1. Introduction

The temperature rise of drive motor bearings in new energy vehicles is a critical factor affecting their reliability and lifespan, with grease performance and driving conditions being the primary determinants of this rise. High temperatures accelerate grease oxidation, degradation, and failure, which can lead to increased friction, wear, and, ultimately, catastrophic bearing failure [

1,

2,

3,

4,

5]. Therefore, investigating the temperature rise characteristics under realistic driving conditions is essential for bearing life prediction and design optimization [

6]. In summary, the temperature rise of drive motor bearings is primarily governed by operating conditions, grease formulation, lubrication regime, and structural heat dissipation. Rapid acceleration, high rotational speeds, and combined loads increase frictional heat and limit grease replenishment, shifting the bearing toward boundary or mixed lubrication. Meanwhile, grease parameters such as base oil viscosity, thickener type, and oil release behavior further influence shear heating and film stability. Bearings positioned near the loading end also tend to exhibit higher temperatures due to poorer heat dissipation. However, a significant gap exists in the comparative analysis of how different grease types affect the temperature rise of drive motor bearings under complex operational conditions, which this study aims to address.

At present, for new energy vehicle drive motor bearings under actual complex driving conditions [

7], such as rapid speed change, fixed speed, limit speed, etc., the influence of different greases on the temperature rise characteristics has produced a lot of results. Zheng and Chen et al. [

8] investigated heat generation and heat transfer in high-speed angular contact ball bearings and predicted their thermal behavior, but the model was over-simplified, and dynamic driving conditions were missing. The performance of grease in rolling bearings is fundamentally governed by its composition, which directly determines the frictional behavior in rolling/sliding concentrated contacts [

9]. Key components such as the base oil type, viscosity, and thickener structure collectively influence shear stress, film formation, and, ultimately, the frictional heat generation that leads to temperature rise.

At the same time, it also has rich results on the simulation theory of grease temperature rise under the driving conditions of new energy vehicles. Guo Yikai et al. [

10] took the main bearing of the shield machine as their research object and, through the establishment of a simulation model and experimental verification, found that the lubricant viscosity and flow rate have less influence on the temperature rise of the bearing. Wang Zhijian et al. [

11] studied 71904C angular contact ball bearings and found that an increase in lubricant kinematic viscosity will lead to an increase in bearing temperature. Drawing on the AI strategy employed by Park et al. [

12] for designing amorphous alloy lattices, future applications of AI-driven methods could optimize grease formulations and bearing thermal management, thereby empowering the development of critical components for new energy vehicles. The temperature rise of drive motor bearings is not merely a performance indicator but a critical precursor to more severe failure modes. Elevated temperatures accelerate grease aging and degradation, which directly influences wear mechanisms [

13] and can lead to complex multi-state wear in precision bearings [

14]. Furthermore, excessive heat exacerbates friction conditions, potentially inducing roll–slip fretting wear in critical applications [

15], and ultimately serves as a key driver for fatigue failure under extreme service [

16]. Therefore, a fundamental understanding of temperature rise characteristics under realistic operating conditions is the essential first step for life prediction and reliability enhancement. Chen Changye et al. [

17] used angular contact ball bearings as their research object and analyzed and studied the parameters affecting the temperature rise of bearings through a simulation and test, the results showing that there was an optimal oil supply for bearings under oil and gas lubrication conditions. Jin Jun et al. [

18] and Dong Yanchun et al. [

19] studied grease lubrication angular contact ball bearings in CFD software Fluent, revealing the relationship between grease lubrication fluidity and temperature rise, but an extreme environment is missing, along with the driving conditions of a single existence and the lack of experimental temperature rise comparison verification. Existing results in the lubrication parameters influence mechanism, phenomenon observation, and numerical methods have made significant progress but are limited by the experimental breadth, mechanism depth, and model verification and have not yet formed a universal theoretical system.

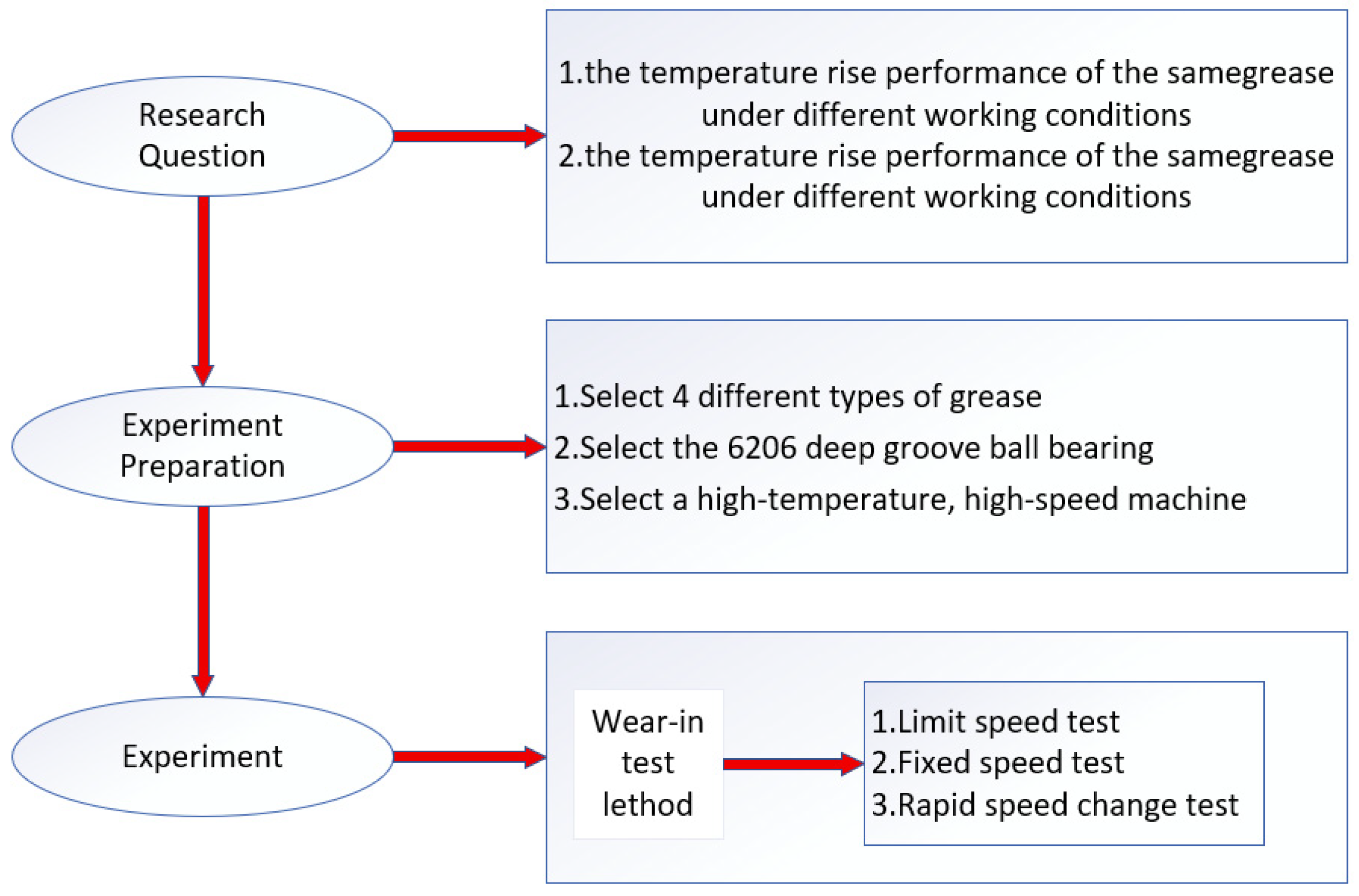

Although existing research on the theoretical calculation of bearing temperature rise and lubrication simulation has yielded significant and practical results, most studies suffer from several limitations. These limitations prevent the theoretical models’ accuracy from being verified and often involve simplified driving conditions. Specifically, the main shortcomings are (a) Over-simplified driving conditions: Most research focuses on single, steady-state speeds or loads, with insufficient attention on temperature rise characteristics under dynamic conditions such as rapid speed changes or extreme operating conditions like limit speeds. (b) Insufficient grease comparison: There is a lack of parallel comparative tests on the temperature rise performance of various greases under the same harsh conditions. This gap makes it difficult to provide direct evidence for grease selection. (c) Poor pertinence: Specifically, there is insufficient targeted research on the temperature rise performance of bearings for new energy vehicles. Given the aforementioned research gap, this paper focuses on the commonly used 6206 deep groove ball bearings in new energy vehicle drive motors. Utilizing a high-temperature, high-speed endurance test rig for new energy drive motor bearings, we employ a decomposition simulation approach. We deconstruct the complex real-world driving cycle into three fundamental operating conditions that are most critical for bearing thermomechanical stress: (1) rapid gear changes, simulating sudden acceleration and deceleration in urban driving conditions; (2) constant speed operation, simulating highway cruising; (3) maximum speed operation, simulating extreme maneuvers like high-speed overtaking or sustained uphill climbing. By reproducing these typical conditions on the test rig, we conducted temperature rise tests on 6206 bearings using four different greases. High-precision temperature sensors continuously monitored and recorded the temperature rise profiles at critical points on the bearing outer ring in real time. The system focuses on analyzing and comparing (a) the temperature rise performance of the same lubricant under different driving conditions; (b) the temperature rise differences among different lubricants under identical conditions.

2. Design of the Temperature Rise Test Under Grease and Driving Conditions of the Drive Motor Bearing

2.1. Drive Motor Bearing Testing Machine

2.1.1. Mechanical Structure

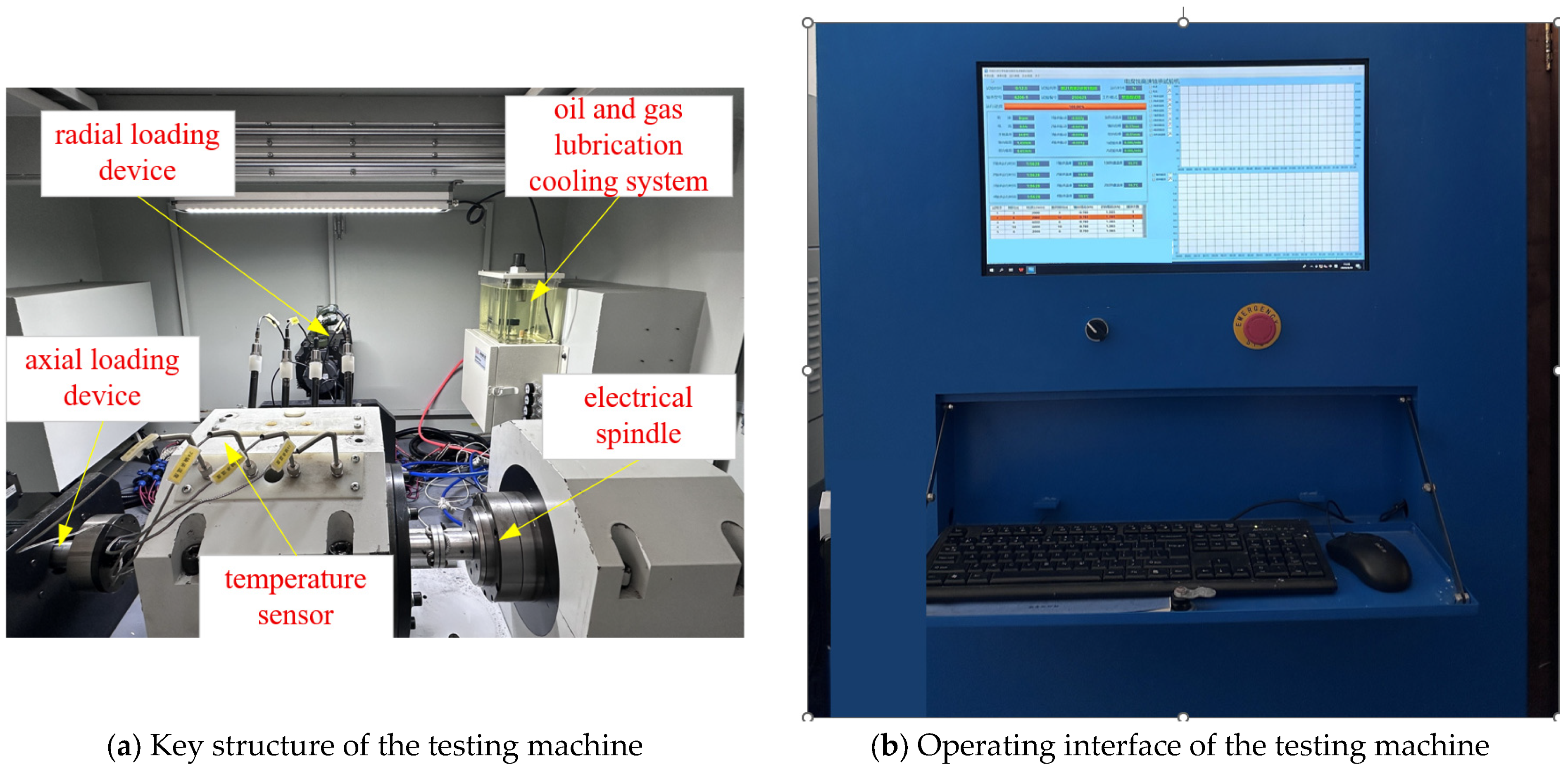

A high-temperature and high-speed endurance testing machine for new energy vehicle drive motor bearings (Model: SYJ-GW-GSd20-60) was used in this study to reproduce the thermal and mechanical environment experienced during actual driving. The system consists of a main testing unit, a control cabinet, and an air-cooled water chiller. The main unit integrates the drive system, loading system, measurement system, and oil–air lubrication and cooling system. The key technical specifications of the machine are listed in

Table 1.

The drive system employs an electric spindle as the power source, which is connected to the test shaft through a coupling equipped with a protective cover to prevent accidental injury in the event of a failure. The loading system is capable of applying both axial and radial loads and uses servo-electric cylinders to precisely control the loading amplitude, position, and rate. The measurement system incorporates a PT100 RTD temperature sensor to continuously monitor the outer ring temperature of the test bearing. The sensor operates over a range of −50 °C to 200 °C and provides high accuracy and fast response suitable for transient thermal measurements. The lubrication and cooling system adopts an oil–air lubrication scheme combined with a dedicated cooling circuit, ensuring a sufficient lubrication supply and effective heat dissipation under high-speed operation. The structural layout of the testing machine is illustrated in

Figure 1.

The test device offers several advantages. It can accommodate four bearings simultaneously—two test bearings and two auxiliary bearings—allowing parallel testing under identical conditions. The system supports the real-time acquisition, processing, and display of key operating parameters, such as rotational speed, load, and temperature. It also enables automated data recording during bearing life tests and is compatible with various lubrication methods, providing strong adaptability. In addition, the device can monitor vibration and motor currents during bearing operation and loading. The functional workflow of the system is illustrated in

Figure 2.

2.1.2. Operation Flow

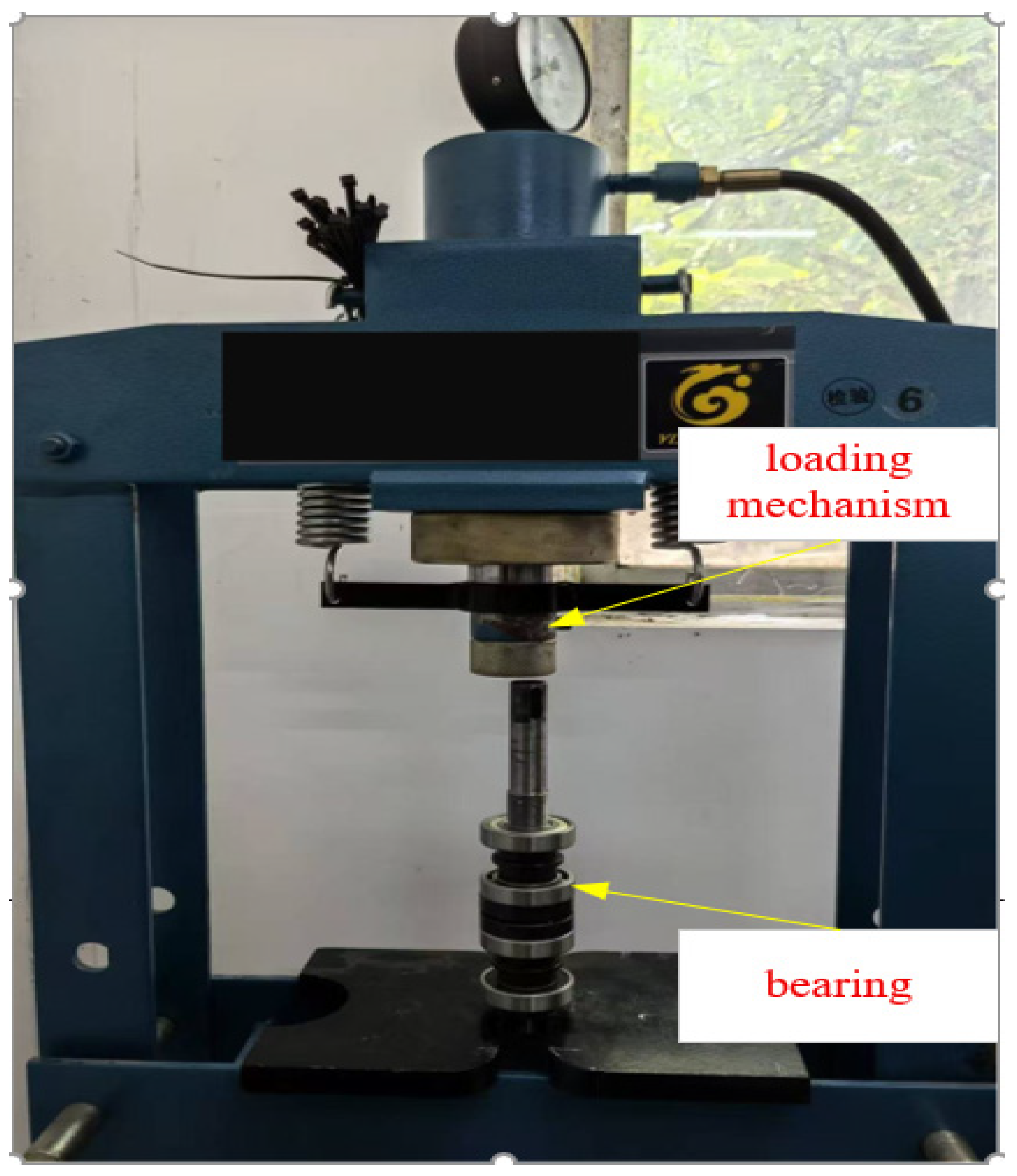

When assembling the bearing tooling, it is necessary to operate in a certain order to ensure the accuracy and safety of each link. Before installation, carefully check whether there are any defects in the tooling to ensure that all components are intact. If there are no defects, install the bearings on the shaft system. Firstly, put the shaft system on the press, press the bearings on the shaft system according to the order of Test Bearing 1#, accompanying Test Bearing 2#, accompanying Test Bearing 3#, and Test Bearing 4#, and then, finally, use the lock nut to fix it at the two ends, as shown in

Figure 3.

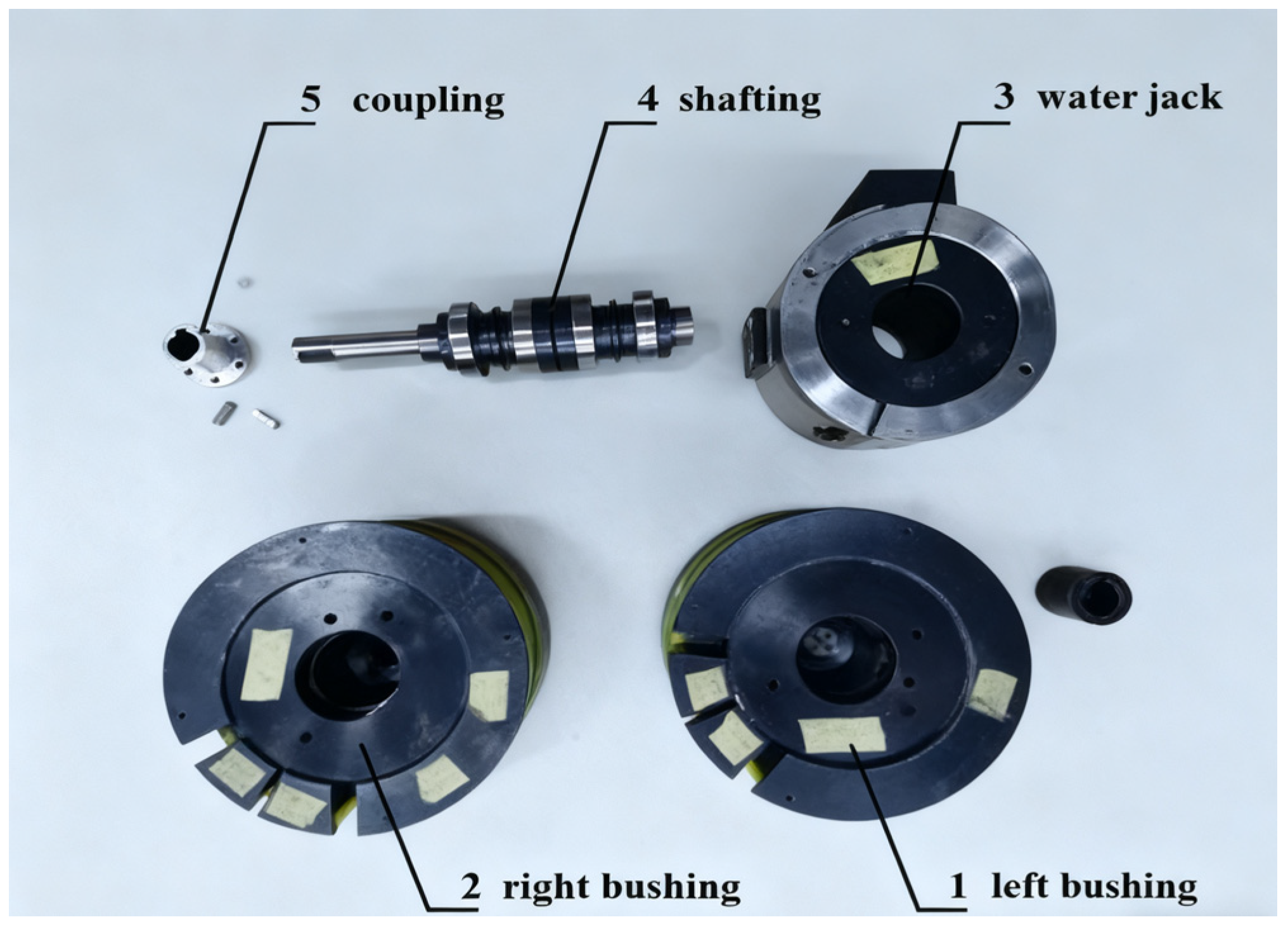

The workpiece of the test device mainly consists of the left bushing (near the axial load loading end), the right bushing (near the drive end of the spindle), the water jacket, the shaft system, and the coupling, as shown in

Figure 4. It is important to note the distinct installation positions of the two test bearings, as this directly influences their heat dissipation characteristics. The 1# test bearing is located closest to the drive spindle, which acts as a heat sink and promotes better heat exchange. In contrast, the 4# test bearing is positioned adjacent to the axial load loading block, a region with more restricted airflow and poorer convective cooling. Consequently, the 4# test bearing consistently operates at a higher temperature under identical test conditions, providing a more conservative and critical assessment of the grease’s high-temperature performance.

The left bushing and the shaft system assemble, followed by the shaft system and the water jacket, and then, the water jacket and the right bushing assemble, followed by the installation of the couplings. Front end assembly of the workpiece is correct. The overall test workpiece is lifted into the test machine, with the upper end covered to ensure that the equipment is safely closed, and then, finally, the bolts installed in turn; dismantling occurs in the reverse order. After completion of the installation of the test tooling and the axial loading block and radial loading block installation, the newly installed bearing test can be carried out normally, indicating that the test tooling installation is correct. If the test cannot be carried out normally, the tooling needs to be reinstalled.

2.1.3. Drive Motor Bearing

The test selected 6206 deep groove ball bearings widely used in the drive motors of new energy vehicles is widely used in the industry by virtue of its strong bearing capacity, simple structure, and other advantages. 6206 deep groove ball bearings have a high degree of coincidence, and the bearing pitch circle can accommodate the appropriate ball diameter and number of balls, with a high load carrying capacity, making it the most commonly used rolling bearing. 6206 deep groove ball bearings have a contact angle of 0° to withstand the radial load and, in the radial and axial joint load, or even only in the axial load, can also show good performance. This state can also show very good service performance. The 6206 deep groove ball bearings are used by most automobile enterprises for drive motor bearings. The basic parameters are shown in

Table 2.

2.2. Grease Lubrication of the Drive Motor Bearing

In this paper, the lubrication method of 6206 deep groove ball bearings is grease lubrication. Grease can enhance the high-temperature oxidation resistance of the bearings by virtue of its unique rheological properties and, at the same time, slow down the aging process of the bearings, effectively dissolving the carbon deposits so as to optimize the performance and life of the bearings. With the development needs of the industry, people have added a variety of additives such as anti-foam agents, rust inhibitors, anti-wear agents, antioxidants, and other additives to grease so as to meet the different circumstances of the industrial application scenarios [

20].

It should be noted that several grease parameters may influence the temperature rise behavior, including thickener type, base oil category, base oil viscosity, formulation percentage, and the presence of EP/AW additives. More importantly, these parameters exhibit strong interaction effects during operation. The thickener structure determines the mode and rate of base oil release, which directly affects the effectiveness of additives at the asperity scale. Likewise, the viscosity–thickener synergy controls both film formation in the EHD regime and shear heating in mixed lubrication. Therefore, the measured thermal behavior of each grease reflects the combined and interacting influence of its base oil, thickener network, and additive chemistry.

2.2.1. Configuration of the Grease Parameters

The selection of grease for motor bearings requires consideration of the equipment driving conditions, environmental conditions, and the grease’s own performance indicators. Based on parameters such as base oil type, thickener type, additives, dropping point, cone penetration, and base oil viscosity, four representative greases were targeted for investigation [

21,

22]. Specific technical information is shown in

Table 3,

Table 4,

Table 5, and

Table 6.

For all commercial greases used in this study, the exact formulation percentages of base oil, thickener, and additive package are proprietary information and were not disclosed by the manufacturers. However, all greases conform to their respective industrial specifications, and their key compositional characteristics (base oil type, viscosity grade, thickener chemistry, and grease consistency) are fully reported in

Table 3,

Table 4,

Table 5 and

Table 6 to ensure reproducibility of the experiment.

It is imperative to acknowledge that the four grease formulations selected for this comparative study exhibit concurrent variations in the fundamental parameters, including base oil type, kinematic viscosity, and thickener chemistry. This inherent multi-parameter variance mirrors practical engineering selection scenarios but precludes the attribution of performance outcomes to any single variable. Consequently, the subsequent analysis interprets the temperature rise data as the emergent behavior of each grease system as an integrated entity under specific operational conditions.

2.2.2. Comparative Analysis of Selection

According to the different parameters of the four types of grease, combined with the frequent starting and stopping of electric vehicle drive motors, the operating performance of the bearing grease under different test conditions is investigated from the starting point of the taper degree, dropping point, and base oil viscosity. According to the characteristics of electric vehicle drive motor bearing rapid speed change, we designed a rapid speed change test to compare and analyze the performance of four kinds of grease; at the same time, according to the definition of oxidizability, it could be seen that the temperature rise of the bearing had a direct relationship with the grease dropping point, but the performance of the bearing grease was affected by a variety of factors, and the temperature rise test was used to compare the performance of the grease.

2.3. Test Method of the Drive Motor Bearing Method

2.3.1. Wearing-In Test Method

To ensure the accuracy and repeatability of the temperature rise measurements, critical factors, including ambient temperature, bearing position effects, and cooling conditions, were rigorously controlled or accounted for in the experimental design and data processing. Firstly, the ambient temperature was continuously monitored and used to calculate the true temperature rise (ΔT) as the difference between the bearing outer ring temperature and the ambient temperature at any given moment, thereby correcting for any minor fluctuations. Secondly, the systematic temperature difference caused by the distinct installation positions of the 1# and 4# test bearings (as detailed in

Section 2.1.2) was a fixed characteristic of the test rig. All comparative analyses of the grease performance were therefore conducted using data from the same bearing position under identical conditions, effectively neutralizing this positional bias. Finally, the oil–air lubrication and cooling system operated at a constant, predefined setting throughout all tests, ensuring consistent cooling conditions across all grease evaluations.

Before starting the formal test, a break-in test needed to be carried out so that the grease was uniformly distributed. For this test, according to the FAG sample “AC 41 130/7 ChA” [

23] on the open and sealed spindle bearing grease distribution break-in operation of the proposal to design the test program, the specific steps are shown in

Figure 5.

When conducting the break-in test, the temperature is monitored in real time, and if necessary, a longer run is conducted until the temperature is stabilized. When conducting the test, 4 sets of bearings are tested at the same time, with 2 sets of test bearings mounted at the two ends and 2 sets of accompanying bearings in the center. In order to obtain a more accurate picture of the temperature rise, the ambient temperature at the beginning and end of the test should be recorded during the test. During the test, every time after the replacement of bearings, a break-in test needed to be carried out.

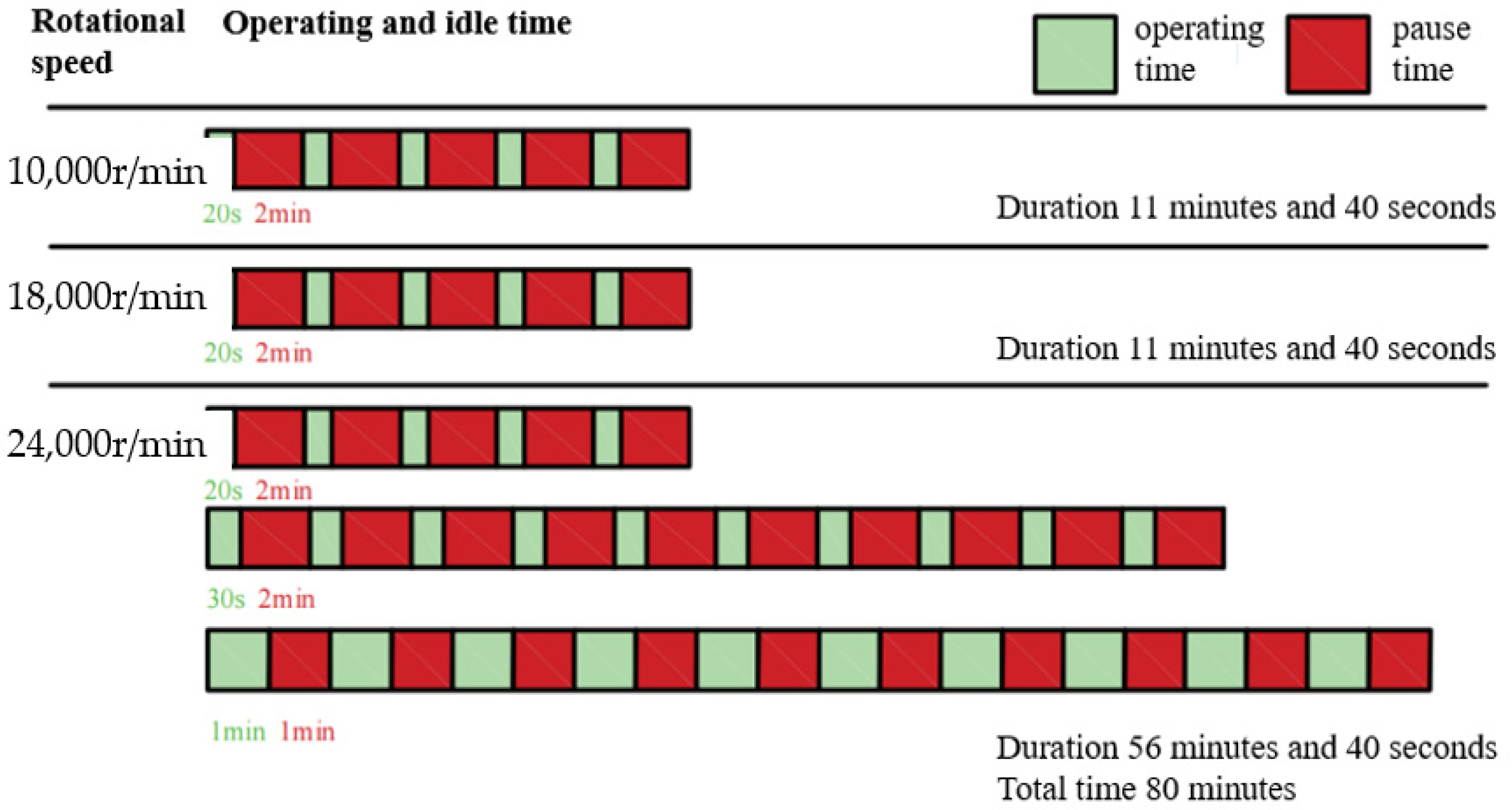

The break-in test was mainly divided into three stages: the first stage was under the conditions of a rotational speed of 12,000 r/min, running for 20 s, stopping for 2 min, and repeating five times, with a duration of 11 min and 40 s; the second stage was under the conditions of a rotational speed of 18,000 r/min, running for 20 s, stopping for 2 min, and repeating five times, with a duration of 11 min and 40 s; the third stage was under the conditions of a rotating speed of 24,000 r/min; running for 20 s, 30 s, and 1 min; and stopping for 2 min, 2 min, and 1 min, respectively, with a duration of 56 min and 40 s, and the total time was 80 min. If the break-in test went through a work cycle and the bearing indicators were not abnormal, we started the official test.

2.3.2. Rapid Speed Change Test Method

This test simulates the frequent acceleration and regenerative braking of urban driving. At present, in the frequent start–stop test of electric vehicle enterprises, the number of start–stops is set to 500–1000 times, and the maximum speed is 20,000/rpm. Accordingly, simulating the actual driving conditions of electric vehicles, and referring to the “New Energy Vehicle EV6206, EV6207 Bearing Test Outline”, the test program of the bearing’s rapid speed change performance is designed, as shown in

Table 7.

In the rapid speed change test, the test device is used to apply a radial load of 1.365 kN and an axial load of 0.195 kN to the bearings, and the rotational speed is frequently changed between 6000 and 20,000 r/min, and after the first step of the test is finished, the cycle is carried out for 2–5 steps, and a total of 1000 cycles are carried out, which can cover the daily starting and stopping of most of the electric vehicles. In the bearing rapid speed change test, the test device will record the temperature rise of the bearings in real time, mainly observe the temperature rise change of the bearings, and use 10 sets of bearings for each kind of grease to conduct the test and ultimately take the set of data with the largest change in temperature rise as the object of study to be analyzed.

2.3.3. Fixed Speed Test Method

This test represents the steady-state thermal performance during highway cruising. The bearing is subjected to a temperature rise test, in which a radial load of 1.365 kN and an axial load of 0.195 kN are applied to the bearing, the rotational speed is set to 15,054 rpm, and the running time is 6 h. When the test bearing samples show abnormal temperature exceeding the standard (≥120 °C) and other abnormal phenomena, they should be shut down and processed in a timely manner, and the specific test program is shown in

Table 8.

The temperature rise test for each type of grease test time is the same, the final analysis of the starting temperature of the bearing and the end of the temperature. In the test process, we tested the beginning and end of the ambient temperature record, the final test bearing samples of the temperature rise of the surface of the outer ring and the ambient temperature of the difference between that moment. To ensure the accuracy of the test results and avoid chance effects, each type of grease was tested using ten sets of bearings, and the temperature rise data of a single set of test bearings with the largest temperature rise among the 10 sets of test bearings were finally selected for analysis.

2.3.4. Limit Speed Test Method

This test emulates extreme scenarios like high-speed overtaking, pushing the system to its limits. In the high-speed performance test, the high-speed performance mainly indicates the limit value of deep groove ball bearings that can rotate continuously without generating frictional heat, leading to burns under the specified conditions. The high-speed performance test is defined as follows: deep groove ball bearings are operated under the specified test conditions, and the rotational speed is gradually increased to monitor the operation of the bearings until the bearings reach the maximum permissible rotational speed.

The limiting speed is the maximum speed at which the bearing can operate safely under certain operating conditions. Beyond this speed, the bearing may fail prematurely or even be seriously damaged due to friction, temperature rise, etc. When lubricated with grease, the temperature of the outer ring of the bearing should not exceed 70 °C. In the test process, the bearing speed increases sequentially. When it reaches the speed that cannot be operated normally (the bearing temperature rises sharply and exceeds the prescribed range or vibration changes and instability), the previous stage can be regarded as the bearing limit speed.

In the test process, we paid attention to each stage of speed and when the bearing temperature was stable at a near-constant value, achieving thermal equilibrium. If it does not reach thermal equilibrium, the bearing operating time increased, along with the speed being changed for the same times. With reference to the existing test specifications, using the indicated bearings and their grease parameters for the test, a high-speed performance test program was formulated, as shown in

Table 9.

The axial load and radial load of the high-speed performance test remain unchanged at 0.195 kN and 1.365 kN, and the rotational speed gradually increased from 16,000 r/min to 21,000 r/min, with stepwise incremental speeds, increasing by 1000 r/min in each step, and each rotational speed was run for 10 min. Eight sets of test bearings were selected for the high-speed performance test, using bearings with each type of grease. In the test, we paid attention to the temperature rise speed of the bearings at each speed. When the bearing temperature changed too fast at a certain speed, it could not reach thermal balance, and the bearings could not work properly at that speed.

3. Drive Motor Bearing Driving Condition Test Results and Discussion

Bearing operation of friction, vibration, and electromagnetic loss will eventually be converted into heat, abnormal temperature rise will appear earlier than the vibration signal, and poor lubrication occurs when the temperature rise rate is three times the rate of normal conditions; therefore, this section will choose the temperature rise as a measure to analyze the bearing three typical driving conditions under the operating performance.

In grease-lubricated rolling bearings, the lubrication regime changes dynamically with the operating speed and load. At low speeds or during rapid acceleration and deceleration, the bearing tends to operate in boundary or mixed lubrication due to insufficient time for grease replenishment. In this state, friction and heating are highly sensitive to thickener chemistry and EP/AW additives. Under high-speed steady operation, an elastohydrodynamic (EHD) film is formed, and the temperature rise becomes primarily governed by base oil viscosity and shear heating. The transition between these lubrication regimes is essential for understanding the temperature rise characteristics observed in this study.

3.1. Running Performance Under Rapid Speed Change Conditions

3.1.1. Temperature Rise of Drive Motor Bearings at Different Times

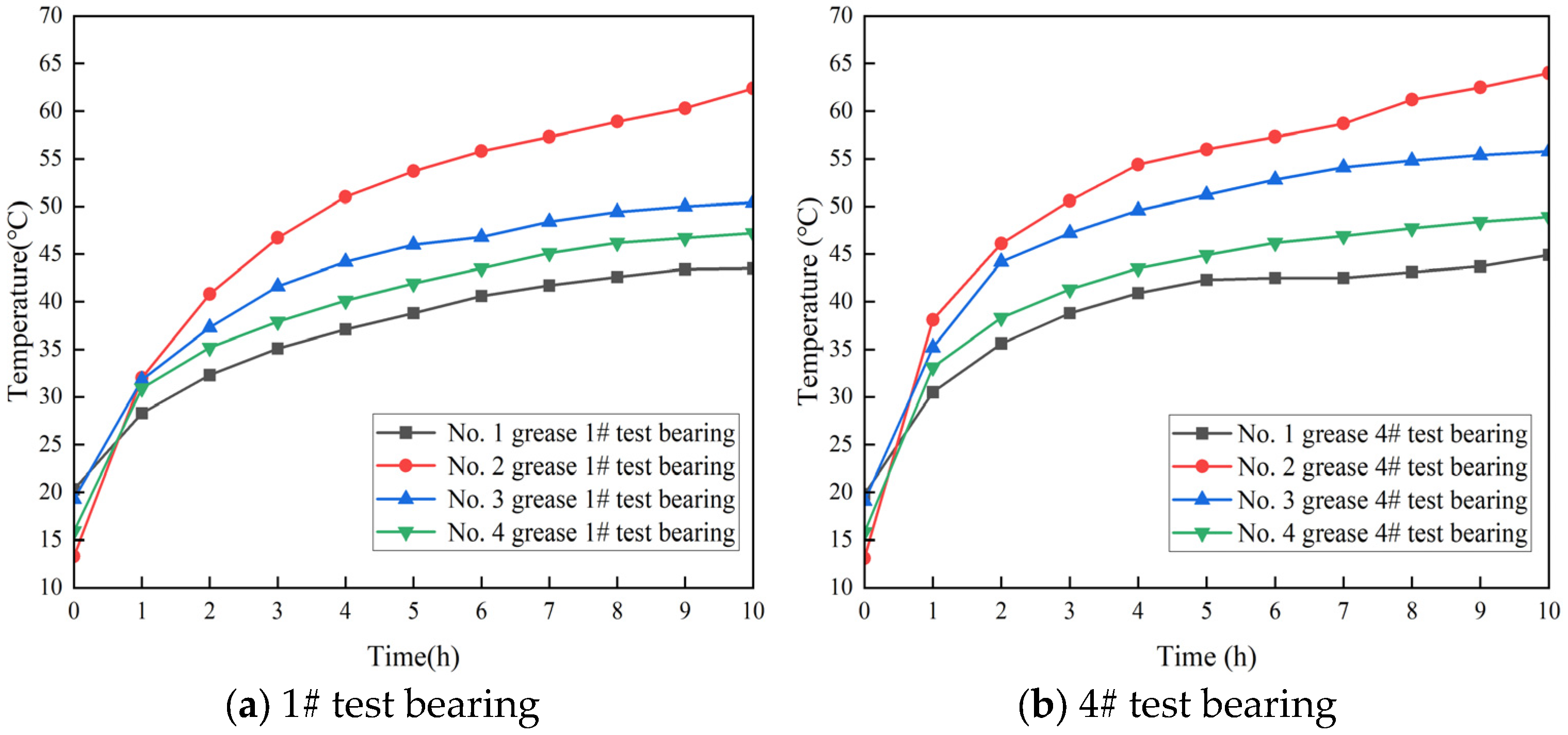

Motor bearings with four kinds of grease are tested for rapid variable speed operation performance, and the temperature rise of the 1# test bearing and 4# test bearing with four kinds of grease are recorded, respectively, and the temperature rise of the bearings is different at different times. The temperature rise of the 1# test bearing and the 4# test bearing at different times is shown in

Figure 6.

A total of 1000 cycles were carried out in the rapid change test, and the total time of a single test was 10 h. The figure shows the temperature changes of the bearings using four kinds of grease at different times in the single test, and it can be seen that the temperatures of the 4# test bearing with No.1 grease and No.2 grease were higher than that of the 1# test bearing, the temperatures of the two test bearings with No.3 grease were close to each other at the early stage, and the temperature of the 4# test bearing was higher than that of the 1# test bearing at the late stage of the test. The temperature of the 4# bearing was higher than the temperature of the 1# test bearing, which was mainly due to the different mounting positions, resulting in poorer heat dissipation of the 4# test bearing. According to the test specifications, the temperature of the 4# test bearing with a higher temperature rise, as shown in

Table 10, was the main object of study.

The temperature rise of the bearing using No.2 grease is the largest and the final temperature is the highest, which indicates that No.2 grease has a serious mismatch between the lubrication mechanism and the bearing kinematic characteristics under the condition of rapid changes of speed, and it cannot effectively inhibit the temperature rise regardless of the individual difference in the bearings, and it is twice as big as that of the bearing using No.1 grease, which is closer to that of the No.1 grease and No.3 grease.

Although the four greases are labeled using different base oil categories (PAO, ester, mineral oil, and fully synthetic), such classification alone is not sufficient to explain their temperature rise differences. The greases also differ in thickener system (polyurea vs. urea), base oil viscosity, and additive chemistry (EP/AW formulation), all of which may strongly affect frictional heating and film formation behavior. Therefore, the observed temperature responses cannot be attributed to the base oil type alone. They are instead a consequence of the formulation-specific synergies between the base oil, thickener, and additives. For example, the more stable temperature rise behavior of the polyurea-based Greases No.1 and No.3, compared to the urea-based greases, underscores the role of the thickener in modulating the base oil release and mechanical stability, which, in interaction with the base oil viscosity, governs the frictional heat generation. The comparative analysis further reveals that the superior performance of Grease No.3 over the similarly polyurea-thickened Grease No.1 under these transient conditions is concomitant with its lower base oil viscosity (55 cSt vs. 87 cSt). This viscosity difference ostensibly reduces hydrodynamic losses and churning torque during rapid acceleration phases. The findings imply a synergistic mechanism wherein the shear-resistant properties of the polyurea thickener are augmented by an optimized viscosity profile, collectively enhancing thermal management under high-shear, transient operation.

3.1.2. Temperature Rise of Bearing Driving Conditions Under Different Cycle Times

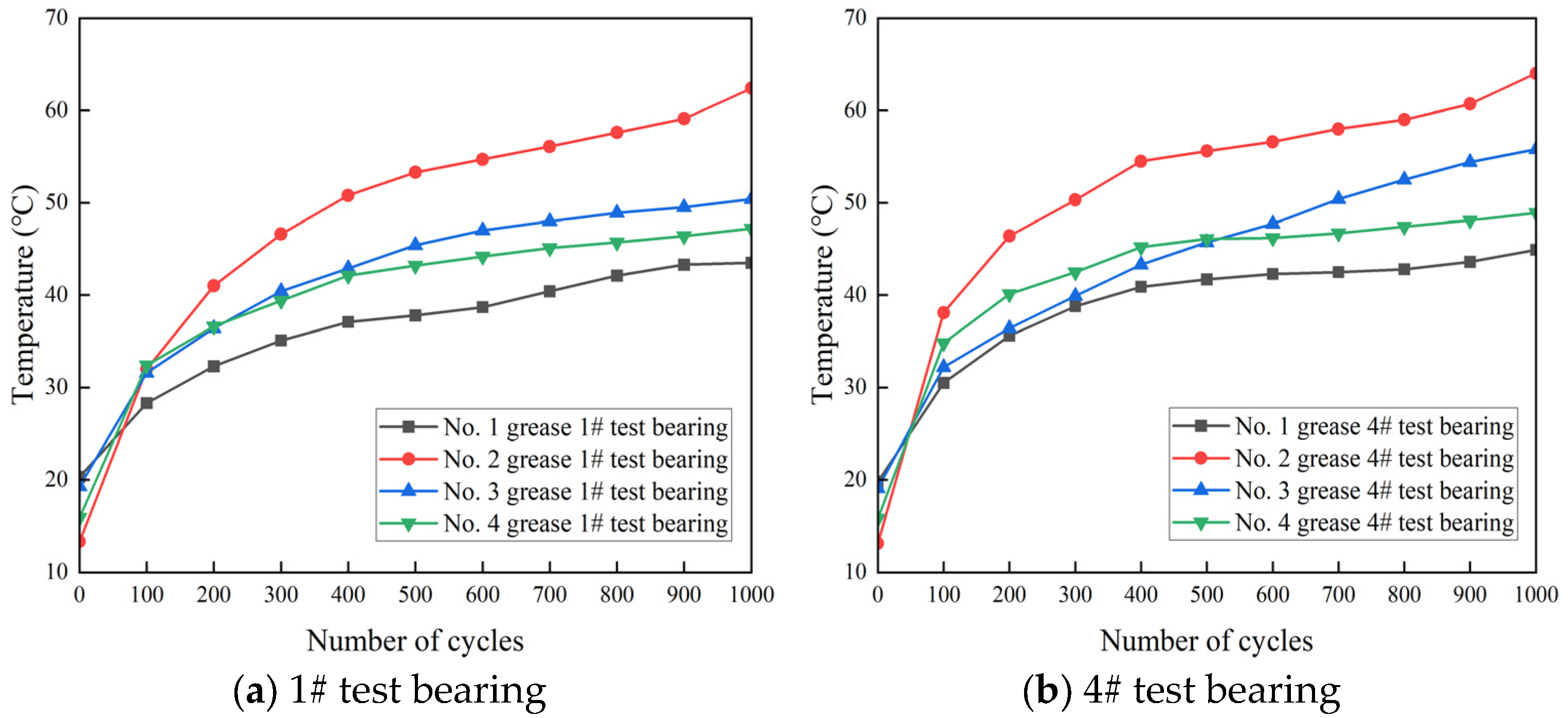

According to the above test program, it can be seen that, in the second to third and fourth to fifth steps of each cycle, the bearing speed is accelerated and decelerated rapidly, and the rapid change of the bearing speed in a short period of time will produce a more obvious change in the bearing temperature. For this reason, the change in bearing temperature for the rapid speed change in each cycle is observed. The 1# test bearing 4# test bearing with different cycle times are shown in

Figure 7.

The figure shows the bearing temperature under the rapid speed change condition for every 100 cycles, and no matter if it is 1# or 4# experimental bearings, with the increase in the cycle times, the temperature of the bearings corresponding to each grease increases. The temperature rises fast in the early stage of the cycle times from 0 to 300 and then slows down and tends to be stable after 300 cycles. The curve corresponding to the curve of No.2 grease (red) always has the highest temperature, and the curve corresponding to No.1 grease (red) always has the lowest temperature. It indicates that, in the two experimental bearings, the heat dissipation performance of No.2 grease is poorer, and No.1 grease has a relatively better temperature control performance. Under rapid speed change testing, No.3 grease demonstrated the most stable temperature behavior (smallest variation and lower steady-state temperature). This performance is attributed to its synthetic ester–PAO blend base oil (balanced viscosity profile) coupled with a polyurea thickener that provides robust shear stability and film retention during repeated acceleration/deceleration events.

3.2. Running Performance Under Fixed Speed Conditions

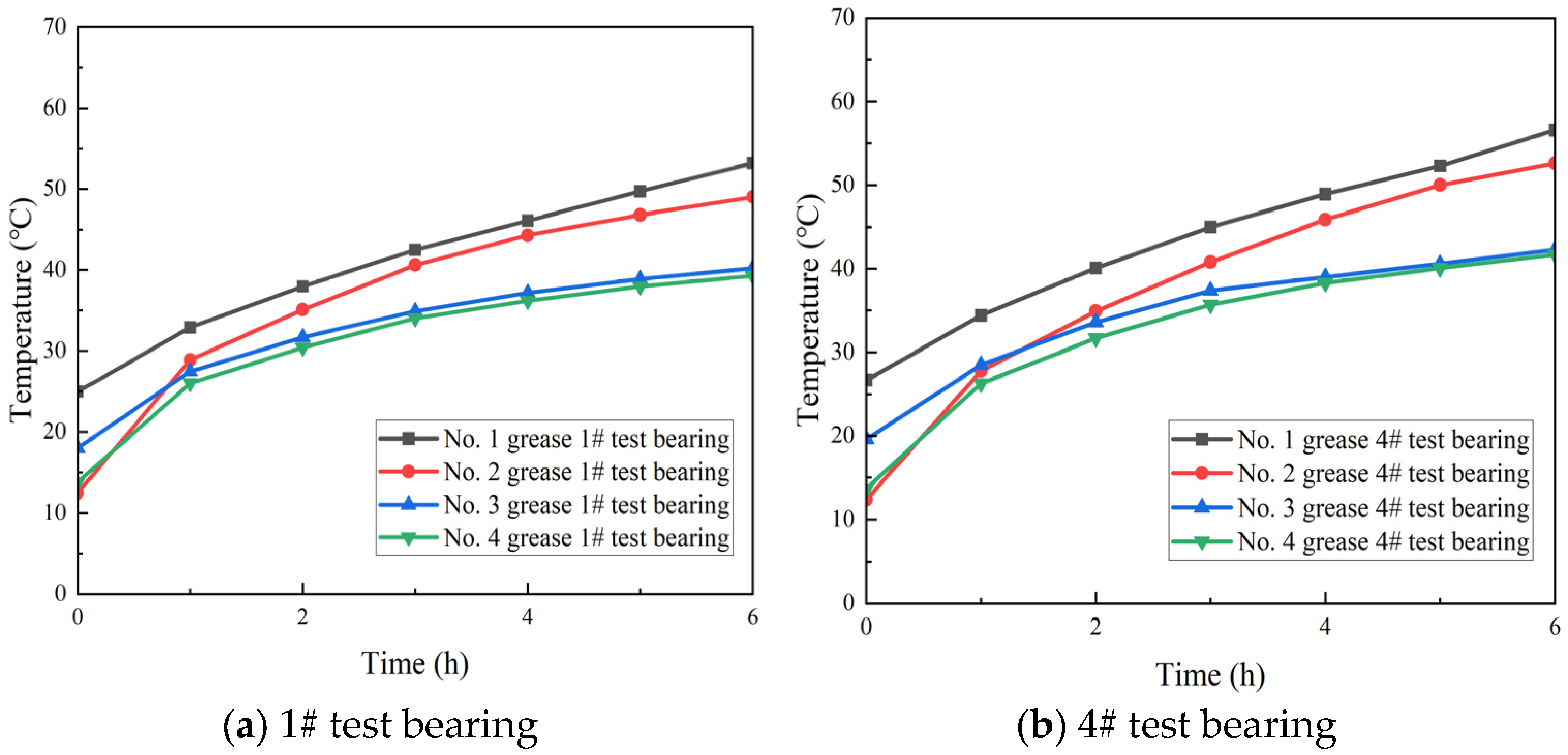

The motor bearings with four types of grease are tested at fixed speeds, and the temperature rise of the 1# test bearing and the 4# test bearing with four types of grease are recorded, respectively, and the temperature rise of the bearings can be obtained to be different at different times. The temperature rise of the 1# test bearing and the 4# test bearing at different time temperatures is shown in

Figure 8.

Figure 8 gives the temperature variation curve with time for bearings using four types of grease under fixed rotational speed conditions for 6 h. From the figure, it can be seen that the temperature of 4# test bearing is higher than that of 1# test bearing, which is mainly caused by the different mounting positions of the bearings, the 1# test bearing mounting position is closer to the electric spindle, and 4# test bearing mounting position is closer to the position of the axial load loading block, which has poorer heat exchange with the environment, and the measured temperature value is higher. According to the temperature rise test specifications, in the subsequent analysis of the results, the 4# test bearing with higher temperature was selected for analysis, as shown in

Table 11.

Overall, the temperature rise performance of No.3 grease is the best, and there is a tendency to slow down the temperature rise speed with the increase in time; the overall temperature growth rate of No.1 grease is close to that of No.1 grease, with no obvious speeding up or slowing down except at the beginning, and the temperature rise performance is more stable. No.2 grease has a faster temperature rise speed and shows a slowing down tendency near the end of the test, and the temperature rise performance is the worst.

The experimental results indicate that base oil viscosity strongly affects the bearing temperature rise. Higher-viscosity oils form thicker lubricating films but increase the internal shear resistance and frictional heat, leading to higher steady-state temperatures. Conversely, lower-viscosity oils reduce the viscous heat but may risk thinner films under high loads. Therefore, an optimal viscosity range is essential for maintaining both thermal stability and lubrication reliability. However, the performance hierarchy cannot be fully elucidated by viscosity alone. The optimal performance of No.3 Grease is ascribed to the conjunction of its lower-viscosity base oil, which minimizes shear-induced heating, and a robust polyurea thickener that ensures consistent elastohydrodynamic film integrity. Conversely, the suboptimal performance of No.4 Grease, despite its lowest viscosity, suggests that the rheological properties and film-forming capability of its urea-based thickener may be inferior under sustained thermal loading. These findings collectively indicate that the steady-state thermal behavior is governed by the coupled effects of the base oil viscosity and thickener-derived rheological stability.

3.3. Running Performance Under Limiting Speed Conditions

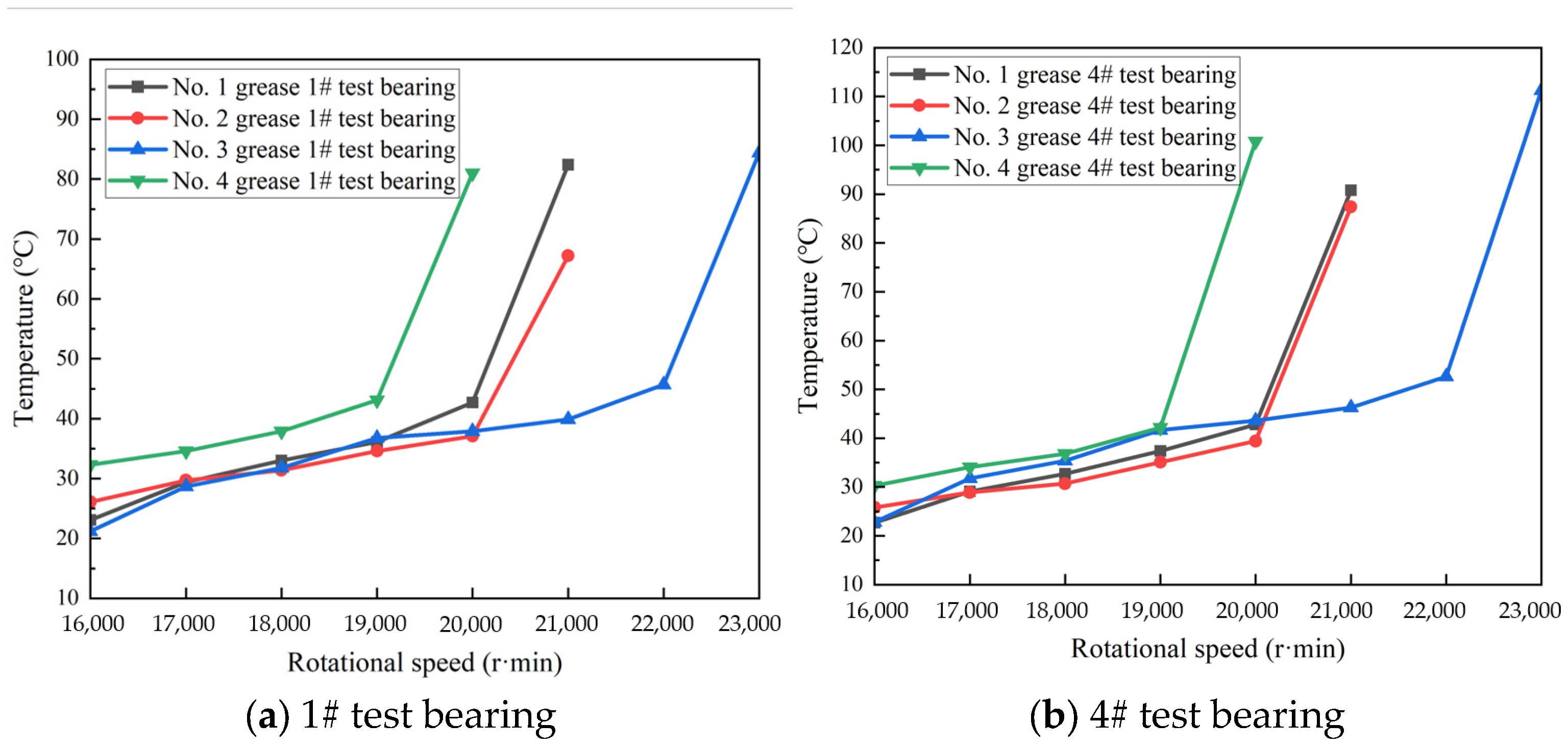

During the test, the bearing speed increases sequentially, and when it reaches a speed that cannot be operated normally (the bearing temperature rises sharply and exceeds the specified range or the vibration changes suddenly and is unstable), the previous speed of this stage can be designated as the limit speed of the bearing. High-speed performance tests were conducted on the motor bearings using four types of grease, and the outer ring temperatures of the four types of grease bearings were recorded, as shown in

Figure 9.

The outer ring temperature of bearings with grease lubrication should not exceed 70 °C as a standard. From

Figure 9, it can be seen that the limiting speed of bearings with four kinds of grease can reach 19,000 rpm, and the outer ring temperature of the bearings increases with the increase in rotational speed, among which, the temperature of bearings with No.1 and No.3 grease increases slower when the rotational speed is 16,000–20,000 rpm and increases more slowly when the speed increases from 20,000 rpm to 20,000 rpm. The temperature of the outer ring of the bearings using No.1 grease and No.3 grease rises slowly when the speed increases from 20,000 rpm to 21,000 rpm. The temperature of the bearings changes suddenly, and the temperature rises to more than 70 °C or even as high as 100 °C after running for a very short time, at the speed of 21,000 rpm, which shows that the bearings cannot continue to work normally at this speed; however, the temperature of the bearings using No.3 grease rises the slowest, and the temperature of the bearings running at the speed of 21,000 rpm rises to more than 70 °C, even as high as 100 °C. However, the temperature rise of the bearing with No.3 grease is the slowest, and the temperature of the outer ring is only 46 °C when the speed is 21,000 rpm. It can be presumed that the bearing with No.3 grease can still continue to work normally under the condition of increasing speed, and its limit speed should be higher than 21,000 rpm. The subsequent high-speed test verification of bearing with No.3 grease is continued, and it is found that the bearing with No.3 grease can still work normally under the speed of 23,000 rpm.

According to

Figure 9, the temperature of the outer ring of the bearing rises slowly at low speeds, but the rate of increase gradually accelerates as the speed rises, which indicates that, at low speeds, the heat generated by friction in the bearing is relatively small, and as the speed rises, the heat generated by friction in the bearing also increases accordingly. The test shows that the bearings with No.3 grease have better friction performance compared with the bearings with No.1 grease, No.2 grease, and No.4 grease; the heat generated by friction is less under the same test conditions, so the temperature is relatively low.

The rheological behavior of grease is jointly determined by its base oil viscosity and the micro-structure of its thickener network. These two factors, in conjunction with the additive package, engage in complex interactions that control oil release, film-forming capability, and shear stress development inside the bearing. Greases with lower viscosity but stronger polyurea networks (such as No.3 Grease ) can release oil more effectively and maintain a stable lubricating film, resulting in lower shear heating and reduced temperature rise. In contrast, greases with higher viscosity or weaker thickener structures may exhibit poorer flow and delayed oil release, leading to higher frictional heating. This interaction effect between viscosity and thickener structure provides a scientifically sound explanation for the temperature rise variations among the four greases.

The exemplary high-speed performance of No.3 Grease, which achieved a stable operational limit of 23,000 rpm, serves as a definitive validation of this interaction model. Its formulation constitutes an optimal compromise: The moderate viscosity base oil (55 cSt) provides sufficient load-bearing film thickness while mitigating internal friction, and the structurally robust polyurea thickener ensures exceptional resistance to mechanical degradation and oil bleed under intense centrifugal forces. This critical synergy between lubricant hydrodynamics and thickener tribology is identified as the principal enabler for extending the operational frontier of greased bearings, underscoring that the limiting speed is governed by the complementarity of viscosity and thickener mechanics.

4. Conclusions

This study investigates the temperature rise characteristics of electric vehicle drive motor bearings lubricated with different greases. Based on an analysis of the bearings’ operating conditions, the basic parameters of the test bearings were determined. The key performance indices of the greases were evaluated, and the corresponding test parameters were selected. A comparative experimental program was developed to assess bearing performance under various operating conditions, and tests using different greases were carried out accordingly. The main conclusions are as follows:

(1) During the rapid speed change, temperature rise, and high-speed tests, test bearing #4—located in a region with inferior heat dissipation capability—consistently exhibited higher temperature rise values than test bearing #1 under all operating conditions and grease types. These results demonstrate a clear and stable relationship between the bearing installation position and its operating temperature, indicating that the outer ring temperature is strongly dependent on the mounting location.

(2) In the rapid speed change test, the temperature rise follows the order No.1 < No.3 < No.4 < No.2. This trend is mainly governed by the combined effects of base oil viscosity and thickener shear stability. No.1 Grease exhibits the lowest temperature rise, because its moderate viscosity and polyurea thickener reduce viscous shear losses during acceleration and deceleration. No.3 grease shows slightly higher initial temperatures but becomes the most stable in the later stage, indicating superior shear stability and more consistent film formation under cyclic high-shear conditions. In contrast, the high-viscosity mineral oil-based No.2 grease generates the greatest heat due to higher internal shear and poorer film replenishment during rapid speed transitions. Therefore, greases with moderate viscosity and shear-stable thickeners (e.g., No.1 and No.3) provide better thermal control in frequent start–stop conditions.

(3) During constant speed testing, the four greases exhibited markedly different temperature rise behaviors, primarily influenced by base oil viscosity and thickener rheological properties. No.1 Grease experienced a faster initial temperature rise due to its thinner initial oil film. No.3 Grease exhibited the smallest and slowest overall temperature rise. Its formulation—using low-viscosity ester/PAO base oils with a polyurea thickener—maintained superior oil film stability and reduced shear heating. No.2 Grease consistently exhibits the highest temperature rise. Its high viscosity increases viscous shear losses, and the thickener structure demonstrates poor stability under loads, frequently transitioning into boundary lubrication conditions. Overall, lower base oil viscosity typically results in smaller steady-state temperature increases, but thickener stability and grease rheological properties modulate this effect.

(4) In lubrication performance testing under high-speed operating conditions, No.3 Grease demonstrated outstanding comprehensive performance. No.3 Grease achieved the highest speed limit (23,000 rpm). This is attributable to its optimized formulation: a medium-viscosity base oil (55 cSt) maintains oil film strength while minimizing shear heat generation, combined with a polyurea thickener that delivers outstanding mechanical stability and resistance to oil separation during high-speed operation.

(5) Based on the experimental results, the following practical recommendations are proposed to enhance drive motor reliability: For motors frequently subjected to emergency stop and start conditions, select greases with excellent shear stability and lower base oil viscosity to minimize temperature rise during transient operation. For motors requiring prolonged high-speed operation, it is critical to use grease formulated with medium-viscosity base oils and highly stable thickeners (such as polyurea) to achieve high limiting speeds and stable thermal performance. Greases with excessively high base oil viscosity should be avoided, as these products are prone to excessive shear heat generation and exhibit poor high-speed performance.

(6) In summary, confronting the inherent multi-parametric nature of grease formulations, this investigation conclusively demonstrates that the thermal performance under complex operating conditions is principally dictated by property synergy rather than by any singular characteristic. The consistently superior performance of No.3 Grease across all test regimes validates that a formulation integrating a moderate-viscosity synthetic base oil with a mechanically stable polyurea thickener constitutes a robust systemic solution for electric vehicle drive motor bearings. Consequently, the paramount recommendation for engineering practice is to prioritize the selection of greases based on the demonstrated compatibility and synergy of key parameters, moving beyond the optimization of individual properties in isolation.