Abstract

Environmental contamination critically affects the durability and performance of lubricants in machine components. Over long operating periods, particles and water ingress through degraded seals accelerate grease degradation and deteriorate tribological behavior. This study evaluates the effects of SiO2 particle concentration and water contamination, alone and in combination, on the performance of calcium-based grease in bearing steel contacts. Friction coefficients, grease temperatures, wear, pitting, and vibration signals were analyzed. The results show that an increase in particle concentration raised both friction and temperature, leading to more severe wear and pitting. The addition of 0.6 wt% water reduced fluctuations in friction and temperature, but when combined with high particle concentrations, it significantly worsened wear and pitting. The vibration-based energy ratio correlated strongly with pitting evolution, highlighting its potential as a sensitive parameter for monitoring surface fatigue. These findings provide insights into lubricant degradation under contaminated conditions and offer guidance for improving the reliability of lubricated systems.

1. Introduction

The ingress of solid contaminants into lubricating greases is a major factor governing the degradation of tribological systems. During service, grease can be contaminated by metallic debris generated from surface wear or by environmental particles introduced during installation, operation, or maintenance. Once entrained in the grease structure, these particles disrupt the lubricant film, promote asperity contact, and increase abrasive and adhesive wear processes. Consequently, frictional resistance increases, thermal stability deteriorates, and the operational lifespan of mechanical components is significantly reduced. Particle contaminants in lubricants are generally classified into three principal groups: (1) wear debris produced from rolling or sliding contact fatigue; (2) environmental particles, such as dust and sand, originating from the surrounding atmosphere; and (3) soot particles formed through incomplete combustion or lubricant degradation. The tribological influence of these contaminants depends on several parameters, including composition, hardness, morphology, size, and concentration. Hard and angular particles typically induce severe three-body abrasion, whereas softer or lamellar particles may form transient protective films that alter contact mechanics. Experimental investigations have confirmed the critical role of particle characteristics in determining lubrication behavior. Jin [] demonstrated that copper and molybdenum disulfide particles in lithium grease may hinder degradation by forming boundary films, while iron and dust particles accelerate abrasive wear and oxidation. Schnabel et al. [] reported that iron ore contamination increases the wear rate and elevates vibration amplitudes in rolling element bearings. Koulocheris et al. [,] further established a direct correlation between particle hardness and wear progression, showing that smaller, harder particles intensify surface damage under severe environmental conditions. Lin and Meehan [] identified three predominant wear debris morphologies (chunk, laminar, and spherical) generated by rolling contact fatigue and crack propagation. These debris particles can further deform through repeated rolling interactions, accelerating grease degradation and leading to seal failure. The compromised sealing subsequently facilitates the ingress of additional environmental particles, thus increasing wear and temperature.

Among various environmental particulates, silicon dioxide (SiO2) is of particular significance due to its high concentration in atmospheric dust, generally accounting for around 40–60 wt% globally and up to ~75 wt% in certain regions []. While numerous studies have reported beneficial effects of SiO2 nanoparticles as lubricant additives that form tribochemical or physical boundary layers and suppress friction and wear [,,], their uncontrolled introduction as environmental contaminants can have detrimental consequences. Qin et al. [] demonstrated that the SiO2 particle size in gear oil influences lubrication behavior, as both nano- and micron-sized particles can degrade lubrication performance and accelerate gearbox wear. Despite these studies, limited attention has been given to the detrimental influence of SiO2 particles as environmental contaminants in grease-lubricated systems.

In addition to particle contamination, water intrusion also plays a significant role in the deterioration of grease-lubricated systems [,]. The accumulation of water within grease can result from several factors, including inadequate sealing, operation under high-humidity environments, and improper handling during maintenance or cleaning procedures. Such conditions promote moisture ingress, which adversely affects the physical stability of grease and accelerates the degradation of lubricated components. When water enters grease, it may interact with the thickener and base oil, influencing both its structure and lubrication behavior. The degree of water retention depends largely on the thickener chemistry; for instance, calcium sulfonate-based greases exhibit approximately eightfold greater resistance to water washout than lithium complex greases []. Absorbed or retained water alters a grease’s consistency, film-forming ability, and frictional properties, ultimately compromising the protection of bearing steel surfaces []. Dittes [] reported that even a small amount of water contamination (around 1.0 wt%) in calcium- and lithium-based greases can reduce service life by up to 90%. Lijesh et al. [,] studied the effects of water on grease performance using contact angle analyses and proposed a standardized procedure for evaluating the water resistance of lubricating greases.

Although several studies have addressed the individual effects of water and particle contamination, the combined influence of these contaminants on grease degradation and surface damage remains insufficiently understood. In practical operating environments, these contaminants frequently coexist, producing synergistic effects that accelerate micro-crack initiation and film breakdown, ultimately causing pitting under rolling–sliding contact. Water can disrupt the thickener–oil structure and weaken boundary film stability, thereby increasing the probability of pitting corrosion on bearing surfaces [,]. Meanwhile, metallic wear particles and high thermal loads act as catalytic agents that promote oxidation and accelerate abrasive surface damage []. As previous research has mainly evaluated water or particle contamination independently, a clear understanding of how combined contaminants influence the onset and progression of pitting in grease-lubricated contacts is still lacking.

Pitting is a critical surface fatigue phenomenon that directly affects the durability of grease-lubricated transmission elements. It manifests as localized depressions or cavities on the contact surfaces of gears, bearings, or other rotating components, typically resulting from repeated rolling or sliding contact stresses that exceed the fatigue strength of the surface material. Pit initiation and propagation are influenced by several parameters, including material hardness, surface topography, lubricant properties, operating temperature, load conditions, and contamination levels. Druet et al. [] examined the relationship between oil aging and pitting resistance using four-ball wear tests. They observed that prolonged lubricant aging significantly shortened the time to pitting failure, whereas shorter aging periods improved fatigue life. Tuszynski et al. [] identified water contamination as the most detrimental factor in reducing oil scuffing resistance, while both dust and water substantially increased rolling contact fatigue and pitting. Similarly, Engelhardt et al. [] demonstrated that the presence of water exacerbates pitting damage in gear teeth, particularly in non-polar lubricants, where tooth flank deterioration was more severe than in polar lubricants. Moreover, the geometric and mechanical properties of contacting surfaces also significantly influence pitting behavior. Studies have shown that rough–smooth surface combinations accelerate micro-pitting initiation, while harder material pairings tend to intensify pit depth and propagation []. Early detection of pitting damage has been widely studied through vibration analysis and wear debris monitoring. Kundu et al. [] developed a correlation-based vibration parameter that exhibited strong sensitivity to pitting fault progression in spur gears. Sonawane and Chandrasekaran [] reported that the vibration acceleration amplitude increases proportionally with pitting severity, transitioning from minor to extensive damage. Cao et al. [] further proposed a diagnostic approach for planetary gear systems, integrating vibration and wear debris analysis to identify early-stage pitting. However, the interaction between environmental particles, water-induced grease softening, and surface fatigue progression has not been comprehensively evaluated under grease-lubricated contact conditions.

To address these gaps, the present work investigates the interactive effects of SiO2 particle contamination and water ingress on the tribological behavior, pitting evolution, and vibration response of calcium complex grease-lubricated steel contacts. Furthermore, a vibration-based indicator is proposed to preliminarily monitor pitting progression during wear, serving as a potential tool to determine a pitting failure threshold and to predict the service life of mechanical components.

2. Materials and Methods

2.1. Tested Lubricants

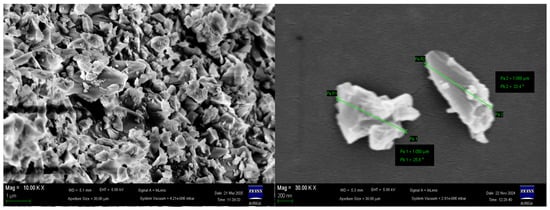

The base grease used in the test was a calcium complex, polyalphaolefin (PAO)-based synthetic grease with a base oil kinematic viscosity of 150 mm2/s at 40 °C, supplied by BECHEM Lubrication Technology (Berulub FG-H 2 EP), Hagen, Germany. The fundamental characteristics of the grease utilized in this study are presented in Table 1. This grease is widely used for lubricating transmission components. To evaluate the impact of water contamination and environmental particles on the tribological performance and vibration behavior of the grease during the wear process, amorphous silicon dioxide (SiO2) particles with irregular morphology and an average particle size of 1000 nm (US Research Nanomaterials, Inc., Houston, TX, USA, CAS: 7631-86-9) were introduced at concentrations of 0.185 wt% and 1.480 wt% into the base grease. Additionally, water was introduced at a concentration of 0.6 wt% to examine its effects, both independently and in combination, with particle concentration, as detailed in Table 2. The presence of water and particles in grease varies depending on operational conditions and specific applications. Previous research, such as the study by Dittes et al. [], investigated water contamination within a range of 0.3 to 5.0 wt%, and 0.6 wt% was selected in this study to represent mild water ingress. The chosen SiO2 concentrations were determined based on particle density per unit area calculations [], corresponding to approximately 109 to 1011 particles per m2 to simulate mild to moderate levels of particulate contamination. As shown in Figure 6b of Ref. [], when the particle diameter is 100 nm and the surface particle density reaches 1011 m−2, the particle-to-surface contact area ratio exceeds 60% of the total actual contact area, regardless of sliding velocity. This indicates that the majority of the contact interface can be separated by particles under such conditions. Therefore, the concentrations employed in this study can be considered moderate contaminant levels, particularly given that the SiO2 particles used in the tests are relatively large and irregular in morphology, as shown in Figure 1.

Table 1.

The fundamental characteristics of the tested grease [].

Table 2.

Experimental concentrations of particle and water contaminants in the base grease.

Figure 1.

SEM micrographs of the tested SiO2 particles.

Particle-contaminated lubricants were prepared following a two-stage dispersion and blending protocol. SiO2-contaminated grease samples were prepared by first dispersing 1 g of SiO2 particles in 1000 mL of ethanol using ultrasonication for 30 min, followed by adding 2 g of oleic acid as a dispersant and continuing ultrasonication for 4 h to achieve uniform particle distribution. The resulting dispersion mixture was then heated at 70 °C to completely evaporate the ethanol, yielding oleic acid-treated SiO2 particles. Based on the target particle concentrations (0.185 wt% and 1.480 wt%), the required grease mass was calculated relative to the final particle mass, and the treated particles were blended into the grease using mechanical mixing for 2 h.

For water-contaminated grease, deionized water was added at 0.6 wt% relative to the grease mass and mixed using ultrasonication for 30 min, followed by sealed conditioning at ambient temperature for 24 h to ensure uniform water absorption before testing. In the samples containing both water and particles, water was first incorporated using the aforementioned procedure, after which SiO2 particles were added and dispersed following the particle contamination protocol described above.

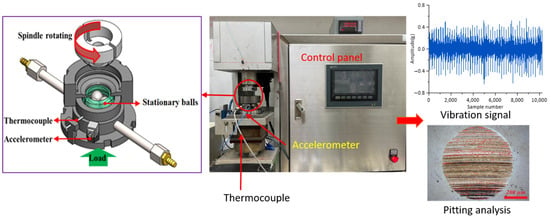

2.2. Tribological Test

A four-ball wear test was conducted, as shown in Figure 2, where a rotating ball made contact with three stationary balls at three distinct contact points. The tested lubricants were introduced into the test mold containing the three stationary balls. The balls were standard AISI 52100 steel-grade G10 bearings (purchased from Tan Kong Precision Tech Co., Ltd., Changhua, Taiwan), a high-carbon chromium bearing steel widely used in rolling contact applications. The ball specifications included a diameter of 12.7 mm, an average surface roughness (Ra) of 0.015 μm, and a hardness of 63.8 HRC. The nominal chemical composition was approximately C 0.97 wt%, Si 0.24 wt%, Mn 0.36 wt%, Cr 1.46 wt%, and Fe 96.97 wt%. Before testing, all balls were cleaned in an ethanol ultrasonic bath for 1 h to remove protective oil and surface contaminants, ensuring a consistent initial surface condition. The test conditions were selected to align with the intended application of the grease in bearing systems. A rotational speed of 1600 rpm, an applied load of 20 kgf, and a test duration of 240 min were employed to ensure adequate running-in and to enable the observation of pitting progression. Before testing, the tested lubricants were pre-heated to 75 °C using a controlled heater, consistent with the temperature regulation specified in ASTM D2266 [], to promote accelerated degradation. These parameters, therefore, constitute a non-standard accelerated test protocol designed to more closely simulate real application severity rather than routine quality inspection practice. For each sample, the test was interrupted at predetermined intervals to examine the surface characteristics of the wear scars formed on the steel balls. At least three repeated tests were conducted for each lubrication condition. The reported results represent the mean values, and the error bars indicate the standard deviations, confirming the measurement repeatability.

Figure 2.

Four-ball wear test machine and post-analysis of vibration signal and pitting.

During the wear process, friction force and temperature changes in the greases contaminated with water and SiO2 particles were continuously monitored using a force transducer and a thermocouple integrated into the four-ball tribotester. The K-type thermocouple (Special Limits of Error, 1.6 mm wire diameter, SUS 304 stainless-steel sheath) was plugged into the test mold to measure the grease temperature near the contact region between the contact balls. A three-axis accelerometer was mounted on the bottom specimen to acquire the acceleration vibrations during the test. A schematic illustrating the exact mounting position is provided in Figure 2. The water content and total acid number (TAN) of the grease samples, both before and after the wear tests, were respectively quantified using Karl Fischer moisture titration MKC-710 and Automatic Potentiometric Titrator KEM AT-710, both from Kyoto Electronics Manufacturing Co., Ltd., Kyoto, Japan . Upon completion of the tests, the morphological features and elemental compositions of the wear scars on the steel balls were characterized using an optical microscope, a 3D optical profilometer, and scanning electron microscopy/energy-dispersive X-ray spectroscopy (SEM/EDS).

3. Experimental Results and Discussion

3.1. Lubricant Properties

Table 3 summarizes the changes in water content, TAN, and consistency (NLGI grade) of the grease samples in the initial and post-test conditions. For the base grease (Ca_G), a slight increase in water content and a decrease in TAN were observed, suggesting mild degradation []. The addition of SiO2 particles (0.185S and 1.480S) led to a noticeable increase in TAN after wear, especially at higher concentrations. This indicates accelerated oxidation or chemical degradation, which agrees with findings that particulate contaminants promote chemical reactions and increase the acid number of lubricants []. In the water-contaminated samples, the initial water contents were higher than in the base grease but decreased after testing, suggesting evaporation or interaction with metal surfaces during wear. The presence of water changed the rheological properties of the greases, as structural integrity depends on thickener type and, subsequently, water escapes during shear and heating []. The TAN values in these samples also increased after wear, particularly in the presence of a high SiO2 content, suggesting that the combined effect of water and abrasive particles accelerates oxidation and possibly corrosion. In terms of consistency, most greases exhibited slight changes in NLGI numbers after the tests. The water-containing samples tended to show lower NLGI numbers, indicating a softening grease structure. Overall, calcium-based lubricating grease naturally absorbs moisture from the environment, where a higher SiO2 content leads to relatively higher moisture levels. Regardless of the initial grease moisture content, post-operation moisture levels stabilize between 0.25 wt% and 0.40 wt%, indicating that the operating system maintains a stable moisture content. For the calcium-based lubricating grease under the specified moisture and particle concentration conditions in this study, the TAN values before and after the experiments remained between 3.20 and 4.66, indicating that the two environmental contaminants have a relatively minor impact on TAN.

Table 3.

Water content, TAN, and consistency of the tested greases before and after wear.

3.2. Tribological Behaviors

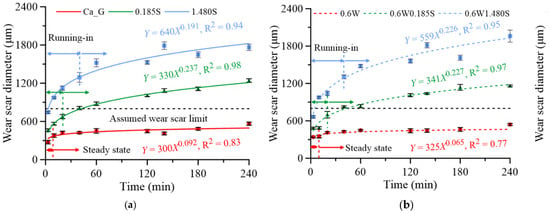

Figure 3 shows the evolution of the wear scar diameter (WSD) on the steel balls lubricated with the calcium-based grease under different contamination conditions, including various concentrations of irregularly shaped SiO2 particles and the presence of 0.0 wt% and 0.6 wt% water. Across all the test conditions, the wear process can be divided into two distinct regimes: the running-in phase and the steady-state phase. The running-in period, typically occurring within the first 40 min, is characterized by a rapid increase in the WSD. Following this, the wear rate tends to stabilize, marking the onset of the steady-state phase, where the wear mechanism becomes more uniform and predictable. The phase transitions in the figure demonstrate that clean grease and grease contaminated with water only maintain a clear distinction between running-in and steady-state. However, the presence of particle contaminants, in a separated state or in combination with water, prolongs the running-in phase and shifts the steady-state wear behavior toward more aggressive regimes. In the dry condition (0.0 wt% water), the base grease exhibited the smallest and slowest increase in the WSD. Consider a precision mechanical component with an allowable wear limit diameter of 800 μm, as shown by the dashed line. The regression model for Ca_G, Y = 300X0.092, indicates mild wear progression. The WSD reached the wear limit at approximately 42,869 min under accelerated grease degradation conditions, suggesting effective lubrication performance in the absence of contaminants. With the addition of 0.158 wt% particles, the WSD increased moderately, described by Y = 330X0.237, and approached the assumed wear scar limit at approximately 42 min. At 1.480 wt% SiO2, the WSD increased significantly and approached the failure threshold in 3 min, revealing the severe abrasive effect of hard particles. In contrast, under the water-contaminated conditions (Figure 3b), the wear behavior varied depending on the combined presence of water and particles. In the 0.6W case, the WSD followed a more gradual trend, with the regression Y = 325X0.065, and reached the wear limit at approximately 1,024,405 min. This indicates that while water softened the grease structure by reducing its consistency (Table 3), the overall wear remained relatively controlled. However, when a low concentration of SiO2 particles was added alongside water (0.6W0.185S), the wear progression became more aggressive, described by Y = 341X0.227, and approached the critical wear scar limit at 43 min. Severe wear behavior was also observed in the 0.6W1.480S condition, with Y = 559X0.226, where rapid WSD growth exceeded the assumed wear scar limit at approximately 5 min. Overall, the synergy between water and abrasive particles can slightly decelerate the wear severity caused by the particles.

Figure 3.

Variation in the WSD for the base grease at different particle concentrations under the (a) 0.0 wt% and (b) 0.6 wt% water conditions.

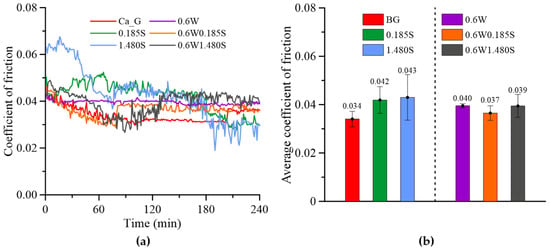

The grease friction behavior and the corresponding average values are shown in Figure 4. For all the tests, the coefficient of friction (COF) generally varied sharply during the initial stages of wear and then stabilized, suggesting the onset of the steady-state lubrication regime. In clean conditions, the COF remained relatively low and stable throughout the test, with an average value of 0.034. When SiO2 particles were introduced at 0.185 wt%, the COF exhibited larger fluctuations and a higher mean value of 0.042. Increasing the particle concentration to 1.480 wt% resulted in a more pronounced fluctuation amplitude, while the average COF showed only a minimal change, increasing to 0.043. This trend suggests that the presence of particles introduced additional friction through three-body interactions, consistent with the increased wear observed in Figure 3. Under water-contamination conditions, the grease containing only 0.6 wt% water showed a moderate COF of 0.040, but it was more stable. Interestingly, the 0.6W0.185S sample exhibited a reduced COF (0.037) compared to the 0.185S sample, indicating that the combined presence of water and a small amount of SiO2 particles may lead to better particle mobility, thus reducing particle accumulation and reducing friction. However, the sample with both water and a high SiO2 content (0.6W1.480S) showed a higher average COF of 0.039, which was still lower than in the 1.480S case, indicative of increased abrasive activity balanced by the lubricant-softening effect of water.

Figure 4.

(a) Friction coefficient variation during wear and (b) the average friction coefficient.

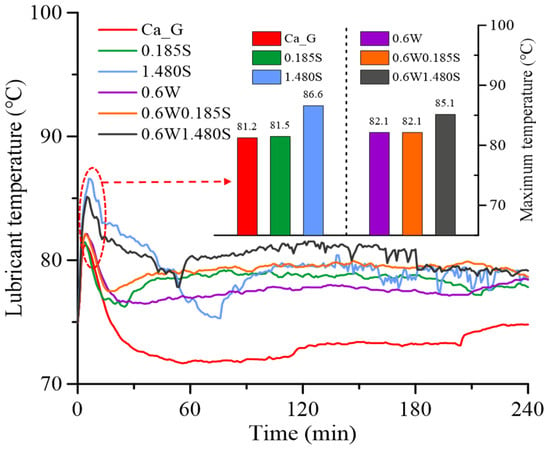

The variation in lubricant temperature over time during the wear tests and the corresponding maximum temperatures under various contamination conditions are shown in Figure 5. The temperature behavior reflects the dynamic interplay between friction heat generation, thermal dissipation, and grease degradation mechanisms during wear. At the initial stage of testing, all samples exhibited a rapid rise in temperature due to the high frictional forces associated with the running-in phase. The peak temperature was particularly pronounced in the 1.480S condition, which reached the highest overall temperature, and then decreased and remained stable throughout the test duration. In contrast, the base grease and low-SiO2 concentration samples showed relatively stable temperatures after the initial peak, which indicates effective boundary lubrication and thermal stability. While a temperature rise generally reflects increased frictional energy loss, the magnitude and stability of the temperature profile are also influenced by the lubricant’s rheological and thermal conduction properties. The water-contaminated samples exhibited slightly more stable temperature profiles compared with the corresponding grease samples containing the same SiO2 particle concentrations but without water addition. This behavior can be attributed to the relatively high specific heat capacity and thermal conductivity of water, which facilitate partial absorption and redistribution of frictional heat, thereby mitigating sudden temperature excursions associated with intermittent asperity contact events []. Consequently, the amplitude of friction fluctuations is reduced. However, this thermal moderation should not be interpreted as improved lubrication performance. Water still compromises the grease structure by disrupting the thickener network, ultimately promoting abrasive interactions and accelerating fatigue-related surface damage. This effect is particularly evident in the 0.6W1.480S condition, where notable abrasive wear persists due to the combined influence of water and hard SiO2 particles.

Figure 5.

Lubricant temperature variation and peak temperature during the wear process.

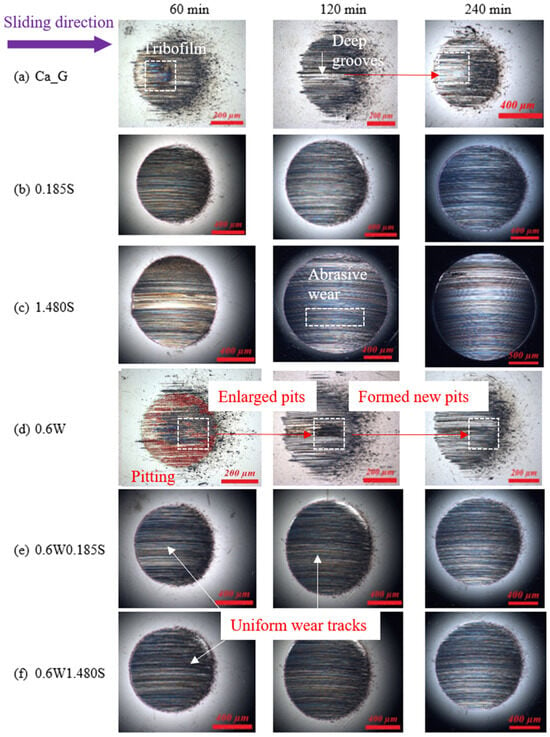

The evolution of wear scar morphology on steel balls under different lubrication conditions was analyzed at time intervals of 60, 120, and 240 min, as shown in Figure 6. For the base grease, the friction conditions remained relatively mild, resulting in shallow wear marks with localized debris accumulation; however, as the test duration increased, progressive abrasive and adhesive features appeared due to limited boundary film protection. The introduction of irregularly shaped silicon dioxide particles increased friction severity and deteriorated wear morphology. At a low concentration (0.185S), the wear scars were moderately degraded, showing clearer grooves and more wear debris compared to the base grease. With a higher SiO2 content (1.480S), the morphology further deteriorated, characterized by deeper grooves and a higher density of abrasive tracks, demonstrating severe wear as a result of intensified abrasive interactions from the hard and irregular-shaped particles. Water contamination alone (0.6W) altered the friction conditions by weakening grease consistency, enabling greater metal-to-metal contact and leading to substantial wear with irregular scarring and possible oxidative or corrosive features. When water and dust contamination were combined (0.6W0.185S and 0.6W1.480S), a more severe frictional environment developed, and the wear scars became more severe with time, showing extensive and deep wear tracks compared to the base grease and water contamination. The synergistic effect of water-induced grease softening and the aggressive abrasive action of irregular SiO2 particles led to the worst wear conditions, especially at higher particle concentrations.

Figure 6.

Surface morphology evolution of wear scars during the wear tests.

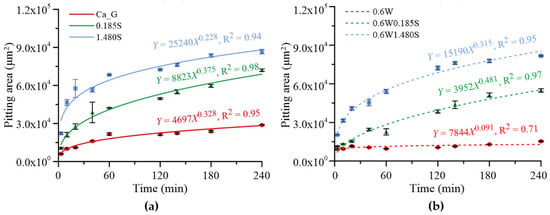

Microscopic examination of the wear scar surfaces, as shown in Figure 6, revealed pitting damage, particularly in the samples contaminated with high concentrations of SiO2 particles with or without water. Figure 7 illustrates the pitting area evolution measured on the wear scar surfaces as a function of sliding time for greases with different contamination conditions. Pitting, characterized by small localized craters on the contact surface, was most evident in the 1.480S and 0.6W1.480S samples after prolonged wear durations. This damage is attributed to the hard, irregularly shaped SiO2 particles acting as abrasive third bodies, repeatedly impacting the steel ball surface under cyclic loading. In these cases, the abrasive particles penetrated the lubricant film and induced micro-cutting or micro-fatigue, leading to surface crack initiation and eventual material detachment in the form of pits. Moreover, in the presence of water, the best-fit equation (Y = 15,190X0.315) demonstrates the synergistic effect of particle and moisture contamination on accelerating fatigue wear and surface degradation. The increased pitting rate in these samples is attributed to the combined effects of third-body abrasion and potential water-induced corrosion fatigue. Conversely, minimal pitting was found on the wear scars of the clean grease and the low-concentration SiO2 sample (0.185S), suggesting that the grease film under these conditions remained sufficiently intact to resist localized stress concentrations.

Figure 7.

The changes in pitting area on the wear marks of grease contaminated with different particle concentrations under two water contents: (a) 0.0 wt% and (b) 0.6 wt%.

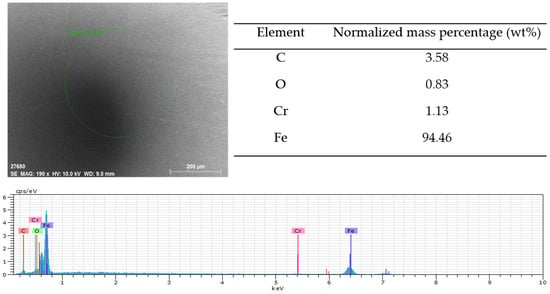

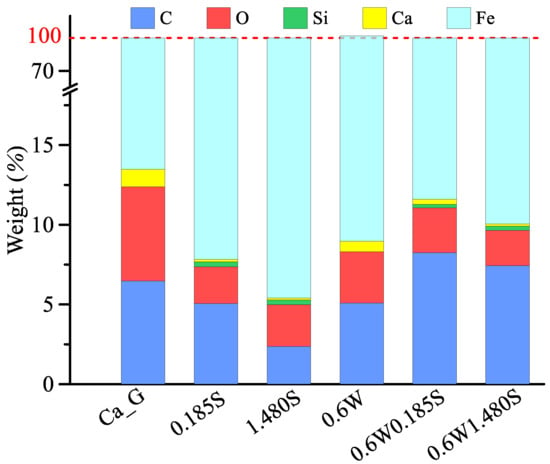

Figure 8 shows the EDS results obtained from an unworn region of the steel ball surface after testing. The calcium complex PAO-based grease employed in this study contains predominantly organic hydrocarbon species derived from both the synthetic base oil and the fatty acid based thickener. These constituents form carbon-rich boundaries and tribochemical films on steel contacts during sliding and rolling interactions. Accordingly, the detected carbon element (3.58 wt%) is attributed to these surface films rather than to the bulk carbon content of the bearing steel substrate []. The summarized percentage of element materials distributed on the wear mark after testing is shown in Figure 9. Calcium (Ca) was detected under all lubrication conditions, which is attributed to calcium-based thickener residues and tribochemical films remaining on the contact surfaces after testing. A comparatively higher Ca element was observed in the base grease and in the grease containing 0.6 wt% water, whereas the samples contaminated with SiO2 particles exhibited a reduction in Ca concentration. This trend is more likely associated with non-uniform tribofilm retention and abrasive disruption of additive-derived films caused by hard silica particles, rather than a direct inhibition of Ca-containing film formation by SiO2 contamination. Moreover, the silicon (Si) element was found in the tests with SiO2 particle contamination, indicating the presence of silica debris within the worn regions. However, the lack of additional oxygen enrichment shows that the Si element may mainly be derived from mechanically retained silica particles instead of a tribochemical response. Therefore, the incorporation of SiO2 particles is consistent with a three-body abrasive mechanism, where particles intermittently enter the contact zone, disrupt boundary films, and become mechanically entrained at the interface.

Figure 8.

EDS analysis of the surface morphology element distribution on an unworn region of a steel ball’s surface after testing.

Figure 9.

EDS analysis of the wear mark morphology on steel ball surfaces after testing.

4. Vibration Indicator for Monitoring Surface Damage

Vibration signals were acquired simultaneously with friction measurements throughout the wear testing to enable accurate synchronization between mechanical response and tribological behavior. Data acquisition was performed at a sampling frequency of 10,240 Hz to ensure adequate bandwidth for capturing both the fundamental rotational frequency (26.7 Hz) and high-frequency impulsive components associated with abrasive interactions and early-stage pitting while preventing aliasing in accordance with the Nyquist sampling criterion. A similar sampling resolution has been widely adopted in bearing health monitoring and also for four-ball tribological studies to support friction–vibration correlation analysis [,]. The potential influence of the natural frequency of the measuring station was evaluated based on our previous work [], where a modal analysis confirmed that the dominant structural resonances of the test rig occurred well above the excitation frequencies generated at 1600 rpm. In that study, baseline measurements conducted under non-contact rotation showed only minimal vibration amplitudes. Accordingly, the vibration signals acquired during the present wear experiments are interpreted as primarily attributable to friction-induced dynamics and surface damage progression, with a negligible contribution from machine structural resonance.

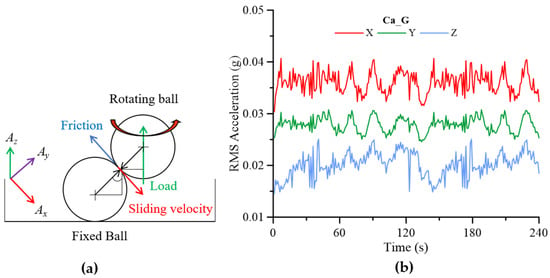

To enhance signal clarity and isolate periodic components related to the shaft motion, the Time Synchronous Averaging (TSA) method was applied during post-processing. This technique effectively reduces random noise and highlights repeatable patterns associated with mechanical interactions. The vibration data were synchronized with the shaft’s rotational speed of 1600 rpm throughout the test. By aligning the signal with the rotational cycle, the TSA method more precisely evaluates periodic disturbances caused by frictional contacts and the presence of wear debris or contaminants. Figure 10a presents the measured vibration signals along three directions: Ax (sliding direction), Ay (radial direction), and Az (normal to the contact surface, parallel to the applied load). Figure 10b shows the root mean square (RMS) acceleration in each direction for the base grease without contaminants, obtained during sliding after noise removal using TSA signal processing. The Az vibration primarily reflects changes in the applied load or test setup rather than the influence of contaminants. Vibration in the Ay direction shows moderate amplitude, higher than Az but lower than Ax, indicating limited sensitivity to dynamic contact variations. The Ax direction exhibits the highest vibration amplitude due to its alignment with the frictional motion, thereby serving as the most responsive axis to interactions at the sliding interface. Consequently, the Ax signal is selected for detailed analysis, as it effectively captures vibration characteristics associated with frictional behavior and the presence of solid contaminants.

Figure 10.

(a) The three measured directions of vibration and (b) RMS acceleration in three directions of the base grease .

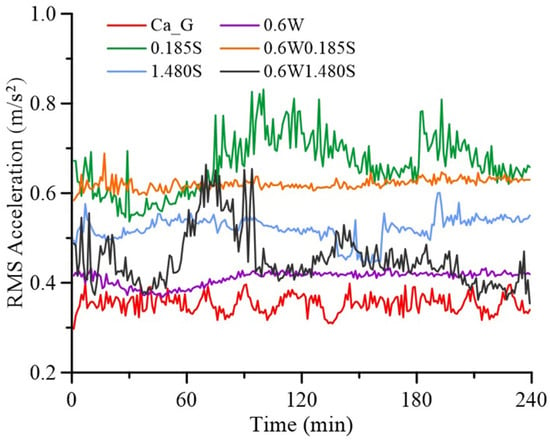

The variations in root mean square (RMS) acceleration during the wear test at the same interval as the friction coefficient measurement for all the tested lubricants and their average values are presented in Figure 11 and Table 4. The base grease showed the lowest average RMS acceleration of 0.35 m/s2, indicating stable wear with minimal vibration under good lubrication performance. Adding 0.185 wt% SiO2 particles caused the vibration magnitude to nearly double (0.66 m/s2), showing strong abrasive effects and increased vibration severity. At 1.480 wt% particles, RMS was lower than 0.185S but still higher than Ca_G. This suggests that at higher particle concentrations, debris tends to accumulate within the contact interface, where it can compact or reorganize into third-body or tribo-layers. Such layers alter the local stiffness and damping properties of the contact, which may partly stabilize the vibration response despite the persistence of severe wear and surface damage. Similar mechanisms have been reported in studies of third-body dynamics, where debris flow and compaction significantly influence the transmission of stresses and the evolution of contact conditions []. Moreover, particle-laden lubricants and nanofluids have been shown to enhance damping performance under dynamic loading, supporting the possibility that accumulated particles or tribo-films could modulate vibration characteristics []. However, while these effects may reduce vibration fluctuations, the overall severity of wear and pitting remains high, consistent with previous findings on contaminated grease in rolling bearings []. When only 0.6 wt% was added to the grease, the RMS acceleration rose slightly to 0.41 m/s2 compared to the clean grease, indicating that water alone weakened lubrication by degrading the grease structure. Under the mixed conditions, both were slightly lower than those with only particles at the same particle concentration. This could be due to a mild damping effect from water, possibly absorbing some frictional heat from the interaction between particles and the steel surface. Although these effects reduce vibration compared to the particle-only case, the overall wear and surface damage remain dominated by SiO2 particles.

Figure 11.

Variation in RMS acceleration during the test.

Table 4.

Average RMS acceleration.

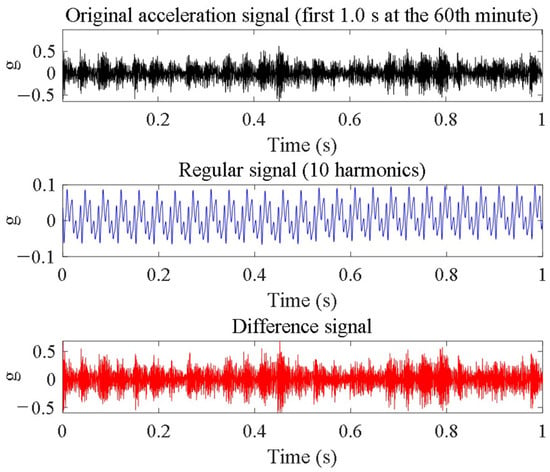

While the overall vibration energy can reflect the influence of contaminants on grease performance, a more specific vibration indicator that directly correlates measured acceleration with surface damage characteristics, such as pitting, is still required. Such an indicator could be employed to predict the threshold for pitting damage and to estimate the service lifetime of components. In this study, the energy ratio (ER) indicator, traditionally used in gear condition monitoring, was adapted to evaluate wear in a point-contact system formed by two rotating balls. Assuming the measured raw vibration signal is denoted as X(t), a regular signal associated with the deterministic contact response of the rotating ball can be extracted using the TSA as follows:

where N is the number of averaged revolutions and T is the rotation period of the ball. Xreg (t) represents the periodic vibration components, including the fundamental order and its harmonics. A difference signal is obtained by subtracting the regular signal from the original signal:

where Xdiff (t) contains non-periodic components, such as random impacts, broadband energy, and irregularities caused by surface damage, such as pitting. Then, the ER is subsequently defined as the ratio between the standard deviations of the difference signal (σdiff) to that of the regular signals (σreg):

Xdiff (t) = X(t) − Xreg (t)

ER = σdiff/σreg

Figure 12 presents an example of extracting the TSA signal into the regular and difference signals to calculate the ER. The ratio is low when the contact surface is smooth, and the difference signal is weak compared to the regular signal. As pitting initiates and grows, impacts and irregular vibrations increase the standard deviation of the difference signal, while the regular component changes less. Hence, the increase in the ER value represents more severe surface degradation.

Figure 12.

Decomposition of the TSA vibration signal into regular and difference components.

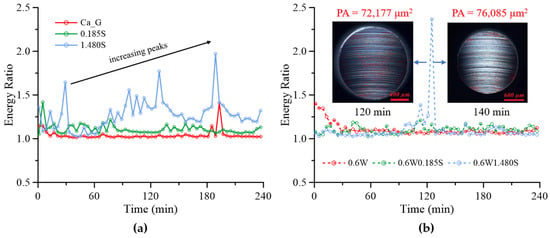

Figure 13 presents the variation in the ER during the wear tests under different contamination conditions. The results reveal a correlation between vibration features and the progression of surface damage in the form of wear and pitting. Under clean grease and a low particle concentration, the ER value remained stable at approximately 1.0, reflecting smooth contact conditions where the vibration response was dominated by the deterministic, periodic vibration of the rotating ball with minimal irregularities. This corresponded to low wear and pitting, indicating that a low ER is characteristic of a healthy tribological interface. With 1.480 wt% particle contamination, the ER increased progressively and displayed sharp peaks, reaching values near 2.0 after 180 min of the wear process. These increases coincided with severe wear scars and the onset of extensive pitting. Pitting introduces localized discontinuities that induce impulsive excitations and high-frequency vibration, which are captured in the difference signal of the TSA analysis. As wear progresses, pits may accumulate and enlarge, generating stronger impulsive responses and leading to sharp increases in the ER. Conversely, some pits may wear out or flatten during sliding, temporarily reducing vibration intensity. This explains the ER fluctuations observed during long-term testing, as the contact surface evolves dynamically through cycles of pit initiation, growth, and partial removal. When water was introduced at 0.6 wt% together with particles, the ER values were lower than those of the particle-only cases at the same concentration. This confirms that water provided a mild damping as the liquid phase may absorb part of the frictional heat and soften the grease matrix, thereby reducing the stiffness of the contact interface. As a result, the impulsive vibration response caused by hard particles was partly reduced, leading to slightly decreased ER values compared to the particle-only conditions. However, the wear scar observations confirmed that surface degradation remained severe, with extensive pitting present after 120–140 min. This indicates that while water can moderate the vibration amplitude associated with particle impacts, it does not prevent the accumulation of damage.

Figure 13.

Variation in the ER value during wear for lubricants with (a) 0.0 wt% and (b) 0.6 wt% water mixed with different concentrations of particles.

An important observation of this study is that the ER values correspond more directly to the contamination concentration than overall RMS vibration levels. While RMS acceleration provides a general measure of system energy, it is influenced by both deterministic periodic responses and random components, making it less sensitive to localized surface defects. In contrast, the ER isolates impulsive, broadband components associated with surface damage. As the contamination concentration increased, particularly at high SiO2 levels, the ER values rose sharply and exhibited distinct peaks, reflecting pit onset and growth on the contact surface. Meanwhile, the overall RMS values showed only modest increases that did not clearly distinguish between the low and high contamination cases. This indicates that the ER provides a more reliable parameter for evaluating the severity of contaminant-induced degradation, as it directly reflects the transition from smooth contact to surface fatigue.

5. Conclusions

In this work, a four-ball tribotester was used to investigate the combined effects of SiO2 particle concentration and water contamination on the tribological performance and degradation behavior of calcium complex synthetic grease. Variations in the friction coefficient, lubricant temperature, wear scar diameter, pitting area, and vibration signals were analyzed to evaluate the dominant surface damage mechanisms. The results show the following:

- The influence of SiO2 contamination exhibited a concentration-dependent behavior. However, unlike the nanoscale spherical silica previously reported to promote mild polishing or tribofilm repair at low concentrations, the relatively large (~1 µm) and irregularly shaped SiO2 particles used in this work did not produce a beneficial polishing effect. Instead, even at 0.185 wt%, the particles introduced intermittent three-body contacts and local micro-abrasion, and further increasing the concentration to 1.480 wt% resulted in pronounced abrasive wear, higher frictional heating, and accelerated surface fatigue.

- The introduction of 0.6 wt% water reduced temperature and friction variability, primarily due to enhanced heat dissipation and transient softening of the grease microstructure. However, when water coexisted with a high SiO2 concentration, lubricant degradation was intensified due to weakened thickener integrity and more severe abrasive interaction, resulting in accelerated pitting and wear progression.

- The energy ratio vibration indicator corresponded well with the progression of pitting, suggesting it can serve as an important parameter for monitoring pitting evolution.

While the present findings provide valuable insights, certain limitations should be acknowledged. The test durations were relatively short and may not fully capture long-term grease degradation or the steady-state evolution of pitting fatigue. Furthermore, only one particle size and an irregular morphology of SiO2 were evaluated, but different contaminant geometries or nanoscale particles may also alter lubrication mechanisms. Future work will therefore focus on extended operational testing to establish critical degradation thresholds associated with pitting initiation and failure. The investigation will also be expanded to include a broader range of environmental contaminants, such as soot and metallic debris, to better reflect real-world operating environments. Moreover, we will extend the testing duration and investigate broader contaminant concentrations to help identify a critical energy ratio threshold that may serve as a criterion for determining the pitting failure limit.

Author Contributions

Conceptualization, T.-N.T. and J.-H.H.; methodology, T.-N.T., J.-H.H. and S.-Y.C.; validation, J.-H.H. and S.-Y.C.; formal analysis, T.-N.T. and J.-H.H.; investigation, C.-W.K. and S.-J.L.; data curation, T.-N.T. and C.-W.K.; writing—original draft preparation, T.-N.T.; writing—review and editing, T.-N.T., J.-H.H. and S.-Y.C.; visualization, T.-N.T. and S.-Y.C.; supervision, T.-N.T. and J.-H.H.; project administration, J.-H.H.; funding acquisition, J.-H.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Science and Technology Council, R.O.C., grant number 114-2221-E-006-212.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Jin, X. The Effect of Contamination Particles on Lithium Grease Deterioration in Sealed Ball Bearings. Lubr. Sci. 1995, 7, 233–245. [Google Scholar] [CrossRef]

- Schnabel, S.; Marklund, P.; Larsson, R. Study of the Short-term Effect of Fe3O4 Particles in Rolling Element Bearings: Observation of Vibration, Friction and Change of Surface Topography of Contaminated Angular Contact Ball Bearings. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2014, 228, 1063–1070. [Google Scholar] [CrossRef]

- Koulocheris, D.; Stathis, A.; Costopoulos, T.h.; Gyparakis, G. Comparative Study of the Impact of Corundum Particle Contaminants Size on Wear and Fatigue Life of Grease Lubricated Ball Bearings. Mod. Mech. Eng. 2013, 3, 161–170. [Google Scholar] [CrossRef]

- Koulocheris, D.; Stathis, A.; Costopoulos, T.h.; Tsantiotis, D. Experimental Study of the Impact of Grease Particle Contaminants on Wear and Fatigue Life of Ball Bearings. Eng. Fail. Anal. 2014, 39, 164–180. [Google Scholar] [CrossRef]

- Lin, C.L.; Meehan, P.A. Morphological and Elemental Analysis of Wear Debris Naturally Formed in Grease Lubricated Railway Axle Bearings. Wear 2021, 484–485, 203994. [Google Scholar] [CrossRef]

- Mir, A.H. Improved Concrete Properties using Quarry Dust as Replacement for Natural Sand. Int. J. Eng. Res. Dev. 2015, 11, 46–52. [Google Scholar] [CrossRef]

- Razavi, S.; Sabbaghi, S.; Rasouli, K. Comparative Investigation of the Influence of CaCO3 and SiO2 Nanoparticles on Lithium-based Grease: Physical, Tribological, and Rheological Properties. Inorg. Chem. Commun. 2022, 142, 109601. [Google Scholar] [CrossRef]

- Singh, Y.; Rahim, E.A.; Singh, N.K.; Sharma, A.; Singla, A.; Palamanit, A. Friction and Wear Characteristics of Chemically Modified Mahua (madhuca indica) Oil Based Lubricant with SiO2 Nanoparticles as Additives. Wear 2022, 508–509, 204463. [Google Scholar] [CrossRef]

- Szwajka, K.; Trzepieciński, T.; Szewczyk, M.; Zielińska-Szwajka, J. Effect of SiO2 and MoS2 Particles as Lubricant Additives on Lubrication Performance in Sheet Metal Forming. Materials 2025, 18, 4605. [Google Scholar] [CrossRef]

- Qin, C.; He, S.; Zhou, X.; Li, Q.; Li, Q.; Yang, Z. Research on the Effect of Nano/micron SiO2 Particles on Actual Wear of the Main Gear Box of Large-scale Mechanical Equipment. Tribol. Lett. 2024, 72, 12. [Google Scholar] [CrossRef]

- Kamaya, M. Environmental Effect on Fatigue Strength of Stainless Steel in PWR Primary Water–Role of Crack Growth Acceleration in Fatigue Life Reduction. Int. J. Fatigue 2013, 55, 102–111. [Google Scholar] [CrossRef]

- Chopra, O.K.; Stevens, G.L.; Tregoning, R.A.; Rao, S. Effect of Light Water Reactor Water Environments on the Fatigue Life of Reactor Materials. J. Press. Vessel. Technol. 2017, 139, 060801. [Google Scholar] [CrossRef]

- ASTM D1264; Standard Test Method for Determining the Water Washout Characteristics of Lubricating Greases. ASTM International: West Conshohocken, PA, USA, 2020.

- Hudedagaddi, C.B.; Raghav, A.G.; Tortora, A.M.; Veeregowda, D.H. Water Molecules Influence the Lubricity of Greases and Fuel. Wear 2017, 376–377, 831–835. [Google Scholar] [CrossRef]

- Dittes, N. Mixing Grease with Water. In Proceedings of the 1st European Conference on Improvement in Bearing Technology Through European Research Collaboration (iBETTER), Utrecht, The Netherlands, 23–24 February 2015; SKF Engineering and Research Center: Nieuwegein, The Netherlands, 2015. [Google Scholar]

- Lijesh, K.P.; Khonsari, M.M.; Miller, R.A. Assessment of Water Contamination on Grease using the Contact Angle Approach. Tribol. Lett. 2020, 68, 103. [Google Scholar] [CrossRef]

- Lijesh, K.P.; Miller, R.A.; Shah, R.; Shirvani, K.; Khonsari, M.M. The Standard for Assessing Water Resistance Properties of Lubricating Grease Using Contact Angle Measurements. Lubricants 2023, 11, 440. [Google Scholar] [CrossRef]

- Blaine, S.; Savage, P.E.P. Reaction Pathways in Lubricant Degradation. Reaction Model for n-hexadecane Autoxidation. Ind. Eng. Chem. Res. 1992, 31, 69–75. [Google Scholar] [CrossRef]

- Soltanahmadi, S.; Morina, A.; Eijk, M.C.P.V.; Nedelcu, I.; Neville, A. Tribochemical Study of Micropitting in Tribocorrosive Lubricated Contacts: The Influence of Water and Relative Humidity. Tribol. Int. 2017, 107, 184–198. [Google Scholar] [CrossRef]

- Lancaster, J.K. A Review of the Influence of Environmental Humidity and Water on Friction, Lubrication and Wear. Tribol. Int. 1990, 23, 371–389. [Google Scholar] [CrossRef]

- Druet, K.; Olszewski, O.; Romanowski, P. Viscosity and Influence on Pitting of Laboratory-aged Gear Oil. Wear 1991, 141, 321–333. [Google Scholar] [CrossRef]

- Tuszynski, W.; Michalczewski, R.; Piekoszewski, W.; Szczerek, M. Effect of Ageing Automotive Gear Oils on Scuffing and Pitting. Tribol. Int. 2008, 41, 875–888. [Google Scholar] [CrossRef]

- Engelhardt, C.; Witzig, J.; Tobie, T.; Stahl, K. Influence of Water Contamination in Gear Lubricants on Wear and Micro-pitting Performance of Case Carburized Gears. Ind. Lubr. Tribol. 2017, 69, 612–619. [Google Scholar] [CrossRef]

- Yazid, I.I.M.; Komata, H.; Hashimoto, S.; Ueda, K. An Experimental Study of Surface Damage on Rolling Bearings in Low Lambda Conditions. Tribol. Online 2023, 18, 1–9. [Google Scholar] [CrossRef]

- Kundu, P.; Darpe, A.K.; Kulkarni, M.S. A Correlation Coefficient Based Vibration Indicator for Detecting Natural Pitting Progression in Spur Gears. Mech. Syst. Signal Process. 2019, 129, 741–763. [Google Scholar] [CrossRef]

- Sonawane, P.R.; Chandrasekaran, M. Investigation of Gear Pitting Defect Using Vibration Characteristics in a Single-stage Gearbox. Int. J. Electr. Eng. Educ. 2020, 57, 272–278. [Google Scholar] [CrossRef]

- Cao, W.; Han, Z.; Yang, Z.Z.; Wang, N.; Qu, J.X.; Wang, D. Deterioration State Diagnosis and Wear Evolution Evaluation of Planetary Gearbox Using Vibration and Wear Debris Analysis. Measurement 2022, 193, 110978. [Google Scholar] [CrossRef]

- Dittes, N.; Sjödahl, M.; Pettersson, A.; Lang, D. Corrosion Sensor for Water-contaminated Grease. Tribol. Trans. 2020, 63, 891–896. [Google Scholar] [CrossRef]

- Zhao, Y.; Chang, L. A Micro-contact and Wear Model for Chemical–mechanical Polishing of Silicon Wafers. Wear 2002, 252, 220–226. [Google Scholar] [CrossRef]

- Horng, J.H.; Yu, C.C.; Chen, Y.Y. Tribological Characteristics and Load-Sharing of Point-Contact Interface in Three-Body Mixed Lubrication. J. Tribol. 2022, 144, 052201. [Google Scholar] [CrossRef]

- Grease Data Sheets. Available online: https://www.bechem.de/de_en/products/lubricating-greases/berulub-fg-h-2-ep.html (accessed on 29 October 2025).

- ASTM D2266-01; Standard Test Method for Wear Preventive Characteristics of Lubricating Grease (Four-Ball Method). ASTM International: West Conshohocken, PA, USA, 2015.

- Horng, J.H.; Ta, T.N.; Jheng, R.Y.; Huang, M.W.; Zhang, K.S.; Torskaya, E. Effect of Liquid Contaminants on Tribological Performance of Greases. Wear 2023, 530–531, 205054. [Google Scholar] [CrossRef]

- Hirani, H.; Jangra, D.; Sidh, K.N. Experimental Analysis of Chemically Degraded Lubricant’s Impact on Spur Gear Wear. Lubricants 2023, 11, 201. [Google Scholar] [CrossRef]

- Cyriac, F.; Lugt, P.M.; Bosman, R. Impact of Water on the Rheology of Lubricating Greases. Tribol. Trans. 2016, 59, 679–689. [Google Scholar] [CrossRef]

- Acar, N.; Franco, J.M.; Kuhn, E.; Gonçalves, D.E.P.; Seabra, J.H.O. Tribological Investigation on the Friction and Wear Behaviors of Biogenic Lubricating Greases in Steel-steel Contact. Appl. Sci. 2020, 10, 1477. [Google Scholar] [CrossRef]

- Larsson, E.; Westbroek, R.; Leckner, J.; Jacobson, S.; Rudolphi, A.K. Grease-lubricated Tribological Contacts–Influence of Graphite, Graphene Oxide and Reduced Graphene Oxide as Lubricating Additives in Lithium Complex (LiX)-and Polypropylene (PP)-thickened Greases. Wear 2021, 486–487, 204107. [Google Scholar] [CrossRef]

- Singh, J.; Kumar, D.; Tandon, T. Tribological and Vibration Studies on Newly Developed Nanocomposite Greases Under Boundary Lubrication Regime. J. Triobol. 2018, 140, 032001. [Google Scholar] [CrossRef]

- Ta, T.N.; Horng, J.H.; Hwang, Y.L. Correlation Between Tribological and Vibraiton Behaviors in Sliding Lubricated Contacts. J. Tribol. 2022, 144, 111603. [Google Scholar] [CrossRef]

- Ciprari, S.; Ripard, V.; Saulot, A.; Massi, F. Investigation of Third Body Role in Dry Contacts: Experimental Procedure to Dissociate the Effects of Substrate and Interface Layer on the Contact Pair Frictional Response. Tribol. Int. 2023, 190, 109047. [Google Scholar] [CrossRef]

- Pawar, A.A.; Patil, K.A.; Mohite, D.D. Impact of CuO Nanoparticles on the Viscosity and Vibration Damping Characteristics of Shock Absorber Oil. Discov. Nano 2024, 19, 131. [Google Scholar] [CrossRef] [PubMed]

- Ikhsan, A.; Gasni, D.; Rusli, M. Wear Patterns on Ball Bearings Lubricated by Grease Contaminated with Several Large Solid Particles. Tribol. Ind. 2025, 47, 202–216. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).