Abstract

Grain-oriented silicon steels were produced by the shortest processing route involving twin-roll strip casting, two-stage cold rolling with intermediate annealing, and simulated continuous annealing. The secondary recrystallization behavior of grain-oriented silicon steels under different inhibition conditions was in-situ observed by combining the confocal laser scanning microscopy (CLSM) and electron backscattered diffraction (EBSD) techniques. The results revealed that the optimal temperature of secondary recrystallization showed a proportional relationship with the Zenner pinning force. In the case of weak pinning force, the abnormal grain growth occurred quickly at ~1050 °C. The corresponding growth rates were in the range of 60–1400 μm/min and decreased gradually as the secondary recrystallization proceeded. In the case of strong pinning force, the incubation time and onset temperature of the secondary recrystallization was significantly increased, but the total time of the secondary recrystallization was obviously shortened from 685 s to 479 s, and the final magnetic induction of B8 was increased from 1.7 T to 1.85 T. After the secondary annealing, some island grains and coarse primary grains were retained. The formation of island grain was related to the low migration of grain boundaries. The findings of coarse γ- grains indicated that the primary grain size also played a crucial role during secondary recrystallization, apart from the primary recrystallized texture, which attracted more attention previously.

1. Introduction

Grain-oriented silicon steel is an important soft magnetic material, which is mainly used as the core material of transformers [1]. Its excellent magnetic properties are attributed to the extremely strong Goss texture obtained by secondary recrystallization. Since this steel was proposed in 1934, remarkable progress has been made in sharping Goss texture and in improving the magnetic properties [2,3,4,5]. To date, the maximum magnetic induction of B8 is 1.98 T, approaching the theoretical limit of 2.03 T [6,7]. However, the excessive aspiring after the magnetic properties lead to a complicated processing route. From the melting states to finished products, the grain-oriented silicon steel undergoes a series of physical metallurgical processes such as continuous casting, slab reheating, hot rolling, normalization, cold rolling, decarburization annealing, nitriding, and secondary annealing, among others. Recently, a simplified processing route known as twin-roll strip casting was proposed to manufacture the grain-oriented silicon steel [8,9]. This novel process directly provides the thin as-cast strip from the liquid steels, which has similar thickness as the conventional hot-rolled sheet. Thus, some conventional processes such as continuous casting, slab reheating, and hot rolling can be eliminated. Furthermore, this twin-roll strip casting process has significant potential to obtain the desired microstructure and texture for secondary recrystallization and magnetic properties due to its advantages of rapid solidification [10,11].

It is well established that secondary annealing is the most time-consuming process in both the conventional route and twin roll casting route. This is because the heating rate is extremely slow (15–20 °C/h), which is responsible for secondary recrystallization and the temperature homogeneity of steel coils in the box furnace. After that, a long-term isothermal purification annealing at 1180–1200 °C is adopted to remove impurities from steel and then further decrease the iron loss in the industry. The whole process of secondary batch annealing usually takes 7–10 days, leading to a high cost and low efficiency [12]. Therefore, simplifying the secondary annealing has attracted much attention. Fortunati [13,14] stated that the secondary recrystallization could be achieved in continuous annealing within ~8 min by the integration of high-temperature nitriding into this cycle. The subsequent purification annealing was still processed by batching annealing and the length of time can be shortened into 10 h. Afterward, Kovac [15] used the vanadium carbide (VC) particle as addition inhibitors and introduced a low strain following decarburization annealing. They demonstrated that the kinetic of secondary recrystallization was significantly accelerated by strain induced boundary migration mechanism. Recently, Jiao [16] reported a low-cost grain-oriented silicon steel manufacturing method by using a reduced inhibition state and two-stage cold rolling, and the secondary recrystallization was complete in continuous annealing. Furthermore, Lu [17] observed that some non-Goss {110} <227> grains abnormally grew during short-term isothermal secondary annealing in strip-cast Fe-4.5%Si grain-oriented silicon steel, and deemed that this non-Goss abnormal growth would lead to the decrease of magnetic properties. As mentioned above, the previous studies mainly concentrated on the relationship between the annealing parameters and final magnetic properties. The detailed secondary recrystallization behavior, especially the effect of the pinning force on the secondary recrystallization, is still far from being understood.

In this study, a simplified processing route involving twin-roll casting process two-stage cold rolling and simulated continuous secondary annealing was introduced to manufacture grain-oriented silicon steel. The secondary recrystallization was in-situ observed by combining the confocal laser scanning microscopy (CLSM) and electron backscattered diffraction (EBSD) techniques. This study aims to clarify the secondary recrystallization behavior of grain-oriented silicon steel with different inhibition states.

2. Experimental Procedure

The chemical composition (%, in weight percent) of the grain-oriented silicon steel used in this study is C 0.0043, Si 3.0, Mn 0.21, S 0.017, Al 0.033, N 0.083. The molten steel was directly poured into a twin-roll strip caster as described previously [8,18]. The width and thickness of the as-cast strip were 254 mm and ~2.0 mm, respectively. The as-cast strip was firstly cold rolled to 0.6 mm with reduction rate of 70%, and then the cold rolled sheets intermediate annealed at 1050 °C for 15 min, 2 h, and 20 h, respectively. After that, all the three intermediate annealed sheets were cold rolled to 0.2 mm. The final cold rolled sheets were secondary annealed at 1000 °C, 1025 °C, 1050 °C, 1075 °C, and 1100 °C for 20 min to simulate the continue annealing. Both the intermediate annealing and secondary annealing were carried out under 100% H2 atmosphere by a special atmospheric furnace made by our group [17]. Note that here, the actual annealing time is 5–8 min shorter than the setting value due to the non-negligible decrease of temperature caused by steel specimens and transport devices.

The microstructure and texture of intermediate annealed sheets along the longitudinal section defined by rolling direction (RD) and normal direction (ND) were characterized by electron backscattered diffraction (EBSD) attached to a Zeiss ultra 55 field emission scanning electron microscope. The EBSD samples were mechanically polished slightly with 1500# waterproof abrasive paper and then electropolished at 25 V for 20 s in a mixed solution of 10% perchloric acid and 90% ethanol. The EBSD measurement was performed at 20 kV, and the work distance was 16.3 mm. The step size was 1 μm. The EBSD data was processed by the software package (HKL-CHANNEL 5, Oxford, UK) and presented in the form of orientation maps and orientation distribution functions (ODF) in φ2 = 45° section. The ODFs were calculated by series expansion method (Lmax = 22) assuming orthorhombic sample symmetry and by superimposing a Gaussian peak for each orientation with a spread of 5° around the exact orientation. The precipitation observation was carried out in a Tecnai G2 F20 transmission electron microscope (TEM, FEI, Hillsboro, OR, USA). The TEM samples were prepared by twin jet polishing in a solution of 10% perchloric acid and 90% ethanol. The magnetic induction at 800 A/m (B8) was measured using a single sheet tester in the rolling direction of the secondary annealed specimens of 100 mm length and 30 mm width. Finally, the in-situ observation of secondary recrystallization was carried out by confocal laser scanning microscopy (CLSM). The CLSM samples were cut to a circle with 7.5 mm diameter and then mechanically polished slightly with 1500# waterproof abrasive paper. The heating rate is 300 °C/min and the isothermal annealing temperature is 1050 °C and 1100 °C for different inhibition specimens. To prevent the oxidation of the observed surface, Ar gas was used during annealing. After the in-situ observation, the corresponding texture analysis was also carried out by EBSD.

3. Results and Discussions

3.1. The Microstructure, Texture, and Precipitates in Intermediate Annealed Sheets

In conventional processing routes, both the formation of Goss texture acting as the seeds of secondary recrystallization and the precipitation of MnS inhibitors occurred in hot rolled step. However, the hot-rolled step was omitted in strip casting processing routes. The microstructure refinement, texture optimization, and precipitation control can be achieved by two-stage cold rolling and intermediate annealing.

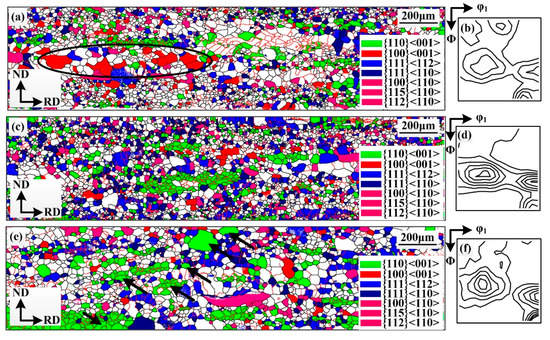

Figure 1 shows the microstructure and texture of intermediate annealed sheets with different annealing time. The intermediate annealed sheets were mainly composed of fine-equiaxed recrystallized grains and a few of elongated recovery grains (indicated by the black oval in Figure 1a), together with a strong γ-fiber with a peak of {111} <112>, a moderate Goss texture and a weak cube and α-fiber with {001} <110>–{112} <110> (as shown in Figure 1b,d,f). The average grain size of the intermediate sheets annealed at 1000 °C for 15 min, 2 h, and 20 h was 19.4 μm, 18.7 μm, and 26.4 μm, respectively (as shown in Figure 1a,c,e). It is noteworthy that the average grain size did not increase, but decrease slightly with increasing annealing time from 15 min to 2 h. This is because the recrystallization behavior was not complete in the intermediate sheet annealed for 15 min. The existence of some elongated grains showing cube texture or α-fiber brings about a relatively larger average grain size (19.4 μm) and a slight inhomogeneity of microstructure. With the annealing time extended to 2 h, most of the elongated grains were consumed by the recrystallized grains, leading to smaller average grain size (18.7 μm) and higher homogeneity. Correspondingly, the sum fraction of cube and α-fiber decreased from 15.8% to 13.4%, and the fraction of recrystallized Goss texture and γ-fiber (sum of {111} <112> and {111} <110>) increased from 11.5% to 13.8% and 17.4% to 26%. When the annealing time was further extended to 20 h, the average grain size was obviously increased to 26.4 μm, and the microstructure homogeneity deteriorated slightly once more. Simultaneously, the fraction of Goss texture increased from 13.8% to 19.2%, while the γ-fiber decreased from 26.01% to 18.64%. These results indicated the precipitates, which are called grain growth inhibitors in grain-oriented silicon steel, have been coarsened to some extent, and the Goss texture preferential grows by consuming the γ-fiber grains.

Figure 1.

EBSD mainly orientation maps (a,c,e) and the corresponding φ2 = 45° sections of ODFs of intermediate sheets annealed at 1000 °C for different times. (a,b) 15 min; (c,d) 2 h; (e,f) 20 h.

To be interesting, the Goss texture was distributed homogeneously through the normal direction of intermediate sheets (indicated by black arrows in Figure 1e), which was different from that of the conventional route. In the conventional route, the Goss texture was formed due to the high fraction between rollers and hot-rolled sheets and mainly distributed in the subsurface layer of hot-rolled sheets [18]. However, in the strip casting processing route, the hot rolling was omitted and the Goss texture mainly nucleated in the cold-rolled shear bands [19]. It is known that the shear band is closely related to the initial grain size prior to deformation. The as-cast strip containing coarse initial grains are prone to form shear bands due to the strong geometrical softening effect [20]. The shear bands were widely distributed through the thickness of cold-rolled sheets, which lead to the Goss texture distributed homogeneously in the subsequent intermediate sheet [19].

The distribution of Goss texture had a significant effect on the kinetics of secondary recrystallization. Usually, abnormal growth occurs first in the subsurface layer where the Goss texture is aggregated. Then the abnormal Goss grains extend to the center layer with stronger {111} <112> texture. Finally, the growing Goss grains consume the surface layer and other island grains [21]. Based on this, Kawasaki Steel Corp [22] demonstrated that the rate of secondary recrystallization was obviously increased when the surface layer of the primary recrystallized sheets was removed. In this study, the abnormal growth of Goss texture may occur simultaneously in the whole region of the annealed sheets because of the homogeneity distribution of Goss texture, which was beneficial for accelerating the process of secondary recrystallization.

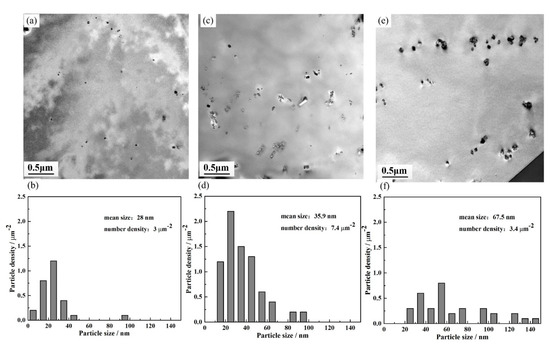

Figure 2 displays the TEM images of the precipitates and their distributions in the intermediate sheets annealed at 1000 °C for different times. The average size of precipitates in intermediate sheets annealed for 15 min, 2 h, and 20 h was 28 nm, 35.9 nm, and 67.5 nm, and the corresponding density in number was 3.0 um−2, 7.4 um−2 and 3.4 um−2, respectively. We can see that the average size of precipitates increases while the number density first increases and then decreases with increasing annealing time. These results illustrate that these precipitates experienced a process of precipitation first and then coarsening. According to the Zener pinning theory [23], the pinning force was inversely proportional to the precipitate’s diameter and proportional to the number density. We can conclude that the specimen annealed for 2 h had the highest pinning force, followed by the specimen annealed for 15 min, and the weakest specimen for 20 h.

Figure 2.

Precipitates micrographs (a,c,e) by TEM and size and distribution of precipitates (b,d,f) in the intermediate sheets annealed at 1000 °C for 15 min (a,b), 2 h (c,d), and 20 h (e,f).

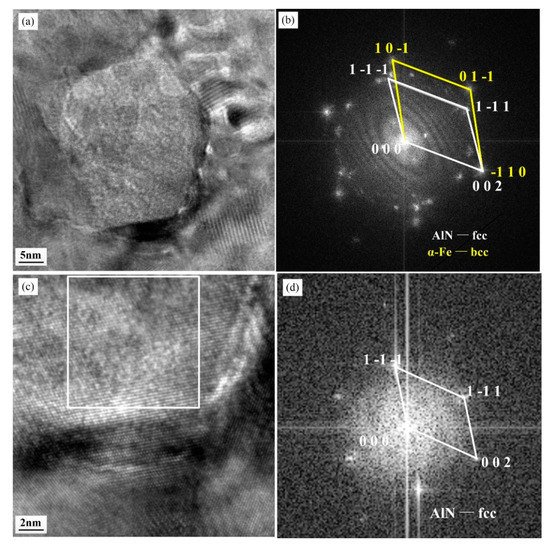

Figure 3 displays the high resolution-TEM (HR-TEM) images of the typical precipitate in the intermediate sheet annealed at 1000 °C for 15 min. The particle is hexagonal type and its average size is ~25 nm (Figure 3a). The fast Fourier transform (FFT) diffractogram (Figure 3d) shows that the precipitate is in a face-centered cubic (fcc) structure and the lattice constant is ~0.412 nm. Combining the chemical composition of the test steels and the FFT diffractogram, we can confirm that the precipitate is AlN, whose lattice constant is in the rage of 0.410–0.417 nm [24]. Furthermore, the AlN precipitate bears the following orientation relationship with ferrite matrix [110] γ-AlN//[111] α-Fe and {002} γ-AlN//{110} α-Fe (Figure 3b).

Figure 3.

HR-TEM micrograph of the precipitate (a) and the corresponding FFT diffractogram (b) in the intermediate sheet annealed at 1000 °C for 15 min; (c) the magnified micrograph of precipitate, and (d) the FFT diffractogram of the white square zone.

It should be noted that the AlN precipitation behavior was totally different between the strip casting route and the conventional route. In the conventional route, a great number of AlN inhibitors precipitated quickly during the cooling stage of hot band annealing with the help of austenite to ferrite transformation [25]. While, in the strip casting route, an ultra-low carbon design was gradually accepted to eliminate the subsequent decarburization annealing [8]. There was no transformation occurrence in the solid state. The AlN inhibitors were supersaturated solved in the as-cast strip due to the rapid solidification, and mainly precipitated during the intermediate annealing. Compared to the conventional route, the size and distribution of AlN inhibitors can be controlled flexibly by adjusting the intermediate annealing process.

3.2. The Magnetic Properties and Secondary Recrystallization

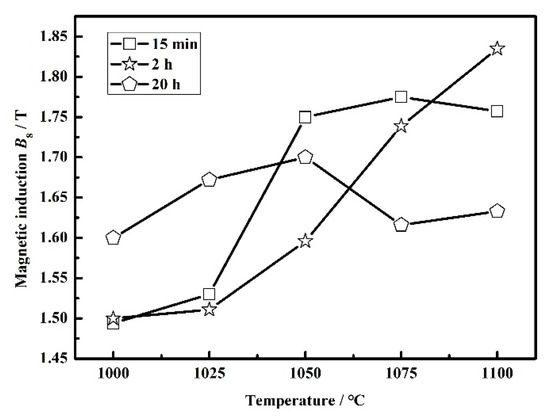

It is well established that the magnetic induction of grain-oriented silicon steel is closely related to the secondary recrystallization of Goss texture. Therefore, the condition of secondary recrystallization can be deduced by its magnetic induction. Figure 4 shows the magnetic induction of grain-oriented silicon steel after secondary isothermal annealing at different temperatures for 20 min. With the increasing of annealing temperature, the magnetic induction firstly increased and then decreased. This result means that grain-oriented silicon steels have an optimum temperature for secondary recrystallization. The specimen intermediate annealed for 20 h showed a weak inhibition state, and the onset temperature (1000 °C) and optimum temperature (1050 °C) for secondary recrystallization was lower. The corresponding magnetic induction (B8 is 1.7 T) was also inferior. In the case of the specimen intermediate annealed for 2 h, the pinning force of precipitates was relatively high. After isothermal annealing at 1100 °C for 20 min, a good magnetic induction (B8 is 1.85 T) was obtained. These results indicated that the kinetic of secondary recrystallization was closely related to the inhibition conditions and the isothermal annealing temperature.

Figure 4.

Magnetic induction of grain-oriented silicon steel isothermally annealed at different temperatures for 20 min.

In addition, the atmosphere of isothermal annealing has a significant influence on secondary recrystallization and magnetic properties of grain-oriented silicon steel. Cardoso [26] also studied the relationship between the isothermal annealed temperature and magnetic properties of the grain-oriented silicon steel, and reported that excellent magnetic properties (B8 is 1.9 T) could be achieved by isothermal annealing at 1070 °C for 50 h under an atmosphere of 75% H2 and 25% N2. The suitable annealing atmosphere can decrease the coarsening rate of AlN particles and is beneficial to improve magnetic properties. However, the occurrence of secondary recrystallization is also delayed. In this work, an atmosphere of 100% H2 was applied, which will accelerate the decomposition of AlN particles, leading to a significant decrease of isothermal secondary annealing times, although the magnetic properties decreased slightly.

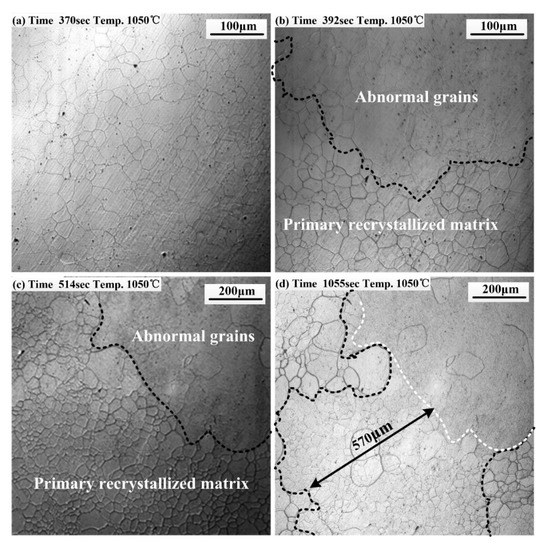

In order to further investigate the secondary recrystallization behavior, the high-temperature in-situ observation analysis was adopted by CLSM. Figure 5 shows the microstructure evolution of silicon steel with weak inhibition states (intermediate annealed for 20 h) during secondary recrystallization annealing. The primary recrystallization was complete at just 370 s, and the average grain size was ~20 μm (as shown in Figure 5a). After annealing for 392 s, the abnormal growth occurred. The secondary grain size was over 500 μm, and the corresponding primary matrix, with a grain size of ~20.8 μm was nearly unchanged (as shown in Figure 5b). The average growth rate of secondary recrystallized grains was about 1400 μm/min. Figure 5c,d displayed the in-situ microstructure evolution from 514 s to 1055 s. The black dotted lines in Figure 5c,d represent the secondary grain boundaries. The white dotted line in Figure 5d represents the previous secondary grain boundary, which is the same boundary as shown Figure 5c. During this period, the secondary grains boundaries migrated ~570 μm. The average growth rate of secondary recrystallized grains was about 60 μm/min. It should be noted that the annealing atmosphere in CLSM is Ar gas, which is different from the H2 atmosphere during simulated continuous annealing. It is known that the atmosphere of secondary annealing has a significant influence on the surface energy of different orientations. Compared to Ar atmosphere, H2 atmosphere can reduce the surface energy of {110} grains and promote the Goss grain selective growth. Moreover, H2 atmosphere can accelerate the coarsening and decomposition of the inhibitors, and further promote the occurrence of secondary recrystallization. Thus, the secondary recrystallization observed by CLSM is not complete, and some island grains with a size of 20–80 μm were observed in the interior of secondary recrystallized grains (as shown in Figure 5c,d). Even if we continue to extend the annealing time, the fraction of secondary recrystallization is not increased significantly, and thus we can deem that the secondary recrystallization has been finished when the samples annealed time extended to 1055 s. However, in this case, the aim of secondary recrystallization has not been achieved.

Figure 5.

Microstructure evolution of weak inhibition specimens during secondary recrystallization by CLSM (intermediate annealed for 20 h). (a) 370 s; (b) 392 s; (c) 514 s; (d) 1055 s.

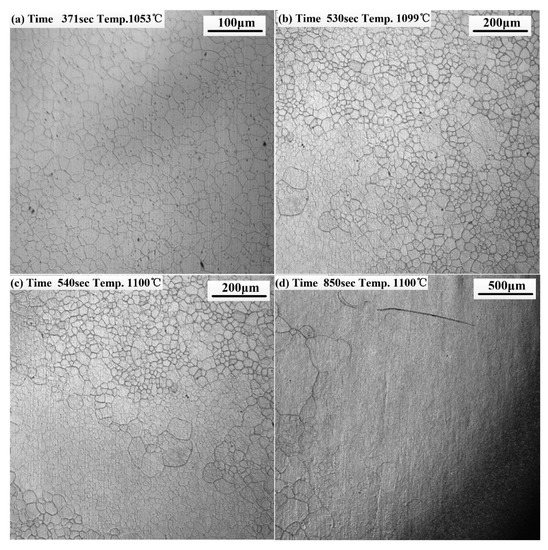

Figure 6 shows the microstructure evolution of silicon steel with strong inhibition states (intermediate annealed for 2 h). The average grain size of the steels after primary recrystallization was 16.7 μm, which was obviously refined than the specimen with weak inhibition states (as shown in Figure 5a and Figure 6a). The abnormal growing grains were observed in the specimens with annealing time in the rage of 530–540 s (as shown in Figure 6b,c). The secondary recrystallization was almost finished when the annealing time was increased to 850 s (as shown in Figure 6d). Compared to the specimens with weak inhibition states, the onset of secondary recrystallization was delayed (shown in Figure 5b and Figure 6b), while the whole time of secondary recrystallization was significantly shortened from 685 s to 479 s. These findings revealed that the secondary recrystallization proceeded very quickly in the weak inhibition states, and the growing rate of secondary recrystallization was gradually decreasing during short-term isothermal annealing.

Figure 6.

Microstructure evolution of strong inhibition specimens during secondary annealing by CLSM (intermediate annealed for 2 h). (a) 371 s; (b) 530 s; (c) 540 s; (d) 850 s.

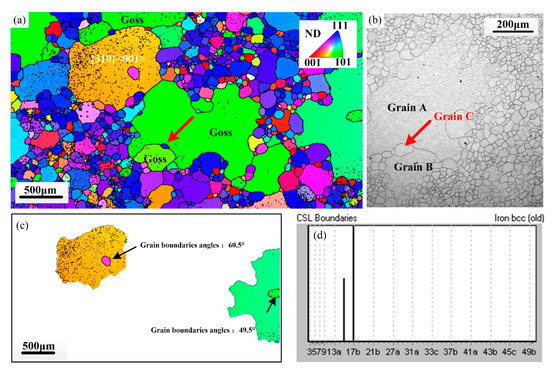

It is noteworthy that there were two kinds of grains hindering the secondary recrystallization. One was the coarse primary recrystallized grain, the other was the island grains in the interior of secondary recrystallized grains. Figure 7 shows the texture and grain boundaries characterization of these grains. In the early stage of secondary recrystallization, some of the primary grains were located at the grain boundaries between two abnormal Goss grains (as indicated by grain A and grain B). After the secondary annealing, the fine primary grains were consumed by the abnormal grains, while the coarse primary grain (as indicated by grain C) was retained. Chang et al. [27] studied the effect of primary grain size on the behavior of secondary recrystallization. They found that the primary recrystallization can be divided into two types. One was the large grain with {110} <001>texture, the other was smaller grain with {111} <112> texture. The large grains of primary recrystallization provide sites for Goss orientation of secondary recrystallization, while the small primarily recrystallized grains provide a place for the growth of secondary recrystallization Goss texture. In this work, surprisingly, this grain C showed an ideal γ-fiber measured by the microstructure in-situ observation and EBSD technique. Usually, the {111} <112> grains are easy to be consumed by abnormal Goss grains due to their special grain boundaries, especially for the γ-fiber. However, this finding indicated that the grain size of primary recrystallization also played a significant role in the secondary recrystallization, besides the primary recrystallized texture.

Figure 7.

Orientation image map after secondary annealing in weak inhibition specimens (a), early stage of secondary annealing in the same position (b), orinetion image map of the island grains and abnormal grains (c), and the CSL boundaries distribution of island grains (d).

In the case of the island grains, the grain boundaries angle was 50° and 60° (as shown in Figure 7c), which can be explained by the high-energy (HE) boundary theory of secondary recrystallization. This theory assumes that grain boundaries with 20–45° angles have a high migration; the preferential growth of Goss grain is attributed to the highest density of HE boundaries around it [28,29]. In contrast, the formation of island grains, which cannot be consumed by abnormal growth grains, is related to the lower migration of boundaries showing angles in the range of less than 20° or greater than 45°. Additionally, it was also found that some specific coincidence site lattice boundaries (CSL, Σ15 and Σ17b) were formed between the island grains and the secondary recrystallized grains. This seems to contradict the CSL secondary recrystallization theory, which indicates that grain boundaries with higher migration are CSL boundaries rather than HE boundaries [30,31]. In fact, the migration of grain boundaries is determined by grain boundary energy and distribution of inhibitors. Before the secondary annealing, the distributions of inhibitors play a dominant role in grain boundaries migration. The low energy of CSL boundaries will lead to fewer inhibitors precipitated at them. Hence, the CSL boundaries possess higher migration. However, the pinning effect of inhibitors was obviously decreased at the later stage of secondary annealing, the migration of grain boundaries was mainly governed by grain boundaries’ energy. Therefore, the lower energy CSL boundaries have lower migration, and it is reasonable that the island grains show special CSL grain boundaries with secondary recrystallized grains.

4. Conclusions

- (1).

- Three inhibition states of grain-oriented silicon steel can be obtained by intermediate annealing in strip casting routes. In the case of weak inhibition conditions, the optimum secondary recrystallization temperature was 1050 °C. After continuous annealing for 392 s, secondary recrystallization occurred. It took ~685 s to complete the secondary recrystallization. The growth rates of secondary recrystallized grains were in the range of 1400–60 min/μm. In the case of strong inhibition conditions, although the onset of secondary recrystallization was relatively late, the total time of the secondary recrystallization was shortened to ~479 s, and the optimum magnetic induction (B8 was 1.85 T) was obtained.

- (2).

- After the secondary annealing, two types of residual grains were found. One was coarse primary grains with γ-fiber located at the secondary grain boundaries. The other was island grains in the interior of secondary recrystallized grains. It was not easy for the larger primary recrystallized grain size to be consumed by the secondary recrystallized grains, although it had an ideal texture. The boundaries of island grains not only met the inference of HE theory, but also presented a special feature of CSL grain boundary, which is of certain significance in further understanding of the formation of island grains.

Author Contributions

Conceptualization, Y.W. and G.Y.; methodology, Y.Z.; software, F.F.; validation, Y.W. and X.L.; formal analysis, Y.W.; investigation, Y.W.; resources, G.Y.; data curation, Y.W.; writing-original draft preparation, Y.W.; writing-review and editing, Y.W.; visualization, X.L.; supervision, G.Y.; project administration, G.W.; funding acquisition, G.W. All authors have read and agreed to the published version of the manuscript.

Funding

This work was financially supported by the National Natural Science Foundation of China (51801022), the Fundamental Research Funds for the Central Universities (N170703006), and the China Postdoctoral Science Foundation (2019M651129, 2019TQ0053).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Moses, A.J. Energy efficient electrical steels: Magnetic performance prediction and optimization. Scr. Mater. 2012, 67, 560–565. [Google Scholar] [CrossRef]

- Xia, Z.; Kang, Y.; Wang, Q. Developments in the production of grain-oriented electrical steel. J. Magn. Magn. Mater. 2008, 320, 3229–3233. [Google Scholar] [CrossRef]

- Belyaevskikh, A.S.; Lobanov, M.L.; Rusakov, G.M.; Redikul’tsev, A.A. Improving the production of super thin anisotropic electrical steel. Steel Transl. 2015, 45, 982–986. [Google Scholar] [CrossRef][Green Version]

- Choi, G.S.; San Lee, C.; Woo, J.S.; Hong, B.D. Method for Manufacturing Oriented Electrical Steel Sheet by Heating Slab at Low Temperature. U.S. Patent 5,653,821, 5 August 1997. [Google Scholar]

- Kumano, T.; Haratani, T.; Fujii, N. Effect of nitriding on grain oriented silicon steel bearing aluminum. ISIJ Int. 2005, 45, 95–100. [Google Scholar] [CrossRef]

- Fang, F.; Zhang, Y.; Lu, X.; Wang, Y.; Cao, G.; Yuan, G.; Xu, Y.; Wang, G.; Misra, R.D.K. Inhibitor induced secondary recrystallization in thin-gauge grain oriented silicon steel with high permeability. Mater. Des. 2016, 105, 398–403. [Google Scholar] [CrossRef]

- Ushigami, Y.; Abe, N.; Kousaka, S.; Nozawa, T.; Honjo, O.; Nakayama, T. Very Thin Electrical Steel Strip Having Low Core Loss and High Magnetic Flux Density and a Process for Producing the Same. U.S. Patent 5,415,703, 16 May 1995. [Google Scholar]

- Wang, Y.; Zhang, Y.X.; Lu, X.; Fang, F.; Xu, Y.B.; Cao, G.M.; Li, C.G.; Misra, R.D.K.; Wang, G.D. A novel ultra-low carbon grain oriented silicon steel produced by twin-roll strip casting. J. Magn. Magn. Mater. 2016, 419, 225–232. [Google Scholar] [CrossRef]

- Song, H.Y.; Liu, H.T.; Lu, H.H.; An, L.Z.; Zhang, B.G.; Liu, W.Q.; Cao, G.M.; Cheng-Gang, L.; Liu, Z.Y.; Wang, G.D. Fabrication of grain-oriented silicon steel by a novel way: Strip casting process. Mater. Lett. 2014, 137, 475–478. [Google Scholar] [CrossRef]

- Park, J.Y.; Oh, K.H.; Ra, H.Y. The effects of superheating on texture and microstructure of Fe-4.5wt%Si steel strip by twin-roll strip casting. ISIJ Int. 2001, 41, 70–75. [Google Scholar] [CrossRef]

- Park, J.Y.; Oh, K.H.; Ra, H.Y. Texture and deformation behavior through thickness direction in strip-cast 4.5 wt%Si steel sheet. ISIJ Int. 2000, 40, 1210–1215. [Google Scholar] [CrossRef]

- Birosca, S.; Nadoum, A.; Hawezy, D.; Robinson, F.; Kockelmann, W. Mechanistic approach of Goss abnormal grain growth in electrical steel: Theory and argument. Acta Mater. 2020, 185, 370–381. [Google Scholar] [CrossRef]

- Fortunati, S.; Cicale, S.; Abbruzzese, G. Process for the Production of Grain Oriented Electrical Steel Strips. U.S. Patent 6,488,784, 3 December 2002. [Google Scholar]

- Klaus, G. Recent technology development in the production of grain oriented electrical steel. Steel Res. Int. 2005, 76, 413–421. [Google Scholar]

- Kovac, F.; Petryshynets, I.; Marcin, J.; Skorvanek, I. Effect of VC nano-inhibitors and dynamic continuous annealing on the magnetic properties of GO steels. IEEE Trans. Magn. 2013, 49, 4196–4199. [Google Scholar] [CrossRef]

- Jiao, Y.; Yang, P.; Zhang, N.; Mao, W. Low-Cost Grain Oriented Silicon Steels Manufactured by Continuous Annealing. Steel Res. Int. 2016, 87, 1417–1425. [Google Scholar] [CrossRef]

- Lu, X.; Fang, F.; Zhang, Y.X.; Wang, Y.; Yuan, G.; Misra, R.D.K.; Zhang, W.N.; Wang, G.D. Secondary recrystallization behavior in strip-cast grain-oriented silicon steel processed by isothermal secondary annealing. Mater. Charact. 2018, 142, 68–76. [Google Scholar] [CrossRef]

- Matsuo, M.; Sakai, T.; Suga, Y. Origin and development of through-the-thickness variations of texture in the processing of grain-oriented silicon steel. Metall. Trans. A Phys. Metall. Mater. Ence 1986, 17, 1313–1322. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, Y.B.; Zhang, Y.X.; Fang, F.; Lu, X.; Liu, H.T.; Wang, G.D. Development of microstructure and texture in strip casting grain oriented silicon steel. J. Magn. Magn. Mater. 2015, 379, 161–166. [Google Scholar] [CrossRef]

- Liu, J.L.; Sha, Y.H.; Zhang, F.; Li, J.C.; Yao, Y.C.; Zuo, L. Development of {2 1 0} <001> recrystallization texture in Fe-6.5 wt.% Si thin sheets. Scr. Mater 2011, 65, 292–295. [Google Scholar] [CrossRef]

- Yan, M.; Qian, H.; Yang, P.; Mao, W.; Jian, Q.; Jin, W. Analysis of micro-texture during secondary recrystallization in a Hi-B electrical steel. J. Mater. Sci. Technol. 2011, 27, 1065–1071. [Google Scholar] [CrossRef]

- He, Z.Z.; Zhao, Y.; Luo, H.W. Electrical Steel; Metallurgical Industry Press: Beijing, China, 2012. (In Chinese) [Google Scholar]

- Humphreys, F.J.; Hatherly, M. Recrystallization and Related Annealing Phenomena; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Suwas, S.; Ray, R.K. Crystallographic Texture of Materials; Springer: London, UK, 2014. [Google Scholar]

- Tsai, M.C.; Hwang, Y.S. The quenching effects of hot band annealing on grain-oriented electrical steel. J. Magn. Magn. Mater. 2010, 322, 2690–2695. [Google Scholar] [CrossRef]

- Cardoso, A.V.D.M.; Paolinelli, S.D.C.; Silveira, C.C.; Cota, A.B. Secondary recrystallization characteristics of 3%Si grain-oriented electrical steel. J. Mater. Res. Technol. 2018, 8, 217–221. [Google Scholar] [CrossRef]

- Chang, S.K.; Hong, B.D. Secondary Recrystallization Behavior in 3% Si Grain Oriented Steels. ISIJ Int. 2004, 44, 1086–1092. [Google Scholar] [CrossRef]

- Maazi, N.; Rouag, N.; Etter, A.L.; Penelle, R.; Baudin, T. Influence of neighbourhood on abnormal Goss grain growth in Fe–3% Si steels: Formation of island grains in the large growing grain. Scr. Mater. 2006, 55, 641–644. [Google Scholar] [CrossRef]

- Liu, Z.; Yang, P.; Li, X.; Wang, X.; Ma, J.; Liu, G. Formation of island grains in high-permeability grain-oriented silicon steel manufactured by the acquired inhibitor method. J. Phys. Chem. Solids 2020, 136, 109165. [Google Scholar] [CrossRef]

- Shimizu, R.; Harase, J. Coincidence grain boundary and texture evolution in Fe-3% Si. Acta Metall. 1989, 37, 1241–1249. [Google Scholar] [CrossRef]

- Kumano, T.; Ushigami, Y. Grain boundary characteristics of isolated grains in conventional grain oriented silicon steel. ISIJ Int. 2007, 47, 890–897. [Google Scholar] [CrossRef][Green Version]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).