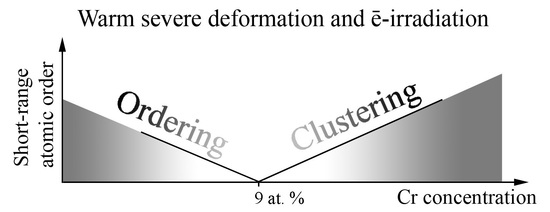

Inversion of the Sign of the Short-Range Order as a Function of the Composition of Fe–Cr Alloys at Warm Severe Plastic Deformation and Electron Irradiation

Abstract

1. Introduction

2. Materials and Methods

3. Experimental Results

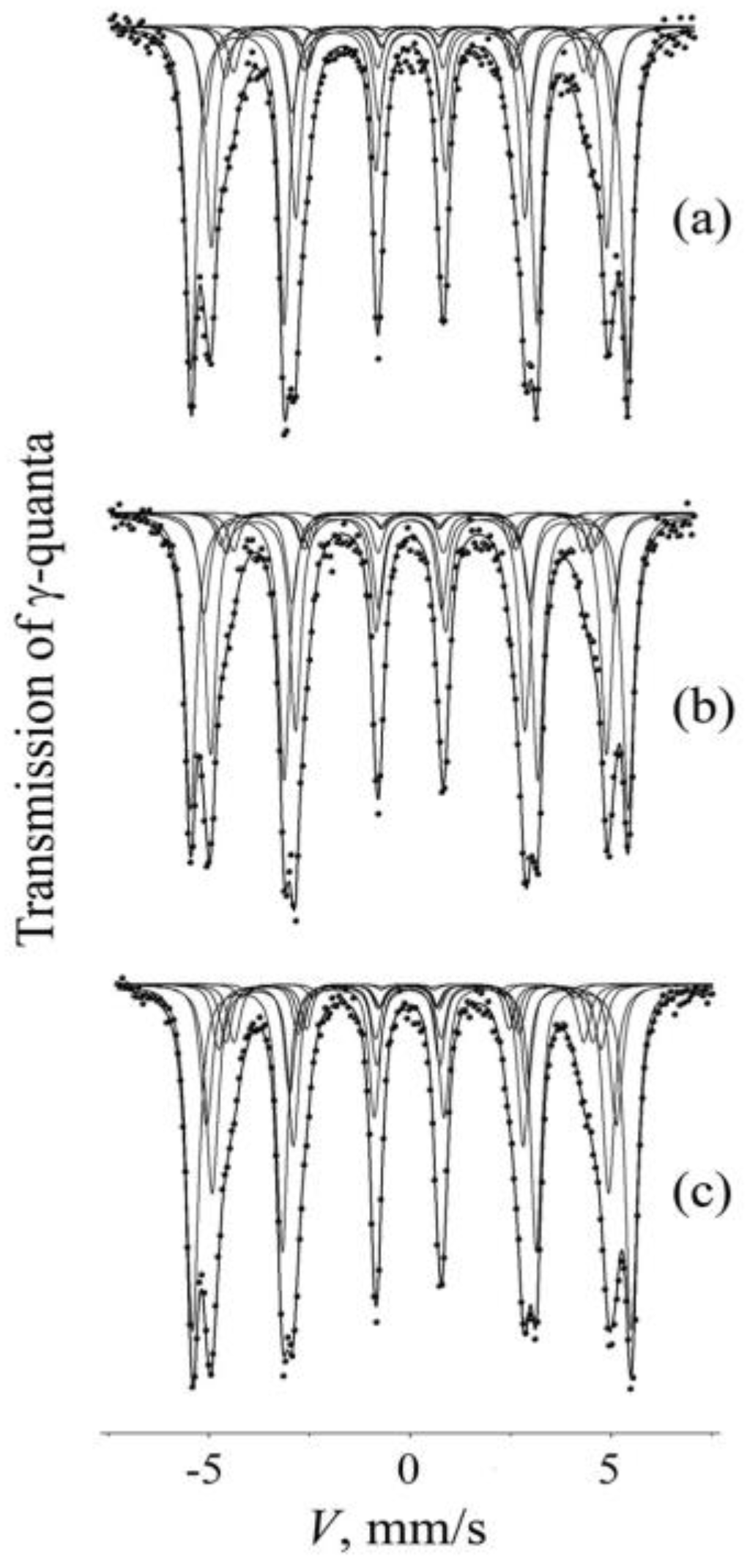

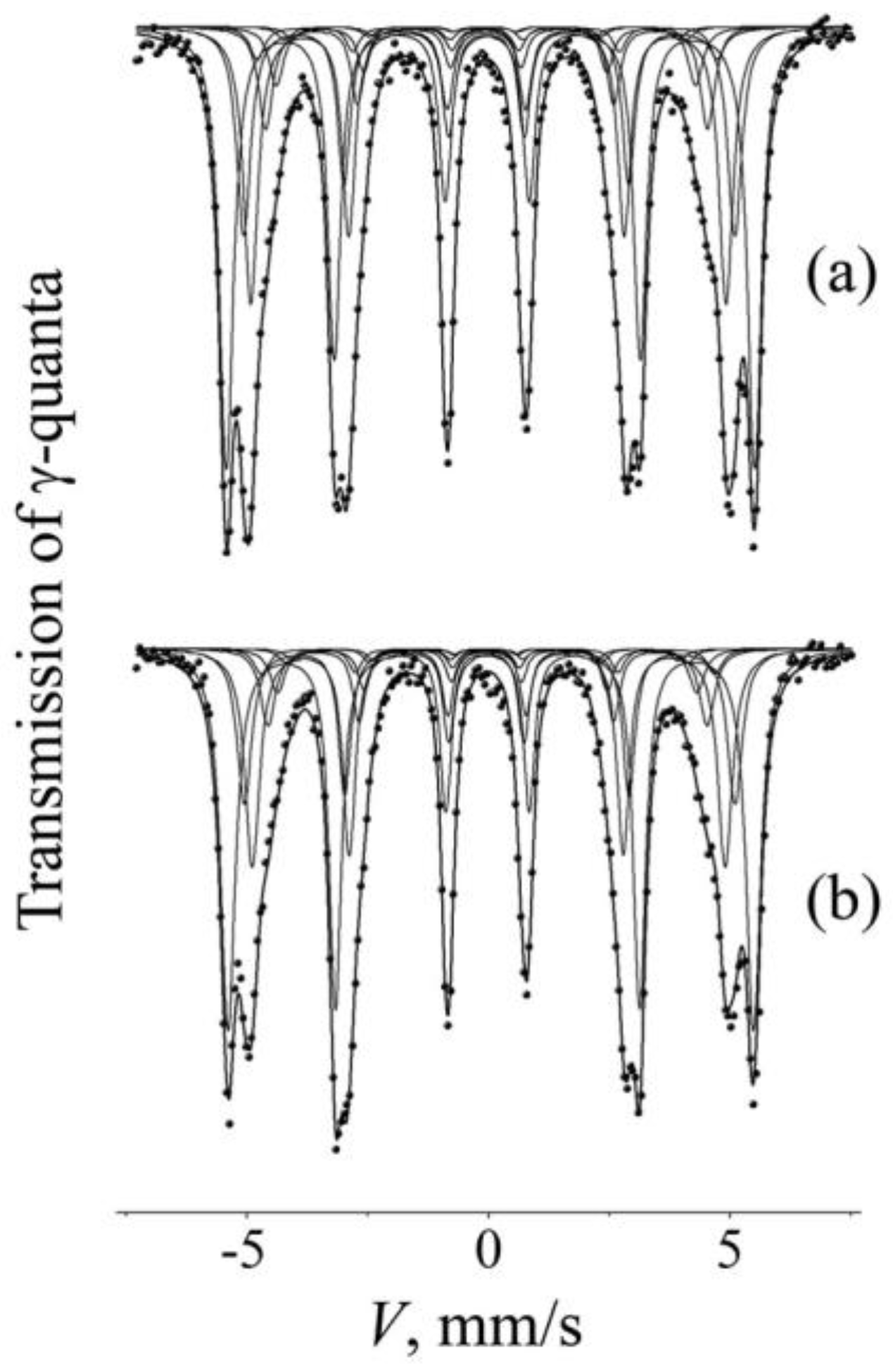

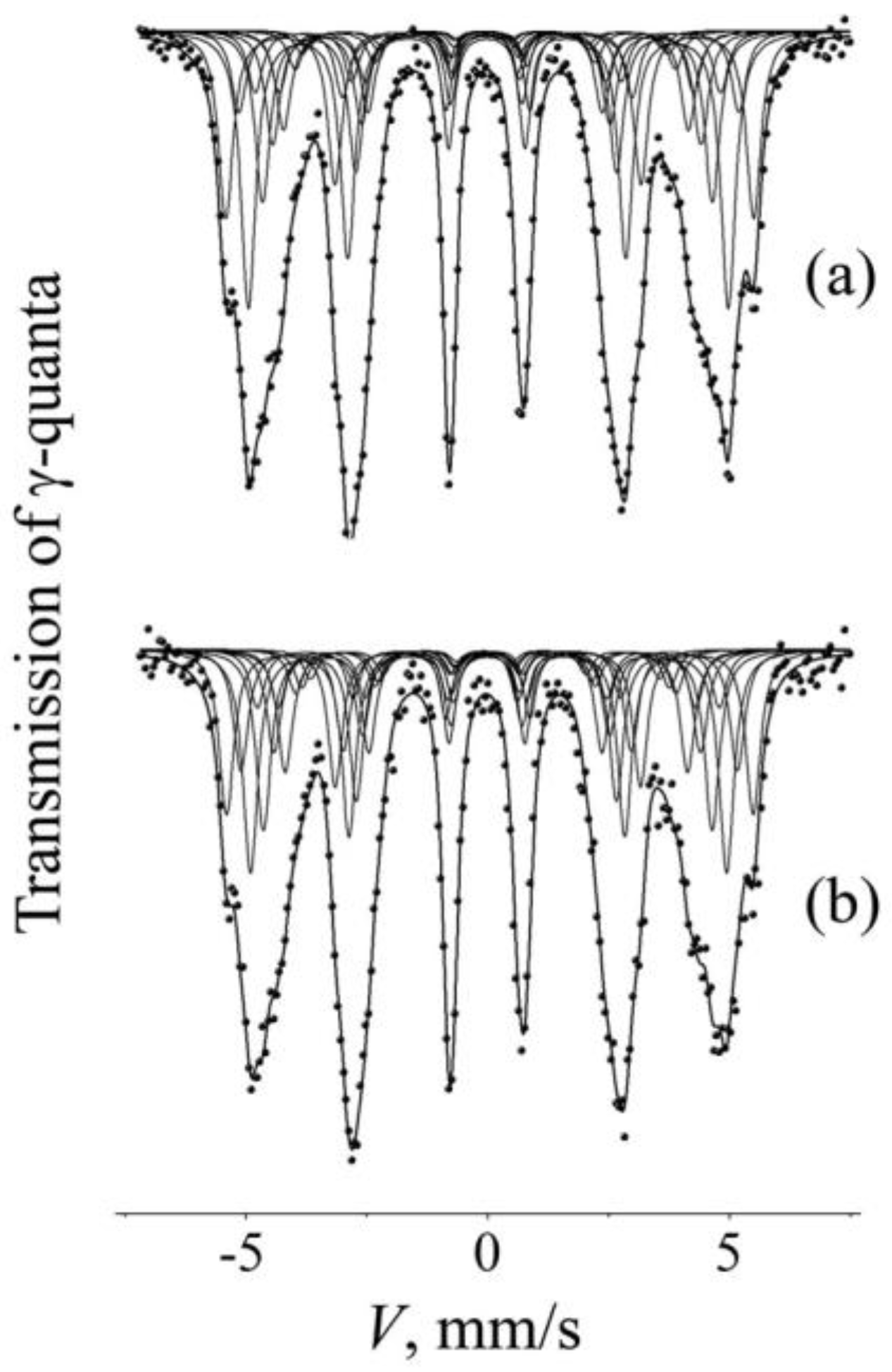

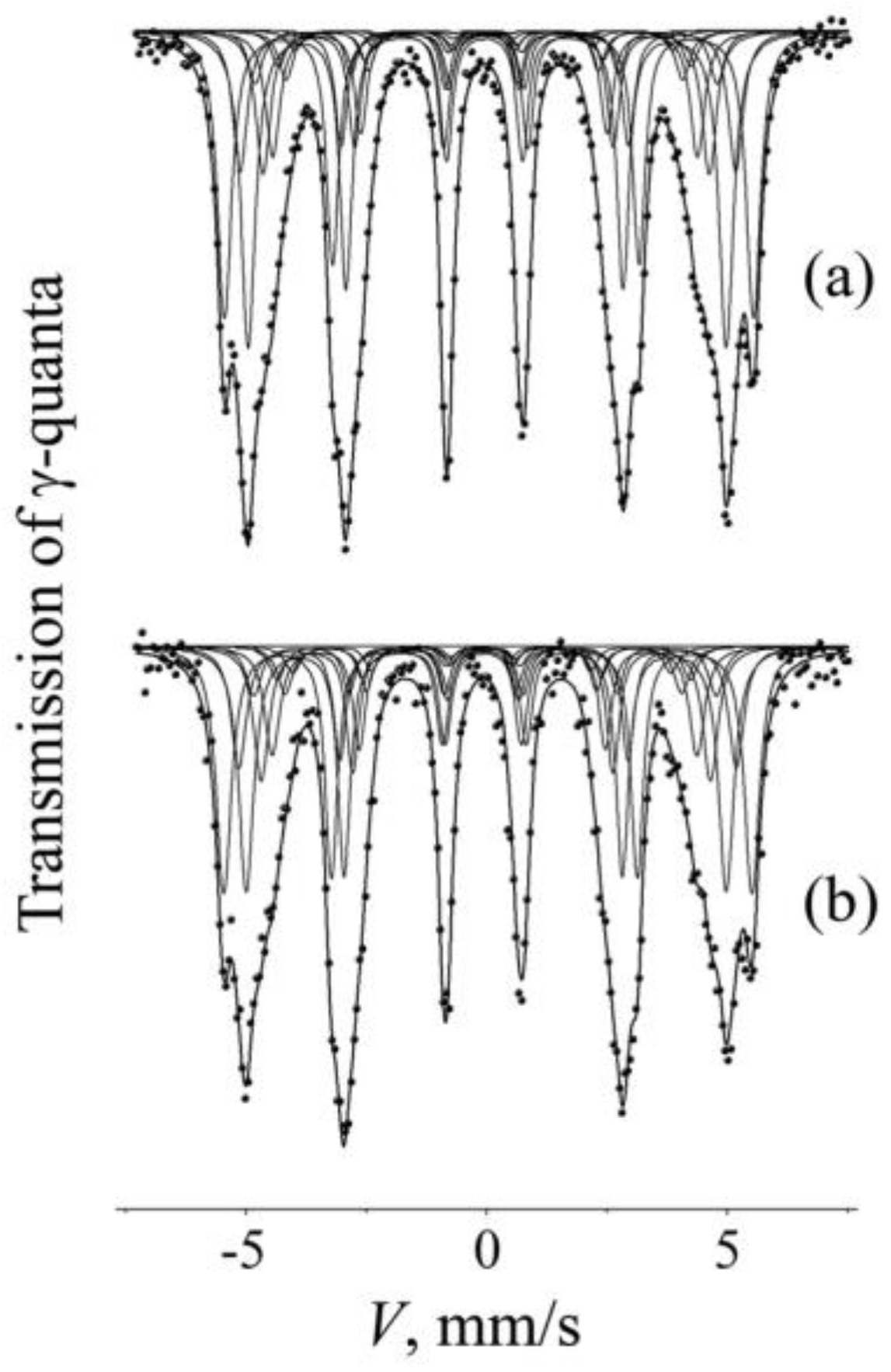

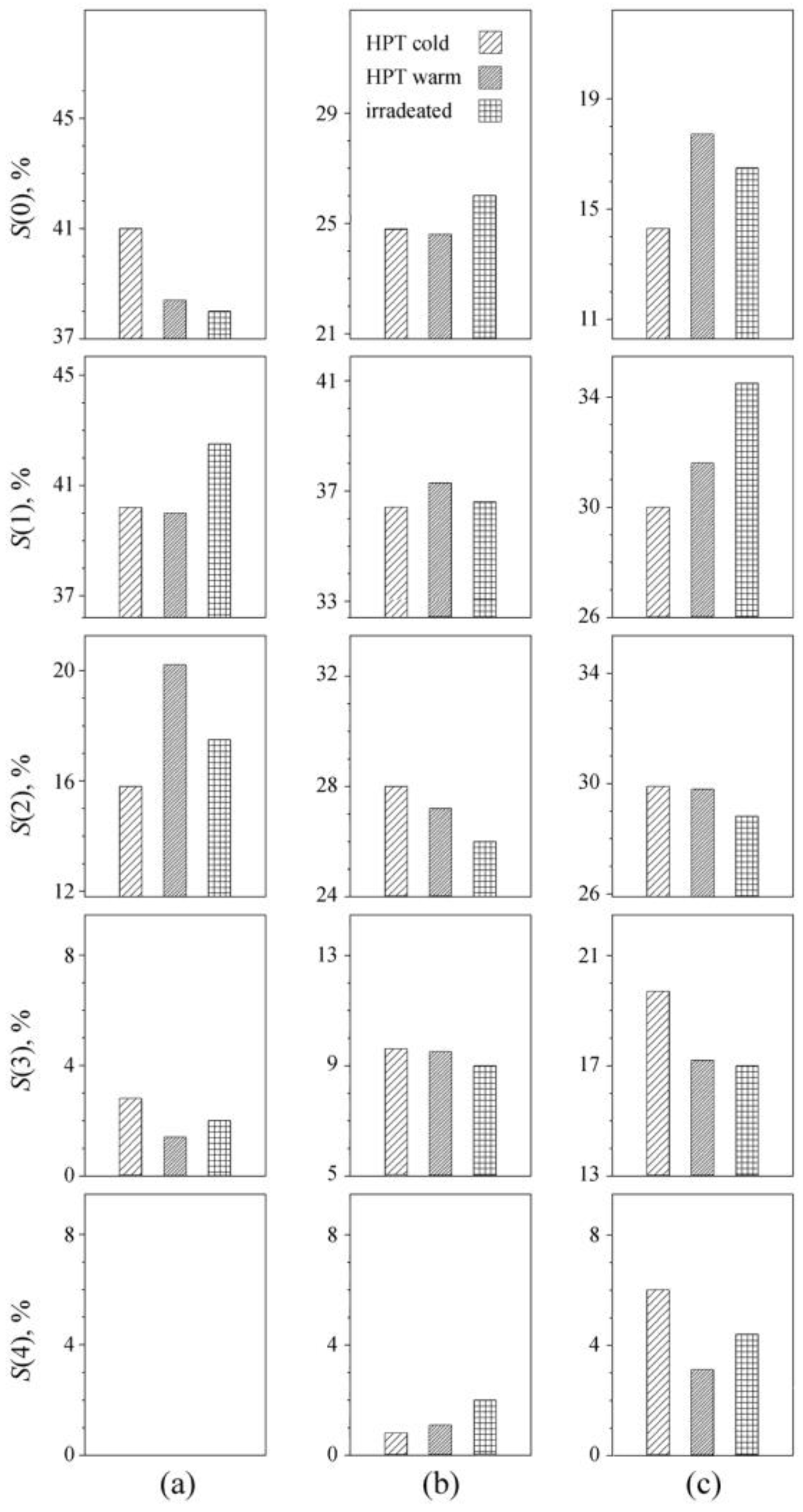

3.1. The Initial (As-Received) Condition of the Alloys

3.2. Thermal Annealing and Irradiation of Fe–Cr Alloys by Electrons

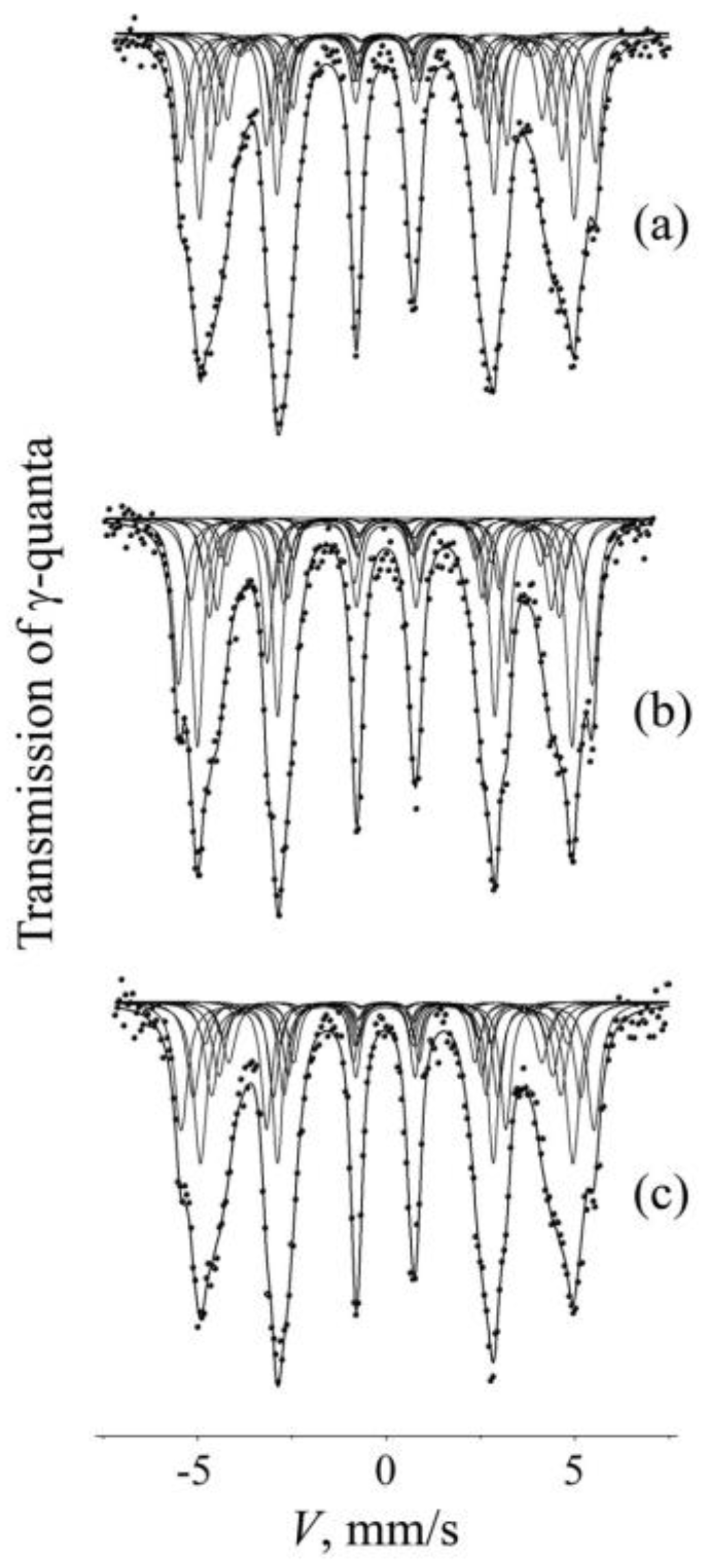

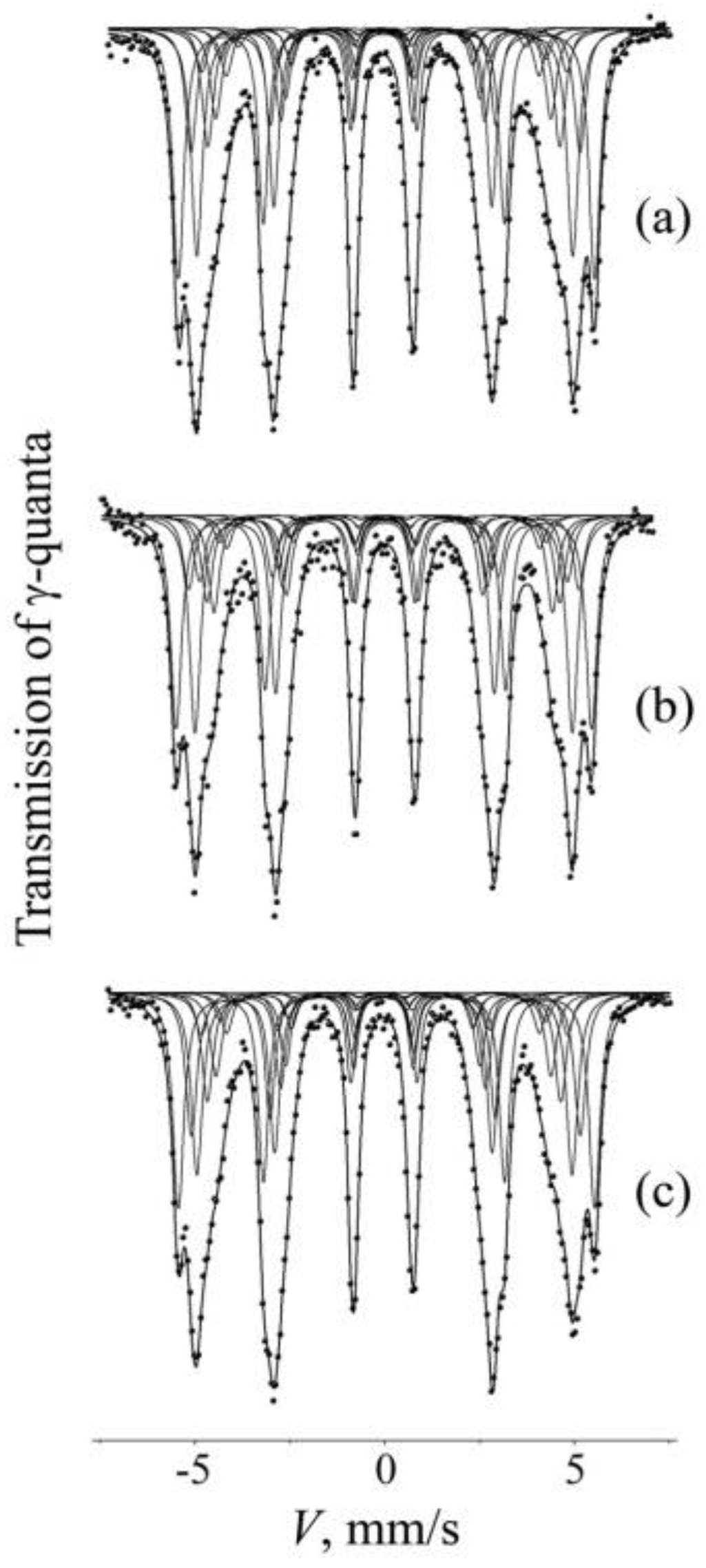

3.3. HPT of Fe–Cr Alloys at 573 K

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Cook, I. Materials research for fusion energy. Nat. Mater. 2006, 5, 77–80. [Google Scholar] [CrossRef] [PubMed]

- Panin, V.E.; Derevyagina, L.S.; Lemeshev, N.M.; Korznikov, A.V.; Panin, A.V.; Kazachenok, M.S. On the nature of low-temperature brittleness of BCC steels. Phys. Mesomech. 2014, 17, 89–96. [Google Scholar] [CrossRef]

- Rogozhkin, S.V.; Korchuganova, O.A.; Aleev, A.A. Kinetics of α’-phase nucleation during thermal aging of Fe–22% Cr alloy. Inorg. Mat. Appl. Res. 2016, 7, 210–213. [Google Scholar] [CrossRef]

- Shabashov, V.A.; Kozlov, K.A.; Nikolaev, A.L.; Zamatovskii, A.E.; Sagaradze, V.V.; Novikov, E.G.; Lyashkov, K.A. The short-range clustering in Fe–Cr alloys enhanced by severe plastic deformation and electron irradiation. Philos. Mag. 2020, 100, 1–17. [Google Scholar] [CrossRef]

- Shabashov, V.; Sagaradze, V.; Kozlov, K.; Ustyugov, Y. Atomic order and submicrostructure in iron alloys at megaplastic deformation. Metals 2018, 8, 995. [Google Scholar] [CrossRef]

- Shabashov, V.A.; Kozlov, K.A.; Zamatovskii, A.E.; Lyashkov, K.A.; Sagaradze, V.V.; Danilov, S.E. Short-range atomic ordering accelerated by severe plastic deformation in FCC invar Fe–Ni alloy. Phys. Met. Metall. 2019, 120, 686–693. [Google Scholar] [CrossRef]

- Sagaradze, V.V.; Koloskov, V.M.; Goshchitskii, B.N.; Shabashov, V.A. Dissolution kinetics of intermetallics in aging austenitic steels during neutron irradiation. J. Nucl. Mater. 2002, 307–311, 317–321. [Google Scholar] [CrossRef]

- Sagaradze, V.; Shabashov, V.; Kataeva, N.; Kozlov, K.; Arbuzov, V.; Danilov, S.; Ustyugov, Y. Low temperature diffusion transformations in Fe–Ni–Ti alloys during deformation and irradiation. Metal. Mater. Int. 2018, 24, 249–254. [Google Scholar] [CrossRef]

- Hennion, M. Chemical SRO effects in ferromagnetic Fe alloys in relation to electronic band-structure. J. Phys. F. 1983, 13, 2351–2358. [Google Scholar] [CrossRef]

- Mirebeau, I.; Hennion, M.; Parette, G. First Measurement of short-range-order inversion as a function of concentration in a transition alloy. Phys. Rev. Lett. 1984, 53, 687–690. [Google Scholar] [CrossRef]

- Filippova, N.P.; Shabashov, V.A.; Nikolaev, A.L. Mössbauer study of irradiation-accelerated short-range ordering in binary Fe-Cr alloys. Phys. Met. Metall. 2000, 90, 145–152. [Google Scholar]

- Olsson, P.; Abrikosov, I.A.; Vitos, L.; Wallenius, J. Ab initio formation energies of Fe–Cr alloys. J. Nucl. Matter. 2003, 321, 84–90. [Google Scholar] [CrossRef]

- Ruban, A.V.; Korzhavyi, P.A.; Johansson, B. First-principles theory of magnetically driven anomalous ordering in bcc Fe-Cr alloys. Phys. Rev. B. 2008, 77, 094436. [Google Scholar] [CrossRef]

- Korzhavyi, P.A.; Ruban, A.V.; Odqvist, J.; Nilsson, J.-O.; Johansson, B. Electronic structure and effective chemical and magnetic exchange interactions in bcc Fe-Cr alloys. Phys. Rev. B. 2009, 79, 054202. [Google Scholar] [CrossRef]

- Shabashov, V.A.; Kozlov, K.A.; Sagaradze, V.V.; Nikolaev, A.L.; Semyonkin, V.A.; Voronin, V.I. Short-range order clustering in BCC Fe–Mn alloys induced by severe plastic deformation. Philos. Mag. 2018, 98, 560–576. [Google Scholar] [CrossRef]

- Degtyarev, M.V.; Chashchukhina, T.I.; Voronova, L.M.; Patselov, A.M.; Pilyugin, V.P. Influence of the relaxation processes on the structure formation in pure metals and alloys under high-pressure torsion. Acta Mat. 2007, 55, 6039–6050. [Google Scholar] [CrossRef]

- Rusakov, V.S.; Kadyrzhanov, K.K. Mössbauer spectroscopy of locally inhomogeneous systems. Hyperfine Interact. 2005, 164, 87–97. [Google Scholar] [CrossRef]

- Dubiel, S.M.; Zukrowski, J. Mössbauer effect study of charge and spin transfer in Fe–Cr. J. Mag. Mag. Mat. 1981, 23, 214–228. [Google Scholar] [CrossRef]

- Yamamoto, H. A study on the nature of aging of Fe-Cr alloys by means of the Mössbauer effect. Jap. J. Appl. Phys. 1964, 3, 745–748. [Google Scholar] [CrossRef]

- Dubiel, S.M.; Zukrowski, J. Phase-decomposition-related short-range ordering in an Fe–Cr alloy. Acta Mat. 2013, 61, 6207–6212. [Google Scholar] [CrossRef][Green Version]

- Dubiel, S.M.; Zukrowski, J.; Serruys, Y. Effect of 0.25 and 2.0 MeV He-ion irradiation on short-range ordering in model (EFDA) Fe–Cr alloys. Metall. Mater. Trans. A. 2018, 49, 3729–3737. [Google Scholar] [CrossRef]

- Dubiel, S.M.; Zukrowski, J. Distribution of Cr atoms in a strained and strain-relaxed Fe89.15Cr10.75 alloy: A Mössbauer effect study. Phil. Mag. 2017, 97, 386–392. [Google Scholar] [CrossRef]

- Shabashov, V.A.; Sagaradze, V.V.; Zamatovskii, A.E.; Pilyugin, V.P.; Kozlov, K.A.; Litvinov, A.V.; Kataeva, N.V. Dynamic aging in an Fe–Ni–Al alloy upon megaplastic deformation. Effect of the temperature and deformation rate. Phys. Met. Metall. 2016, 117, 805–816. [Google Scholar] [CrossRef]

- Gubicza, J.; Dobatkin, S.V.; Khosravi, E. Reduction of vacancy concentration during storage of severely deformed Cu. Mater. Sci. Eng. A 2010, 527, 6102–6104. [Google Scholar] [CrossRef]

- Cizek, J.; Janecek, M.; Srba, O.; Kuzel, R.; Barnovska, Z.; Prochazka, I.; Dobatkin, S. Evolution of defects in copper deformed by high-pressure torsion. Acta Mat. 2011, 59, 2322–2329. [Google Scholar] [CrossRef]

- Glezer, A.M.; Metlov, L.S. Physics of megaplastic (severe) deformation in solids. Phys. Sol. State 2010, 52, 1162–1169. [Google Scholar] [CrossRef]

- Razumov, I.K.; Gornostyrev, Y.N.; Ermakov, A.E. Scenarios of nonequilibrium phase transformations in alloys depending on the temperature and intensity of plastic deformation. Phys. Met. Metall. 2018, 112, 1133–1140. [Google Scholar] [CrossRef]

| Configuration | Isomer Shift | Hyperfine Magnetic Field | Sub-Spectrum Intensity S(N1,N2) ~ W(N1,N2), % (±1) | |||||

|---|---|---|---|---|---|---|---|---|

| (N1,N2) | Is, mm/s (±0.010) | H, kOe (±1) | Srandom | Sas-rec. | Sirr. | SHPT (573) | Saged | SHPT (80) |

| 0.0 | 0.015 | 338 | 42.0 | 40 | 38 | 38 | 38 | 41 |

| 0.1 | −0.006 | 316 | 16.1 | 17 | 18 | 16 | 18 | 17 |

| 1.0 | −0.020 | 305 | 21.5 | 23 | 24 | 24 | 24 | 23 |

| 0.2 | −0.029 | 294 | 2.7 | 3 | 3 | 5 | 3 | 3 |

| 1.1 | −0.039 | 283 | 8.2 | 9 | 9 | 9 | 9 | 8 |

| 2.0 | −0.054 | 272 | 4.8 | 5 | 6 | 6 | 6 | 5 |

| 1.2 | −0.066 | 261 | 1.3 | 2 | 1 | 1 | 1 | 2 |

| 2.1 | −0.076 | 250 | 1.8 | 1 | 1 | 1 | 1 | 1 |

| <c1,2>, at. % (±0.2) | 5.6 | 5.7 | 6.0 | 6.2 | 6.0 | 5.7 | ||

| Configuration | Isomer Shift | Hyperfine Magnetic Field | Sub-Spectrum Intensity S(N1,N2) ~ W(N1,N2), % (±1) | |||||

|---|---|---|---|---|---|---|---|---|

| (N1,N2) | Is, mm/s(±0.010) | H, kOe (±1) | Srandom | Sas-rec. | Sirr. | SHPT (573) | Saged | SHPT (80) |

| 0.0 | 0.017 | 341 | 13.8 | 14 | 16 | 17 | 17 | 13 |

| 0.1 | −0.002 | 322 | 12.6 | 12 | 7 | 13 | 7 | 11 |

| 1.0 | −0.016 | 308 | 16.8 | 21 | 28 | 23 | 25 | 20 |

| 0.2 | −0.024 | 300 | 4.8 | 6 | 6 | 6 | 6 | 5 |

| 1.1 | −0.034 | 289 | 15.3 | 14 | 13 | 13 | 15 | 15 |

| 2.0 | −0.049 | 276 | 8.9 | 10 | 10 | 10 | 10 | 9 |

| 1.2 | −0.053 | 269 | 5.8 | 6 | 5 | 5 | 5 | 6 |

| 2.1 | −0.065 | 258 | 8.1 | 10 | 9 | 8 | 9 | 12 |

| 3.0 | −0.076 | 244 | 2.7 | 2 | 3 | 2 | 3 | 3 |

| 2.2 | −0.085 | 236 | 3.1 | 3 | 2 | 2 | 2 | 3 |

| 3.1 | −0.096 | 224 | 2.5 | 2 | 1 | 1 | 1 | 3 |

| <c1,2>, at. % (±0.5) | 12.0 | 11.9 | 10.8 | 10.8 | 11.4 | 12.5 | ||

| Configuration | Isomer Shift | Hyperfine Magnetic Field | Sub-Spectrum Intensity S(N1,N2) ~ W(N1,N2), % (±1) | |||||

|---|---|---|---|---|---|---|---|---|

| (N1,N2) | Is, mm/s (±0.010) | H, kOe (±1) | Srandom | Sas-rec. | Sirr. | SHPT (573) | Saged | SHPT (80) |

| 0.0 | 0.015 | 340 | 25.1 | 26 | 26 | 25 | 24 | 24 |

| 0.1 | −0.027 | 320 | 15.6 | 13 | 13 | 14 | 12 | 12 |

| 1.0 | −0.012 | 308 | 20.8 | 23 | 23 | 23 | 26 | 24 |

| 0.2 | −0.019 | 300 | 4.1 | 4 | 4 | 4 | 4 | 5 |

| 1.1 | −0.028 | 288 | 13.0 | 12 | 13 | 13 | 12 | 13 |

| 2.0 | −0.039 | 274 | 7.6 | 10 | 9 | 10 | 11 | 10 |

| 1.2 | −0.046 | 266 | 3.4 | 3 | 3 | 3 | 3 | 3 |

| 2.1 | −0.059 | 256 | 4.7 | 5 | 4 | 4 | 4 | 5 |

| 3.0 | −0.060 | 242 | 1.6 | 1 | 2 | 2 | 2 | 2 |

| 2.2 | −0.077 | 235 | 1.2 | 2 | 1 | 1 | 1 | 1 |

| 3.1 | −0.088 | 221 | 1.0 | 0 | 1 | 1 | 1 | 1 |

| <c1,2>, at. % (±0.2) | 8.8 | 8.9 | 8.8 | 8.9 | 8.9 | 8.9 | ||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kozlov, K.; Shabashov, V.; Zamatovskii, A.; Novikov, E.; Ustyugov, Y. Inversion of the Sign of the Short-Range Order as a Function of the Composition of Fe–Cr Alloys at Warm Severe Plastic Deformation and Electron Irradiation. Metals 2020, 10, 659. https://doi.org/10.3390/met10050659

Kozlov K, Shabashov V, Zamatovskii A, Novikov E, Ustyugov Y. Inversion of the Sign of the Short-Range Order as a Function of the Composition of Fe–Cr Alloys at Warm Severe Plastic Deformation and Electron Irradiation. Metals. 2020; 10(5):659. https://doi.org/10.3390/met10050659

Chicago/Turabian StyleKozlov, Kirill, Valery Shabashov, Andrey Zamatovskii, Evgenii Novikov, and Yurii Ustyugov. 2020. "Inversion of the Sign of the Short-Range Order as a Function of the Composition of Fe–Cr Alloys at Warm Severe Plastic Deformation and Electron Irradiation" Metals 10, no. 5: 659. https://doi.org/10.3390/met10050659

APA StyleKozlov, K., Shabashov, V., Zamatovskii, A., Novikov, E., & Ustyugov, Y. (2020). Inversion of the Sign of the Short-Range Order as a Function of the Composition of Fe–Cr Alloys at Warm Severe Plastic Deformation and Electron Irradiation. Metals, 10(5), 659. https://doi.org/10.3390/met10050659