Abstract

High-entropy alloys (HEAs) were fabricated by powder metallurgy using gas-atomized powder and spark plasma sintering (SPS) followed by surface modification (plasma nitriding) of the sintered sample. Plasma nitriding forms nitride and induces solid-soluting of N; it enables the diffusion of N atoms by removing the passive film formed on the surface of alloys such as stainless steel, Al alloys, and Ti alloys, via the sputtering of cations during glow discharge. Therefore, plasma nitriding has the potential to process HEAs that contain strong oxidizing elements such as Cr, Al, and Ti. In this work, a sintered CoCrFeMnNi HEA was plasma-nitrided and its properties were subsequently evaluated. A uniform microstructure without segregation was obtained in the SPS sample, and its hardness and wear resistance were found to have improved. Analysis of the sample surface after nitriding revealed that an expanded face-centered cubic phase formed on the surface plasma-nitrided at 673 K and that a CrN phase formed on the surface plasma-nitrided at temperatures greater than 723 K. The surface hardness of the plasma-nitrided sample was 1200 HV or greater, and the wear resistance and pitting corrosion resistance were improved compared with those of the untreated sample.

1. Introduction

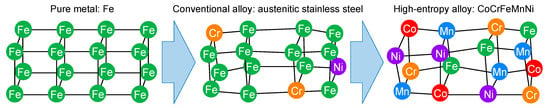

High-entropy alloys (HEAs) have recently become a subject of extensive research because they are expected to be used in applications such as molds, tools, and functional coatings [1,2]. Unlike traditional alloys, HEAs are composed of at least five major elements with concentrations in the range 5–35 at% [2]. Surprisingly, the large number of components contained in HEAs does not lead to the formation of the intermetallic phase expected on the basis of a ternary phase diagram. Rather, single-phase solid solutions are preferentially formed. Despite being a single-phase solid solution, a HEA contains more elements than conventional alloys such as austenitic stainless steel, as shown in Figure 1. Therefore, HEAs exhibit severe lattice distortion. Nevertheless, because of their simple microstructure, HEAs possess a unique combination of properties not found in traditional metallic materials, such as high strength at elevated temperatures, ductility, and corrosion resistance [3,4,5].

Figure 1.

Schematic of the atomic lattices of metals and alloys.

Numerous HEAs with various phase-structures have been reported, such as face-centered cubic (fcc), body-centered cubic (bcc), hexagonal close-packed (hcp), and fcc + bcc [6,7,8,9,10,11,12,13]. The CoCrFeMnNi system reported by Cantor et al. was the first HEA manufactured and is an fcc single-phase alloy [1]. HEAs are usually manufactured by arc melting or casting. However, inhomogeneous structures have been observed in these methods [14]. In addition, the mechanical properties of these materials differ from those of the corresponding materials produced by powder metallurgy (PM) [15,16,17].

In the present work, an HEA was fabricated using the spark plasma sintering (SPS) process of PM. This method generates high temperatures at the powder-contact region via a large applied pulse current. This high energy is used to promote sintering. In contrast to traditional metallurgy, PM offers numerous advantages, including excellent material efficiency and geometric complexity. In addition, SPS can suppress grain growth by rapid heating and rapidly consolidate powders at high densities within a short time. The usefulness of SPS has recently been demonstrated in functional materials, metal/ceramic nanomaterials, hard materials, and composites systems [18,19,20]. Various HEAs have also been produced by the SPS method [21,22,23,24,25].

A CoCrFeMnNi HEA with an fcc structure is soft and ductile [26,27,28,29]. Therefore, improvement of the hardness of soft HEAs is important. Surface modification was also performed on different HEA systems [30,31,32,33]. Plasma nitriding is a thermochemical method in which a glow discharge is generated under a mixed gas of N2 and H2, forming nitride and solid-soluting N by diffusion. This processing is an excellent surface-modification technology that improves wear resistance, corrosion resistance, and fatigue life of parts such as gears, cams, and molds. It can also be applied to materials that are difficult to nitride by conventional methods, such as Al alloys, Ti alloys, and stainless steels. The passivation film formed on the surface of such alloys is removed by the sputtering action of cations during glow discharge, enabling diffusion of N atoms [34,35,36,37,38,39,40]. Therefore, plasma nitriding has the potential to process HEAs that contain strong oxidizing elements such as Cr, Al, and Ti [41,42,43,44]. In the present study, CoCrFeMnNi HEA was manufactured using SPS, subsequently plasma-nitrided, and then evaluated by the characterization of its material properties.

2. Materials and Methods

2.1. Materials

CoCrFeMnNi alloy powder prepared by gas atomization (Sanyo Special Steel Co., Ltd., Hyogo, Japan) was used as a starting material and was split <32 µm by sieving. The composition of the powder measured by inductively coupled plasma-optical emission spectroscopy (ICP-OES) was 20.4 at% Co, 20.00 at% Cr, 19.76 at% Fe, 19.52 at% Mn, and 19.83 at% Ni.

2.2. Spark Plasma Sintering

The alloy powder was placed in a graphite die (ϕ20 mm) into which a graphite punch was subsequently inserted. The powder was sintered using an SPS apparatus (SPS-1020, Sumitomo Coal Mining Co., Tokyo, Japan) at a pressure of 50 MPa and under a reduced pressure of 10−3 Pa by passing a large pulse current. Sintering was carried out at 1173 K for 10 min. When the sintering process was completed, the sample was cooled in the furnace. The thickness of the sintered compact was 5 mm. After sintering, the sample surface was polished to 2000-grit SiC paper, polished using Al2O3 powder (1.0 µm in diameter), ultrasonically degreased, and dried in air.

2.3. Plasma Nitriding

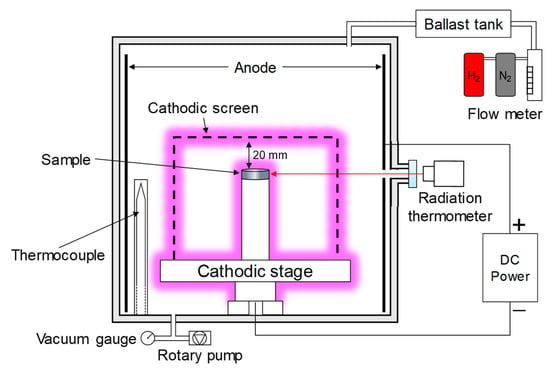

Nitriding was carried out in a plasma nitriding device (JIN-1S, NDK Inc., Kanagawa, Japan). Figure 2 shows a schematic of the plasma nitriding process. An auxiliary screen and samples were placed on the cathodic sample stage. As a result, plasma was formed on both the sample and the auxiliary cathode screen. This auxiliary screen suppresses the edge effect by increasing the supply of active species such as N+, N2+, and H+ and heating the sample surface uniformly [45,46,47,48,49]. The auxiliary screen material was an expanded mesh of AISI316L austenitic stainless steel (ASS) with 38% open area, a diameter of 200 mm, and a height 70 mm. The distance between the sample and the screen was approximately 20 mm. After the chamber was evacuated to approximately 10 Pa, N2 and H2 flowed into the chamber and a direct-current voltage was applied. Plasma nitriding was carried out for 15 h at 673–773 K under a 25% N2–75% H2 atmosphere with a pressure of 200 Pa. After nitriding was completed, the samples were cooled in the furnace.

Figure 2.

Schematic of the setup for plasma nitriding.

2.4. Characterization

The phase structure of sintered and nitrided sample surfaces was characterized by X-ray diffraction (XRD). The microstructure and composition of the treated samples were analyzed using scanning electron microscopy (SEM), electron-probe microanalysis (EPMA), and glow-discharge optical-emission spectroscopy (GD-OES). The relative density of the sintered sample was measured using the Archimedes method. The surface hardness was measured under a load of 0.1 N using a Vickers microhardness tester. Seven indentations were made on each sample, and a five-point average value (excluding the maximum and minimum values) was reported as the hardness. Wear tests were conducted at room temperature using a ball-on-disk tribometer. The conditions for wear testing were as follows: running a distance of up to 300 m, wear load of 2 N, rotation speed of 100 rpm, wear radius of 3 mm, and a diameter of 6.35 mm for the Al2O3 ball used as the counter material. The cross-sectional profile of the wear tracks was measured using a surf-corder. Pitting corrosion tests were carried out using a potentiostat. DC polarization was performed potentiodynamically from −1.0 to +1.5 VAg/AgCl, and the anodic polarization curves were recorded at a sweep speed of 1.6 mV/s. On the basis of these polarization curves, the potential corresponding to a current density of 100 μA/cm2 was selected as the pitting potential. Details of these characterization methods are described elsewhere [42].

3. Results and Discussion

3.1. Fabrication of HEAs by SPS

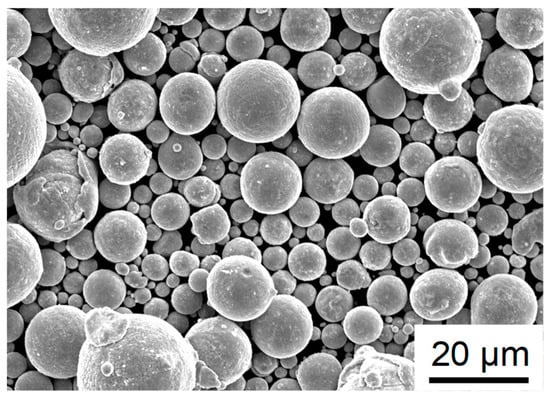

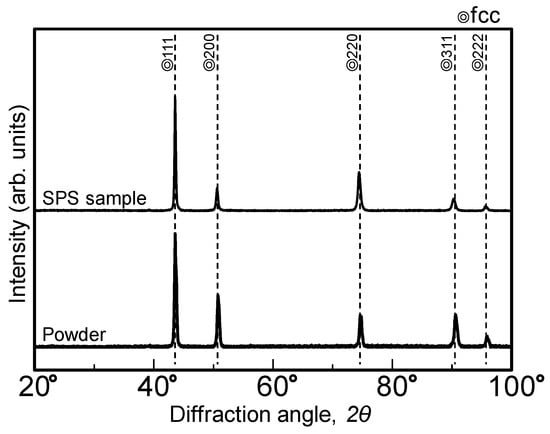

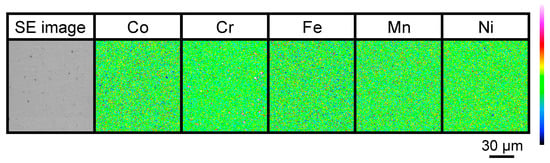

A secondary electron image (SE image) of the CoCrFeMnNi alloy powder prepared by gas atomization is shown in Figure 3. The powder exhibited an almost spherical particle shape. Figure 4 shows a comparison of the diffractograms of the SPS samples and the alloy powder. The diffractogram of the alloy powder is similar to the values reported in the literature, as shown in Figure 4 [50,51]. The distinct peaks detected in the powder diffractogram indicate that a single phase with an fcc crystal structure was produced. After consolidation by SPS, no obvious difference was observed between the SPS sample and the powder. In HEAs prepared using mechanical alloying (MA) and SPS, ZrO2 ball contamination during MA and carbon contamination during SPS have been reported [52]. However, in the present study, only an fcc single phase was found; no minor peaks of impurities such as carbides or oxides were observed. The microstructure and EPMA element mapping images of Co, Cr, Fe, Mn, and Ni in the SPS sample are shown in Figure 5, which shows a homogeneous microstructure with no visible precipitates. The density, as determined by the Archimedes method, was 7.73 g/cm3; the apparent porosity was 2.3%. A nonuniform structure was observed in the HEA produced by arc melting or casting [14]. All elements in the SPS sample were uniform, exhibiting no segregation [53].

Figure 3.

A secondary electron (SE) image of the CoCrFeMnNi alloy powder prepared by gas atomization.

Figure 4.

XRD patterns of gas-atomized high-entropy alloy (HEA) powder and the spark plasma sintering (SPS) sample sintered for 10 min at 1173 K.

Figure 5.

SE image and electron-probe microanalysis (EPMA) elemental mapping images of Co, Cr, Fe, Mn, and Ni for the SPS sample sintered for 10 min at 1173 K.

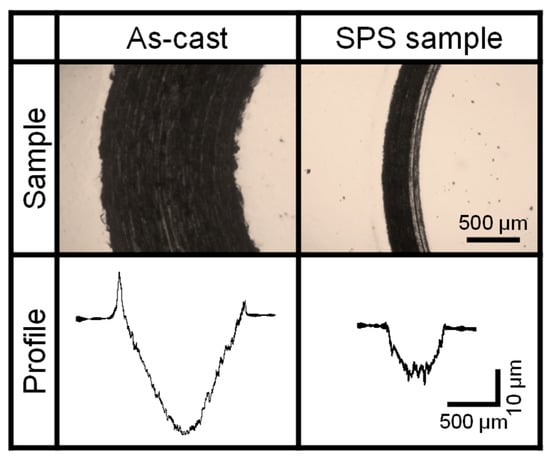

Hardness tests and ball-on-disk wear tests were performed to measure the mechanical properties of the samples. The average and standard deviation of hardness of the SPS sample were 310 HV and 12 HV, respectively, which are greater than the hardness of similar HEAs fabricated by casting (average of 185 HV and standard deviation of 10 HV [42]) because of differences in their microstructures [54]. The ball-on-disk test results are shown in Figure 6. The wear amount of the SPS sample was lower than that of the cast material, and the abrasion resistance was improved. This reduction in wear amount can be considered an effect of the improved hardness due to the microstructure [55].

Figure 6.

Wear track and its cross-sectional profile for as-cast and SPS CoCrFeMnNi samples.

3.2. Properties of Plasma-Nitrided HEAs

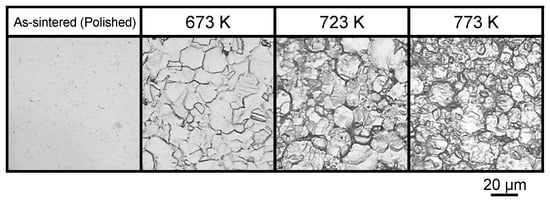

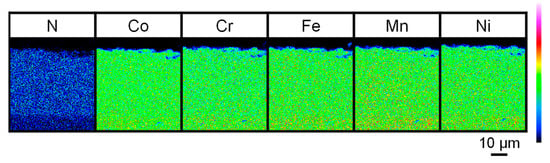

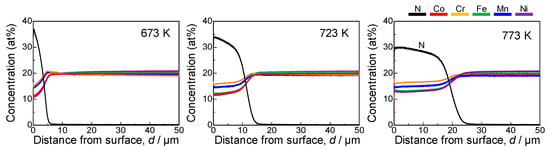

The surface morphologies of the HEA samples after plasma nitriding are shown in Figure 7. Grain boundaries are clearly visible on each plasma-nitrided surface. The soluting of N atoms into the HEA lattice obviously induced a large lattice expansion; this phenomenon has also been observed on the surface of ASS after plasma nitriding [56]. Figure 8 shows the cross-sectional EPMA element mapping images for the N, Co, Cr, Fe, Mn, and Ni of the plasma-nitrided samples. N enrichment was clearly observed in the surface region in the EPMA element maps. The diffusion of N into the sample was observed under all of the investigated nitriding temperatures. GD-OES profiles of the samples plasma-nitrided at temperatures from 673 to 773 K are shown in Figure 9. The profiles show a surface area comprising of a layer rich in N. Moreover, higher nitriding temperatures led to deeper N diffusion. The N-enriched region at the surface is considered to be the compound layer, and the graded region below this layer is the diffusion layer. The constituent elements in the nitriding layer of the HEAs were approximately the same. Such elemental distributions correspond to the EPMA element mapping images (Figure 8).

Figure 7.

Surface morphology of plasma-nitrided CoCrFeMnNi samples.

Figure 8.

EPMA element mapping images of N, Co, Cr, Fe, Mn, and Ni for CoCrFeMnNi samples plasma-nitrided for 15 h at 773 K.

Figure 9.

Glow-discharge optical-emission spectroscopy (GD-OES) profiles of the N, Co, Cr, Fe, Mn, and Ni concentrations for plasma-nitrided CoCrFeMnNi samples.

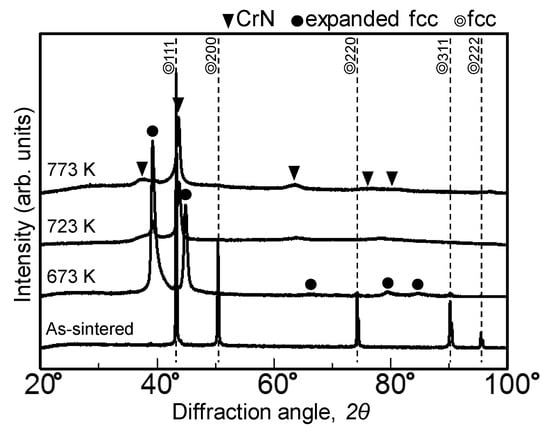

XRD patterns of the samples plasma-nitrided at temperatures between 673 and 773 K are shown in Figure 10. The pattern of the HEA sample plasma-nitrided at 673 K shows an expanded fcc phase whose peaks are shifted to lower angles compared with those in the pattern of the as-sintered HEA sample. This pattern supports an expanded fcc phase with a supersaturated N solid solution with an fcc structure. The pattern of the HEA sample plasma-nitrided at 773 K indicates the presence of the CrN phase. Expanded fcc and CrN phases have previously been observed in cast CoCrFeMnNi HEAs after gas-nitrocarburizing or plasma nitriding [33,42]. The same tendency has been reported for plasma nitriding of ASS. The expanded fcc phase, referred to as the expanded austenite or S-phase, has been previously identified at <723 K in plasma-nitrided ASS [57,58]. We concluded from the aforementioned results that the expanded fcc layer is formed on the HEA sample surface plasma-nitrided at 673 K. In contrast, at nitriding temperatures greater than 723 K, a broad CrN phase is identified by XRD and N enrichment is indicated by EPMA and GD-OES. We inferred that an NaCl-type homogeneous solid solution such as (Co,Cr,Fe,Mn,Ni)N is formed as a nitriding layer on the HEA surface [42].

Figure 10.

XRD patterns of plasma-nitrided CoCrFeMnNi samples.

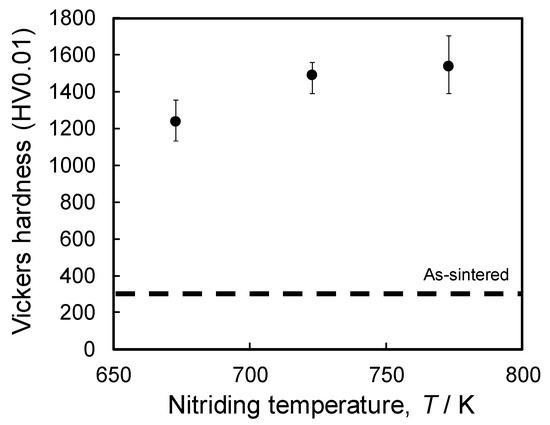

Figure 11 shows the results of the surface hardness tests after plasma nitriding. The hardness of all of the plasma-nitrided samples was greater than that of the as-sintered sample. Their hardness increased with increasing nitriding temperature, and a hardness of 1500 HV was observed for the sample nitrided at 773 K. This increase in surface hardness is explained by the formation of the expanded fcc phase at 673 K or the NaCl-type solid solution at temperatures greater than 723 K because of N diffusion induced by plasma nitriding [42], as shown in Figure 8 and Figure 9.

Figure 11.

Surface hardness of plasma-nitrided CoCrFeMnNi samples.

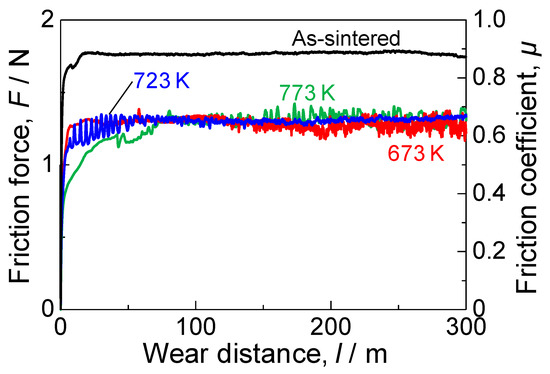

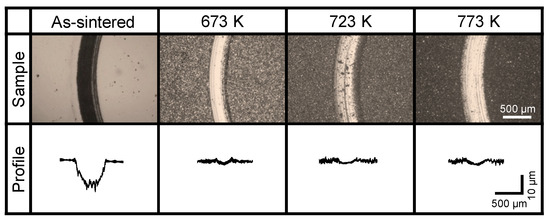

Figure 12 and Figure 13 show the results of the tribology tests. Figure 12 shows that the plasma-nitrided samples exhibited a lower coefficient of friction than the as-sintered substrate. The coefficient of friction reached approximately 0.66 irrespective of the nitriding temperature. Furthermore, the variation amplitude of the coefficient of friction of the plasma-nitrided samples was larger than that of the as-sintered sample. These large variation amplitudes of the coefficient of friction were caused by the wear debris with a higher hardness during the wear testing [59]. Wear tracks and profiles of sections after the ball-on-disk test are shown in Figure 13. The wear track and profile of the as-sintered sample indicate poor wear resistance. The wear tracks and profiles of the plasma-nitrided samples indicate substantially less wear than observed for the as-sintered sample. This superior wear resistance is attributed to the high hardness and low coefficient of friction of the nitrided samples.

Figure 12.

Friction coefficient of plasma-nitrided CoCrFeMnNi samples during wear tests.

Figure 13.

Wear track and its cross-sectional profile for plasma-nitrided CoCrFeMnNi samples after the wear test.

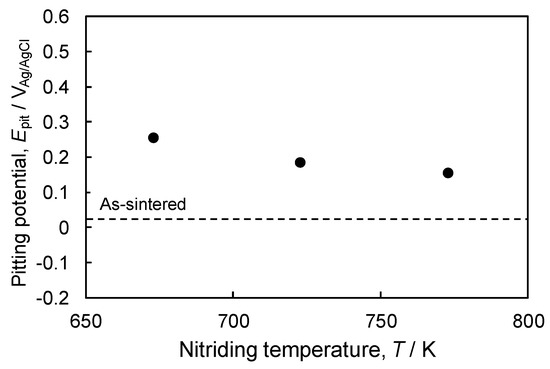

The results of pitting corrosion tests of plasma-nitrided samples using a corrosive aqueous solution of 3.5 mass% NaCl are shown in Figure 14. The pitting potential of the plasma-nitrided samples was higher than that for the as-sintered sample. The pitting potential decreased with increasing nitriding temperature. Some authors have reported that the S-phase that forms on ASS suppresses pitting corrosion in solutions containing chloride ions [38,57,60]. N in ASS is believed to dissolve into solution when the steel is exposed to corrosive media. These N atoms react with H+ in the pits to form NH4+. This reaction increases the local pH and promotes repassivation [57,60]. Due to the nitrides formed on HEA samples, a similar mechanism may have occurred, resulting in improved pitting corrosion resistance. By contrast, in the case samples nitrided at temperatures greater than 723 K, HEAs and ASS tended to differ. The plasma-nitrided HEAs have higher pitting potentials than the as-sintered sample, whereas the plasma-nitrided stainless steels exhibited lower pitting potentials. We attributed these results to the effect of the Cr concentration in the base metal. In the case of ASS, the formation of CrN and the depletion of Cr in the S-phase reduce the pitting corrosion resistance [61]. However, the HEA used in the present study has a higher Cr concentration than ASS, so Cr is not depleted. The aforementioned results show that the formation of expanded fcc or (Co,Cr,Fe,Mn,Ni)N results in high hardness, superior wear resistance, and enhanced pitting corrosion resistance.

Figure 14.

Pitting potential of plasma-nitrided CoCrFeMnNi samples.

4. Conclusions

In this study, CoCrFeMnNi HEA was manufactured using SPS and then plasma-nitrided. The microstructure, mechanical, and corrosion properties of the processed samples were investigated. The results are summarized as follows:

- 1)

- The SPS sample exhibited a uniform microstructure with no segregation, which improved hardness and wear resistance.

- 2)

- After nitriding, N diffused and formed an expanded fcc structure that was considered a supersaturated N solid solution with an fcc structure at 673 K and a NaCl-type solid solution of (Co,Cr,Fe,Mn,Ni)N at 773 K.

- 3)

- Therefore, the plasma-nitrided HEA samples exhibited improved hardness, wear resistance, and pitting corrosion resistance compared with the as-sintered sample.

Author Contributions

T.K. and A.N. conceived and designed the experiments and wrote the paper. T.K. performed the experiments and analyzed the data. A.N. directed the research and contributed to the discussion and interpretation of the results. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by a grant for the high-entropy alloys research group of ORDIST, Kansai University.

Acknowledgments

The authors wish to express their gratitude to Toru Maruyama and Yasuhiro Hoshiyama, Kansai University, for their valuable comments and direction.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H. Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Gludovatz, B.; Hohenwarter, A.; Catoor, D.; Chang, E.H.; George, E.P.; Ritchie, R.O. A fracture-resistant high-entropy alloy for cryogenic applications. Science 2014, 345, 1153–1158. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Pradeep, K.G.; Deng, Y.; Raabe, D.; Tasan, C.C. Metastable high-entropy dual-phase alloys overcome the strength-ductility trade-off. Nature 2016, 534, 227–230. [Google Scholar] [CrossRef] [PubMed]

- Kauffmann, A.; Stüber, M.; Leiste, H.; Ulrich, S.; Schlabach, S.; Vinga Szabó, D.; Seils, S.; Gorr, B.; Chen, H.; Seifert, H.-J.; et al. Combinatorial exploration of the high entropy alloy system Co-Cr-Fe-Mn-Ni. Surf. Coat. Technol. 2017, 325, 174–180. [Google Scholar] [CrossRef]

- Zhou, Y.J.; Zhang, Y.; Wang, Y.L.; Chen, G.L. Solid solution alloys of AlCoCrFeNiTix AlCoCrFeNiTix with excellent room-temperature mechanical properties. Appl. Phys. Lett. 2007, 90, 181904. [Google Scholar] [CrossRef]

- Senkov, O.N. Microstructure and room temperature properties of a high-entropy TaNbHfZrTi alloy. J. Alloys Compd. 2011, 509, 6043–6048. [Google Scholar] [CrossRef]

- Takeuchi, A.; Amiya, K.; Wada, T.; Yubuta, K.; Zhang, W. High-entropy alloys with a hexagonal close-packed structure designed by equi-atomic alloy strategy and binary phase diagrams. JOM 2014, 66, 1984–1992. [Google Scholar] [CrossRef]

- Baker, I.; Meng, F.; Wu, M.; Brandenberg, A. Recrystallization of a novel two-phase FeNiMnAlCr high entropy alloy. J. Alloys Compd. 2016, 656, 458–464. [Google Scholar] [CrossRef]

- Okamoto, N.L.; Fujimoto, S.; Kambara, Y.; Kawamura, M.; Chen, Z.M.T.; Matsunoshita, H.; Tanaka, K.; Inui, H.; George, E.P. Size effect, critical resolved shear stress, stacking fault energy, and solid solution strengthening in the CrMnFeCoNi high-entropy alloy. Sci. Rep. 2016, 6, 35863. [Google Scholar] [CrossRef]

- Bhattacharjee, T.; Wani, I.S.; Sheikh, S.; Clark, I.T.; Okawa, T.; Guo, S.; Bhattacharjee, P.P.; Tsuji, N. Simultaneous strength-ductility enhancement of a nano-lamellar AlCoCrFeNi2.1 eutectic high entropy alloy by cryo-rolling and annealing. Sci. Rep. 2018, 8, 3276. [Google Scholar] [CrossRef] [PubMed]

- He, J.; Wang, Q.; Zhang, H.; Dai, L.; Mukai, T.; Wu, Y.; Liu, X.; Wang, H.; Nieh, T.G.; Lu, Z. Dynamic deformation behavior of a face-centered cubic FeCoNiCrMn high-entropy alloy. Sci. Bull. 2018, 63, 362–368. [Google Scholar] [CrossRef]

- Nagase, T.; Takemura, M.; Matsumuro, M.; Maruyama, T. Solidification microstructure of AlCoCrFeNi2.1 eutectic high entropy alloy ingots. Mater. Trans. 2018, 59, 255–264. [Google Scholar] [CrossRef]

- Guo, S.; Ng, C.; Liu, C.T. Anomalous solidification microstructures in Co-free AlxCrCuFeNi2 high-entropy alloys. J. Alloys Compd. 2013, 557, 77–81. [Google Scholar] [CrossRef]

- Fu, Z.; Chen, W.; Wen, H.; Zhang, D.; Chen, Z.; Zheng, B.; Zhou, Y.; Lavernia, E.J. Microstructure and strengthening mechanisms in an FCC structured single-phase nanocrystalline Co25Ni25Fe25Al7.5Cu17.5 high-entropy alloy. Acta Mater. 2016, 107, 59–71. [Google Scholar] [CrossRef]

- Xie, Y.; Cheng, H.; Tang, Q.; Chen, W.; Chen, W.; Dai, P. Effects of N addition on microstructure and mechanical properties of CoCrFeNiMn high entropy alloy produced by mechanical alloying and vacuum hot pressing sintering. Intermetallics 2018, 93, 228–234. [Google Scholar] [CrossRef]

- Moravcik, I.; Cizek, J.; Gouvea, L. de A.; Cupera, J.; Guban, I.; Dlouhy, I. Nitrogen interstitial alloying of CoCrFeMnNi high entropy alloy through reactive powder milling. Entropy 2019, 21, 363. [Google Scholar] [CrossRef]

- Nishimoto, A.; Nakao, K.; Akamatsu, K.; Ikeuchi, K. Pulsed electric-current bonding of SiC to Cu with Ti intermediate layer. J. Jan. Inst. Metals 2003, 67, 432–435. [Google Scholar] [CrossRef][Green Version]

- Tokita, M. The potential of spark plasma sintering (SPS) method for the fabrication on an industrial scale of functionally graded materials. Adv. Sci. Technol. 2010, 63, 322–331. [Google Scholar] [CrossRef]

- Karimoto, T.; Nishimoto, A. Simultaneous boronizing and carburizing of titanium via spark plasma sintering. Mater. Trans. 2019, 60, 2387–2391. [Google Scholar]

- Wang, C.; Ji, W.; Fu, Z. Mechanical alloying and spark plasma sintering of CoCrFeNiMnAl high-entropy alloy. Adv. Powder Technol. 2014, 25, 1334–1338. [Google Scholar] [CrossRef]

- Ji, W.; Wang, W.; Wang, H.; Zhang, J.; Wang, Y.; Zhang, F.; Fu, Z. Alloying behavior and novel properties of CoCrFeNiMn high-entropy alloy fabricated by mechanical alloying and spark plasma sintering. Intermetallics 2015, 56, 24–27. [Google Scholar] [CrossRef]

- Moravcik, I.; Cizek, J.; Zapletal, J.; Kovacova, Z.; Vesely, J.; Minarik, P.; Kitzmantel, M.; Neubauer, E.; Dlouhy, I. Microstructure and mechanical properties of Ni1,5Co1,5CrFeTi0,5 high entropy alloy fabricated by mechanical alloying and spark plasma sintering. Mater. Des. 2017, 119, 141–150. [Google Scholar] [CrossRef]

- Pohan, R.M.; Gwalani, B.; Lee, J.; Alam, T.; Hwang, J.Y.; Ryu, H.J.; Banerjee, R.; Hong, S.H. Microstructures and mechanical properties of mechanically alloyed and spark plasma sintered Al0.3CoCrFeMnNi high entropy alloy. Mater. Chem. Phys. 2018, 210, 62–70. [Google Scholar] [CrossRef]

- Vaidya, M.; Muralikrishna, G.M.; Murty, B.S. High-entropy alloys by mechanical alloying: A review. J. Mater. Res. 2019, 34, 664–686. [Google Scholar] [CrossRef]

- Ye, Q.; Feng, K.; Li, Z.; Lu, F.; Li, R.; Huang, J.; Wu, Y. Microstructure and corrosion properties of CrMnFeCoNi high entropy alloy coating. Appl. Surf. Sci. 2017, 396, 1420–1426. [Google Scholar] [CrossRef]

- Ayyagari, A.; Barthelemy, C.; Gwalani, B.; Banerjee, R.; Scharf, T.W.; Mukherjee, S. Reciprocating sliding wear behavior of high entropy alloys in dry and marine environments. Mater. Chem. Phys. 2018, 210, 162–169. [Google Scholar] [CrossRef]

- Joseph, J.; Haghdadi, N.; Shamlaye, K.; Hodgson, P.; Barnett, M.; Fabijanic, D. The sliding wear behaviour of CoCrFeMnNi and AlxCoCrFeNi high entropy alloys at elevated temperatures. Wear 2019, 428–429, 32–44. [Google Scholar] [CrossRef]

- Xiao, J.-K.; Tan, H.; Wu, Y.-Q.; Chen, J.; Zhang, C. Microstructure and wear behavior of FeCoNiCrMn high entropy alloy coating deposited by plasma spraying. Surf. Coat. Technol. 2020, 385, 125430. [Google Scholar] [CrossRef]

- Lindner, T.; Löbel, M.; Sattler, B.; Lampke, T. Surface hardening of FCC phase high-entropy alloy system by powder-pack boriding. Surf. Coat. Technol. 2019, 371, 389–394. [Google Scholar] [CrossRef]

- Cui, P.; Li, W.; Liu, P.; Zhang, K.; Ma, F.; Chen, X.; Feng, R.; Liaw, P.K. Effects of nitrogen content on microstructures and mechanical properties of (AlCrTiZrHf)N high-entropy alloy nitride films. J. Alloys Compd. 2020, 834, 155063. [Google Scholar] [CrossRef]

- Sha, C.; Zhou, Z.; Xie, Z.; Munro, P. FeMnNiCoCr-based high entropy alloy coatings: Effect of nitrogen additions on microstructural development, mechanical properties and tribological performance. Appl. Surf. Sci. 2020, 507, 145101. [Google Scholar] [CrossRef]

- Lindner, T.; Löbel, M.; Saborowski, E.; Rymer, L.-M.; Lampke, T. Wear and corrosion behaviour of supersaturated surface layers in the high-entropy alloy systems CrMnFeCoNi and CrFeCoNi. Crystals 2020, 10, 110. [Google Scholar] [CrossRef]

- Sun, Y.; Bell, T. Plasma surface engineering of low alloy steel. Mater. Sci. Eng. A 1991, 140, 419–434. [Google Scholar] [CrossRef]

- Tong, W.P.; Tao, N.R.; Wang, Z.B.; Lu, J.; Lu, K. Nitriding iron at lower temperatures. Science 2003, 299, 686–688. [Google Scholar] [CrossRef]

- Miyamoto, G.; Yonemoto, A.; Tanaka, Y.; Furuhara, T.; Maki, T. Microstructure in a plasma nitrided Fe-18mass%Cr alloy. Acta Mater. 2006, 54, 4771–4779. [Google Scholar] [CrossRef]

- Nishimoto, A.; Akamatsu, K. Effect of pre-deforming on low temperature plasma nitriding of austenitic stainless steel. Plasma Process. Polym. 2009, 6, s306–s309. [Google Scholar] [CrossRef]

- Dong, H. S-phase surface engineering of Fe-Cr, Co-Cr and Ni-Cr alloys. Int. Mater. Rev. 2010, 55, 65–98. [Google Scholar] [CrossRef]

- Nagamatsu, H.; Ichiki, R.; Yasumatsu, Y.; Inoue, T.; Yoshida, M.; Akamine, S.; Kanazawa, S. Steel nitriding by atmospheric-pressure plasma jet using N2/H2 mixture gas. Surf. Coat. Technol. 2013, 225, 26–33. [Google Scholar] [CrossRef]

- Miyamoto, J.; Abraha, P. The effect of plasma nitriding treatment time on the tribological properties of the AISI H13 tool steel. Surf. Coat. Technol. 2019, 375, 15–21. [Google Scholar] [CrossRef]

- Tang, W.Y.; Chuang, M.H.; Chen, H.Y.; Yeh, J.W. Microstructure and mechanical performance of new Al0.5CrFe1.5MnNi0.5 high-entropy alloys improved by plasma nitriding. Surf. Coat. Technol. 2010, 204, 3118–3124. [Google Scholar] [CrossRef]

- Nishimoto, A.; Fukube, T.; Maruyama, T. Microstructural, mechanical, and corrosion properties of plasma-nitrided CoCrFeMnNi high-entropy alloys. Surf. Coat. Technol. 2019, 376, 52–58. [Google Scholar] [CrossRef]

- Wang, W.; Song, S.; Reddy, K.M.; Li, W.; Liu, P.; Wang, X. Deformation behavior of ultrahard Al0.3CoCrFeNi high-entropy alloy treated by plasma nitriding. Mater. Lett. 2019, 255, 126566. [Google Scholar] [CrossRef]

- Hou, J.; Song, W.; Lan, L.; Qiao, J. Surface modification of plasma nitriding on AlxCoCrFeNi high-entropy alloys. J. Mater. Sci. Technol. 2020, 48, 140–145. [Google Scholar] [CrossRef]

- Nishimoto, A.; Bell, T.E.; Bell, T. Feasibility study of active screen plasma nitriding of titanium alloy. Surf. Eng. 2010, 26, 79–84. [Google Scholar] [CrossRef]

- Nishimoto, A.; Nii, H.; Narita, R.; Akamatsu, K. Simultaneous duplex process of TiN coating and nitriding by active screen plasma nitriding. Surf. Coat. Technol. 2013, 228, S558–S562. [Google Scholar] [CrossRef]

- Naeem, M.; Waqas, M.; Jan, I.; Zaka-ul-Islam, M.; Díaz-Guillén, J.C.; Rehman, N.U.; Shafiq, M.; Zakaullah, M. Influence of pulsed power supply parameters on active screen plasma nitriding. Surf. Coat. Technol. 2016, 300, 67–77. [Google Scholar] [CrossRef]

- Nishimoto, A.; Fukube, T.; Tanaka, T. Effect of surface deposits on nitriding layer formation of active screen plasma nitriding. Mater. Trans. 2016, 57, 1811–1815. [Google Scholar] [CrossRef]

- Toshioka, N.; Nishimoto, A. Surface-modified layer formed by plasma nitriding using chromium screen. Mater. Trans. 2020, 61, 1115–1121. [Google Scholar] [CrossRef]

- He, J.Y.; Liu, W.H.; Wang, H.; Wu, Y.; Liu, X.J.; Nieh, T.G.; Lu, Z.P. Effects of Al addition on structural evolution and tensile properties of the FeCoNiCrMn high-entropy alloy system. Acta Mater. 2014, 62, 105–113. [Google Scholar] [CrossRef]

- Zaddach, A.J.; Niu, C.; Koch, C.C.; Irving, D.L. Mechanical properties and stacking fault energies of NiFeCrCoMn high-entropy alloy. JOM 2013, 65, 1780–1789. [Google Scholar] [CrossRef]

- Joo, S.H.; Kato, H.; Jang, M.J.; Moon, J.; Kim, E.B.; Hong, S.J.; Kim, H.S. Structure and properties of ultrafine-grained CoCrFeMnNi high-entropy alloys produced by mechanical alloying and spark plasma sintering. J. Alloys Compd. 2017, 698, 591–604. [Google Scholar] [CrossRef]

- Laurent-Brocq, M.; Akhatova, A.; Perrière, S.; Chebini, L.; Sauvage, X.; Leroy, E.; Champion, Y. Insights into the phase diagram of the CrMnFeCoNi high entropy alloy. Acta Mater. 2015, 88, 355–365. [Google Scholar] [CrossRef]

- Schuh, B.; Mendez-Martin, F.; Völker, B.; George, E.P.; Clemens, H.; Pippane, R.; Hohenwarter, A. Mechanical properties, microstructure and thermal stability of a nanocrystalline CoCrFeMnNi high-entropy alloy after severe plastic deformation. Acta Mater. 2015, 96, 258–268. [Google Scholar] [CrossRef]

- Rogal, Ł.; Szklarz, Z.; Bobrowski, P.; Kalita, D.; Garzeł, G.; Tarasek, A.; Kot, M.; Szlezynger, M. Microstructure and mechanical properties of Al–Co–Cr–Fe–Ni base high entropy alloys obtained using powder metallurgy. Metals Mater. Int. 2019, 25, 930–945. [Google Scholar] [CrossRef]

- Stinville, J.C.; Templier, C.; Villechaise, P.; Pichon, L. Swelling of 316L austenitic stainless steel induced by plasma nitriding. J. Mater. Sci. 2011, 46, 5503–5511. [Google Scholar] [CrossRef]

- Ichii, K.; Fujimura, K.; Takase, T. Structure of the ion-nitrided layer of 18–8 stainless steel. Tech. Rep. Kansai Univ. 1986, 27, 135–144. [Google Scholar]

- Zhang, Z.L.; Bell, T. Structure and corrosion resistance of plasma nitrided stainless steel. Surf. Eng. 1985, 1, 131–136. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, Y.; Yang, H.; Zhang, M.; Ma, S.; Qiao, J. Microstructure and wear properties of nitrided AlCoCrFeNi high-entropy alloy. Mater. Chem. Phys. 2018, 210, 233–239. [Google Scholar] [CrossRef]

- Fossati, A.; Borgioli, F.; Galvanetto, E.; Bacci, T. Corrosion resistance properties of glow-discharge nitrided AISI 316L austenitic stainless steel in NaCl solutions. Corros. Sci. 2006, 48, 1513–1527. [Google Scholar] [CrossRef]

- Li, X.Y. Low temperature plasma nitriding of 316 stainless steel – nature of S phase and its thermal stability. Surf. Eng. 2001, 17, 147–152. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).