Influence of Concentration of Sodium Metasilicate and Descaling on the High Temperature Lubricating Effects Evaluated by Hot Rolling Mill

Abstract

:1. Introduction

2. Materials and Methods

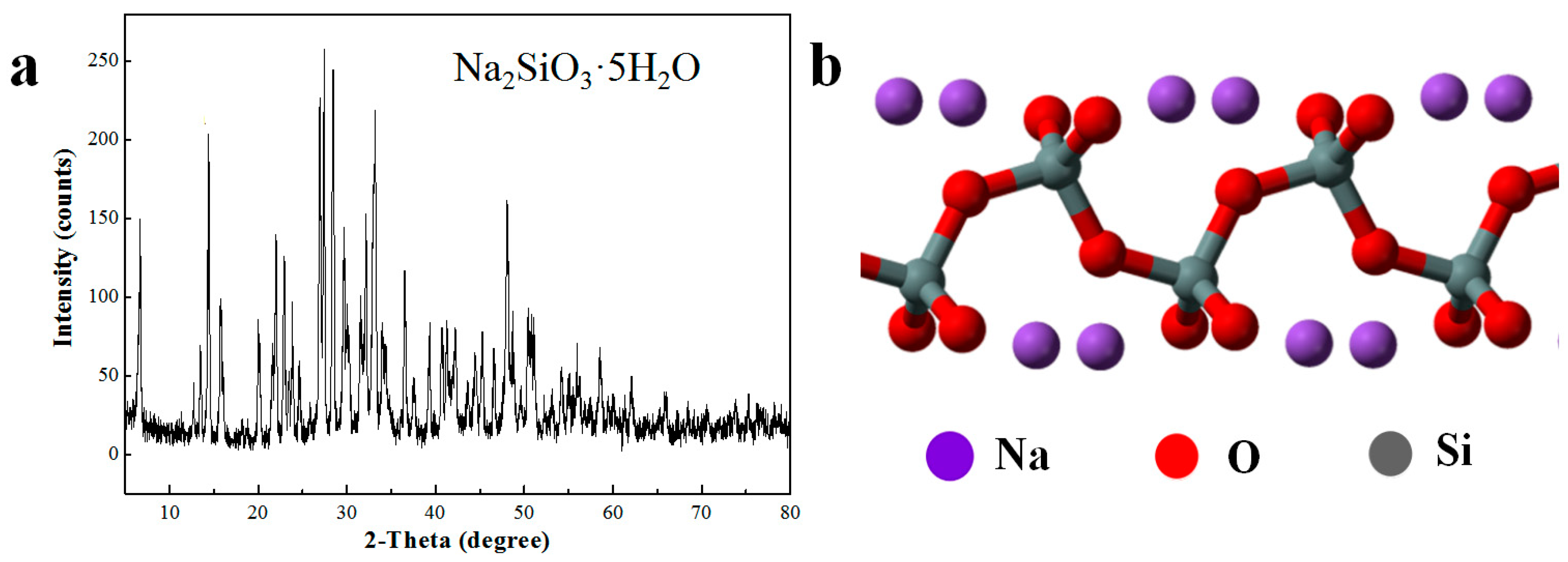

2.1. Materials

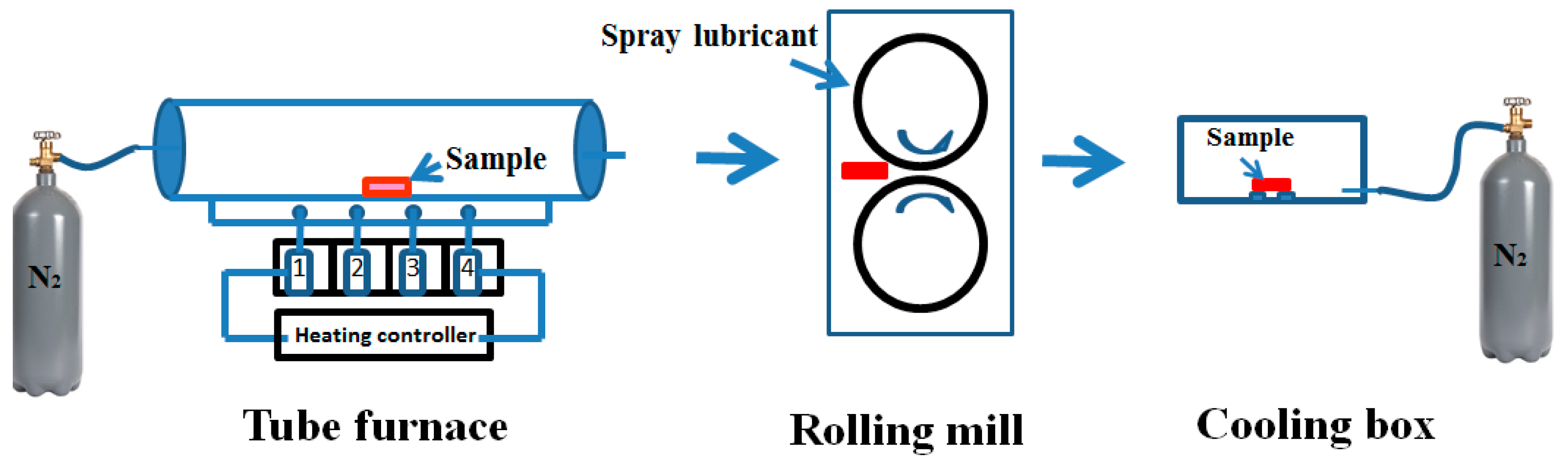

2.2. Hot Rolling Experiment

2.3. Characterizations

3. Result and discussion

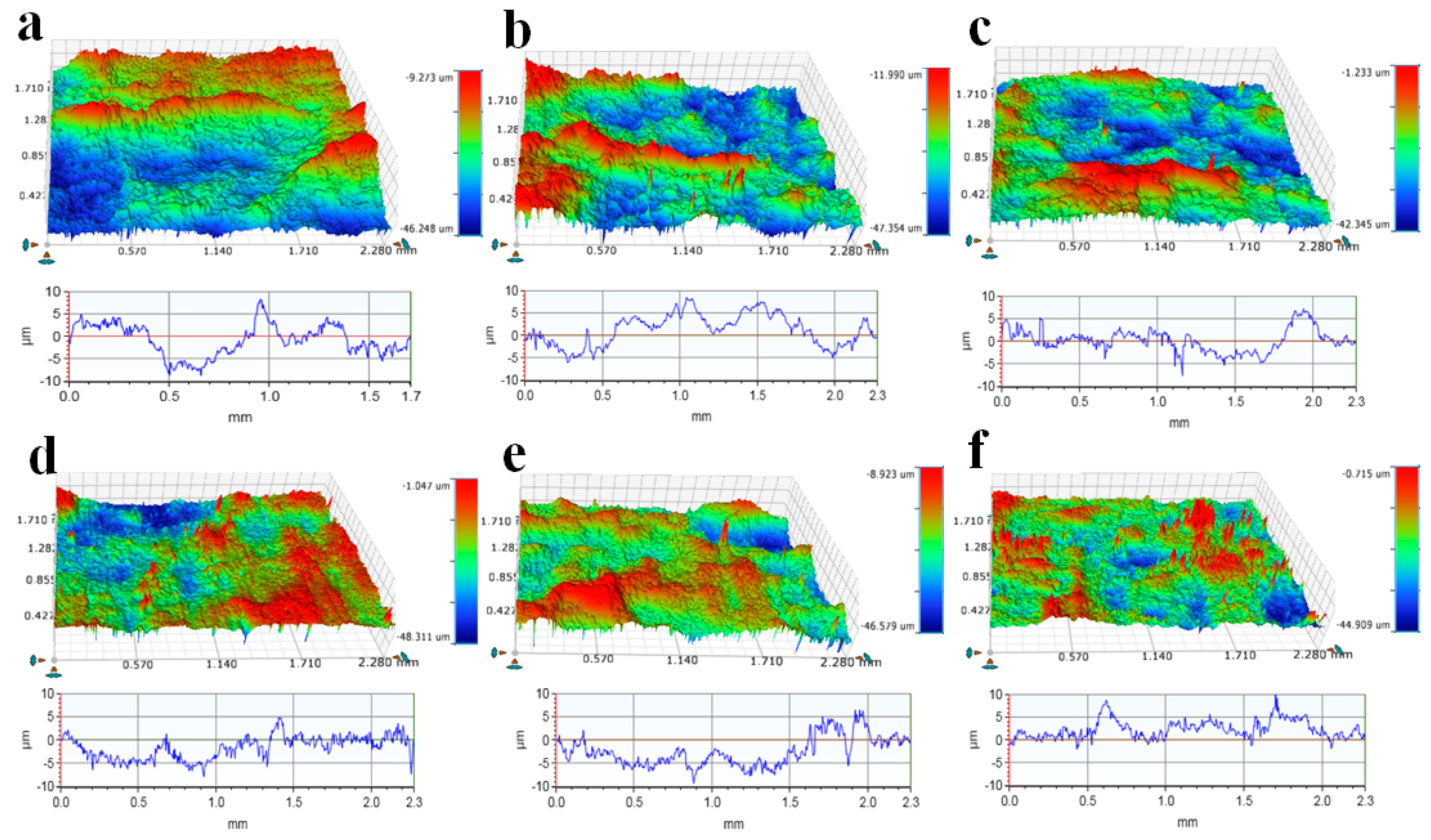

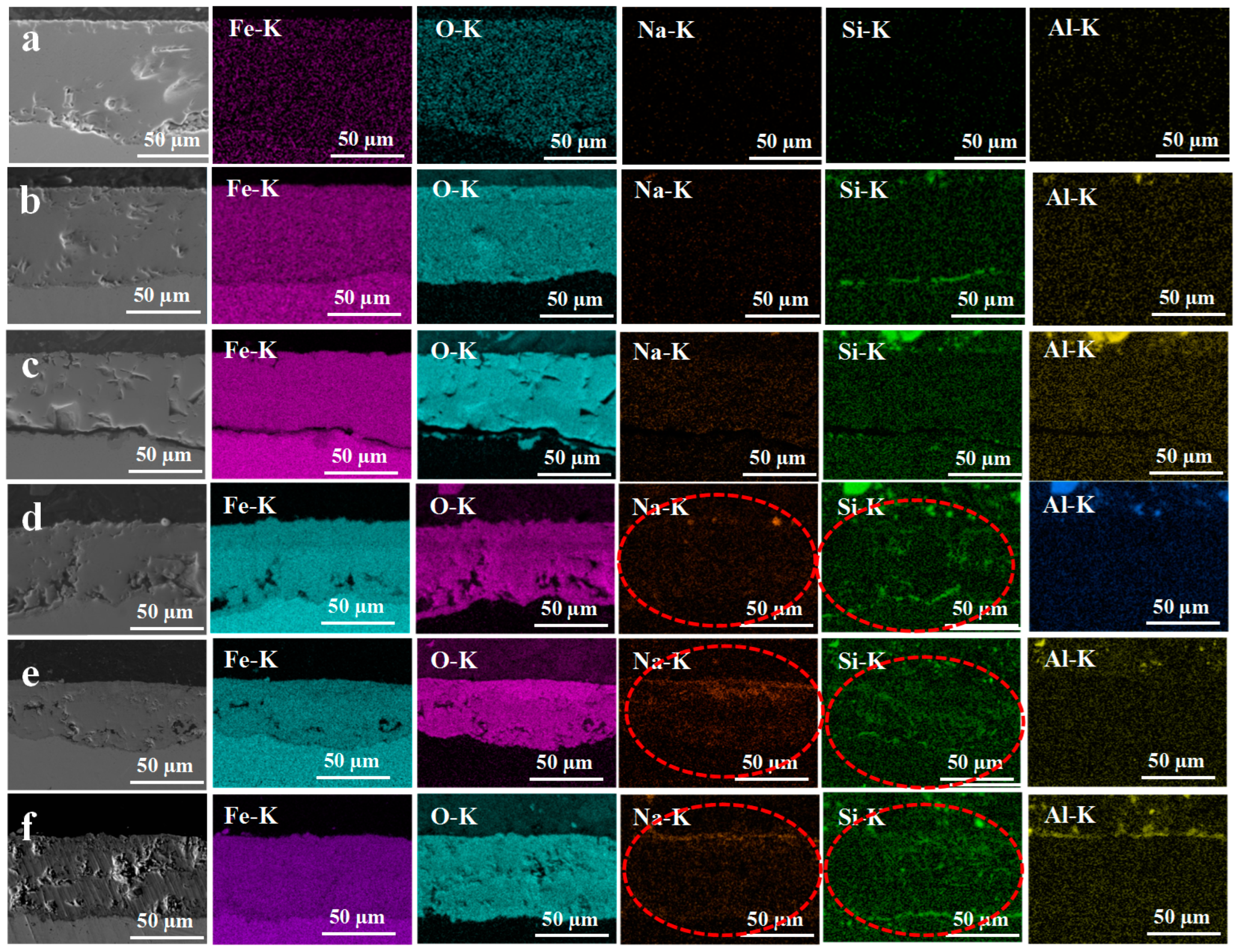

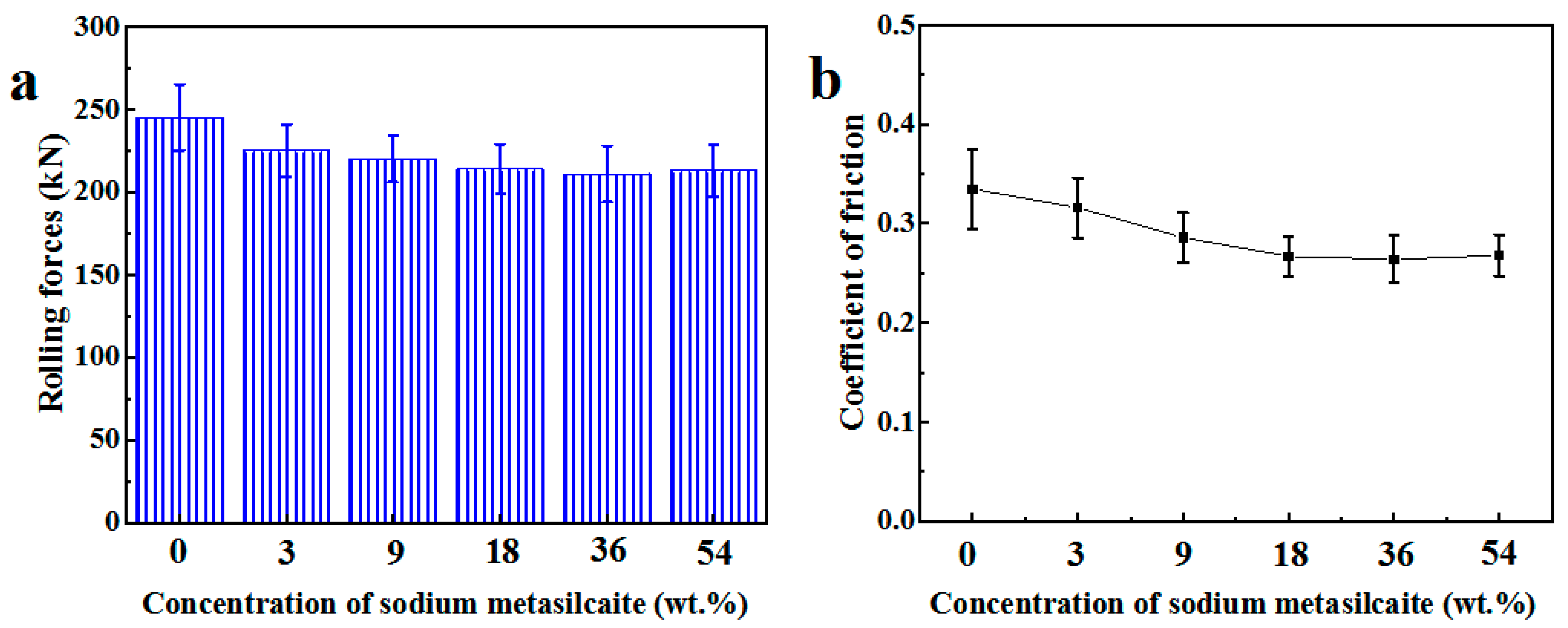

3.1. Hot Rolling Results for Un-Descaled Conditions

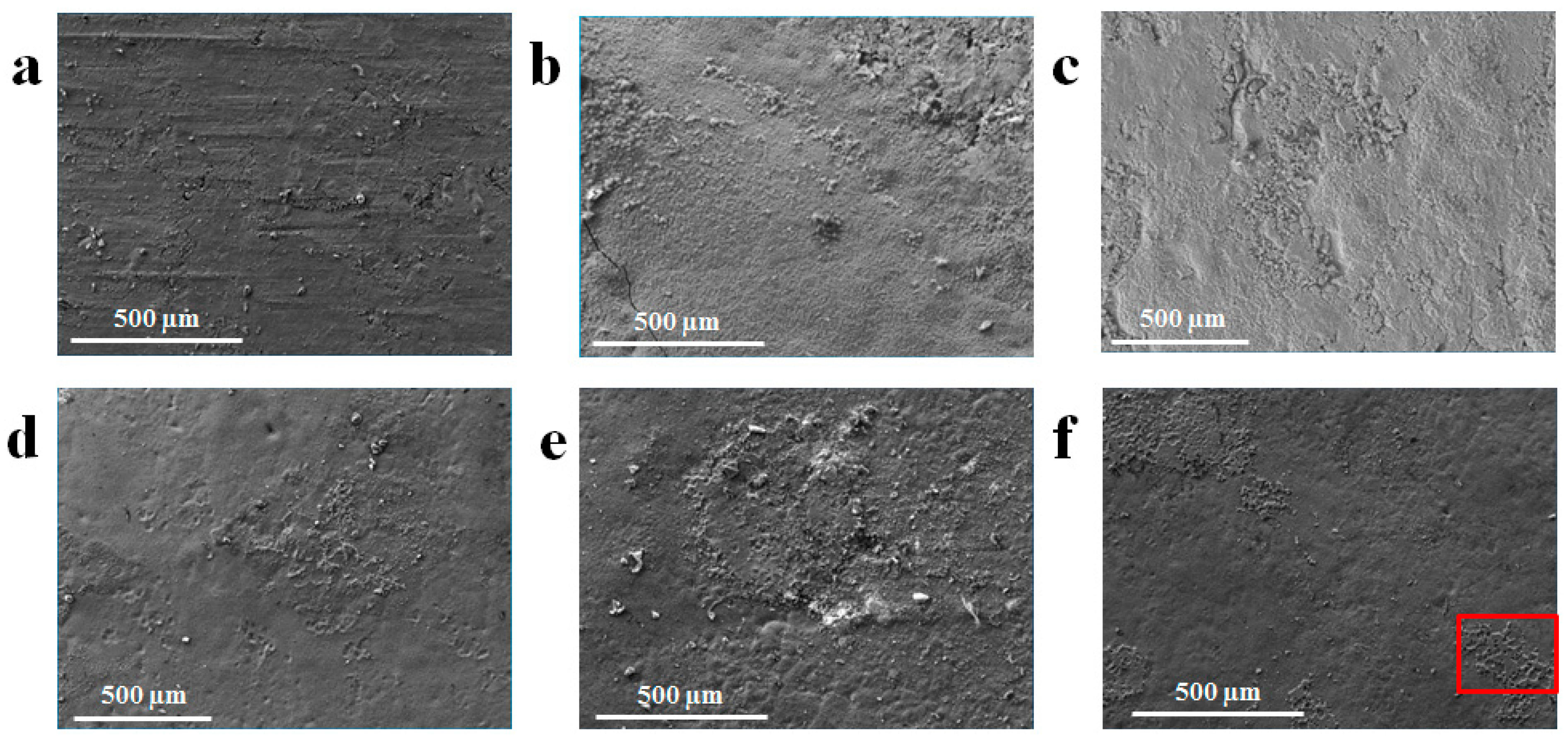

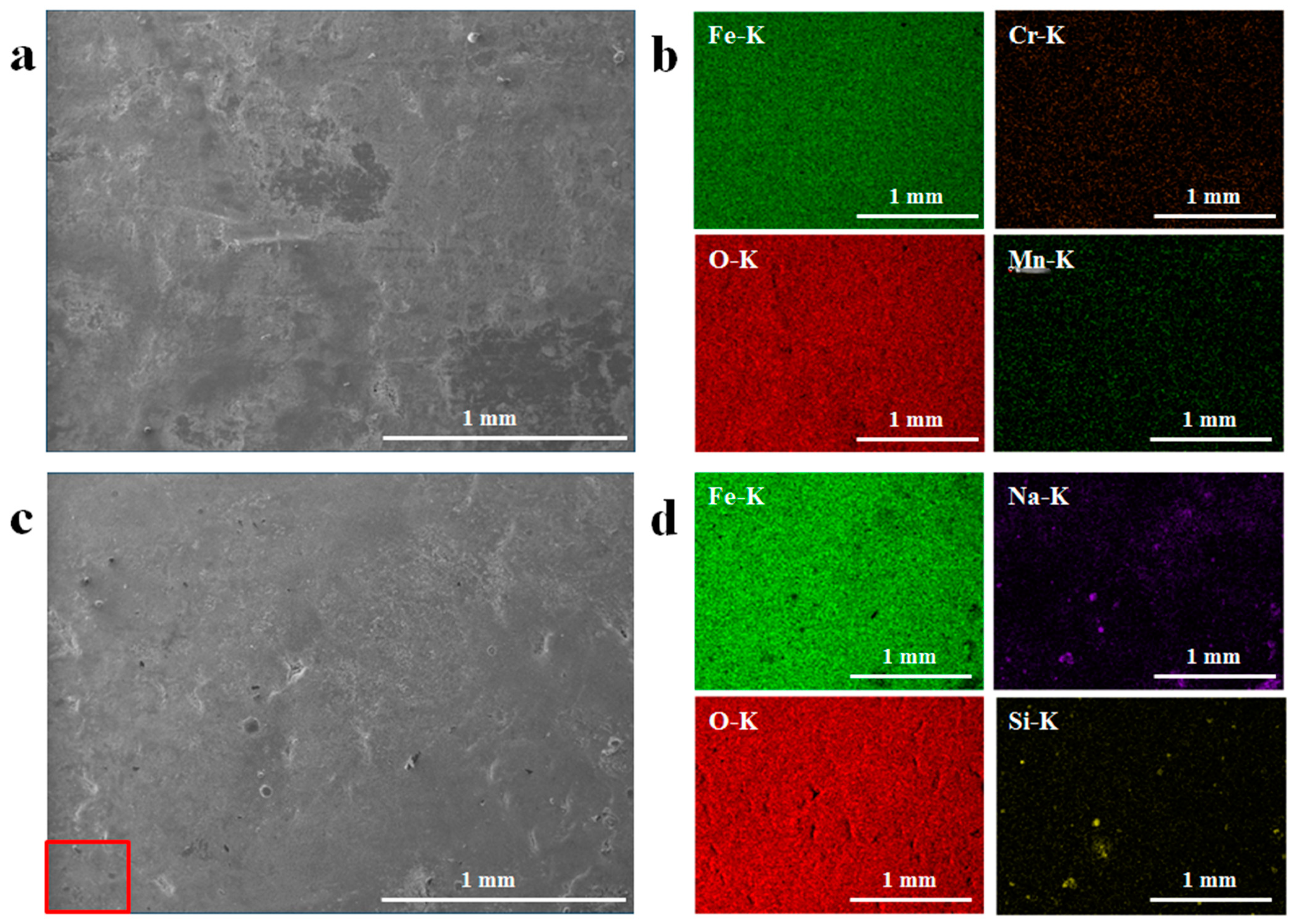

3.2. Surface Observation of Rolled Strips under Un-Descaled Condition

3.3. Hot Rolling Results for Descaled Conditions

3.4. Surface Observation of Rolled Strips under Descaled Condition

4. Conclusions

- (1)

- The lubrication effect of sodium metasilicate was concentration and descaling dependent; when the concentration of NSO is 18 wt.% and above, the optimal lubricating effect is obtained. It results from the coverage difference of NSO on the strip surface.

- (2)

- Descaling that removing the oxide scale can influence the lubricating effects. The dense strips exposed after descaling will provide a substrate for the melt NSO and offer a hard-soft interface for easy shearing; thus, the destructive abrasive wear is reduced, contributing to a smooth surface and a significant reduction in friction and wear.

- (3)

- For the un-descaling conditions, the NSO will be compacted and mixed with the oxide scale, and thus weaken the lubricating effect in some effect.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dohda, K.; Boher, C.; Rezai-Aria, F.; Mahayotsanun, N. Tribology in metal forming at elevated temperatures. Friction 2015, 3, 1–27. [Google Scholar] [CrossRef]

- Wang, L.; Geng, Y.; Tieu, A.K.; Hai, G.; Tan, H.; Chen, J.; Yang, J. In-situ formed graphene providing lubricity for the FeCoCrNiAl based composite containing graphite nanoplate. Compos. Part B Eng. 2021, 221, 109032. [Google Scholar] [CrossRef]

- Zhang, H.; Le, K.; Wang, C.; Sun, J.; Xu, S.; Liu, W. Influence of Deposition Temperature on the Structure and Current-Carrying Friction Performance of Cu Films by DC Magnetron Sputtering Technology. Lubricants 2022, 11, 8. [Google Scholar] [CrossRef]

- Geng, Y.; Chen, W.; Tan, H.; Cheng, J.; Zhu, S.; Yang, J.; Liu, W. Remarkable Wear Resistance in a Complex Concentrated Alloy with Nanohierarchical Architecture and Composition Undulation. Research 2023, 6, 0160. [Google Scholar] [CrossRef]

- Nguyen, C.; Tieu, A.K.; Deng, G.; Wexler, D.; Vo, T.D.; Wang, L.; Yang, J. Tribological performance of a cost-effective CrFeNiAl0.3Ti0.3 high entropy alloy based self-lubricating composite in a wide temperature range. Tribol. Int. 2022, 174, 107743. [Google Scholar] [CrossRef]

- Zhen, J.; Han, Y.; Cheng, J.; Chen, W.; Yang, J.; Jia, Z.; Zhang, R. Enhancing the wide temperature dry sliding tribological performance of nickle-alloy by adding MoS2/CaF2. Tribol. Int. 2022, 165, 107254. [Google Scholar] [CrossRef]

- Beynon, J. Tribology of hot metal forming. Tribol. Int. 1998, 31, 73–77. [Google Scholar] [CrossRef]

- Chun, Y.-D.; Lee, J.; Lee, J.; Suh, J. Thermal preload for predicting performance change due to pad thermal deformation of tilting pad journal bearing. Lubricants 2022, 11, 3. [Google Scholar] [CrossRef]

- Cui, S.; Liu, Y.; Wang, T.; Tieu, K.; Wang, L.; Zeng, D.; Li, Z.; Li, W. Tribological behavior comparisons of high chromium stainless and mild steels against high-speed steel and ceramics at high temperatures. Friction 2022, 10, 436–453. [Google Scholar] [CrossRef]

- Huang, S.; Wu, H.; Jiang, Z.; Huang, H. Water-based nanosuspensions: Formulation, tribological property, lubrication mechanism, and applications. J. Manuf. Process. 2021, 71, 625–644. [Google Scholar] [CrossRef]

- Wang, L.; Tieu, A.K.; Wang, J.; Sang, P.T.; Xia, C.; Zhu, H.; Deng, G. High load capability, sticking scale inhabitation and promising lubrication of sodium carbonate coating for steel/steel contact at high temperature. Tribol. Int. 2021, 153, 106594. [Google Scholar] [CrossRef]

- Deng, G.; Tieu, A.K.; Su, L.; Wang, P.; Wang, L.; Lan, X.; Cui, S.; Zhu, H. Investigation into reciprocating dry sliding friction and wear properties of bulk CoCrFeNiMo high entropy alloys fabricated by spark plasma sintering and subsequent cold rolling processes: Role of Mo element concentration. Wear 2020, 460–461, 203440. [Google Scholar] [CrossRef]

- Wang, W.; Wei, P.; Liu, H.; Zhu, C.; Deng, G.; Liu, H. A micromechanics-based machine learning model for evaluating the microstructure-dependent rolling contact fatigue performance of a martensitic steel. Int. J. Mech. Sci. 2023, 237, 107784. [Google Scholar] [CrossRef]

- Cheng, J.; Zhu, S.; Tan, H.; Wang, S.; Sun, Q.; Ding, Y.; Yang, J. High temperature tribological behaviors of MoAlB ceramic from 800–1200 °C. Tribol. Int. 2023, 185, 108522. [Google Scholar]

- Schell, L.; Emele, M.; Holzbeck, A.; Groche, P. Investigation of different lubricant classes for aluminium warm and hot forming based on a strip drawing test. Tribol. Int. 2022, 168, 107449. [Google Scholar] [CrossRef]

- Astakhov, V.P. Tribology of metal cutting. In Mechanical Tribology; Marcel Dekker: New York, NY, USA, 2004; pp. 307–346. [Google Scholar]

- Tieu, A.; Kosasih, P.B.; Godbole, A. A thermal analysis of strip-rolling in mixed-film lubrication with O/W emulsions. Tribol. Int. 2006, 39, 1591–1600. [Google Scholar] [CrossRef]

- Edla, S.; Thampi, A.D.; Prasannakumar, P.; Rani, S. Evaluation of physicochemical, tribological and oxidative stability properties of chemically modified rice bran and karanja oils as viable lubricant base stocks for industrial applications. Tribol. Int. 2022, 173, 107631. [Google Scholar] [CrossRef]

- Valigi, M.C.; Malvezzi, M.; Logozzo, S. A numerical procedure based on Orowan’s theory for predicting the behavior of the cold rolling mill process in full film lubrication. Lubricants 2020, 8, 2. [Google Scholar] [CrossRef]

- Moshkovich, A.; Perfilyev, V.; Rapoport, L. Effect of Plastic Deformation and Damage Development during Friction of fcc Metals in the Conditions of Boundary Lubrication. Lubricants 2019, 7, 45. [Google Scholar] [CrossRef]

- Wu, C.; Zhang, L.; Qu, P.; Li, S.; Jiang, Z. A multi-field analysis of hydrodynamic lubrication in high speed rolling of metal strips. Int. J. Mech. Sci. 2018, 142–143, 468–479. [Google Scholar] [CrossRef]

- Xia, W.; Zhao, J.; Wu, H.; Zhao, X.; Zhang, X.; Xu, J.; Jiao, S.; Wang, X.; Zhou, C.; Jiang, Z. Effects of oil-in-water based nanolubricant containing TiO2 nanoparticles in hot rolling of 304 stainless steel. J. Mater. Process. Technol. 2018, 262, 149–156. [Google Scholar] [CrossRef]

- Xia, W.; Zhao, J.; Wu, H.; Zhao, X.; Zhang, X.; Xu, J.; Jiao, S.; Jiang, Z. Effects of oil-in-water based nanolubricant containing TiO2 nanoparticles in hot rolling of 304 stainless steel. Procedia Eng. 2017, 207, 1385–1390. [Google Scholar] [CrossRef]

- Altan, T.; Tekkaya, A.E. Sheet Metal Forming: Fundamentals; ASM International: Almere, The Netherlands, 2012. [Google Scholar]

- Cui, S.; Zhu, H.; Wan, S.; Tieu, K.; Tran, B.H.; Wang, L.; Zhu, Q. Effect of loading on the friction and interface microstructure of lubricated steel tribopairs. Tribol. Int. 2017, 116, 180–191. [Google Scholar] [CrossRef]

- Yaseen, M.; Rawat, S.K.; Shah, N.A.; Kumar, M.; Eldin, S.M. Ternary hybrid nanofluid flow containing gyrotactic microorganisms over three different geometries with Cattaneo–Christov Model. Mathematics 2023, 11, 1237. [Google Scholar] [CrossRef]

- Yaseen, M.; Rawat, S.K.; Khan, U.; Negi, A.S.; Kumar, M.; Sherif, E.-S.M.; Hassan, A.M.; Pop, I. Inspection of unsteady buoyancy and stagnation point flow incorporated by Ag-TiO2 hybrid nanoparticles towards a spinning disk with Hall effects. Case Stud. Therm. Eng. 2023, 44, 102889. [Google Scholar] [CrossRef]

- Wei, P.; Lu, C.; Tieu, K.; Su, L.; Deng, G.; Huang, W. A study on the texture evolution mechanism of nickel single crystal deformed by high pressure torsion. Mater. Sci. Eng. A. 2017, 684, 239–248. [Google Scholar] [CrossRef]

- Bay, N.; Azushima, A.; Groche, P.; Ishibashi, I.; Merklein, M.; Morishita, M.; Nakamura, T.; Schmid, S.; Yoshida, M. Environmentally benign tribo-systems for metal forming. CIRP Ann. 2010, 59, 760–780. [Google Scholar] [CrossRef]

- Morishita, M. Tribology in manufacturing processes of automobiles at Toyota. Proc. ICTMP 2007, 1, 35–48. [Google Scholar]

- Xiong, S.; Liang, D.; Wu, H.; Lin, W.; Chen, J.; Zhang, B. Preparation, characterization, tribological and lubrication performances of Eu doped CaWO4 nanoparticle as anti-wear additive in water-soluble fluid for steel strip during hot rolling. Appl. Surf. Sci. 2021, 539, 148090. [Google Scholar] [CrossRef]

- Bao, Y.; Sun, J.; Kong, L. Effects of nano-SiO2 as water-based lubricant additive on surface qualities of strips after hot rolling. Tribol. Int. 2017, 114, 257–263. [Google Scholar] [CrossRef]

- Shah, F.U.; Glavatskih, S.; Antzutkin, O.N. Boron in tribology: From borates to ionic liquids. Tribol. Lett. 2013, 51, 281–301. [Google Scholar] [CrossRef]

- Choudhary, R.; Pande, P. Lubrication potential of boron compounds: An overview. Lubr. Sci. 2002, 14, 211–222. [Google Scholar] [CrossRef]

- Yabuuchi, N.; Yoshida, H.; Komaba, S. Crystal structures and electrode performance of alpha-NaFeO2 for rechargeable sodium batteries. Electrochemistry 2012, 80, 716–719. [Google Scholar] [CrossRef]

- Wang, L.; Tieu, A.K.; Zhu, H.; Deng, G.; Cui, S.; Zhu, Q. A study of water-based lubricant with a mixture of polyphosphate and nano-TiO2 as additives for hot rolling process. Wear 2021, 477, 203895. [Google Scholar] [CrossRef]

- Cui, S.; Wan, S.; Zhu, Q.; Tieu, A.K.; Zhu, H.; Wang, L.; Cowie, B. Tribochemical behavior of phosphate compounds at an elevated temperature. J. Phys. Chem. C 2016, 120, 25742–25751. [Google Scholar] [CrossRef]

- Wan, S.; Tieu, A.K.; Zhu, Q.; Zhu, H.; Cui, S.; Mitchell, D.R.; Kong, C.; Cowie, B.; Denman, J.A.; Liu, R. Chemical nature of alkaline polyphosphate boundary film at heated rubbing surfaces. Sci. Rep. 2016, 6, 26008. [Google Scholar] [CrossRef]

- Wang, L.; Tieu, A.K.; Deng, G.; Wang, J.; Tran, B.H.; Zhu, H.; Yang, J. In-situ interfacial tribochemistry toward eliminating red-scale of silicon steel in friction process. Tribol. Int. 2020, 143, 106077. [Google Scholar] [CrossRef]

- Kong, N.; Tieu, A.K.; Zhu, Q.; Zhu, H.; Wan, S.; Kong, C. Tribofilms generated from bulk polyphosphate glasses at elevated temperatures. Wear 2015, 330, 230–238. [Google Scholar] [CrossRef]

- Yue, W.; Wang, C.; Liu, Y.; Huang, H.; Wen, Q.; Liu, J. Study of the regenerated layer on the worn surface of a cylinder liner lubricated by a novel silicate additive in lubricating oil. Tribol. Trans. 2010, 53, 288–295. [Google Scholar] [CrossRef]

- Nan, F.; Xu, Y.; Xu, B.; Gao, F.; Wu, Y.; Li, Z. Tribological behaviors and wear mechanisms of ultrafine magnesium aluminum silicate powders as lubricant additive. Tribol. Int. 2015, 81, 199–208. [Google Scholar] [CrossRef]

- Gao, K.; Chang, Q.; Wang, B.; Zhou, N.; Qing, T. The tribological performances of modified magnesium silicate hydroxide as lubricant additive. Tribol. Int. 2018, 121, 64–70. [Google Scholar] [CrossRef]

- Singh, D.; Thakre, G.; Konathala, L.; Prasad, V. Friction reduction capabilities of silicate compounds used in an engine lubricant on worn surfaces. Adv. Tribol. 2016, 2016, 1901493. [Google Scholar] [CrossRef]

- Yu, H.; Xu, Y.; Shi, P.; Wang, H.; Wei, M.; Zhao, K.; Xu, B. Microstructure, mechanical properties and tribological behavior of tribofilm generated from natural serpentine mineral powders as lubricant additive. Wear 2013, 297, 802–810. [Google Scholar] [CrossRef]

- Bass, J.L.; McDonald, M.J.; Urquhart, J.C. Lubricating Method for Silicate Drilling Fluids. US Patent 6,642,183, 4 November 2003. [Google Scholar]

- Matsumoto, K.; Izawa, M.; Nakanishi, T.; Tsubouchi, K. Tribological properties of water glass lubricant for hot metalworking. Tribol. Trans. 2009, 52, 553–559. [Google Scholar] [CrossRef]

- Alexander, J.M. On the theory of rolling. Proc. R. Soc. Lond. A Math. Phys. Sci. 1972, 326, 535–563. [Google Scholar]

- Pietrzyk, M.; Cser, L.; Lenard, J. Mathematical and Physical Simulation of the Properties of Hot Rolled Products; Elsevier: Amsterdam, The Netherlands, 1999. [Google Scholar]

- Wang, L.; Tieu, A.K.; Cui, S.; Deng, G.; Wang, P.; Zhu, H.; Yang, J. Lubrication mechanism of sodium metasilicate at elevated temperatures through tribo-interface observation. Tribol. Int. 2020, 142, 105972. [Google Scholar] [CrossRef]

- Wang, L.; Tieu, A.K.; Zhu, H.; Deng, G.; Hai, G.; Wang, J.; Yang, J. The effect of expanded graphite with sodium metasilicate as lubricant at high temperature. Carbon 2020, 159, 345–356. [Google Scholar] [CrossRef]

| Elemrnt | Fe | C | Si | Mn | W | Al | Cu | P | S |

|---|---|---|---|---|---|---|---|---|---|

| content | 98.17 | 0.5502 | 0.1626 | 0.8383 | 0.1008 | 0.00241 | 0.0038 | 0.0231 | 0.0516 |

| Name | Symbol | SI Units |

|---|---|---|

| Sodium metasilicate | NSO | |

| Mild steel | MS | |

| Roughness | Ra | µm |

| Rolling force | P | N |

| Coefficient of friction | µ | |

| Strip width | B | m |

| Radius of roll | R1 | |

| Rolling reduction | ||

| Front tension stress | t1 | Pa |

| Back tension stress | t2 | Pa |

| Yield stress | Pa | |

| Base yield stress | 0 | Pa |

| Temperature | T | K |

| Stain | ε | |

| Stain rate | έ | s−1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Wu, X.; Huang, J.; Shao, X.; Wang, P.; Deng, G.; Wang, L. Influence of Concentration of Sodium Metasilicate and Descaling on the High Temperature Lubricating Effects Evaluated by Hot Rolling Mill. Lubricants 2023, 11, 352. https://doi.org/10.3390/lubricants11080352

Liu H, Wu X, Huang J, Shao X, Wang P, Deng G, Wang L. Influence of Concentration of Sodium Metasilicate and Descaling on the High Temperature Lubricating Effects Evaluated by Hot Rolling Mill. Lubricants. 2023; 11(8):352. https://doi.org/10.3390/lubricants11080352

Chicago/Turabian StyleLiu, Hongliang, Xun Wu, Jiaxuan Huang, Xibo Shao, Pei Wang, Guanyu Deng, and Long Wang. 2023. "Influence of Concentration of Sodium Metasilicate and Descaling on the High Temperature Lubricating Effects Evaluated by Hot Rolling Mill" Lubricants 11, no. 8: 352. https://doi.org/10.3390/lubricants11080352

APA StyleLiu, H., Wu, X., Huang, J., Shao, X., Wang, P., Deng, G., & Wang, L. (2023). Influence of Concentration of Sodium Metasilicate and Descaling on the High Temperature Lubricating Effects Evaluated by Hot Rolling Mill. Lubricants, 11(8), 352. https://doi.org/10.3390/lubricants11080352