Reynolds Equation for a Micro-Scale Lubrication of a Gas Between Eccentric Circular Cylinders with an Arbitrary Temperature Difference Based on Slip-Flow Theory

Abstract

1. Introduction

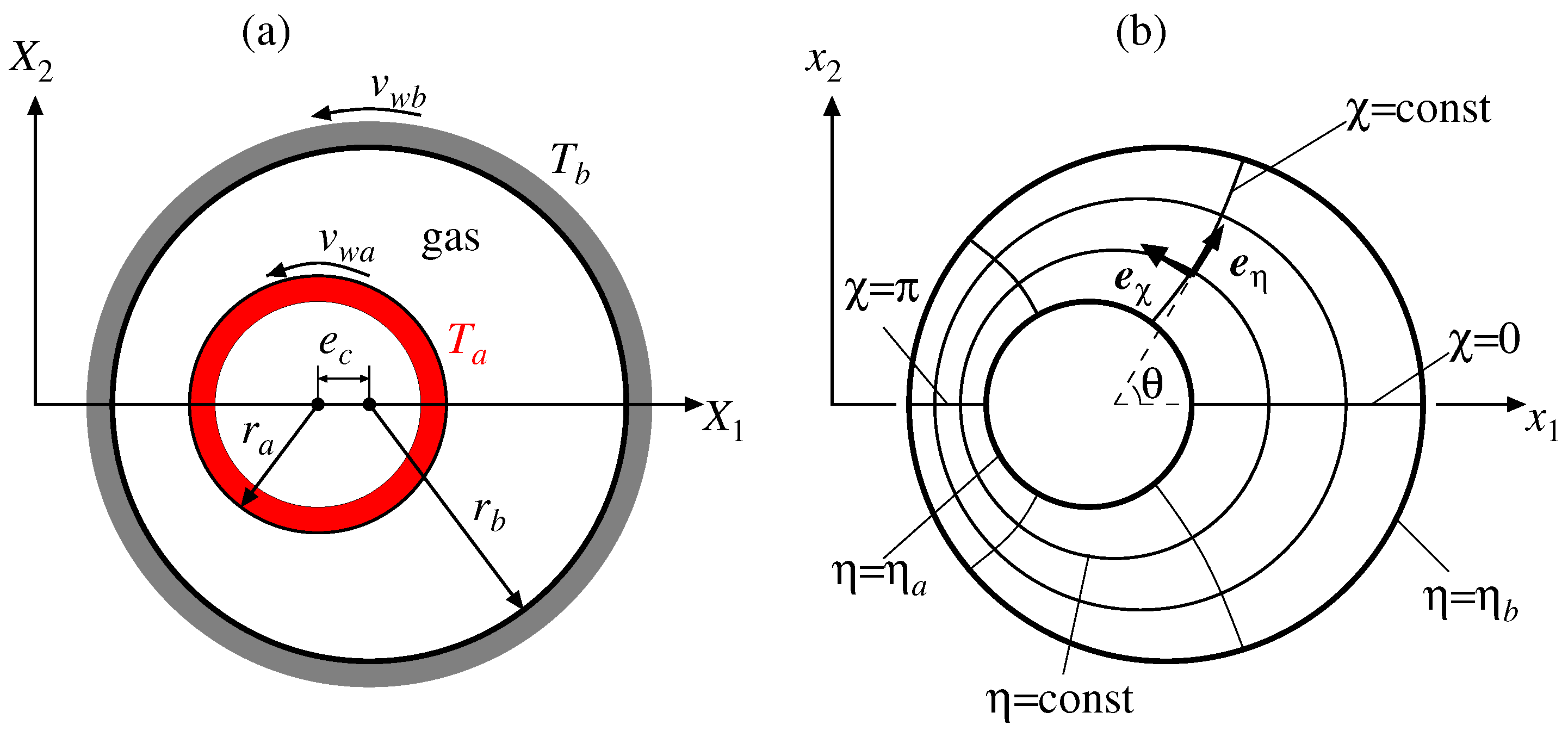

2. Problem and Basic Equations

2.1. Problem

2.2. Basic Equation

2.3. Preparation for Analysis

3. Analysis

4. Results and Discussion

4.1. Preliminary Remarks

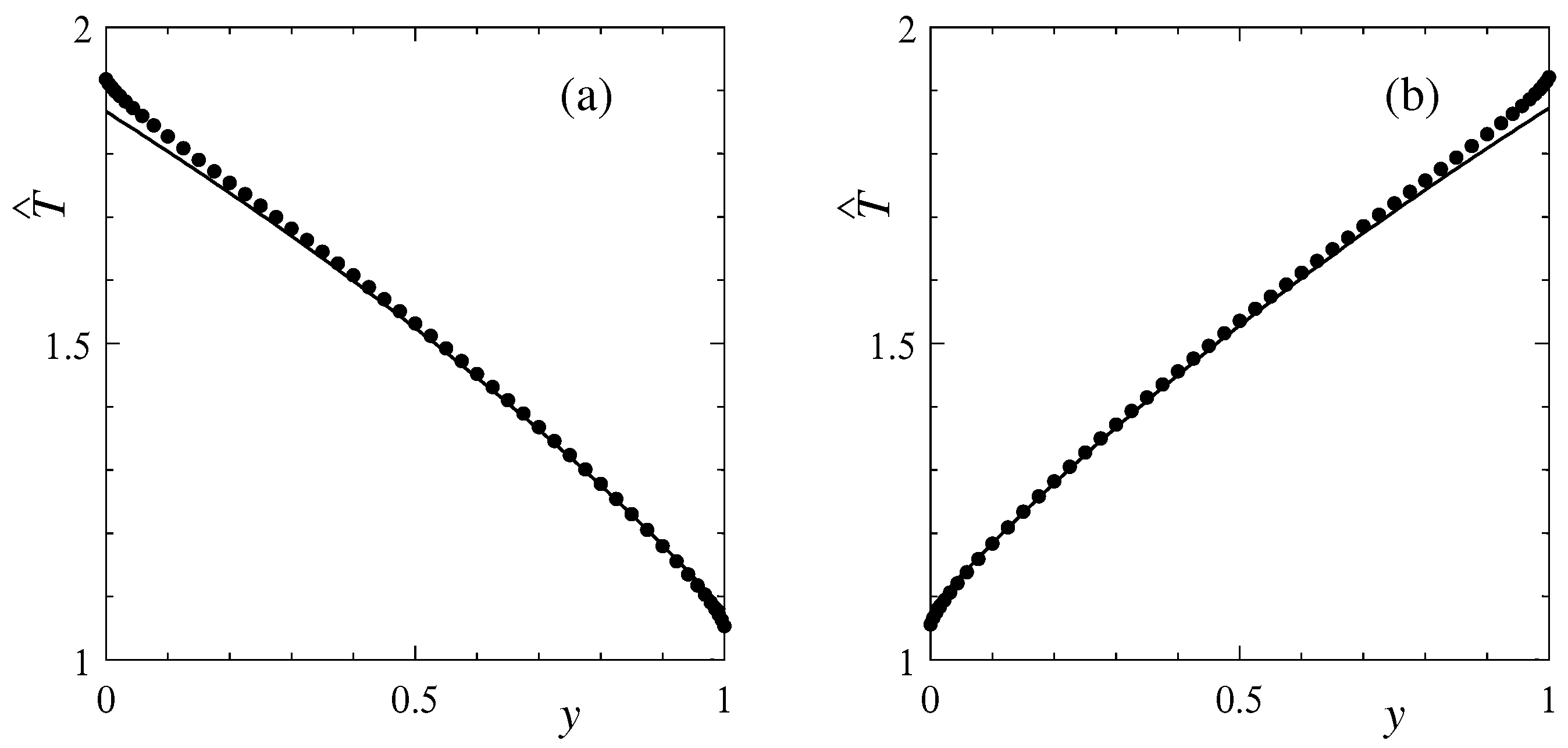

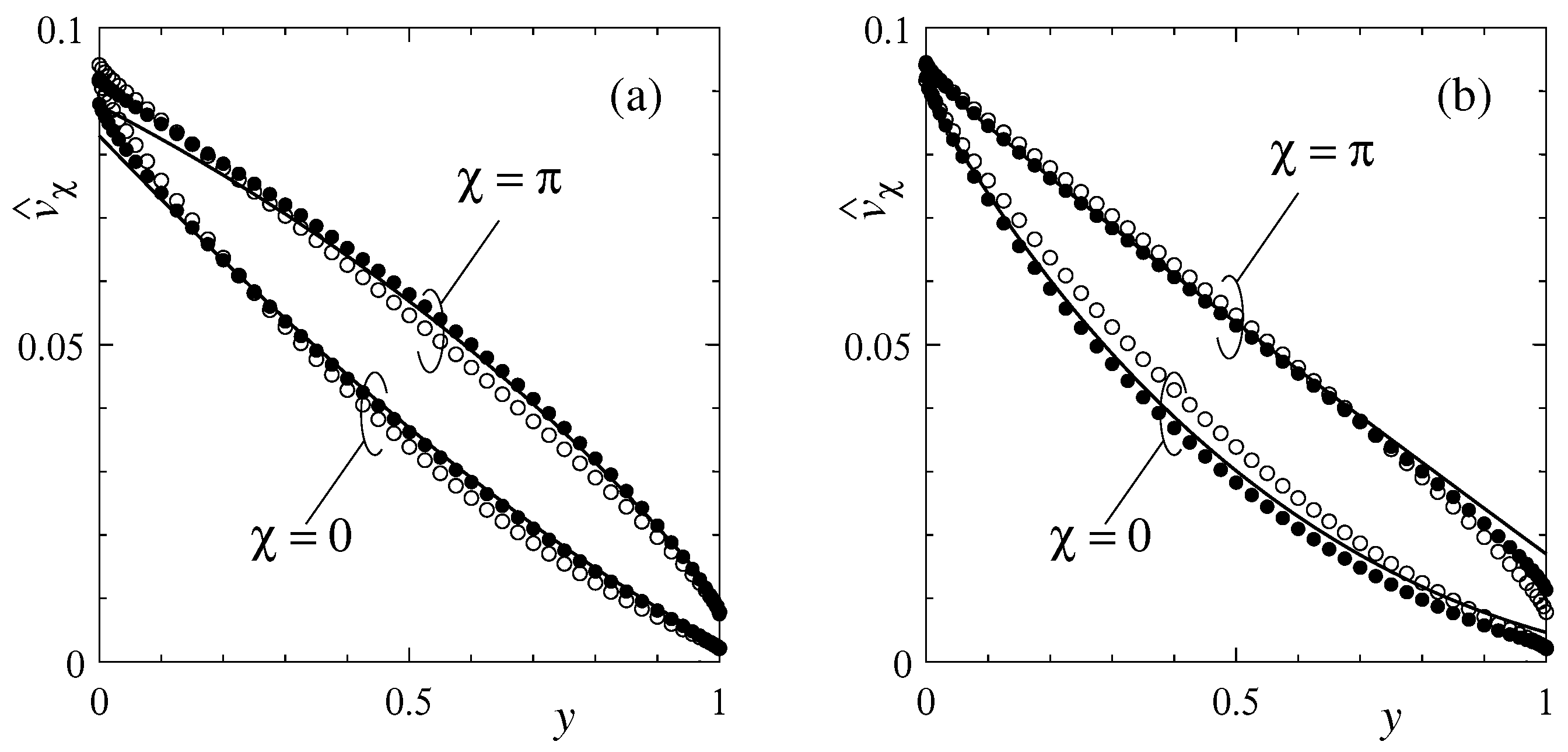

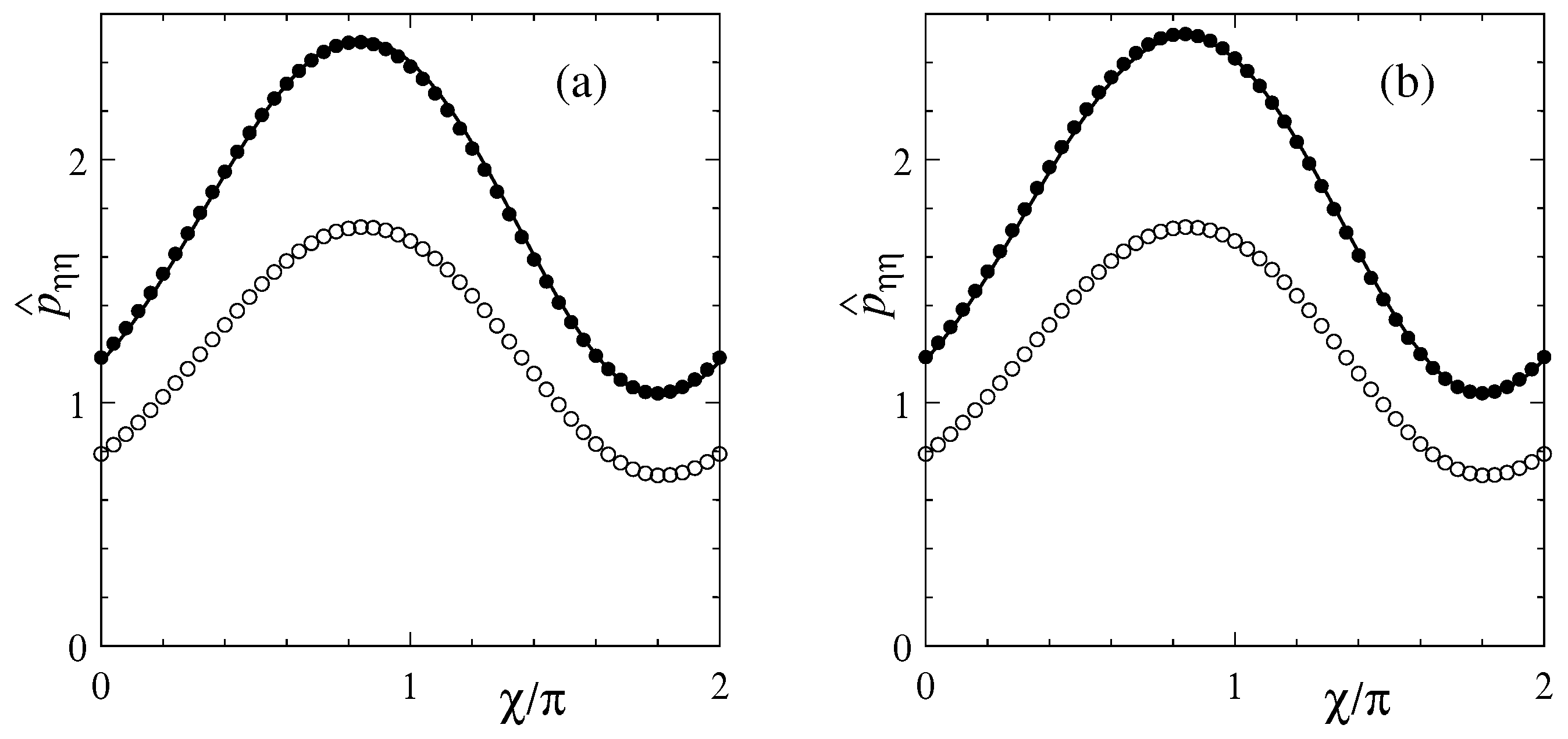

4.2. Temperature, Velocity, and the Normal Stress

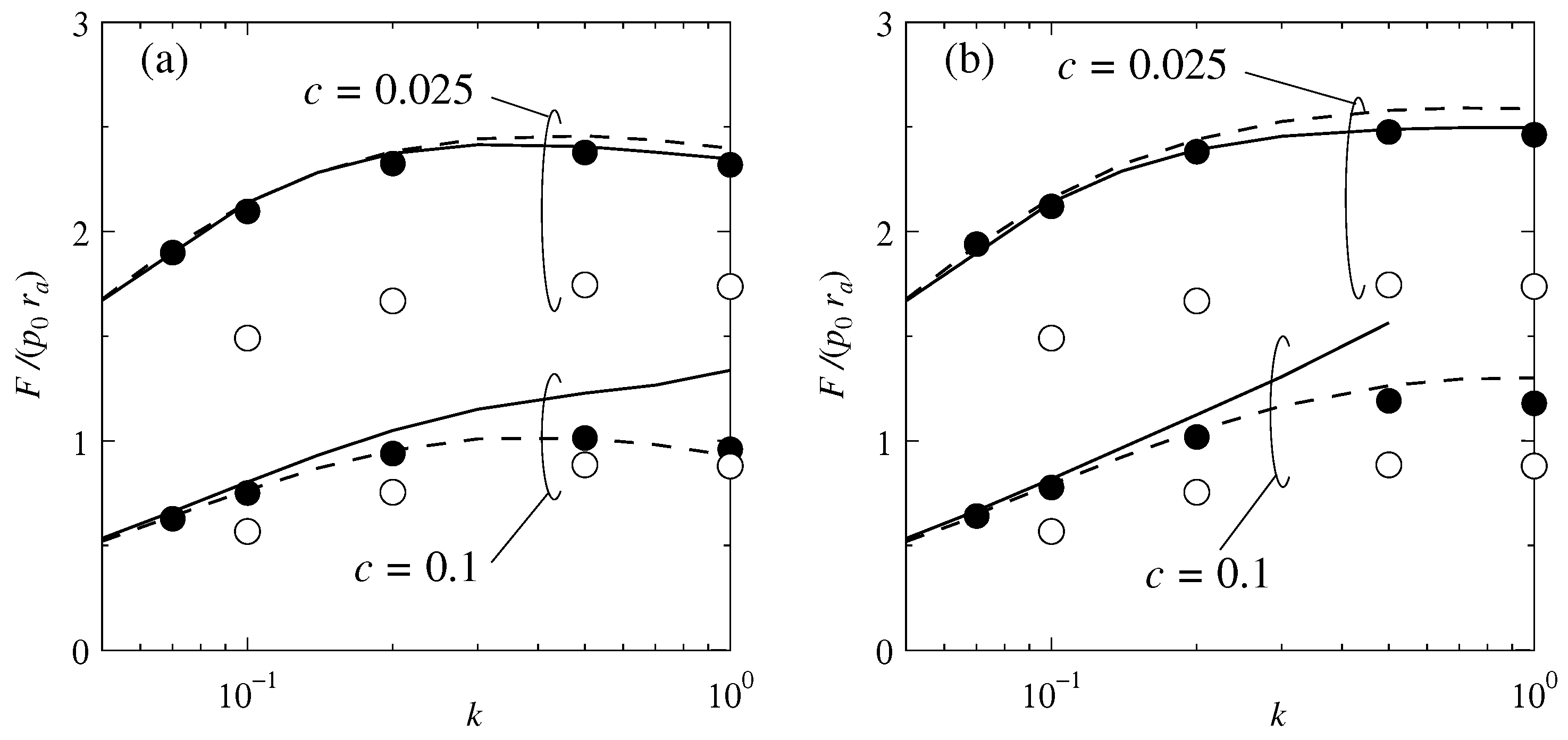

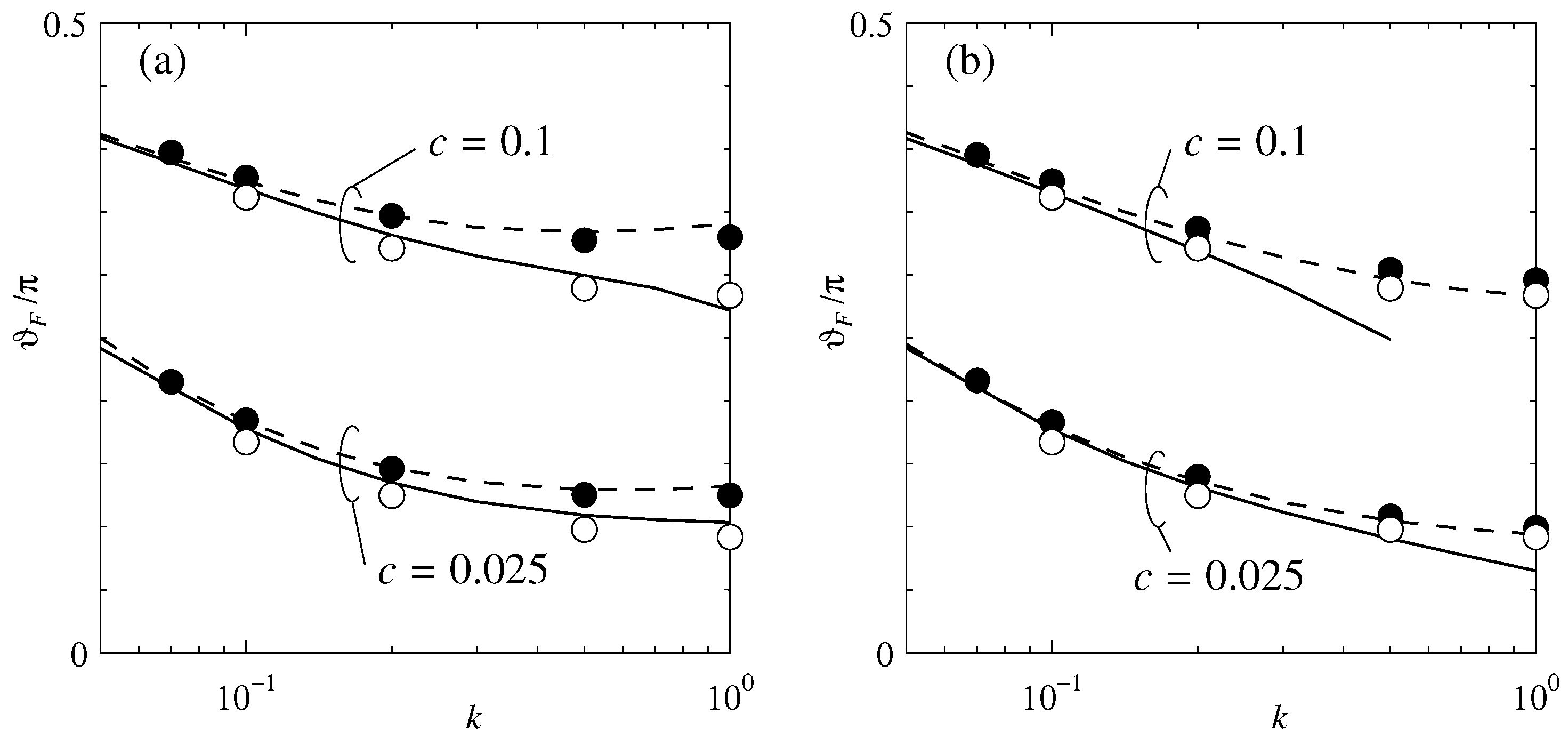

4.3. Eccentric Force and Torque

5. Conclusions

- (1)

- In the range of the Knudsen number less than 0.1, the present solution agrees with the reference solution satisfactorily. For the Knudsen number beyond 0.1, however, the disagreement is non-negligible. Therefore, this solution is applicable only in the slip flow regime, approximately, .

- (2)

- The performance of this model is as good as that of the lubrication model B proposed in [17]; no definite superiority over the other is found. From the practical view point, however, the advantage of the present solution is evident in that the analysis of the spatially 1D Boltzmann equation, which was a prerequisite for the use of model B, is unnecessary. Furthermore, the Reynolds equation was derived analytically, and the present solution is applicable for an arbitrarily small k and c as well. In this sense, the present solution is a better alternative to the lubrication analysis in the slip flow regime.

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| BGKW | Bhatnagar–Gross–Krook–Welander |

| 1D | one-dimensional |

| CPU | central processing unit |

Appendix A. Details of the Solution

References

- Reynolds, O. On the theory of lubrication and its application to Mr. Beauchamp Tower’s experiments, including an experimental determination of the viscosity of olive oil. Philos. Trans. R. Soc. Lond. Ser. A 1886, 177, 157–234. [Google Scholar]

- Elrod, H.G. A derivation of the basic equations for hydrodynamic lubrication with a fluid having constant properties. Quart. Appl. Math. 1960, 17, 349–359. [Google Scholar] [CrossRef]

- Burgdorfer, A. The influence of the molecular mean free path on the performance of hydrodynamic gas lubricated bearings. ASME J. Basic Eng. 1959, 81, 94–98. [Google Scholar] [CrossRef]

- Ng, E.Y.-K.; Liu, N. A multicoefficient slip-corrected Reynolds equation for micro-thin film gas lubrication. Int. J. Rotating Mach. 2005, 2005, 105–111. [Google Scholar] [CrossRef]

- Shi, B.-J.; Yang, T.-Y. Simplified model of Reynolds equation with linearized flow rate for ultra-thin gas film lubrication in hard disk drives. Microsyst. Technol. 2010, 16, 1727–1734. [Google Scholar] [CrossRef]

- Chen, D.; Bogy, D.B. Comparisons of slip-corrected Reynolds lubrication equations for the air bearing film in the head-disk interface of hard disk drives. Tribol. Lett. 2010, 37, 191–201. [Google Scholar] [CrossRef][Green Version]

- Gans, R.F. Lubrication theory at arbitrary Knudsen numbers. ASME J. Tribol. 1985, 107, 431–433. [Google Scholar] [CrossRef]

- Fukui, S.; Kaneko, R. Analysis of ultra-thin gas film lubrication based on linearized Boltzmann equation: First report—derivation of a generalized lubrication equation including thermal creep flow. ASME J. Tribol. 1988, 110, 253–262. [Google Scholar] [CrossRef]

- Veijola, T.; Kuisma, H.; Lahdenperä, J. The influence of gas-surface interaction on gas-film damping in a silicon accelerometer. Sens. Actuators A 1998, 66, 83–92. [Google Scholar] [CrossRef]

- Karniadakis, G.; Beskok, A.; Aluru, N. Microflows and Nanoflows: Fundamentals and Simulation; Springer: New York, NY, USA, 2005. [Google Scholar]

- Cercignani, C. Slow Rarefied Flows; Birkhaüser: Boston, MA, USA, 2006. [Google Scholar]

- Sone, Y. Molecular Gas Dynamics; Birkhaüser: Boston, MA, USA, 2007. [Google Scholar]

- Doi, T. A model of micro lubrication between two walls with an arbitrary temperature difference based on kinetic theory. Phys. Fluids 2020, 32, 052005. [Google Scholar] [CrossRef]

- Myo, K.S.; Zhou, W.; Yu, S.; Hua, W. Direct Monte Carlo simulation of air bearing effects in heat-assisted magnetic recording. Microsyst. Technol. 2011, 17, 903–909. [Google Scholar] [CrossRef]

- Bhatnagar, P.L.; Gross, E.P.; Krook, M. A model for collision processes in gases. I. Small amplitude processes in charged and neutral one-component systems. Phys. Rev. 1954, 94, 511–525. [Google Scholar] [CrossRef]

- Welander, P. On the temperature jump in a rarefied gas. Ark. Fys. 1954, 7, 507–553. [Google Scholar]

- Doi, T. Kinetic theory analysis of microscale lubrication of a gas between eccentric circular cylinders with an arbitrary temperature difference. Phys. Fluids 2024, 36, 042016. [Google Scholar] [CrossRef]

- Milićev, S.S.; Stevanović, N.D. A microbearing gas flow with different wall’s temperatures. Thermal Sci. 2012, 16, 119–132. [Google Scholar] [CrossRef]

- Milićev, S.S.; Stevanović, N.D. Influence of transport coefficients’ dependence on temperature for gas flow in microbearing. Adv. Mech. Eng. 2022, 14, 1–16. [Google Scholar] [CrossRef]

- Doi, T. Kinetic theory analysis of microscale lubrication of a gas between eccentric circular cylinders: Effect of rotation of the outer cylinder. Phys. Rev. Fluids 2025, 10, 24201. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Doi, T. Reynolds Equation for a Micro-Scale Lubrication of a Gas Between Eccentric Circular Cylinders with an Arbitrary Temperature Difference Based on Slip-Flow Theory. Lubricants 2025, 13, 353. https://doi.org/10.3390/lubricants13080353

Doi T. Reynolds Equation for a Micro-Scale Lubrication of a Gas Between Eccentric Circular Cylinders with an Arbitrary Temperature Difference Based on Slip-Flow Theory. Lubricants. 2025; 13(8):353. https://doi.org/10.3390/lubricants13080353

Chicago/Turabian StyleDoi, Toshiyuki. 2025. "Reynolds Equation for a Micro-Scale Lubrication of a Gas Between Eccentric Circular Cylinders with an Arbitrary Temperature Difference Based on Slip-Flow Theory" Lubricants 13, no. 8: 353. https://doi.org/10.3390/lubricants13080353

APA StyleDoi, T. (2025). Reynolds Equation for a Micro-Scale Lubrication of a Gas Between Eccentric Circular Cylinders with an Arbitrary Temperature Difference Based on Slip-Flow Theory. Lubricants, 13(8), 353. https://doi.org/10.3390/lubricants13080353