Tribo-Electric Performance of Nano-Enhanced Palm Oil-Based Glycerol Grease for Electric Vehicle Bearings

Abstract

1. Introduction

2. Materials and Methods

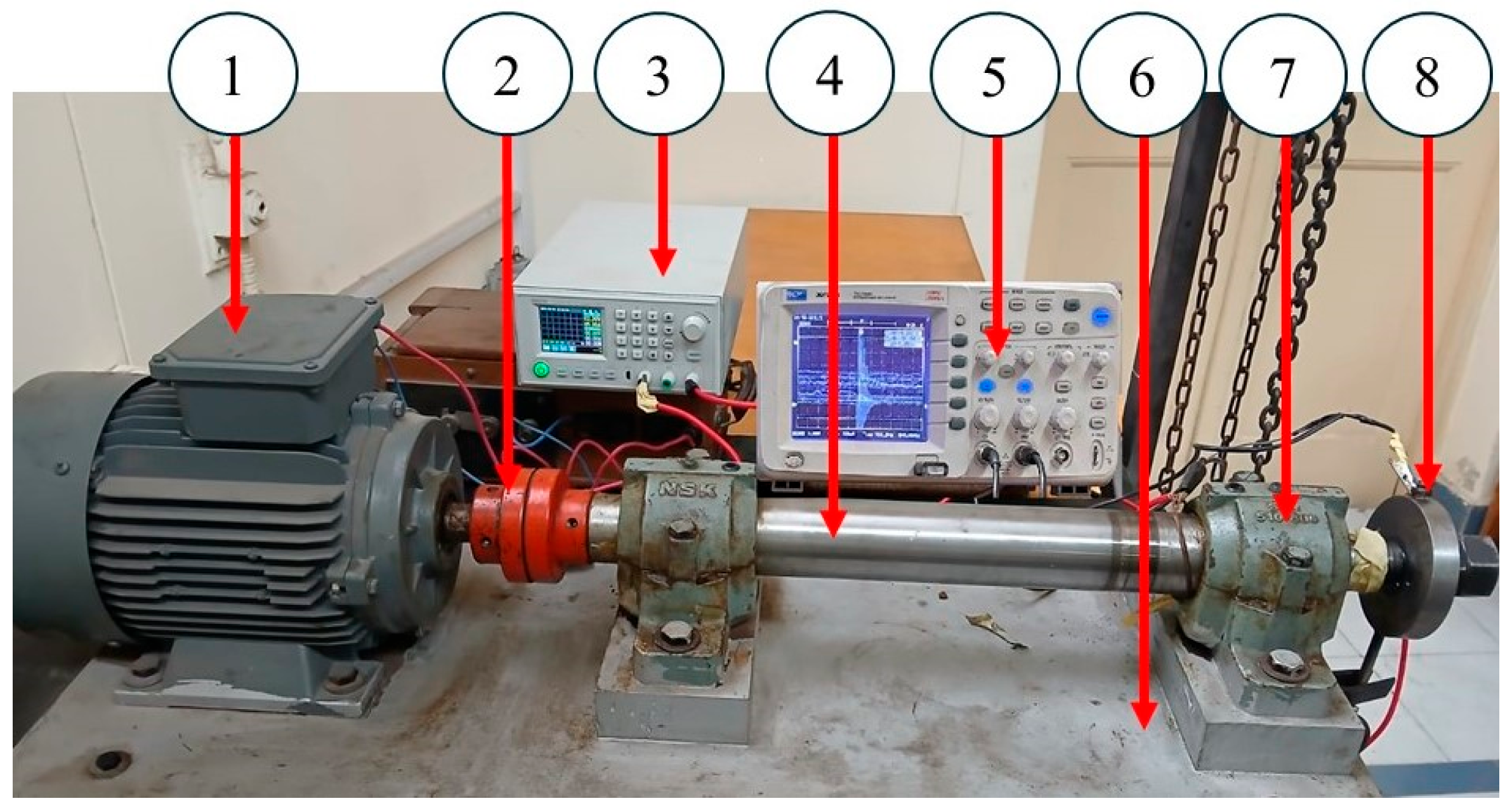

2.1. Test Rig

2.2. Characterization of Nanomaterials

2.3. Grease Synthesis

2.4. Kinematic Viscosity Test

2.5. Dropping Point Test

2.6. Thickener Consistency and Oil Bleeding Test

2.7. Tribological Test

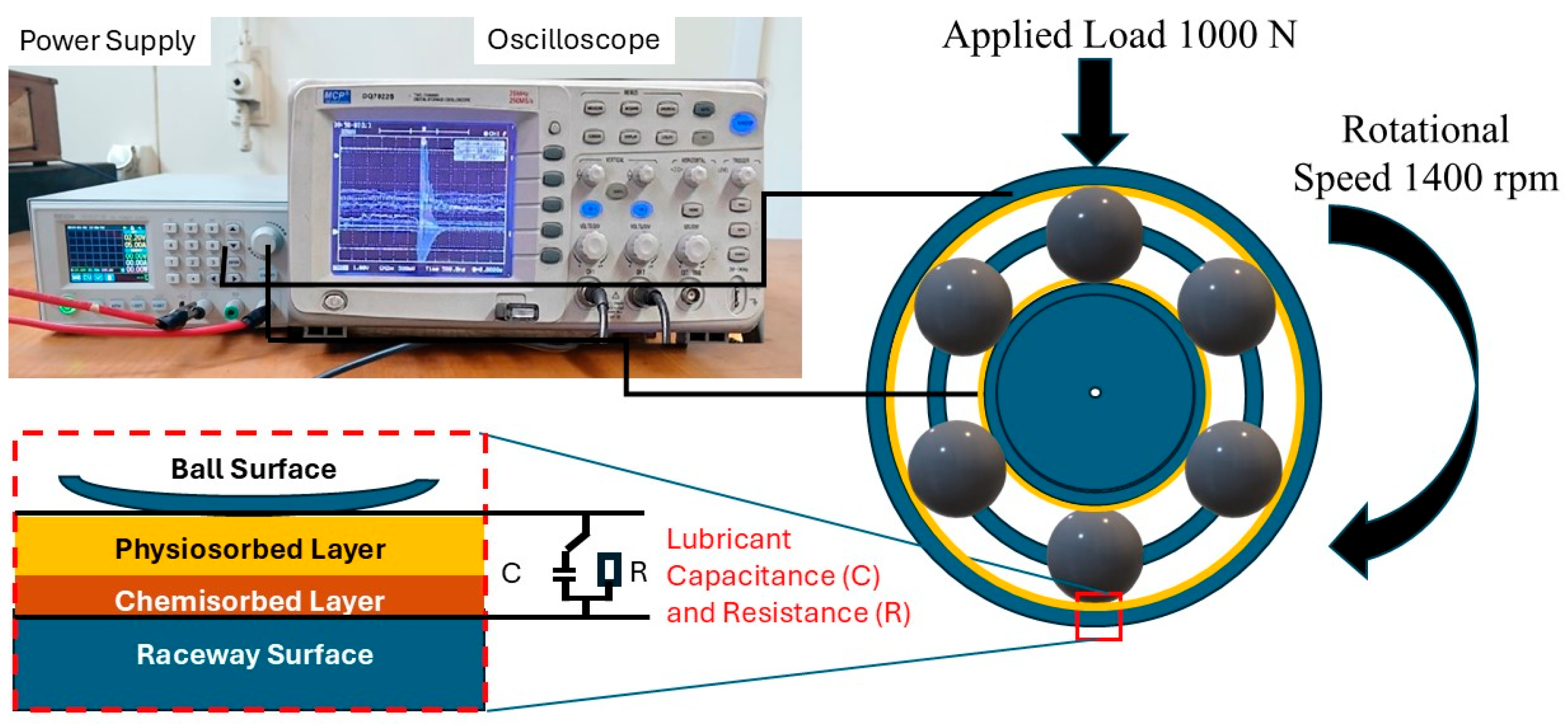

2.8. Electric Tests

2.9. Vibrations Analysis Test

3. Results and Discussion

3.1. SEM and TEM Results

3.2. Physical–Chemical Results

| Test Description | Test Standard | Lithium Grease | Sodium Grease | Palm Grease A |

|---|---|---|---|---|

| Unworked penetration test (dmm) | ASTM D217 [62,78] | 250 (NLGI 3) | 265 (NLGI 2) | 185 (NLGI 4) |

| Static bleeding value 40 °C (oil mass %) | ASTM D1742 [81] | 1–3 | 3–4 | 7.1 |

| Dropping point (°C) | ASTM D2265 [79,80] | 180–200 | 180–200 | 55–60 |

| Kinematic viscosity at 40 °C (cSt) | ASTM D445 [77] | 125 | 135 | 41 |

| Kinematic viscosity at 100 °C (cSt) | ASTM D445 [77] | 12 | 10 | 9 |

| Viscosity Index (VI) | 82 | 20 | 209 | |

| Pour point (°C) | ASTM D7346 [92] | −15 | −5 to −10 | 9 |

3.3. Estimated Lubrication Regime and Minimum Film Thickness

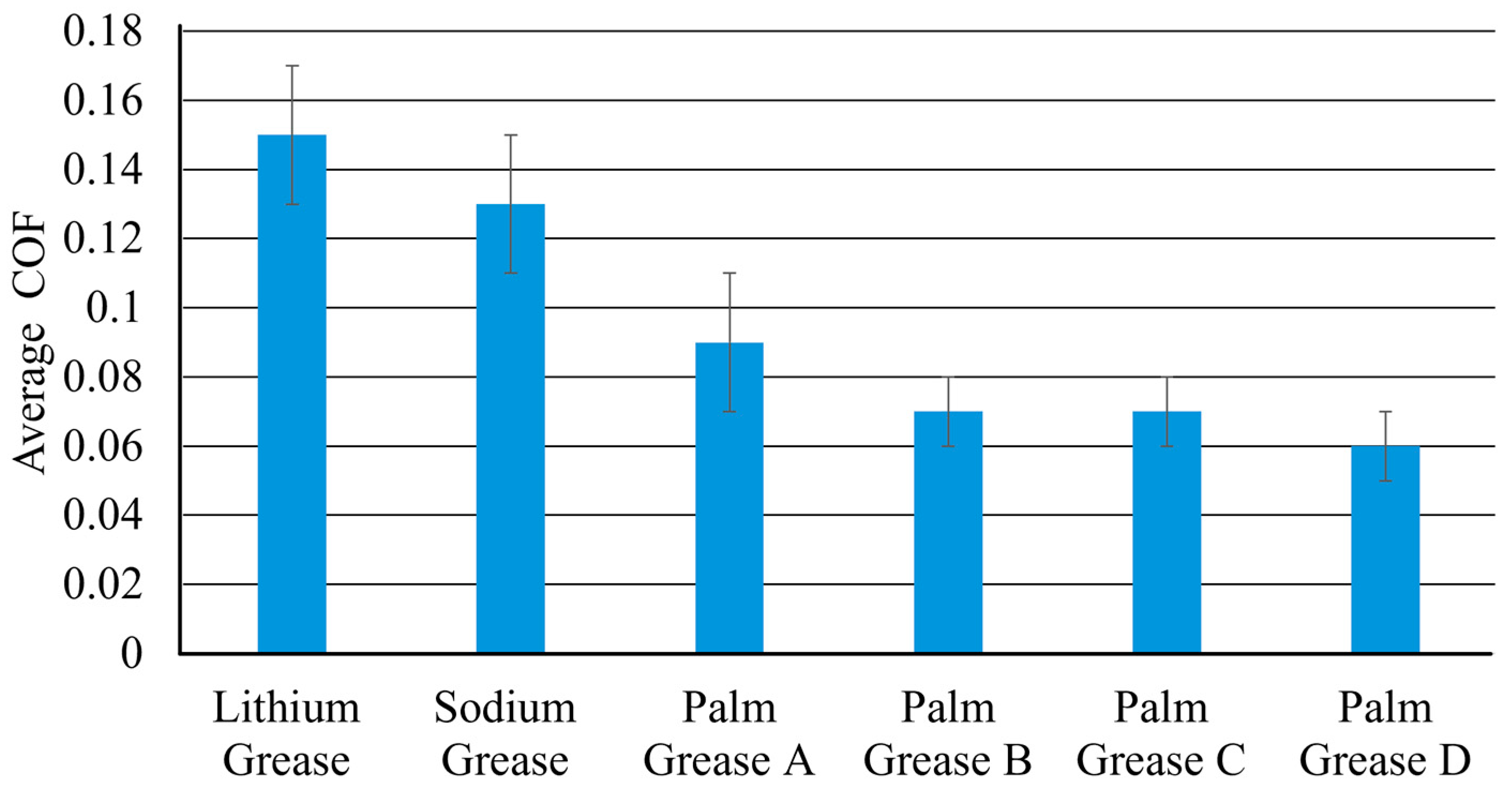

3.4. Tribological Results

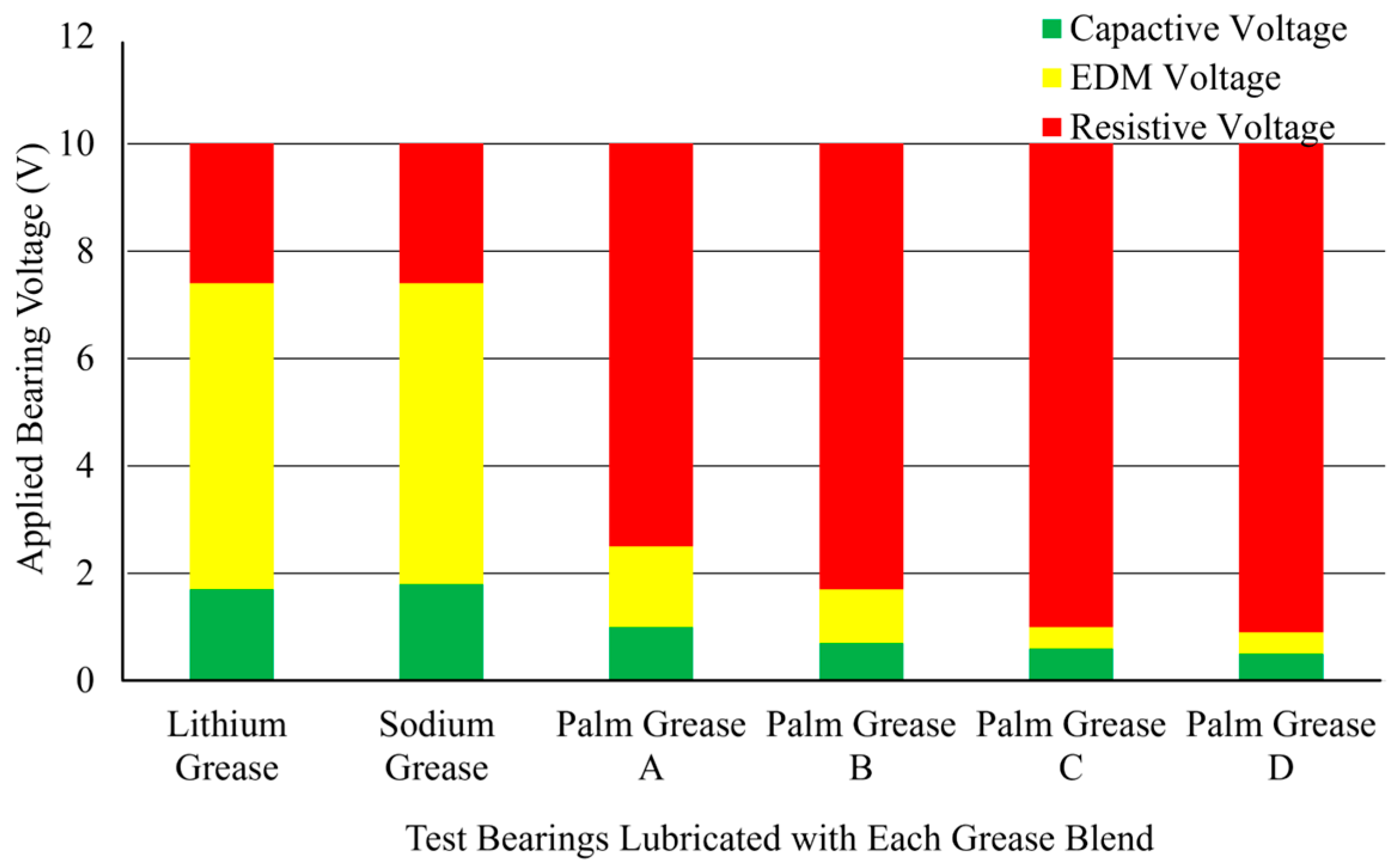

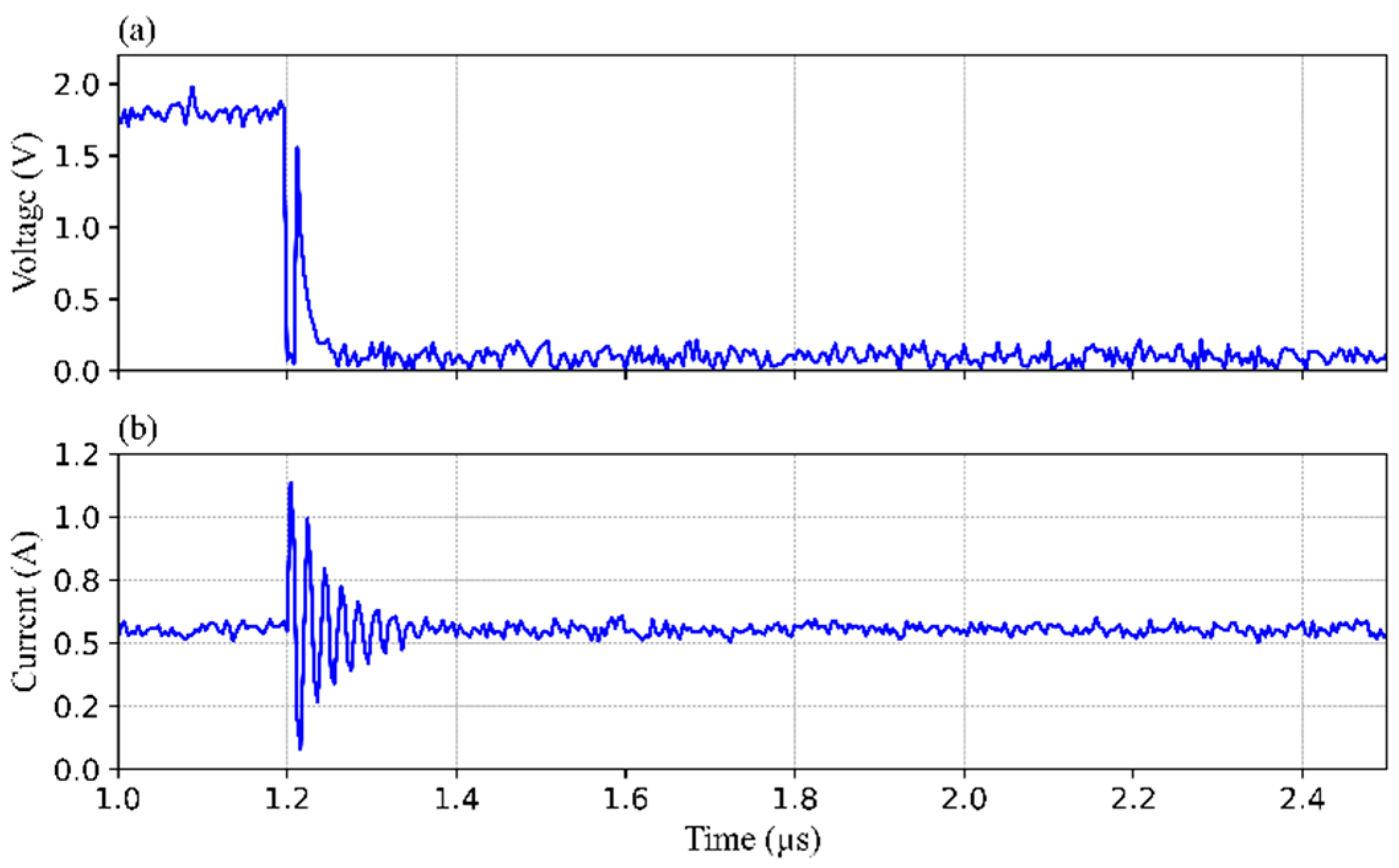

3.5. Electrical Conductivity and EDM Voltage Analysis

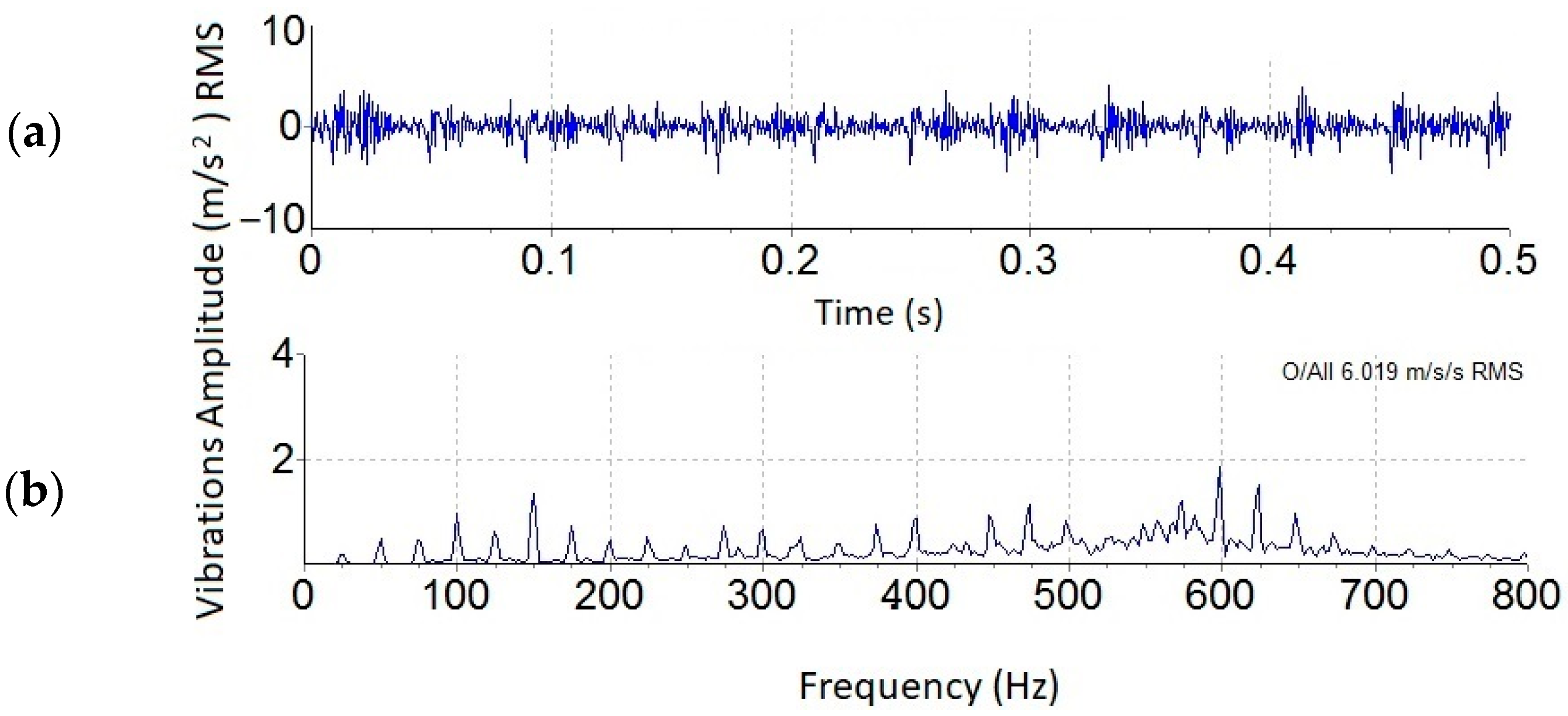

3.6. Vibration Analysis Results

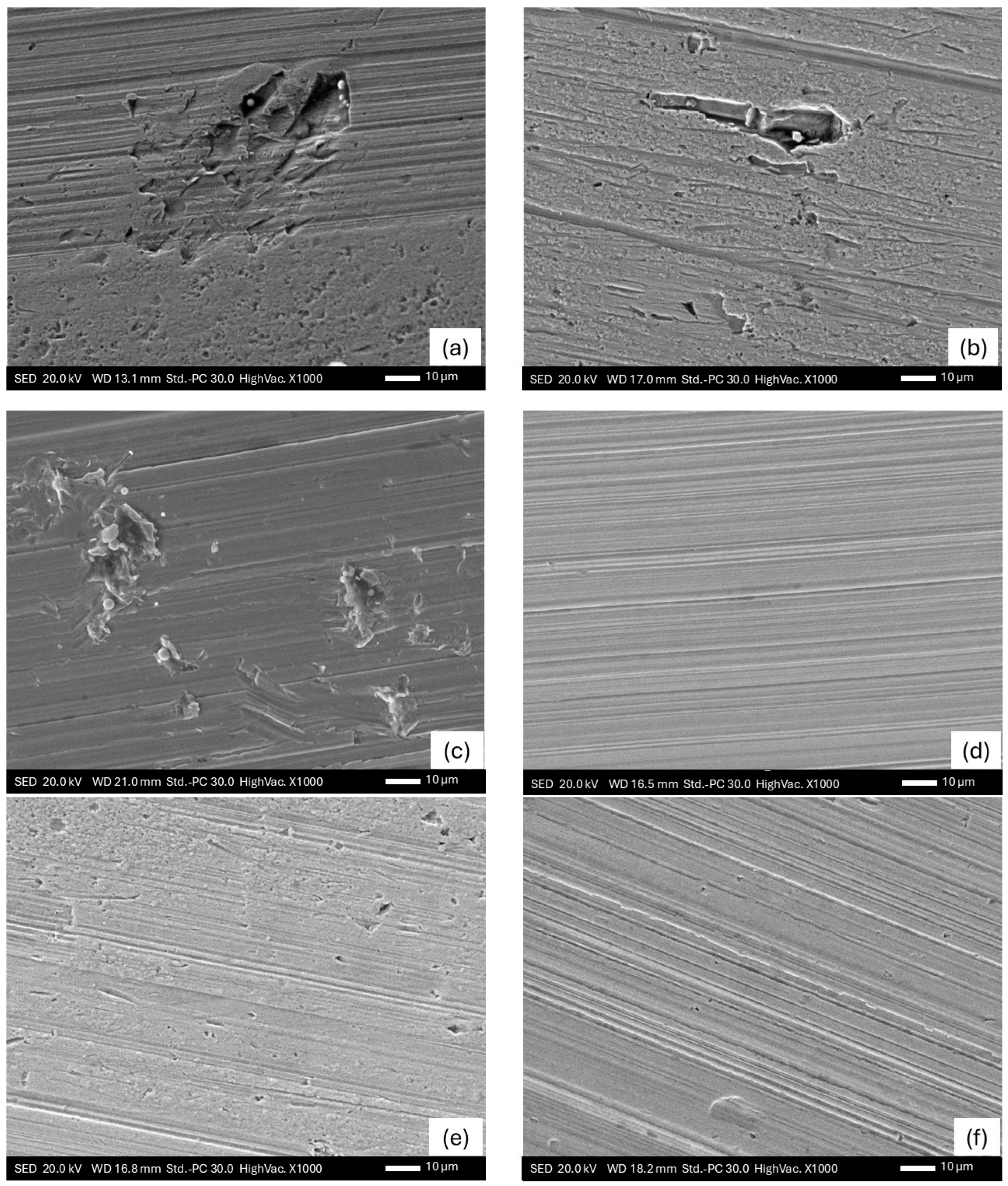

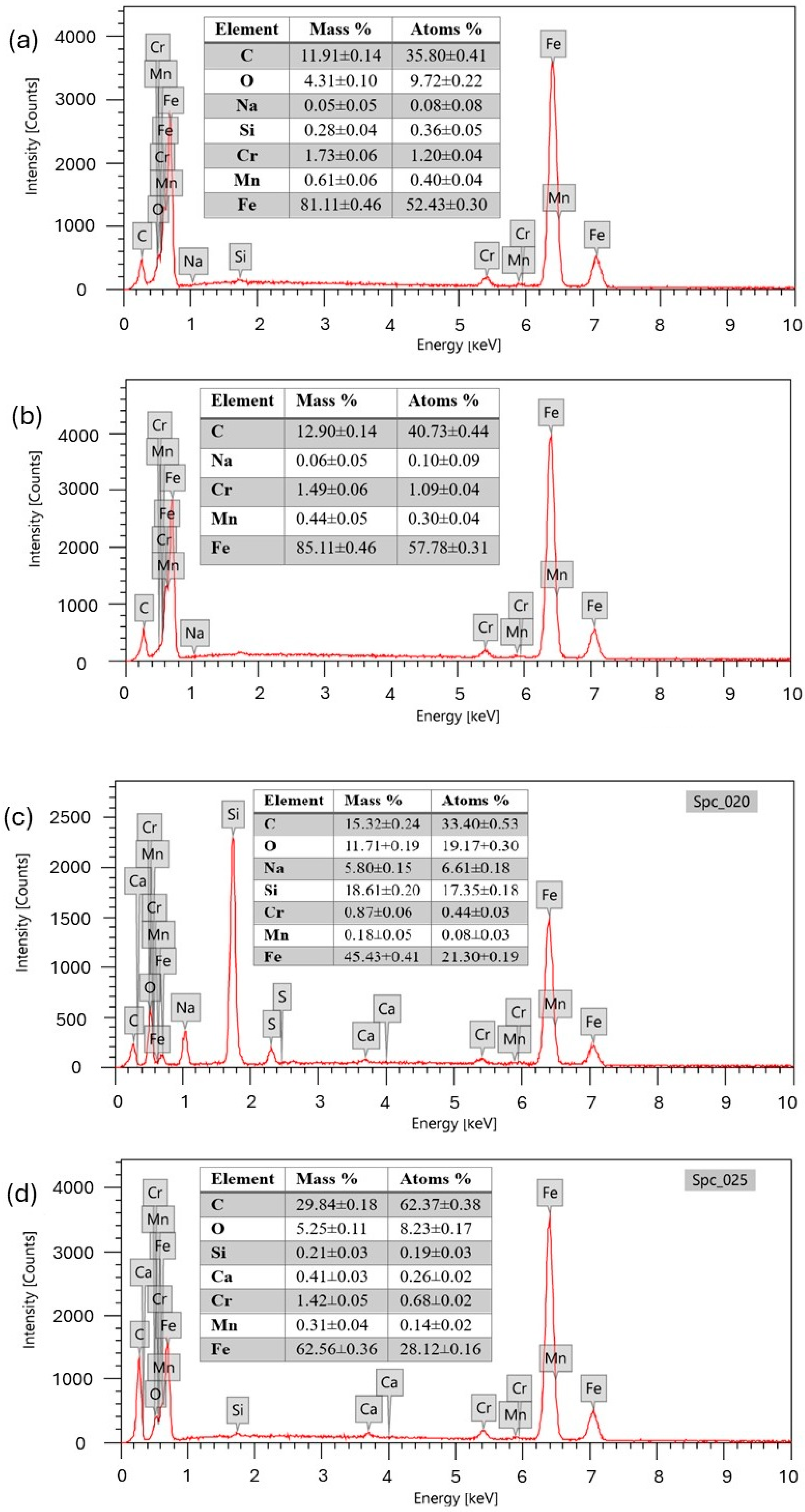

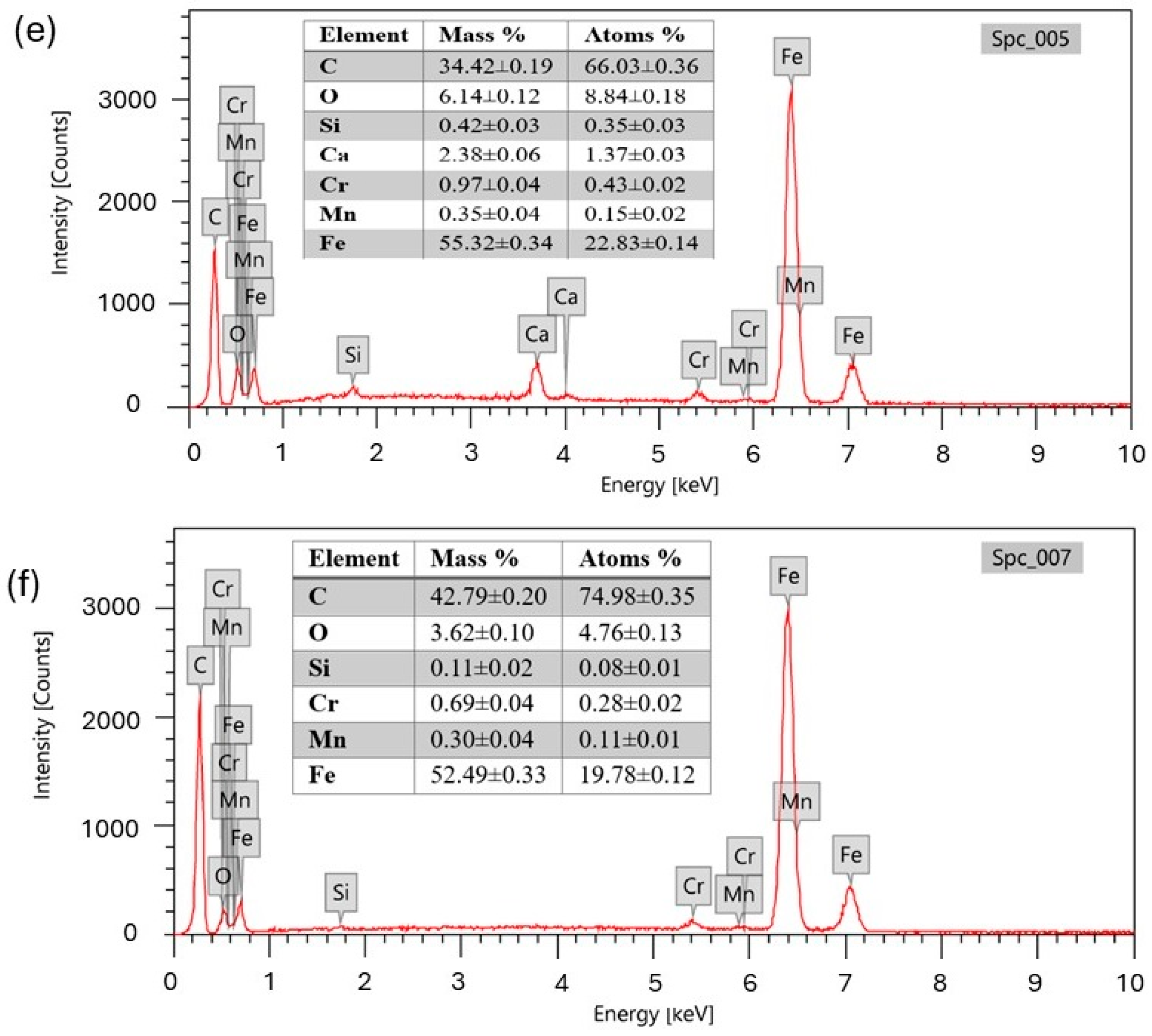

3.7. Surface Damage Analysis

4. Conclusions

- The palm-based bio-grease demonstrated superior consistency (NLGI 4) and thermal stability compared to commercial lithium and sodium greases, with a high viscosity index (209) ensuring performance across temperatures.

- Palm grease reduced the coefficient of friction (COF) by 40% versus lithium grease and 30% versus sodium grease. Incorporating multi-walled carbon nanotubes (MWCNTs) further lowered COF to 0.06 (3 wt.%), reducing friction by up to 60 %. The results indicate better physical and chemical adsorption of palm grease to the surface, providing a protective layer.

- Benchmark greases resulted in higher EDM voltage thresholds and ranges, with lithium grease entering the EDM phase at 1.7 V and sodium grease at 1.2 V. Exposed bearing raceways to these frequent current discharges resulted in severe localized and distributed surface damage along with high vibration levels in subsequent bearing runs.

- Palm grease exhibited a lower EDM voltage range (1.0–2.2 V), reducing harmful bearing currents. MWCNT additives (2–3 wt.%) further decreased EDM thresholds (0.5–0.75 V), mitigating surface damage from electric discharges as evident by subsequent vibration analysis and SEM-EDX examination of damaged surface. Palm grease with 2 wt.% MWCNTs achieves optimal vibration damping, reducing vertical and horizontal vibrations by 28.41 % and 32.37 %, respectively, outperforming commercial greases.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- SEI; Climate Analytics; E3G; IISD; UNEP. Phasing Down or Phasing Up? Top Fossil Fuel Producers Plan Even More Extraction Despite Climate Promises: Production Gap Report 2023. Available online: https://www.sei.org/publications/production-gap-report-2023/ (accessed on 10 June 2025).

- Perera, F. Pollution from Fossil-Fuel Combustion Is the Leading Environmental Threat to Global Pediatric Health and Equity: Solutions Exist. Int. J. Environ. Res. Public Health 2017, 15, 16. [Google Scholar] [CrossRef] [PubMed]

- IEA. CO2 Emissions in 2023; IEA: Paris, France, 2024; Available online: https://www.iea.org/reports/co2-emissions-in-2023 (accessed on 10 June 2025).

- U.S. Environmental Protection Agency (EPA). Carbon Pollution from Transportation. Transportation, Air Pollution, and Climate Change Program. Last Updated 25 April 2025. Available online: https://www.epa.gov/transportation-air-pollution-and-climate-change/carbon-pollution-transportation (accessed on 20 June 2025).

- Jose, P.S.; Natarajan, A.; Karthikeyan, S.; Bogaraj, T. Environmental and Social Impact of Electric Vehicles. In Advanced Technologies in Electric Vehicles; Gali, V., Canha, L.N., Resener, M., Ferraz, B., Varaprasad, M.V.G., Eds.; Academic Press: Cambridge, MA, USA, 2024; pp. 107–125. [Google Scholar] [CrossRef]

- IEA. Global EV Outlook 2024; IEA: Paris, France, 2024; Available online: https://www.iea.org/reports/global-ev-outlook-2024 (accessed on 20 June 2025).

- Li, S.; Tong, L.; Xing, J.; Zhou, Y. The Market for Electric Vehicles: Indirect Network Effects and Policy Design. J. Assoc. Environ. Resour. Econ. 2017, 4, 89–133. [Google Scholar] [CrossRef]

- European Environment Agency. Electric Vehicles from Life Cycle and Circular Economy Perspectives; TERM Report 2018; Publications Office of the European Union: Luxembourg, 2018; ISBN 978-92-9213-985-8. [Google Scholar] [CrossRef]

- Boztas, G.; Yildirim, M.; Aydogmus, O. Design and Analysis of Multi-Phase BLDC Motors for Electric Vehicles. Eng. Technol. Appl. Sci. Res. 2018, 8, 2646–2650. [Google Scholar] [CrossRef]

- Yildirim, M.; Polat, M.; Kürüm, H. A Survey on Comparison of Electric Motor Types and Drives Used for Electric Vehicles. In Proceedings of the 2014 16th International Power Electronics and Motion Control Conference and Exposition (EPE-PEMC 2014), Antalya, Turkey, 21–24 September 2014; pp. 218–223. [Google Scholar] [CrossRef]

- Chun, Y.-D.; Park, B.-G.; Kim, D.-J.; Choi, J.-H.; Han, P.-W.; Um, S. Development and Performance Investigation on a 60kW Induction Motor for EV Propulsion. J. Electr. Eng. Technol. 2016, 11, 609–617. [Google Scholar] [CrossRef]

- Nam, K.H. AC Motor Control and Electrical Vehicle Applications, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2018; 574p. [Google Scholar] [CrossRef]

- Qureshi, M.S.; Kerai, A.A.; Fatima, S.A.; Shah, S.J.; Khan, K.A.; Ali, A.; Maheshwari, L.; Makda, I.; Usman, A. Effects of Parasitic Elements in High Frequency GaN-based DC–DC Converters for Electric Vehicle Applications. In Proceedings of the 2023 25th International Multitopic Conference (INMIC), Lahore, Pakistan, 4–5 November 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Landa, T.V.; Moore, A. Analysis of Parasitic Components in the PWM Inverter in an Electric Vehicle. Int. J. Eng. Res. Technol. 2013, 2, IJERTV2IS90671. [Google Scholar]

- Busse, D.; Erdman, J.; Kerkman, R.J.; Schlegel, D.; Skibinski, G. Bearing Currents and Their Relationship to PWM Drives. IEEE Trans. Power Electron. 1997, 12, 243–252. [Google Scholar] [CrossRef]

- Mütze, A. Bearing Currents in Inverter-Fed AC Motors, 1st ed.; Shaker-Verlag GmbH: Aachen, Germany, 2004; ISBN 978-3-8322-2528-5. Available online: https://tugraz.elsevierpure.com/en/publications/bearing-currents-in-inverter-fed-ac-motors (accessed on 20 June 2025).

- Schneider, V.; Behrendt, C.; Höltje, P.; Cornel, D.; Becker-Dombrowsky, F.M.; Puchtler, S.; Gutiérrez Guzmán, F.; Ponick, B.; Jacobs, G.; Kirchner, E. Electrical Bearing Damage, A Problem in the Nano- and Macro-Range. Lubricants 2022, 10, 194. [Google Scholar] [CrossRef]

- Loos, J.; Bergmann, I.; Goss, M. Influence of High Electrical Currents on WEC Formation in Rolling Bearings. Tribol. Trans. 2021, 64, 708–720. [Google Scholar] [CrossRef]

- Mütze, A.; Binder, A. Techniques for Measurement of Parameters Related to Inverter-Induced Bearing Currents. IEEE Trans. Ind. Appl. 2007, 43, 1274–1283. [Google Scholar] [CrossRef]

- Wang, F. Motor Shaft Voltages and Bearing Currents and Their Reduction in Multilevel Medium-Voltage PWM Voltage-Source-Inverter Drive Applications. IEEE Trans. Ind. Appl. 2000, 36, 1336–1341. [Google Scholar] [CrossRef]

- Maruyama, T.; Nakano, K. In Situ Quantification of Oil Film Formation and Breakdown in EHD Contacts. Tribol. Trans. 2018, 61, 1057–1066. [Google Scholar] [CrossRef]

- Binder, A.; Muetze, A. Scaling Effects of Inverter-Induced Bearing Currents in AC Machines. IEEE Trans. Ind. Appl. 2008, 44, 769–776. [Google Scholar] [CrossRef]

- Collin, R.; Yokochi, A.; von Jouanne, A. EDM Damage Assessment and Lifetime Prediction of Motor Bearings Driven by PWM Inverters. In Proceedings of the 2022 IEEE Energy Conversion Congress and Exposition (ECCE), Detroit, MI, USA, 9–13 October 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Xu, Y.; Liang, Y.; Yuan, X.; Wu, X.; Li, Y. Experimental Assessment of High Frequency Bearing Currents in an Induction Motor Driven by a SiC Inverter. IEEE Access 2021, 9, 40540–40549. [Google Scholar] [CrossRef]

- Im, J.-H.; Kang, J.-K.; Lee, Y.-K.; Hur, J. Shaft Voltage Elimination Method to Reduce Bearing Faults in Dual Three-Phase Motor. IEEE Access 2022, 10, 81042–81053. [Google Scholar] [CrossRef]

- Muetze, A.; Oh, H.W. Application of Static Charge Dissipation to Mitigate Electric Discharge Bearing Currents. IEEE Trans. Ind. Appl. 2008, 44, 135–143. [Google Scholar] [CrossRef]

- Ma, J.; Xue, Y.; Han, Q.; Li, X.; Yu, C. Motor Bearing Damage Induced by Bearing Current: A Review. Machines 2022, 10, 1167. [Google Scholar] [CrossRef]

- Muetze, A.; Binder, A. Calculation of Influence of Insulated Bearings and Insulated Inner Bearing Seats on Circulating Bearing Currents in Machines of Inverter-Based Drive Systems. IEEE Trans. Ind. Appl. 2006, 42, 965–972. [Google Scholar] [CrossRef]

- Hoffe, S.J.; Meyer, A.S.; Cronje, W.A. Determination of Shaft Position from Shaft Voltage on a Synchronous Generator. In Proceedings of the 2005 5th IEEE International Symposium on Diagnostics for Electric Machines, Power Electronics and Drives (DEMPED), Vienna, Austria, 7–9 September 2005; pp. 1–4. [Google Scholar] [CrossRef]

- CW. E-Mobility Bearings: Customized Ball Bearings for E-Mobility Drives; CW Bearing GmbH: Hockenheim, Germany; Available online: https://www.izb-online.com/fileadmin/_migrated/exhibitor_database/upload/257/CW-E-Mobility-Brochure-EU.pdf (accessed on 20 June 2025).

- He, F.; Xie, G.; Luo, J. Electrical Bearing Failures in Electric Vehicles. Friction 2020, 8, 4–28. [Google Scholar] [CrossRef]

- Xie, G. Lubrication Under Charged Conditions. Tribol. Int. 2015, 84, 22–35. [Google Scholar] [CrossRef]

- Xie, G.; Si, L.; Guo, D.; Liu, S.; Luo, J. Interface Characteristics of Thin Liquid Films in a Charged Lubricated Contact. Surf. Interface Anal. 2015, 47, 315–324. [Google Scholar] [CrossRef]

- Fan, X.; Xia, Y.; Wang, L. Tribological Properties of Conductive Lubricating Greases. Friction 2014, 2, 343–353. [Google Scholar] [CrossRef]

- Freschi, M.; Paniz, A.; Cerqueni, E.; Colella, G.; Dotelli, G. The Twelve Principles of Green Tribology: Studies, Research, and Case Studies—A Brief Anthology. Lubricants 2022, 10, 129. [Google Scholar] [CrossRef]

- Bustami, B.; Rahman, M.M.; Shazida, M.J.; Islam, M.; Rohan, M.H.; Hossain, S.; Nur, A.S.M.; Younes, H. Recent Progress in Electrically Conductive and Thermally Conductive Lubricants: A Critical Review. Lubricants 2023, 11, 331. [Google Scholar] [CrossRef]

- Walther, H.C.; Holub, R.A. Lubrication of Electric Motors as Defined by IEEE Standard 841-2009, Shortcomings and Potential Improvement Opportunities. In Proceedings of the 2014 IEEE Petroleum and Chemical Industry Technical Conference (PCIC), San Francisco, CA, USA, 8–10 September 2014; pp. 91–98. [Google Scholar] [CrossRef]

- Mustafa, W.A.A.; Dassenoy, F.; Sarno, M.; Senatore, A. A review on potentials and challenges of nanolubricants as promising lubricants for electric vehicles. Lubr. Sci. 2022, 34, 1–29. [Google Scholar] [CrossRef]

- Parenago, O.P.; Lyadov, A.S.; Maksimov, A.L. Development of Lubricant Formulations for Modern Electric Vehicles. Russ. J. Appl. Chem. 2022, 95, 765–774. [Google Scholar] [CrossRef]

- Pape, F. Investigation of Graphene Platelet-Based Dry Lubricating Film Formation in Tribological Contacts. Coatings 2024, 14, 360. [Google Scholar] [CrossRef]

- Duan, L.; Li, J.; Duan, H. Nanomaterials for Lubricating Oil Application: A Review. Friction 2023, 11, 647–684. [Google Scholar] [CrossRef]

- Nassef, M.G.A.; Soliman, M.; Nassef, B.G.; Daha, M.A.; Nassef, G.A. Impact of Graphene Nano-Additives to Lithium Grease on the Dynamic and Tribological Behavior of Rolling Bearings. Lubricants 2022, 10, 29. [Google Scholar] [CrossRef]

- Pape, F.; Poll, G. Investigations on Graphene Platelets as Dry Lubricant and as Grease Additive for Sliding Contacts and Rolling Bearing Application. Lubricants 2020, 8, 3. [Google Scholar] [CrossRef]

- Liu, J.; Bai, Q.; Li, X.; Zhang, L.; Pape, F.; Guo, F.; Poll, G. Evolution Processes of Electrical Discharge in EHD Contact Lubricated with Conductive Grease. Tribol. Int. 2025, 209, 110725. [Google Scholar] [CrossRef]

- Zhang, P.; Gong, J.; Jiang, Y.; Long, Y.; Lei, W.; Gao, X.; Guo, D. Application of Silver Nanoparticles in Parasite Treatment. Pharmaceutics 2023, 15, 1783. [Google Scholar] [CrossRef]

- Jonjo, E.R.; Ali, I.; Megahed, T.F.; Nassef, M.G.A. Mitigation of Electrical Discharge Damage in Electric Vehicle Bearings: Comparative Study of Multi-Walled Carbon Nanotubes and Alumina Nanoparticles in Lubricating Grease. Vehicles 2025, 7, 19. [Google Scholar] [CrossRef]

- United Nations. Sustainable Consumption and Production. United Nations Sustainable Development Goals Knowledge Platform. Available online: https://sdgs.un.org/topics/sustainable-consumption-and-production (accessed on 14 February 2025).

- Sharma, N.; Bari, S.K.; Nagendramma, P.; Thakre, G.; Ray, A. Tribological Investigations of Sustainable Bio-Based Lubricants for Industrial Applications. In Green Tribology; Kasolang, S.B., Xie, G., Katiyar, J.K., Rani, A.M., Eds.; CRC Press: Boca Raton, FL, USA, 2021; pp. 45–72. Available online: https://www.taylorfrancis.com/chapters/edit/10.1201/9781003139386-3/tribological-investigations-sustainable-bio-based-lubricants-industrial-applications-neha-sharma-sayed-khadija-bari-ponnekanti-nagendramma-gananath-thakre-anjan-ray (accessed on 15 March 2025).

- Nassef, B.G.; Pape, F.; Poll, G. Enhancing the Performance of Rapeseed Oil Lubricant for Machinery Component Applications through Hybrid Blends of Nanoadditives. Lubricants 2023, 11, 479. [Google Scholar] [CrossRef]

- Syahrullaila, S.; Kamitani, S.; Shakirin, A. Tribological Evaluation of Mineral Oil and Vegetable Oil as a Lubricant. Jurnal Teknologi 2014, 66, 43–48. [Google Scholar] [CrossRef]

- Habibullah, M.; Masjuki, H.H.; Kalam, M.A.; Ashraful, A.M.; Habib, M.A.; Mobarak, H.M. Effect of Bio-Lubricant on Tribological Characteristics of Steel. In Proceedings of the 10th International Conference on Mechanical Engineering (ICME 2013), Dhaka, Bangladesh, 20–22 December 2013; Procedia Engineering. Volume 90, pp. 740–745. [Google Scholar] [CrossRef]

- Agrawal, S.M.; Lahane, S.; Patil, N.G.; Brahmankar, P.K. Experimental Investigations into Wear Characteristics of M2 Steel Using Cotton Seed Oil. Procedia Eng. 2014, 97, 4–14. [Google Scholar] [CrossRef]

- Barbera, E.; Hirayama, K.; Maglinao, R.L.; Davis, R.W.; Kumar, S. Recent Developments in Synthesizing Biolubricants—A Review. Biomass Conv. Biorefinery 2024, 14, 2867–2887. [Google Scholar] [CrossRef]

- Woma, T.Y. Vegetable Oil Based Lubricants: Challenges and Prospects. Tribol. Online 2019, 14, 60–69. [Google Scholar] [CrossRef]

- Dube, N.N.; ElKady, M.; Noby, H.; Nassef, M.G.A. Developing a Sustainable Grease from Jojoba Oil with Plant-Waste-Based Nanoadditives for Enhancement of Rolling Bearing Performance. Sci. Rep. 2024, 14, 539. [Google Scholar] [CrossRef] [PubMed]

- Masudi, A.; Muraza, O. Vegetable Oil to Biolubricants: Review on Advanced Porous Catalysts. Energy Fuels 2018, 32, 10295–10310. [Google Scholar] [CrossRef]

- Masjuki, H.H. Palm Oil and Mineral Oil-Based Lubricants—Their Tribological and Emission Performance. Tribol. Int. 1999, 32, 209–215. [Google Scholar] [CrossRef]

- Sukirno, R.F.; Bismo, S.; Nasikin, M. Biogrease Based on Palm Oil and Lithium Soap Thickener: Evaluation of Antiwear Property. World Appl. Sci. J. 2009, 6, 401–407. [Google Scholar]

- Hassan, M.Y.; Ani, F.N.; Syahrullail, S. Tribological Performance of Refined, Bleached and Deodorised Palm Olein Blends as Bio-Lubricants. J. Oil Palm Res. 2016, 28, 510–519. [Google Scholar] [CrossRef]

- Syahrullail, S.; Yahya Wira, J.; Wan Nik, W.B.; Fawwaz, W.N. Friction Characteristics of RBD Palm Olein Using Four-Ball Tribotester. Appl. Mech. Mater. 2013, 315, 936–940. [Google Scholar] [CrossRef]

- Nassef, B.G.; Moradi, A.; Bayer, G.; Pape, F.; Abouelkasem, Z.A.; Rummel, F.; Schmölzer, S.; Poll, G.; Marian, M. Biogenic Palm Oil-Based Greases with Glycerol Monostearate and Soy Wax: A Rheological and Tribological Study. Results Eng. 2025, 25, 103728. [Google Scholar] [CrossRef]

- Nassef, M.G.A.; Nassef, B.G.; Hassan, H.S.; Nassef, G.A.; Elkady, M.; Pape, F. Tribological and Chemical–Physical Behavior of a Novel Palm Grease Blended with Zinc Oxide and Reduced Graphene Oxide Nano-Additives. Lubricants 2024, 12, 191. [Google Scholar] [CrossRef]

- Est-Aegis. How Do VFDs Cause Bearing Damage? Est-Aegis Blog. Available online: https://blog.est-aegis.com/how-do-vfds-cause-bearing-damage (accessed on 14 February 2025).

- Pei, T.; Zhang, H.; Hua, W.; Zhang, F. Comprehensive Review of Bearing Currents in Electrical Machines: Mechanisms, Impacts, and Mitigation Techniques. Energies 2025, 18, 517. [Google Scholar] [CrossRef]

- Tong, W. Mechanical Design and Manufacturing of Electric Motors, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2022; Chapter 6. [Google Scholar] [CrossRef]

- Farfan-Cabrera, L.I. Tribology of Electric Vehicles: A Review of Critical Components, Current State and Future Improvement Trends. Tribol. Int. 2019, 138, 473–486. [Google Scholar] [CrossRef]

- Tawfiq, K.B.; Güleç, M.; Sergeant, P. Bearing Current and Shaft Voltage in Electrical Machines: A Comprehensive Research Review. Machines 2023, 11, 550. [Google Scholar] [CrossRef]

- Romanenko, A. Study of Inverter-Induced Bearing Damage Monitoring in Variable-Speed-Driven Motor Systems. Doctoral Dissertation, Lappeenranta University of Technology, Lappeenranta, Finland, December 2017. Acta Universitatis Lappeenrantaensis, ISBN 978-952-335-185-1. Available online: https://lutpub.lut.fi/handle/10024/147584 (accessed on 20 January 2025).

- Yousuf, A.; Spikes, H.; Guo, L.; Kadiric, A. Influence of Electric Potentials on Surface Damage in Rolling–Sliding Contacts Under Mixed Lubrication. Tribol. Lett. 2025, 73, 45. [Google Scholar] [CrossRef]

- Êvo, M.T.A.; Alzamora, A.M.; Zaparoli, I.O.; de Paula, H. Inverter-Induced Bearing Currents: A Thorough Study of the Cause-and-Effect Chains. IEEE Ind. Appl. Mag. 2022, 29, 2–12. [Google Scholar] [CrossRef]

- Zhu, X.; Shi, N.; Li, Y.; Yang, Y.; Wang, X. Bearing Capacitance Estimation of Electric Vehicle Driving Motor. IOP Conf. Ser. Earth Environ. Sci. 2018, 199, 032065. [Google Scholar] [CrossRef]

- NSK Ltd. Rolling Bearings Catalog; (CAT No. E1102m); NSK Ltd.: Tokyo, Japan, 2013; Available online: https://www.nsk.com/content/dam/nsk/common/catalogs/ctrgPdf/e1102m.pdf (accessed on 29 March 2025).

- Nik Roselina, N.R.; Mohamad, N.S.; Kasolang, S. Evaluation of TiO2 Nanoparticles as Viscosity Modifier in Palm Oil Bio-lubricant. IOP Conf. Ser. Mater. Sci. Eng. 2020, 834, 012032. [Google Scholar] [CrossRef]

- Nair, S.S.; Nair, K.P.; Rajendrakumar, P.K. Evaluation of Physicochemical, Thermal and Tribological Properties of Sesame Oil (Sesamum indicum L.): A Potential Agricultural Crop Base Stock for Eco-Friendly Industrial Lubricants. Int. J. Agric. Resour. Governance Ecol. 2017, 13, 77–90. [Google Scholar] [CrossRef]

- Ngatirah, N.; Kusumastuti, K.; Tarigan, C.W.; Suparyanto, T.; Trinugroho, J.P.; Pardamean, B. Glycerolysis of Palm Kernel Oil Catalyzed by MgO on Mono and Diglyceride Composition and Their Antibacterial Activity. BIO Web Conf. 2024, 94, 02009. [Google Scholar] [CrossRef]

- Faridah, D.N.; Sumitra, N.R.; Hariyadi, P.; Triana, R.N.; Laksana, A.J.; Andarwulan, N. Laboratory-Scale Synthesis of Mono-Diacylglycerol from Palm Oil Stearin Using Glycerolysis. In Proceedings of the 2nd SEAFAST International Seminar (2nd SIS 2019), Yogyakarta, Indonesia, 25–26 November 2019; SciTePress: Setúbal, Portugal, 2019. Available online: https://www.scitepress.org/Papers/2019/99777/99777.pdf (accessed on 21 May 2025).

- ASTM D445-24; Standard Test Method for Kinematic Viscosity of Transparent and Opaque Liquids (and Calculation of Dynamic Viscosity). ASTM International: West Conshohocken, PA, USA, 2024.

- ASTM D217-21a; Standard Test Methods for Cone Penetration of Lubricating Grease. ASTM International: West Conshohocken, PA, USA, 2021. Available online: https://store.astm.org/d0217-21a.html (accessed on 2 January 2025).

- Lugt, P.M. Grease Lubrication in Rolling Bearings; Wiley: West Sussex, UK, 2013. [Google Scholar] [CrossRef]

- ASTM D2265-22; Standard Test Method for Dropping Point of Lubricating Grease Over Wide Temperature Range. ASTM International: West Conshohocken, PA, USA, 2022. Available online: https://store.astm.org/d2265-22.html (accessed on 20 April 2025).

- ASTM D1742-20; Standard Test Method for Oil Separation from Lubricating Grease During Storage. ASTM International: West Conshohocken, PA, USA, 2020. [CrossRef]

- ASTM G99-17; Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus. ASTM International: West Conshohocken, PA, USA, 2017. Available online: https://store.astm.org/g0099-17.html (accessed on 7 February 2025).

- Cañellas, G.; Emeric, A.; Combarros, M.; Navarro, A.; Beltran, L.; Vilaseca, M.; Vives, J. Tribological Performance of Esters, Friction Modifier and Antiwear Additives for Electric Vehicle Applications. Lubricants 2023, 11, 109. [Google Scholar] [CrossRef]

- Bechev, D.; Capan, R.; Gonda, A.; Sauer, B. Method for the Investigation of the EDM Breakdown Voltage of Grease and Oil on Rolling Bearings. Bear. World J. 2019, 4, 83–91. [Google Scholar]

- Joshi, A.; Blennow, J. Investigation of the Static Breakdown Voltage of the Lubricating Film in a Mechanical Ball Bearing. In Proceedings of the Nordic Insulation Symposium (NORDIS), Trondheim, Norway, 9–12 June 2013; pp. 1–8. [Google Scholar] [CrossRef]

- Beroual, A.; Khaled, U.; Mbolo Noah, P.S.; Sitorus, H. Comparative Study of Breakdown Voltage of Mineral, Synthetic and Natural Oils and Based Mineral Oil Mixtures under AC and DC Voltages. Energies 2017, 10, 511. [Google Scholar] [CrossRef]

- Gonda, A.; Capan, R.; Bechev, D.; Sauer, B. The Influence of Lubricant Conductivity on Bearing Currents in the Case of Rolling Bearing Greases. Lubricants 2019, 7, 108. [Google Scholar] [CrossRef]

- Graf, S.; Koch, O.; Sauer, B. Influence of Parasitic Electric Currents on an Exemplary Mineral-Oil-Based Lubricant and the Raceway Surfaces of Thrust Bearings. Lubricants 2023, 11, 313. [Google Scholar] [CrossRef]

- Shen, T.; Wang, D.; Yun, J.; Liu, Q.; Liu, X.; Peng, Z. Mechanical Stability and Rheology of Lithium–Calcium-Based Grease Containing ZDDP. RSC Adv. 2016, 6, 11637–11647. [Google Scholar] [CrossRef]

- ASTM D1831-21; Standard Test Method for Measuring Oxidation Stability of Automatic Transmission Fluids (Rotating Pressure Vessel Oxidation Test—RPVOT). ASTM International: West Conshohocken, PA, USA, 2021. Available online: https://store.astm.org/d1831-21.html (accessed on 20 March 2025).

- Tan, K.-H.; Awala, H.; Mukti, R.R.; Wong, K.-L.; Ling, T.C.; Mintova, S.; Ng, E.-P. Zeolite Nanoparticles as Effective Antioxidant Additive for the Preservation of Palm Oil-Based Lubricant. J. Taiwan Inst. Chem. Eng. 2016, 58, 565–571. [Google Scholar] [CrossRef]

- ASTM D7346-15R21; Standard Test Method for No Flow Point and Pour Point of Petroleum Products and Liquid Fuels. ASTM International: West Conshohocken, PA, USA, 2021. [CrossRef]

- Hamrock, B.J.; Dowson, D. Isothermal Elastohydrodynamic Lubrication of Point Contacts: Part 1—Theoretical Formulation. ASME J. Lubr. Technol. 1976, 98, 223–228. [Google Scholar] [CrossRef]

- Hamrock, B.J.; Dowson, D.; Tallian, T.E. Ball Bearing Lubrication (The Elastohydrodynamics of Elliptical Contacts). ASME J. Lubr. Technol. 1982, 104, 279–281. [Google Scholar] [CrossRef]

- Biresaw, G.; Bantchev, G.B. Pressure Viscosity Coefficient of Vegetable Oils. Tribol. Lett. 2013, 49, 501–512. [Google Scholar] [CrossRef]

- Maruyama, T.; Radzi, F.; Sato, T.; Iwase, S.; Maeda, M.; Nakano, K. Lubrication Condition Monitoring in EHD Line Contacts of Thrust Needle Roller Bearing Using the Electrical Impedance Method. Lubricants 2023, 11, 223. [Google Scholar] [CrossRef]

- Paredes, X.; Comuñas, M.J.P.; Pensado, A.S.; Bazile, J.-P.; Boned, C.; Fernández, J. High Pressure Viscosity Characterization of Four Vegetable and Mineral Hydraulic Oils. Ind. Crops Prod. 2014, 54, 281–290. [Google Scholar] [CrossRef]

- Lotfizadeh Dehkordi, B.; Shiller, P.J.; Doll, G.L. Pressure- and Temperature-Dependent Viscosity Measurements of Lubricants with Polymeric Viscosity Modifiers. Front. Mech. Eng. 2019, 5, 18. [Google Scholar] [CrossRef]

- Cen, H.; Lugt, P.M.; Morales-Espejel, G.E. On the Film Thickness of Grease-Lubricated Contacts at Low Speed. Tribol. Trans. 2014, 57, 668–678. [Google Scholar] [CrossRef]

- Cen, H.; Lugt, P.M.; Morales-Espejel, G.E. Film Thickness of Mechanically Worked Lubricating Grease at Very Low Speeds. Tribol. Trans. 2014, 57, 1066–1071. [Google Scholar] [CrossRef]

- Cen, H.; Lugt, P.M. Film Thickness in a Grease Lubricated Ball Bearing. Tribol. Int. 2019, 134, 26–35. [Google Scholar] [CrossRef]

- Hamrock, B.J.; Schmid, S.R.; Jacobson, B.O. Fundamentals of Fluid Film Lubrication, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar] [CrossRef]

- Gropper, D.; Wang, L.; Harvey, T.J. Hydrodynamic Lubrication of Textured Surfaces: A Review of Modeling Techniques and Key Findings. Tribol. Int. 2016, 94, 509–529. [Google Scholar] [CrossRef]

- Garg, P.; Kumar, A.; Thakre, G.; Jain, A.K. Influence of Temperature on the Tribological Behavior of Bio-Ester Based Lubricant. J. Comput. Theor. Nanosci. 2016, 22, 3805–3809. [Google Scholar] [CrossRef]

- Schneider, V.; Bader, N.; Liu, H.; Poll, G. Method for In Situ Film Thickness Measurement of Ball Bearings under Combined Loading Using Capacitance Measurements. Tribol. Int. 2022, 171, 107524. [Google Scholar] [CrossRef]

- Bader, N.; Furtmann, A.; Tischmacher, H.; Poll, G. Capacitances and Lubricant Film Thicknesses of Grease and Oil Lubricated Bearings. In Proceedings of the 72nd STLE Annual Meeting & Exhibition, Rolling Element Bearings II, Atlanta, GA, USA, 21–25 May 2017; Available online: https://www.stle.org/images/pdf/STLE_ORG/AM2017%20Presentations/Rolling%20Element%20Bearings/STLE2017_Rolling%20Element%20Bearings%20II_Session%206C_N.%20Bader_Capacitances%20and%20Lubricant%20Film%20Thicknesses%20of%20Grease%20and%20Oil%20Lubricated%20Bearings.pdf (accessed on 21 February 2025).

- Maruyama, T.; Maeda, M.; Nakano, K. Lubrication Condition Monitoring of Practical Ball Bearings by Electrical Impedance Method. Tribol. Online 2019, 14, 327–338. [Google Scholar] [CrossRef]

- Joly-Pottuz, L.; Martin, J.M.; De Barros Bouchet, M.I.; Mogne, T.L.; Belin, M.; Montagnac, G.; Reynard, B.; Epicier, T.; Kano, M.; Enomoto, Y.; et al. Anomalous Low Friction Under Boundary Lubrication of Steel Surfaces by Polyols. Tribol. Lett. 2009, 34, 21–29. [Google Scholar] [CrossRef]

- Ng, W.S.; Lee, C.S.; Cheng, S.-F.; Chuah, C.H.; Wong, S.F. Biocompatible Polyurethane Scaffolds Prepared from Glycerol Monostearate-Derived Polyester Polyol. J. Polym. Environ. 2018, 26, 2881–2900. [Google Scholar] [CrossRef]

- Gulzar, M.; Masjuki, H.H.; Kalam, M.A.; Varman, M.; Zulkifli, N.W.M.; Mufti, R.A.; Zahid, R. Tribological Performance of Nanoparticles as Lubricating Oil Additives. J. Nanopart. Res. 2016, 18, 223. [Google Scholar] [CrossRef]

- Mang, T.; Dresel, W. (Eds.) Lubricants and Lubrication; Wiley-VCH: Weinheim, Germany, 2007. [Google Scholar] [CrossRef]

- Alves, S.M.; Barros, B.S.; Trajano, M.F.; Ribeiro, K.S.B.; Moura, E. Tribological behavior of vegetable oil-based lubricants with nanoparticles of oxides in boundary lubrication conditions. Tribol. Int. 2013, 65, 28–36. [Google Scholar] [CrossRef]

- Rojacz, H.; Maierhofer, D.; Piringer, G. Environmental impact evaluation of wear protection materials. Wear 2025, 560–561, 205612. [Google Scholar] [CrossRef]

- Nugroho, A.; Kozin, M.; Mamat, R.; Zhang, B.; Ghazali, M.F.; Kamil, M.P.; Puranto, P.; Fitriani, D.A.; Azahra, S.A.; Suwondo, K.P.; et al. Enhancing Tribological Performance of Electric Vehicle Lubricants: Nanoparticle-Enriched Palm Oil Biolubricants for Wear Resistance. Heliyon 2024, 10, e39742. [Google Scholar] [CrossRef]

- Vyavhare, K.; Aswath, P.B. Tribological Properties of Novel Multi-Walled Carbon Nanotubes and Phosphorus-Containing Ionic Liquid Hybrids in Grease. Front. Mech. Eng. 2019, 5, 15. [Google Scholar] [CrossRef]

- Guo, L.; Mol, H.; Nijdam, T.; de Vries, L.; Bongaerts, J. Study on the Electric Discharge Behaviour of a Single Contact in EV Motor Bearings. Tribol. Int. 2023, 187, 108743. [Google Scholar] [CrossRef]

- Schneider, V.; Krewer, M.; Poll, G.; Marian, M. Effect of Harmful Bearing Currents on the Service Life of Rolling Bearings: From Experimental Investigations to a Predictive Model. Lubricants 2024, 12, 230. [Google Scholar] [CrossRef]

- Muangpratoom, P.; Suriyasakulpong, C.; Maneerot, S.; Vittayakorn, W.; Pattanadech, N. Experimental Study of the Electrical and Physiochemical Properties of Different Types of Crude Palm Oils as Dielectric Insulating Fluids in Transformers. Sustainability 2023, 15, 14269. [Google Scholar] [CrossRef]

- Slita, A.; Filali, N.; El Hammari, L.; Hassanain, I.; Sifou, A.; Saoiabi, S.; El Belghiti, M.A. Study of the Electrical Resistivity of Several Vegetable Oils: Nigella, Olive, Argan, Prickly Pear and Palm. Pharm. Lett. 2016, 8, 62–64. [Google Scholar]

- Emebu, S.; Osaikhuiwuomwan, O.; Mankonen, A.; Udoye, C.; Okieimen, C.; Janáčová, D. Influence of Moisture Content, Temperature, and Time on Free Fatty Acid in Stored Crude Palm Oil. Sci. Rep. 2022, 12, 9846. [Google Scholar] [CrossRef] [PubMed]

- Hossain, M.K.; Khan, M.A.G. An Auspicious Dielectric in High Voltage Engineering: Vegetable Oil. In Proceedings of the 2015 International Conference on Electrical & Electronic Engineering (ICEEE), Rajshahi, Bangladesh, 4–6 November 2015; IEEE: Piscataway, NJ, USA, 2016; pp. 153–156. [Google Scholar] [CrossRef]

- Rajab, A.; Sulaeman, A.; Sudirham, S.; Suwarno, S. A Comparison of Dielectric Properties of Palm Oil with Mineral and Synthetic Types Insulating Liquid under Temperature Variation. J. Eng. Technol. Sci. 2011, 43, 191–208. [Google Scholar] [CrossRef]

- Singh, S.P.; Kumar, P.; Manohar, R.; Shukla, J.P. Dielectric Properties of Some Oil Seeds at Different Concentration of Moisture Contents and Micro-fertilizer. Int. J. Agric. Res. 2006, 1, 293–304. [Google Scholar] [CrossRef][Green Version]

- ISO 13373-2:2016; Condition Monitoring and Diagnostics of Machines—Vibration Condition Monitoring—Part 2: Processing, Analysis and Presentation of Vibration Data, 2nd ed. ISO: Geneva, Switzerland, 2016. Available online: https://www.iso.org/standard/68128.html (accessed on 10 January 2025).

- ISO 10816-7:2009; Mechanical Vibration—Evaluation of Machine Vibration by Measurements on Non-Rotating Parts—Part 7: Rotodynamic Pumps for Industrial Applications, Including Measurements on Rotating Shafts, 1st ed. ISO: Geneva, Switzerland, 2009. Available online: https://www.iso.org/standard/41726.html (accessed on 15 February 2025).

- Feng, Z.; Ma, H.; Zuo, M.J. Spectral Negentropy Based Sidebands and Demodulation Analysis for Planet Bearing Fault Diagnosis. J. Sound Vib. 2017, 410, 124–150. [Google Scholar] [CrossRef]

- Albezzawy, M.N.; Nassef, M.G.A.; Elsayed, E.S.; Elkhatib, A. Early Rolling Bearing Fault Detection Using A Gini Index Guided Adaptive Morlet Wavelet Filter. In Proceedings of the 2019 IEEE 10th International Conference on Mechanical and Aerospace Engineering (ICMAE), Brussels, Belgium, 22–25 July 2019; pp. 314–322. [Google Scholar] [CrossRef]

- Reddy, A.B.; Shah, F.U.; Leckner, J.; Rutland, M.W.; Glavatskih, S. Ionic Liquids Enhance Electrical Conductivity of Greases: An Impedance Spectroscopy Study. Colloids Surf. A Physicochem. Eng. Asp. 2024, 683, 132875. [Google Scholar] [CrossRef]

- Prashad, H. Appearance of Craters on Track Surface of Rolling Element Bearings by Spark Erosion. Tribol. Int. 2001, 34, 39–47. [Google Scholar] [CrossRef]

- Kostal, D.; Sperka, P.; Chmelar, J.; Vitek, P.; Polak, M.; Krupka, I. Comparison of Grease and Solid Lubrication of Rolling Bearings under Small-Stroke Reciprocation for Space Applications. Tribol. Ind. 2020, 42, 146–158. [Google Scholar] [CrossRef]

- Chen, Y.; Peng, K.; Li, X.; Sun, L.; Su, T.; Zhang, W.; Zhang, D.; Fan, S.; Yin, H.; Zhou, M. Lubricating and Conductive Properties of Modified Graphene/Silver Nanoparticles Under Current-Carrying Friction Conditions. Lubricants 2025, 13, 38. [Google Scholar] [CrossRef]

- Jason, Y.J.J.; How, H.G.; Teoh, Y.H.; Chuah, H.G. A Study on the Tribological Performance of Nanolubricants. Processes 2020, 8, 1372. [Google Scholar] [CrossRef]

- Bhaumik, S.; Prabhu, S.; Singh, K.J. Analysis of Tribological Behavior of Carbon Nanotube-Based Industrial Mineral Gear Oil (250 cSt Viscosity). Adv. Tribol. 2014, 2014, 341365. [Google Scholar] [CrossRef]

- ASTM D3336-20; Standard Test Method for Life of Lubricating Greases in Ball Bearings at Elevated Temperatures. ASTM International: West Conshohocken, PA, USA, 2020. Available online: https://store.astm.org/d3336-20.html (accessed on 20 June 2025).

| Dimensions (mm) | d | D | B | r |

| 30 | 55 | 13 | 1 | |

| Mass (kg) | 0.116 | |||

| Dynamic load rating, C (N) | 13,200 | |||

| Static load rating, Co (N) | 8300 | |||

| Clearances (µm) | C3 (13–28) | |||

| Component | Specifications |

|---|---|

| Electric Motor | GAMAK (3 hp, and 1400 rpm) |

| Base | C45 Carbon Steel |

| Shaft | SUS 420 Stainless Steel |

| Two Support Bearings | NU1011M Roller Bearing |

| Dc power supply | RD6024/RD6024-W |

| Digital oscilloscope | DQ7022S, two-channel (25 MHz) |

| Grease Sample Label | Grease Blends |

|---|---|

| Palm Grease A | Palm-oil-based glycerol grease (in its plain form) |

| Palm Grease B | Palm grease with 1 wt.% MWCNTs |

| Palm Grease C | Palm grease with 2 wt.% MWCNTs |

| Palm Grease D | Palm grease with 3 wt.% MWCNTs |

| Lubricant Blend | Operating Speed (rpm) | Bearing Radial Load (N) | Interacting Raceway | Hmin (µm) | λ |

|---|---|---|---|---|---|

| Lithium grease | 1400 | 100 | Inner | 1.03 | 7.28 |

| Outer | 1.21 | 8.60 | |||

| Sodium grease | Inner | 1.20 | 8.52 | ||

| Outer | 1.42 | 9.65 | |||

| Palm grease A | Inner | 0.50 | 3.53 | ||

| Outer | 0.59 | 4.16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abozeid, A.A.; Youssef, M.M.; Megahed, T.F.; El-Helaly, M.; Pape, F.; Nassef, M.G.A. Tribo-Electric Performance of Nano-Enhanced Palm Oil-Based Glycerol Grease for Electric Vehicle Bearings. Lubricants 2025, 13, 354. https://doi.org/10.3390/lubricants13080354

Abozeid AA, Youssef MM, Megahed TF, El-Helaly M, Pape F, Nassef MGA. Tribo-Electric Performance of Nano-Enhanced Palm Oil-Based Glycerol Grease for Electric Vehicle Bearings. Lubricants. 2025; 13(8):354. https://doi.org/10.3390/lubricants13080354

Chicago/Turabian StyleAbozeid, Amany A., May M. Youssef, Tamer F. Megahed, Mostafa El-Helaly, Florian Pape, and Mohamed G. A. Nassef. 2025. "Tribo-Electric Performance of Nano-Enhanced Palm Oil-Based Glycerol Grease for Electric Vehicle Bearings" Lubricants 13, no. 8: 354. https://doi.org/10.3390/lubricants13080354

APA StyleAbozeid, A. A., Youssef, M. M., Megahed, T. F., El-Helaly, M., Pape, F., & Nassef, M. G. A. (2025). Tribo-Electric Performance of Nano-Enhanced Palm Oil-Based Glycerol Grease for Electric Vehicle Bearings. Lubricants, 13(8), 354. https://doi.org/10.3390/lubricants13080354