Abstract

Chalcocite (Cu2S) has the fastest kinetics of dissolution of Cu in chlorinated media of all copper sulfide minerals. Chalcocite has been identified as having economic interest due to its abundance, although the water necessary for its dissolution is scarce in many regions. In this work, the replacement of fresh water by sea water or by reject brine with high chloride content from desalination plants is analyzed. Additionally, the effect of adding MnO2 from available manganese nodules in vast quantities at the bottom of the sea is studied. Reject brine shows better results than sea water, and the addition of MnO2 to the brine significantly increases the kinetics of chalcocite dissolution in a short time. H2SO4 concentration is found to be irrelevant when working at high concentrations of chloride and MnO2. The best results, 71% Cu extractions in 48 h, are obtained for reject brine, 100 mg of MnO2 per 200 g of mineral and H2SO4 0.5 mol/L. The results are expected to contribute to a sustainable process of dissolution of chalcocite by using the reject brine from desalination plants.

1. Introduction

Currently, 19.7 million tons of copper are produced worldwide [1,2], mainly by pyrometallurgical processes (75%) and, to a lesser extent, by hydrometallurgy (25%) [3,4].

The vast majority of copper minerals in the world correspond to sulfide minerals and a smaller quantity to oxidized minerals [5,6,7,8]. Among the sulfurous minerals, the most abundant copper mineral is chalcopyrite [9,10,11], followed by chalcocite [12]. However, chalcopyrite is a very refractory mineral to be treated hydrometallurgically [13]. On the other hand, chalcocite has been shown to be relatively easy to treat using hydrometallurgical processes [14]. The literature reports an important number of works on the dissolution of chalcocite in acidic media, pressure leaching [15], bioleaching [15,16,17] and leaching in chlorinated media [18,19,20,21]. This last process is very attractive because it is cost effective and leads to high coper extractions.

There is no record in the literature on the use of MnO2 as an oxidizing agent in the leaching of chalcocite in chlorinated media. However, there are records in which this oxidant is added to improve the dissolution of chalcopyrite with good results [22,23,24]. Havlik et al. [24] use HCl and manganese nodules to extract Cu from chalcopyrite. This study finds that, when working at high concentrations of MnO2 (MnO2/CuFeS2 ratio of 4/1) and HCl (4 mol/L), the best copper extractions are obtained, reaching values above 40% at room temperature and near 70% at 50 °C.

The dissolution of chalcocite in chlorinated media has been analyzed several times [14,20,21,25,26], obtaining high copper extraction in the presence of oxidants, such as ferric or cupric, at high temperature, which greatly improves the leaching kinetics of this mineral. To evaluate the effect of chloride, both the concentration and the source have been analyzed, that is, sea water, HCl, NaCl, FeCl3, etc. Cheng and Lawson [25] have proposed that chloride acts as a catalyst that forms long sulfur crystals that allow the diffusion of oxidizing agents within the mineral avoiding the formation of a passivating layer that retards the dissolution of the mineral. Several authors [27,28] have obtained similar results, and to demonstrate the mechanism they have measured the porosity at the mineral surface when copper sulfides are leached in the presence of NaCl, HCl, FeCl3 or other sources of chloride. It is this porosity that allows the mineral to contact the leaching agent through these sulfur layers that form on the mineral surface.

Two reactions are proposed for the dissolution of chalcocite in chlorinated media and in the presence of manganese (IV) as an oxidizing agent.

2 Cu2S + MnO2 + 4 Cl− + 4H+ = 2 CuCl2− + Mn2+ + 2 H2O + 2 CuS ΔG0 = −138.59 kJ

2 CuS + MnO2 + 4 Cl− + 4H+ = 2 CuCl2− + Mn2+ + 2 H2O + 2 S ΔG0 = −84.512 kJ

In the first leaching stage (Equation (1)), chalcocite is converted to covellite; this reaction is thermodynamically possible according to the Gibbs free energy that is negative under the described conditions. The second reaction (Equation (2)) is slower. The energies were calculated using the HSC 5.1 software. Thus, Equation (1) is more likely to occur than Equation (2) as suggested by other authors [12,29].

The shortage of fresh water in various regions of the world is a major economic, environmental and social problem [30]. The use of sea water has become increasingly important for mining, for example, in northern Chile, not only for its positive effects on leaching processes due to its chloride content, but as a strategic and indispensable resource for the sustainability of the industry [4,31,32]. A very attractive alternative is the use of wastewater from desalination plants, which, following the example of Chile, are abundant in the north of the country. Desalination plants produce drinking water for the population, but the reject brine pollutes the sea, threatening the marine ecosystem, and therefore alternatives are required to recycle or reuse this concentrated brine.

In this study, the kinetics of chalcocite dissolution in acid solution and at room temperature in chlorinated media and in the presence of manganese nodules are determined. The kinetics of chalcocite dissolution in sea water and in reject brine from a desalination plant are compared, and the effect of MnO2 and sulfuric acid on the percentage of copper extraction is evaluated, at short and long times.

2. Materials and Methods

2.1. Chalcocite

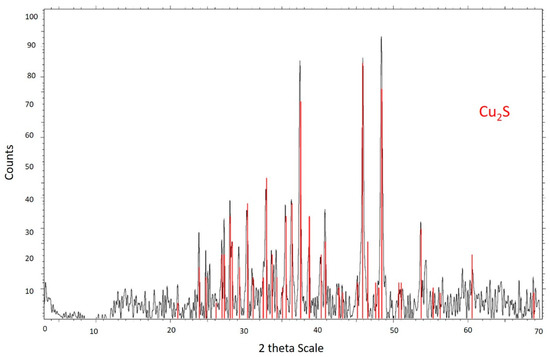

The chalcocite mineral sample was obtained from Mina Atómica, located in Antofagasta, Chile. The material was reduced to reach a size range between −150 and +106 μm. The grinding was done in a porcelain mortar to avoid contamination. The chemical composition was determined by inductively coupled plasma atomic emission spectrometry (ICP-AES, (FEI Company, Brisbane, Australia)). Table 1 shows the results. In addition, the mineralogy of the sample was analyzed using a Bruker X-ray diffractometer (Bruker, Billerica, MA, USA), automatic and computerized model D8, Figure 1 shows the results. The sample was 99.90% chalcocite.

Table 1.

Chemical analysis of the chalcocite ore sample.

Figure 1.

X-ray spectrum of the chalcocite mineral sample.

2.2. Manganese Nodules

The MnO2 used came from manganese nodules collected during the 1970s from the Blake Plateau in the Atlantic Ocean. The sample was reduced in size in a porcelain mortar until reaching a size range between −140 and +100 μm. The chemical composition was determined by inductively coupled plasma atomic emission spectrometry (ICP-AES). Table 2 shows the results. The mineralogy of the sample was analyzed using Bruker® M4-Tornado µ-XRF table-top equipment (Fremont, CA, USA). µ-XRF data interpretation showed the sample is comprised of a pre-existent nodule fragment forming the core with concentric layers precipitated around it at later stages. The experiments showed pyrolusite (MnO2) as the predominant phase (See Table 3).

Table 2.

Chemical analysis of manganese ore.

Table 3.

Mineralogical analysis of manganese ore.

2.3. Reagents and Leaching Tests

Sea water from Antofagasta (Chile) and reject brine from Aguas Antofagasta, Antofagasta (Chile), were used. The sulfuric acid used in the leaching tests is Merck, grade p.a., purity 95–97%, density 1.84 kg/L and molecular weight 98.08 g/mol. Leaching tests were carried out in a 50 mL glass reactor with a 0.01 solid to liquid (S/L) ratio of leaching solution. A total of 200 mg of chalcocite ore was kept suspended by agitation with the use of a 5-position magnetic stirrer (IKA ROS, CEP 13087-534, Campinas, Brazil) at a speed of 600 rpm. The tests were conducted at room temperature of 25 °C at different concentrations of sulfuric acid and chloride, and leaching times. The tests were performed in duplicate. Analyses were performed on 5 mL undiluted samples using atomic absorption spectrometry with a coefficient of variation ≤5% and a relative error between 5% and 10%. Measurements of pH and oxidation-reduction potential (ORP) of the suspensions were made using a pH-ORP meter (HANNA HI-4222, St. Louis, MO, USA). An ORP electrode cell combination consisting of a platinum working electrode and a saturated Ag/AgCl reference electrode was used.

2.4. Experimental Design

Two sources of water that provide chloride, sea water (20 g/L Cl−) and reject brine (39 g/L Cl−), were evaluated. The copper extraction was determined every 4 h until reaching a total time of 48 h. The total mass of calchocite in all tests was always 200 mg. The tests were repeated adding MnO2 to the reactor with the chalcocite pulp and measuring every 4 h until completing 48 h. Two concentrations of MnO2 were used, 0.25:1 and 0.5:1, with respect to the total mass of chalcocite. Finally, to evaluate the effect of H2SO4 on all the tests carried out, three concentrations were used, 0.1, 0.5 and 1 M.

3. Results

3.1. Effect of Chloride Concentration on Copper Extraction

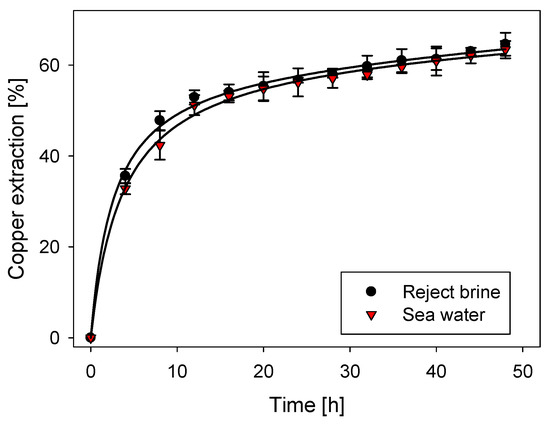

The effect of chloride ions in leaching processes has proven beneficial for the treatment of sulphide minerals [14,25,26]. On the other hand, recent studies have shown the benefits of oxidizing primary sulphides incorporating MnO2 into the system [22,23,24]. Figure 2 for chalcocite shows better results in chloride-concentrated water such as the brine reject from reverse osmosis plants (ca. 39 g/L of Cl−) than in seawater (20 g/L of Cl−) both in the presence of MnO2 in a concentration 0.25:1 w/w with respect to the chalcocite mass. Using reject brine, extractions over 50% Cu are obtained in 8 h and 67.5% Cu in 48 h, apart from the fact that other ions present such as calcium, magnesium and carbonate do not adversely affect the Cu2S dissolution. Figure 2 shows that 80% or more of the copper extraction occurs quickly within the first 8 h.

Figure 2.

Cu extraction from chalcocite in two water sources and the addition of MnO2 in a ratio 0.25:1 w/w with respect to the chalcocite mass.

3.2. Effect of MnO2 Concentration on Copper Extraction

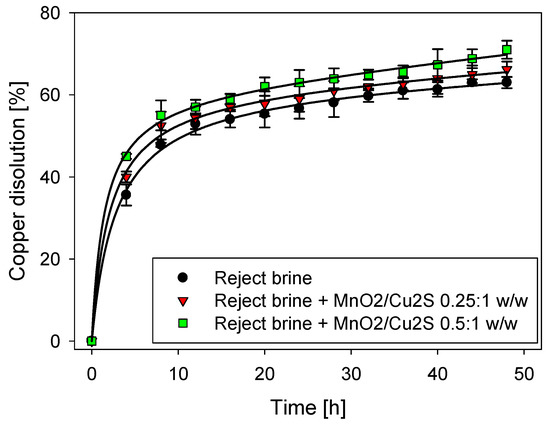

Figure 3 shows the effect of MnO2 concentration on chalcocite dissolution in reject brine. As the MnO2 concentration increases, the dissolution of chalcocite increases. This is consistent with the results presented by Devi et al. [22] and Havlik et al. [24], which show that MnO2 increases the dissolution of even a more refractory sulfide such as chalcopyrite when working at very high concentrations of MnO2 and HCl. Figure 3 shows that the kinetics of chalcocite dissolution is faster in the presence of MnO2 but it is more so when the concentration of MnO2 is higher (ratio 0.5:1 w/w or more with respect to the chalcocite mass). In the latter case, a greater dissolution is obtained at very short times (less than 10 h) which slowly stabilizes at higher dissolution values at longer times.

Figure 3.

Kinetics of chalcocite dissolution in reject brine. Effect of MnO2 concentration.

Table 4 compares the results of chalcocite dissolution in chlorinated media (sea water and reject brine) in two cases: Without the addition of an oxidizing agent and with the incorporation of a small amount of MnO2 under the same operating conditions. The table shows that the higher the chloride concentration, the greater the leaching performance, and that the presence of MnO2 increases the dissolution in all cases. Dissolution data without MnO2 in Table 4 are from Toro et al. [14]. Note that for reject brine the data is very similar to that shown in Figure 3. MnO2 increases chalcocite dissolution at short times of 4 h by 8% in sea water and by 10% in reject brine. At long times of 48 h the increase is more moderate, 2% in sea water and 2.5% in reject brine. More interesting are the short time data considering that in a field operation the leaching solution is continuously refreshed.

Table 4.

Comparison of chalcocite dissolution in sea water and reject brine and the effect of MnO2.

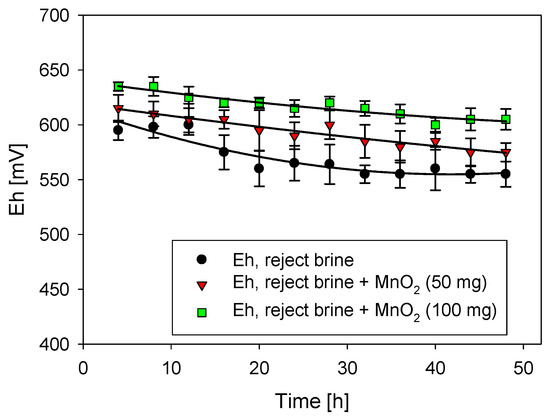

Figure 4 shows the potential for the tests performed in Figure 3. The potential varies between 550 and 630 mV in agreement with Senanayake [33], which indicates that for the dissolution of chalcocite in a chloride-iron solution at 25 °C it is necessary to reach potential values greater than 500 mV. Figure 4 shows higher potentials and copper extractions at short leaching times. Furthermore, Miki et al. [29] have stated that upon dissolving 50% of chalcocite, the dissolution kinetics becomes slower because the mineral changes phase to covellite, which implies the need to reach potentials greater than 600 mV to dissolve it.

Figure 4.

Effect of potential on the extraction of Cu from chalcocite in reject brine concentrate at different masses of MnO2.

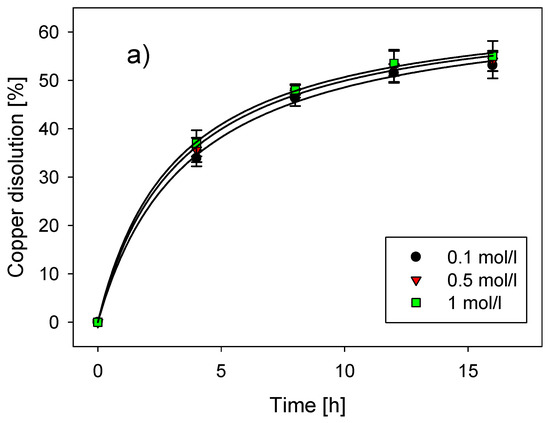

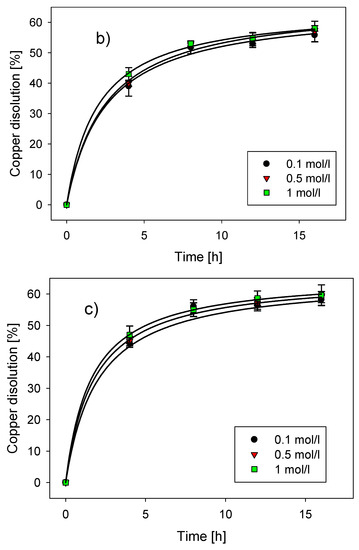

3.3. Effect of Sulfuric Acid Concentration on Copper Extraction

The effect of the sulfuric acid concentration on the chalcocite dissolution in reject brine from desalination is presented in Figure 5. In general, the H2SO4 concentration does not have a significant effect on the Cu2S dissolution in a chlorinated medium; this is in agreement with Cheng and Lawson [25] who determined that only a minimal amount of sulfuric acid is needed. An increase in the concentration of sulfuric acid has no significant effect on the dissolution of chalcocite in the presence of MnO2, whatever its concentration.

Figure 5.

Effect of sulfuric acid concentration on copper extraction using reject brine, (a) without MnO2, (b) MnO2/Cu2S 0.25:1 w/w and (c) MnO2/Cu2S 0.5:1 w/w.

The results of this study confirm the findings of Toro et al. [14], Dutrizac [34], Cheng and Lawson [25] and Senanayake [26] regarding that high concentrations of chloride favor dissolution kinetics of chalcocite, and of other copper sulfides such as chalcopyrite and covellite [27,28,29], other variables or conditions are not as relevant. At the same time, the results of this study suggest that the addition of MnO2 enhances the dissolution of chalcocite regardless of the concentration of chlorides.

4. Conclusions

Rejection brine from desalination plants and manganese nodules improve the dissolution kinetics of chalcocite, especially at short times. The main conclusions of this work are:

- Reject brine shows higher Cu extracts from chalcocite compared to sea water due to its higher chloride concentrations.

- Low concentrations of MnO2 significantly improve the dissolution kinetics of chalcocite in a short time, which is important for continuous leaching operations.

- High concentration of H2SO4 is not important when working at high concentrations of chloride and MnO2.

- Best results are obtained in reject brine, with MnO2/Cu2S 0.5:1 w/w and 0.5 mol/L H2SO4, that is, 71% Cu extractions in 48 h.

- Results are expected to contribute to a sustainable process of dissolution of chalcocite.

In future works, these expressions should be replicated but reusing black copper minerals, in order to reuse MnO2 from waste, and thus justify the additional cost of adding an oxidizing agent. Finally, these new results should be compared with those presented in this study.

Author Contributions

N.T. and R.I.J. contributed in project administration, W.H.L., P.G.T. contributed in investigation and D.T. and N.T. wrote paper. E.T. contributed in validation and supervision and P.R. contributed in review and editing. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Acknowledgments

The authors thank the Scientific Equipment Unit-MAINI of the Universidad Católica del Norte for all the chemical analyses in this work. The authors are grateful for the contribution of the Scientific Equipment Unit-MAINI of the Universidad Católica del Norte for facilitating the chemical analysis of the solutions. Pedro Robles thanks the Pontificia Universidad Católica de Valparaíso for the support provided. Pedro G. Toledo and Ricardo I. Jeldres thank Centro CRHIAM Project Anid/Fondap/15130015.

Conflicts of Interest

The authors declare they have no conflict of interest.

References

- COCHILCO. Sulfuros Primarios: Desafíos y Oportunidades; COCHILCO: Santiago, Chile, 2017.

- Toro, N.; Pérez, K.; Saldaña, M.; Salinas-Rodríguez, E.; Hernández, P. Treatment of black copper with the use of iron scrap–Part I. Hem. Ind. 2020, 74, 237–245. [Google Scholar] [CrossRef]

- ICSG. The World Copper Factbook 2017; International Copper Study Group: Lisbon, Portugal, 2017. [Google Scholar]

- Toro, N.; Pérez, K.; Saldaña, M.; Jeldres, R.I.; Jeldres, M.; Cánovas, M. Dissolution of pure chalcopyrite with manganese nodules and waste water. J. Mater. Res. Technol. 2019, 9, 798–805. [Google Scholar] [CrossRef]

- Sokić, M.; Marković, B.; Stanković, S.; Kamberović, Z.; Štrbac, N.; Manojlović, V.; Petronijević, N. Kinetics of chalcopyrite leaching by hydrogen peroxide in sulfuric acid. Metals 2019, 9, 1173. [Google Scholar] [CrossRef]

- Sokic, M.; Milosevic, V.; Stankovic, V.; Matkovic, V.; Markovic, B. Acid leaching of oxide-sulphide copper ore prior the flotation: A way for an increased metal recovery. Chem. Ind. 2015, 69, 453–458. [Google Scholar] [CrossRef]

- Ghorbani, Y.; Kuan, S.H. A review of sustainable development in the Chilean mining sector: Past, present and future. Int. J. Min. Reclam. Environ. 2017, 31, 137–165. [Google Scholar] [CrossRef]

- Saldaña, M.; Ayala, L.; Torres, D.; Toro, N. Global sensitivity analyses of a neural networks model for a flotation circuit. Chem. Ind. 2020, 74, 247–256. [Google Scholar] [CrossRef]

- Miroslav, S.; Vladislav, M.; Branislav, M.; Nada, S.; Dragana, Z. Passivation of chalcopyrite during the leaching with sulphuric acid solution in presence of sodium nitrate. Hem. Ind. 2010, 64, 343–350. [Google Scholar] [CrossRef]

- Bogdanović, G.D.; Petrović, S.; Sokić, M.; Antonijević, M.M. Chalcopyrite leaching in acid media: A review. Met. Mater. Eng. 2020, 26, 177–198. [Google Scholar] [CrossRef]

- Aguirre, C.L.; Toro, N.; Carvajal, N.; Watling, H.; Aguirre, C. Leaching of chalcopyrite (CuFeS2) with an imidazolium-based ionic liquid in the presence of chloride. Miner. Eng. 2016, 99, 60–66. [Google Scholar] [CrossRef]

- Niu, X.; Ruan, R.; Tan, Q.; Jia, Y.; Sun, H. Study on the second stage of chalcocite leaching in column with redox potential control and its implications. Hydrometallurgy 2015, 155, 141–152. [Google Scholar] [CrossRef]

- Hernández, P.; Dorador, A.; Martínez, M.; Toro, N.; Castillo, J.; Ghorbani, Y. Use of seawater/brine and caliche’s salts as clean and environmentally friendly sources of chloride and nitrate ions for chalcopyrite concentrate leaching. Minerals 2020, 10, 477. [Google Scholar] [CrossRef]

- Toro, N.; Briceño, W.; Pérez, K.; Cánovas, M.; Trigueros, E.; Sepúlveda, R.; Hernández, P. Leaching of pure chalcocite in a chloride media using sea water and waste water. Metals 2019, 9, 780. [Google Scholar] [CrossRef]

- Muszer, A.; Wódka, J.; Chmielewski, T.; Matuska, S. Covellinisation of copper sulphide minerals under pressure leaching conditions. Hydrometallurgy 2013, 137, 1–7. [Google Scholar] [CrossRef]

- Ruan, R.; Zhou, E.; Liu, X.; Wu, B.; Zhou, G.; Wen, J. Comparison on the leaching kinetics of chalcocite and pyrite with or without bacteria. Rare Met. 2010, 29, 552–556. [Google Scholar] [CrossRef]

- Lee, J.; Acar, S.; Doerr, D.L.; Brierley, J.A. Comparative bioleaching and mineralogy of composited sulfide ores containing enargite, covellite and chalcocite by mesophilic and thermophilic microorganisms. Hydrometallurgy 2011, 105, 213–221. [Google Scholar] [CrossRef]

- Herreros, O.; Quiroz, R.; Viñals, J. Dissolution kinetics of copper, white metal and natural chalcocite in Cl2/Cl− media. Hydrometallurgy 1999, 51, 345–357. [Google Scholar] [CrossRef]

- Herreros, O.; Viñals, J. Leaching of sulfide copper ore in a NaCl–H2SO4–O2 media with acid pre-treatment. Hydrometallurgy 2007, 89, 260–268. [Google Scholar] [CrossRef]

- Phyo, H.A.; Jia, Y.; Tan, Q.; Zhao, S.; Liang, X.; Ruan, R.; Niu, X. Effect of particle size on chalcocite dissolution kinetics in column leaching under controlled Eh and its implications. Physicochem. Probl. Miner. Process. 2020, 56, 676–692. [Google Scholar] [CrossRef]

- Pérez, K.; Jeldres, R.; Nieto, S.; Salinas-Rodríguez, E.; Robles, P.; Quezada, V.; Hernández-Ávila, J.; Toro, N. Leaching of pure chalcocite in a chloride media using waste water at high temperature. Metals 2020, 10, 384. [Google Scholar] [CrossRef]

- Devi, N.B.; Madhuchhanda, M.; Rao, K.S.; Rath, P.C.; Paramguru, R.K. Oxidation of chalcopyrite in the presence of manganese dioxide in hydrochloric acid medium. Hydrometallurgy 2000, 57, 57–76. [Google Scholar] [CrossRef]

- Devi, N.B.; Madhuchhanda, M.; Rath, P.C.; Rao, K.S.; Paramguru, R.K. Simultaneous leaching of a deep-sea manganese nodule and chalcopyrite in hydrochloric acid. Met. Mater. Trans. B 2001, 32, 777–784. [Google Scholar] [CrossRef]

- Havlik, T.; Laubertova, M.; Miskufova, A.; Kondas, J.; Vranka, F. Extraction of copper, zinc, nickel and cobalt in acid oxidative leaching of chalcopyrite at the presence of deep-sea manganese nodules as oxidant. Hydrometallurgy 2005, 77, 51–59. [Google Scholar] [CrossRef]

- Cheng, C.Y.; Lawson, F. The kinetics of leaching chalcocite in acidic oxygenated sulphate-chloride solutions. Hydrometallurgy 1991, 27, 249–268. [Google Scholar] [CrossRef]

- Senanayake, G. Chloride assisted leaching of chalcocite by oxygenated sulphuric acid via Cu(II)-OH-Cl. Miner. Eng. 2007, 20, 1075–1088. [Google Scholar] [CrossRef]

- Carneiro, M.F.C.; Leão, V.A. The role of sodium chloride on surface properties of chalcopyrite leached with ferric sulphate. Hydrometallurgy 2007, 87, 73–82. [Google Scholar] [CrossRef]

- Dutrizac, J. Elemental sulphur formation during the ferric chloride leaching of chalcopyrite. Hydrometallurgy 1990, 23, 153–176. [Google Scholar] [CrossRef]

- Miki, H.; Nicol, M.; Velásquez-Yévenes, L. The kinetics of dissolution of synthetic covellite, chalcocite and digenite in dilute chloride solutions at ambient temperatures. Hydrometallurgy 2011, 105, 321–327. [Google Scholar] [CrossRef]

- Tundisi, J. Water resources in the future: Problems and solutions. Estud. Avançados 2008, 22, 7–16. [Google Scholar] [CrossRef]

- Cisternas, L.A.; Gálvez, E.D. The use of seawater in mining. Miner. Process. Extr. Met. Rev. 2018, 39, 18–33. [Google Scholar] [CrossRef]

- Jeldres, M.; Piceros, E.; Robles, P.A.; Toro, N.; Jeldres, R.I. Viscoelasticity of quartz and kaolin slurries in seawater: Importance of magnesium precipitates. Metals 2019, 9, 1120. [Google Scholar] [CrossRef]

- Senanayake, G. A review of chloride assisted copper sulfide leaching by oxygenated sulfuric acid and mechanistic considerations. Hydrometallurgy 2009, 98, 21–32. [Google Scholar] [CrossRef]

- Dutrizac, J.E. The leaching of sulphide minerals in chloride media. Hydrometallurgy 1992, 29, 1–45. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).