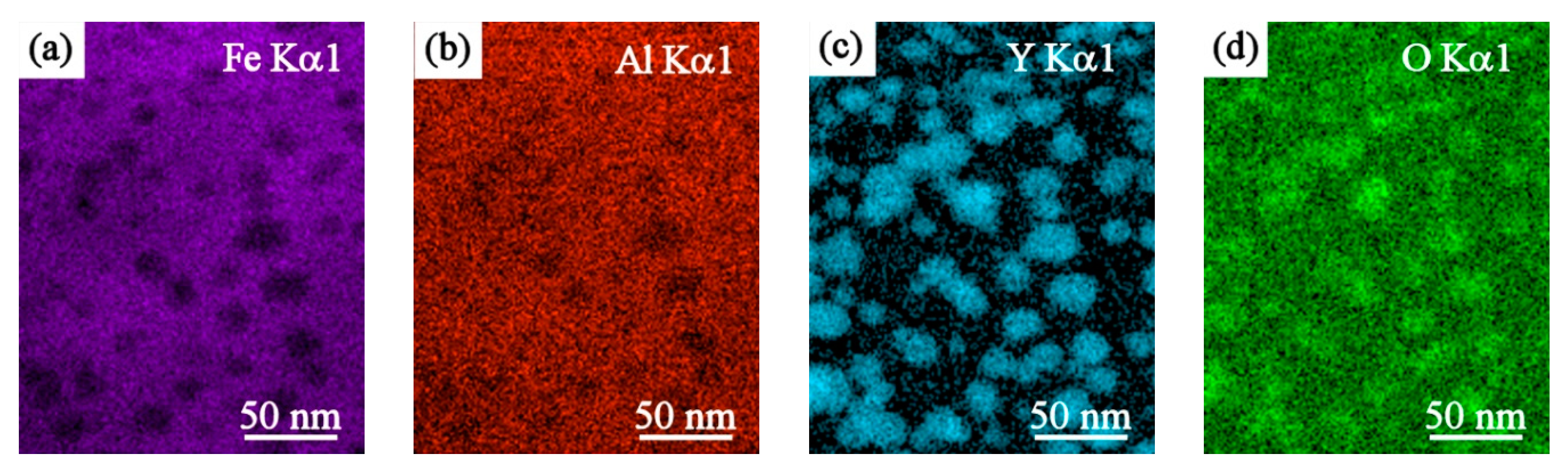

The chemical composition of nano-sized spherical particles from

Figure 3b was further analyzed using STEM-EDX mapping, which confirmed the yttrium nanoparticles as the dominant strengthening agent (see

Figure 4).

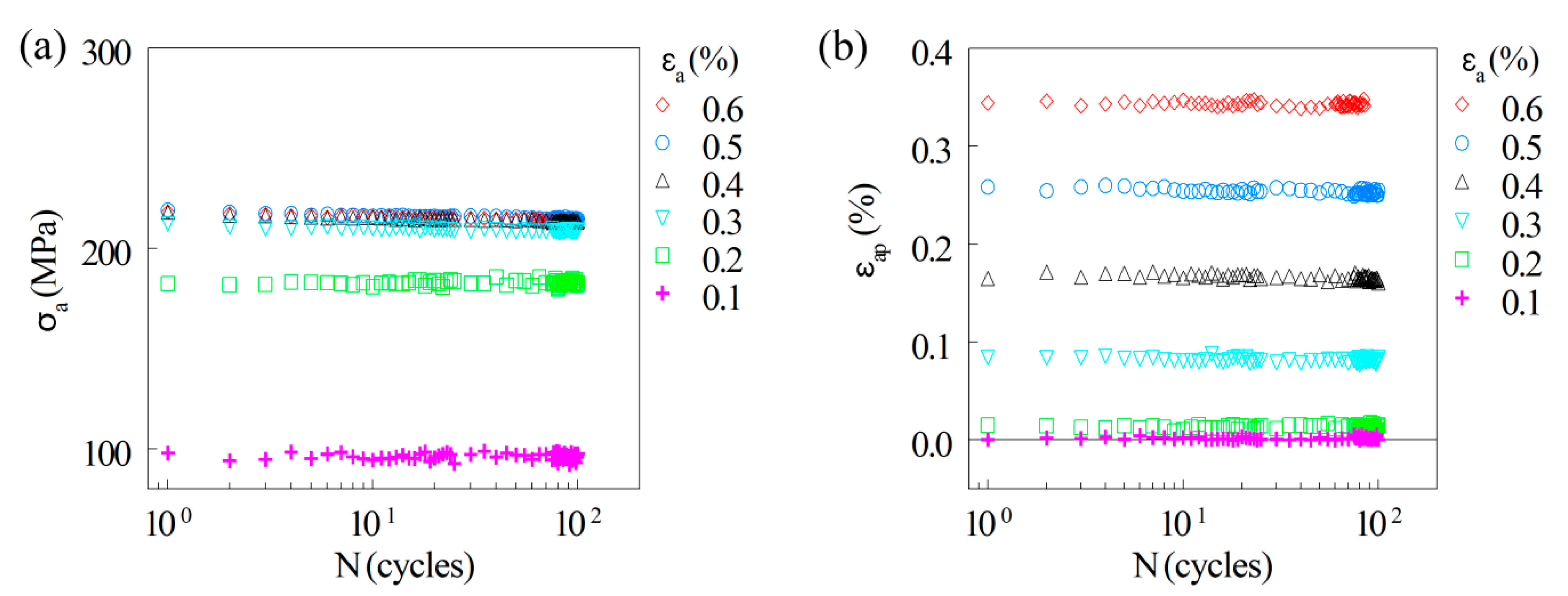

During fatigue loading, the individual levels of total strain amplitude were increased from 0.1% to 0.6%. The number of cycles in the block for each strain level was set to 100. The recorded stress amplitude was then plotted in the dependence on the applied number of cycles (see

Figure 5a). At the last level of stress amplitude (i.e., at the stress for the strain amplitude ε

a = 0.6%), the number of cycles to fracture reached the value of 84. Fatigue loading at 800 °C resulted in a stable stress response in all tested strain levels (i.e., neither hardening nor softening was observed), and therefore according to [

17], the final data points can be used for the construction of the CSSC. The same character of fatigue response (i.e., neither hardening nor softening) was observed when the plastic strain amplitude ε

ap was evaluated from the saturated hysteresis loops. These data are plotted in the dependence on the number of applied cycles (see

Figure 5b).

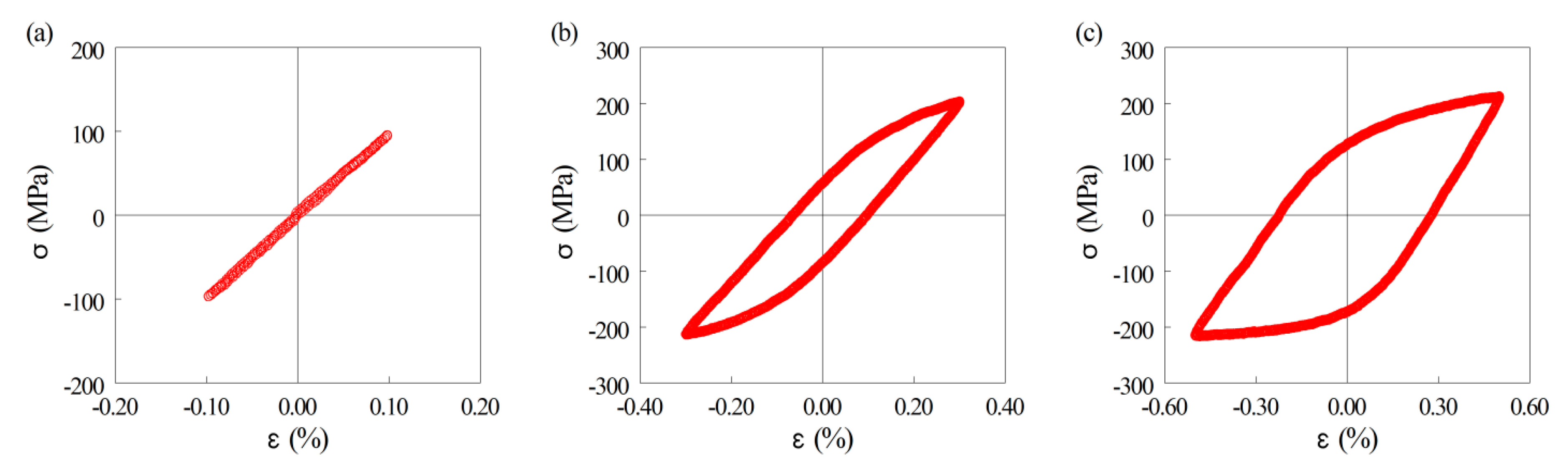

Saturated hysteresis loops at the end of each block of strain amplitude were recorded and evaluated.

Figure 6 shows a comparison of hysteresis loops for the selected total strain amplitudes. At the smallest applied strain amplitude (0.1%-

Figure 6a), the material showed nearly pure elastic behavior, whereas the medium strain amplitude (0.3%,

Figure 6b) and the highest strain amplitude (0.6%,

Figure 6c) presented rather pronounced elastoplastic behavior.

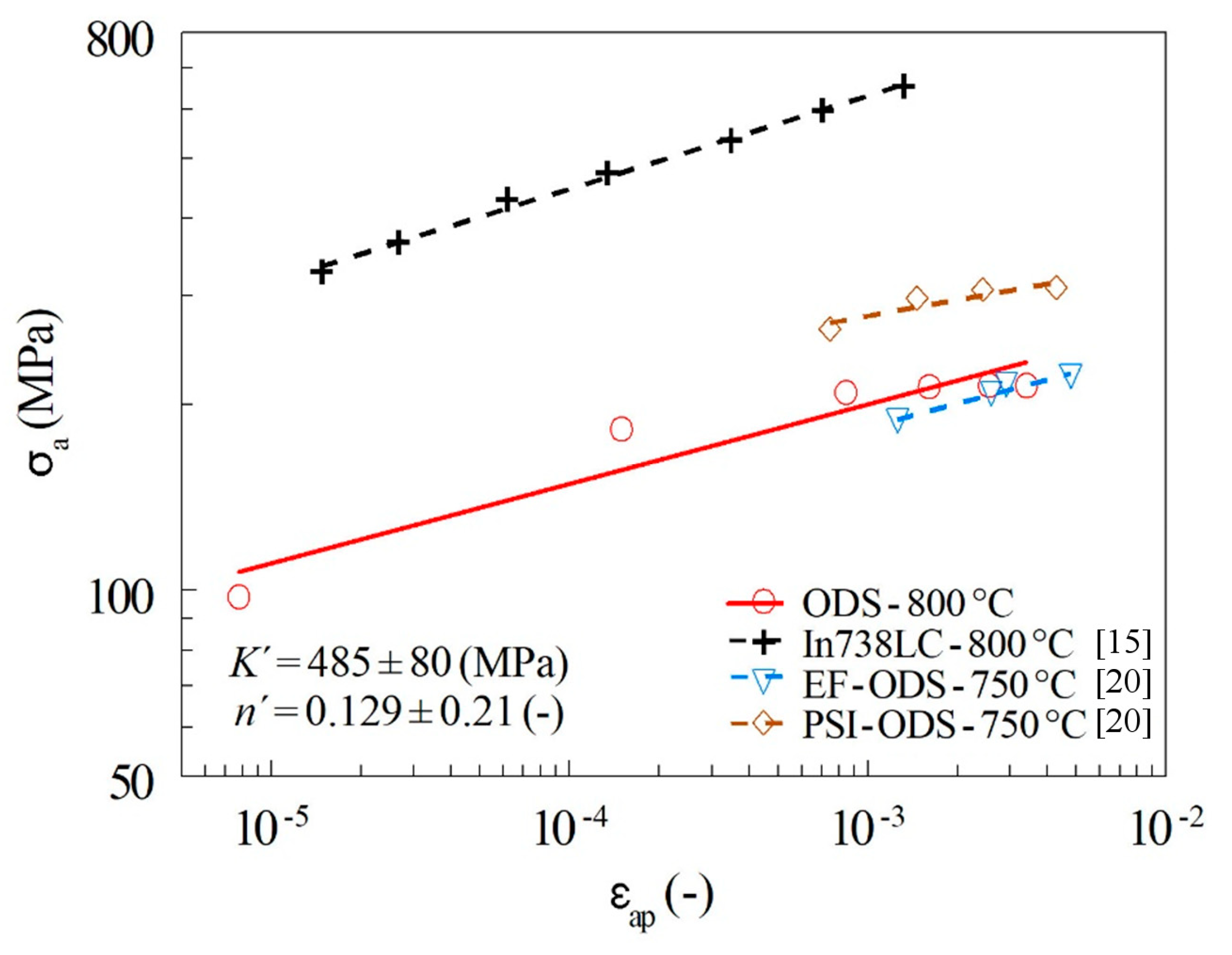

A short-cut procedure was applied according to the work of Polák [

17] with very similar conclusions. The saturated values of stress and strain amplitudes were achieved and the final data points from the saturated hysteresis loops were used for the construction of the incremental CSSC.

Figure 7 shows the dependence of the stress amplitude on the plastic strain amplitude of the 100th hysteresis loop in each block of the short-cut procedure. To judge the high temperature behavior of the new-generation ODS alloy, the data of the CSSC for Inconel 738LC, being highly resistant to cyclic loading at 800 °C [

15], are also presented (dashed line in

Figure 7). From the comparison, it is evident that the CSSC for the ODS alloy was below the CSSC for Inconel 738LC and the shift in the values of stress amplitude was between 200 MPa and 400 MPa for the lowest and highest plastic strain amplitudes, respectively. It should be mentioned that Ni-based superalloys are strengthened by ordered cube-shaped γ’precipitates exhibiting instabilities due to coalescence [

18] and coarsening [

19] at a temperature above 900 °C. This is not the case of ODS steels containing very stable Y-based oxides and thus they are preferred for applications at temperatures over 1000 °C [

16]. The difference between the CSSC data for the investigated new-generation ODS alloy and Inconel [

15] is therefore not crucial. Moreover, the saturation of the stress amplitude and the ability to absorb a significant amount of the cumulative plastic strain indicates promising reliability (resistance against brittle fracture) and possible hot workability of the new-generation ODS alloy at 800 °C.

In order to compare the studied new-generation ODS alloy with other ODS steels, CSSCs determined for two types of ODS material (i.e., ODS Eurofer (EF-ODS), tempered ferritic–martensitic steel and ODS ferritic steel (PSI–ODS) presented by Kuběna [

20]) were incorporated into the plot in

Figure 7. The CSSC of ferritic–martensitic steel (EF–ODS) shifted to lower stress amplitudes than the CSSC of the ODS material under investigation, but the vice versa was true for ferritic steel (PSI–ODS). Both dependencies published in [

20] were nevertheless obtained at the test temperature of 750 °C. If the difference of testing temperature had been taken into account, we can expect that the new-generation ODS alloy investigated in this paper may have comparable or even better properties than EF–ODS and PSI–ODS.

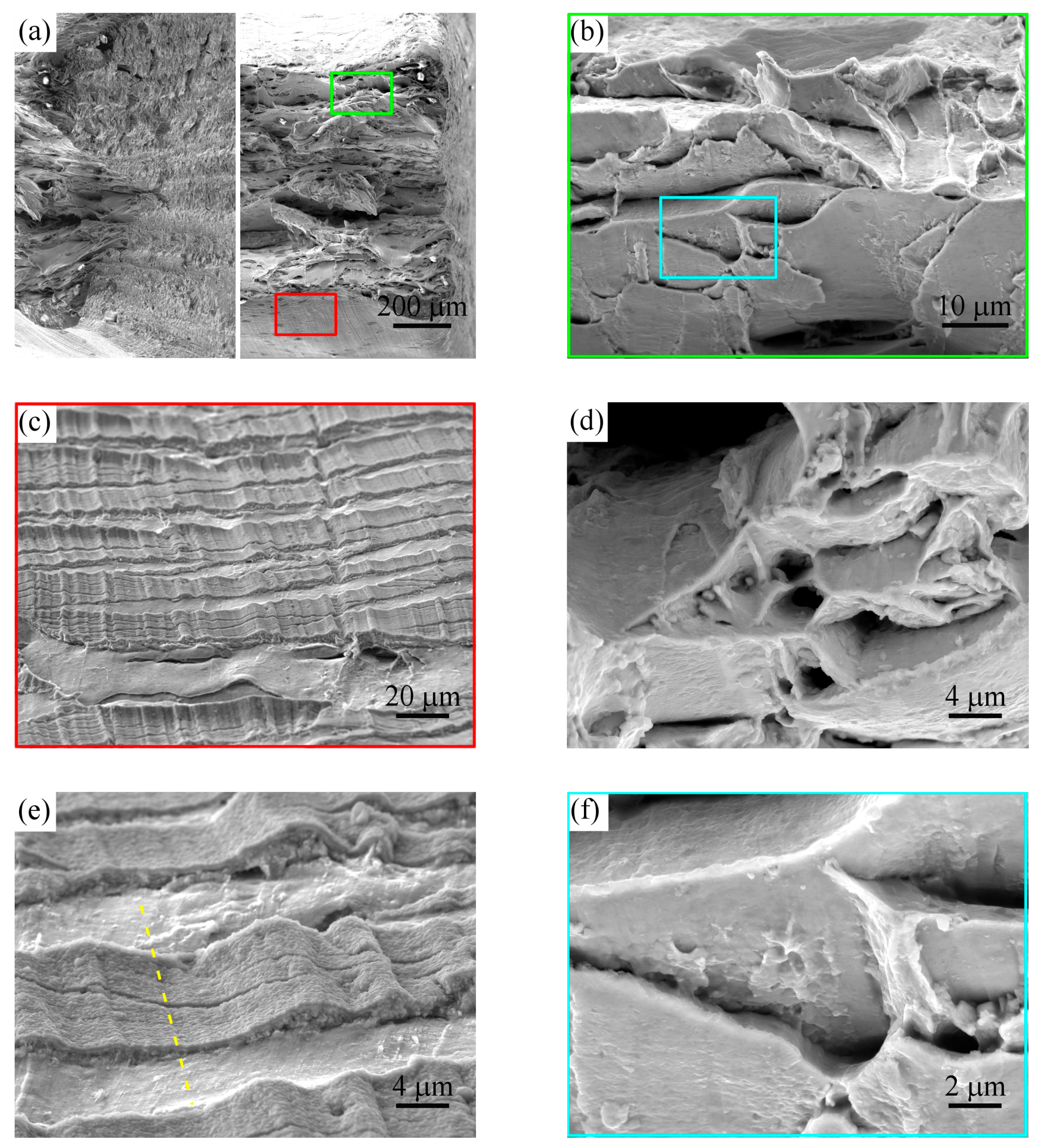

After the test termination (i.e., fracture of the specimen), both the surface of the gauge length and fracture surface were observed and the SEM micrographs are shown in

Figure 8. On a macroscopic scale (see

Figure 8a), the fracture surface exhibited a rough profile. In the left part of

Figure 8a, one can see a side view of the specimen, where a highly pronounced necking caused by a high plastic strain in the last level of the incremental step test (ε

a = 0.6%) is visible. A top view on the rough fracture reveals a surface exhibiting ductile fracture with a high number of V-shaped troughs or tongue like features arranged into the almost lamellar pattern in the right part of

Figure 8a. This feature could be attributed to the method of material processing, leading to large pan-cake grains parallel to the rolling plane. This layered structure then forms a lamellar pattern at the fracture surface. In contrast, the fracture surface of conventional ductile materials in the form of sheets usually has a roof-like pattern (see [

21]). A micrograph with a higher magnification of tongues marked by the green rectangle is presented in

Figure 8b. The surface of the gauge length (see red rectangle in

Figure 8a) exhibits the wavelike pattern shown in

Figure 8c. This pattern originated from the expressive plastic deformation of the necking area with the slightly oxidized surface. During the fatigue test at 800 °C, the specimen was exposed to a high temperature in air for a few hours, and a brittle thin layer of oxides was not able to deform in the same way as the ductile substrate of the ODS alloy. Details of the oxide layer with a wavy pattern present on a highly deformed area of specimen necking is shown in

Figure 8e. Ductile dimples with spherical particles deposited at the bottoms of the dimples can be observed in the middle part of

Figure 8d. Similar dimples were also detectable on the sides of the tongues at higher magnification (see

Figure 8f). The presence of Al nitrides was not detected on the fracture surface of the investigated ODS steel (i.e., they do not play an important role in the initiation or propagation of fatigue crack).

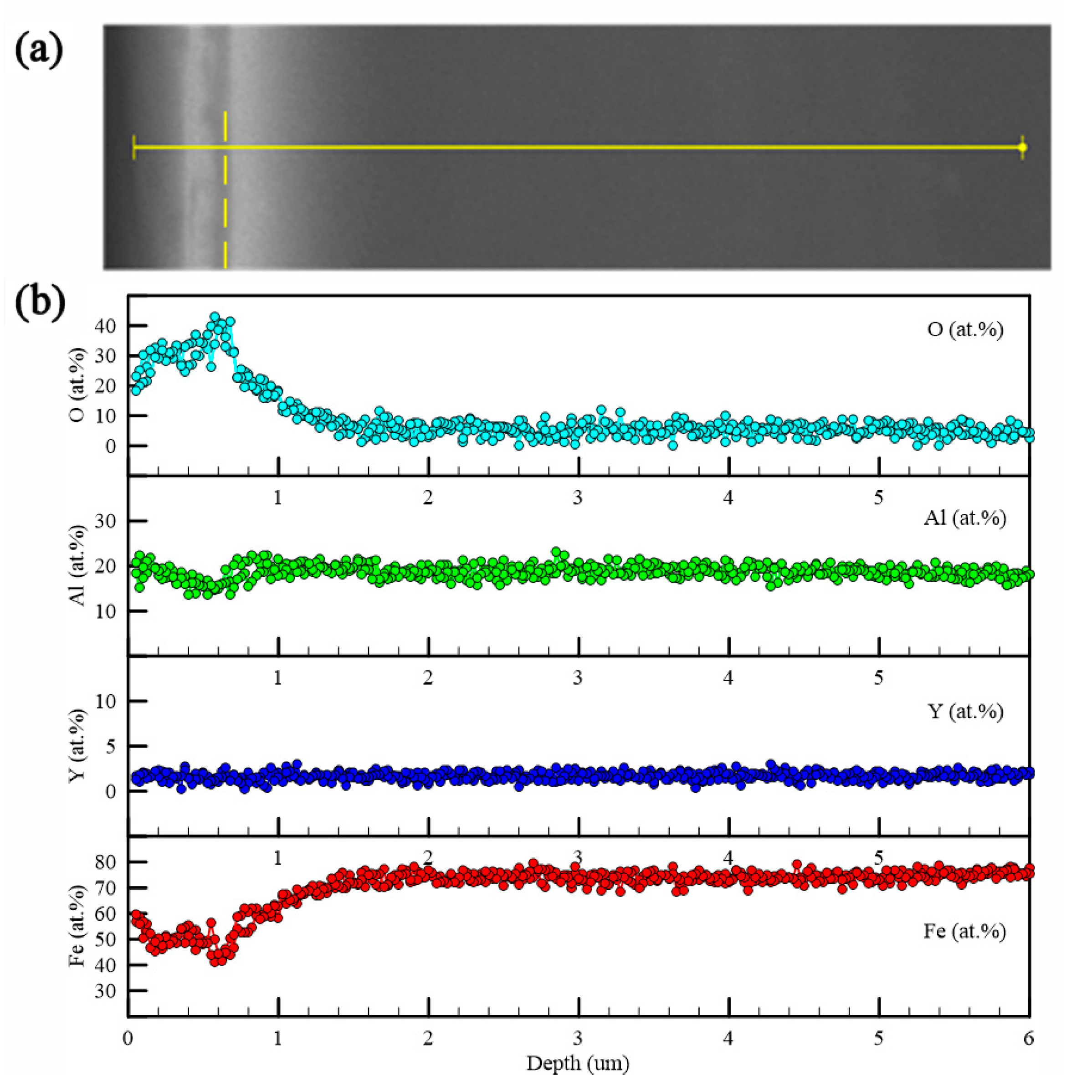

The yellow dashed line in

Figure 8e indicates the place from which the metallographic section was prepared and where the chemical analysis of the oxide layer created on the surface was performed. The results of this line analysis presented in

Figure 9 indicate that the surface was oxidized up to the depth of approximately 0.5 μm and was formed by mixed Al–Y oxides because a rather significant depletion of Fe was observed in the oxide layer.